HONDA CR-V 2000 RD1-RD3 / 1.G Owners Manual

Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 322, PDF Size: 4.64 MB

Page 201 of 322

Engin

e Oi l

Addin g Oi l

T o ad d oil , unscre w an d remov e th e

engin e oi l fil l ca p o n to p o f th e valv e

cover . Pou r i n th e oil , an d instal l th e

engin e oi l fil l cap . Tighte n i t securely .

Wai t a fe w minute s an d rechec k th e

oi l level . D o no t fil l abov e th e uppe r

mark ; yo u coul d damag e th e engine .Recommende

d Oi l

Oi l i s a majo r contributo r t o you r

engine' s performanc e an d longevity .

Alway s us e a premium-grad e deter -

gen t oil . I t i s highl y recommende d

tha t yo u us e Genuin e Hond a Moto r

Oi l i n you r vehicl e fo r a s lon g a s yo u

ow n it .

Yo u ca n determin e a n oil' s SA E

viscosit y an d Servic e Classificatio n

fro m th e AP I Servic e labe l o n th e oi l

container .

A fuel-efficien t oi l i s recommende d

fo r you r Honda . Thi s i s show n o n th e

AP I Servic e labe l b y th e word s

"Energ y Conserving. " Thi s oi l i s

formulate d t o hel p you r engin e us e

les s fuel . Th

e AP I Servic e labe l als o tell s yo u

th e servic e classificatio n o f th e oil .

Alway s us e a n oi l tha t i s labele d "AP I

Servic e SJ. " Thi s servic e ratin g ma y

includ e othe r classifications , suc h a s

CD . Thes e additiona l classification s

ar e no t a problem , a s lon g a s th e

labe l als o carrie s th e S J classification .

AP I SERVIC E LABE L

CONTINUED

Maintenanc e

ENGIN

E OI L FIL L CA P

Page 202 of 322

Engin

e Oi l

Th e oi l containe r ma y als o displa y

th e AP I Certificatio n seal . Mak e sur e

i t say s "Fo r Gasolin e Engines. "

AP I CERTIFICATIO N MAR K Th

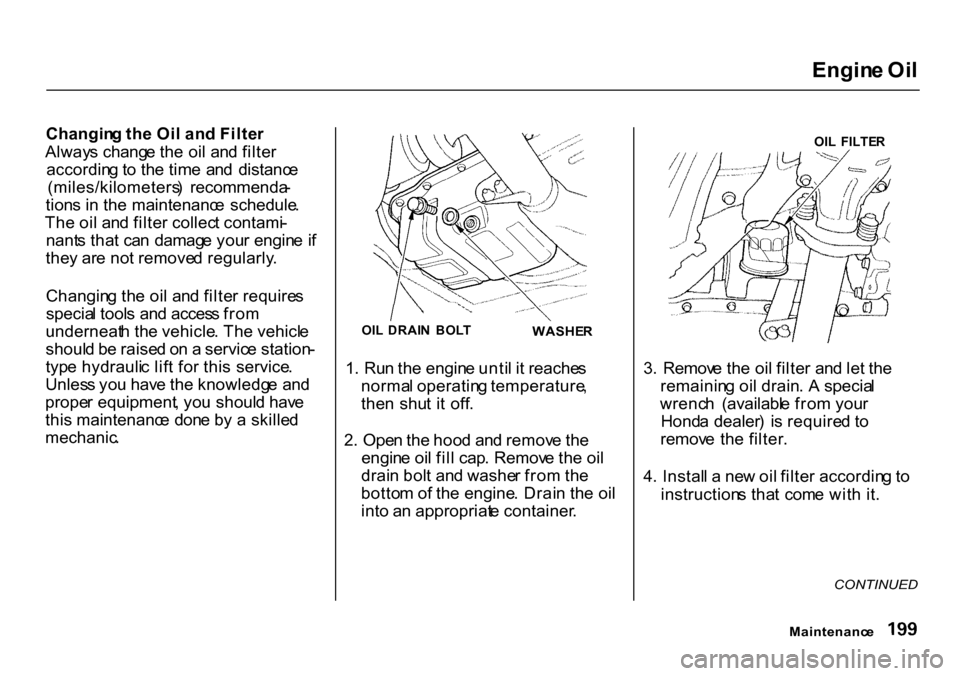

e SA E number s tel l yo u th e oil' s

viscosit y o r weight . Selec t th e oi l fo r

you r vehicl e accordin g t o thi s chart .

A n oi l wit h a viscosit y o f 5W-3 0 is

preferre d fo r improve d fue l econom y

an d year-roun d protectio n in you r

Honda . Yo u ma y us e a 10W-3 0 oi l i f

th e temperatur e i n you r are a neve r

goe s belo w 20° F ( — 7°C) . Syntheti

c Oi l

Yo u ma y us e a syntheti c moto r oi l i f

i t meet s th e sam e requirement s

give n fo r conventiona l moto r oil :

energ y conserving , a servic e

classificatio n o f SJ , an d th e prope r

weigh t a s show n o n th e chart . Whe n

usin g syntheti c oil , yo u mus t follo w

th e oi l an d filte r chang e interval s

give n in th e maintenanc e schedule .

Additive s

You r Hond a doe s no t nee d an y oi l

additives . Purchasin g additive s fo r

th e engin e o r transmissio n wil l no t

increas e you r vehicle' s performanc e

o r longevity . I t onl y increase s th e

cos t o f operatin g you r vehicle .

Maintenanc e

Ambien

t Temperatur e

Page 203 of 322

Engin

e Oi l

Changin g th e Oi l an d Filte r

Alway s chang e th e oi l an d filte r

accordin g to th e tim e an d distanc e

(miles/kilometers ) recommenda -

tion s i n th e maintenanc e schedule .

Th e oi l an d filte r collec t contami -

nant s tha t ca n damag e you r engin e if

the y ar e no t remove d regularly .

Changin g th e oi l an d filte r require s

specia l tool s an d acces s fro m

underneat h th e vehicle . Th e vehicl e

shoul d b e raise d o n a servic e station -

typ e hydrauli c lif t fo r thi s service .

Unles s yo u hav e th e knowledg e an d

prope r equipment , yo u shoul d hav e

thi s maintenanc e don e b y a skille d

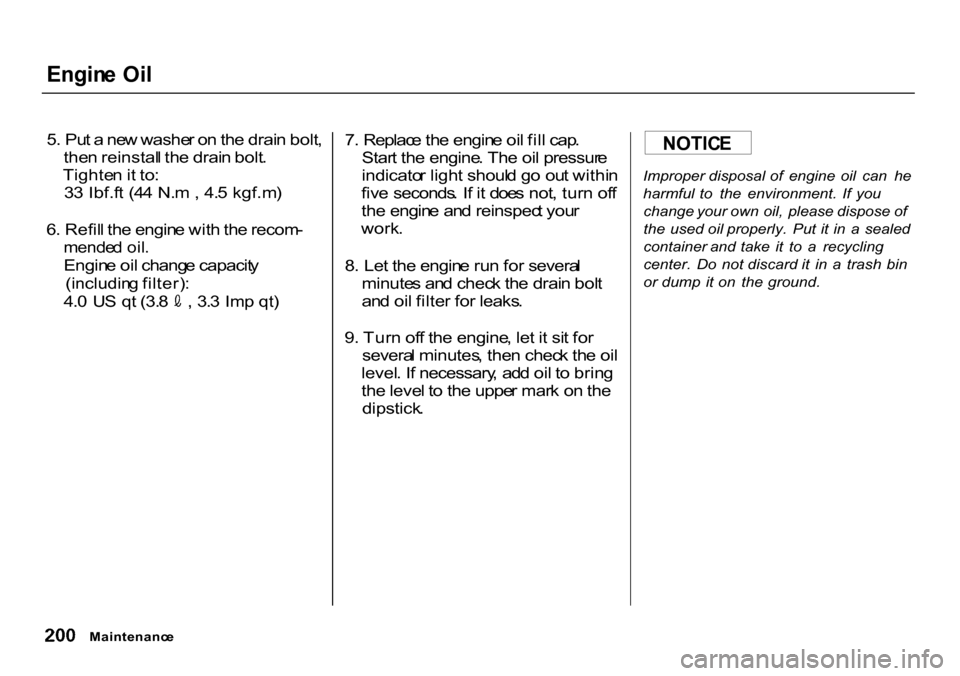

mechanic . 1

. Ru n th e engin e unti l i t reache s

norma l operatin g temperature ,

the n shu t i t off .

2 . Ope n th e hoo d an d remov e th e

engin e oi l fil l cap . Remov e th e oi l

drai n bol t an d washe r fro m th e

botto m o f th e engine . Drai n th e oi l

int o a n appropriat e container .3

. Remov e th e oi l filte r an d le t th e

remainin g oi l drain . A specia l

wrenc h (availabl e fro m you r

Hond a dealer ) i s require d t o

remov e th e filter .

4 . Instal l a ne w oi l filte r accordin g to

instruction s tha t com e wit h it .

CONTINUED

Maintenanc e

OI

L DRAI N BOL T

WASHER

OI

L FILTE R

Page 204 of 322

Engin

e Oi l

5 . Pu t a ne w washe r o n th e drai n bolt ,

the n reinstal l th e drai n bolt .

Tighte n it to :

3 3 Ibf.f t (4 4 N. m , 4. 5 kgf.m )

6 . Refil l th e engin e wit h th e recom -

mende d oil .

Engin e oi l chang e capacit y

(includin g filter) :

4.

0 U S q t (3. 8 , 3.3 Im p qt ) 7

. Replac e th e engin e oi l fil l cap .

Star t th e engine . Th e oi l pressur e

indicato r ligh t shoul d g o ou t withi n

fiv e seconds . I f i t doe s not , tur n of f

th e engin e an d reinspec t you r

work .

8 . Le t th e engin e ru n fo r severa l

minute s an d chec k th e drai n bol t

an d oi l filte r fo r leaks .

9 . Tur n of f th e engine , le t i t si t fo r

severa l minutes , the n chec k th e oi l

level . I f necessary , ad d oi l t o brin g

th e leve l t o th e uppe r mar k o n th e

dipstick .

Improper

disposal of engine oil can he

harmful to the environment. If you

change your own oil, please dispose of

the used oil properly. Put it in a sealed

container and take it to a recycling

center. Do not discard it in a trash bin

or dump it on the ground.

Maintenanc e

NOTIC

E

Page 205 of 322

Coolin

g Syste m

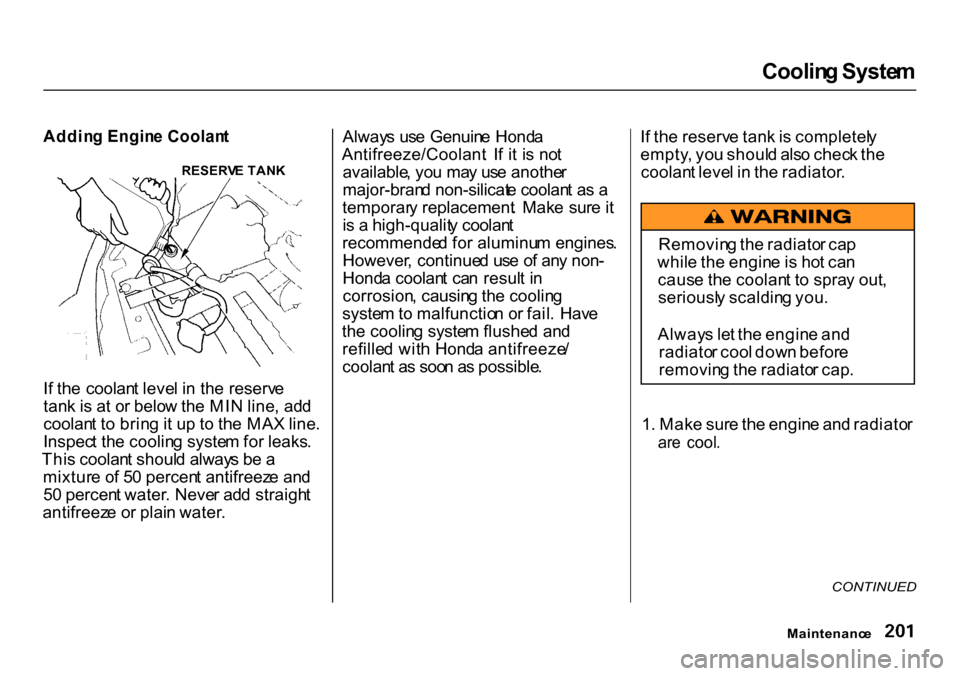

Addin g Engin e Coolan t

I f th e coolan t leve l i n th e reserv e

tan k i s a t o r belo w th e MI N line , ad d

coolan t t o brin g it u p t o th e MA X line .

Inspec t th e coolin g syste m fo r leaks .

Thi s coolan t shoul d alway s b e a

mixtur e o f 5 0 percen t antifreez e an d

5 0 percen t water . Neve r ad d straigh t

antifreez e o r plai n water . Alway

s us e Genuin e Hond a

Antifreeze/Coolant . I f i t i s no t

available , yo u ma y us e anothe r

major-bran d non-silicat e coolan t a s a

temporar y replacement . Mak e sur e it

i s a high-qualit y coolan t

recommende d fo r aluminu m engines .

However , continue d us e o f an y non -

Hond a coolan t ca n resul t i n

corrosion , causin g th e coolin g

syste m to malfunctio n o r fail . Hav e

th e coolin g syste m flushe d an d

refille d wit h Hond a antifreeze /

coolan t a s soo n a s possible . I

f th e reserv e tan k is completel y

empty , yo u shoul d als o chec k th e

coolan t leve l i n th e radiator .

1 . Mak e sur e th e engin e an d radiato r

ar e cool .

CONTINUED

Maintenanc e

Removin

g th e radiato r ca p

whil e th e engin e is ho t ca n

caus e th e coolan t t o spra y out ,

seriousl y scaldin g you .

Alway s le t th e engin e an d

radiato r coo l dow n befor e

removin g th e radiato r cap .

RESERV

E TAN K

Page 206 of 322

Coolin

g Syste m

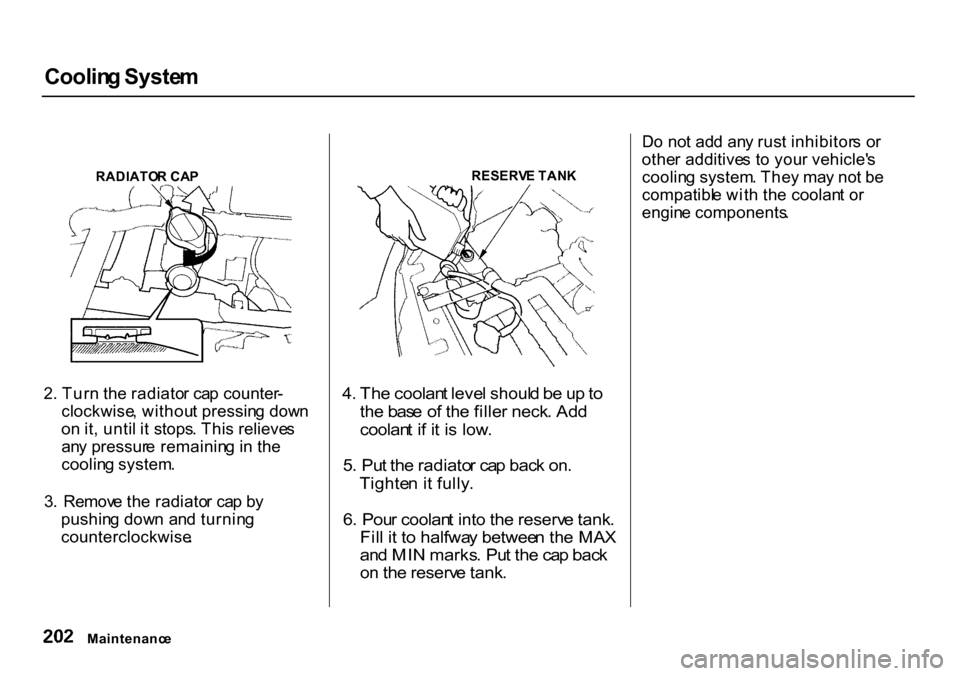

RADIATO R CA P

2 . Tur n th e radiato r ca p counter -

clockwise , withou t pressin g dow n

o n it , unti l i t stops . Thi s relieve s

an y pressur e remainin g in th e

coolin g system .

3 . Remov e th e radiato r ca p b y

pushin g dow n an d turnin g

counterclockwise . RESERV

E TAN K

4 . Th e coolan t leve l shoul d b e u p to

th e bas e o f th e fille r neck . Ad d

coolan t i f i t i s low .

5 . Pu t th e radiato r ca p bac k on .

Tighte n i t fully .

6 . Pou r coolan t int o th e reserv e tank .

Fil l i t t o halfwa y betwee n th e MA X

an d MI N marks . Pu t th e ca p bac k

o n th e reserv e tank .

D

o no t ad d an y rus t inhibitor s o r

othe r additive s t o you r vehicle' s

coolin g system . The y ma y no t b e

compatibl e wit h th e coolan t o r

engin e components .

Maintenanc e

Page 207 of 322

Coolin

g Syste m

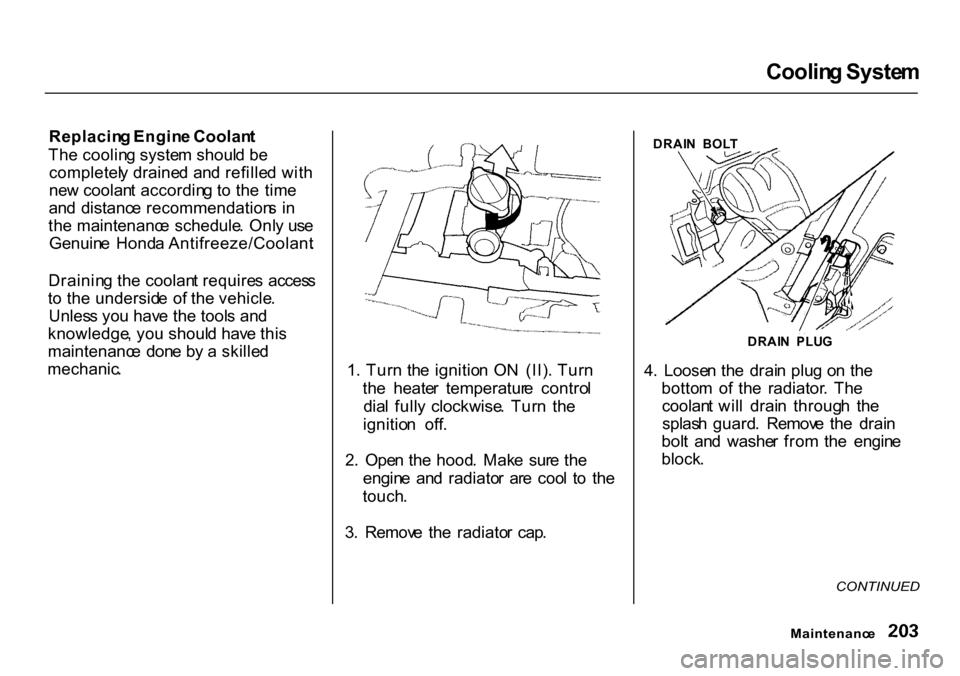

Replacin g Engin e Coolan t

Th e coolin g syste m shoul d b e

completel y draine d an d refille d wit h

ne w coolan t accordin g t o th e tim e

an d distanc e recommendation s i n

th e maintenanc e schedule . Onl y us e

Genuin e Hond a Antifreeze/Coolant .

Drainin g th e coolan t require s acces s

t o th e undersid e o f th e vehicle .

Unles s yo u hav e th e tool s an d

knowledge , yo u shoul d hav e thi s

maintenanc e don e b y a skille d

mechanic .

1. Tur n th e ignitio n O N (II) . Tur n

th e heate r temperatur e contro l

dia l full y clockwise . Tur n th e

ignitio n off .

2 . Ope n th e hood . Mak e sur e th e

engin e an d radiato r ar e coo l t o th e

touch .

3 . Remov e th e radiato r cap . 4

. Loose n th e drai n plu g o n th e

botto m o f th e radiator . Th e

coolan t wil l drai n throug h th e

splas h guard . Remov e th e drai n

bol t an d washe r fro m th e engin e

block .

CONTINUED

Maintenanc e

DRAI

N BOL T

DRAI N PLU G

Page 208 of 322

Coolin

g Syste m

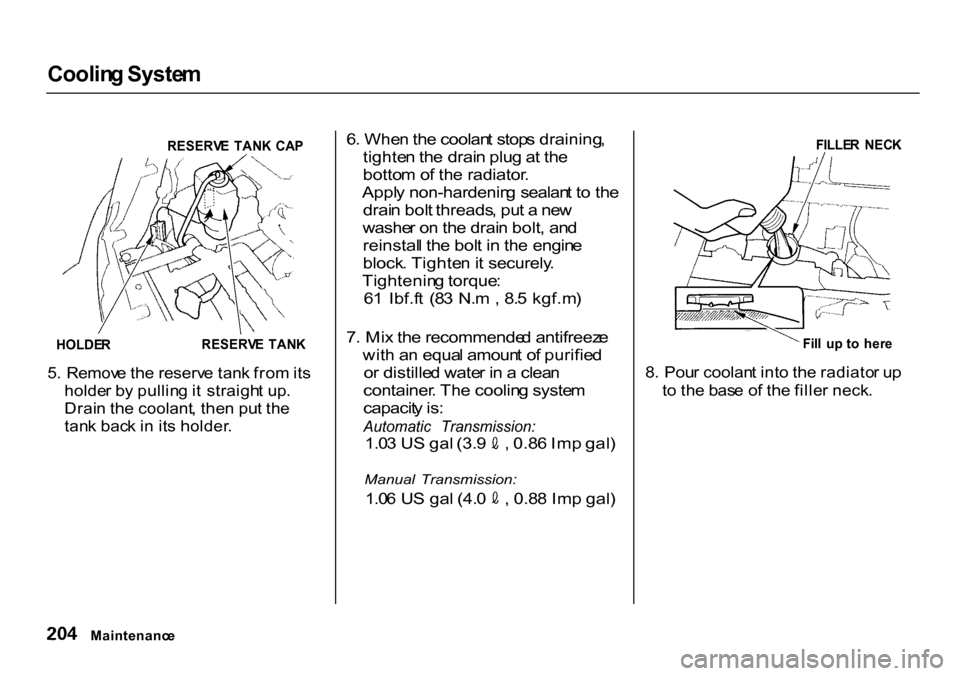

RESERV E TAN K CA P

HOLDE R RESERV

E TAN K

5 . Remov e th e reserv e tan k fro m its

holde r b y pullin g it straigh t up .

Drai n th e coolant , the n pu t th e

tan k bac k i n it s holder .

6

. Whe n th e coolan t stop s draining ,

tighte n th e drai n plu g a t th e

botto m of th e radiator .

Appl y non-hardenin g sealan t t o th e

drai n bol t threads , pu t a ne w

washe r o n th e drai n bolt , an d

reinstal l th e bol t i n th e engin e

block . Tighte n it securely .

Tightenin g torque :

6 1 Ibf.f t (8 3 N. m , 8. 5 kgf.m )

7 . Mi x th e recommende d antifreez e

wit h a n equa l amoun t o f purifie d

o r distille d wate r i n a clea n

container . Th e coolin g syste m

capacit y is :

Automatic Transmission:

1.0

3 U S ga l (3. 9 , 0.8 6 Im p gal )

Manual Transmission: 1.0

6 U S ga l (4. 0 , 0.8 8 Im p gal )

FILLE

R NEC K

Fil l u p t o her e

8 . Pou r coolan t int o th e radiato r u p

t o th e bas e o f th e fille r neck .

Maintenanc e

Page 209 of 322

Coolin

g Syste m

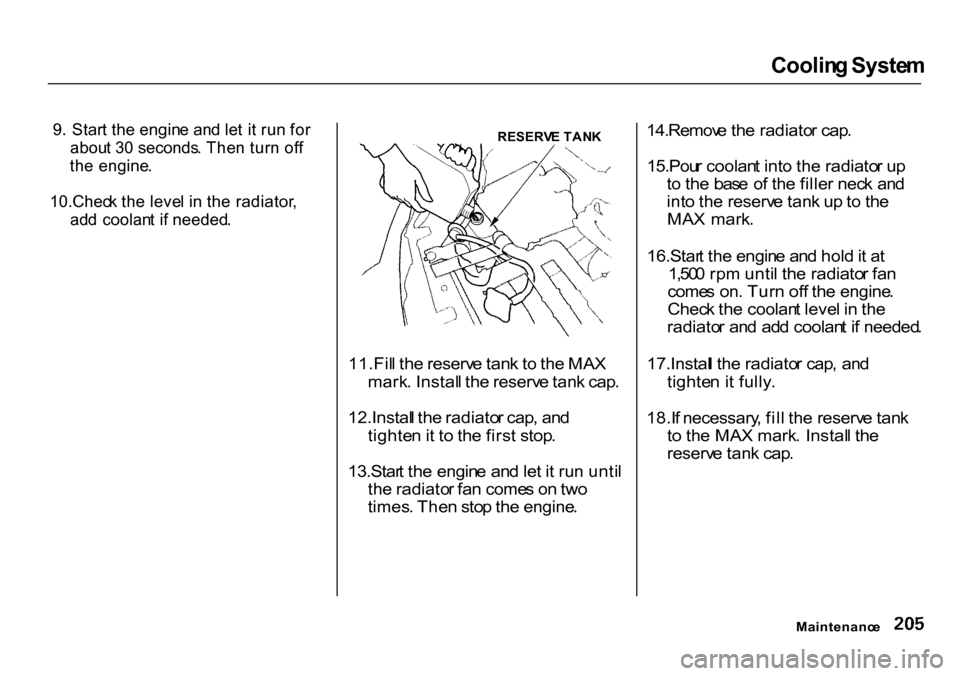

9 . Star t th e engin e an d le t i t ru n fo r

abou t 3 0 seconds . The n tur n of f

th e engine .

10.Chec k th e leve l i n th e radiator ,

ad d coolan t i f needed .

RESERV

E TAN K

11.Fil l th e reserv e tan k t o th e MA X

mark . Instal l th e reserv e tan k cap .

12.Instal l th e radiato r cap , an d

tighte n it t o th e firs t stop .

13.Star t th e engin e an d le t i t ru n unti l

th e radiato r fa n come s o n tw o

times . The n sto p th e engine . 14.Remov

e th e radiato r cap .

15.Pou r coolan t int o th e radiato r u p

t o th e bas e o f th e fille r nec k an d

int o th e reserv e tan k u p to th e

MA X mark .

16.Star t th e engin e an d hol d it a t

1,50 0 rp m unti l th e radiato r fa n

come s on . Tur n of f th e engine .

Chec k th e coolan t leve l i n th e

radiato r an d ad d coolan t i f needed .

17.Instal l th e radiato r cap , an d

tighte n i t fully .

18.I f necessary , fil l th e reserv e tan k

t o th e MA X mark . Instal l th e

reserv e tan k cap .

Maintenanc e

Page 210 of 322

Windshiel

d Washer s

Chec k th e leve l i n th e windshiel d

washe r reservoi r a t leas t monthl y

durin g norma l usage . I n ba d weather ,

whe n yo u us e th e washer s often ,

chec k th e leve l ever y tim e yo u sto p

fo r fuel .

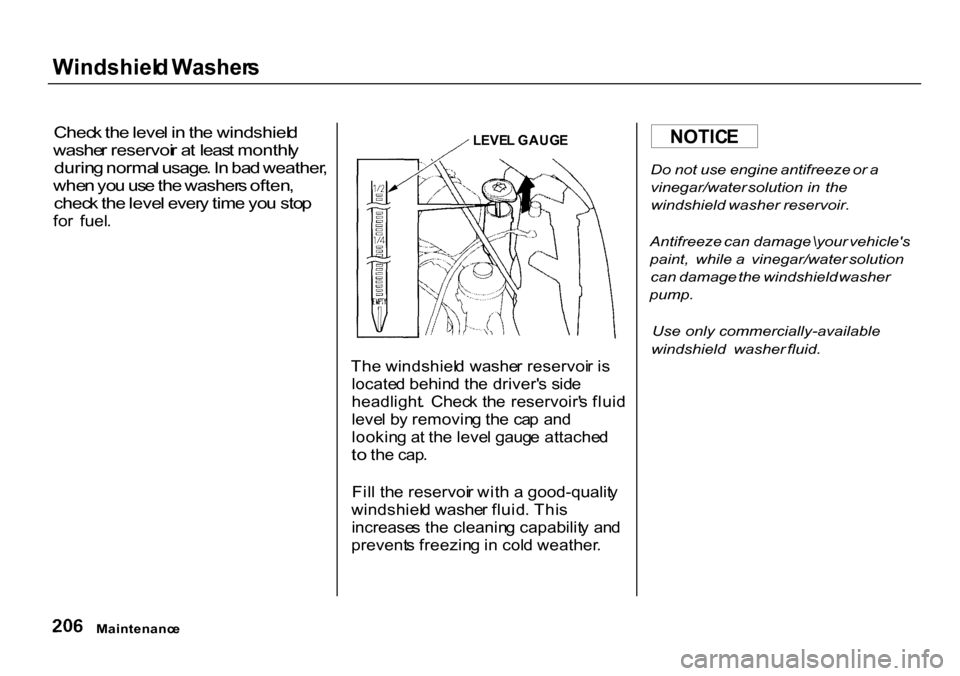

The windshiel d washe r reservoi r i s

locate d behin d th e driver' s sid e

headlight . Chec k th e reservoir' s flui d

leve l b y removin g th e ca p an d

lookin g a t th e leve l gaug e attache d

t o

th e cap .

Fil l th e reservoi r wit h a good-qualit y

windshiel d washe r fluid . Thi s

increase s th e cleanin g capabilit y an d

prevent s freezin g in col d weather .

Do

not use engine antifreeze or a

vinegar/water solution in the

windshield washer reservoir.

Antifreeze can damage \your vehicle's

paint, while a vinegar/water solution

can damage the windshield washer

pump.

Use only commercially-available

windshield washer fluid.

Maintenanc e

NOTIC

E

LEVE L GAUG E