Connectors HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 1257 of 1395

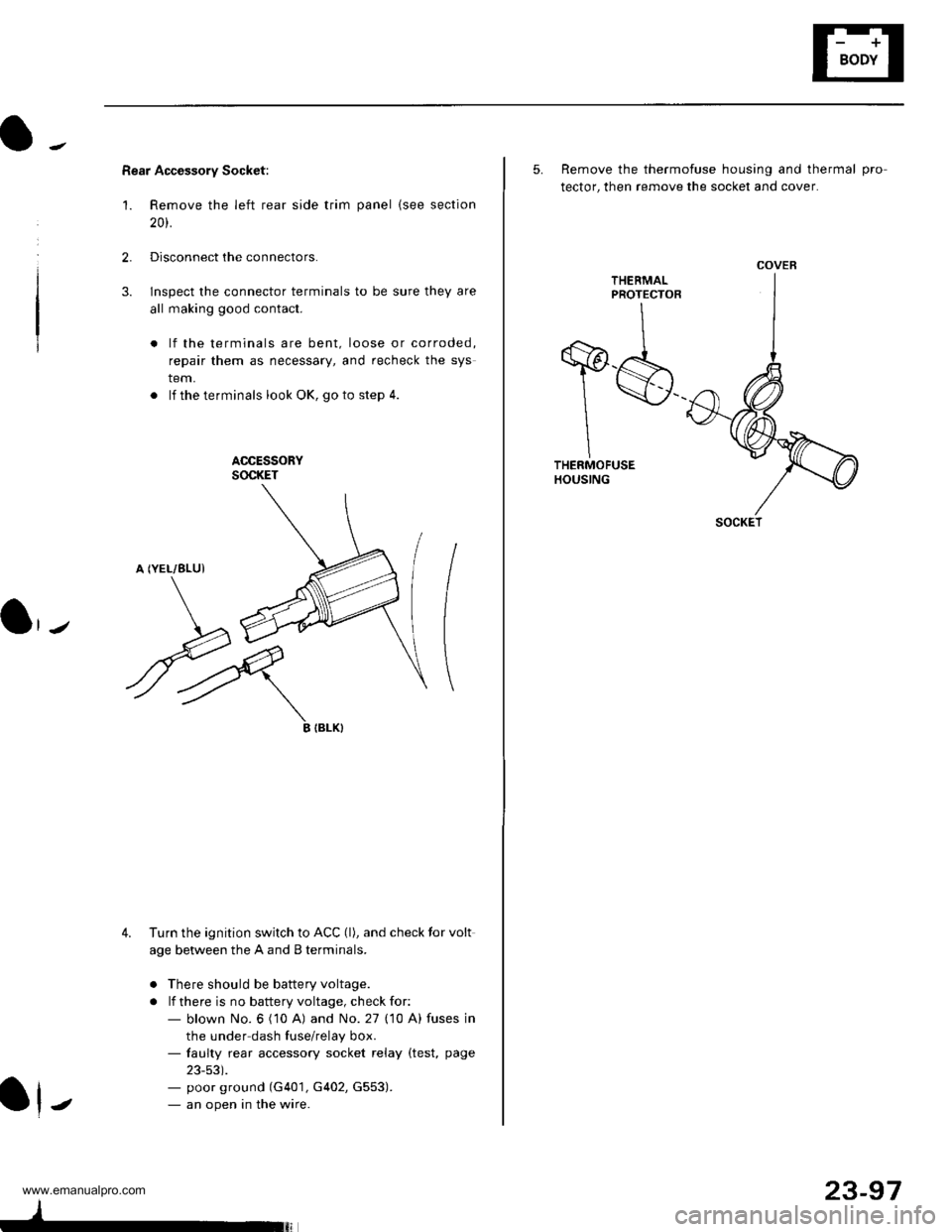

Rear Accessory Socket:

'1. Remove the left rear side trim panel {see section

20t.

2.Disconnect the connectors.

lnspect the connector terminals to be sure they are

all making good contact.

lf the terminals are bent, loose or corroded,

repair them as necessary, and recheck the sys

tem.

. lf theterminals look OK, goto step 4.

ACCESSORYSOCKET

A (YEL/8LUI

3.

\J

ryIIBLK}

4. Turn the ignition switch to ACC (l), and check tor volt

age between the A and B terminals.

o There should be battery voltage.

. lf there is no battery voltage, check for:- blown No. 6 ('10 A) and No. 27 (10 A) fuses in

the under dash fuse/relay box.- faulty rear accessory socket relay (test, page

23-53).- poor ground (G401, G402, G553).- an open in the wire.J

23-97

5. Remove the thermofuse housing and thermal pro

tector, then remove the socket and cover.

THEEMALPROTECTOR

T$THERMOFUSEHOUSING

COVER

SOCKET

www.emanualpro.com

Page 1266 of 1395

Horns

Switch Test

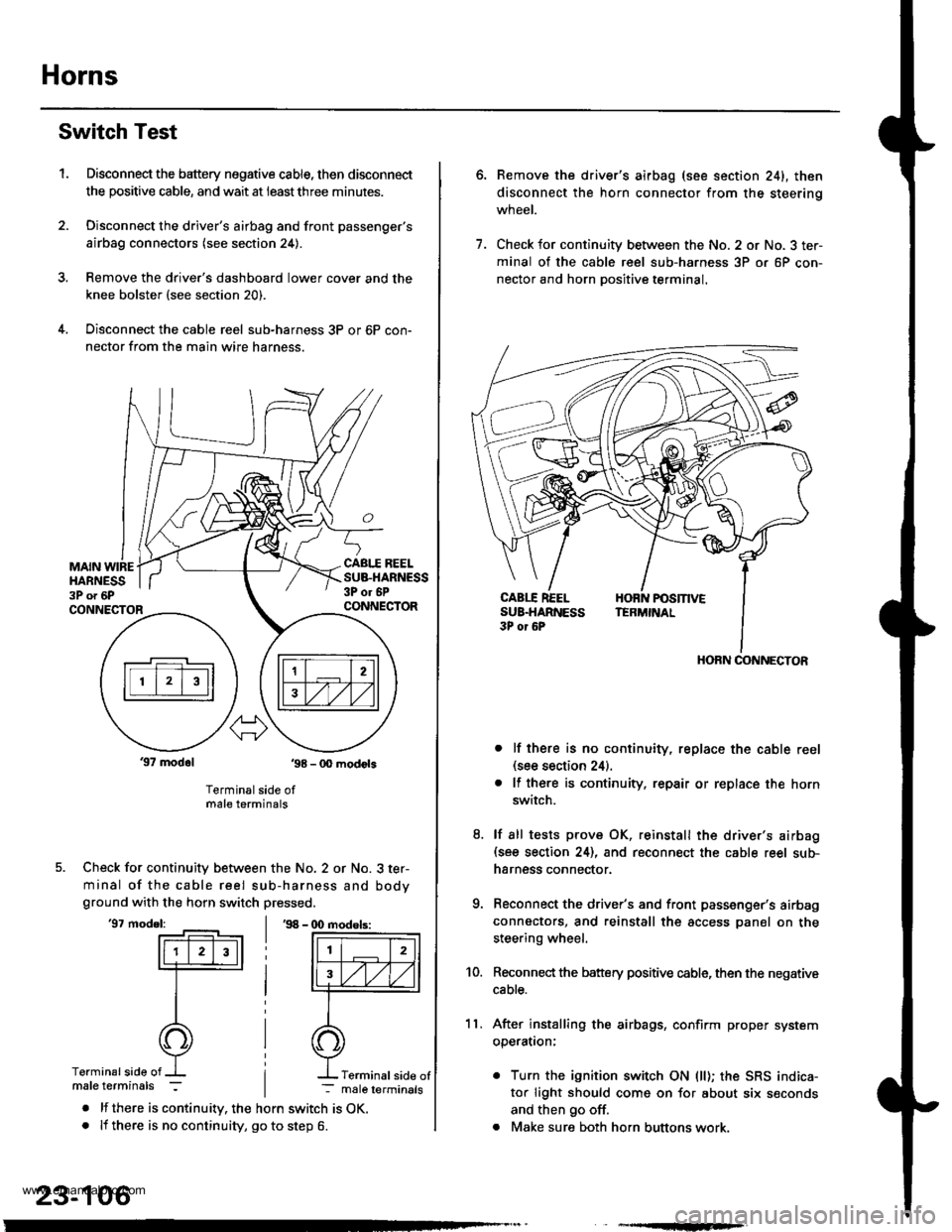

Disconnect the battery negative cable, then disconnect

the positive cable, and wait at ieastthree minutes.

Disconnect the driver's airbag and front passenger's

airbag connectors (see section 24).

Remove the drive.'s dashboard lower cover and the

knee bolster (see section 20).

Disconnect the cable reel sub-harness 3P or 6P con-

nector from the main wire harness.

1.

MAIN WIREHARNESS3P o. 6P

CABI.I REELSUB.HARNESS3P or 6PCONNECTORCONNECTOR

37 modol ,98 - 0O modots

Terminal side ofmale terminals

Check for continuity between the No. 2 or No. 3 ter-

minal of the cable reel sub-harness and bodyground with the horn switch pressed.

'97 model:'98 - (X) modols:

Terminalside of

. lf there is continuity. the horn switch is OK.. lf there is no continuity, go to step 6.

23-106

Terminal side of

6.Remove the driver's airbag (see section 241, then

disconnect the horn connector from the steerinq

wneet.

Check for continuity between the No. 2 or No. 3 ter-

minal of the cable reel sub-harness 3P or 6P con-

nector and horn Dositive terminal.

lf there is no continuity, replace the cable reel(see section 24).

lf there is continuity. repair or replace the horn

switch.

lf sll tests prove OK, reinstall the driver's airbag(see section 24), and reconnect the cable reel sub-

harness connector.

Reconnect the driver's and front passenger's airbag

connectors, and reinstall the access panel on the

steering wheel.

Reconnect the battery positive cable, then the negative

cable.

After installing the airbags, confirm proper system

operatron:

. Turn the ignition switch ON (ll); the SRS indica-

tor light should come on for about six seconds

and then go off.

. Make sure both horn buttons work.

7.

11.

8.

9.

10.

HORN CONNECTOR

www.emanualpro.com

Page 1279 of 1395

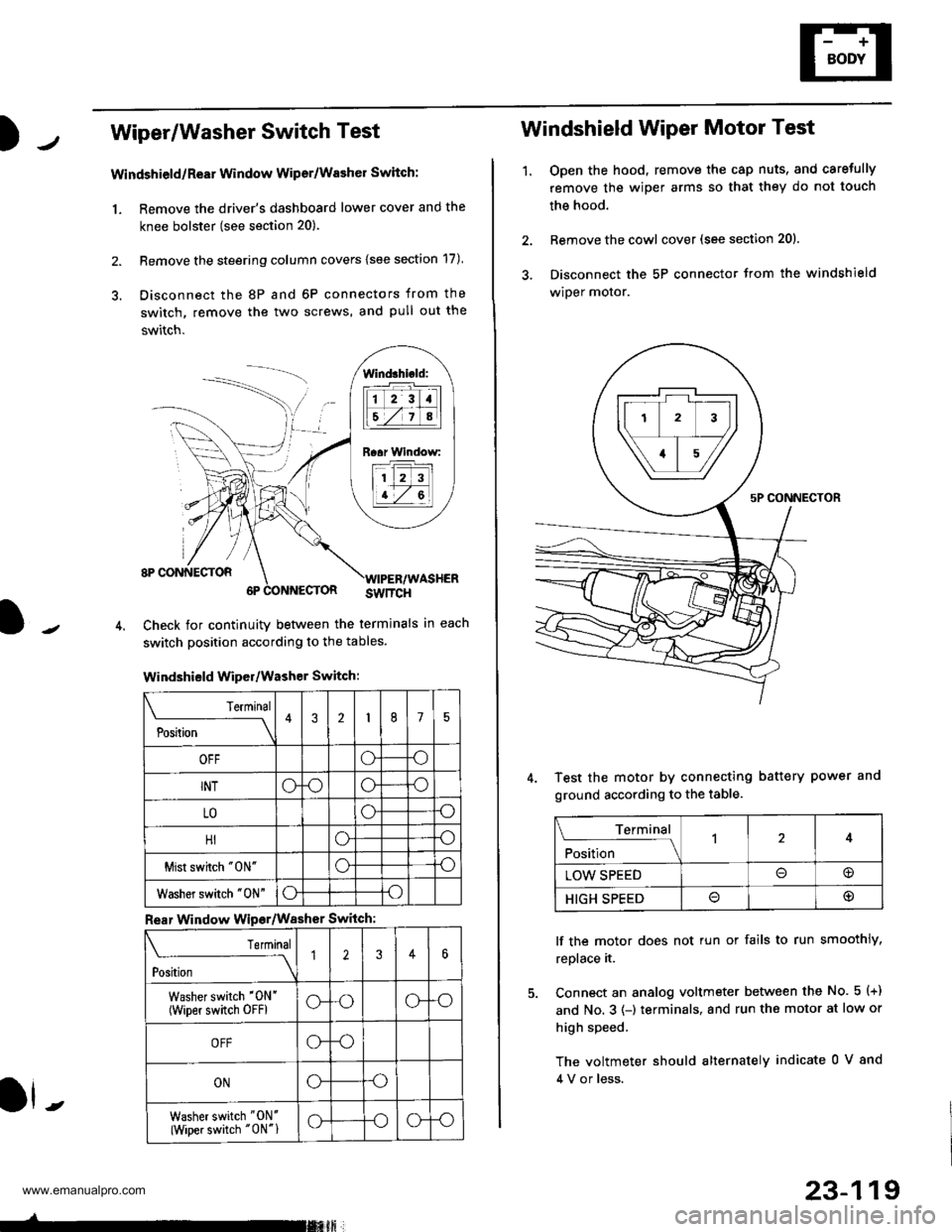

Wiper/Washer Switch Test

Windshield/ReEr Window Wiper/Washer Switch:

1. Remove the driver's dashboard lower cover and the

knee bolster (see section 20).

2. Remove the steering column covers {see section 17)

3. Disconnect the 8P and 6P connectors from the

switch, remove the two screws, and pull out the

switch.

J-

lind3hi.ld:

tilt-rltl

IEZIA

Raar Window:

11 2 3

I t-7 al

ll -

Check for continuity betlveen the termlnals in each

switch position according to the tables.

Windshield Wiper/Washer Switch:

Terminal

P*t-

---__\432175

OFFoo

INToooo

LOoo

HIoo

Mist swhch "0N"oo

Washer switch "0N"oo

Rear Window Wipsr/Washer Switch

Teminal

ti'"

---\12346

Washer switch '0N'

(wiper switch oFFlG-oG-o

OFFG-o

ONGo

Washer switch "ON'

(Wiper switch "0N"1G-oG-o

-rmxft

23-119

1.

Windshield Wiper Motor Test

Open the hood, remove the cap nuts, and caretully

remove the wiper arms so that they do not touch

the hood.

Remove the cowl cover (see section 201.

Disconnect the 5P connector trom the windshield

wiper motor.

Test the motor by connecting battery power and

ground according to the table.

lf the motor does not tun or fails to run smoothly,

replace it.

Connect an analog voltmeter between the No. 5 (+)

and No. 3 (-) terminals, and run the motor at low or

high speed.

The voltmeter should alternately indicate 0 V 8nd

4 V or less.

Terminal

;fi;"

-l4

LOW SPEED@

HIGH SPEED@

www.emanualpro.com

Page 1280 of 1395

Wipers/Washers

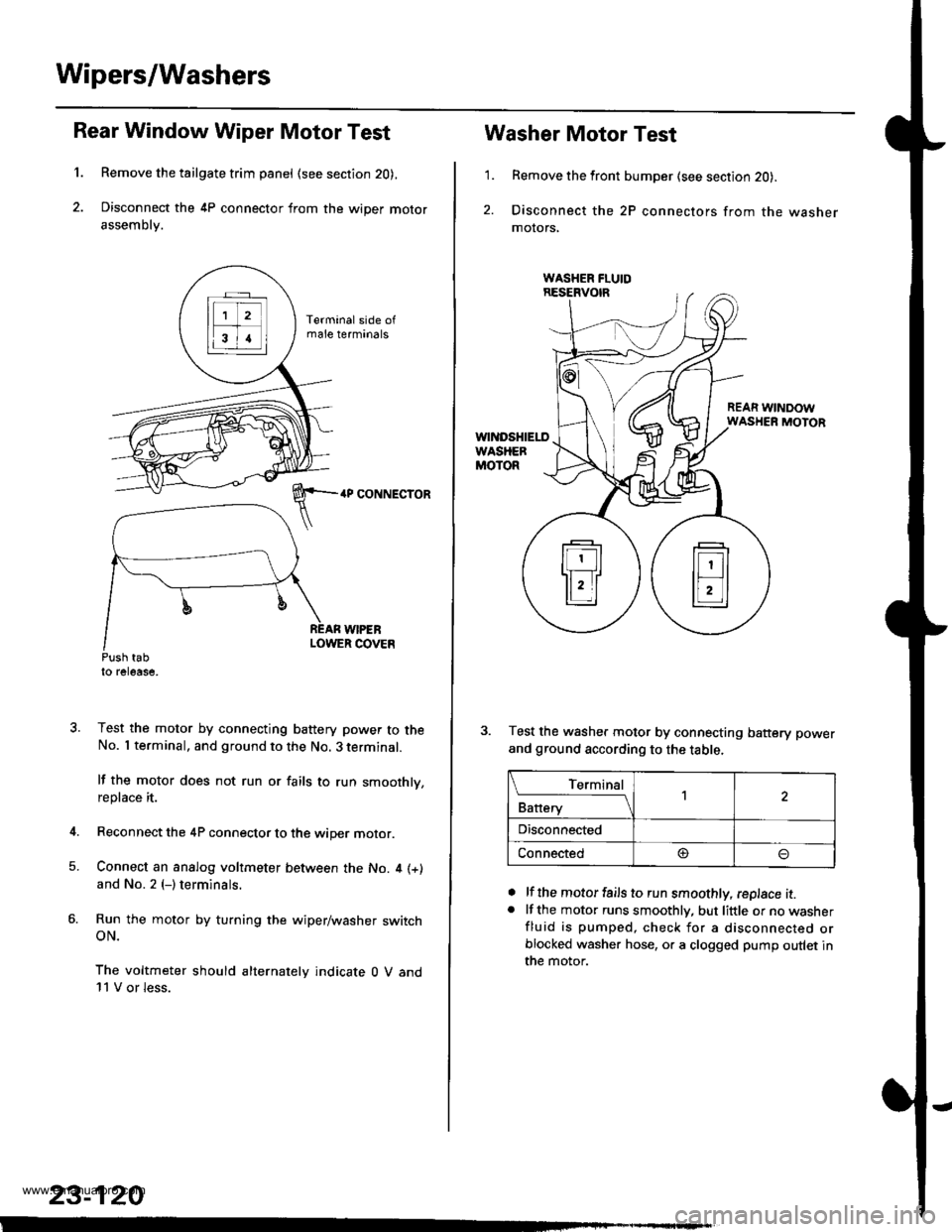

1.

Rear Window Wiper Motor Test

Remove the tailgate trim panel (see section 20),

Disconnect the 4P connector from the wiper motor

assembly.

4P CONNECTOR

WIPEBLOWER COVEnPush tabto release,

Test the motor by connecting battery power to theNo. I terminal, and ground to the No. 3 terminal.

lf the motor does not run or fails to run smoothly,replace it.

Reconnect the 4P connector to the wiper motor.

Connect an analog voltmeter between the No. 4 (+)

and No. 2 (-) terminals.

Run the motor by turning the wiper/washer switchoN.

The voltmeter should alternately indicate 0 V and11 V or less.

4.

5.

23-120

1.

Washer Motor Test

Remove the front bumper (see section 20).

Disconnect the 2P connectors from the washermolors,

REAR WINDOWWASHER MOTOR

Test the washer motor by connecting battery power

and ground according to the table.

lf the motor fails to run smoothly, replace it.lf the motor runs smoothly, but little or no washerfluid is pumped, check for a disconnected orblocked washer hose, or a clogged pump outlet inthe motor.

a

a

L_Iq'.r91

Battery

,l

Disconnected

Connected@

www.emanualpro.com

Page 1294 of 1395

Power Windows

Master Switch Input Test

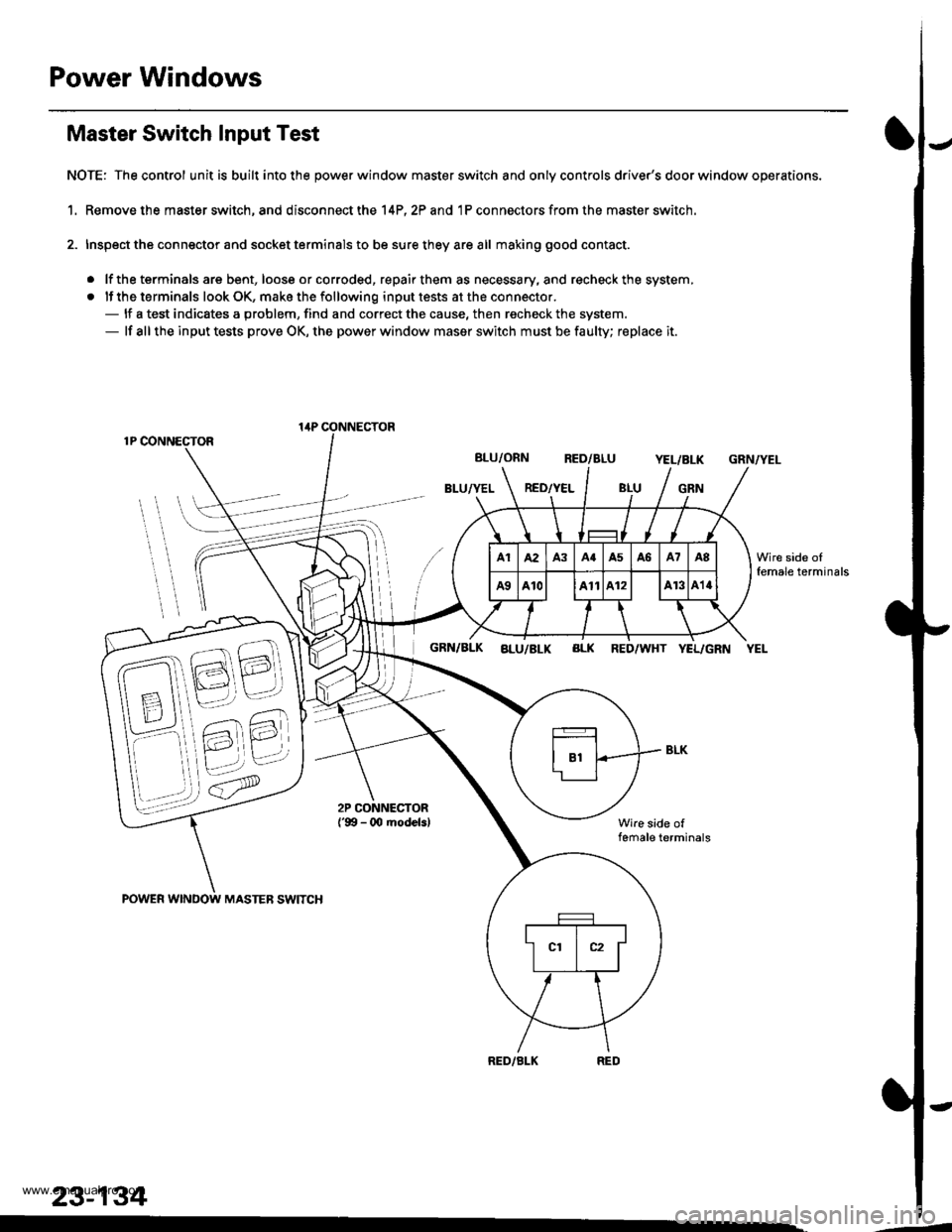

NOTE: The control unit is built into the power window master switch and only controls driver's door window operations.

1. Remove the master switch, and disconnect the 14P,2? and 1P connectors from the master switch.

2. Inspect the connector and socket terminals to be sure they are all making good contact.

. lf the terminals are bent, loose or corroded, repair them as necessary, and recheck the system,

. lf the terminals look OK, make the following input tests at the connector.- lf a test indicates a problem, find and correct the cause, then recheck the system.- lf all the input tests prove OK, the power window maser switch must be faulty; replace it.

1P CONNECTOR

BLU/ORN RED/BLUYEL/BLK

BLU/YEL RED/YELGRN

GRN/YEL

POWER WINDOW MASTEB SWITCH

GRN/BLK aLu/BLK BLK RED/WHT YEL/GRN YEL

Wire side offemale terminals

RED/BLK

lirP CONNECTOR

23-134

Wire side oIfemale terminals

.-

www.emanualpro.com

Page 1296 of 1395

Power Windows

1.

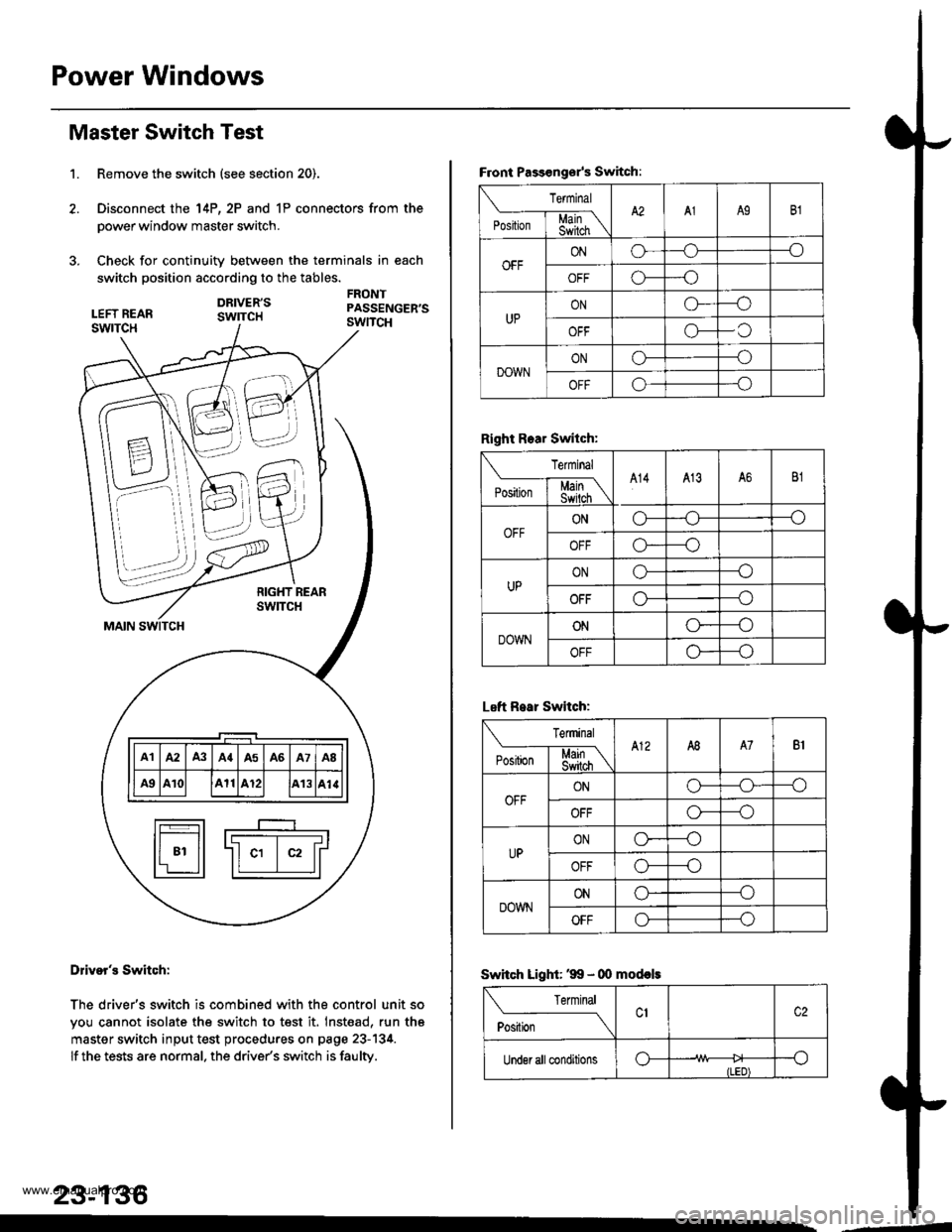

Master Switch Test

Remove the switch (see section 20).

Disconnect the 14P, 2P and 1P connectors from the

power window master switch.

Check for continuity between the terminals in each

switch position according to the tables.

DRIVER'SswrTcH

FRONTPASSENGER'SswncH

B \\N

7-.i::,,,

\\'. )),,

t-_____r-__I F---T-----r-----r----r-----T---------T-----'r Illal lA2 lA3 lA{lA5 lA6 lA7 laB ll

lF#lll ae lA10l lA11lA12l lA13lal.llI r________r_____J t-t___Jl

fr---r-l r----

I t-------- -------r l

ll 81 ll -ll c1 | c2 lrl'r ll ll I llL--:J

Dliver's Switch:

The driver's switch is combined with the control unit so

you cannot isolate the switch to test it. Inst€ad, run th6

master switch input test procedures on page 23-134.

lf the tests are normal. the drive/s switch is faulty.

23-136

--d

F.ont Passongsr's Switch:

rermrnal

'**[ffiA2A1A9B1

OFFONo--_o

o---o

UPONG---o

OFFo-C

DOWNONo---o

OFFo---o

Right Rear Switch:

Terminal

'".'*l-$j[\A14413A6B1

OFFONo---o

OFFo*--o

UPONo---o

OFFo---o

DOWNONo----o

OFFo---o

Left R.ar Switch:

Terminal

e*Li*l$[\A12A8A7B1

OFFONo-o--o

OFFo---o

UPONo----o

OFFo---o

DOWNONo--_o

OFFo---o

Swhch Light: '99 - 00 mod€ls

Terminal

ti.*----_\

Under all conditionso--o

ILED)

www.emanualpro.com

Page 1297 of 1395

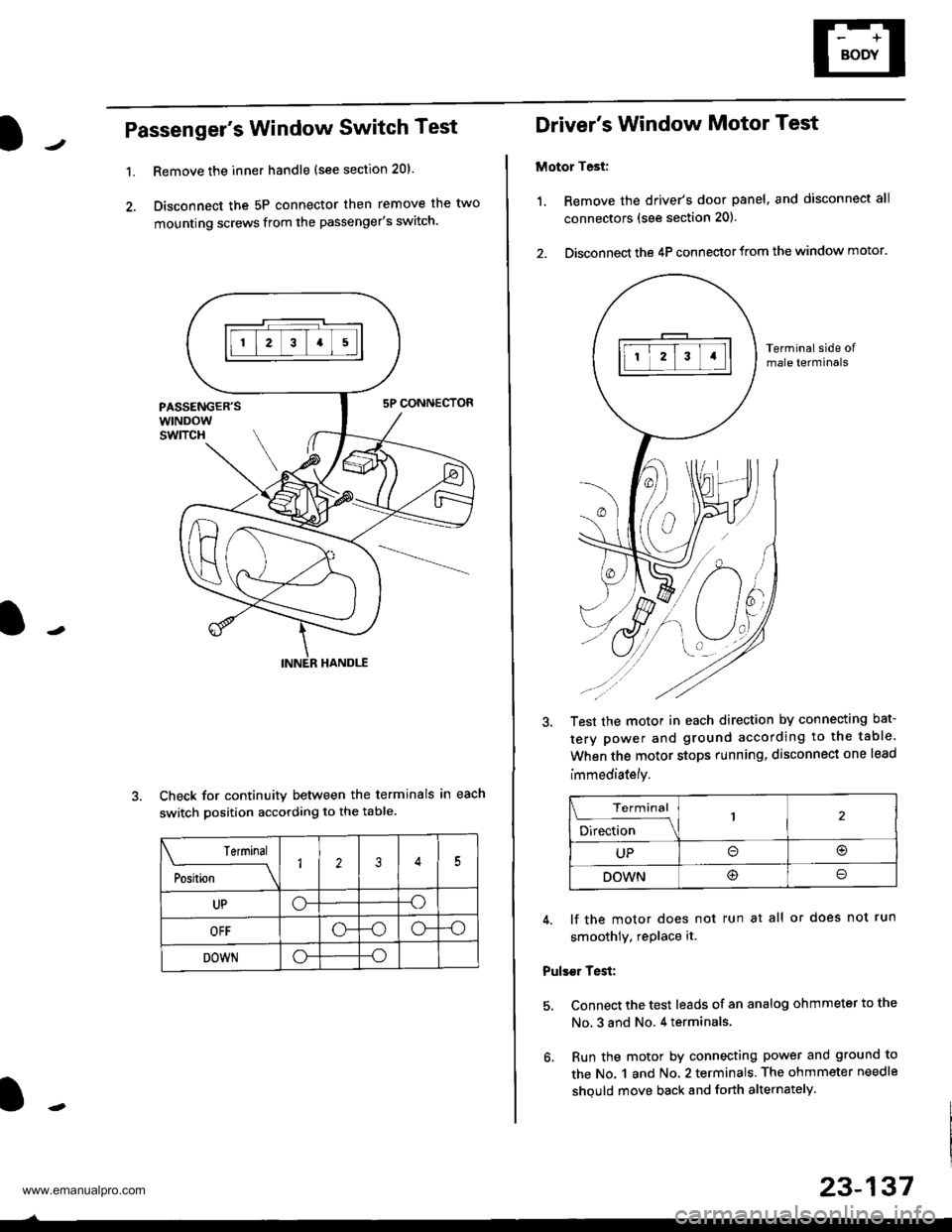

Passenger's Window Switch Test

1.Remove the inner handle (see section 20).

Disconnect the 5P connector then remove the two

mounting screws from the passenger's switch.

Check for continuity between the terminals in each

switch position according to the table

Terminal

;"rL-

__\1235

UPo--o

OFF-oo--o

DOWNo--o

Driver's Window Motor Test

Motor Test:

1. Remove the driver's door panel, and disconnect all

connectors (see section 201.

2. Disconnect the 4P connector from the window motor.

Terminal side ofmale terminals

Test the motor in each direction by connecting bat-

tery power and ground according to the table.

When the motor stops running. disconnect one lead

immediately.

Terminal

;;b"

-\

UPo(!r

DOWN@o

4. lf the motor does not run at all or does not run

smoothly. rePlace it.

Pulser Test:

5. Connect the test leads of an analog ohmmeter to the

No, 3 and No. 4 terminals.

6. Run the motor by connecting power and ground to

the No. 1 and No. 2 terminals. The ohmmeter needle

shquld move back and forth alternately.

23-137

www.emanualpro.com

Page 1298 of 1395

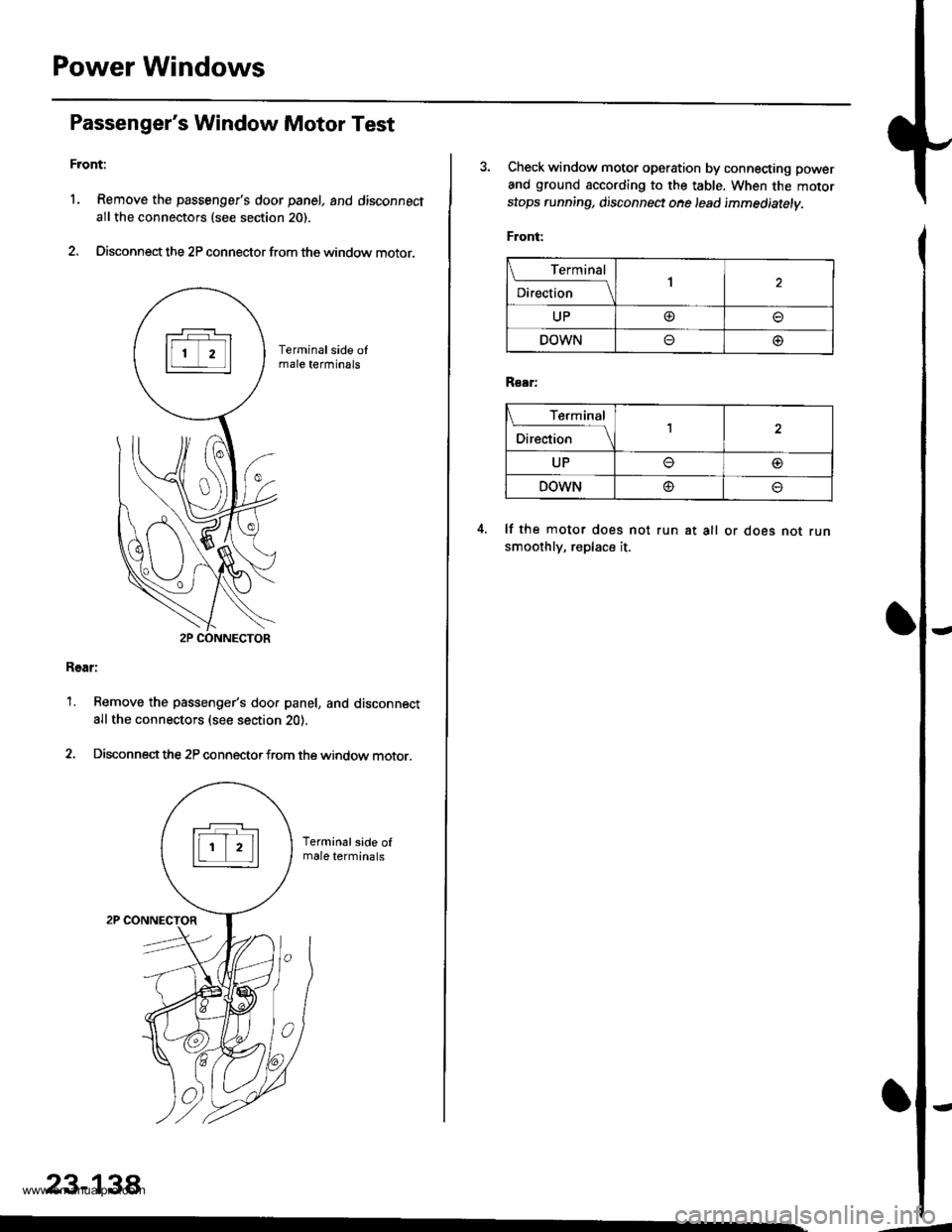

Power Windows

Passenger's Window Motor Test

Front:

l. Remove the passenger's door panel, and disconnect

allthe connectors (see section 20).

2. Disconnect the 2P connector from the window motor.

Rear:

1. Remove the passenger's doo. panel, and disconnect

allthe connectors (see section 20).

2. Disconnectthe 2P connectorfrom the window motor.

23-138

3. Check window motor operation by connecting power

and ground according to the table. When the motor

stops running, disconnect ohe lead immediatelv.

Front:

Terminal

;."b"

.l\

UP@

DOWNo@

R€ar:

I Terminal

;*r*

-l\

UPo@

DOWN@o

lf the motor does not run at all or does not runsmoothly, replace it.

www.emanualpro.com

Page 1310 of 1395

)

Supplemental Restraint System (SRS)

Special Tools .."....."" 24-14

Component/Wring Location

lndex - '97 model ..........'.." '.....""" 24-15

Component/Wiring Location

lndex - '98 - 00 models ..............." 24-16

Description .'.........."'.24'17

Circuit Diagram .........24'14

Precautions/Procedures

General Precautions ......".."'........... 24-19

Airbag/Seat Belt Tensioner

Handling and Stolage ....''........... 24-19

SRS Unit Precautions ...............'...... 24-20

lnspeciion After Deployment .......'.24'20

)

with Built-in Short Contact '...'....24-21

Spring-loaded Lock Connectors .."' 24-22

BackProbing SPring-loaded Lock

Conneetors ,.......24-22

Disconnecting the Airbag Connectors and

the Seat Beh Tensioner

Connectors ....'....24-23

Steering-lelated Precautions .......... 24-25

Troubleshooting

Self -diagnostic Procedures ............. 24-26

Reading the DTC .................. .....".."' 24'26

Erasing the DTC Memory ................24-28

Troubleshooting lntermittent

Faifures "'...........24'24

Diagnostic Trouble Gode {DTC}

Chart -'97 model ....""....... "......24-29

Diagnostic Trouble Gode (DTCI

Chart -'98 - 00 models ............. 24-31

SRS Indicator Light Wire

Connections ','," 24'33

Ff owcharts ....-........24'34

Driver's Airbag

Repf acement ..'......21'87

Front Passenger's Airbag

Repfacement .....'.',24'AS

Gable Reel

Replacement .......'.24-91

SRS Unit

Replacement .........24-95

Airbag/Seat Belt Tensioner

Disposaf .................24'97

)-e

www.emanualpro.com

Page 1313 of 1395

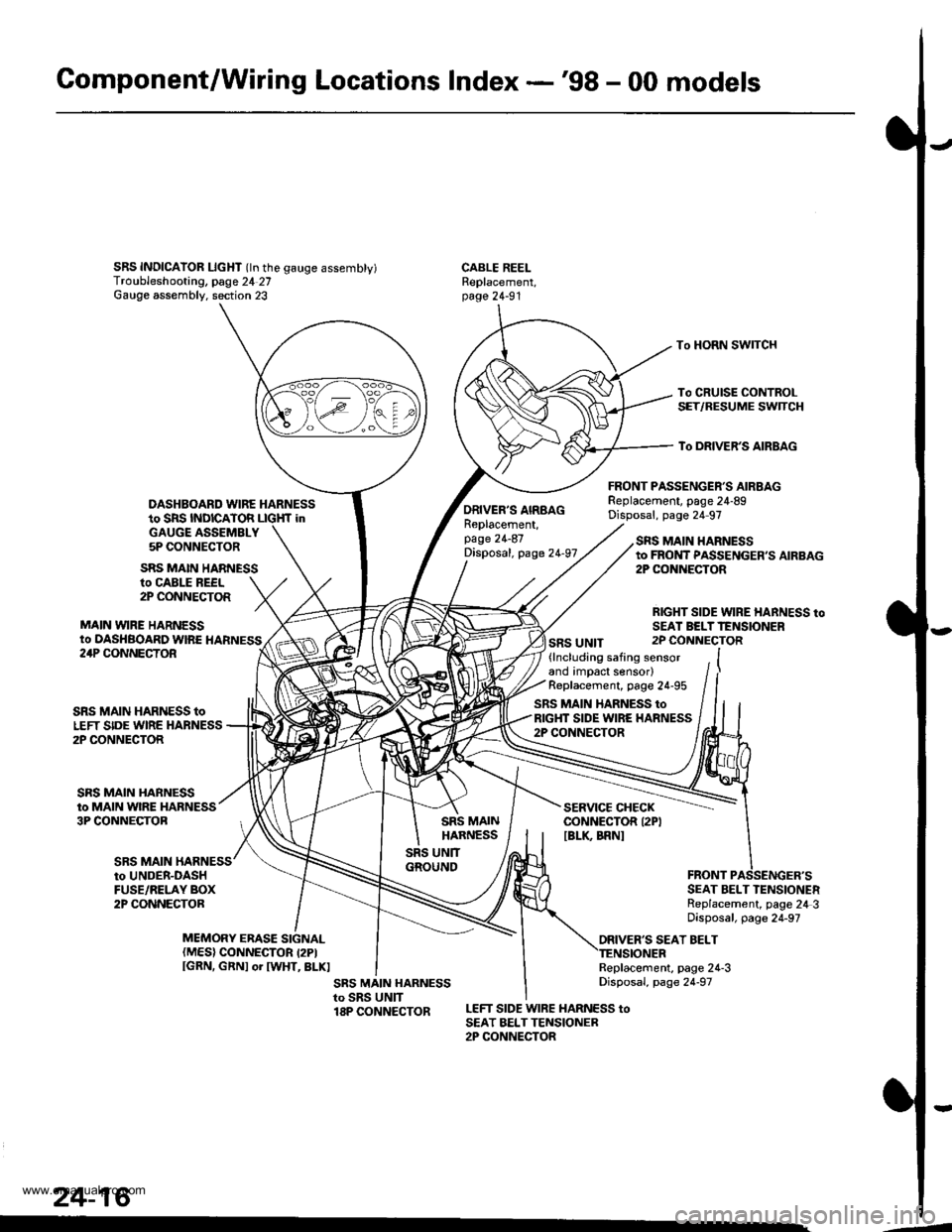

Gomponent/Wiring Locations Index -'98 - 00 models

SRS INDICAIOR LIcHT (ln the gauge assembty)Troubleshooting, page 24 27Gauge assembly. section 23

DASHBOARD WIRE HARNESSto SRS INDICATOR LIGHf inGAUGE ASSEMBLY5P CONNECTOR

FRONT PASSENGER'S AIRBAGReplacement, page 24-89Disposal, page 24 97

CABLE REELReplacement,page 24-91

To HORN SWITCH

To CRUISE CONTROLSET/RESUME SWTCH

To DRIVER'S AIRBAG

ro CABLE REEL2P CONNECTOR

MAIN VYIRE HARNESSto DASHBOARD WIRE HARNESS

SRS MAIN HARNESS

ORIVER'S AIRBAGReplacement,page 24-87Disposal, page 24-97

SRS UNIT

SRS MAIN HARNESSto FROI{T PASSENGER,S AIRBAG2P CONiIECTOR

RIGHT SIDE WIRE HARNESS toSEAI BELTTENSIONER2P CONNECTOR24P CONNECTOR

SRS MAIN

SRS MAIN HARNESS toLEFT SIDE WIRE HARNESS2P CONNECTOR

SRS MAIN HARNESSto MAIN WIRE HARNESS3P CONNECTOB

(lncluding safing sensorand impact sensor)Replacement, page 24-95

SRS MAIN HARNESS toRIGHT SIDE WIRE HARNESS2P CONNECTOR

SERVICE CHECKCONNECTOR I2PIIBLK BRNI

to UNDER-DASHFUSE/RELAY BOX2P CONNECTORSEAT BELT TENSIONERReplacement, page 24 3Disposal, page 24-97

ORIVER'S SEAT BELTMEMORY ERASE SIGNAL(MES) CONNECTOR I2PIIGRN, GRNI or IWHT, BLKIReplacement, page 24-3Disposal, page 24-97

LEFT SIDE WIRE HARNESS toSEAT BELTTENSIONER2P CONNECTOR

24-16

.4

www.emanualpro.com