Connectors HONDA CR-V 2000 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 1316 of 1395

Precautions/Procedures

)General Precautions

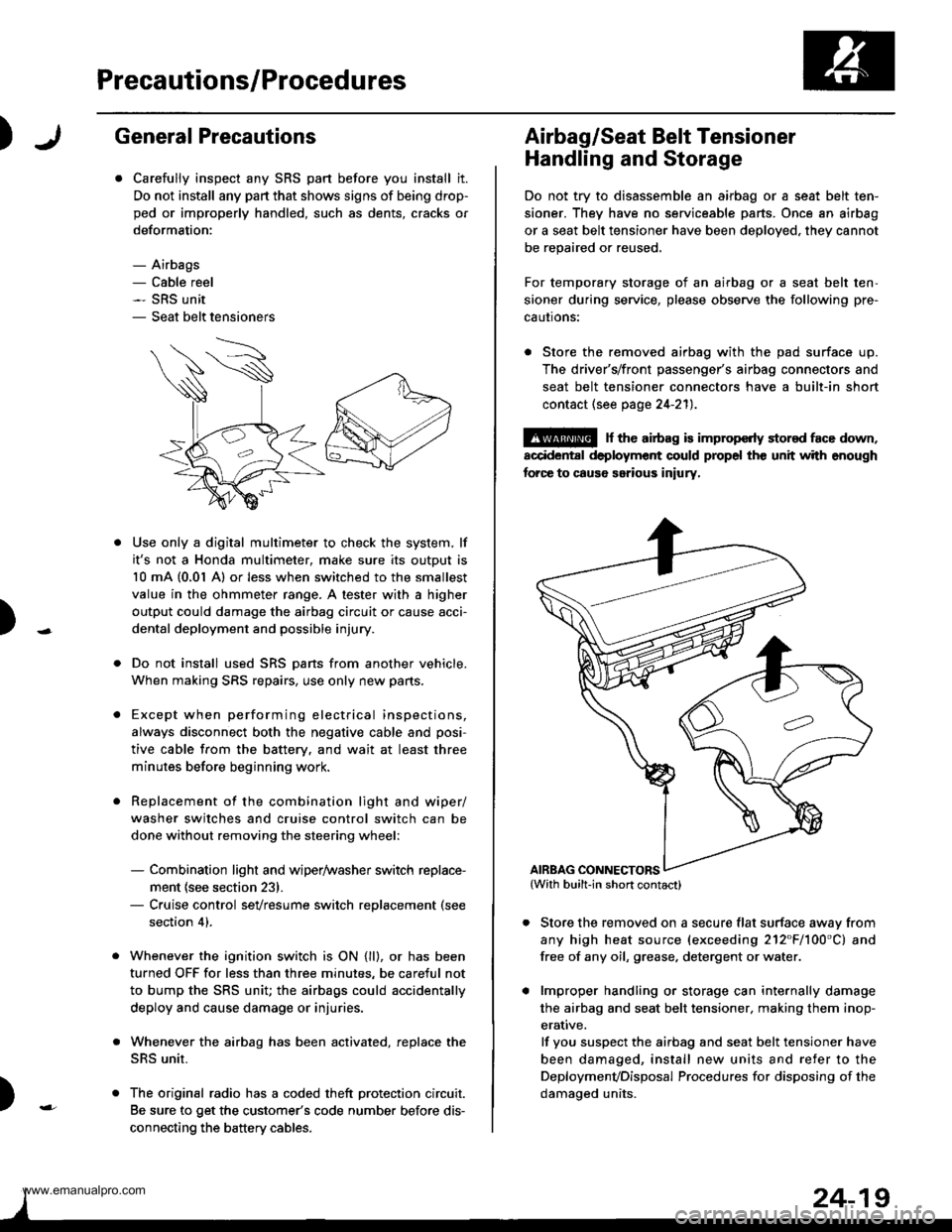

Carefully inspect any SRS part before you install it.

Do not install any part that shows signs of being drop-

ped or improperly handled, such as dents, cracks or

deformation:

- Airbags- Cable reel- SRS unit- Seat belt tensioners

N

)-

Use only a digital multimeter to check the system, lf

it's not a Honda multimeter, make sure its output is

10 mA (0,01 A) or less when switched to the smallest

value in the ohmmeter range. A tester with a higher

output could damage the airbag circuit or cause acci-

dental deployment and possible injury.

Do not install used SRS Dans from another vehicle,

When making SRS repairs, use only new pans.

Except when performing electrical inspections,

always disconnect both the negative cable and posi-

tive cable from the batterv. and wait at least three

minutes before beginning work.

Replacement of the combination light and wiper/

washer switches and cruise control switch can be

done without removing the steering wheel:

- Combination light and wiper/washer switch replace-

ment {see section 231.- Cruise control sevresume switch replacement (see

section 41.

Whenever the ignition switch is ON {ll}, or has been

turned OFF for less than three minutes, be careful not

to bump the SRS unit; the airbags could accidentally

deploy and cause damage or injuries.

Whenever the airbag has been activated, replace the

SRS unit.

The original radio has a coded theft protection circuit.

Be sure to get the customer's code number before dis-

connecting the battery cables.

)

Airbag/Seat Belt Tensioner

Handling and Storage

Do not try to disassemble an airbag or a seat belt ten-

sioner. They have no serviceable parts. Once an airbag

or a seat belt tensioner have been deployed. they cannot

be repaired or reused.

For temporary storage of an airbag or a seat belt ten-

sioner during service, please observe the following pre-

cautons:

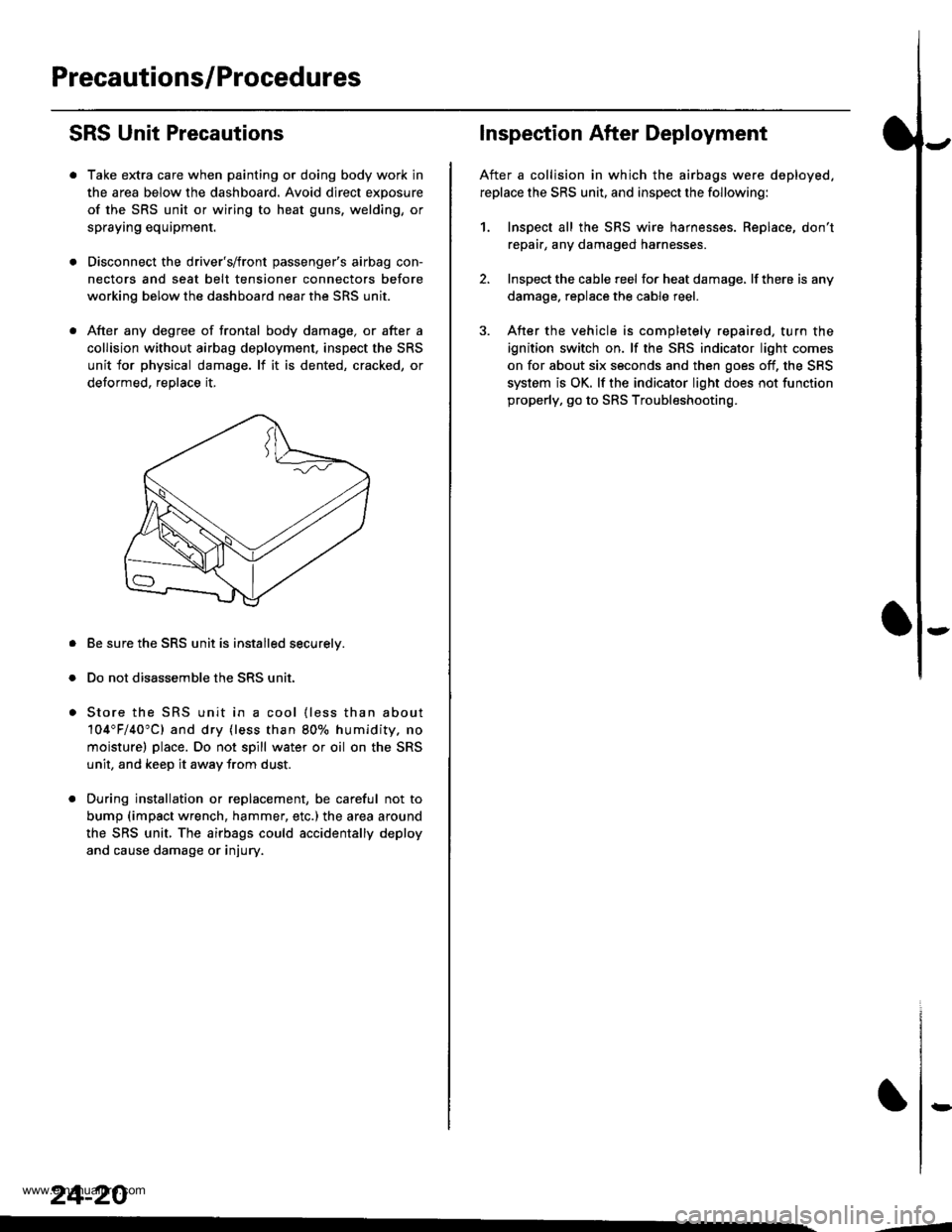

. Store the removed airbag with the pad surface up.

The driver's/front passenger's airbag connectors and

seat belt tensioner connectors have a built-in short

contact (see page 24-211.

@ r th€ airb.g is impropcrty stor€d face down,

accidental deployment could propel the unit with enough

forc€ to caus6 serious iniury,

Store the removed on a secure flat surface awav from

any high heat source (exceeding 212"F/100'C) and

free of any oil, grease. detergent or water.

lmproper handling or storage can internally damage

the airbag and seat belt tensioner. making them inop-

erative.

lf you suspect the airbag and seat belt tensioner have

been damaged, install new units and refer to the

Deploymenvoisposal Procedures for disposing of the

damaoed units.

AIRBAG CONNECTORS

www.emanualpro.com

Page 1317 of 1395

Precautions/Procedures

SRS Unit Precautions

Take extra care when painting or doing body work in

the area below the dashboard. Avoid direct exposure

of the SRS unit or wiring to heat guns, welding, or

spraying equipment.

Disconnect the driver's/front passenger's airbag con-

nectors and seat belt tensioner connectors before

working below the dashboard near the SRS unit.

After any degree of frontal body damage, or after a

collision without airbag deployment, inspect the SRS

unit for physical damage. lf it is dented, cracked, or

detormed, reolace it,

Be sure the SRS unit is installed securelv.

Do not disassemble the SRS unit.

Store the SRS unit in a cool {less than about

104"F/40"C) and dry {less than 80o/o humidity. no

moisture) place. Do not spill water or oil on the SRS

unit, and keep it awav from dust.

During installation or replacement, be careful not to

bump (impact wrench, hammer, etc.) the area a[ound

the SRS unit, The airbags could accidentally deploy

and cause damage or injury.

24-20

,..4

Inspection After Deployment

After a collision in which the airbags were deployed.

replace the SRS unit, and inspect the following:

1. Inspect all the SRS wire harnesses. Replace, don't

repair, any damaged harnesses

2. Inspect the cable reel for heat damage, lf there is any

damage. replace the cable reel.

3. After the vehicle is completely repaired, turn the

ignition switch on. lf the SRS indicator light comes

on for about six seconds and then goes off, the SRS

system is OK. lf the indicator light does not function

properly, go to SRS Troubleshooting.

rD

www.emanualpro.com

Page 1319 of 1395

Precautions/Procedures

Spring-loaded Lock Connectors

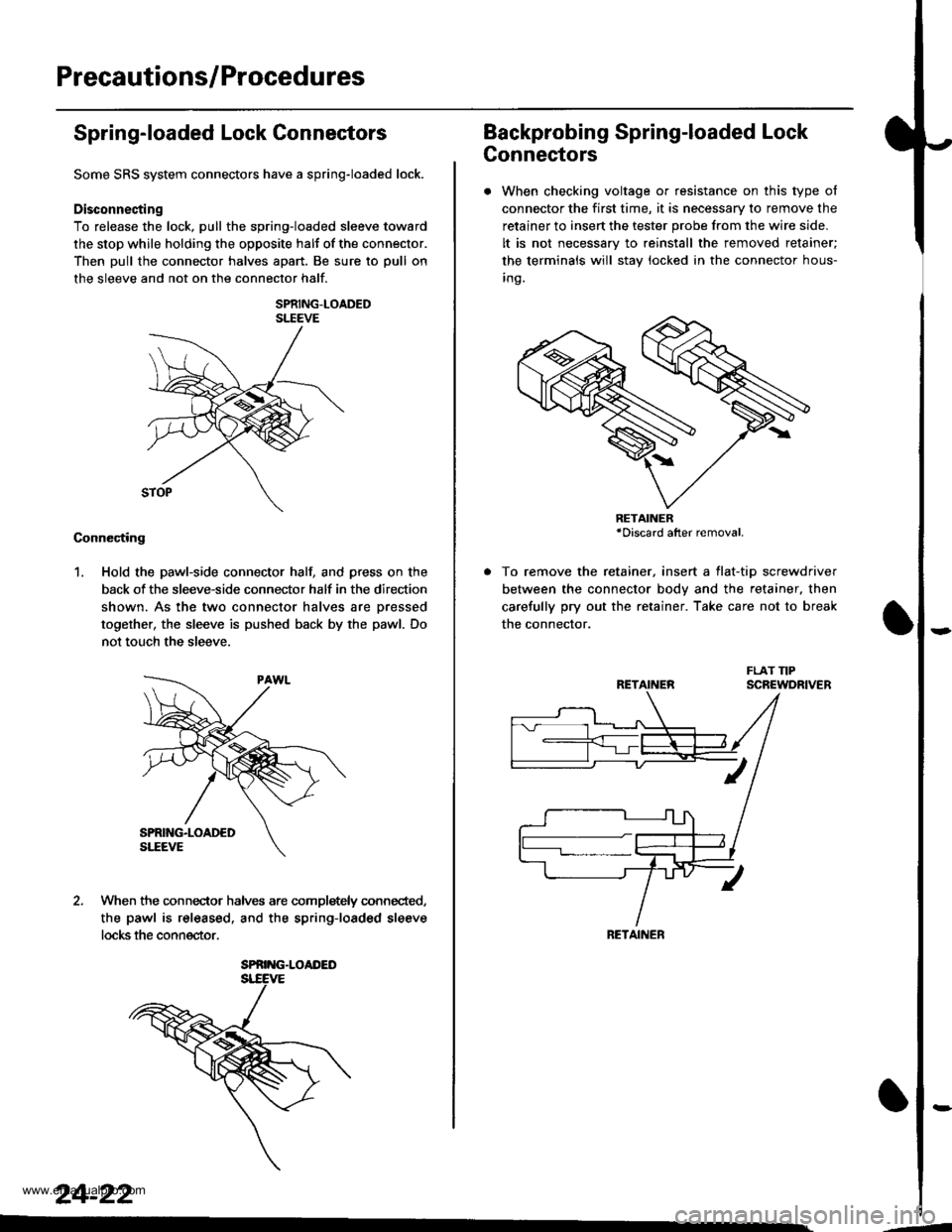

Some SRS system connectors have a spring-loaded lock.

Disconnecting

To release the lock, pull the spring-loaded sleeve toward

the stop while holding the opposite halt of the connector.

Then pull the connector halves apart. Be sure to pull on

the sleeve and not on the connector half.

SPRING-LOADEDSLEEVE

Connecting

1. Hold the pawl-side connector hall and press on the

back of the sleeve-side connector half in the direction

shown. As the two connector halves are Dressed

together, the sleeve is pushed back by the pawl. Do

not touch the sleeve.

When the connec-tor halves are completely connected,

the pawl is released. and the spring-loaded sleeve

locks the connector.

SPRING.LOAI'ED

24-22

Backprobing Spring-loaded Lock

Connectors

. When checking voltage or resistance on this type of

connector the first time, it is necessary to remove the

retainer to insert the tester probe from the wire side.

It is not necessary to reinstall the removed retainer;

the terminals will stay locked in the connector hous-

inq.

To remove the retainer, insert a tlat-tip screwdriver

between the connector body and the retainer. then

carefully pry out the retainer. Take care not to break

the connector.

RETAINER*Discard after removal.

RETAINEN

RETAINER

---

www.emanualpro.com

Page 1320 of 1395

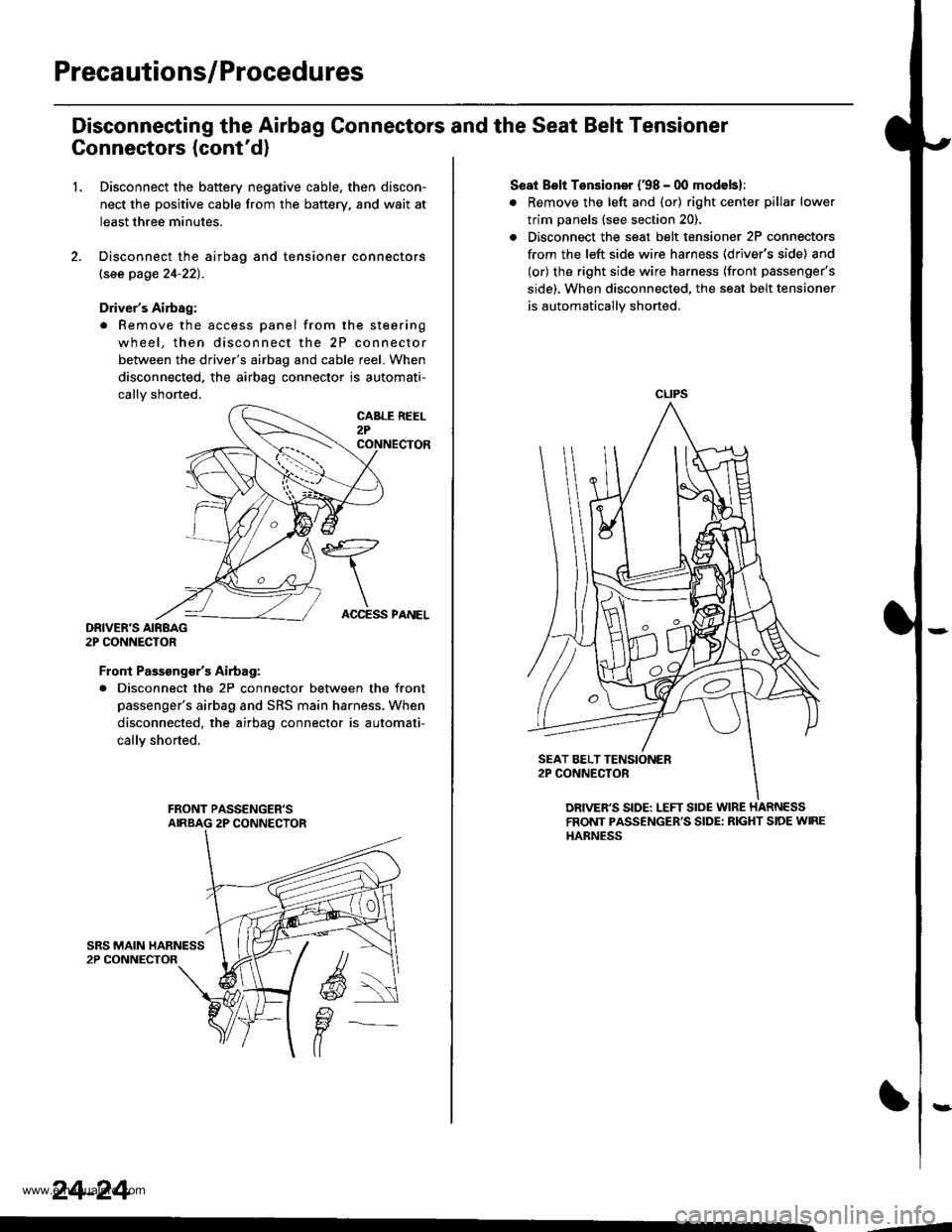

)1,Disconnecting the Airbag Gonnectors and the Seat Belt Tensioner Connectors

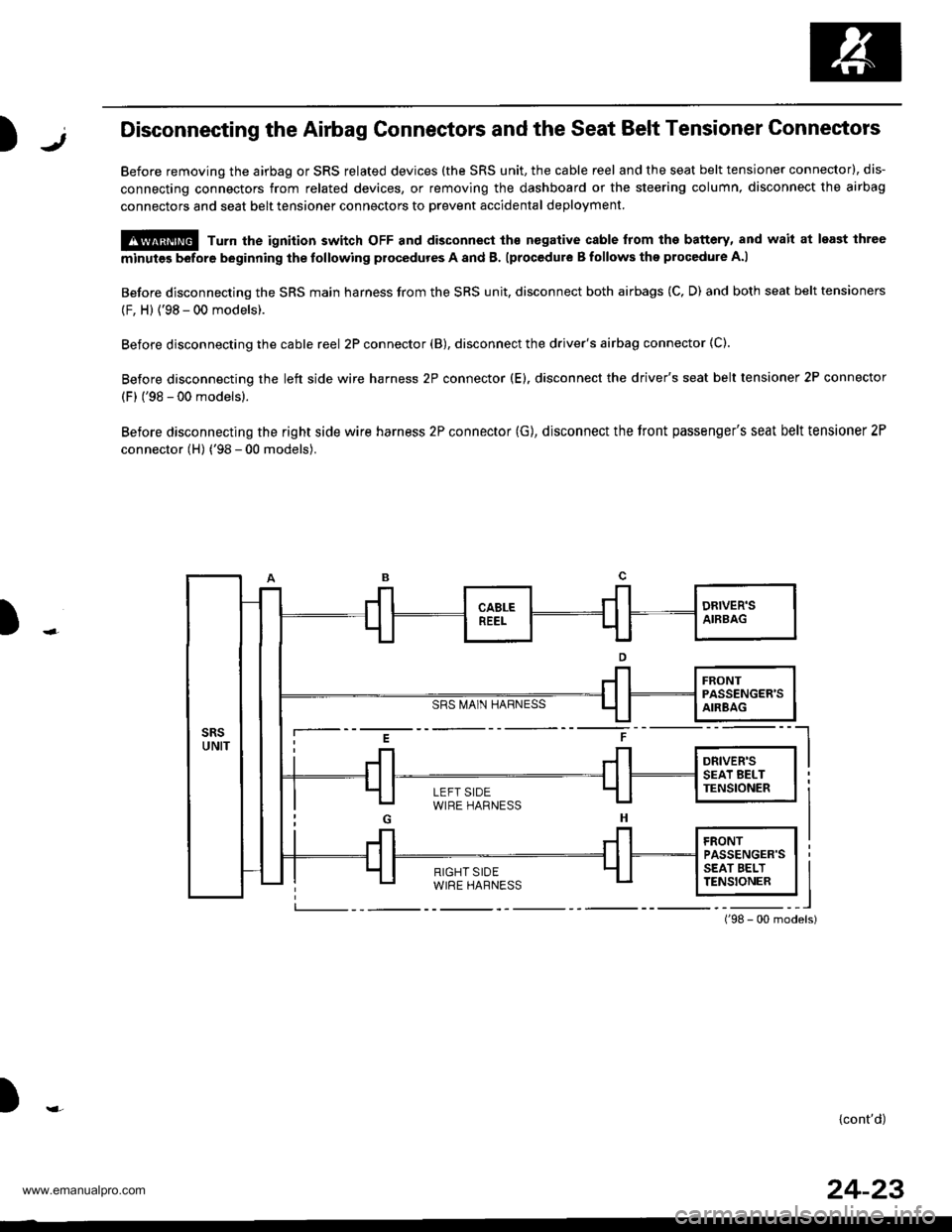

Before removing the airbag or SRS related devices (the SRS unit, the cable reel and the seat belt tensioner connector), dis-

connecting connectors from related devices, or removing the dashboard or the steering column, disconnect the airbag

connectors and seat belt tensioner connectors to Drevent accidental deployment

@ Turn the ignition switch oFF and disconnect ths nogative cable from the battery, and wait at least ihree

minutes before beginning the tollowing procedures A and B. lprocedure B follows the procedure A.l

Before disconnecting the SRS main harness from the SRS unit, disconnect both airbags (C, D) and both seat belt tensioners

(F, H) {'98 - 00 models).

Before disconnecting the cable reel 2P connector (B), disconnect the driver's airbag connector (C).

Before disconnecting the left side wire harness 2P connector (E). disconnect the driver's seat belt tensioner 2P connector

(F) ('98 - 00 models).

Before disconnecting the right side wire harness 2P connector (G), disconnect the tront passenger's seat belt tensioner 2P

connector (H) ('98 - 00 models).

SRS MA1N HARNESS

)

i--- E t ----l

i Jl Jl l*",r* I I

LEFT SIDEWIRE HARNESS

){cont'd)

24-23

www.emanualpro.com

Page 1321 of 1395

Precautions/Procedures

Disconneeting the Airbag Connectors and the Seat Belt Tensioner

Connectors (cont'd)

1.Disconnect the battery negative cable, then discon-

nect the positive cable from the battery. and wait at

least three minutes.

Disconnect the airbag and tensioner connectors

lsee page 24-22).

Driver's Airbag:

. Remove the access panel from the steering

wheel, then disconnect the 2P connector

between the driver's airbag and cable reel. When

disconnected, the airbag connector is automati-

callv shorted.

DRIVER'S AIRBAG2P CONNECTOR

Front Passsng€/sAirtag:

. Disconnect the 2P connector between the front

passenger's airbag and SRS main harness. When

disconnected. the airbag connector is automati-

callY shorted.

24-24

ACCESS PANEL

Seat Bslt Tensioner (38 - 00 modebl:

. Remove the left and (or) right center pillar lower

trim panels (see section 20).

. Disconnect the seat belt tensioner 2P connectors

from the left side wire harness (driver's side) and

(or) the right side wire harness (front passenger's

side). When disconnected. the seat belt tensioner

is automatically shorted.

CLIPS

DRIVER'S SIDE: LEFT SloE WIRE HARNESSFRONT PASSENGER'S SIDE: RIGHT SIDE WIREHARNESS

,--4

www.emanualpro.com

Page 1323 of 1395

Troubleshooting

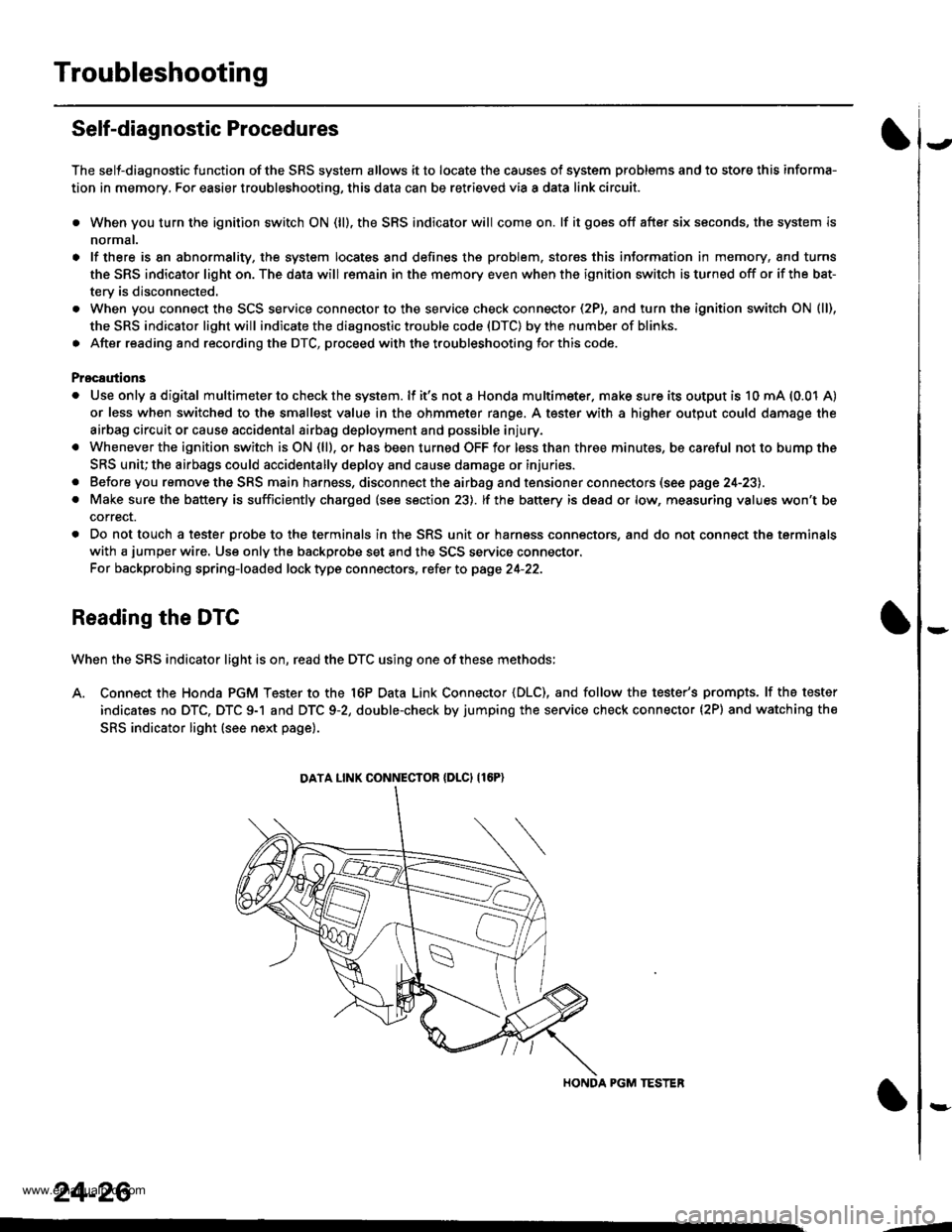

Self-diagnostic Procedures

The self-diagnostic function of the SRS system allows it to locate the causes of system problems and to store this informa-

tion in memory, For easier troubleshooting, this data can be retrieved via a data link circuit.

. When you turn the ignition switch ON (ll). the SRS indicator will come on. lf it goes off after six seconds, the system is

normal.

. lf there is 8n abnormality, the system locates and defines the problem. stores this information in memory, and turns

the SRS indicator light on. The data will remain in the memory even when the ignition switch is turned off or if the bat-

terv is disconnected.

. When you connect the SCS service connector to the service check connector (2P), and turn the ignition switch ON (ll),

the SRS indicator light will indicate the diagnostic trouble code (DTC) by the number of blinks.

. After reading and recording the DTC, proceed with the troubleshooting forthis code.

Precsutions

. Use only a digital multimeter to check the system. lf it's not a Honda multimeter. make sure its output is 10 mA (0.01 A)

or less when switched to the smallest value in the ohmmeter range. A tester with a higher output could damage the

airbag circuit or cause accidental airbag deployment and possible injury.

. Whenever the ignition switch isON (ll). or has been turned OFF for less than three minutes, be careful nottobumpthe

SRS unit; the airbags could accidentally deploy and cause damage or injuries.

. Before you remove the SRS main harness, disconnect the airbag and tensioner connectors (see page 24-23).

. Make sure the battery is sufficiently charged (see section 23). lf the battery is dead or low, measuring values won't be

correct.

. Do not touch a tester probe to the terminals in the SRS unit or harness connectors, and do not connect the terminals

with a jumper wire. Use only the backprobe set and the SCS service connector.

For backprobing spring-loaded lock type con nectors, .efet to page 24-22.

Reading the DTC

When the SRS indicator light is on, read the DTC using one of these methods;

A. Connect the Honda PGM Tester to the 16P Data Link Connector {DLC), and follow the tester's prompts. lf the tester

indicates no DTC, DTC 9-1 and DTC 9-2, double-check by jumping the service check connector (2P) and watching the

SRS indicator light (see next page).

HONDA PGM TESTER

DATA LINK CONNECIOR {DLCI {16P)

24-26

,1

www.emanualpro.com

Page 1333 of 1395

Troubleshooting

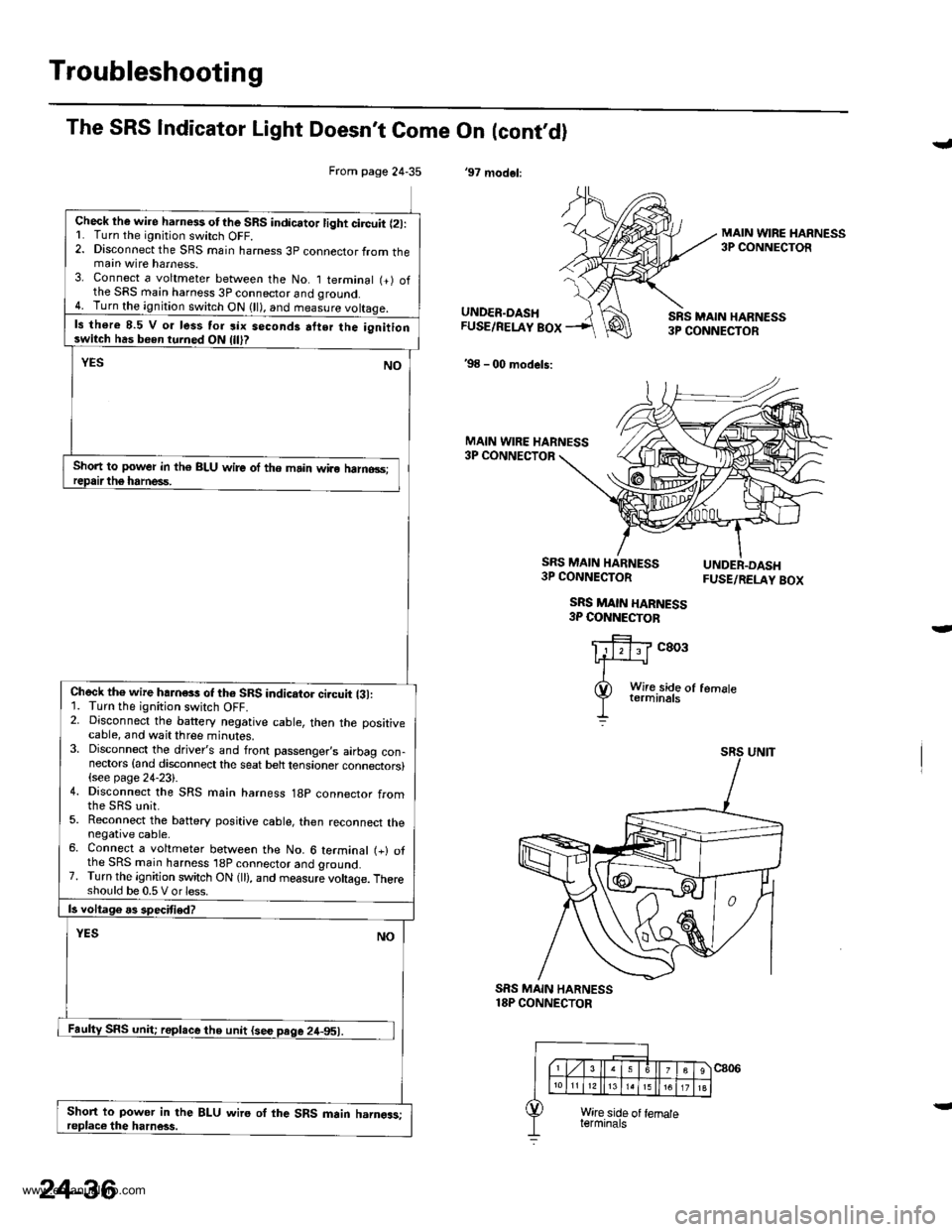

From page 24-35

Check lhe wire harness otthe SRS indicator light circuit l2l:L Turn the ignitjon switch OFF.2. Disconnect the SRS main harness 3p connector from themain wire harness.3. Connect a voltmeter between the No. I terminal (+) ofthe SRS main harness 3P connector and qround.4. Turn the ignition switch ON (ll), and measure voltaqe.

ls there 8.5 V o. less tor six seconds atter the ignitionswitch has been turned ON

Short to power in th€ BLU wire of the main wiro halno3s;

Check th€ wire hahess of th6 SRS indicator ci.cuit {31:1. Turn the ignition switch OFF.2. Disconnect the battery negative cable, then the positivecable, and wait three minutes.3. Disconnect the driver's and front passenger,s airbag con-nectors {and disconnect the seat belt tensioner connectors}(see page 24-23).4. Disconnect the SRS main harness 18p connector from

5. Reconnect the battery positive cable, then reconnect thenegative cable.6. Connect a voltmeter between the No. 6 terminal (+) ofthe SRS main harness 'l8P connector and ground.7. Turn the ignition switch ON (ll), and measure voltage. Thereshould be 0.5 V or less.

Short to power in the BLU wire oI the SRS main harngas;

The SRS Indicator Light Doesn't Come On (cont,dl

'97 modol:

J

MAIN WIRE HARNESS3P CONNECTOR

UNDER.DASHFUSE/RELAY BOX

'98 - 00 models:

SRS MAIN HARN€SS3P CONNECTOR

MAIN WIRE HARNESS3P CONNECTOR

SRS MAIN HARNESS3P CONNECTOR

SRS MAIN HARNESS3P COI{NECTOB

FUSE/RELAY BOX

c803

SRS MAIN HARNESS18P CONNECTOR

24-36

www.emanualpro.com

Page 1338 of 1395

)

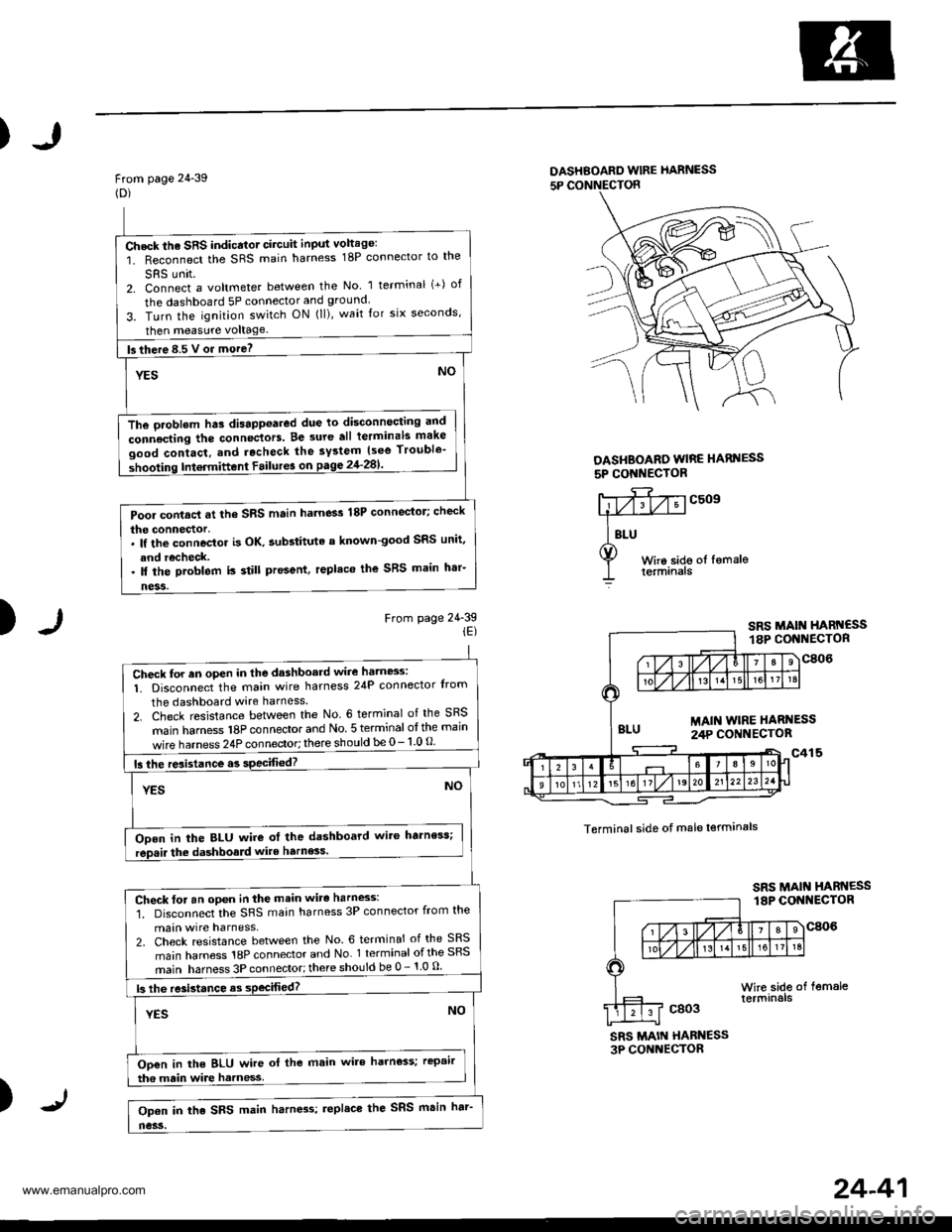

From page 24-39(D)

DASHBOARD wlRE hARNESS

5P CONNECTON

DASHBOARO WIRE HARI{ESS

5P CONI{EC'OR

)From page 24-39iE)

c509

Terminal side of male lerminals

SRS MAIN HABN€SS3P CONNECTOR

)

Check the SRS indicator circuit input voltage:

1. Reconnect the SRS main harness 18P connector to the

SRS unit2. Connect a voltmeter between the No 1 terminal (+) of

the dashboard 5P connector and ground.

3. Turn the ignition switch ON (ll), wait for six seconds,

then measure voltage

fs there 8.5 V or more? -

YESNO

The oroblem hts disappoared due to disconnocting and

connecting the connectors. Be 3ure all terminals make

good contact, and rocheck the system {see Trouble'

shooting Intermittent Failur6 on pagg 2'l-281'

Pool contacl at the SRS main harness 18P connector; check

the connector.. lf the connoctor is OK. aubstituta a known-good SRS unit,

and recheck.. ll the problem is still present, replaco the SRS main h'r-

ness.

Check for an oPen in the dashboard wire hatn8s:

1. Disconnect the main wire harness 24P connector Irom

the dashboard wire harness

2. Check resistance between the No. 6 terminal of the SRS

main hamess 18P connector and No 5 terminal otthe main

wire harness 24P connector; there should be 0- 1 0 O

15 the resistance.s specified?

YESNO

ODen in the BLU wire ot the dashboard wit6 harness;

rep.ir the dashboald wite harness.

Check for an open in the main wirc harness:'1. Disconnect the SRS main harness 3P connector from the

main wire harness,2. Check resistance between the No. 6 terminal of the SRS

main harness 18P connector and No 1 terminal ofthe SRS

main harness 3P connector;there should be 0 - 1 0 u

|3 lhe re3istance as sPecifiod?

YESNO

Oo€n in the BLU wire ol the main wire harness; rcpair

tha main wire harness

Op€n in the SRS main harn4s; replace the SRS msin har'

no3s.

24-41

www.emanualpro.com

Page 1339 of 1395

Troubleshooting

The SRS Indicator Light Doesnt Go Off - ,99 - 00 models

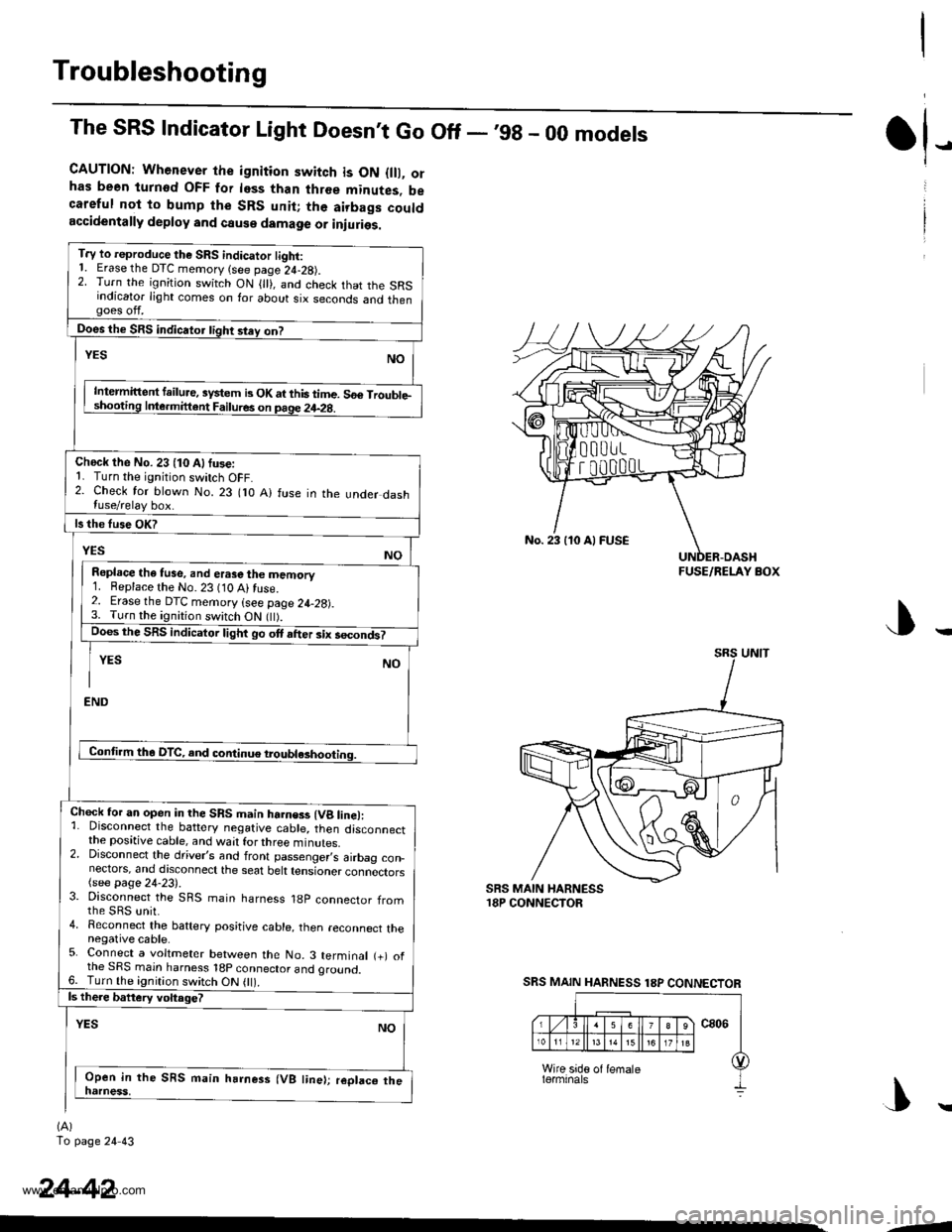

CAUTION: Whenever the ignition switch is ON {lll, orhas been turnod OFF for less than three minutes, becareful not to bump the SRS unit; the airbags couldaccidentally deploy and cause damage or iniuries.

T.y to reproduce the SRS indicator tight:1. Erase the DTC memory (see page 24-28).2. Turn the ignition switch ON { }, and check that the SRSindicator light comes on for about six seconds and thengoes off.

Does the SRS indicator tight stey on?

NOYES

Intermittent failure, system b OK at this time. 56€ Trouble-shooting Inle.mittent Failures on page 24-2g.

Check the No. 23 (10 Alfuse:1. Turn the ignition switch OFF.2. Check for blown No. 23 flO A) fuse in the under dashluse/relay box.

ls the fuse OK?

YESNO

Repl.ce the tuse, and erase the memory1. Beplace the No. 23 (10 Ai fuse.2. Erase the DTC memory (see page 24-28).3. Turn the ignition switch ON flt).Does the SRS indicator light go ott after six secondt

YES NO

I

END

Conti.m tha DTC, and continue troubl*hooting.

Chock for an open in the SRS main harness (Vg line):1. Disconnect the battery negative cable, then disconnectthe positive cable, and wait for three minutes.2. Disconnect the driver,s and front passenger,s airbag con_nectors, and discoonect the seat belt tensioner connectors(see page 24-23).3. Disconnect the SRS main harness 18p connector fromthe sRs unit.4. Reconnect the baftery positive cable, then reconnect thenegative cable.5. Connect a voltmeter between the No. 3 terminal (+) ofthe SRS main harness 18p connector and oround.6. Turn the ignition switch ON 0l).ls there battery voltage?

YESNO

Open in the SRS main harness (VB line); replaco thenatness,

(A)

To page 24 43

tl-

24-42

No. 23 110 Al FUSE

FUSE/RELAY BOX

SRS MAIN HARNESS 18P CONNECTOR

|\

-1

www.emanualpro.com

Page 1343 of 1395

Troubleshooting

The SRS Indicator Light Doesn't Go Off -,99 - 00 models (cont,d)

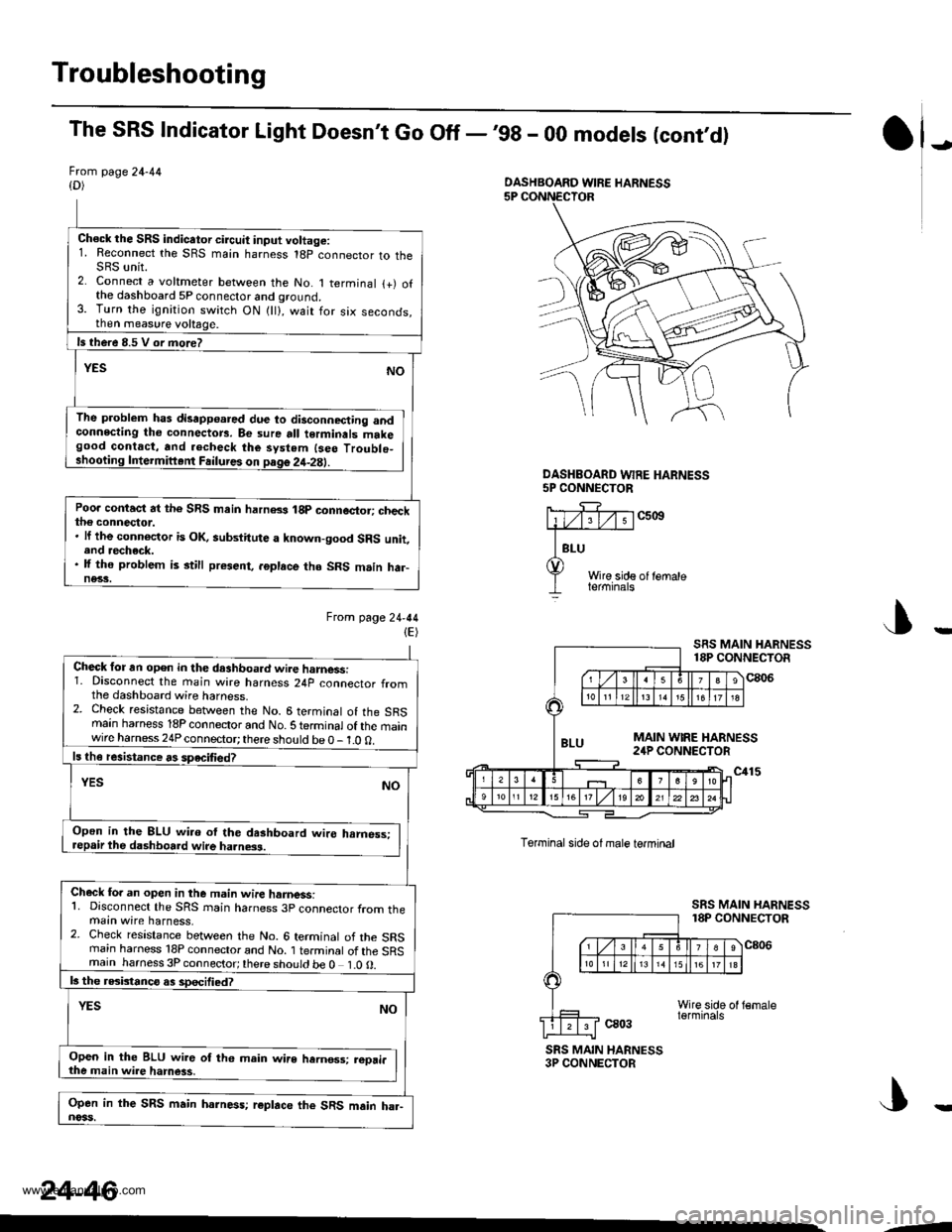

Frcm page 24-44{D)

Ch€ck the SRS indicator circuit input voltage:1. Reconnect the SRS main harness 18p connector to theSRS unit.2. Connect a voltmeter between the No. 1 terminal {+) ofthe dashboard 5P connector and ground.3. Turn the ignition switch ON {ll}, wait for six seconds,then measure voltage.

ls there 8.5 V or more?

YESNO

The problem has disapp€ared due to disconnecting andconnecting tho connectors. Be sure all terminals makegood contact, and .echeck the system {seo Troublo_shooting Intermiftent Failures on page 2it-2E).

Poo. contact at the SRS main harn8s 18p connector; checkthe connector.. lf the connoctor is OK, aubstitute a known-good SRS unit,end recheck.. lf the problem is still present, .6place tho SRS m.in har-ne33.

Ftom lage24-44(E)

J)

DASHEOARD WFE HARNESS5P CONNECTOR

c5ott

Wire side of lemaleterminals

J

Torminal side ol male termtnal

ca03

SRS MAIN HARNESS18P CONNECTOR

c806

SRS MAIN HARNESS3P CONNECTOR

DASHBOARD WIRE HARNESS

Check for an open in the dashboa.d wire harnessi1. Disconnect the main wire harness 24p connector fromthe dashboard wire harness.2. Check resistance between the No. 6 terminal of the SRSmain harness 18P connector and No. S te.minal of the mainwire harness 24P connector; there should be 0 - 1.0 0.

ls th€ resistance rs speciliedT

YESNO

Open in the 8LU wi.o ol the dashboard wire hrmess:repair the dashboard wire ha.ness.

Check fo. an open in the m.in wire hamess:1. Disconnect the SRS rnain harness 3p connector from themain wire harness,2. Check resistance between the No. 6 terminal of the SRSrnain harness 18P connector and No. 1 terminal of the SRSmain harness 3P connector;there should be 0 1.0O.

b the rGbtanco as sDecified?

NOYES

Open in the BLU wir6 of th6 main wire hernos3; reori.the main wire hamess,

Open in the SRS main harness; r€place the SRS main ha.-noss.

24-46

--

www.emanualpro.com