Valve clea HONDA CR-V 2000 RD1-RD3 / 1.G Owner's Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2000, Model line: CR-V, Model: HONDA CR-V 2000 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 396 of 1395

Intake Air System

Air Cleaner

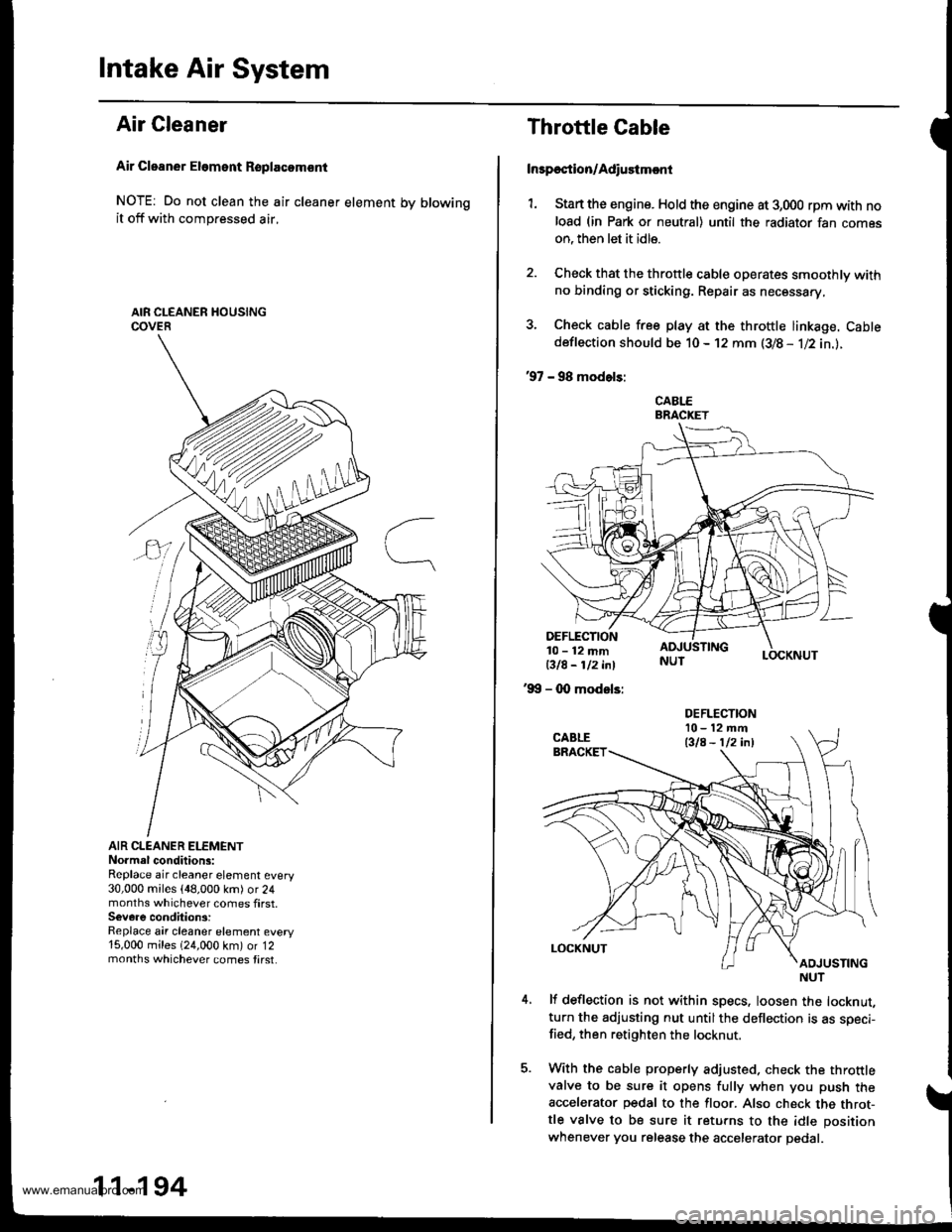

Air Cleaner Eloment Rsplacomsnt

NOTE: Do not clean the air cleaner element by blowingit off with compressed air,

AIR CLEANER ELEMENTNo.mal conditions:Replace air cleaner element every30,000 miles {48,000 km) or 24months whichever comes first.Severe condition3:Replace air cleaner element every15,000 miles 124,000 km) or 12months whichever comes tirst.

m

11-194

Throttle Cable

Inrpection/Adiustmcnt

1. Stan the engine. Hold the engine at 3,000 rpm with noload (in Park or neutral) until the radiator fan comeson, then let it idle.

2. Check that the throttle cable operates smoothly withno binding or sticking. Repair as necessary,

3. Check cable free play at the throttle linkage. Cabtedeflection should be 10- 12 mm (3/8 - 1l2in.l.

'97 - 98 modols:

CABLEBRACKET

LOCKNUT

DEFLECTION10-12mmBIA- 112 i^l

'99 - 0O modsls:

lf deflection is not within specs, loosen the locknut,turn the adjusting nut untilthe deflection is as speci-fied, then retighten the locknut.

With the cable properly adjusted. check the throttlevalve to be sure it opens fully when you push theaccelerator pedal to the floor. Also check the throt-tle valve to be sure it returns to the idle position

whenever you release the accelerator pedal.

DEFLECTIONl0-12mft

Bla - 112 inl

NUT

www.emanualpro.com

Page 397 of 1395

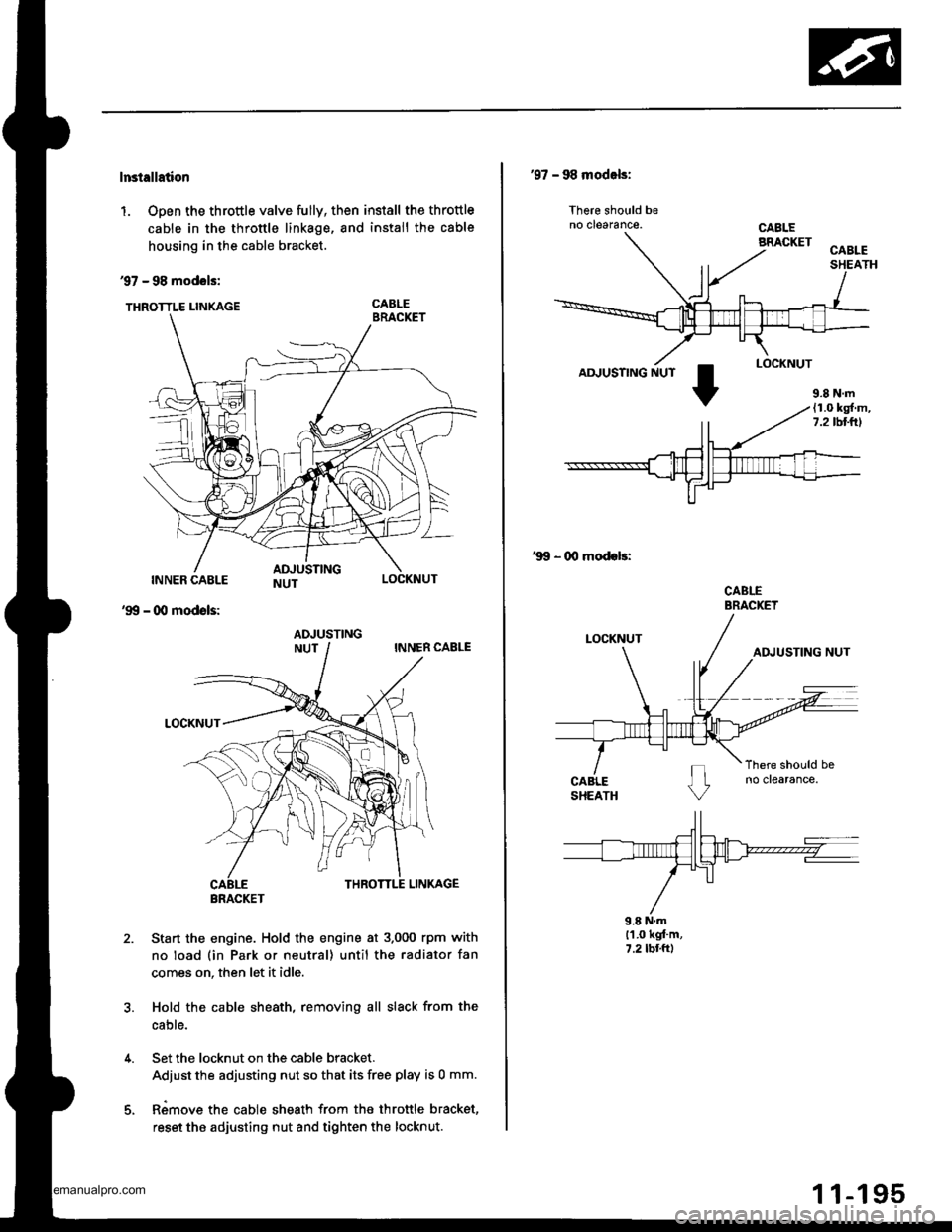

lnstellation

1. Open the throttle valve fully, then install the throttle

cable in the throttle linkage, and install the cable

housing in the cable bracket.

97 - 98 modols:

THRoTTLE LINKAGE CABLE

INNER CABLE

- (Xl modols:

LOCKNUT

'99

2.Sta.t the engine. Hold the engine at 3.000 rpm with

no load (in Park or neutral) until the radiator fan

comes on, then let it idle.

Hold the cable sheath, removing all slack from the

cable.

Set the locknut on the cable bracket.

Adiust the adjusting nut so that its free play is 0 mm.

Rimove the cable sheath from the throttle bracket,

reset the adjusting nut and tighten the locknut.

ADJUSTING

BRACKET

'97 - 98 modals:

lhere should beno clearance.

AD.'USTING NUT

'99 - 00 modeb:

CABLEBRACKET

9.8 N.ml'1.0 kgt'm,7.2 tbr.ft)

9.8 N.m(1.0 kg{.m,7.2lbllrl

www.emanualpro.com

Page 398 of 1395

Intake Air System

Throttle Body

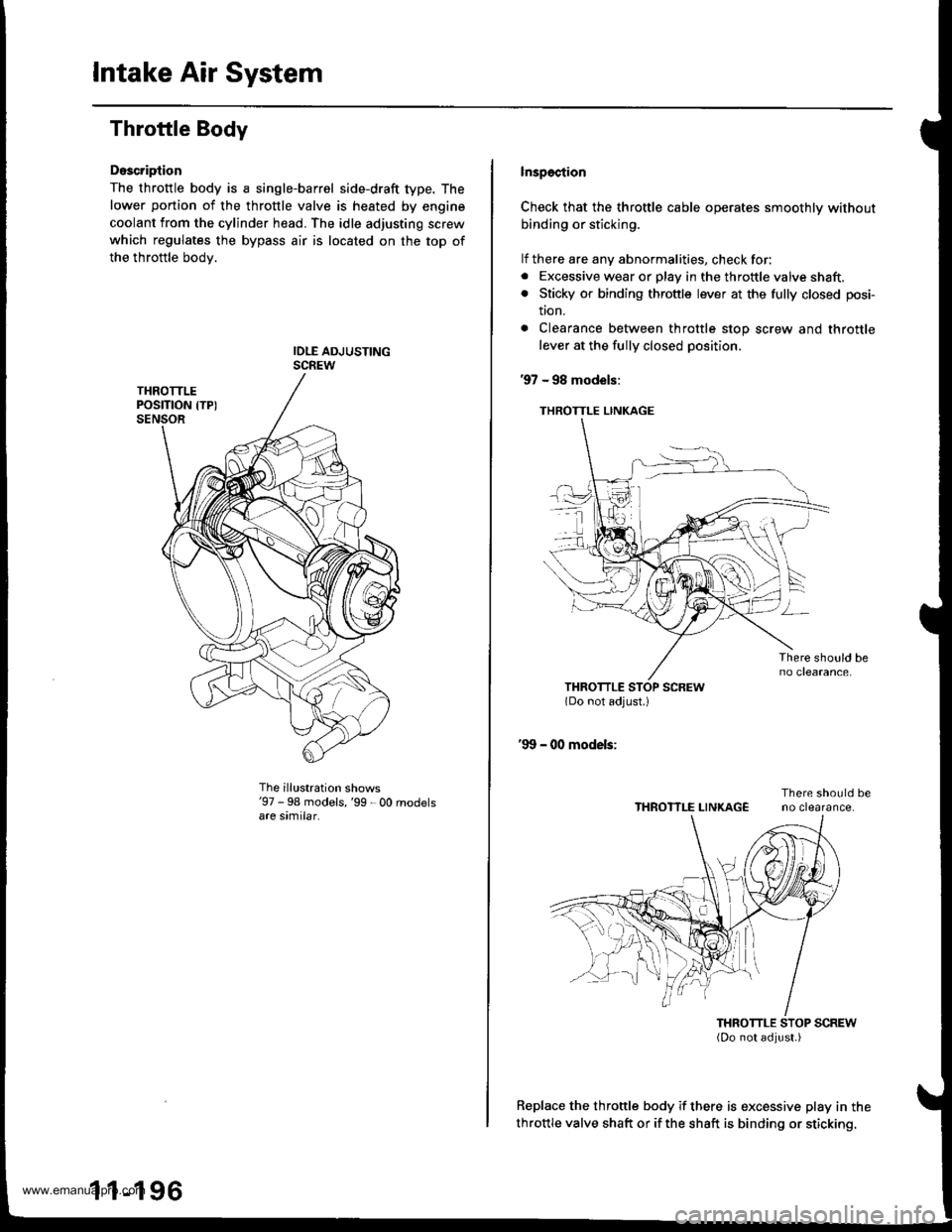

Doscription

The throttle body is a single-barrel side-draft type. The

lower portion of the throttle valve is heated by engine

coolant from the cylinder head. The idle adjusting screw

which regulates the bypass air is located on the top of

the throttle bodv.

The illustration shows'97 - 98 models,'99 - 00 rnodelsare similar.

1 1-196

lnspection

Check that the throttle cable operates smoothly without

binding or sticking.

lf there are any abnormalities, check for:. Excessive wear or play in the throftle valve shaft.. Sticky or binding throttle lever at the fully closed posi-

tton.

. Clearance between throttle stop screw and throttle

lever at the fully closed position.

97 - 98 models:

THROTTLE LINKAGE

Replace the throttle body if there is excessive play in the

throttle valve shaft or if the shaft is binding or sticking.

THROTTLE LINKAGE

www.emanualpro.com

Page 517 of 1395

Automatic Transmission

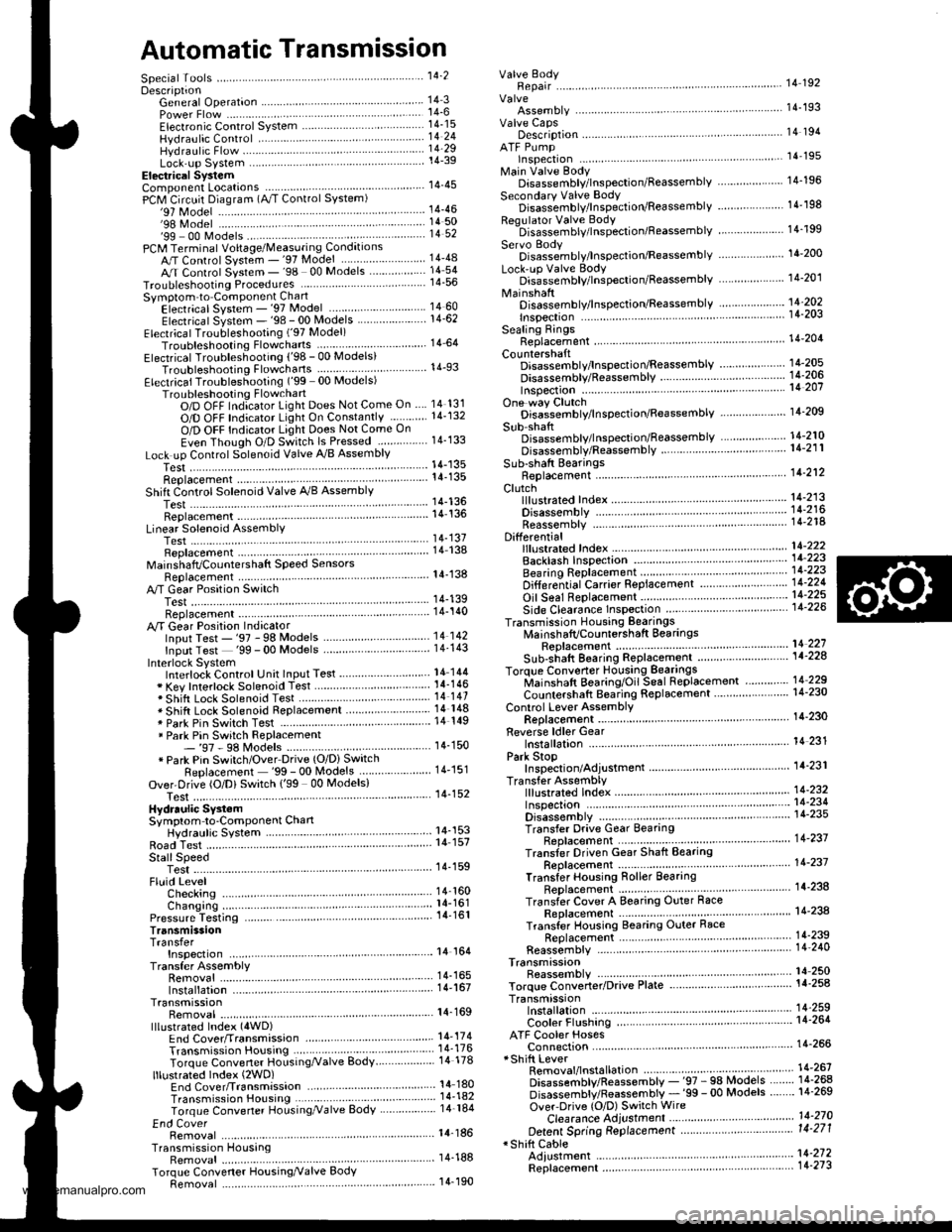

Special Tools . 14'2OescriptionGeneral Operation . .... 14 3Power Flow . . .. '14_6

Electronic Control System .. .. . . .. .14_15Hydraulic Control .. 14 24Hydraulic Flow....-....... .. . .... .. .. . 14_29Lock'up Syslem .. .'t4'39Electrical SystemComponenl Locdlrons 14 45

PCM Circuil Dragram (A/T Control Svstem)'97 Model ....................... . . .. - . ... .14-46'98Model ................. . ... .. .. .1450'99 00Models.... . .... . . . 1452

PCM Terminal Voltage/Measuring ConditionsA"/T Control System-'97Model ...... ..14'48A,/T Control System -'98 00 Models . . .. . . 14 54

Troubleshooting Procedures .. ..... ... - 14_56Svmotom to comoonent CharlEiectr,cal Syslem -'97 Model . . 14 60Electrical System -'98 - OO Models . .. . . 14_62Electrical Troubleshooting ('97 Model)Troubleshooting Flowaharts .... ..... . .. . . 14_64

Electrical Troubleshooting ('98 - 00 Models)Troubleshootinq Flowclt"n" .... . ....- . .14-93ElectricalTroublesliooting('99 00Models)Troubleshootino FlowchartO/D OFF Indicator Light Does Not Come On 14 131

O/D OFF Indicator Liaht On ConstantlY . . . .1!-132O/D OFF Indicator Light Does Not Come OnEven Though O/D Switch ls Pressed . .... - 14_133

Lock up Control Solenoid Valve A,/B AssemblyTest....................-......... . .14-135Replacement . .ll_135Shifr ControlSolenoid Valve Ay'B Assembl,Test .............................. . .. 14-136

Replacement..............- . .14'136Linear Solenoid AssemblYTest.............................................. .. .... . 14_137Replacement .. . 14138Marnshaftlcountershafl Speed SensorsReplacement ...-... 14_138A/T Gear Position SwitchTest ..........................-... . .. 14-139ReplacementA/T Gear Positionlndicator.................. 14-140

Valve Eodynepair ............................... ..... . . .. - . .. ... 14 192

Assembly .................... .. 1{_193

Valve CapsDesciiption....-........................ .. ...... 14194

tnspeition ................... .. 14' 195

N4ain Valve BodyDisassembly/lnspection/Reassemblv - ...... .. 14_196

Secondarv Valve BodYDisassemblv4nspectron/ReassemblY .. . 14 198

Reoulator Valve Bodvbisassembtv,lnspiction/Reassemblv . 14199

Servo EodvDisassembly/lnspection/Reassembly ... ....14'200

Lock'uo Valve BodYDis;ssembly/lnspection/Reassembly .... . 14_201

MainshaftDisassembly/lnspection/Reassembly .. .. .. ..14'202

Inspection ....-.............. ..11_203

Sealing RingsReilaceient ...... ..... . 14'204

CountershaftDisassembly/lnspection/Reassembly .. . . . . . 11-205

Disassembly/Reassemb|y . . ........ ...... . .. 14_206Inspedron ................ . .... . 14 207

One wav ClutchDisassembly/lnspection/ReassemblY ... 11_209

Sub-shaftDisassembly/lnspection/Reassembly ... . .. . 14-210

oisassembly/Re6ssembly . . ... .-...... . . ..14-211

Sub-shaft BearingsReplacement .......14'212

Clutchllfustrated Index .......... . . .14-213

Disassembly .... .. .....14-216Reassembfy .... . .. .. . 14'218

Differentialllfustrated Index " 14-222Backlash Inspection . .... . .14'223

Bearing Repiacement .. 11-223

Differe-ntial Carrier Replacement .. .. . . . .. ..11-2?4

OifSeal Replacement. . .. 14'225

Side Clearance lnspection . . - .. ... . - ...... . .. 11'226

Transmission Housing BearingsMainshaJVCountershaft EearingsRepfacement .......14221Sub'siralt Eearing Replacement . . . . . . . . . ..11'224

Toroue Converter Housing BearingsMainshattEearing/OilSe6lReplacement . .. l4229

Countershaft Bea;ing Replacement.. .... .. ..14-230

Input Test - '97 - 98 ModelsInput Test '99 - 00 Models

Symptom to-Component ChartHydraulic System ...............

Checking

Removal ...,lllustrated Index (4WD)

Interlock SystemInterlock ControlUnit lnputTest. -..... -.. .... . - 14 144* Key Interlock Solenoid Test .- .. . . . - . . . ..... 14_146* Shift Lock Solenoid Test ..............-.-. . .. . ... .... 14 147*Shift LockSolenoidReplacement...... .. . .. .. 14 148* park pin Switch Test ......... 14 119' Park Pin Switch Replacement- '97 - 98 Models ....... 14-150* Park Pin Swirch/Over Drive (O/Di SwitchReplacemenl '99-00Models . .. 14_151over-Drive (O/D) Switch {'99 00 [4odels]Test........_..................... .......14-152Hydr.ulic System

..............._............... t4 142.................................. 14-143

Control Lever AssemblyR6placement ......,.,Reverse ldler Gear

lllustrated lndex

.......... 14-230

14 231

11-231

1nsta1|ation ..................Park StopInspeclion/AdjustmenlTransfer AssemblY.......14.232

RoadTest.............-.... ........ .StallSpeedTest ....._........................ ....... 14-159Fluid Level......_................... 14'160

Disessembly .................... 14-235Transfer Drive Gear BearingReplacementTrans{er Driven Gesf Shaft BearingReplacementTransfer Housing Roller BearingReplacementTransfer Cov€r A Bearing Outer RaceReplacementTransfer Housing Bearing Outer RaceReplacement ......-..,,,,,.....ReassemblvTransmassaonBeassembly ... -.. .... .14 250

Torque Converier/Drive Plate . .-. .... .. . ... .....14_258

Transmissionlnstatlation .................. ....... 14'259

Cooler Flushing . . ......11-261ATF Cooler HosesConnection.................. ....... 14-266I Shift LeverRemoval/lnstallation . .. 14'261

Disassemblv/Reassemblv - '97 - 98 Models . . 14_264

Disassembli/Reassemblv -'99 - 00 Models . 14-269

Over'Orive (O/D) Switch WireClearanceAdjustment. - ... . . . .. .. . 14'270

Detent Spring Replscement . . -.. ... .14'271*Shift CableAdiustment ....... 14'272

Repfacement.............. . 11'273

14 15711-237

11-237

14-238

$-234

11-23914-240

Transmigrion

Inspeclron ....., ...........Transfer AssemblyRemova1,.,,,..............,lnstallalion ........... .. ...Transmission

14 164

14-16514,167

14-169

End Cover/Transmissio . 14'174Transmission Housing .... ... .. . . .... .. 14-176Torque Converter Housingly'alve Body.. - ... -. 14 178

lllustrated lndex (2WD)End Cover/Transmissio ....... 14 180Transmission Housing . . ... . .. .... ... 14'182Torque Convener Housing/r'alve Body ......- 14-184

End CovefRemovat ...................... ....... 14'186Transmission HousingRemoval ...................... .. 14_188Torque Convener HousingA/alve BodYRemovat ................-..... .-..... 14-190

www.emanualpro.com

Page 609 of 1395

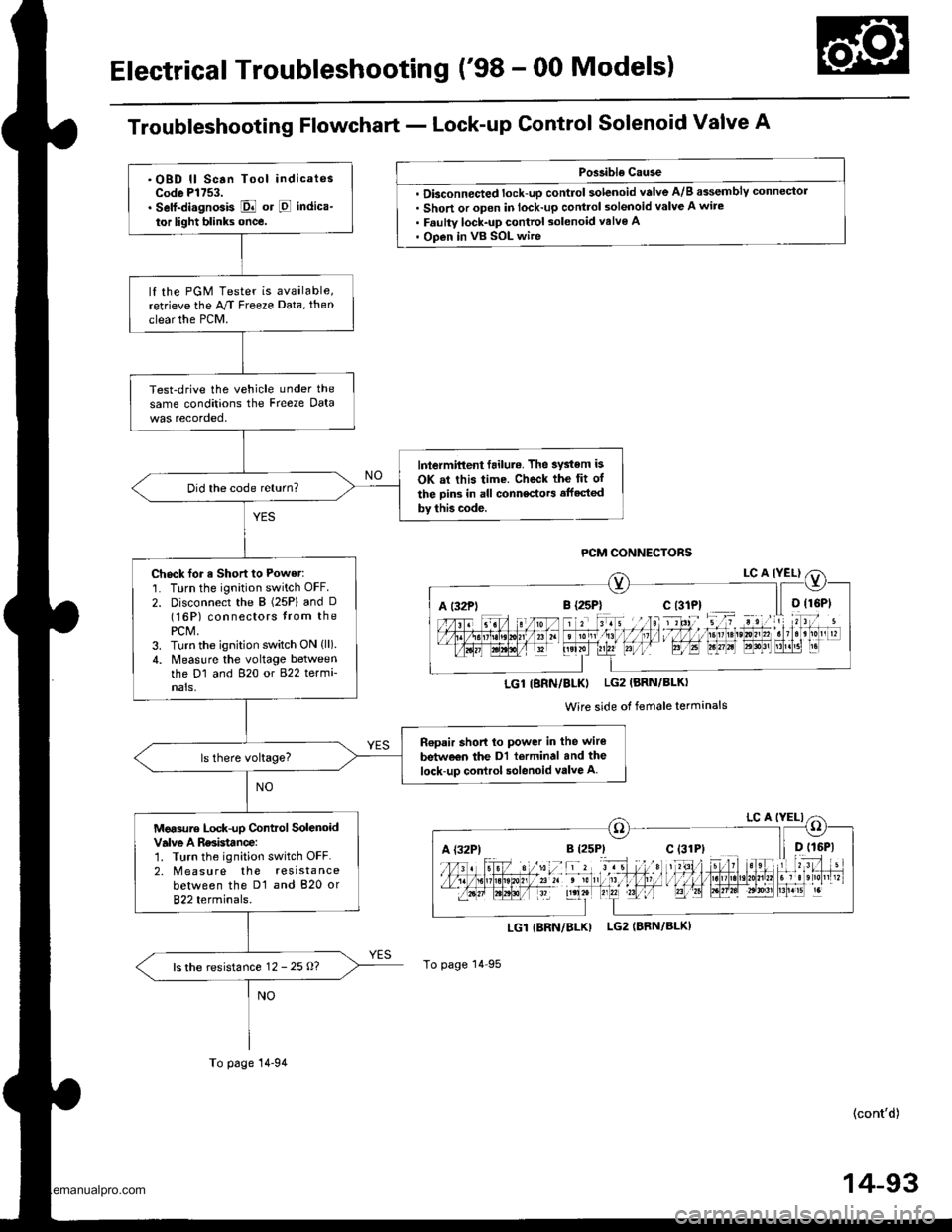

Electrical Troubleshooting ('98 - 00 Models)

Troubleshooting Flowchart - Lock-up Control Solenoid Valve A

Poslible Cause

. Dbconnected lock-up control solenoid valve A/B assemblY connector. Short or open in lock-up control solenoid valve A wire. Faulty lock-up control solenoid valve A' Open in vB SOL wire

LGI|BRN/BLK) LG2IBRN/BLK)

To page 14 95

(cont'd)

14-93

A t32Pli r rriltI l,1 I I ltDrste,0n,,2. t3r B'r!51 r.

LGl IBRN/BLKI LG2 (BRN/BLKI

Wire side of female terminals

A {32P)

.OBD ll Scan Tool indicatesCode Pl753.. Self-di.gnosis E or E indica-

tor light blinks once.

lf the PGM Tester is available,retrieve the M Freeze Data, then

clear the PCM.

Test-drive the vehicle under the

same conditions the Freeze Data

lntermittent failul.. The system is

OK at this time. Check the fit of

the Din3 in all connectors affected

by thb code.

Did the code return?

Check for a Short to Power:'1. Turn the ignition switch OFF.

2. Disconnect the B (25P) and D(16P) connectors trom thePCM,3. Turn the ignition switch ON (ll).

4. Measlre the voltage betweenthe D1 and 820 or 822 termi-nals,

n€pair short lo power in the wire

betw€€n the Dl terminal and the

lock-up control solenoid valve A

Mg.sure Lock-up Control SolenoidValve A Rssistance:1. Turn the ignition switch OFF.2. M easu re the resistancebetween the D1 and 820 or822 terminals.

ls the resistance 12 - 25 o?

To page 14-94

www.emanualpro.com

Page 612 of 1395

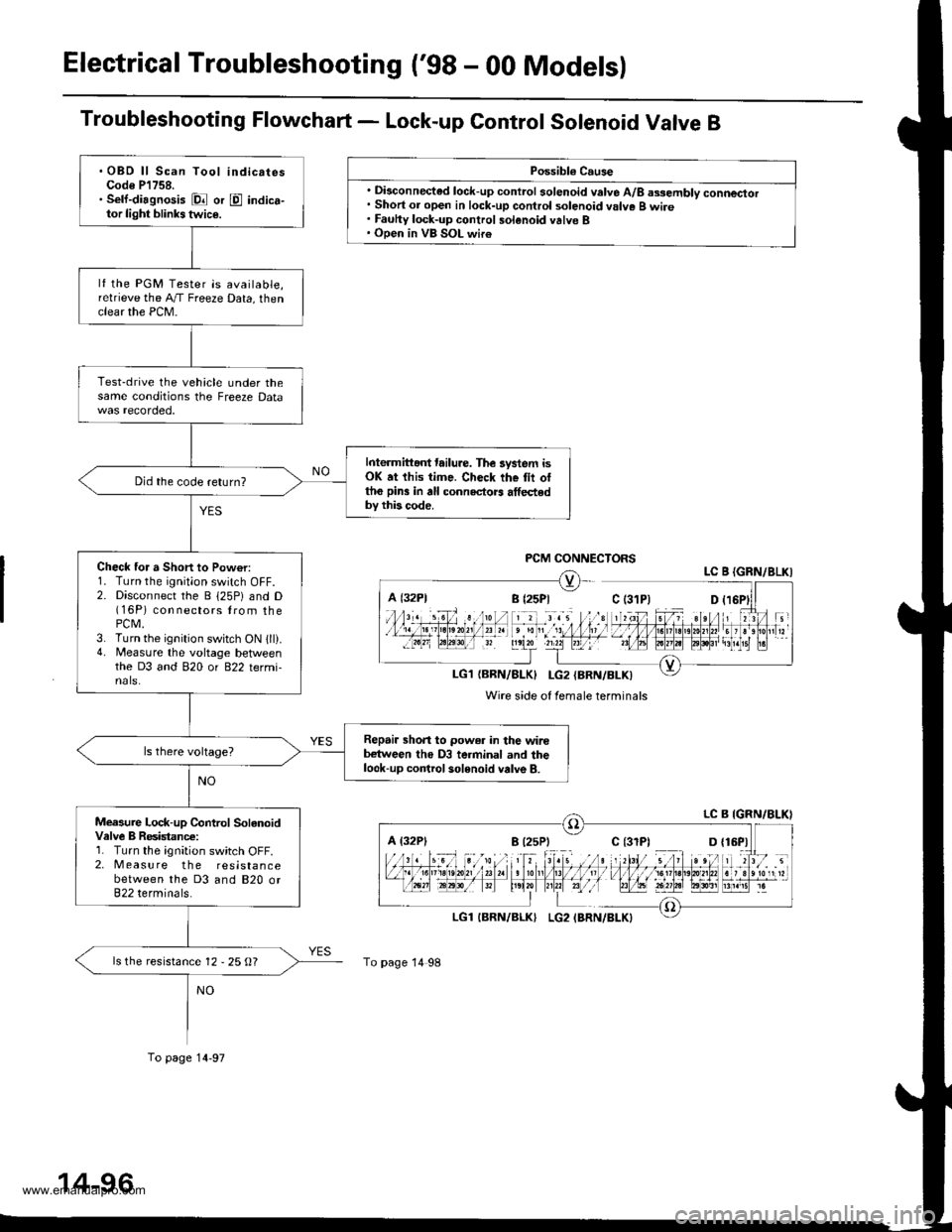

Electrical Troubleshooting ('98 - 00 Models)

Troubleshooting Flowchart - Lock-up Control Sotenoid Valve B

Possibl€ Cause

. Disconnected lock-up control solenoid valve A/8 assembly connector. Short or open in lock-up control solenoid valve B wire. Fauhy lock-up control solenoid valve B. Open in VB SOL wir€

PCM CONNECTORSLC B {GRN/8LKI

LG1{BRN/BLK} I-G2{BRN/BLK)

Wire side of female terminals

A {32P1

To page 14 98

.OBD ll Scan Tool indicatesCode P'l758.. Sell-diagnosis Dl or E indica-tor light blinks twic€.

lf the PGM Tester is available,relrieve the A,/T Freeze Data, thenclear the PCM-

Test-drive the vehicle under thesame conditions the Freeze Data

Interm ittant tailure. The lystem isOK at this time. Check the tii ottho pin3 in all connectors athedby this code.

Did the code return?

Check for a Short to Pow€r:1. Turn the ignition switch OFF.2. Disconnect the B 125P) and D(16P) con nectors lrom thePCM.3. Turn the ignition switch ON 1ll).4. Measure the voltage betlveenthe D3 and 820 or 822 termi-nals.

Repair shon to power in the wirebetween tho D3 terminal and thelook-up control solenoid valve B.

Measure Lock-up Control SolanoidValve B Resistanc€:1. Turn the ignition switch OFF.2. Measure the resistancebetween the D3 and 820 or822 terminals.

ls the resistance 12 - 25 O?

To page 14-97

www.emanualpro.com

Page 622 of 1395

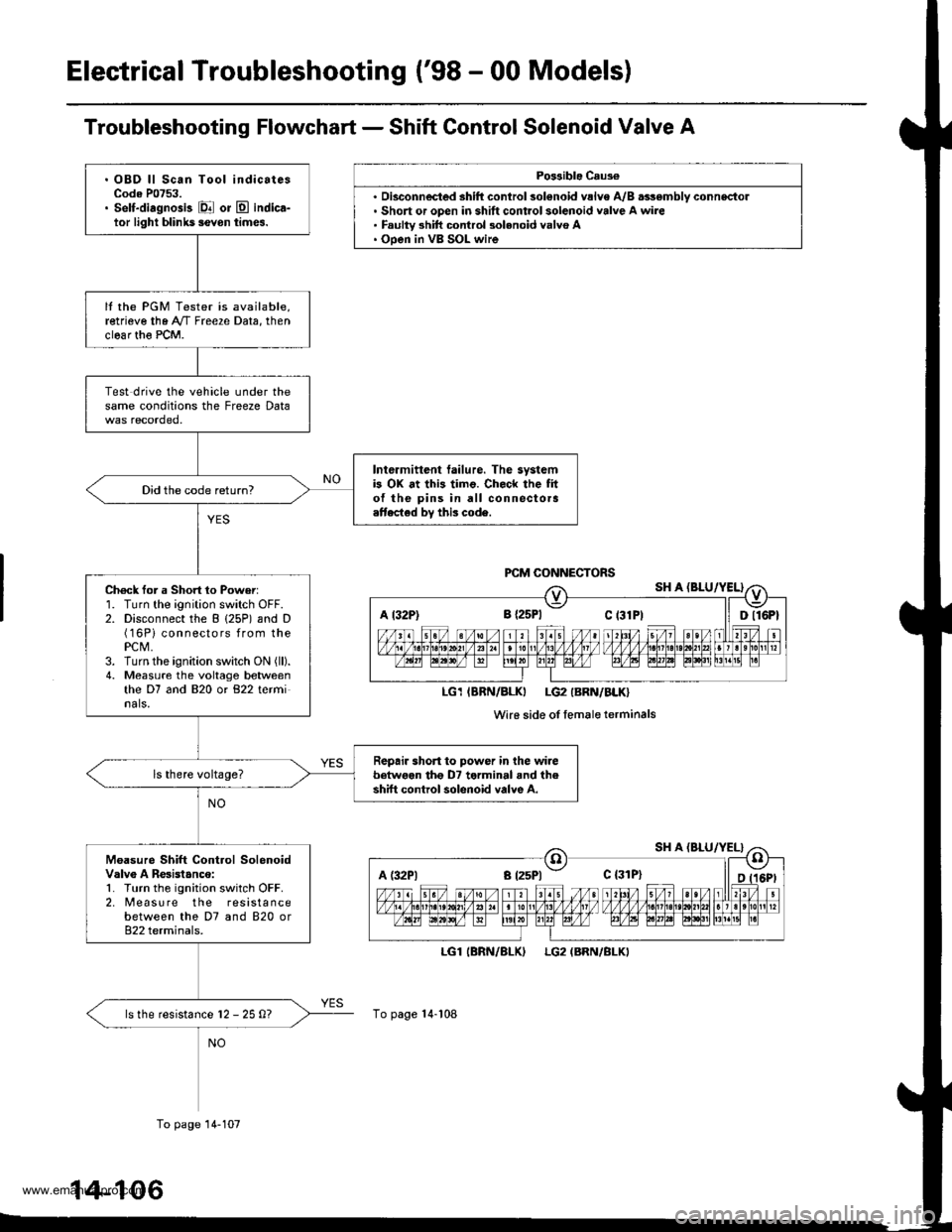

Electrical Troubleshooting ('98 - 00 Models)

Troubleshooting Flowchart - Shift Control Solenoid Valve A

Po$ible Caus€

'. Short or open in shift control solenoid valve A wire. Faulty 3hift control 3olenoid valvo A. Ooen in VB SOL wire

LGl

To page 14-108

(BRN/BLKILG2 (BRN/BLKI

A t32P) 8 {2sPl Ct3lPt ll Dll6Pt

LG1IBRN/BLKI LG2IBRN/BLK}

Wi16 side of femaleterminals

A (:l2Pl a t25Pl - c {31P}

. OBD ll Scan Tool indicatesCode P0753.. Self-diagnosis El or E indica-tor light blihk5 ievon times.

It the PGM Tester is available,retrieve the A"/T Freeze Data, thenclear th€ PCM.

Test drive the vehicle under thesame conditions the Freeze Data

Intermittent tailure. The systemb OX at this timo. Check the fito{ the pins in all connectora.ttected by this code.

Did the code return?

Ch6ck for a Short 1o Power:1. Turn the ignition switch OFF.2. Disconnect the B (25P) and D(16Pi connectors from thePCM,3. Turn the ignition switch ON (ll).

4. Measure the voltage betweenthe D7 and 820 or 822 terminals.

Repair short to power in the wirebetwoen tho D7 terminal and theshift control solenoid valve A.

Moasure Shift Control SolenoidValv6 A Resistanco:1. Turn the ignition switch OFF.2. [reasu re the resistancebetween the D7 and 820 or822 terminals.

ls the resistance l2 - 25 0?

To page 14-107

14-106

www.emanualpro.com

Page 625 of 1395

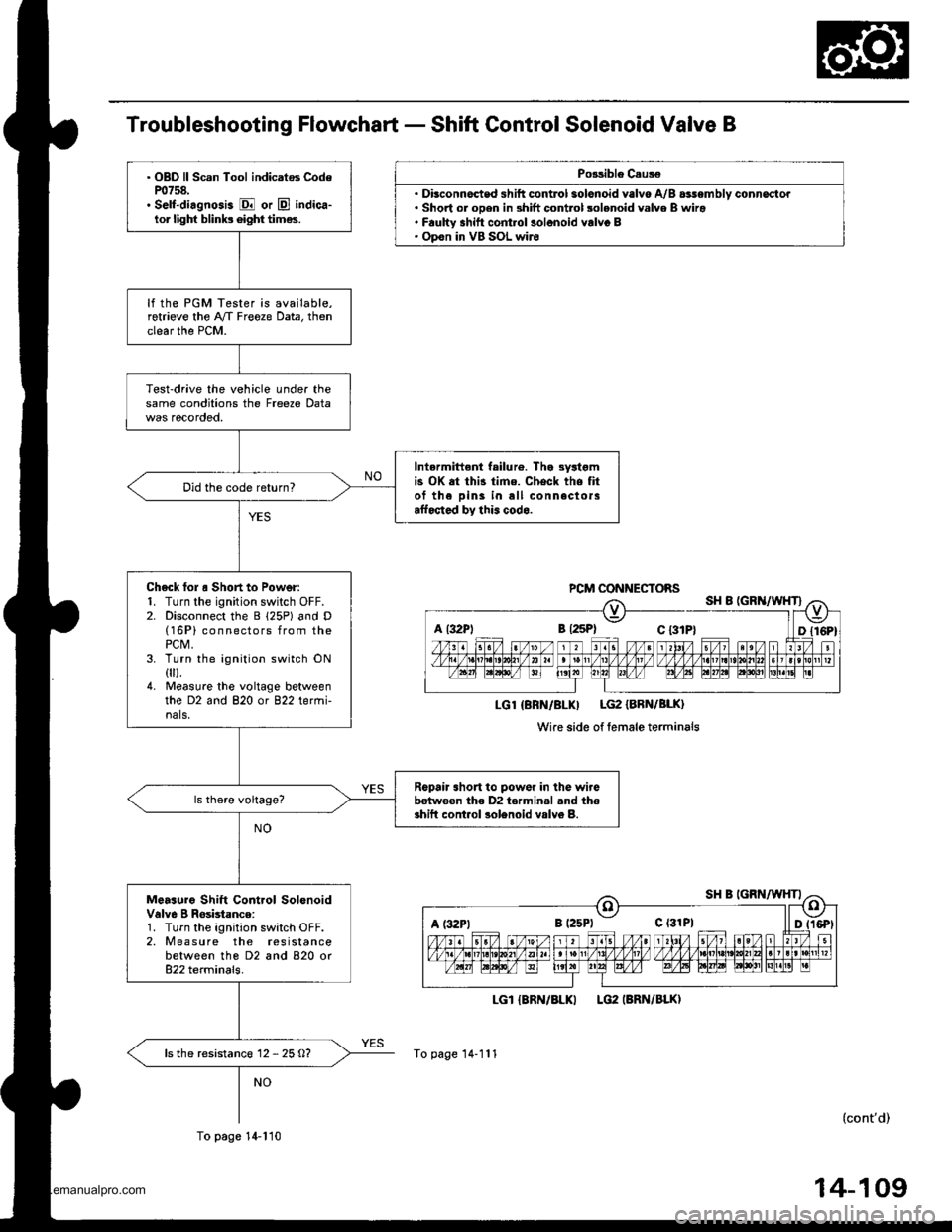

Troubleshooting Flowchart - Shift Control Solenoid Valve B

Po3sible C.us€

.Dt. Short or oDen in shift control solenoid valve B wira' F.ulW shitt cont.ol solonoid valvc B. Opon in VB SOL wir6

LGI {8RN/BLKI

To page 14-111

PCM CONNECTOBS

LGl {BRN/BLKI LG2 {BRN/BLK}

Wire side of lemale terminals

a l32Pl B {2sPl c t3tP}

c (31P1

. OBD ll Scan Tool indicatos CodeP0758.. Self-di.gnosis E or E indica-lor lighf blinb 6ight times.

lf the PGM Tester is available.retrieve the A/f Freeze Data, thenclear the PCM.

Test-drive the vehicle under thesame conditions the Freeze Data

Intermittent failu16. Tha 3yltgmis OK at thi3 time. Check the fitof the Dins in all connectorsaffocted by this codo.

Did the code return?

Check lol o Short to Power:1. Turn the ignition switch OFF.2. Disconnect the B 125P) and D(16P) connectors from thePCM,3. Turn the ignition switch ON0ll.4. Measu.e the voltage betweenthe D2 and 820 or 822 termi-nals.

Ropair short to powor in lhe wirebetwoon the D2 termin.l .nd thoshift cont.ol solenoid vslv6 B.

Measuro Shift Control SolonoidValve I Rosbtance:1. Turn the ignition switch OFF.2. M easu re the resistancebetween tho D2 and 820 or822 terminals.

ls the resistanc€ 12 - 25 O?

To page 14-110

LG2 IBRN/BLKI

(cont'd)

www.emanualpro.com

Page 651 of 1395

Lock-up Control Solenoid Valve A/B Assembly

Test

1.

2.

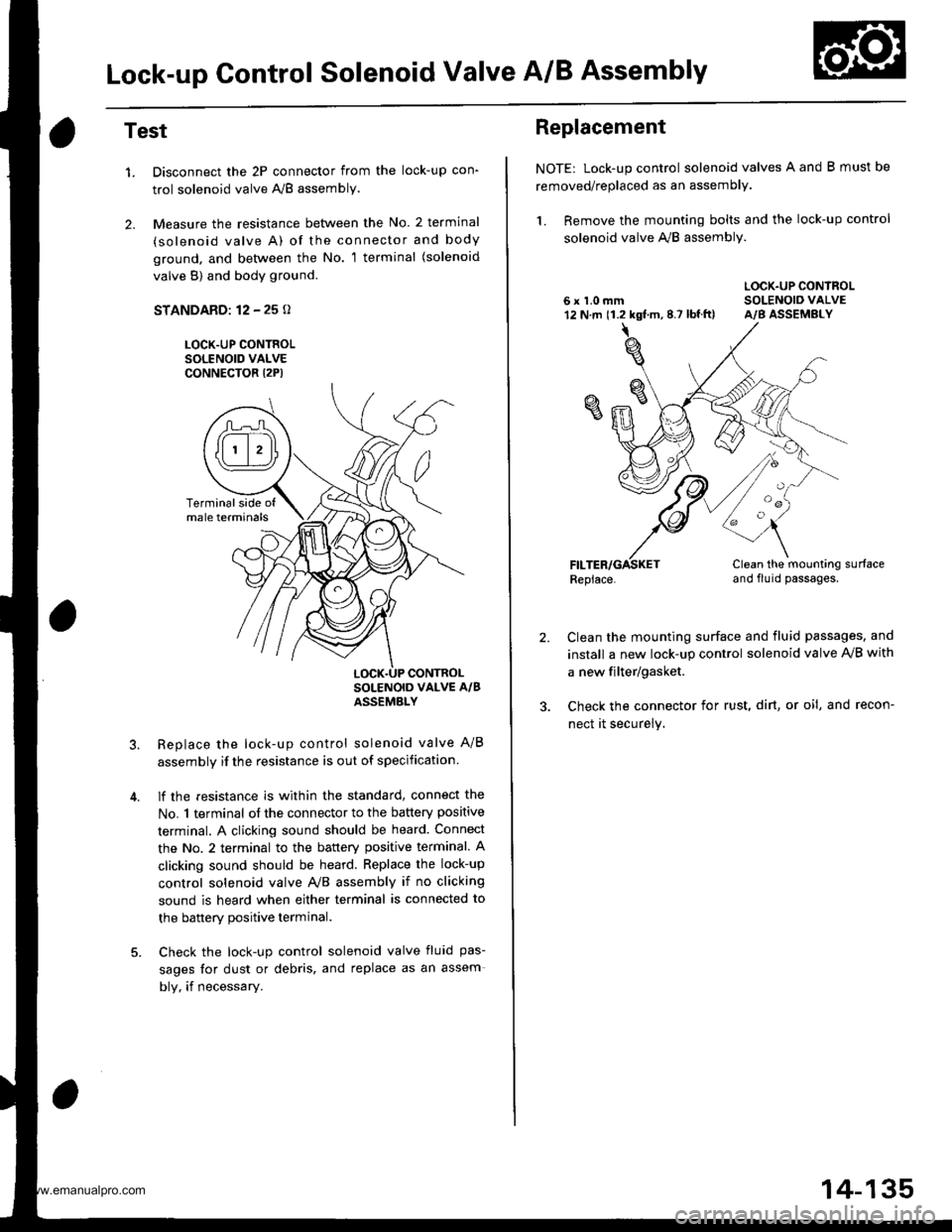

Disconnect the 2P connector from the lock-up con'

trol solenoid valve A'lB assembly.

Measure the resistance between the No. 2 terminal

(solenoid valve A) of the connector and body

ground. and bet\iveen the No. 1 terminal (solenoid

valve B) and body ground.

STANDARD: 12 - 25 o

LOCK-UP CONTROLSOLENOID VALVECONNECTOR I2P)

Replace the lock-up control solenoid valve A/B

assembly if the resistance is out of specification

lf the resistance is within the standard, connect the

No. 1 terminal of the connector to the battery positive

terminal. A clicking sound should be heard Connect

the No. 2 terminal to the battery positive terminal. A

clicking sound should be heard. Replace the lock-up

control solenoid valve Ay'B assembly if no clicking

sound is heard when either terminal is connected to

the banerv Dositive terminal.

Check the lock-up control solenoid valve fluid pas-

sages for dust or debris, and replace as an assem

bly, if necessary.

Terminalside ofmale terminals

LOCK.UP CONTROL

Replacement

NOTE: Lock-up control solenoid valves A and B must be

removed/replaced as an assembly.

1. Remove the mounting bolts and the lock-up control

solenoid valve A,,/B assembly.

LOCK.UP CONTROL6 x 1.0 mm SOLENOIO VALVE12 N.m 11.2 kgf.m,8.7 lbf.ft) A/B ASSEMBLY

Replace.Clean the mounting surfaceand flu id passages.

2.Clean the mounting surface and fluid passages, and

install a new lock-up control solenoid valve IVB with

a new filter/gasket.

Check the connector for rust, dirt, or oi!, and recon-

nect it securely.

oa

14-135

www.emanualpro.com

Page 652 of 1395

Shift Control Solenoid Valve A/B Assembly

Test

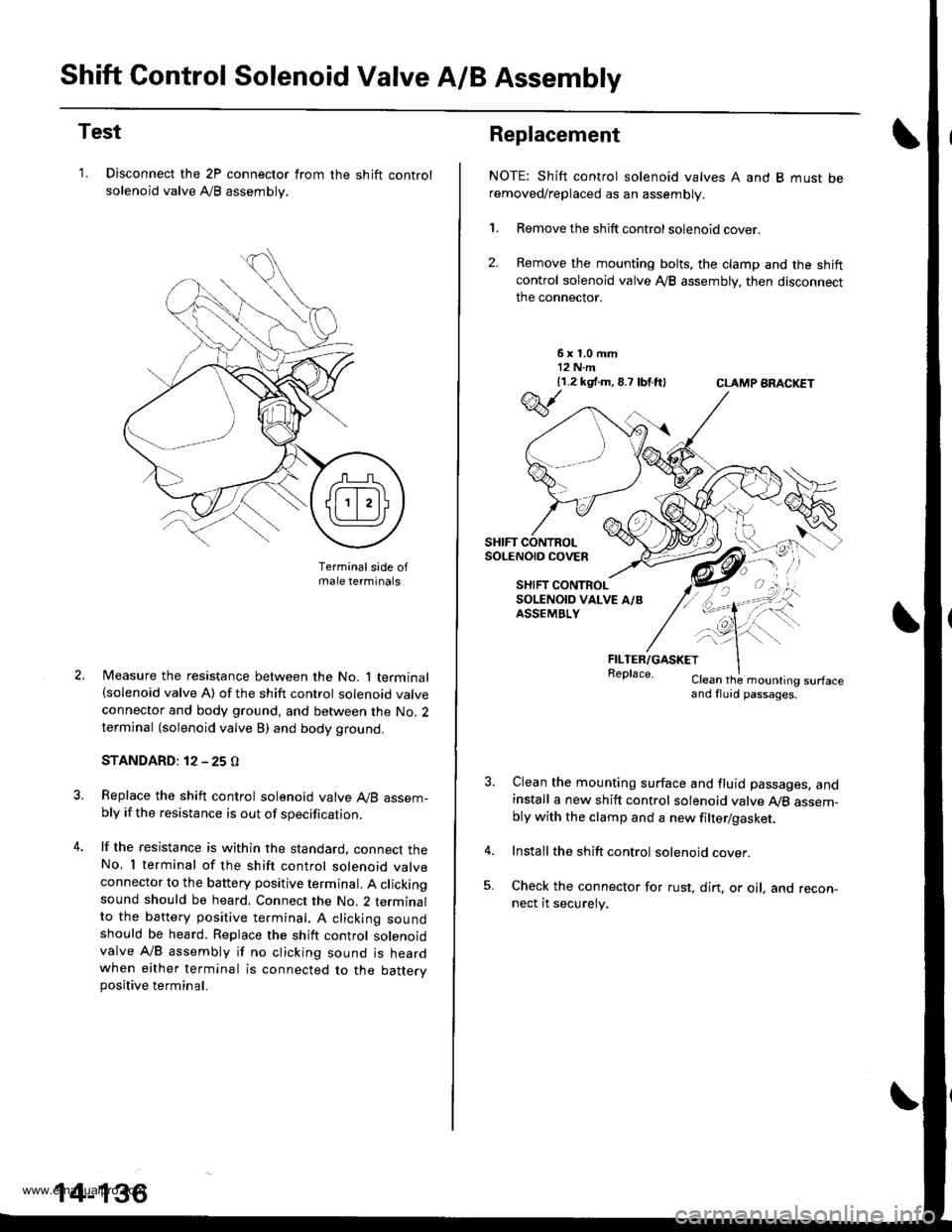

'1. Disconnect the 2P connector from

solenoid valve Ay'B assembly.

the shift control

Terminalsade ofmale terminals

Measure the resistance between the No. 1 terminal(solenoid valve A) of the shift control solenoid valve

connector and body ground, and between the No. 2terminal (solenoid valve B) and body ground.

STANDARD: 12 - 25 O

Replace the shift control solenoid valve A,/B assem-bly if the resistance is out of specification.

lf the resistance is within the standard. connect theNo, I terminal of the shift control solenoid valveconnector to the battery positive terminal. A clickingsound should be heard. Connect the No. 2 terminalto the battery positive te.minal. A clicking soundshould be heard. Replace the shift control solenoidvalve A/B assembly if no clicking sound is heardwhen either terminal is connected to the battervpositive terminal.

14-136

Replacement

NOTE: Shift control solenoid valves A and B must beremoved/replaced as an assembly.

1. Remove the shift control solenoid cover.

2. Remove the mounting bolts, the clamp and the shiftcontrol solenoid valve Ay'B assembly, then disconnect

the connector.

6x1.0mm12 N.m{1.2 k9 .m,8.7 lbtft}CLAMP ARACKET

FILTER/GASKETReplace.Clean the mounling surfaceand fluid passages.

Clean the mounting surface and fluid passages. andinstall a new shift control solenoid valve Ay'B assem-bly with the clamp and a new filter/gasket.

Install the shift control solenoid cover.

Check the connector for rust, dirt. or oil, and recon-nect it securely.

w

SHIFT CONTROLSoLENO|O COVEn

SHIFT CONTROLSOLENOID VALVE A/BASSEMBLY

\--

qK

-!t'">,,

www.emanualpro.com