Page 98 HONDA INTEGRA 1994 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 651 of 1413

Power Steering Pump

lnstallation

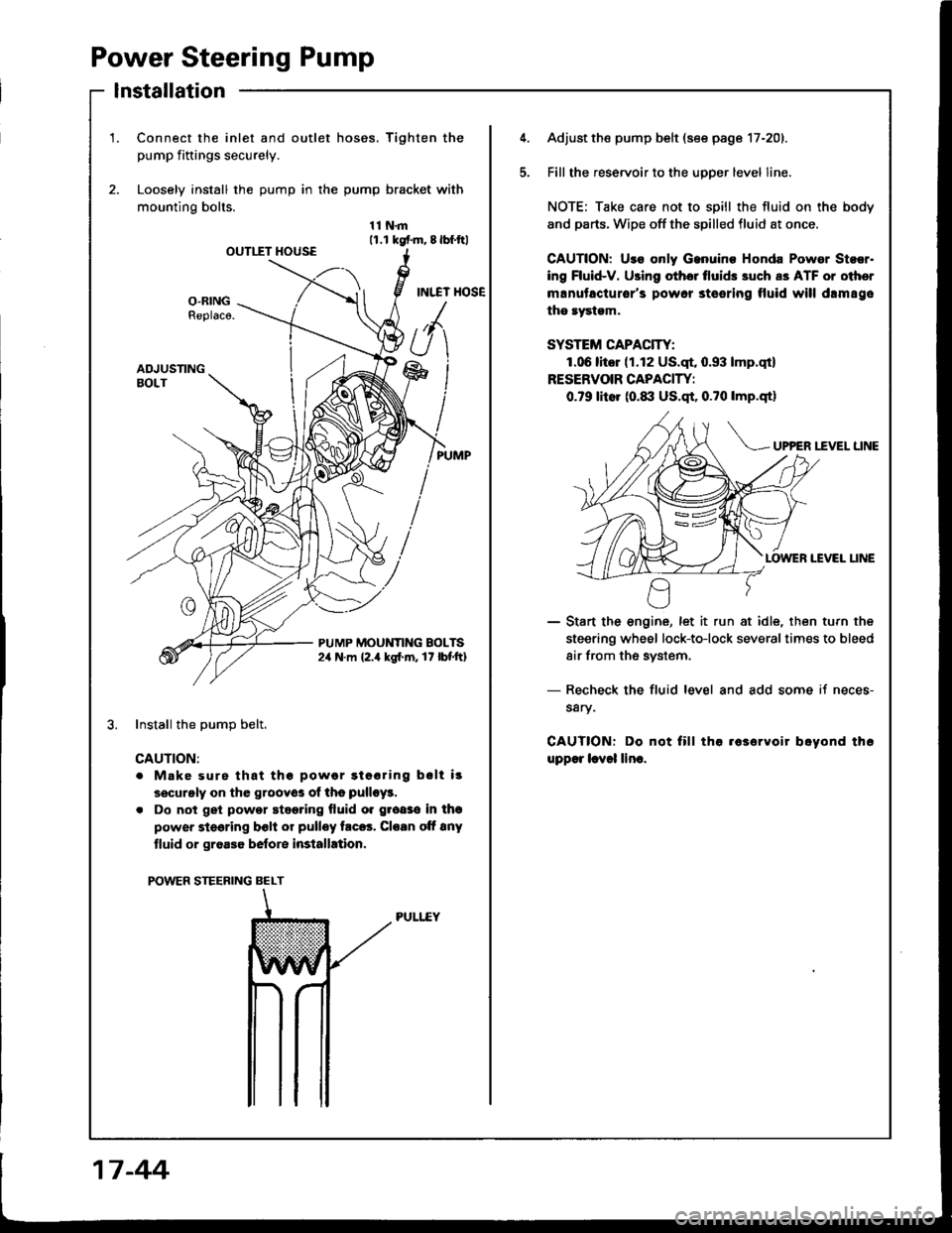

1.Connect the inlet and outlet hoses. Tighten the

pump fiftings securely.

Loosely install the pump in the pump bracket with

mounting bolts.

11N.m11.r kgf.m, 8lbf.ftlOUTIIT HOUSE

INI.TT HOSEO-RINGReplaco.

ADJUSTINGBOLT

PUMP MOUNTING BOLTS2,r N.m {2.4 kgl.m. 17 lbf'ft}

Install the DumD belt.

CAUTION:

. Make surs that thg powor gtooring bslt i!

securgly on the grooyos of ths pulloy!.

. Do not get powor stggring fluid o. groaso in thg

power steering bclt or pulley trc6. Cloan oft 8ny

tluid or groa36 belore installation.

POWER STEERING BELT

PULI..EY

5.

Adjust the pump belt (see page 17-201.

Fill the reservoir to the uoDer level line.

NOTE; Take care not to spill the fluid on the body

and parts. Wipe off the spilled fluid at once.

GAUTION: Uro only Ganuino Honda Powor Stsor.

ing Fluid-V. Using othor tlui& 3uch a3 ATF or oiher

manutacturor's powor steering tluid will drm89e

the rystgm.

SYSTEM CAPACITY:

1.06litor (1.12 US.qt, 0.93 lmp.qt)

RESERVOIR CAPACIW:

0.79 litor (0.1|:| US.qt, 0.?0 lmp.qtl

UP?ER I.fVEL LINE

IEVEI LINE

- Start the engine, let it run at idle, then turn the

steering wheel lock-to-lock severaltimes to bleed

air from the system.

- Recheck the fluid level and add some if neces-

s8ry.

CAUTIONT Do not fill tha .63ervoir boyond th6

upp€r lcvol lino.

17 -44

Page 652 of 1413

Steering Gearbox

Removal

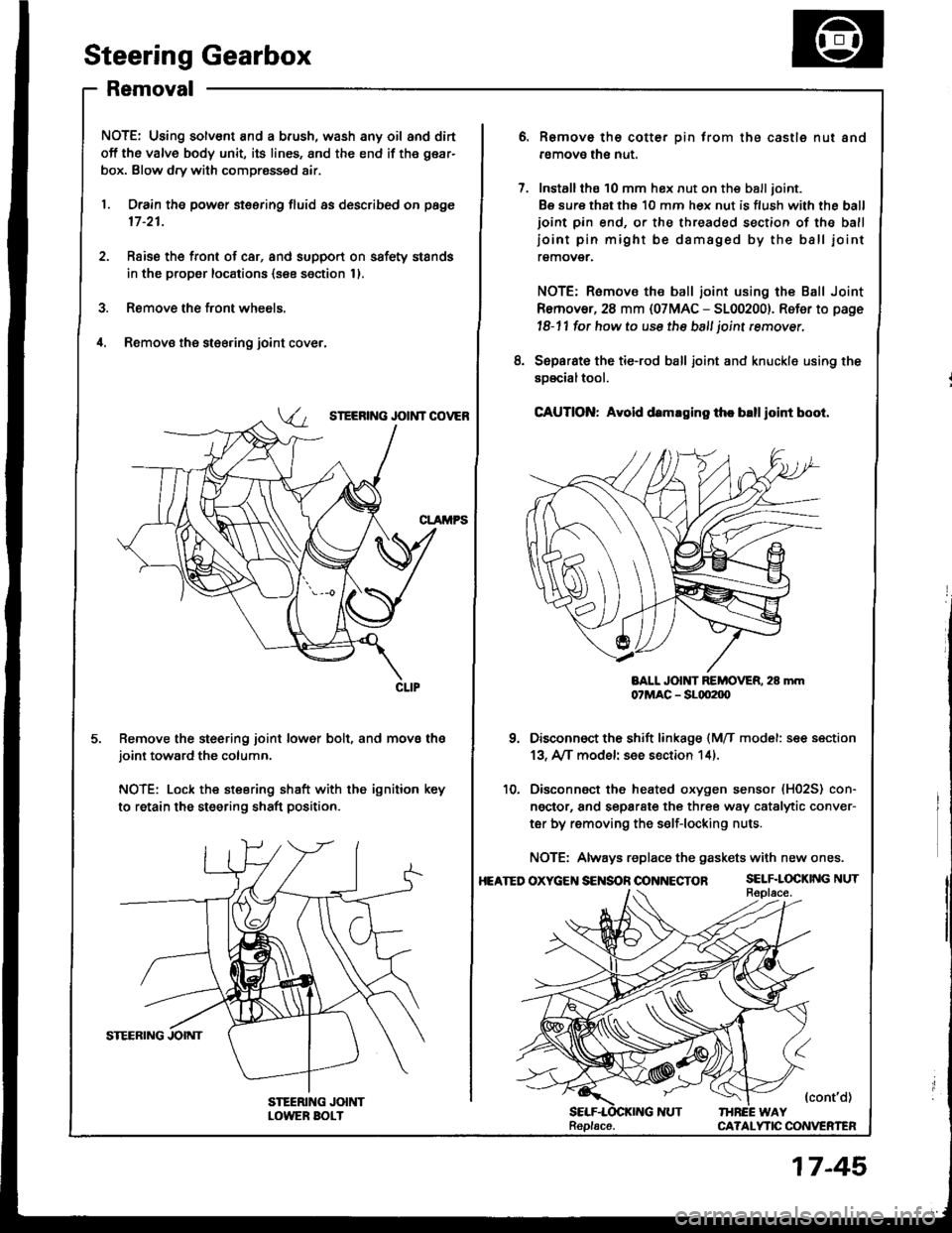

NOTE: Using solvent and a brush, wash any oil and dirt

off the valve body unit, its lines, and the end if the gear-

box. Blow dry with compressed air.

1. Drain the power steering fluid as described on page

17 -21.

2. Rsise the front of car, and support on safety stands

in the propsr locations (see section 1).

3. Remove the front wheels.

il. Removs the st€ering joint cove.,

SIEERING JOIi{T COVEB

Remove the steering joint lower bolt, and move thejoint toward the column.

NOTE: Lock the steering shaft with the ignition key

to retain the steering shaft position.

Remove the cotter pin trom the castle nut and

removo the nut.

Installthe 10 mm hex nut on the balljoint.

Be sure that ths 10 mm hex nut is flush with the ball

ioint pin end, or the threaded section of the ball

ioint pin might be damaged by the ball iointremover.

NOTE: Remove the ball joint using the Ball Joint

Remover, 28 mm {07MAC - 5100200}. Refer to page

l8-11 fot how to use the ball joint rcmover,

Separat€ the tie-rod ball joint and knuckle using the

soscialtool.

CAUTION: Avold d.maging th. blllloint boot.

BALL JOlt{T REMOVER. 28 mm07MAC - SLqt2|X)

Disconnect the shift linkage {MfI model: see section

13, A/[ model see section 14).

Disconnect the heated oxygen sensor (H02S) con-

ngctor, and separate the three way catalytic conver-

ter by removing the s€lf-locking nuts.

NOTE: Always replace the gaskets with new ones.

OXycEt{S€NSOnOONNECTOR SELF.LOCKINGNUT

{cont'd)IHREE WAYCA?ALYTIC CONVERTEN

8.

10.

HEATED

Replacs.

17-45

Page 655 of 1413

Steering Gearbox

Disassembly

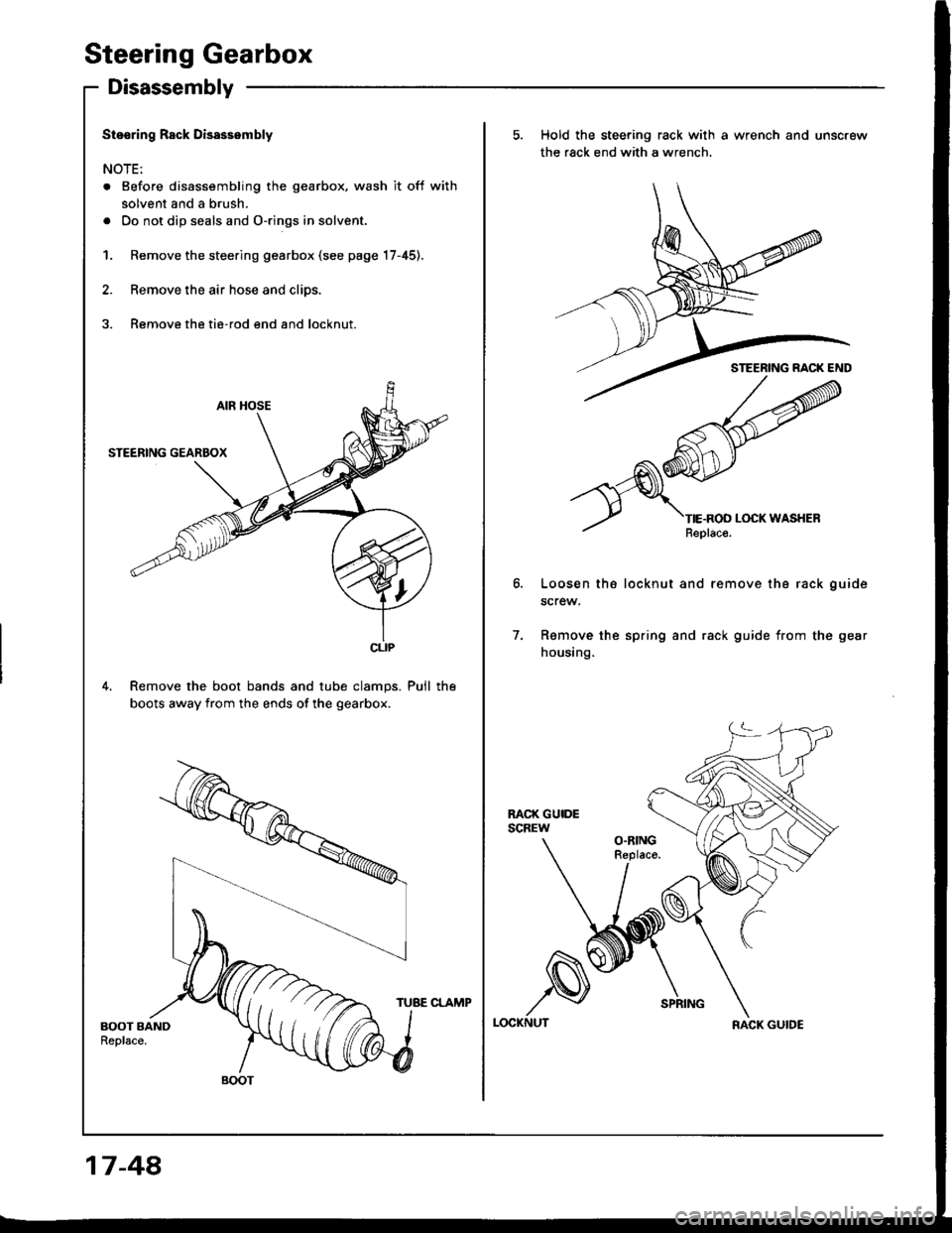

Stssring Rack Disassembly

NOTE:

. Before disassembling the gearbox, wash it off with

solvent and a brush.

. Do not dip seals and O-rings in solvent.

1. Remove the steering gearbox (see page 17-45).

2. Remove the air hose and clips.

3. Remove the tie-rod end and locknut.

4. Remove the boot bands and tube clamps. Pull the

boots away from the ends of the gearbox.

CLIP

BOOT

5. Hold the steering rack with a wrench and unscrew

the rack end with a wrench.

Loosen th6 locknut and remove tha rack guide

screw.

Ramove the spring and rack guide from the gear

housing.

7.

LOCKNUTRACK GUIDE

17-48,

TUBE CLAMP

Page 656 of 1413

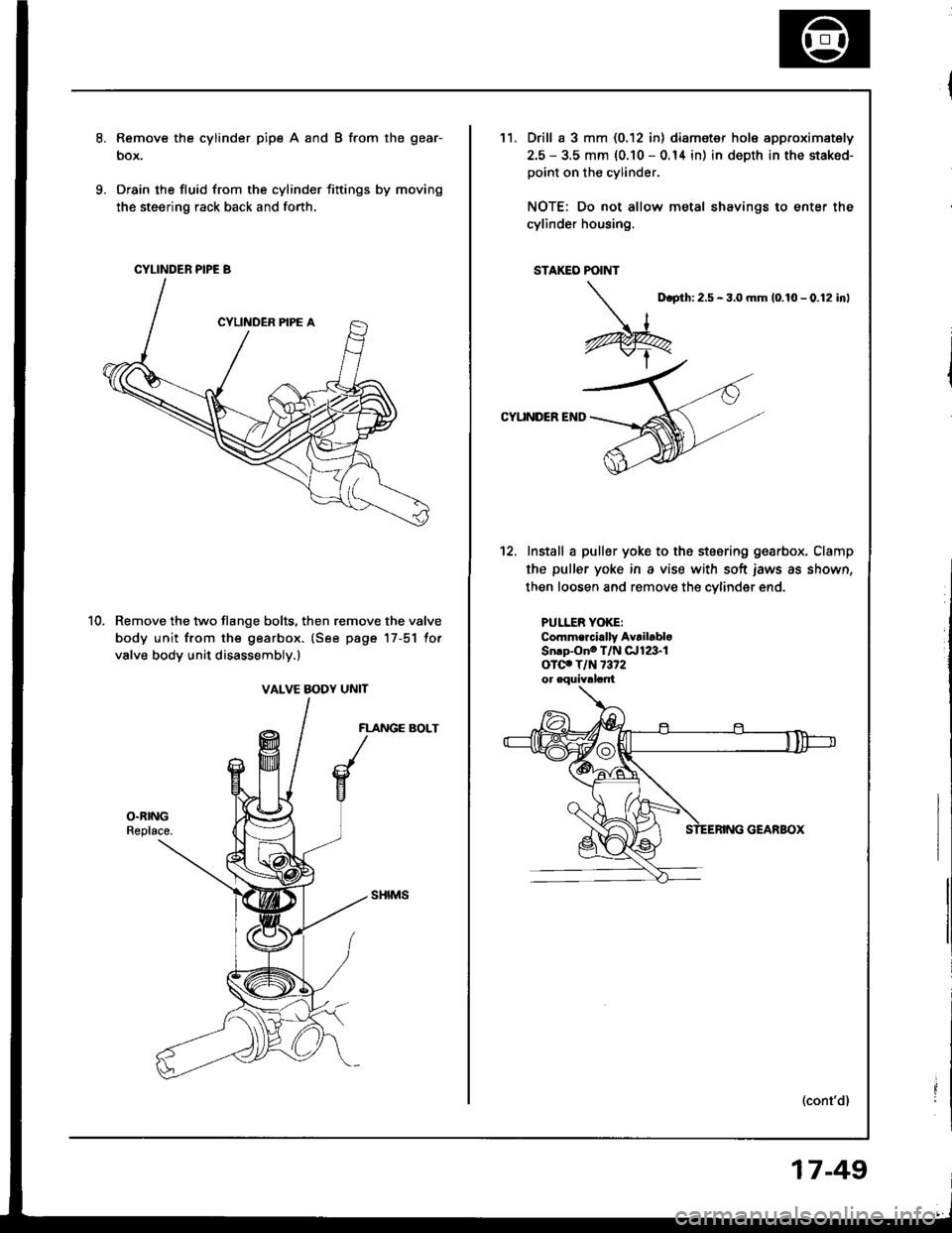

Remove the cylinder pipe A and B from the gear-

box.

Drain the fluid from the cylinder fittings by moving

the steering rack back and forth,

Remove the two flange bolts, then remove the valve

body unit from the gearbox. {See page 17-51 for

valve body unit disassembly.)

FLANGE BOLT

CYLINDER PIPE B

VALVE BODY UNIT

11.Drill a 3 mm {0.12 in) diameter hole approximately

2.5 - 3.5 mm (0.10 - 0.14 in) in depth in the staked-

point on the cylinder.

NOTE: Do not allow metal shavings to enter the

cylinder housing.

STAKEO POINT

D.prh:2.5 - 3,0 mm 10.10 - 0.12 inl

CYUNDER END

12. Install a puller yoke to the stesring gearbox. Clamp

the puller yoke in a vise with soft iaws as shown,

then loosen and remove the cvlinder end.

PULLER YOKE:Commercirlly AvrilabloSn.p-Ono T/N qrie'-1

oTclo T/N 7372

(cont'd)

17-49

Page 667 of 1413

Steering Gearbox

Reassembly lcont'd)

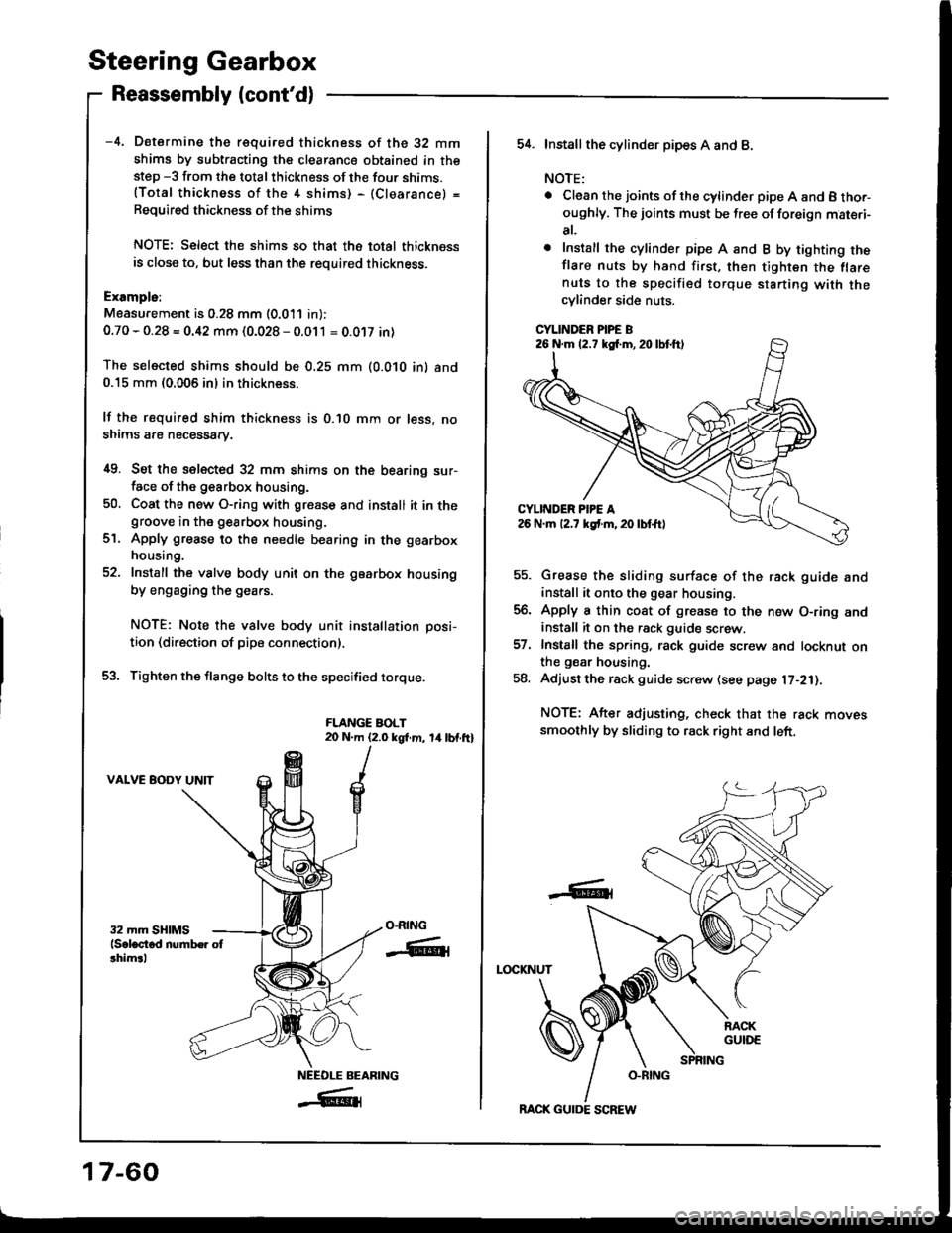

-4. Determine the requifed thickness of the 32 mm

shims by subtracting the clearance obtained in thestep -3 from the total thickness of the four shims.(Total thickness of the 4 shims) - (Clearance) =

Required thickness of the shims

NOTE: Select the shims so that th6 total thicknessis close to, but less than the required thickness.

Exampls:

Measu.ement is 0.28 mm (0.011 in):

0.70 - 0.28 = 0.42 mm (0.028 - 0.011 = 0.0't7 in)

The selected shims should be 0.25 mm (O.O1O in) and0.15 mm (0.005 in) in thickness.

lf the required shim thickness is 0.lO mm or less, no

shims are necessary.

i[9. Set the selected 32 mm shims on the bearing sur-face of the g€arbox housing.

50, Coat the new O-ring with gresse and install it in thegroove in the gearbox housing.

Apply grease to the needle bearing in the gearbox

housing.

Install the valve body unit on the gearbox housing

by engaging the gears.

NOTE: Note the valve body unit installation posi-

tion (direction of pipe connection).

Tighten the flange bolts to the specified torque.

FLANGE BOLT20 N.m (2.0 kgt m, 14lbf.ft)

VALVE BODY UNIT

ct.

O-RING

-ffiti

NEEOLE BEARING

_#{

17-60

BACK GUIDE SCREW

54. Installthe cylind6r pipes A and B.

NOTE:

. Clean the joints ofthe cylinder pipe A and B tho.-oughly. The joints must be free of foreign mat€.i-

at,

o Install the cylinder pipe A and B by tighting theflare nuts by hand first, then tighten the flarenuts to the specified torque starting with thecylinder side nuts.

CYLINDER PIPE B

Grease the sliding surface of the rack guide andinstall it onto the gear housing.

Apply a thin coat of grease to the n€w O-ring andinstall it on the rack guide screw.

Install the spring, rack guide screw and locknut onthe gear housing.

Adjust the rack guide screw (see page l7-21).

NOTE: After adjusting, check that the rack movessmoothly by sliding to rack right and left.

LOCKNUT

-6t

26 N.m (2.7 kg{.m,20lbtft)

Page 672 of 1413

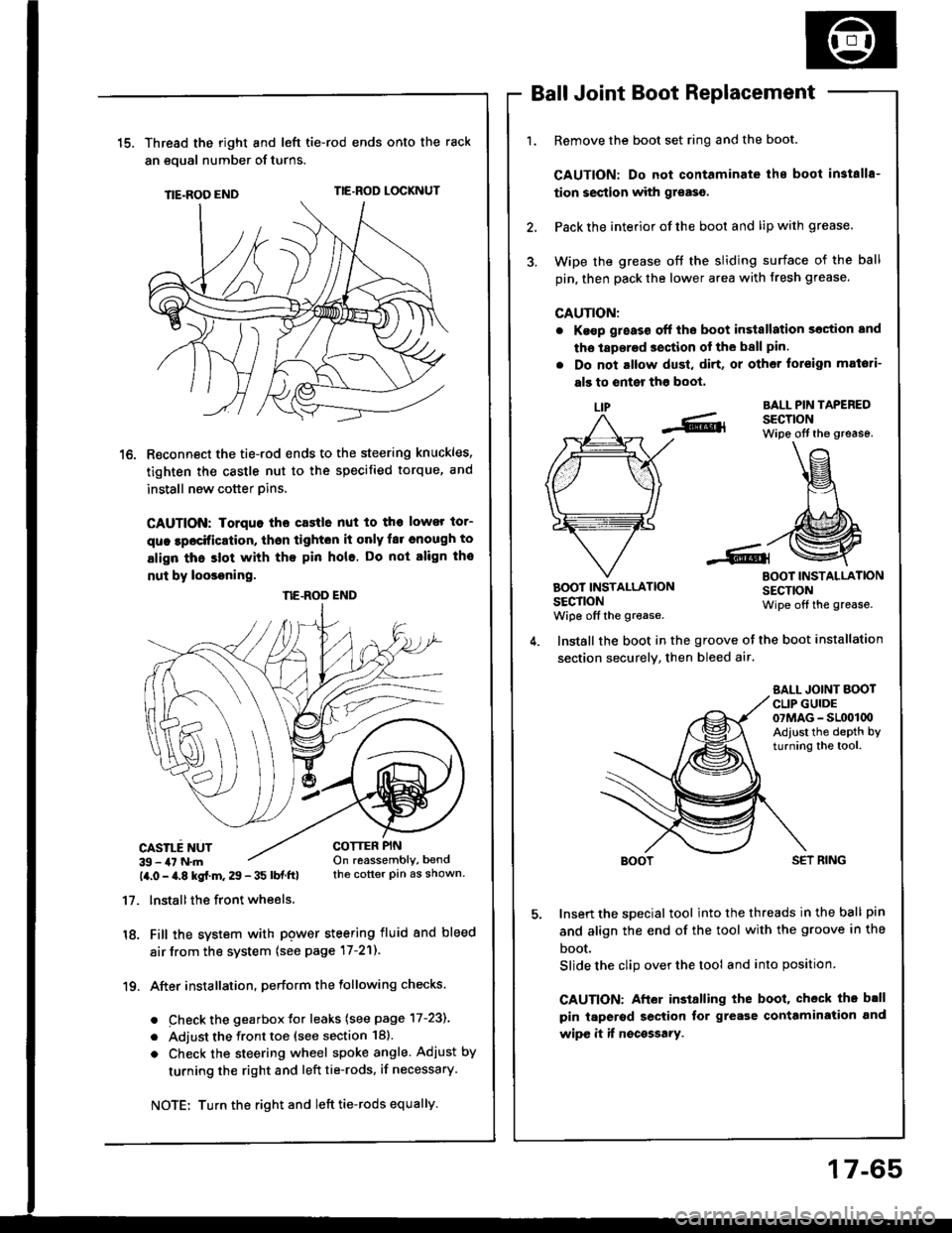

15.Thread the right and lefi tie-rod ends onto the rack

an eoual number of turns.

TIE-ROO ENDTIE.ROD LOCKNUT

R€connect the tie-rod ends to the steering knuckles,

tighten the castle nut to the specified torque, and

install new cotter pins.

CAUTION: Iorquo tho castle nut to tho lower tor-

que lpocification, thsn tighton it only far cnough to

align thc slot with tho pin hole. Do not align tho

nut by loosoning.

CASILE NUT39 - 47 N.m14.0 - a.8 kgf.m. 29 - 35 lbf ftl

17. lnstallthe front wheels.

18. Fill the system with pgwer steering fluid and bleed

air from the system (see page 17-21).

19. After installation. perform the following checks.

. Check the gearbox Jor leaks (see page 17-231

. Adjust the front toe (see section 18).

o Check the steering wheel spoke angle. Adjust by

turning the right and left tie-rods, if necessary.

Ball Joint Boot Replacement

Remove the boot set ring and the boot.

CAUTION: Do not contaminate ihe boot in3talls-

tion section with gr€aso.

Pack the interior of the boot and lip with grease.

Wipe the grease off the sliding surface of the ball

pin, then pack the lower area with fresh grease.

CAUTION:

. Ke€p g;eass off the boot in3tallation section and

tho laperad section of the ball pin.

. Do not altow dust, di.t, or other toreign mat6ti-

als to enter tho boot,

LIPBALL PIN TAPEREDSECTIONWipe off the grease.

BOOT INSTALLATIONSECTIONwiDe off the grease.

BOOT INSTALLATIONSECTIONWipe off the grease.

COTTER PINOn reassembly, bendthe cotter pin as shown.

Install the boot in the groove ot the boot installation

section securely, then bleed air.

SALL JOINT BOOTCLIP GUIDE07MAG - SL(x)l00Adiust the depth byturning the tool.

SET RING

Insert the special tool into the threads in the ball pin

and align the end of the tool with the groove in the

boot.

Slide the clip over the tool and into position

CAUTION: After installing the boot, check th. b.ll

pin taperod section tor grease contamiration and

wipe it if nocossary.

NE.ROD END

Turn the right and left tie-rods equally.

17-65

Page 914 of 1413

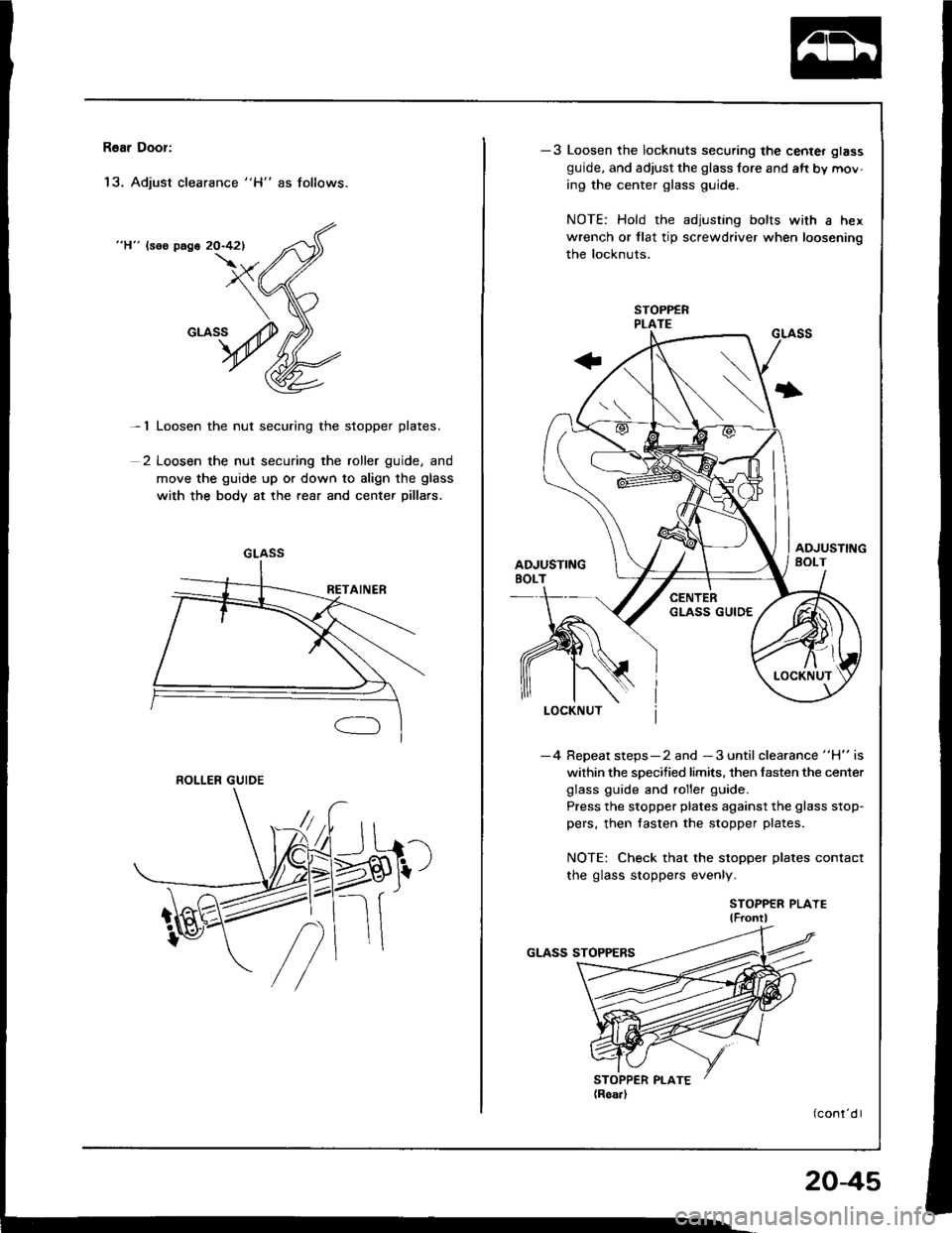

R6ar Door:

'13. Adjust clearance "H" as follows.

"H" lsos page 20-421

- 1 Loosen the nut securing the stopper plates.

2 Loosen the nut securing the roller guide, and

move the guide up or down to align the glass

with the body at the rear and center pillars.

GLASS

ROLLER GUIDE

-3 Loosen the locknuts securing the center glass

guide, and adjust the glass fore and aft by mov-

ing the center glass guide.

NOTE: Hold the adjusting bolts with a hex

wrench or tlat tip screwdriver when loosening

the locknuts.

I

-4 Repeat steps-2 and -3 until clearance "H" is

within the specified limits. then fasten the center

glass guide and roller guide.

Press the stopper plates against the glass stop-

pers, then fasten the stopper plates.

NOTE: Check that the stopper plates contact

the glass stoppers evenly.

STOPPER PLAYElF ontl

204s

Page 915 of 1413

Doors

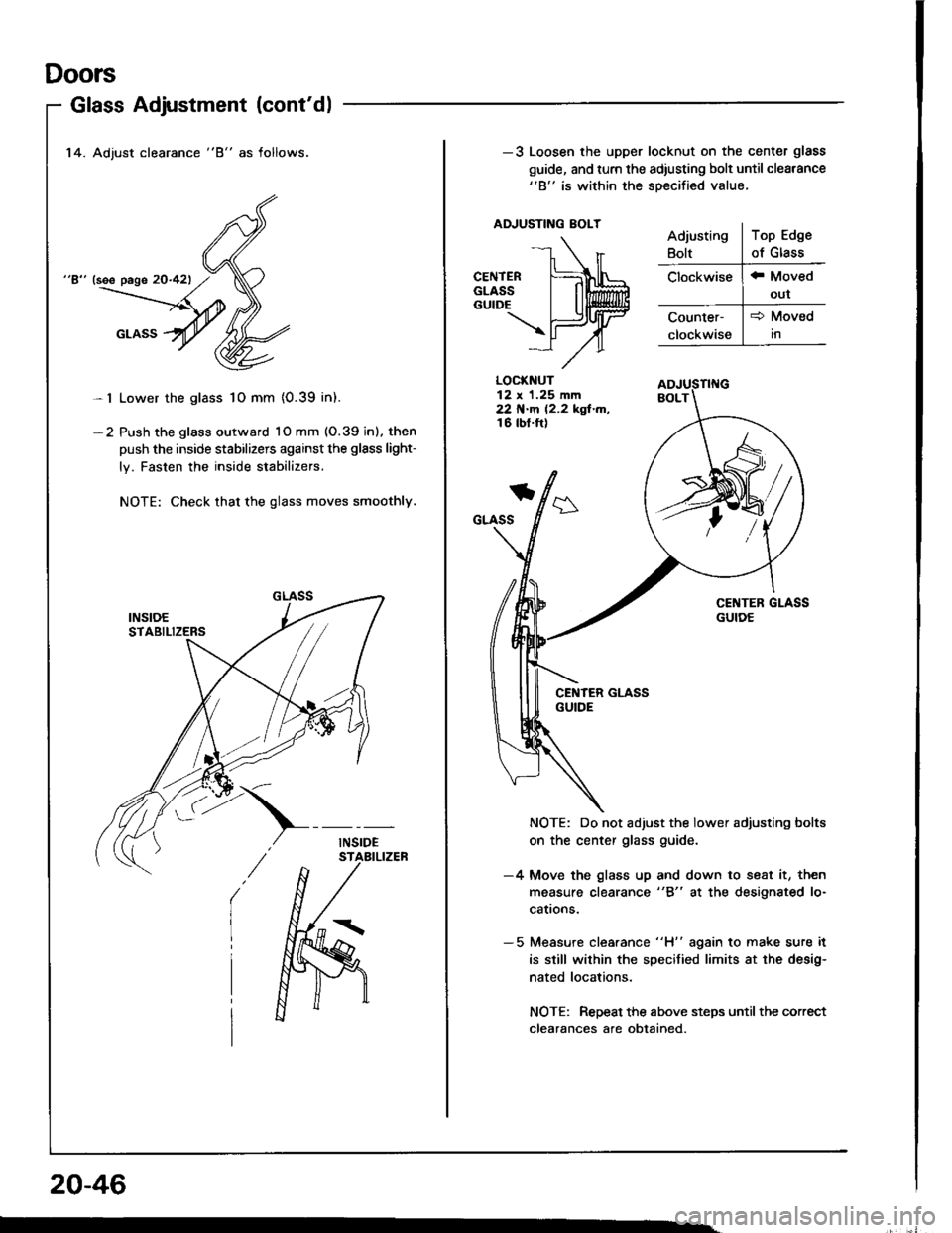

14. Adjust clearance "8" as follows.

"8" (see page 20-421

Lower the glass 1O mm {0.39 in).

Push the glass outward 1O mm (O.39 inl. then

push the inside stabilizers against the glsss light-

ly. Fasten the inside stabilizers.

NOTE: Check that the glass moves smoothly.

Glass Adjustment (cont'dl

-l

-2

20-46

-3 Loosen the upper locknut on the center glass

guide, and turn the adiusting bolt until cleatance"B" is within the soecified value.

ADJUSTING EOLT

LOCKNUT12 x 1.25 mm22 N.m 12.2 kgf.m,16 tbt.ft)

*

GLASS

NOTE: Do not adjust the lower adjusting bolts

on the center glass guide.

-4 Move the glass up and down to seat it, then

measure clearance "8" at the designated lo-

cattons.

- 5 Measure clea.ance "H" again to make sure it

is still wilhin the specified limits at the desig-

nated locations.

NOTE: Repeat the above steps until the correct

clearances afe obtained.

Page 916 of 1413

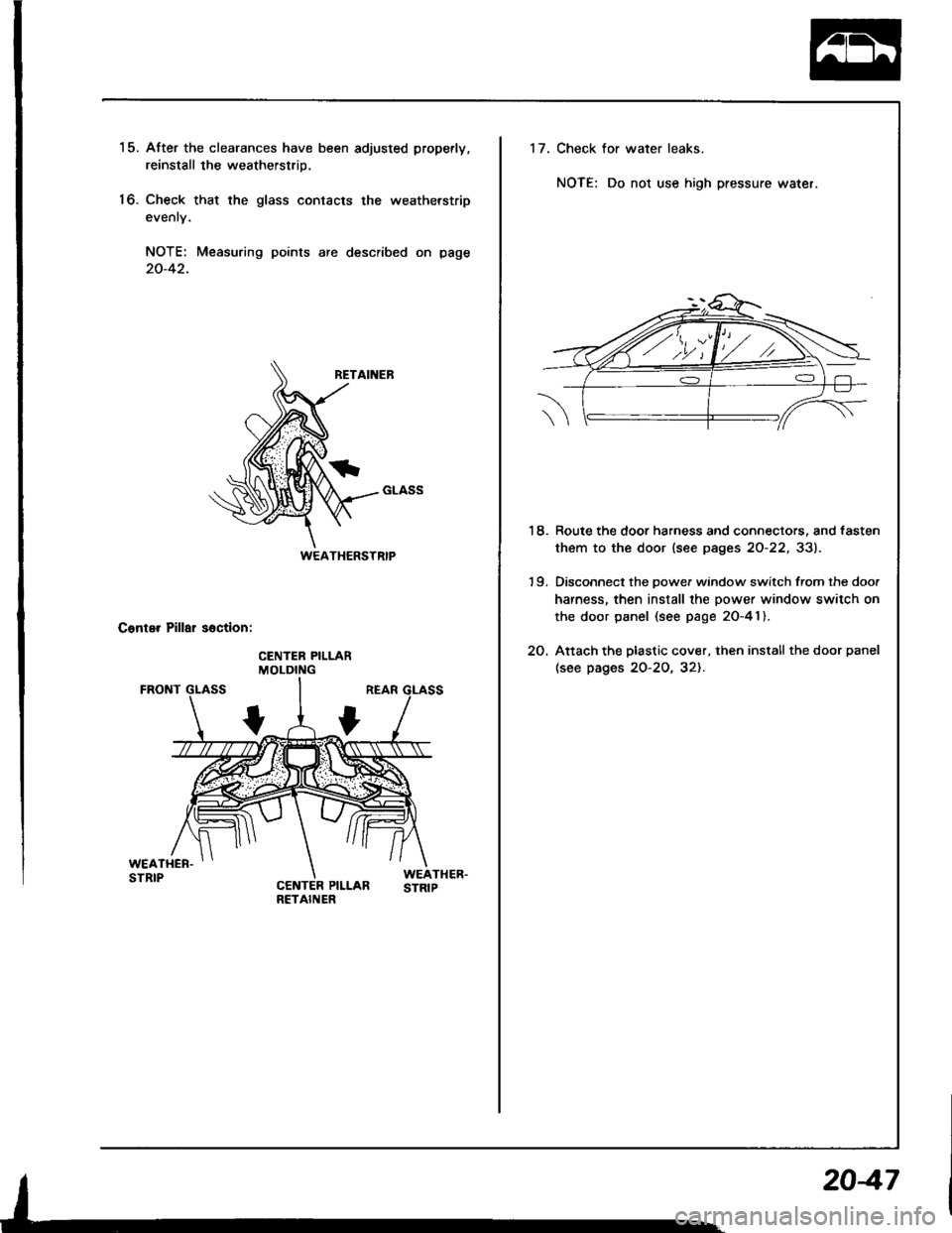

15. After the clearances have been adjusled properly.

reinstall the weatherstrip.

16. Check that the glass contacts the weatherstrip

evenly.

NOTE: Measuring points are described on page

20-42.

Conter Pillar soction:

WEATHERSTRIP

17.Check for water leaks.

NOTE; Do not use high pressure water.

18. Route the door harness and connectors, and fasten

them to the door (see pages 20-22, 331.

19. Disconnect the oowef window switch from the doo.

harness, then install the power window switch on

the door panel (see page 20-41).

2O. Attach the plastic cover, then install the door panel

(see pages 2O-2O, 321.

2047

Page 918 of 1413

Mirrors

Power Door Mirror Replacement

Hstchback

1. Pry out the cover panel with a flat tip screwdriver,

then remove it.

CAUTION: When prying with a flat tip screwdriver.

w'ap it whh protoctiva tapo to pravont damage.

2. Disconnect the connector. Remove the nuts, then

remove the door mirror while holdino it.

< : Nut locltion3, 3

^^ sxo.8mm I

l$9 111 - to.+ rst.. i| +|lmtu.+rgr.m, I3 lbl'lrl - ---J'/

cot{t{EcToB(Doo. mirror ddol

DOOR MIRROR

CONNECTORlDoor harnoss.ide)

CONNECTOR

3. Installation is the reverse o{ the removal procedure.

Sedan

1. Remove the door panel (see page 20-201 and dis-connect the connector.

2. Pry the cover panel out with a flat tip screwdriver,

then remove the cover panel.

CAUTION: Whsn prying with a flat tip scrowd.lv€l,

wrap it with protectiv€ taps to p.svont damag6.

3. Remove the screws while holding the door mirror.

< i Scrow locations

, A< : Scrow, 2 , B< : Scr6w, I

! ,"",''@ I 66

I s'0.4.- | sro.'"e-.

4 N.m (0.4 kst.m, + w.m (0.4 kgt.m,\3_!!t.rrr__ \!Lbllq

CONNECTOR

4. Installation is the reverse of the removal procedure,

HOOKS

20-49