connector HONDA INTEGRA 1994 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 1352 of 1413

Cruise Control

Control Unit Input Test

CAUTION:

a All SRS olectrical wi ng harnessos are covored with

yellow insulation.

a Botore disconnecting any part of th6 SRS wire har-

neaa, connect the short connoctor(sl.

a Roplace the €ntir€ affectod SRS hamass assembly il

il has an opan circuit or damaged wifng.

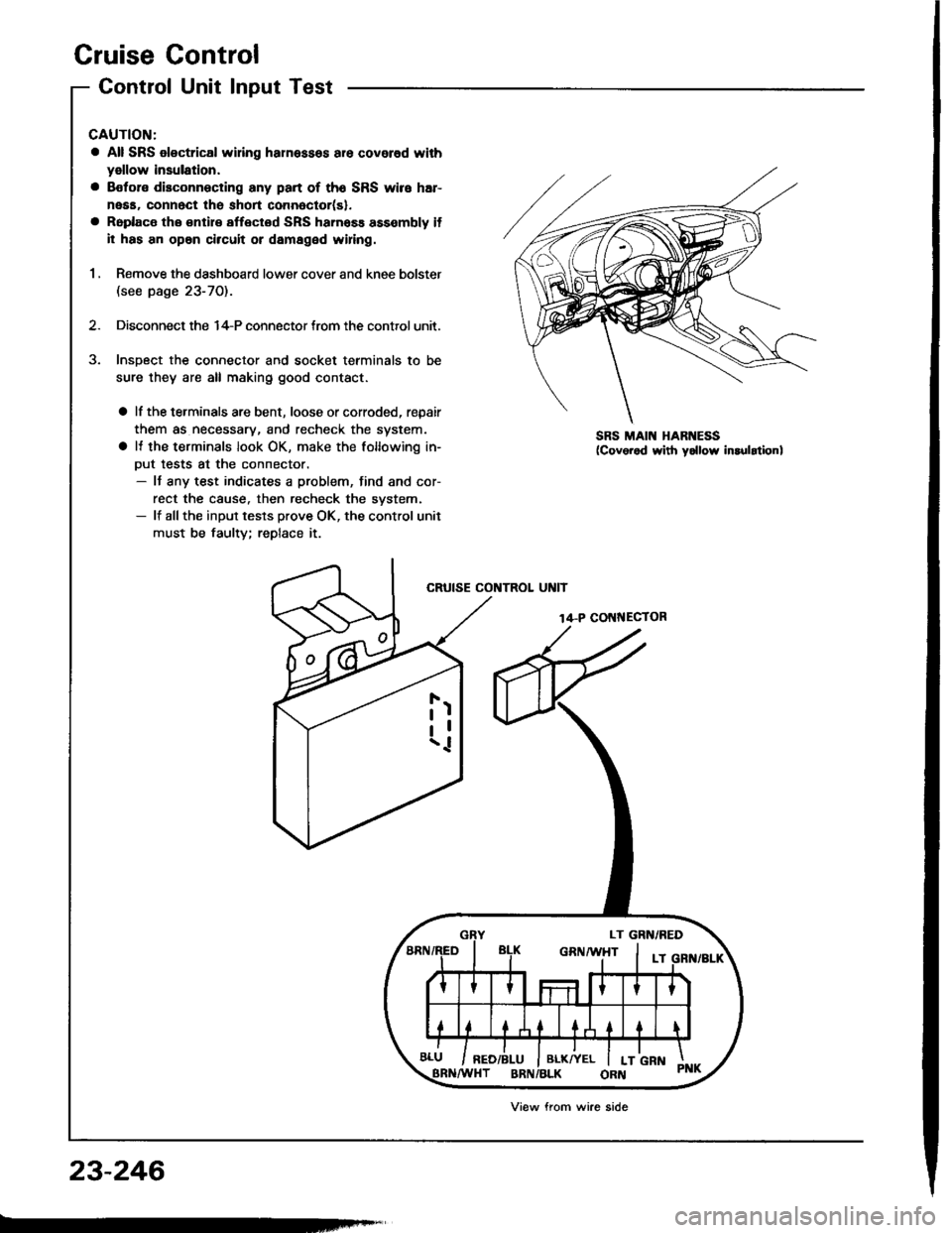

1 , Remove the dashboard lower cover and knee bolster(see page 23-70).

2. Disconnect the 14-P connector trom the control unit.

Insoect the connector and socket terminals to be

sure they are all making good contact.

a lf the terminals are bent, loose or corroded, repair

them as necessary, and recheck the system.

a It the terminals look OK, make the following in-

Dut tests at the connector.- It any test indicates a problem, find and cor-

rect the cause. then recheck the svstem.- lf allthe input tesls prove OK, the control unit

must be faulty; replace it.

CRUISE CONTROL UNIT

14-P COI{NECTOR

SRS MAIN HARNESS

23-246

Viow from wire side

Page 1354 of 1413

Cruise Gontrol

Set/Resume Switch Test/Replacement

CAUTION:

a All SRS ol6ct cal widng herne$a3 err covorod with

y6llow insulation.

a Bototo disconnecting any part ot tho SRS wiro h8r-

n6sa, connoct tho ghort connector(sl,

a Rsplaco the antire aftected SRS harness arsombly if

it has an op6n chcuit or damagod wiring.

NOTE: The original radio has a coded theft protection

circuit, Be sure to get the customer's code number befor€- disconnecting the battery.- removing the No. 32 (7.5 A) fuse from the under-hood

fuse/relay box.- removing the radio.

Afte, service, reconnect power to the radio and turn it

on. When the word "CODE" is displayed, enter the cus-

tomer's s-digit code to restore radio op€ration.

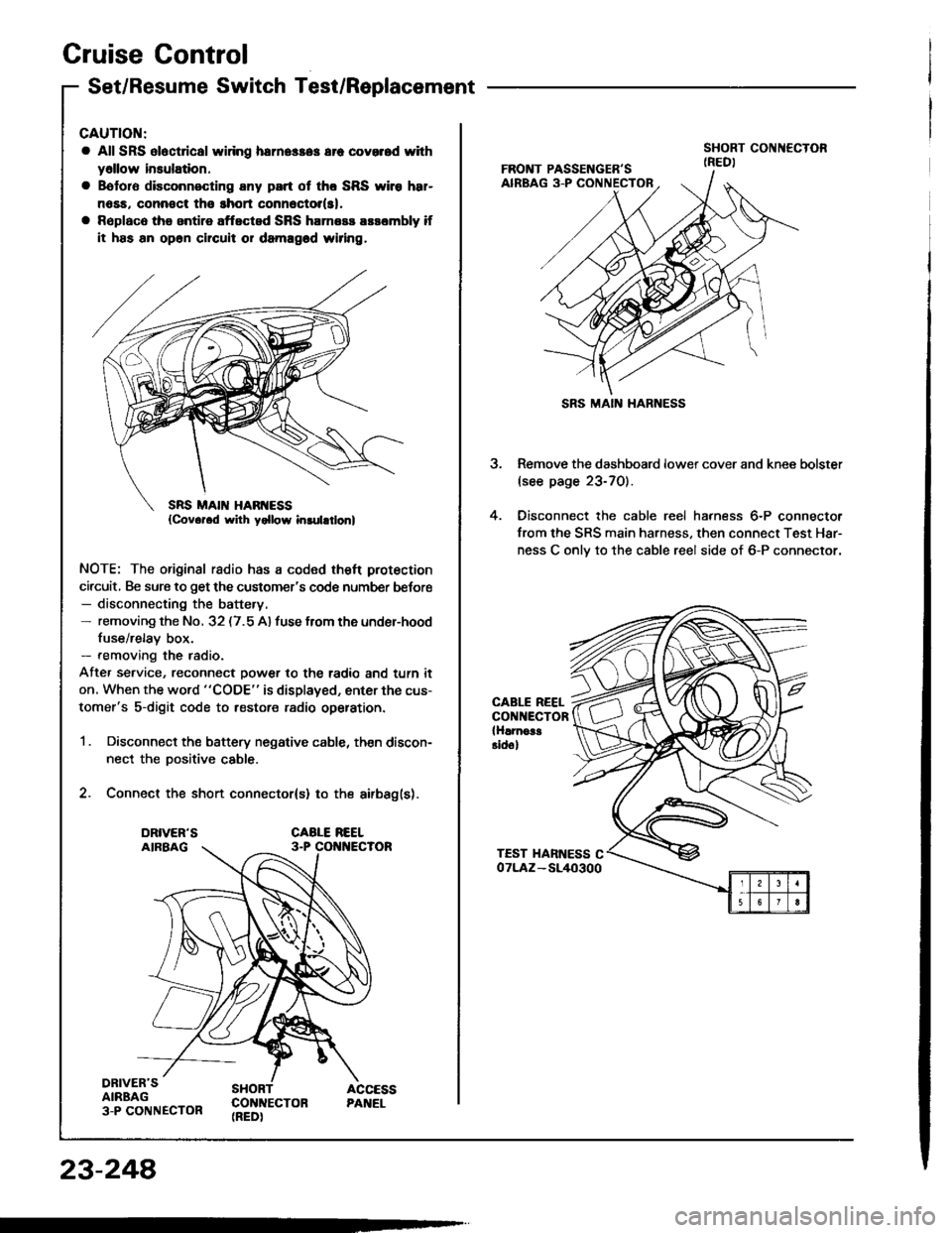

1 . Disconnect the battery negative cable, then discon-

nect the Dositive cable.

2. Connect the short connector(s) to the airbag(s).

DRIVER'SAIRBAG3-P CONNECTOR

SHORT ACCESSCON]TECTON PANEL(REDI

23-248

SRS MAIN HARNESS

3. Remove the dashboard lower cover and knee bolster(see page 23-70).

4. Oisconnect the cable reel harness 6-P connector

from the SRS main harness, then connect Test Har-

ness C onlv to the cable reel side of 6-P connector.

CABLE REELCONNECTORlHlrnoa!Eidol

Page 1357 of 1413

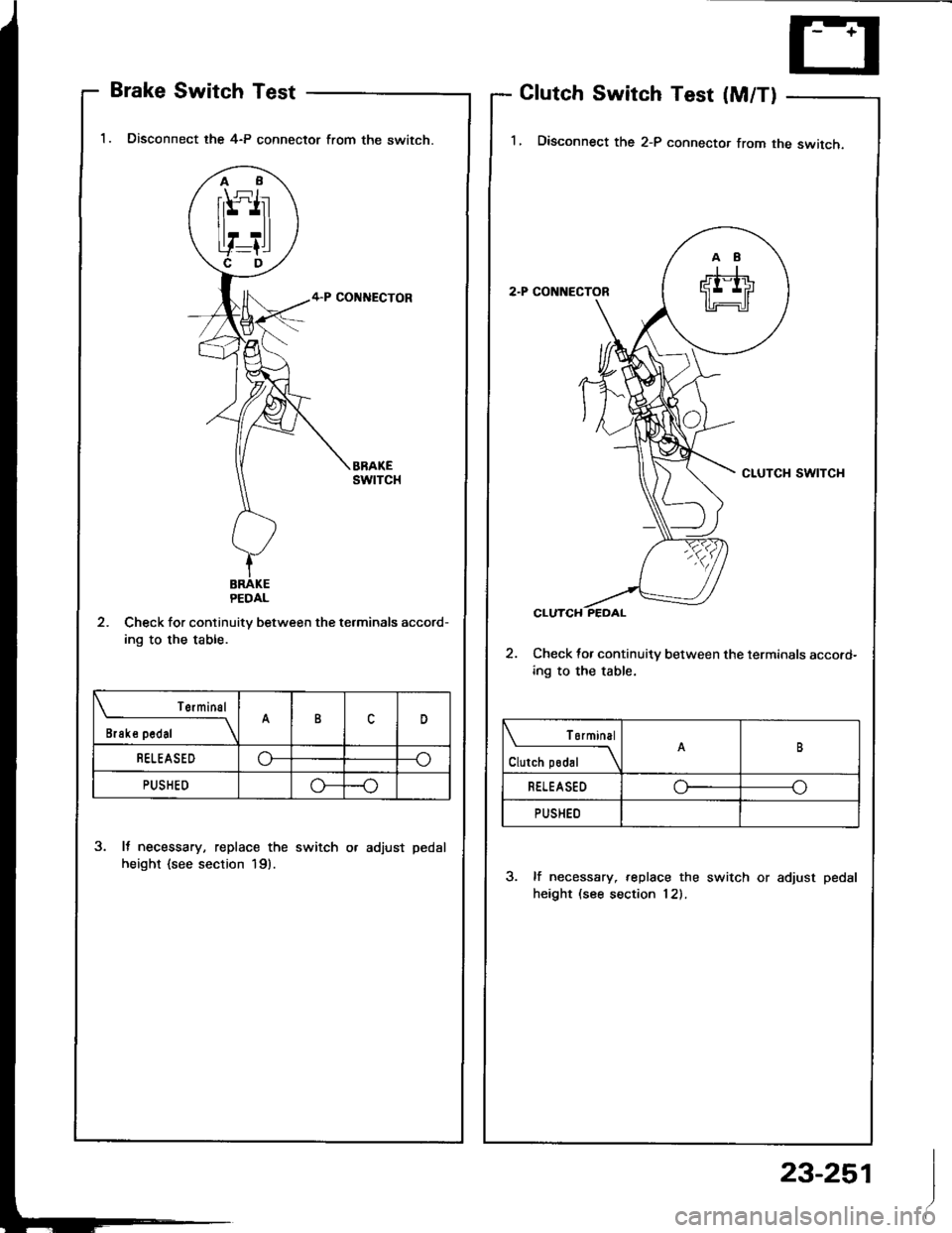

Brake Switch Test

'1. Disconnect the 4-P connector from the switch.

2. Check for continuitv between the terminals accord-

ing to the table.

3. It necessary, replace the switch or adjust pedal

height {see section 19).

Glutch Switch Test (M/T)

I� Disconnect the 2-P connector from the switch,

2. Check {or continuitv between the terminals accord-

ing to the table.

3. lf necessary, replace the switch or adjust pedal

height (see section 12).

I

Terminal

il"*on---\B

BELEASEDo---o

PUSHED-o

| ormtnal

Clutch podal \

RELEASEDoo

PUSHED

23-251

Page 1358 of 1413

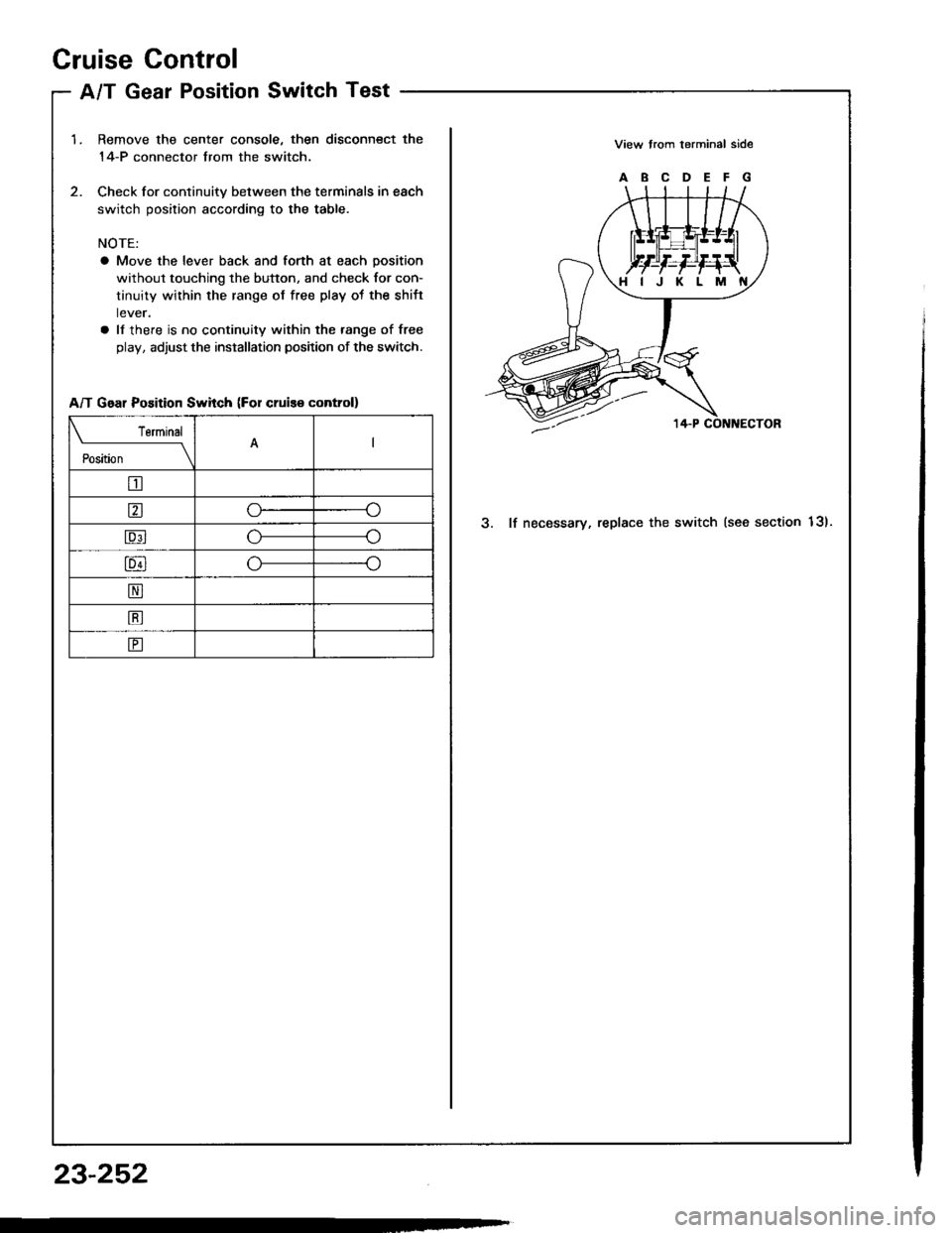

Cruise Control

A/T Gear PositionSwitch Test

1.Remove the center console, then disconnect the

14-P connector trom the switch.

Check for continuitv between the terminals in each

switch position according to the table.

NOTE:

a Move the lever back and forth at each position

without touching the button, and check for con-

tinuity within the range of free play ot the shift

lever.

a ll there is no continuity within the range of free

play, adjust the installation position of the switch.

View trom terminal side

ABCDEFG

3. lf necessary, replace the switch (see section 13).

HIJKLM

A/T Gear Position Swhch (For cruis€ control)

Terminal

il;---t

tr

ao

Eo

lu4lo---o

N

B

E

23-252

Page 1359 of 1413

1.

2.

3.

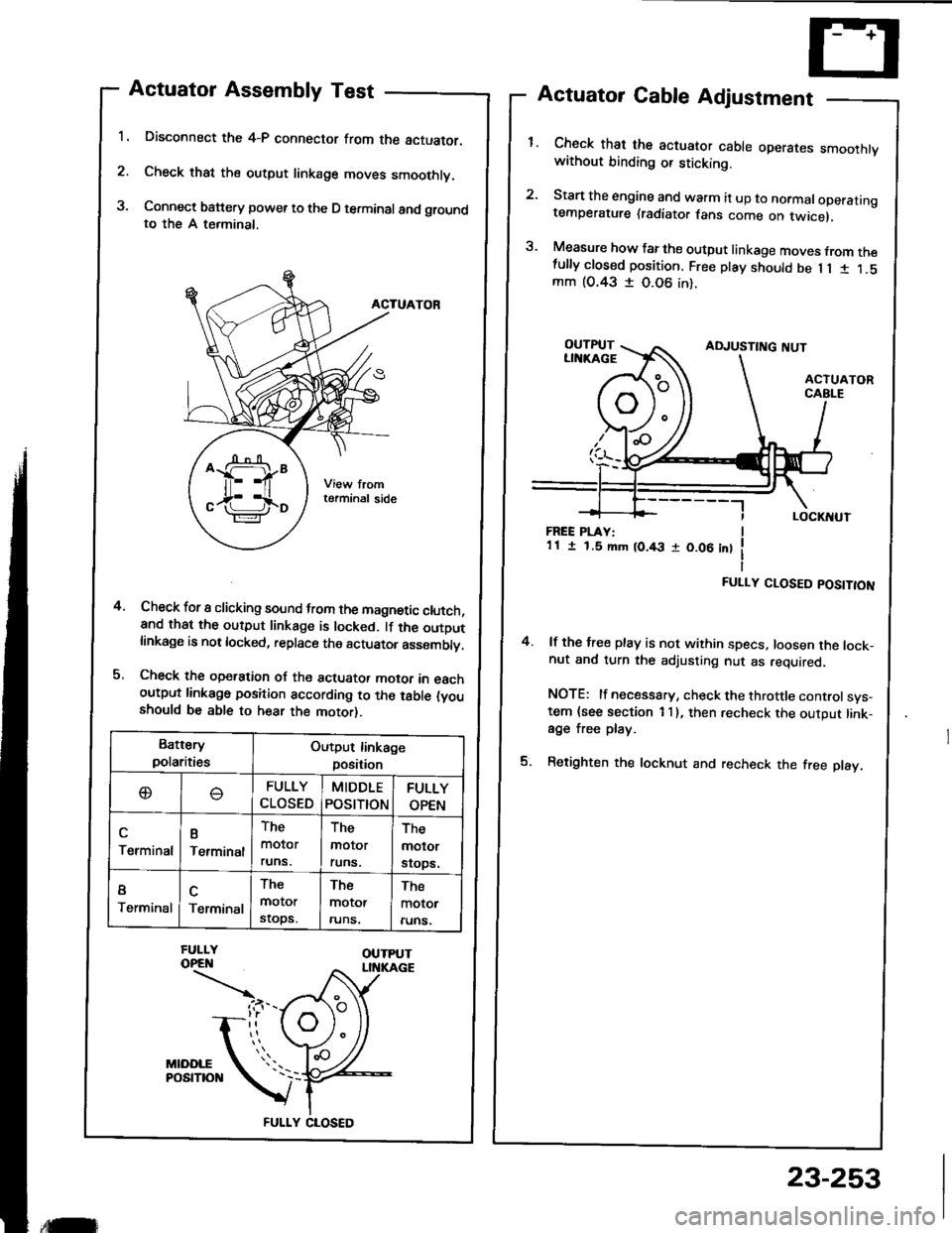

Actuator Assembly Test

Disconnect the 4-P connector from the actuator.

Check that the output linkage moves smoothly.

Connect battery power to the D terminal and groundto the A terminal,

ACTUATOR

Check for I clicking sound trom the magnetic clutch,and that the output linkage is locked. lf the outDutlinkage is not locked, replace the actuator asssmblv.

Check the operation oJ the actuator motor in eachoutput linkago position according to the table (youshould be able to hear the motor).

Actuator Cable Adjustment

Check that the actuator cable operares smoothtvwithout binding or sticking.

Start the engine and warm it up to normaloperatingtemperature (radiator fans come on twicel,

Measure how far the output linkage moves from thefully closed position. Free play should be 1 1 1 1.5mm (O.43 I 0.06 in).

4.

FREE PLAY:1 1 I 1.5 mm (0.43 r 0.06 int

FULLY CLOSED POSITION

4. lf the free play is not within specs, loosen the lock-nut and turn the adjusting nut as required.

NOTE: lf necessary, check the throttle controlsys-tem {see section 1 I }, then recheck the output link-age free play.

5. Retighten the locknut and recheck the free play.

Battery

polaritiesOutput linkage

position

oFULLY

CLOSED

MIDDLE

POStTtON

FULLY

OPEN

Terminal

B

Terminal

The

molor

runs.

The

molor

runs.

The

molor

srops.

I

TerminalTerminal

The

motor

stops.

The

motor

runs.

The

motor

runs.

FULLY CLOSED

,tilr

23-253

Page 1363 of 1413

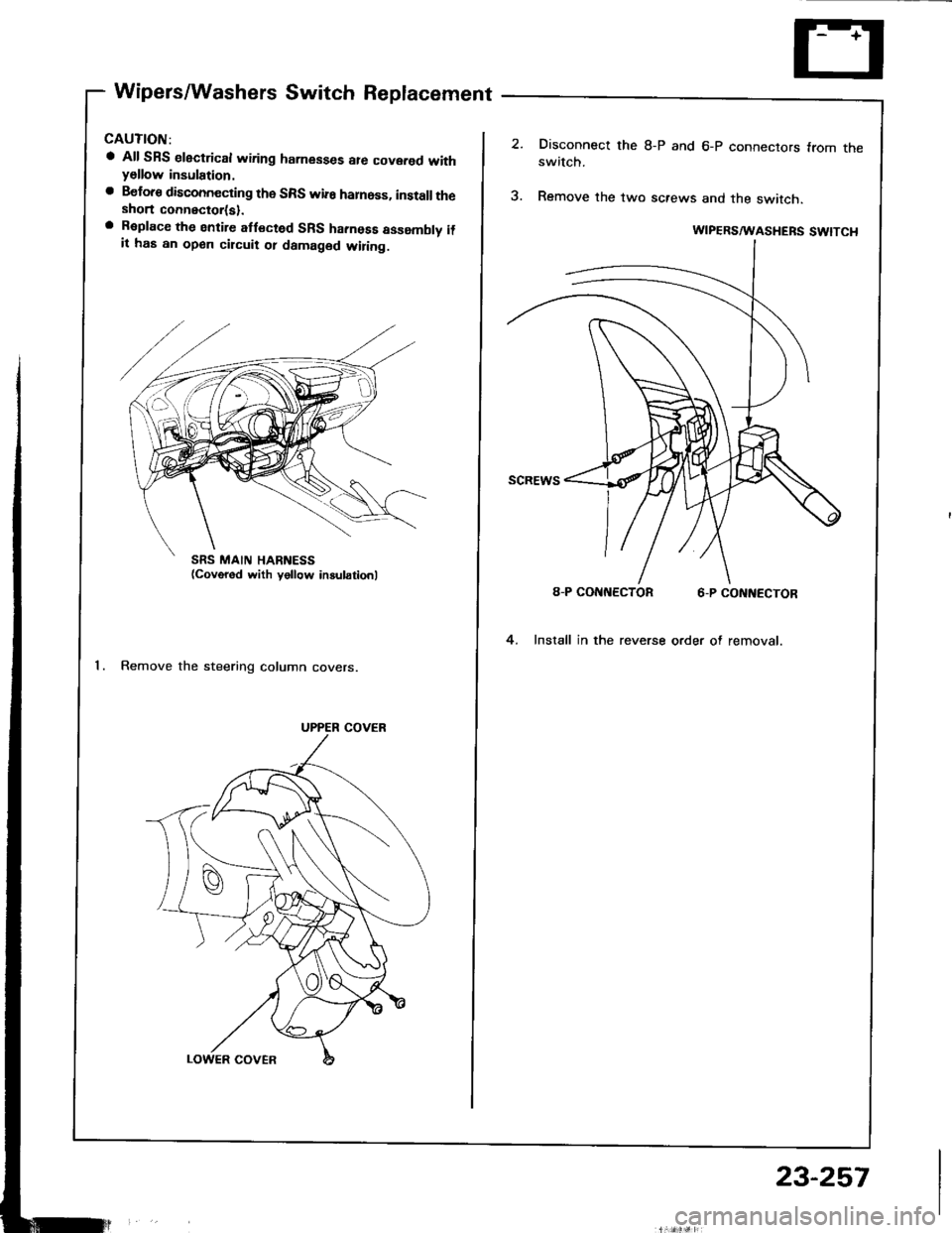

Wipers/Washers Switch Replacement

a All SRS electrical wiring harnesses ale covered withyellow insulation.

a Beloro disconnecting the SRS wif6 harnoss, install theshort connector(sl.a R€place the entire atlscted SRS hamess assombly ilit ha6 an open citcuii ot damaged wiring.

Remove the steering column covers.

UPPER COVER

A-P CONNECTOR

Disconnect the 8-P and 6-p connectors from theswitch.

Remove the two sctews and the switch.

wIPERS^IITASHEBS SWtTCl.t

A-P CONNECTOR 6-P CONNECTOR

4. Install in the reverse order of removal.

23-257

Page 1364 of 1413

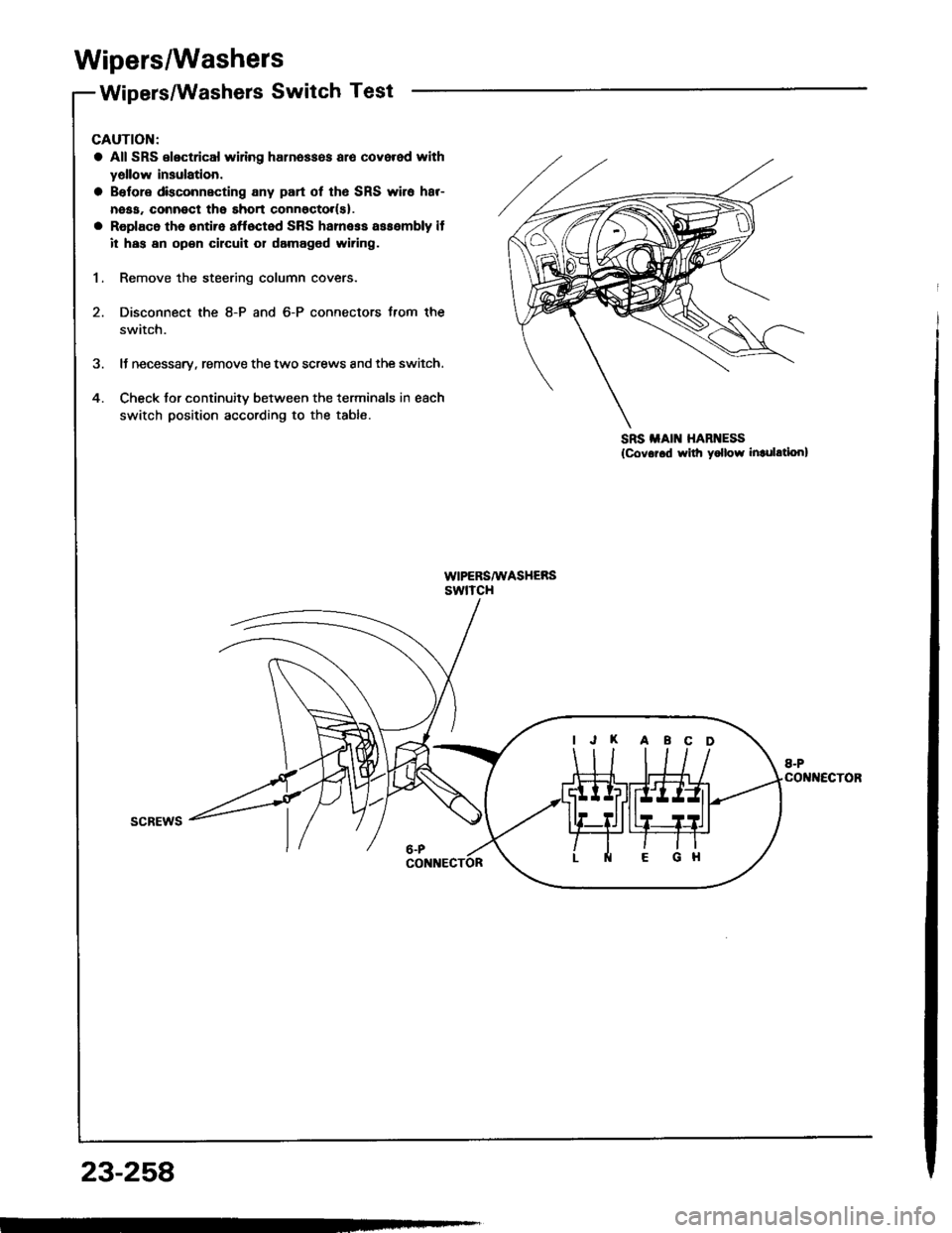

Wipers/Washers

Wipers/Washers Switch Test

5

4

CAUTION:

a All SRS electrical wiring harn6ss6s alo covered with

yellow insulation.

a Belore dkconnecting any part ot th6 SRS wire har-

neaa. connect the short connoctor(sl.

a Replac6 the 6ntire affoctod SRS harness assembly it

it has an open cilcuit 01 damaged wiring.

1. Remove the steering column covers.

2. Disconnect the 8-P and 6-P connectors Jrom the

swatch.

It necessary, remove the two screws and the switch.

Check for continuitv between the terminals in each

switch position according to the table.

scREws

SRS iIAIN HARNESS

{Covor.d rvilh yollow inrulation}

IJK ABCD

23-258

Page 1366 of 1413

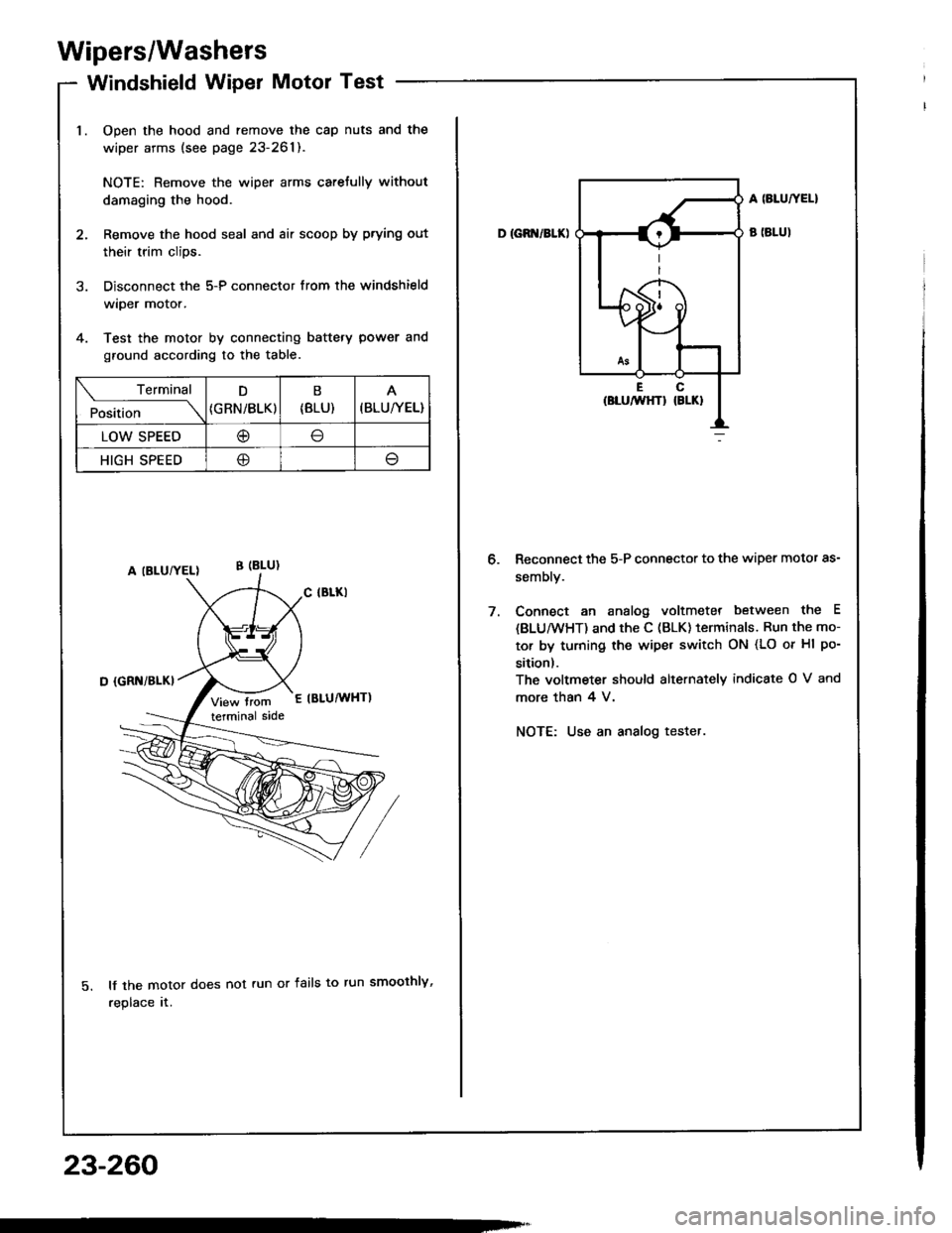

Wipers/Washers

Windshield Wiper Motor Test

Open the hood and remove the cap nuts and the

wiper arms (see page 23-261).

NOTE: Remove the wiper arms carefully without

damaging the hood.

Remove the hood seal and air scoop by prying out

their trim clips.

Disconnect the 5-P connector from the windshield

wiper motor.

Test the motor by connecting battery power and

ground according to the table.

lf the motor does not run or fails to run smoothly,

replace rr.

Terminal

Pi"i,i""---\

D

{GRN/BLK)

B

{8LU)(BLU/YEL}

LOW SPEED@

HIGH SPEED@

23-260

D IGB /BLK)

A SLUTYEL}

B (BLUI

Reconnect the 5-P connector to the wiper motor as-

sembly.

Connect an analog voltmeter between the E

{BLU/wHT) and the C (BLK) terminals. Run the mo-

tor by turning the wipet switch ON (LO or Hl po-

sition).

The voltmeter should alternately indicate O V and

more than 4 V.

NOTE: Use an analog tester.

Page 1367 of 1413

Windshield Wiper Motor Replacement

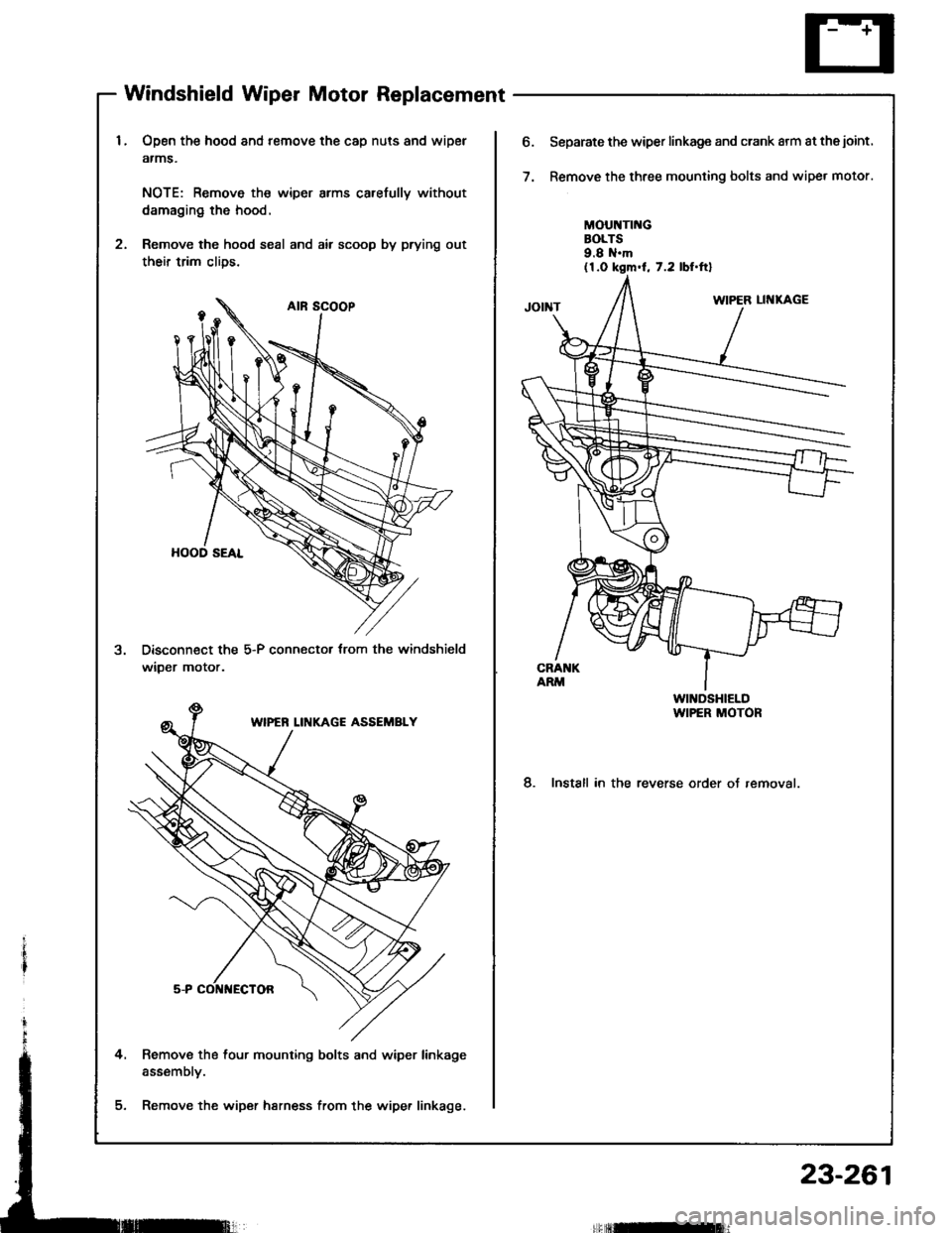

Open the hood and remove the cap nuts and wipel

atms.

NOTE: Remove th€ wiper arms carefully without

damaging the hood.

Remove the hood seal and air scoop by prying out

their trim clios.

Disconnect the 5-P connector trom the windshield

wiDer motor.

Remove the four mounting bolts and wiper linkage

assembly.

Remove the wiper harn€ss from the wipe. linkage.

o.Separate the wiper linkage and crank arm at thejoint.

Remove the three mounting bolts and wipet motor.

MOUNTII{GBOLTS9.8 N.m(1.0 kgm.l, 7.2 lbI.ftl

8. Install in the reverse order of removal.

Irflnfi]

23-261

Page 1368 of 1413

Wipers/Washers

Rear Window Wiper Motor Test-Keal wlnqow wlper |Yloror I esr

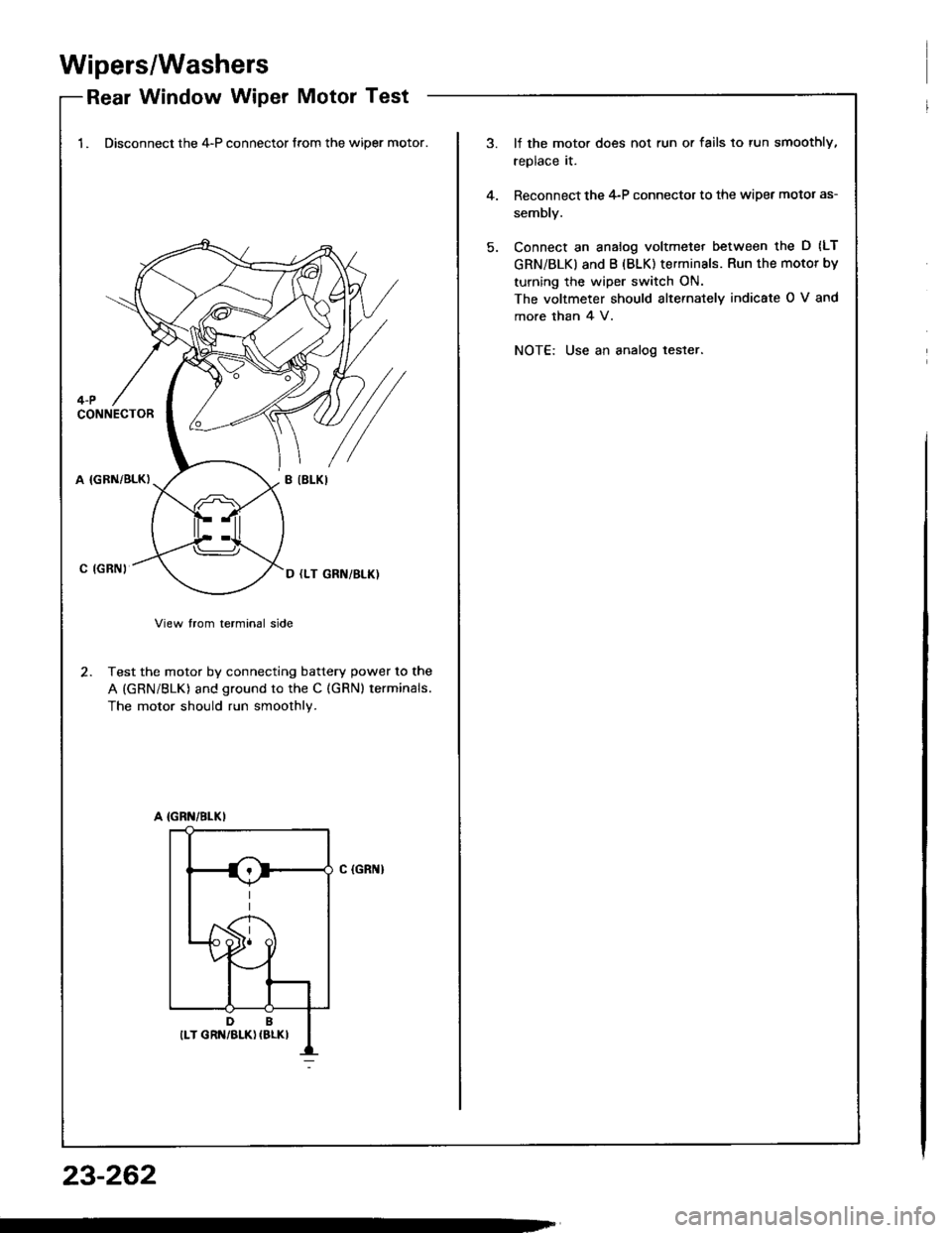

1. Disconnect the 4-P connector from the wiper motor.lf the moto. does not run or fails to tun smoothly,

replace it.

Reconnect the 4-P connector to the wipet motor as-

sembly.

Connect an analog voltmeter between the D (LT

GRN/BLKI and B (BLK) terminals. Run the motor by

turning the wiper switch ON.

The voltmeter should slternately indicate O V and

more than 4 V.

NOT€: Use an analog tester.

4.

4-PCONNECTOR

A (GBN/BLK)

C IGRNI

View trom terminal side

2. Test the motor by connecting battery power to the

A (GRN/BLK) and ground to the C (GRN) terminals.

The motor should run smoothly.

C (GRI{}

23-262