Page 98 HONDA INTEGRA 1994 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 1051 of 1413

Troubleshooting

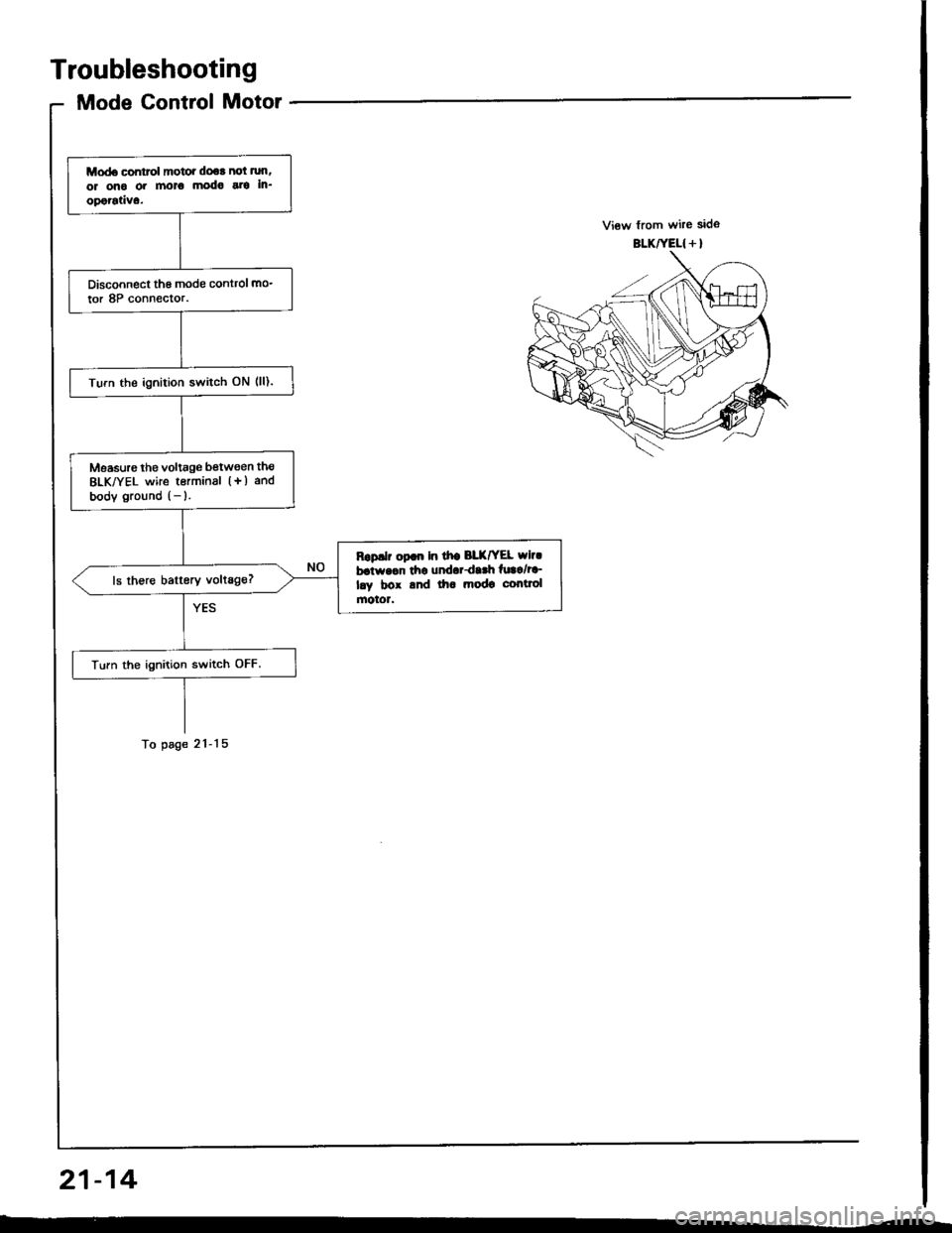

Mode Control Motor

21-14

Modo control motor dooa not nm,

or ono oa moto modo arc In_

oporgtivo.

Disconnect th6 mode control mo_

tor 8P connector.

Turn the ignition switch ON (ll).

Measuroth€ voltage b€tween tho

BLK/YEL wire terminal (+) and

bodv ground (- ).

R.p.lr op.n In lho BLrrYEL wl..

bctw.rn lha undard!.h fuaa/ru-

l.y box .nd ih. mod! corttol

motor.

Turn the ignition switch OFF.

To page 21-1 5

Page 1052 of 1413

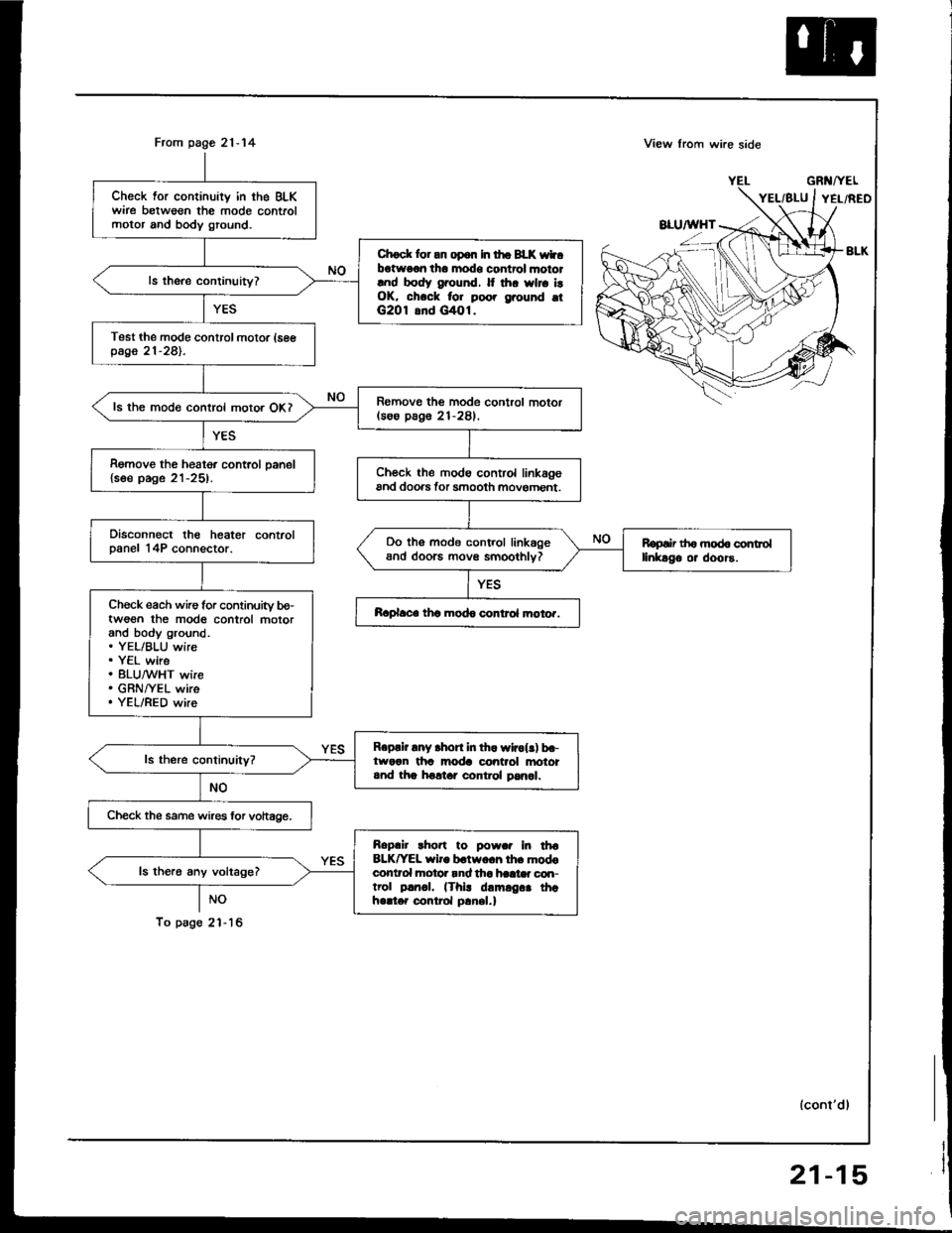

From page 21-14

NO

To psg6 2'l - 16

Check for continuity in the BLKwire betweon the mode controlmotor and body ground.

Chock lor an op6n In tho BLK wtbotwo€n tho modo control mototlnd body ground. It thr wlro i!OK, chock for poo. grouhd otG2O1 8nd G/tOl.

Test the modo control motor (seepage 21-281.

Romovo the mode control motor(soo pag6 21-281.ls the mode control motor OKI

Remove the heater control oanel{soe page 21-25).Ch€ck the modo control linkagoand doo.s tor smooth movoment.

Disconnect the heater controlDanel 14P connector.Do tho mode control linkageand doorc movs smoothlv?Ropair th6 mod6 controllinkago or doors.

Ch€ck each wire for continuity bo-twoon the mod6 control motorand body ground.. YEL/BLU wire. Y€L wire. 8LU,^/VHT wire. GRNI/EL wire. YEL/RED wire

Raplace thc modo control moto..

Roprir any .hort in th. wlrol!) b.-tworn tha moda control anototand tha holtar control pan6l.

Check the same wires lor vohage.

Roplir rho.t to powar In tha8LK^'EL wiro b.two.h lh. modoconlrol hotor rnd tha haat* con-trol p!rr.|. (Thi! damrg.. thahello. control p!nel.)

ls the.6 any voltage?

View lrom wi.e side

GRl{/YEL

lconl'dl

21-15

Page 1053 of 1413

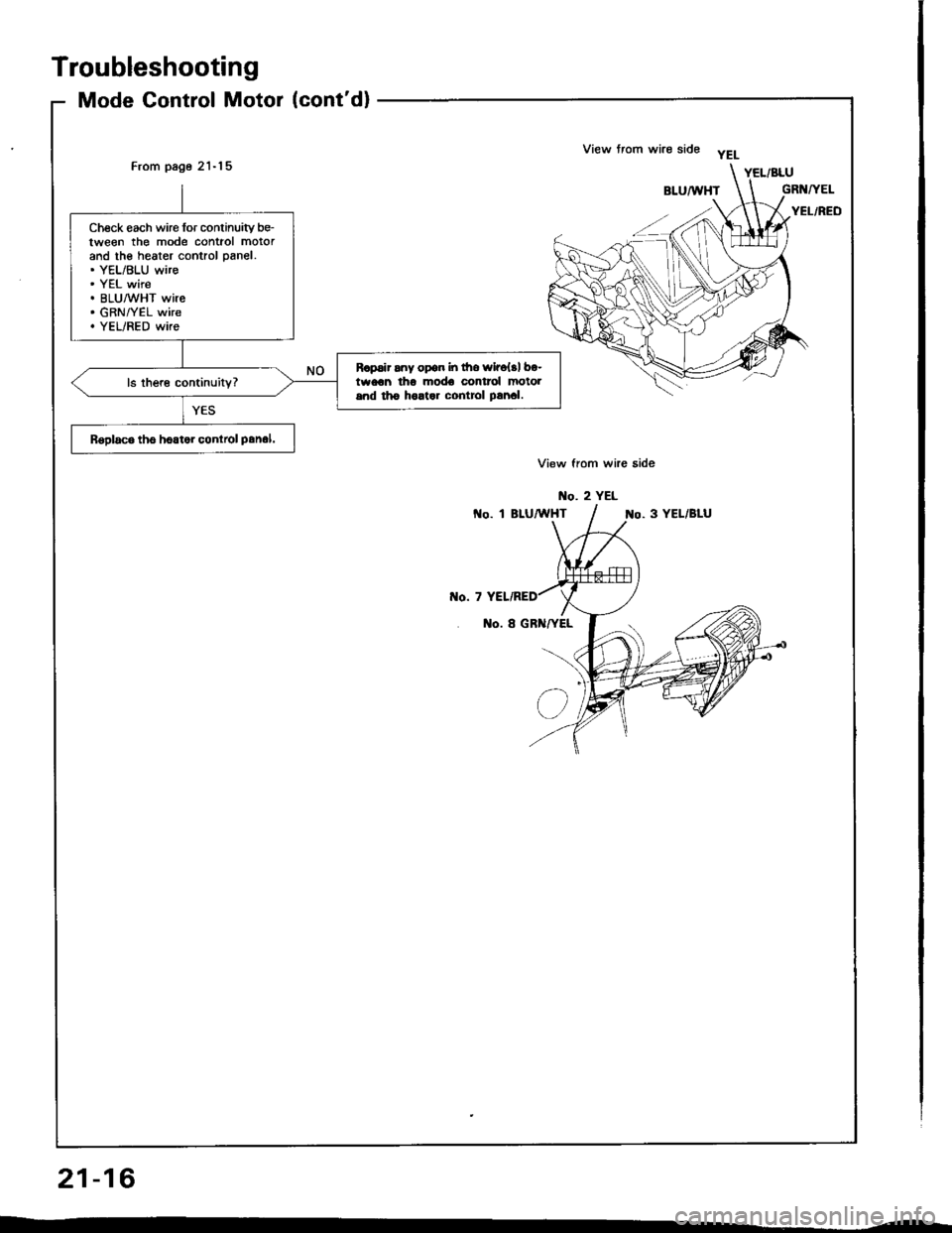

View from wire side yELFrom page 21-'l 5

Check each wire for conlinuity be-tween the mode contiol motorand the heater control panel.. YEL/BLU wire. YEL wire. BLU/WHT wire. GRN/YEL wire. YEL/RED wire

R.psir any opon in fro wir6{.1 bo-twocn tho mod€ control motolsnd tho holtar contiol prnal.

Rsploco tho hoator conlrcl panol.

Troubleshooting

Mode Control Motor (cont'd)

21-16

Page 1054 of 1413

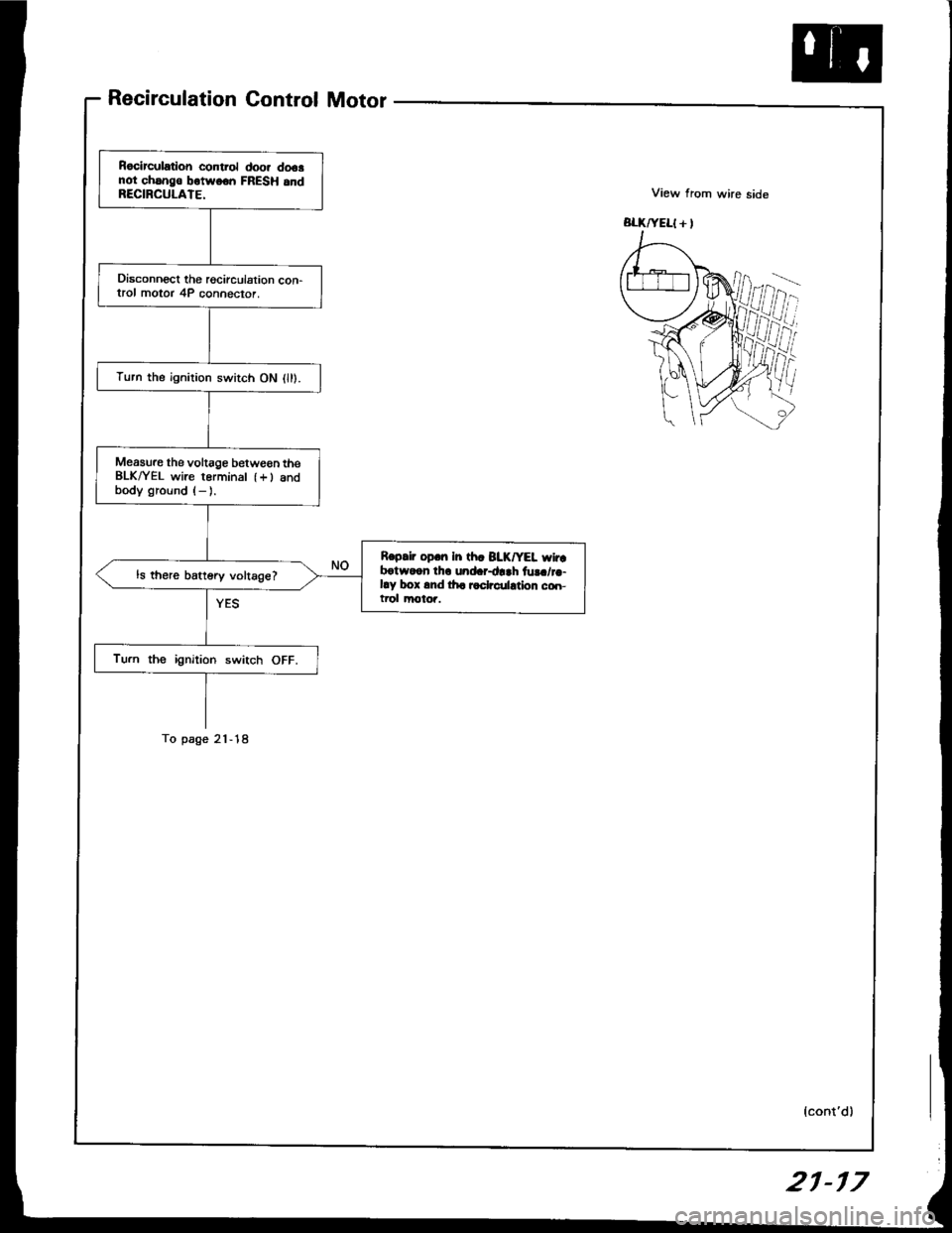

Recirculation Control Motor

ffi

Rocirculation control doo. dooanot chsng€ botwoon FRESH 6ndRECIRCULATE.

Disconnect the rgcirculation con-trol motor 4P connector.

Turn the ignilion switch ON l).

Measure the voltage between theBLK^/EL wire rerminal {+) andbody ground (- ).

Reprir op.n In th. BIK/YEL wir.botwoon thr und.r+rh fu!./r.-by box 6nd lha radrculdion co.r-trol motoi.

ls there battery voltage?

Turn the ignition switch OFF.

To page 21-18

{cont'd)

21-r 7

Page 1055 of 1413

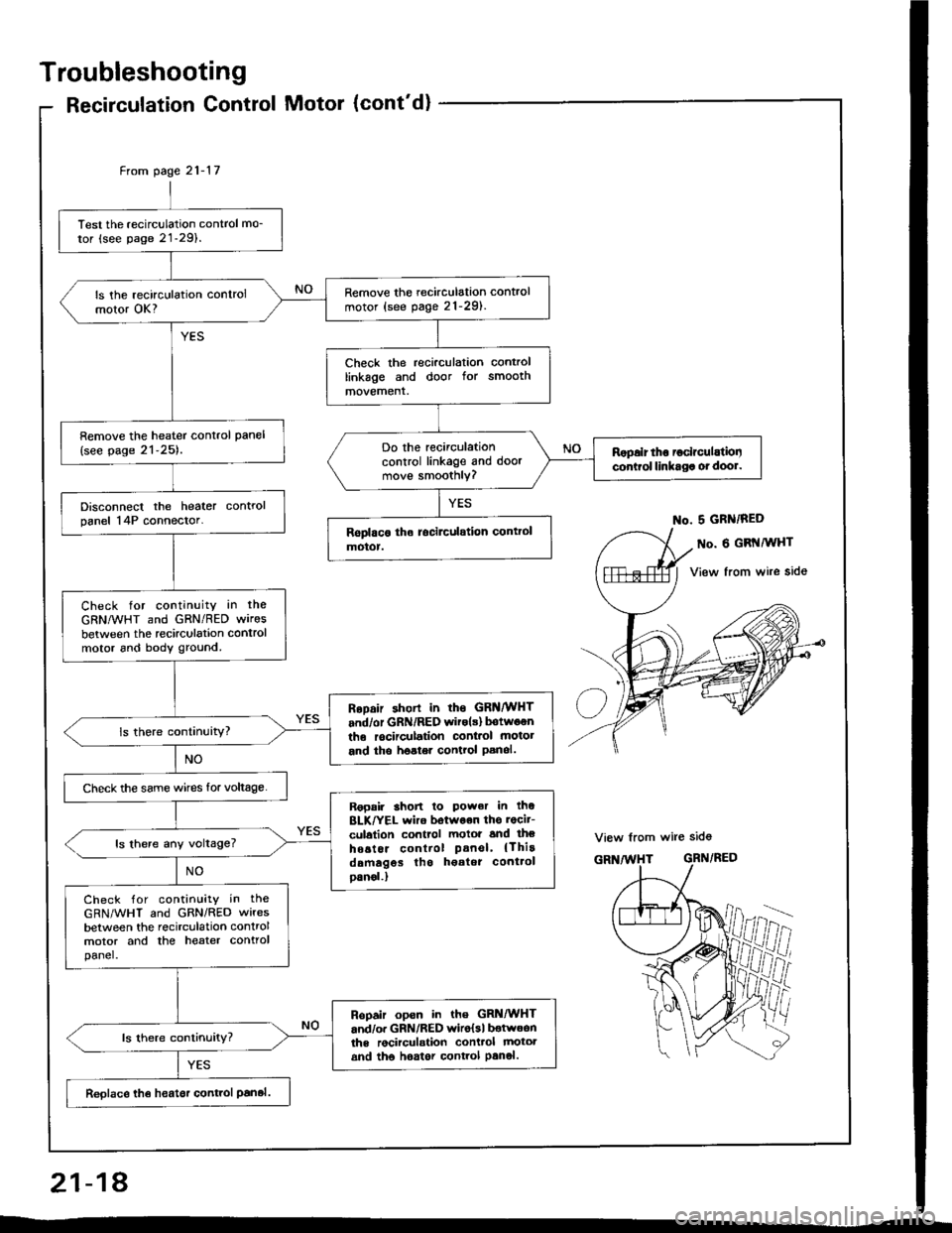

Troubleshooting

Recirculation Control Motor (cont'd)

Test the recirculation control mo_

tor (see page 21-29).

Remove the recirculation control

motor (see pag. 21-291.ls the recirculation controlmotor OK?

Check the recirculation controllinkage and door for smoothmovement.

Remove the heater control pan€l

{see page 21-25).Do the recirculationcontrol linkage and doormove smoothly?

Ropalr tho ioclrculatiooconirol linkaga ot dool.

Disconnect the heater controlpanel 14P connector.

Check for continuity in the

GRNMHT and GRN/RED wires

between the recirculation controlmotor 6nd body ground.

RoDair shorl in rhs GRNMHT

and/or GRN/RED witols) botwoenthe rocirculation conl.ol motot

and tho hoster control Panol.

Check the same wircs for voltage.

Ropair 3hon lo Power in thoBLK/YEL wiro botwoon ths rocit-

culalion control motoi and lheho6tor control Panel' {Thirddmagos tho h€atot cont.ol

oanol.)

ls there any voltage?

Check for contin!ity in the

GRN/WHT and GRN/RED wires

between the recirculation controlmotor and the heater controlpanel.

Ropair opsn in the GRi|/WHTand/o. GRN/RED wiro{sl botwoonths rocirculstion conttol mototand tho hoator control Panol.

Reolace th€ heatsr control Panal.

From page 21- l7

No. 5 GRN/RED

o. 6 GRI{MHT

View from wire side

View from wire sid6

GRN/RED

ffii

21-18

Page 1057 of 1413

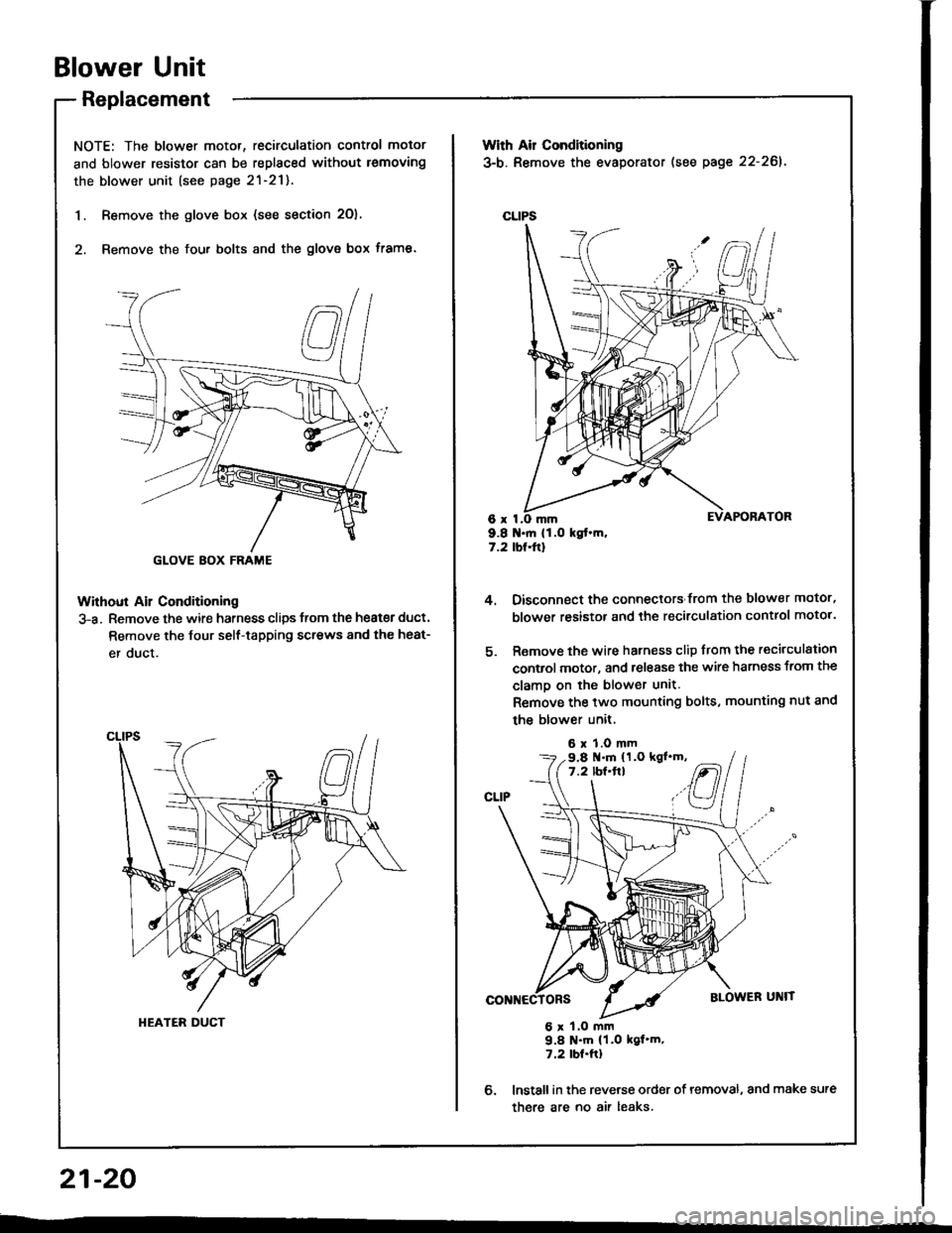

Blower Unit

Replacement

NOTE: The blower motor, recirculation control motor

and blower resistor can be replaced without lemoving

the blower unit (see page 2l-21).

1. Remove the glove box (see section 2O),

2. Remove the fou. bolts and the glove box frame.

Without Ail Conditioning

3-a. Remove the wire harness clips trom the heat€r duct.

Remove the Jour self-tapping screws 8nd the heat-

er duct.

GLOVE BOX FRAME

HEATER DUCT

With Air Conditioning

3-b. Remove the evaporator (see page 22-261.

CLIPS

6x I9.8 .ft 11.O kgt.m,7.2 tbt.ftl

4.

6.

Oisconnect the connectors from the blower motor,

blower resistor and the recirculation control motor.

Remove the wire harness clip from the recirculation

control motor, and release the wire harness from the

clamo on the blower unit.

Remove the two mounting bolts, mounting nut and

the blower unit,

6 x 1.0 mm

6 x 1.O mm9.8 N'm (1.0 kgf'm.7.2 tbt.ftl

lnstall in the reverse order of removal, and make sure

there are no air leaks.

9.8 .m (1.O kgl'm,7.2 lbf'ft}

21-20

--

Page 1060 of 1413

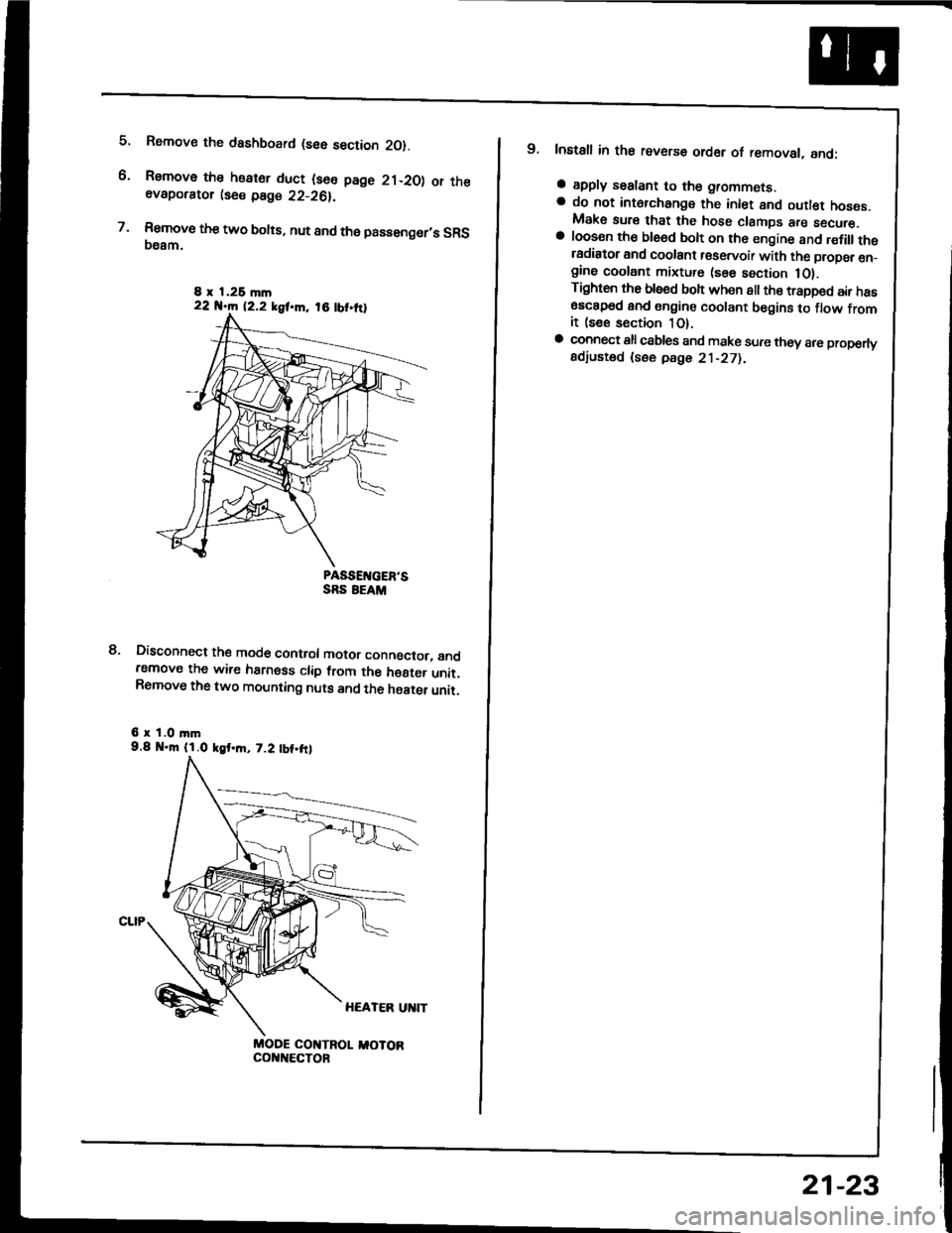

5.

6.

7.

Rsmove the dashboard (see section 2O).

Remove the heater duct (see page 21-20) or theevaporator lse€ page 22-26).

Rsmove the two bolts, nut and the passenger,s SRS(}eam.

PASSEIVGER'SSRS EEAM

Disconnect the mode control motor conngctor, andremove the wire harness clip from the h€8ter unit.Remove the two mounting nuts and the haater unit.

6 r 1.0 mm9.8 .m (l.O kgt.m, 7.2 tbt.frl

MODE COI{TROL I,IOTORcol{t{€cToF

8.

8 x 1,26 mln22 N.m 12.2 kgf.m, 18 tbt.ttl

9. Install in the reverse order of removal, and:

a apply sealant to the grommets.a do not int6rchange the inlet and outl€t hoses.Make sure that the hose clamps are secure.a loosen th€ ble6d bolt on th6 engine and r€fillthetadiator and coolant r€servoir with the propsr en_gine coolant mixture (sse section 1O).Tighten the blsed boh when all the trapped air has6sc8p6d and engine coolant begins to flow fromit (see section 1O).a connect all csbles and make sure they 8re properlyadiusted (see pdge 21-271.

21-23

Page 1062 of 1413

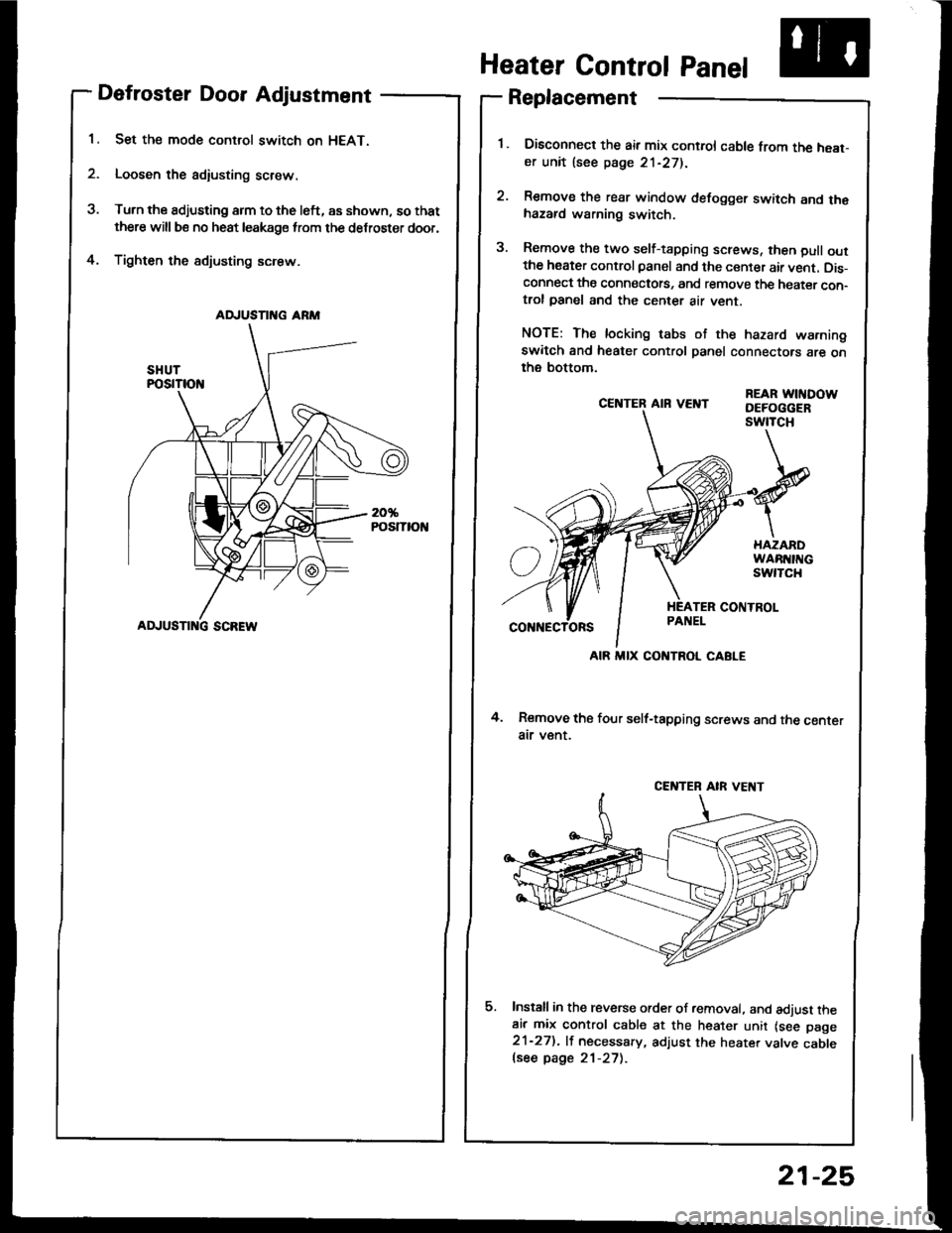

Defroster Door Adjustment

Set the mode control switch on HEAT.

Loosen the adiusting screw.

Turn the adjusting arm to the left, as shown, so that

there will be no heat leakage from the defroster door,

Tighten the sdjusting screw.4.

CE]TTER AIR VEI{T

4. Remove the four self-tapping screws and the centerair v€nt.

Install in the reverse order of removal. and adjust theair mix control cable at the heater unit lsee page21-27). lf necessary, adjust the heater valve cablelsee page 21-27).

REAR WITIDOWDEFOGGERswtTcH

Heater Control Panel

Replacement

Disconned the air mix control cable from the heat-er unit lsee page 21-271.

Remove the rear window defogger switch and thehazard warning switch.

Remove the two self-tapping screws, then pull outthe heater control panel and the center air vent. Dis-connect the connectots, and remove the heater con-trol panel and the center air vent.

NOTE: The locking tabs of the hazard warningswitch and heater control panel connectors are onthe bottom.

AD.'USTII{G ARM

ADJUSTI G SCREW

AIR MIX CONTROL CABLE

CENTEB AIR VE T

21-25

Page 1063 of 1413

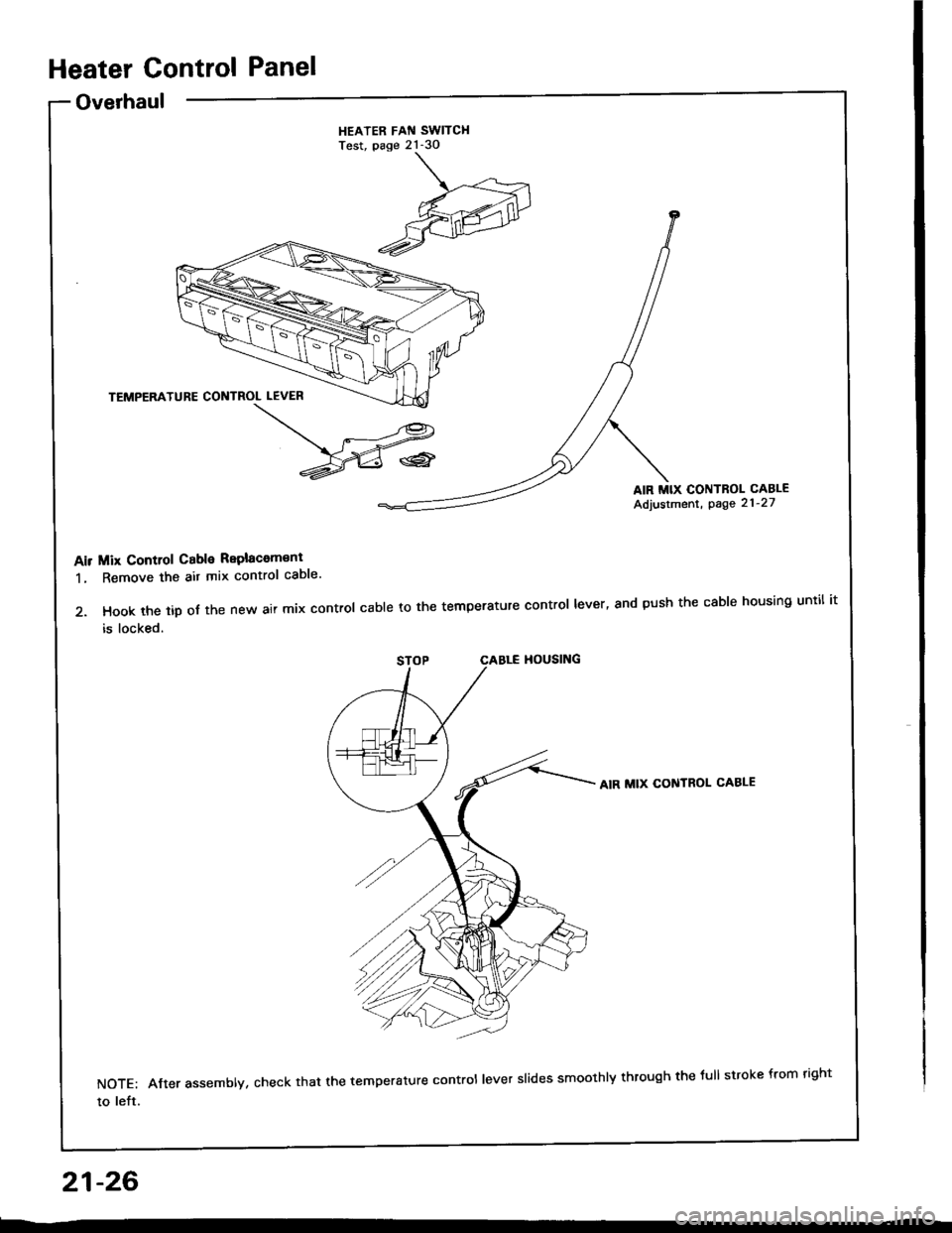

Heater Control Panel

Overhaul

HEATER FAN SWITCHTest, page 21-30

AIR MIX CONTROL CABLE

Adjustment, page 21-27

Air Mix Control Cable Replacom€ni

1. Remove the ait mix control caDle'

2. Hook the tip of the new air max control cable to the temperature control lever, and push the cable housing until it

is locked.

AIR MIX CO]IITROL CABLE

NoTE:Alterassemb|y,checkthatthetemperaturecontro||eve's|idessmooth|ythroughthe'u||strokefromright

to left.

21-26

Page 1071 of 1413

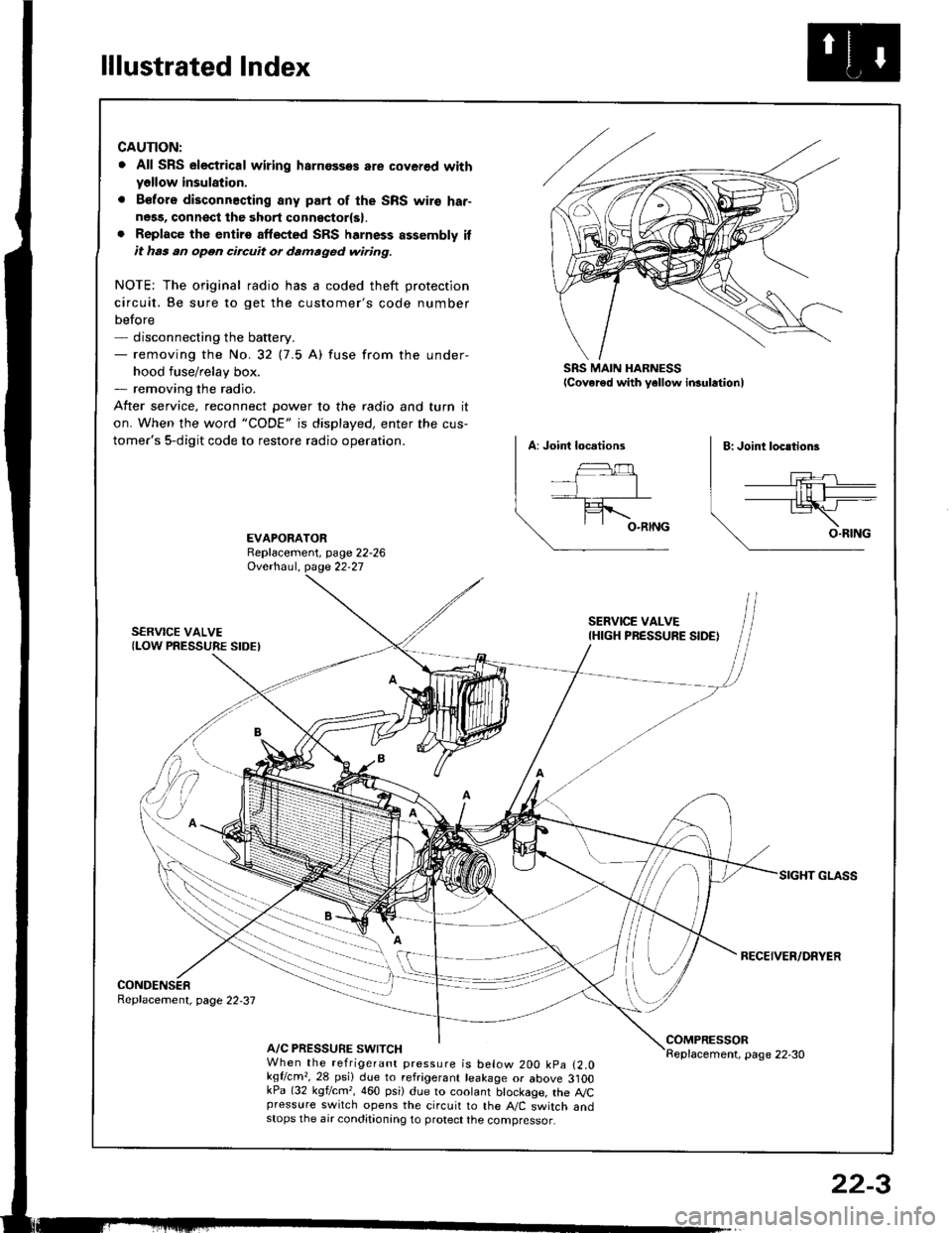

lllustrated Index

CAUTION:

. All SRS electrical wiring harnossos are cover€d withyellow insulation.

. B€fors disconnacting any part of the SRS wire har-ness, connsct the 3hort connsctor(s).. Replace the entirs affscted SRS harness assembly itit has an open circuit or damaged wiring.

NOTE; The original radio has a coded theft protection

circuit. Be sure to get the customer's code number

before- disconnecting the battery.- removing the No.32 (7.5 A) fuse from the under-

hood fuse/relay box.- removing the radio.

After service, reconnect Dower to the radio and turn it

on. When the word "CODE" is displayed, enter the cus-

tomer's 5-digit code to restore radio operation.

SRS MAIN HARNESSlcover€d with yellow insulationl

EVAPORATORReplacement, page 22-26Ovethaul. Oase 22.27

SERVICE VALVE(LOW PRESSURE SIDEI

SERVICE VALVEIHIGH PRESSURE SIDE)

RECEIVER/DRYER

CONDENSERReplacement, page 22,37

A/C PRESSURE SWITCHCOMPRESSORReplacement, page 22-30When the refrigerant pressure is below 200 kpa (2.0kqflcm,,28 psi) due to refrigerant leakage or above 3]OOkPa (32 kgf/cm,, 460 psi) due to coolant btockage, the A,/Cpressure switch opens the circuit to the A"/C switch andstops the air conditionang to protect the compressor.

22-3