cks HONDA INTEGRA 1994 4.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 323 of 1413

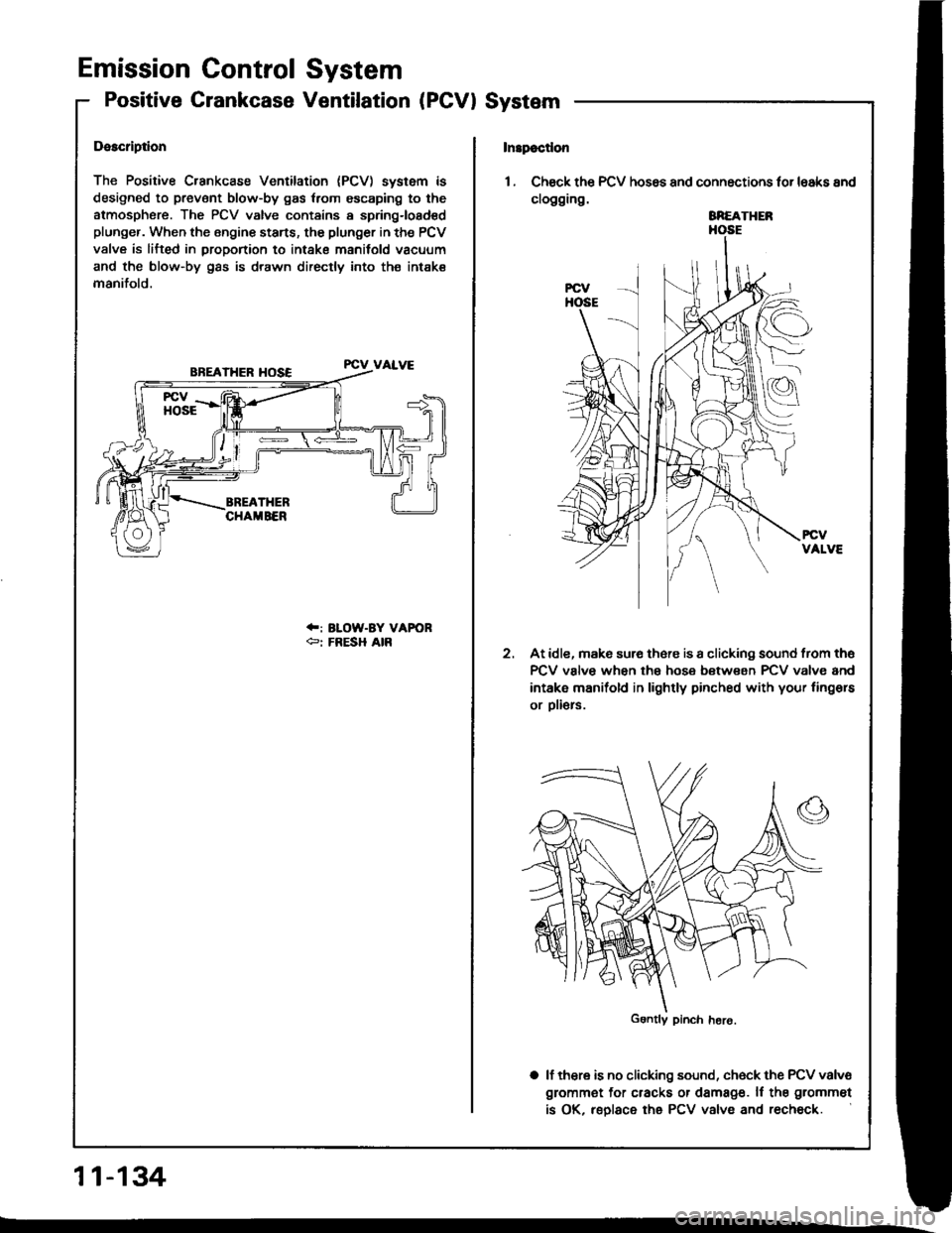

Emission Control System

Positive Crankcase Ventilation (PCVI System

Description

The Positive Crankcase Ventilation (PCV) system is

designed to prevent blow-by gas {rom escaping to the

atmosphsre. The PCV valve contains a spring-loadsd

plunger. When the Bngine starts, the plunger in the PCV

valve is lifted in proportion to intake manifold vacuum

and the blow-by gas is drawn directly into th€ intak€

manifold.

FCV VALVE

.F: ILOW-BY VAFORer FRESH AIR

11-134

Insp€cdon

1. Check th€ PCV hos6s and connections tor lsaks and

clogging.

At idle, mak6 sur€ th6fe is a clicking sound from th6

PCV valve when the hose between rcV valve and

intake manifold in lightly pinched with your fingors

or oli€rs.

a lf thera is no clicking sound, ch6ck the PCV valve

grommet for cracks or damage. ll the grommet

is OK, reolace the PCV valve and recheck.

2.

SREATHER

Gontly pinch hero.

Page 334 of 1413

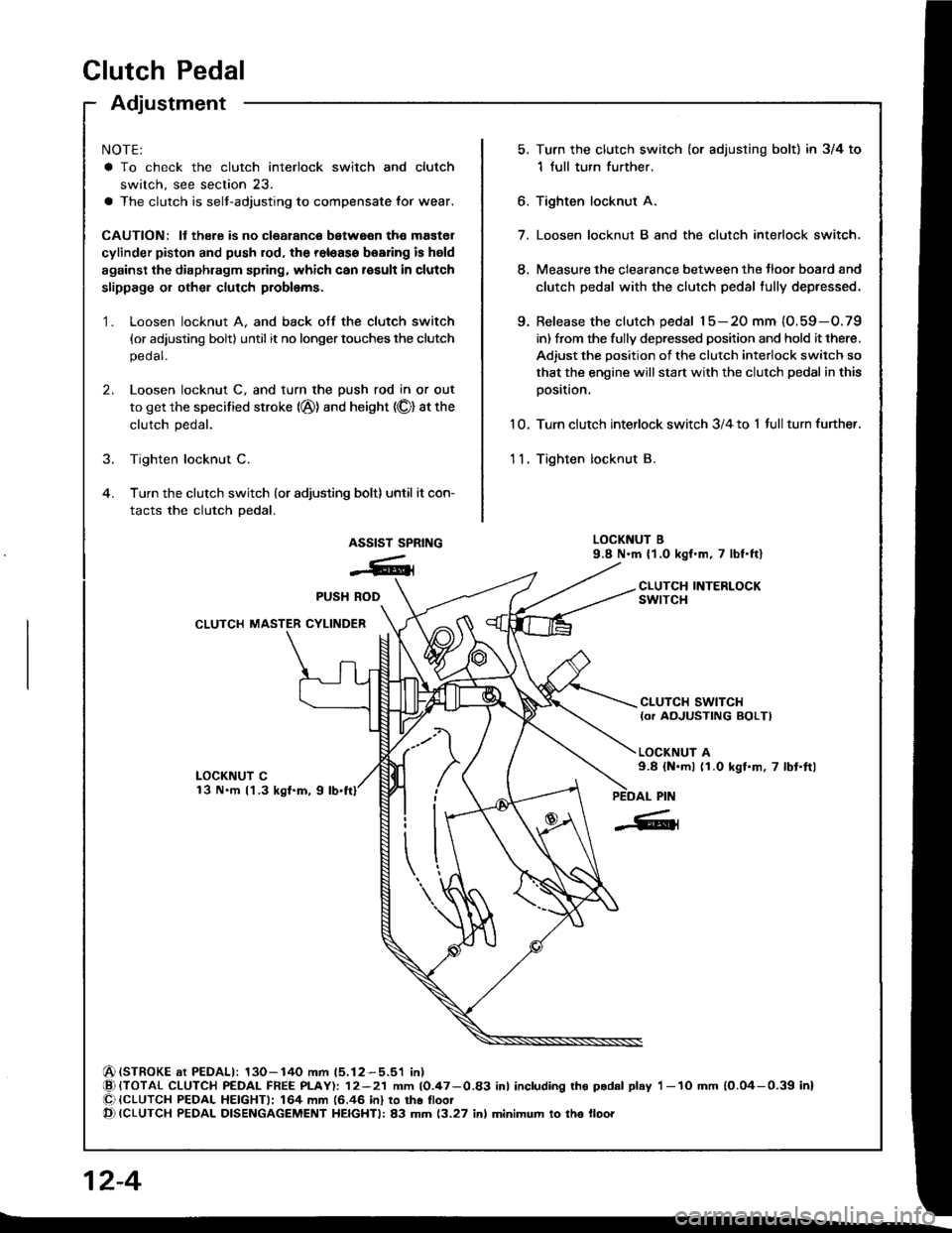

Adjustment

NOTE:

a To check the clutch interlock switch and clutch

switch, see seclion 23.

a The clutch is selt-adjusting to compensate for wear.

CAUTION: It there is no clearanco between the mastel

cylinder piston and push lod. the releaso boaring is held

againsl the diaphragm spring, which can result in clutch

slippage 01 othel clutch problems.

Loosen locknut A, and back otf the clutch switch

{or adjusting bolt) until it no longer touches the clutch

pedal.

Loosen locknut C, and turn the push rod in or out

to get the specified stroke (@) and height (O) at the

clutch pedal.

Tighten locknut C.

Turn the clutch switch (or adjusting bolt) until it con-

tacts the clutch pedal.

Turn the clutch switch (or adjusting bolt) in 3/4 to

1 full turn further.

Tighten locknur A.

7. Loosen locknut B and the clutch interlock switch.

8. Measure the clearance between the tloor board and

clutch pedal with the clutch pedal tully depressed.

9. Release the clutch pedal 15-20 mm {O.59-O.79

in) from the fully depressed position and hold it there.

Adiust the position of the clutch interlock switch so

that the engine will start with the clutch pedal in this

oosition.

1 0. Turn clutch interlock switch 3/4 to 1 tull turn funher.

11. Tighten locknut B.

LOCKNUT B9.8 N.m (1.0 kgf.m, 7 lbf.ftl

CLUTCH INTERLOCKswtrcH

6.

1.

2.

ASSIST SPRING

-6ll

LOCKNUT Cl3 N.m l'l.3 kgf.m, 9

CLUTCH SWITCH{or AOJUSTING BOLTI

LOCKNUT A9.8 {N.ml (1.0 kgl.m, 7 lbt.ftl

(STROKE at PEDALI: 130-140 mm 15.12-5.51 in){TOTAL CLUTCH PEDAL FREE PLAY): 12-21 mm 10.47-0.83 inl including tho p.dal play I -lO mm 10.04-0.39 inl{CLUTCH PEDAL HEIGHTI: 164 mm (6.46 in} to tho lloot{CLUTCH PEDAL DISENGAGEMENT HEIGHTI: 83 mm 13.27 inl minimum to tho lloo.

PUSH ROD

CLUTCH MASTER CYLINDER

Clutch Pedalctutch Pedat I

[-],ll'"-"" f

| :;i:'":fff*tr#:?iff:".,*::,::". | .#::J:::

sb''�'�'""

| |

| "orr,O", It there is no clearanco between the master | ,. aoo""n locknut B and the clutch intertoct switcl. | |cylinder piston and push lod. the releaso boaring is held | | Iagainst the diaphragm spring, which can result in clutch | 8. Measure tne clearance between the floor board and I Islippage 01 othel clutch problems.

I

clutch pedal with the clutch pedal tully deeressed.

I I1. Loosen locknut A, and back otf the clutch switch | 9. Release the clutch pedal 15-2O mm (O.59-O.79 I I

{or adiusting boltl until it no longer touches the clutch I int trom ttre fully depressed position and hold it there. I I

, ::":"" rocknut c, and rurn the push rod in or out | iliiiliffi:l1l:J"'1"-:H"l:tJ:i"i#fT: I I

. il*:*j':"'-(@)andheisht(olatthe

|

,:.;:,nterrockswitch3/4torrurrturnturtner.

I tf

,

::

***r**''

.,".,u"**;

|

'-"'"'';*1,,0*.,.-,.,*,

I I

Page 337 of 1413

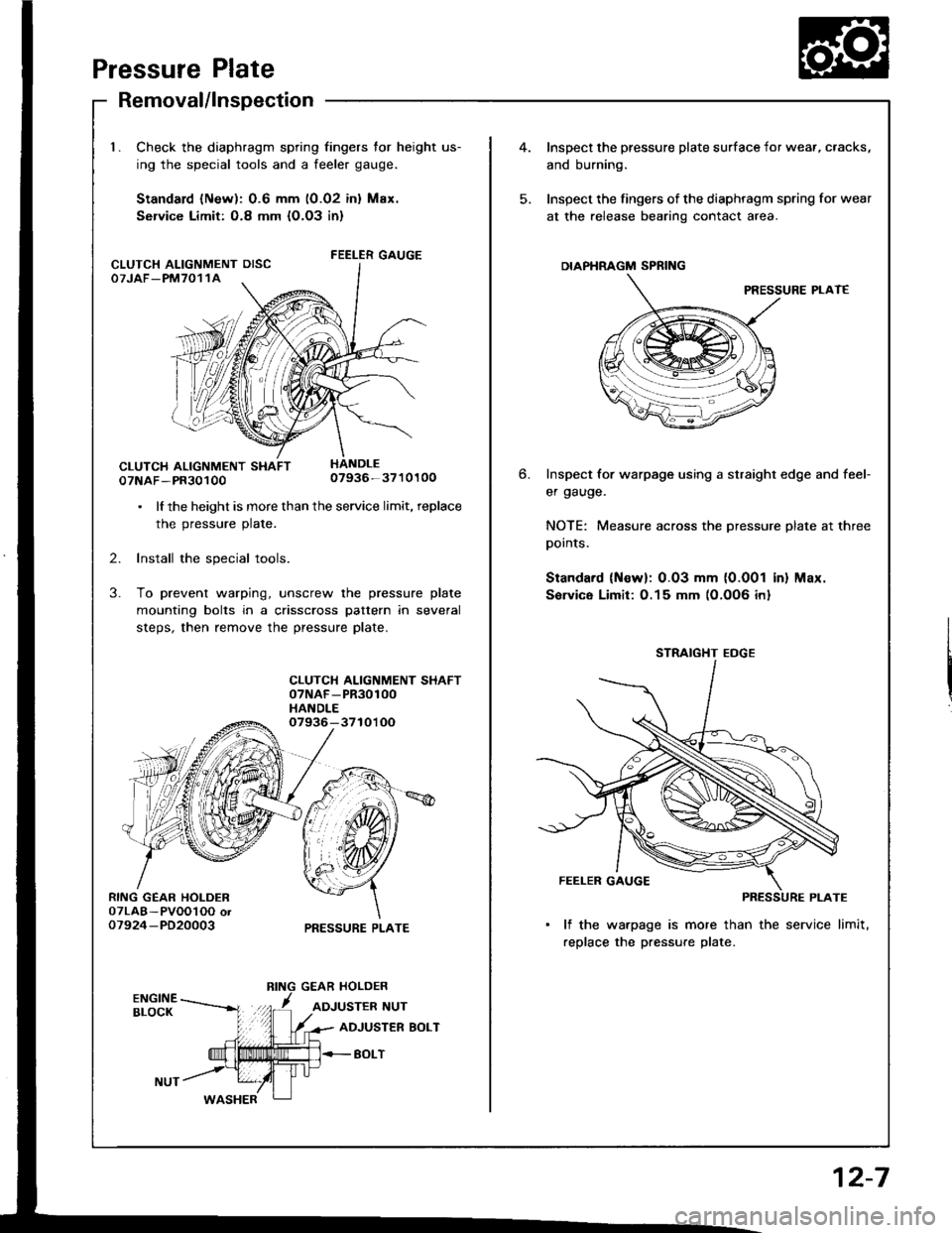

Pressure Plate

RING GEAR HOLDER07LAB-PVOOl OO or07924-PD20003

Removal/lnspection

Check the diaphragm spring fingers for height us-

ing the special tools and a feeler gauge.

Standard lNew): 0.6 mm (0.02 inl Max.

Service Limit: O.8 mm {O.O3 in}

FEELER GAUGE

07NAF-PR3010007936-3710100

. lf the height is more than the service limit, replace

the pressure plate.

2. Install the special tools.

3. To prevent warping, unscrew the pressure plate

mounting bolts in a crisscross pattern in several

steps, then remove the pressure plate.

CLUTCH ALIGNMENT SHAFT07NAF-PR30100HANDLE07936-3710'l OO

PRESSURE PLATE

CLUTCH ALIGNMENT OISCOTJAF_PM7011A

4.Inspect the pressure plate surface

and burning.

Inspect the fingers of the diaphrag

at the release bearing contact ar

DIAPHRAGM SPRING

Inspect for warpage using a stru

er gauge.

NOTE: Measure across the prer

pornls.

Standard (Newl: 0.03 mm (0.0

Sorvice Limit:0.15 mm (0.0O6

STRAIGHT EOGE

FEELER GAUGE

PI

lf the warpage is more than

replace the pressure plate.

6.

I surface for wear, cracks,

diaphragm spring for wear

nracr area.

PRESSURE PLAT€

straight edge and feef

pressure plate at three

0.001 in) Max.

)O6 inl

12-7

Page 339 of 1413

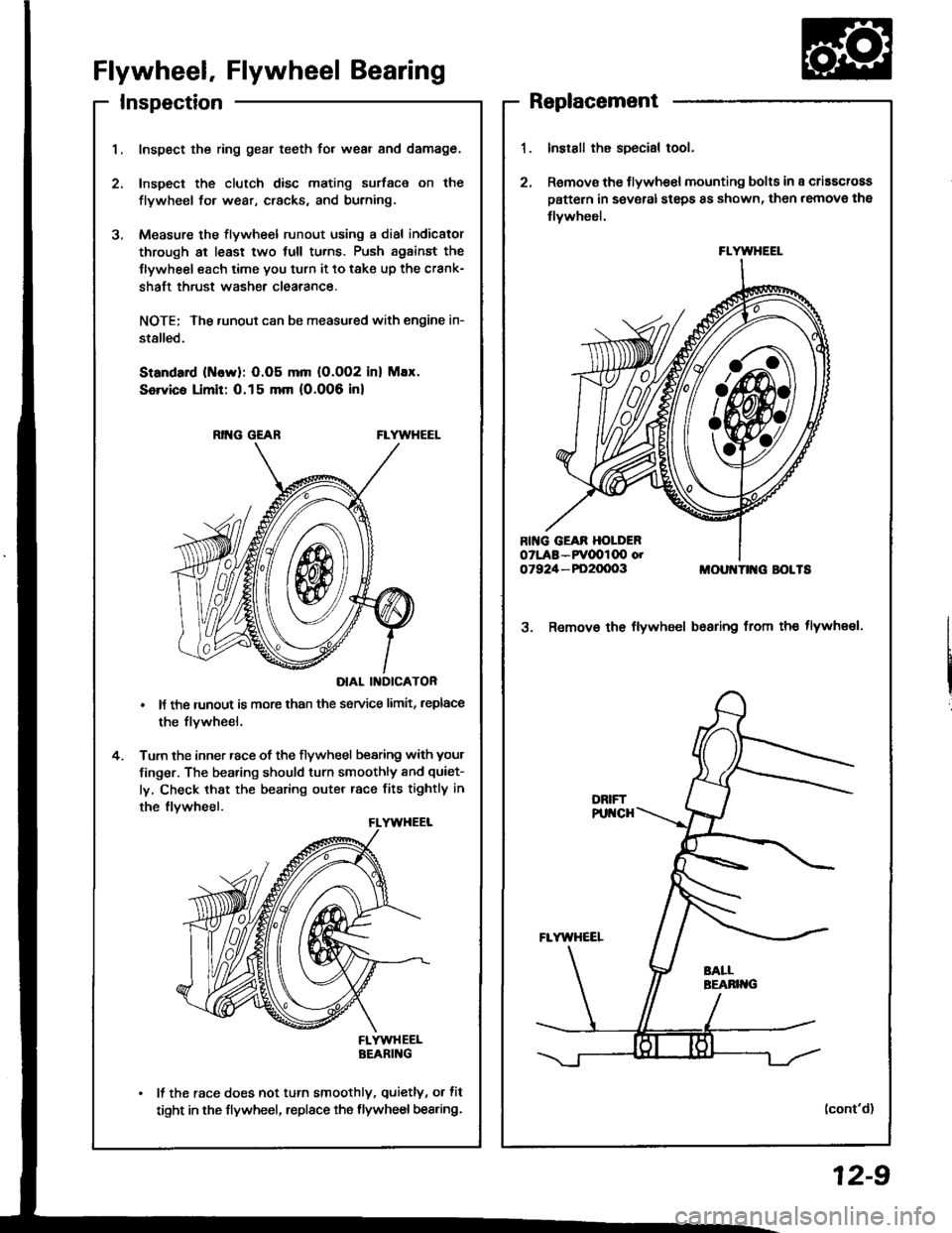

InspectionReplacement

Flywheel, Flywheel Bearing

Inspect the ring gear teeth for wear and damage.

Inspect the clutch disc mating surface on the

flywheel fo. wear, cracks, and burning.

Measure the flywheel runout using a dial indicator

through at least two full tu.ns. Push against the

Ilywheel each time you turn it to take up the crank-

shaft thrust washe. clearance.

NOTE; The runout can be measu.ed with engine in-

stalled.

Standard (ttlervl: O.O5 mm (O.002 inl Max.

Service Limit: 0.15 mm 10.006 inl

RING GEABFLYWHEEL

DIAL II{DICATOR

It the runout is more than the service limit, leplace

the flvwheel.

Turn the inner race of the flywheel bearing with your

finger. The bearing should turn smoothly and quiet-

ly, Check that the bearing outer race fits tightly in

the flvwheel.

FLYWHEELBEARING

It the race does not turn smoothly, quietly, or fit

tight in the flywheel, replace the flywheel bearing.

Install the special tool.

Remov€ the flywhe€l mounting bolts in a criascross

pattern in several steps 8s shown, then remove the

tlywheel.

MOUI{TII{G BOLTS

3. Remov€ the flywheel bsaring from th€ tlywheel.

(cont'd)

FLYWHEEL

12-9

Page 351 of 1413

12 N.m (1.2 kgim,9 lbnft)

15 N.m (1.5 kgnm, 11 lbf.ft)

15 N.m (1.5 kgf.m, 11 lbf.ft)

24 N.m (2.4 kgf.m, 17 lbf'ft)

27 N.m (2.8 kgnm,20 lbnft)

30 N.m (3.1 kgf.m, 22 lbf'ft)

Bolt Size

,l

{

@@69

@

@@@@@@@@6Dq0

o€xv0@

@0!@@@@al

61@

B

c

D

E

F

6x1.0mm

6x1.0mm

I x 1.0 mm

8 x 1.25 mm

8 x 1.25 mm

8 x 1.0 mm

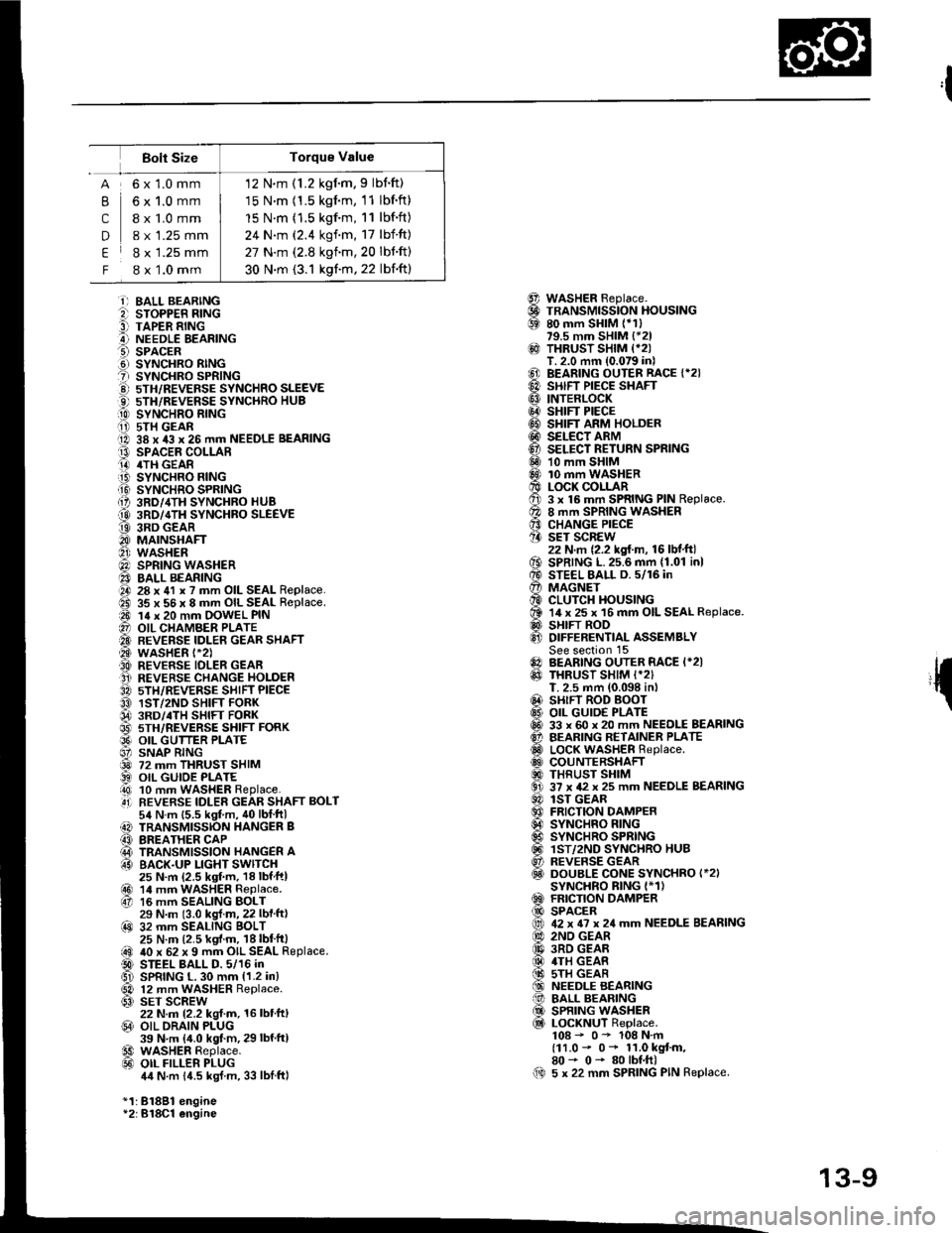

i) BALL BEARINGe sroPPER R|NG9 TAPER RINGA NEEDLE EEARINGO SPACER.d SYNCHRO RINGt sYNcHRo SPR|NG!) 5TH/REVEFSE sYNcHRo SLEEVEO 5TH/REVERSE SYNCHRO HUB[0 sYrucxao nlrucii i) 5TH GEARO 38 x 43 x 26 mm NEEDLE BEARINGt3 SPACEE COLLARO 4TH GEAR.iB SYNCHRO FING.Ii9 SYNCHRO SPRING{, 3RD/,ITH SYNCHRO HUB

@ 3RD/4TH SYNCHBO SLEEVEt9 3RD GEARO MAINSHAFTO wasHER@) SPRING WASHER40 BALL BEARINGO 28 x 41 x ? mm OIL SEAL Replace.ad 35 x 56 x 8 mm OIL SEAL Replace.a0 14 x 20 mm OOWEL PIN@ OIL CHAMBER PLATE'A BEVERSE IDLEN GEAR SHAFT@ wasHER t-2).A REVERSE IDLER GEAFO REVERSE CHANGE HOLDER3A sTH/REVERSE SHIFT PIECEO 1ST/2ND SHIFT FORK04 3RD/.TH sHlFr FoRK@ 5TH/REVERSE SHIFT FORKO9' OIL GUTTER PLATE6' SNAP RING@ 72 mm THRUST SHIM) OIL GUIOE PLATEi!0 10 mm WASHER Replace..4i] REVERSE IDLER GEAR SHAFT BOLT54 N.m {5.5 kgt m, 40lblftl) TRANSMISSION HANGER B(3 BREATHER CAP@ TRANSMISSION HANGER A63 BACK.UP LIGHT SWITCH25 N.m (2.5 ksf.m, 18lbfftl@r 14 mrn waSHER Replace.67 16 mm SEALING BOLT29 N.m (3.0 kgl.m, 22 lbf ft)@ 32 mm SEALING BOLT25 N.m (2.5 kgf.m. 18lbt'ft|@ 40 x 62 x 9 mm OIL SEAL Replace.D STEEL BALL D. 5/16 inGl SPRING L. 30 mm {1.2 in}

@ 12 mm WASHER Replace.63) SET SCREW22 N.m 12.2 kgl.m, 16 lbt'ft,@ OIL ORAIN PLUG39 N.m {4.0 kgt.m, 29 lbf'ftl€9 WASHER Replace.@ oIL FILLER PLUG4,1N.m 14.5 kgJ m, 33 lblftl

*1:81881 engine*2:B18Cl engine

WASHER Beplace.TRANSMISSION HOUSING80 mm SHIM (*1)79.5 mm SHIM {*21THRUST SHIM {*2IT. 2.0 mm (0.079 in)BEARING OUTER RACE {*2}SHIFT PIECE SHAFTINTERLOCKSHIFT PIECESHIFT ARM HOLDERSELECT ARMSELECT RETURN SPRING10 mm SHIM10 mm WASHERLOCK COLLAR3 x 16 mm SPRING PIN Replace.8 mm SPRING WASHERCHANGE PIECESET SCREW22 N.m {2.2 kgf.m, 16 lbf.ft}SPRING L.25.6 mm {1.01 inlSTEEL BALL D. 5/16 inMAGNETCLUTCH HOUSING14 x 25 x 16 mm OIL SEAL Replace.SHIFT RODDIFFERENTIAL ASSEMBLYSee section 15BEARING OUTER RACE I*2ITHRUST SHIM I*2)T. 2.5 mm (0.098 in,SHIFT ROD BOOTOIL GUID€ PLATE33 x 60 x 20 mm NEEDLE BEARINGBEARING RETAINER PLATELOCK WASHER Replace.COUNTERSHAFTTHRUST SHIM37 x 42 x 25 mm NEEDLE BEARINGlST GEARFRICTION DAMPERSYNCHRO RINGSYNCHRO SPRINGlST/2ND SYNCHRO HUBREVERSE GEARDOUBLE CONE SYNCHRO I*2ISYNCHRO BING I*1)FRICTION DAMPERSPACER42 x 6? x 24 mm NEEDLE BEARING2ND GEAR3RD GEAR4TH GEAS5TH GEARNEEDLE BEARINGBALL BEARINGSPRING WASHERLOCKNUT Replace.108 - 0- 108 N.m(11.0 - 0* 11.0 kgt m,80- 0- 80lbf.ft)5 x 22 mm SPRING PIN Replace.00

13-9

Page 367 of 1413

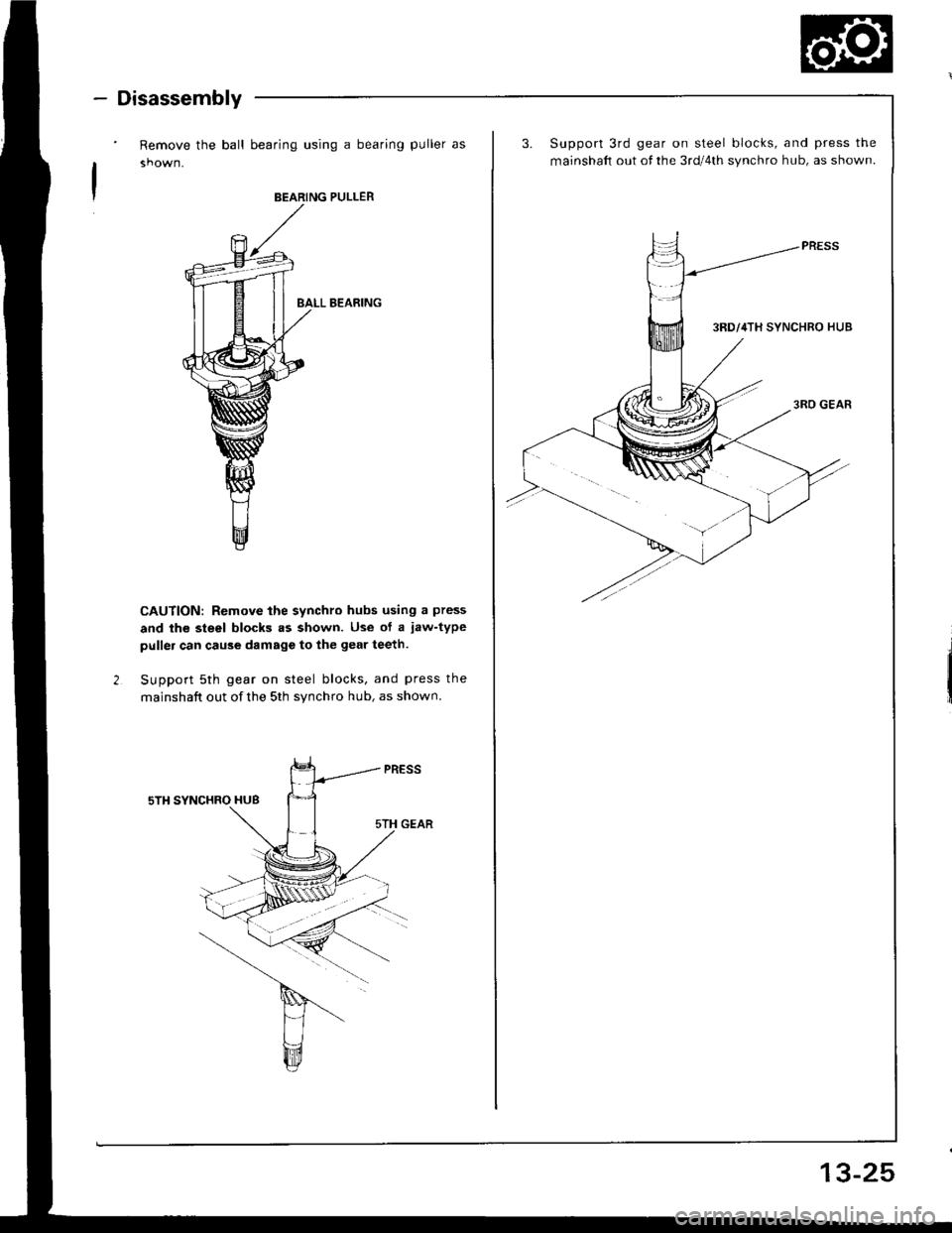

- Disassembly

Remove the ball bearing using a bearing puller as

BEARING PULLER

BALL B€ARING

CAUTION: Remove the synchro hubs using a press

and the steel blocks .s shown. Use of a jaw-type

puller can cau3e damags to the gear teeth.

Support 5th gear on steel blocks, and press the

mainshaft out of the 5th synchro hub, as shown.

3.Support 3rd gear on steel blocks, and press the

mainshaft out of the 3rd/4th synchro hub, as shown.

13-25

Page 369 of 1413

1_

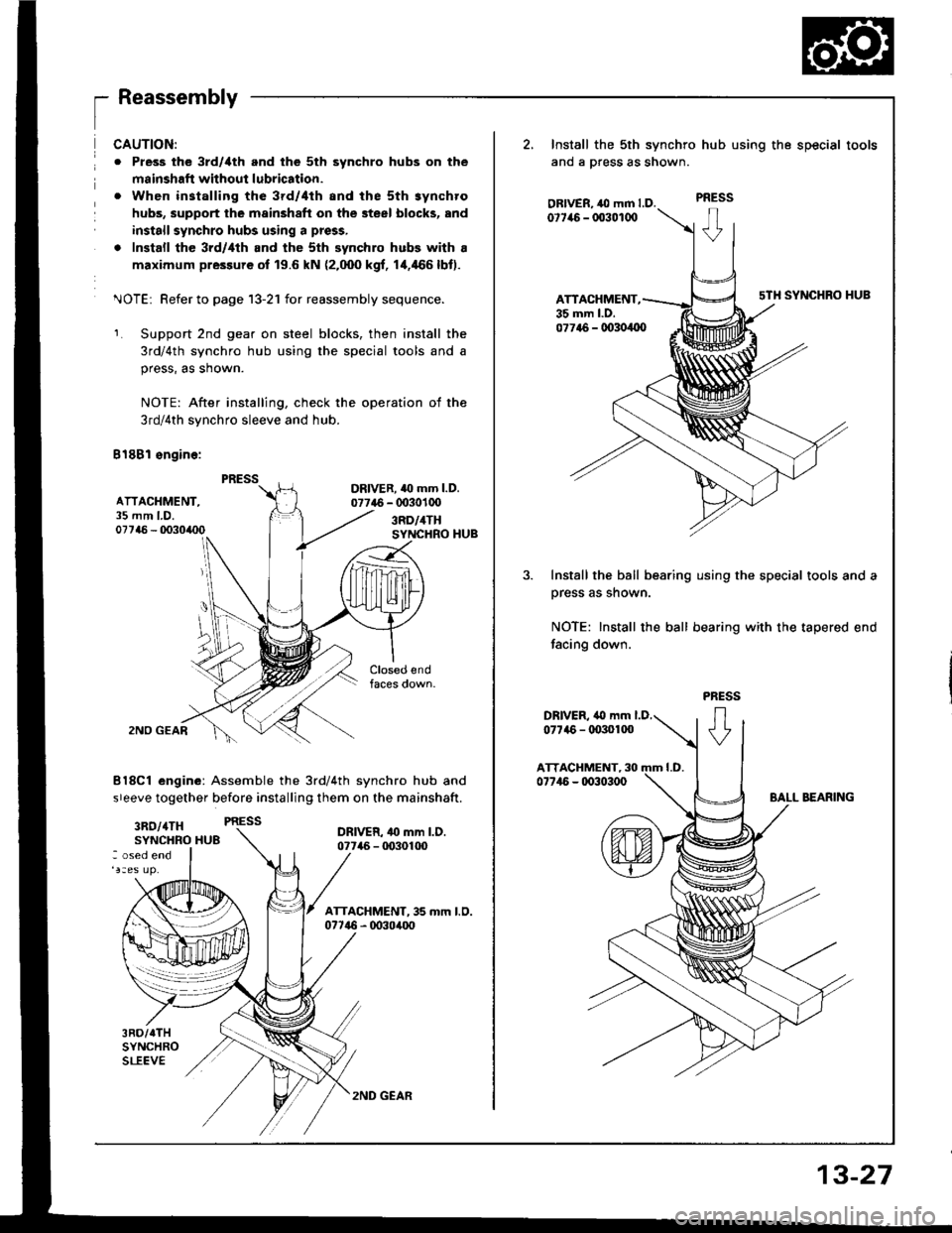

ReassemblV

ATTACHMENT,35 mm LD.07746 - 0o30/rc0

CAUTION:

o Pless the 3rd/ilth and the 5th synchro hubs on the

msinshafi without lubrication.

. When installing the 3rd/4th and the sth synchro

hubs, support the mainshaft on the steel blocks, and

install synchro hubs using a press,

. Install the 3rd/,lth and the sth synchro hubs with a

maximum pressure of 19.6 kN (2.000 kgf, 1+466lbt).

^JOTEi Refer to page 13-21 for reassembly sequence.

Support 2nd gear on steel blocks, then install the

3rd/4th synchro hub using the special tools and a

press, as shown.

NOTE: After installing, check the operation of the

3rd/4th synchro sleeve and hub.

B18Bl sngine:

DRIVER. 40 mm l.D.07746 - 0030100

3RD/4THSYNCHRO HUB

2NO GEAR

8l8Cl engine: Assemble the 3rd/4th synchro hub and

sreeve together before installing them on the mainshaft.

3RO/4TH PRESS

SYNCHRO HU8DRIVER- 4o mm l.D.07746 - tD30100: osed end

3RD/TTHSYNCHROSLEEVE

2, Install the sth synchro

ano a press as snown.

OBIVER, ,O mm LD.0t7it6 - 003010O

ATTACHMENT,35 mm l.D.

hub using the special tools

PRESS

sTH SYNCHRO HUB

077t6 - 00304{x)

Install the ball bearing using the special tools and a

prsss as shown.

NOTE: Install the ball bearing with the tapered end

facing down.

2ND GEAR

13-27

Page 372 of 1413

Countershaft Assembly

Disassembly

13-30

't.Securely clamp the countershaft assembly in a

bench vise with wood blocks.

Raise the locknut tab from the groove in the coun-

tershaft, then remove the locknut and the spring

washer.

4,Remove the bearing outer .ace, then remove the

needle bearing using a bearing puller as shown.

2.

BEARING PULLER

BEARING

Remove the ball bearing using a bearing puller as

shown.

CAUTION: Romove the gclrs using a pross and tho

steol blocks rs shown. U3a of a l.w.typo pullor can

cau36 damagg to tho gsar iocth.

Support 4th gear on steel blocks. and press the

countershaft out of sth and 4th gears, as shown.

PULlTR

\-Y

Page 375 of 1413

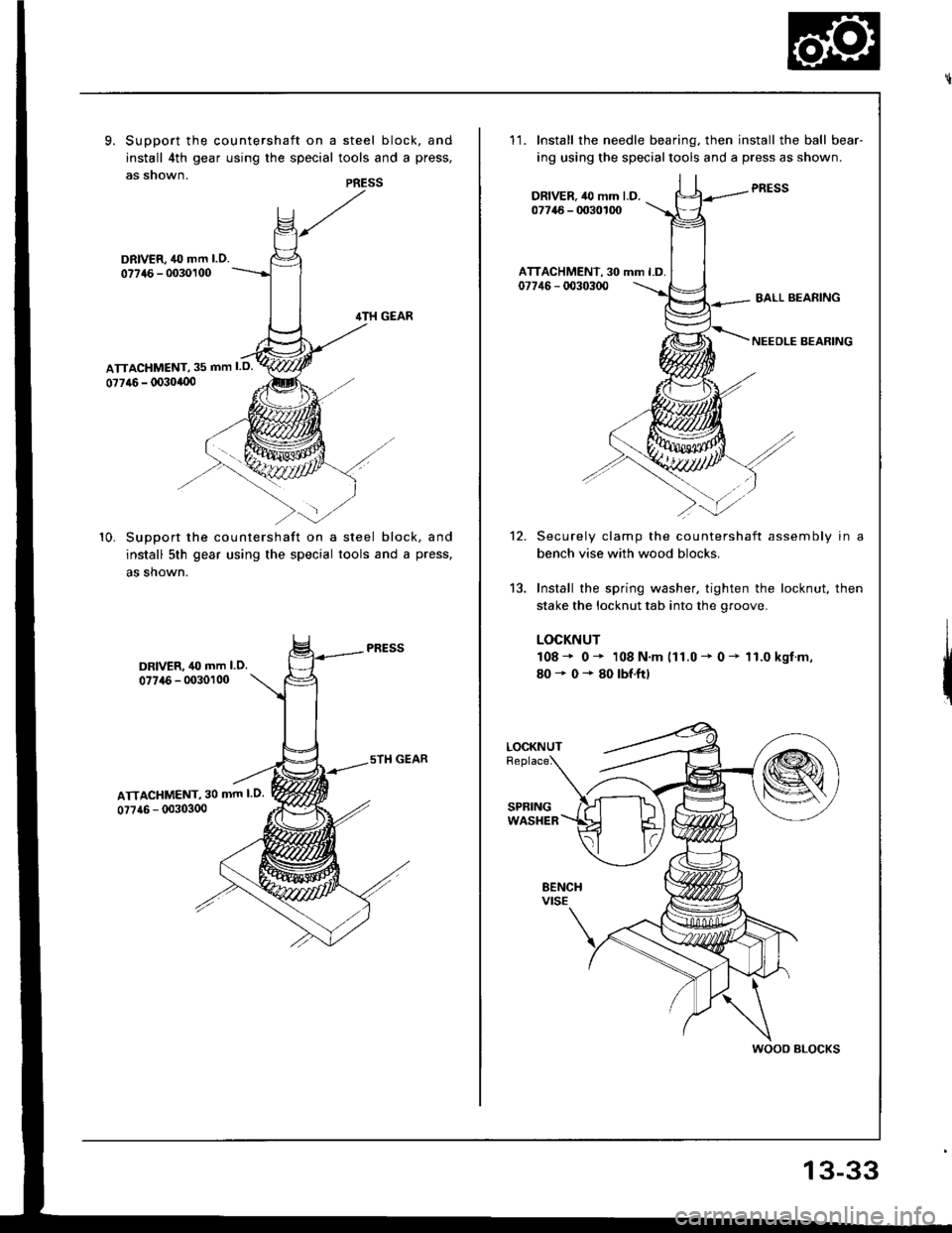

9. Support the countershaft on a steel block, and

install 4th gear using the special tools and a press,

as snown.PRESS

DRIVER, 40 mm l.O.

077{6 - 0030100

10. SuDDort the countershaft on a steel block, and

install 5th gear using the special tools and a press,

as shown.

DRIVER, 40 mm l.O.07746 - 0030100

ATTACHMENT, 30 mm l.O.

0?7a6 - (X)303(x)

11.Install the needle bearing. then install the ball bear-

ing using the specialtools and a press as shown.

PRESSDRIVER.,l0 mm l.D.07746 - 0030100

ATTACHMENT, 30 mm l.D.07746 - d)30300BALL BEARING

NEEDLE BEARING

12.

13.

Securely clamp the countershaft assembly in a

bench vise with wood blocks.

Install the spring washer. tighten the locknut, then

stake the locknut tab into the groove.

LOCKNUT

108* 0* 108 N.m (11.0 - 0 - 11.0 kgf.m,

80+0*80lbf.ftl

LOCKNUT

wooo BLocKs

13-33

Page 377 of 1413

Synchro Ring, Gear

r Inspection

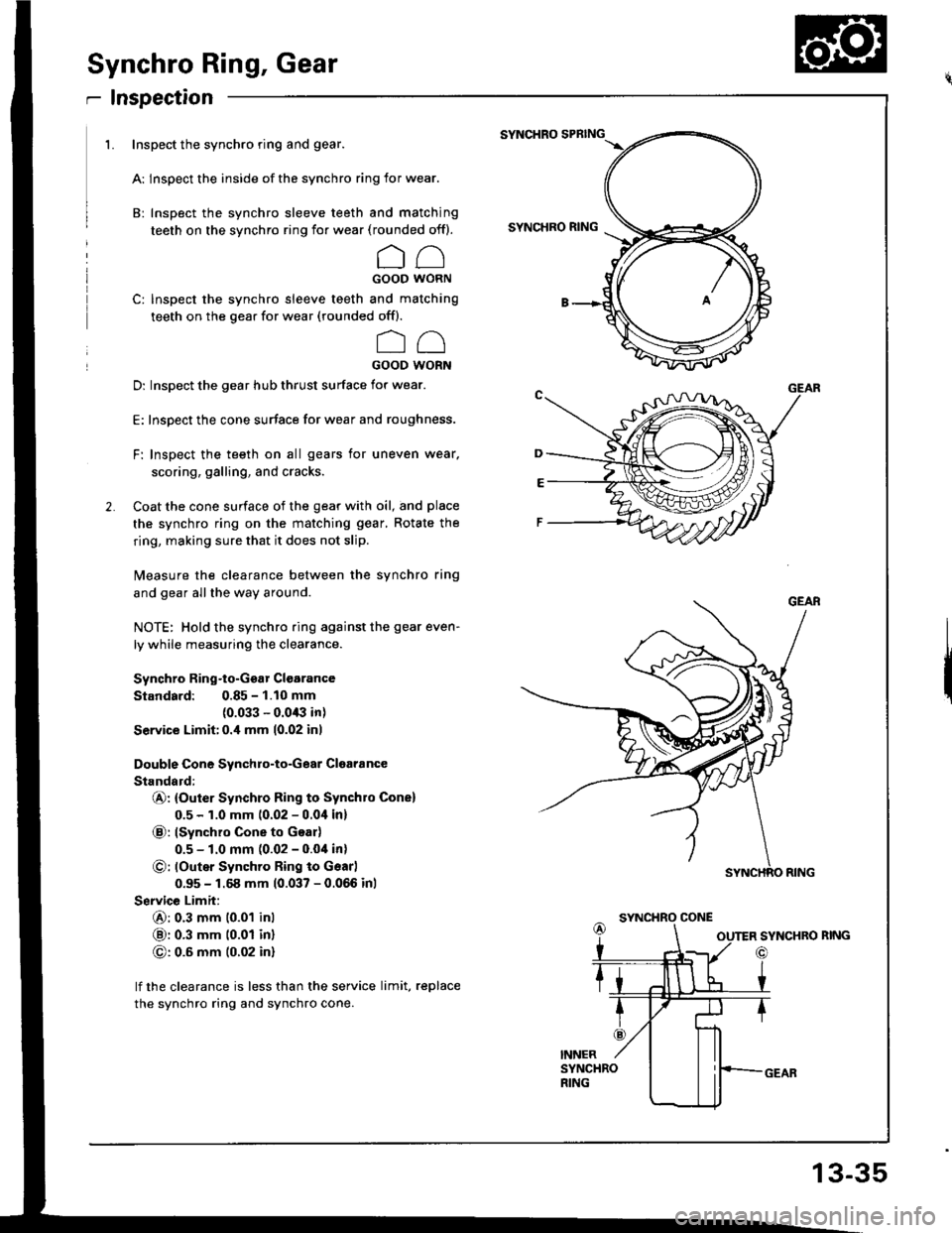

1. Inspect the synchro ring and gear.

A: lnspect the inside of the synchro ring for wear.

B: Inspect the synchro sleeve teeth and matching

teeth on the synchro ring for wear (rounded off).

CCGOOD WORN

C: Inspect the synchro sleeve teeth and matching

teeth on the gear for wear (rounded offl.

oo

GOOD WORN

D: Inspect the gear hub thrust surface for wear.

E: Inspect the cone surface for wear and roughness.

F: Inspect the teeth on all gears for uneven wear.

scoring, galling, and cracks.

Coat the cone surface of the gear with oil, and place

the synchro ring on the matching gear, Rotate the

ring, making sure that it does not slip.

Measure the clearance between the synchro ring

and gear allthe way around.

NOTE: Hold the synchro ring against the gear even-

ly while measuring the clearance.

Synchro Ring-to-Ggar Clgarance

Standard: 0.85 - 1.10 mm(0.033 - 0.0/B in)

Service Limit:0.i1 mm 10.02 inl

Double Cone Synchro-to-Gear Cloaiance

Standald:

@: {Outer Synchro Ring to Synchro Cone)

0.5 - 1.0 mm 10.02 - 0.0i1in)

@: lSynchro Cone to Goar)

0.5 - 1.0 mm (0.02 - 0.04 in)

O: loutsr Synchro Ring to Gsarl

0.95 - 1.68 mm (0.037 - 0.066 inl

Service Limit:

6): 0.3 mm 10.01 inl

@: 0.3 mm t0.01 inl

G): 0.6 mm (0.02 in)

lf the clearance is less than the service limit, replace

the synchro ring and synchro cone.

SYNCHRO SPBING

SYNCHRO RING

SYNCHRO CONE

SYNCHRO RING

o

13-35