connector HONDA INTEGRA 1994 4.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 282 of 1413

![HONDA INTEGRA 1994 4.G Repair Manual Power Steering Pressure (PSP) Switch Signal

This signals the ECM when the power steering load

-;"nection.*."------.ill]

--

;;;;;;;l w

;:"r"tffa;i

connecrors (see

Turn the ignition switch ON.

Measur HONDA INTEGRA 1994 4.G Repair Manual Power Steering Pressure (PSP) Switch Signal

This signals the ECM when the power steering load

-;"nection.*."------.ill]

--

;;;;;;;l w

;:"r"tffa;i

connecrors (see

Turn the ignition switch ON.

Measur](/img/13/6067/w960_6067-281.png)

Power Steering Pressure (PSP) Switch Signal

This signals the ECM when the power steering load

-;"nection.*."------'.ill]

--

;;;;;;;l w

;:"r"tffa;i'

connecrors (see

Turn the ignition switch ON.

Measure voltage between 88 {+ )terminal and A26 {-) terminal.

is high.

o ooooo oooo ooo I oo ooo oo o l.Do€d(iltl ooooooooooo

o oooo ooo ooooQ I oooQ oo oo $aG$ast.l oooooooo oo

A26 l-) Bg l+l

L6s! thsn l.O V?

wire side

Turn the ignition switch OFF.

Disconnect the 2P connector tromthe PSP switch.

ls there less than 1.0 V?

Tu.n the ignition switch ON.

Turn steering wheel slowly.ls there less than 1.O V?

Measure voltage between B8 (+)

terminal and 426 (-) termanalwhile steering wheel is turning.

Ropair opon in GRN wire betwssnECM {88} and PSP srYilch ot BLKwi.o botw6cn PSP switch andG301 (locatod at loft ongin6 com-partm6ntr.

Disconnect the 2P connector lromthe PSP switch.PSP switch signal is OK.

Repair short in GRN wi.e botwoonECM {881 and PSP switch.ll wiro i3 OK, substitute a known-good ECM and.ocheck. lIproscribod vollage is now available, replaco tho original ECM.

GRN

PSP SWITCH

11-93

Page 284 of 1413

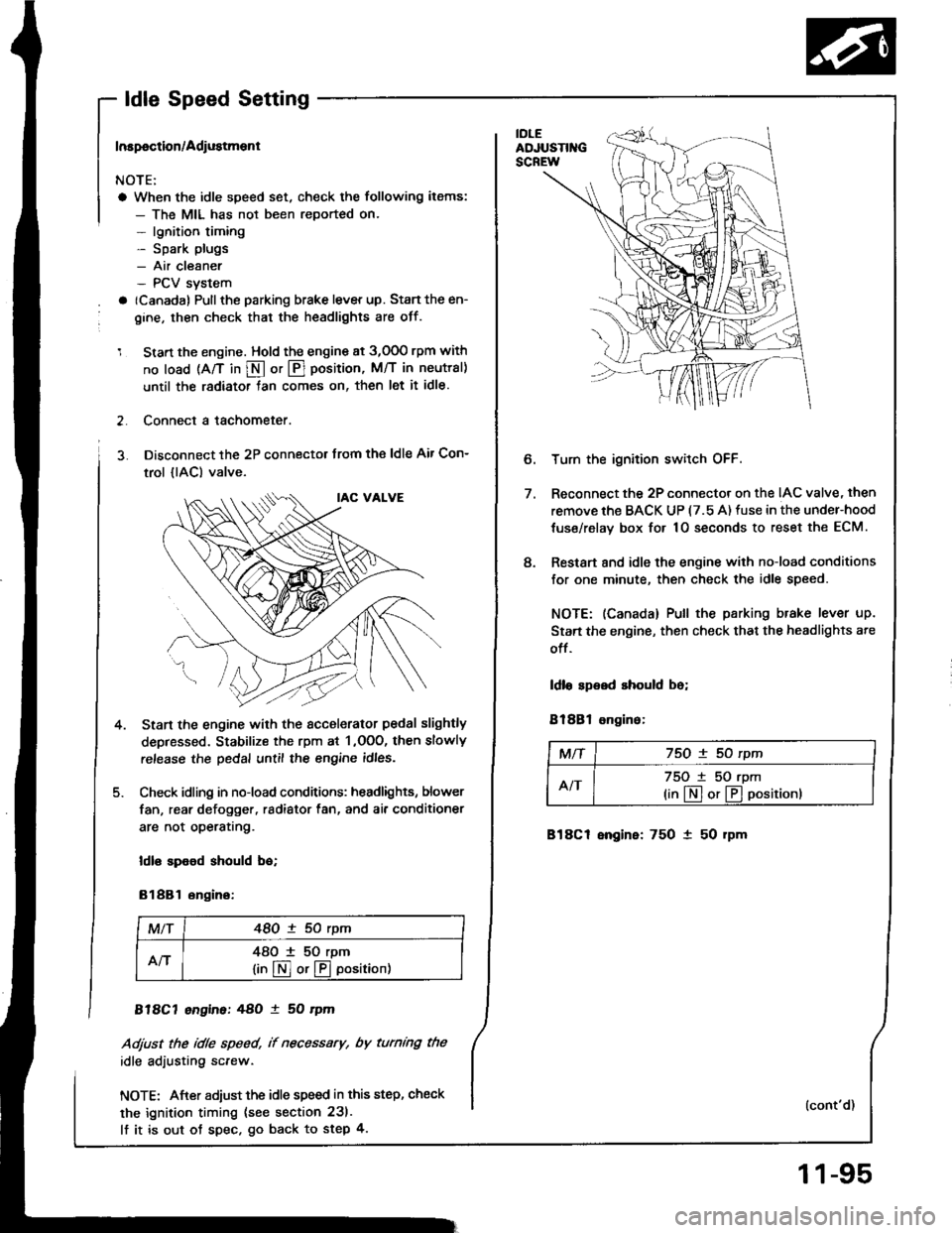

- ldle Speed Setting

Inspoction/Adiustment

NOTE:

a When the idle speed set, check the following items:

- The MIL has not been reported on.- lgnition timing- Spark plugs- Air cleaner- PCV svstem

a (Canada) Pullthe parking brake lever up. Stan the en-

gine, then check that the headlights are off.

1 Start the engine. Hold the engine at 3,000 rpm with

no load (A/T in S or @ position, M/T in neutral)

until the radiator tan comes on, then let it idle.

2. Connect a tachometer.

3. Disconnect the 2P connectot trom the ldle Air Con-

trol {lAC) valve.

Start the engine with the sccelerator pedal slightly

depressed. Stabilize the rpm at 1 ,OOO, then slowly

release the pedal until the engine idles.

Check idling in no-load conditions: headlights, blower

fan, rear defogger, radiator fan, and ai. conditioner

are not operatrng.

ldl€ spood should bo;

81881 ongino:

MlT48O ! 50 rym

An48O I 50 rpm

lin@or@oosition)

818C7 engine:48O ! 50 rym

Adjust the idle speed, if necessary, by turnmg the

idle adiusting screw.

NOTE: After adiust the idle speed in this step, check

the ignition timing (see section 231.

lf it is out ot spec. go back to step 4.

4.

e

Turn the ignition switch OFF.

Reconnect the 2P connector on the IAC valve, then

remove the BACK UP (7.5 A) fuse in the under-hood

tuse/relav box for 1O seconds to reset the ECM.

Restart 8nd idle the engine with no-load conditions

for one minute, then check the idle speed.

NOTE: (Canada) Pull the parking brake lever up.

Start the engine, then check that the headlights ate

off.

ldlo speed should be;

81881 ongino:

MTf75O ! 50 rpm

AIT75O t 50 rpm

(in[]or@positionl

818C1 engine: 750 1 50 rpm

(cont'd)

11-95

Page 293 of 1413

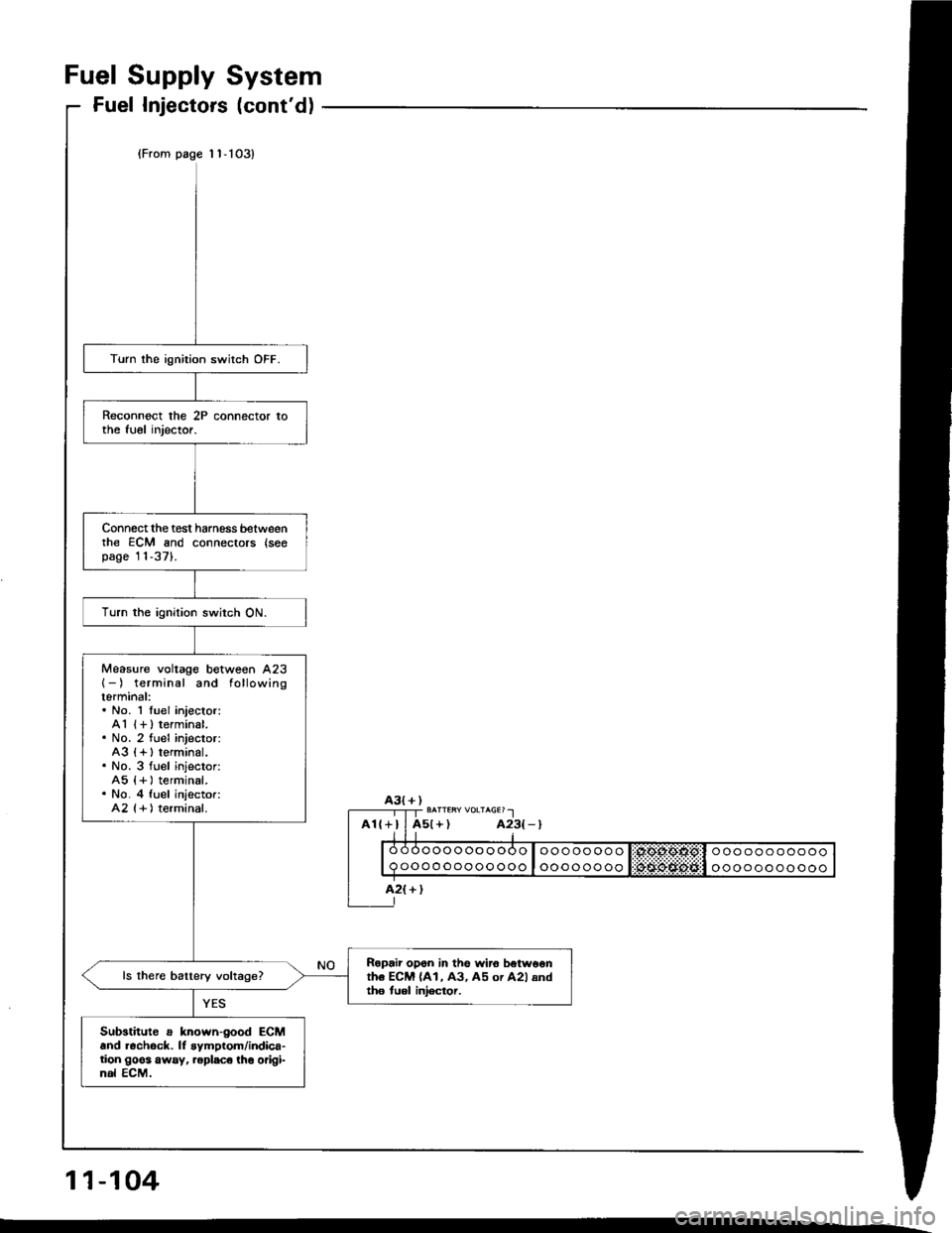

Fuel Supply System

Fuel Injectors (cont'd)

(From page 'l1-103)

Turn lhe ignition switch OFF.

Reconnect the 2P connector tothe tuel injector.

Connect the test harness betweenrhe ECM and connectors {seopage'11-371.

Turn the ignition switch ON.

Measure voltage between A23{-) terminal and followingterminal:. No. 1 tuel injector:A1 (+ ) terminal.. No. 2 fuel injector:A3 {+ I terminal.. No. 3 fuel injector:A5 {+ ) terminal.. No. 4 fuel injector:A2 {+ ) terminal.

Ropair opon in the wi.o betw6onth6 ECM (A1, A3, A5 or A2l andth6 tuel iniector.

Sub3titute a known-good ECMand r6chock. lf symptom/indica-tion goes away, .eplsco tho origi-nal ECM.

oooooooooo

oooooooooooooooooooo

oooooooo

ooooooooooo

ooooooooooo

A3{+)

A2{+}

11-104

Page 294 of 1413

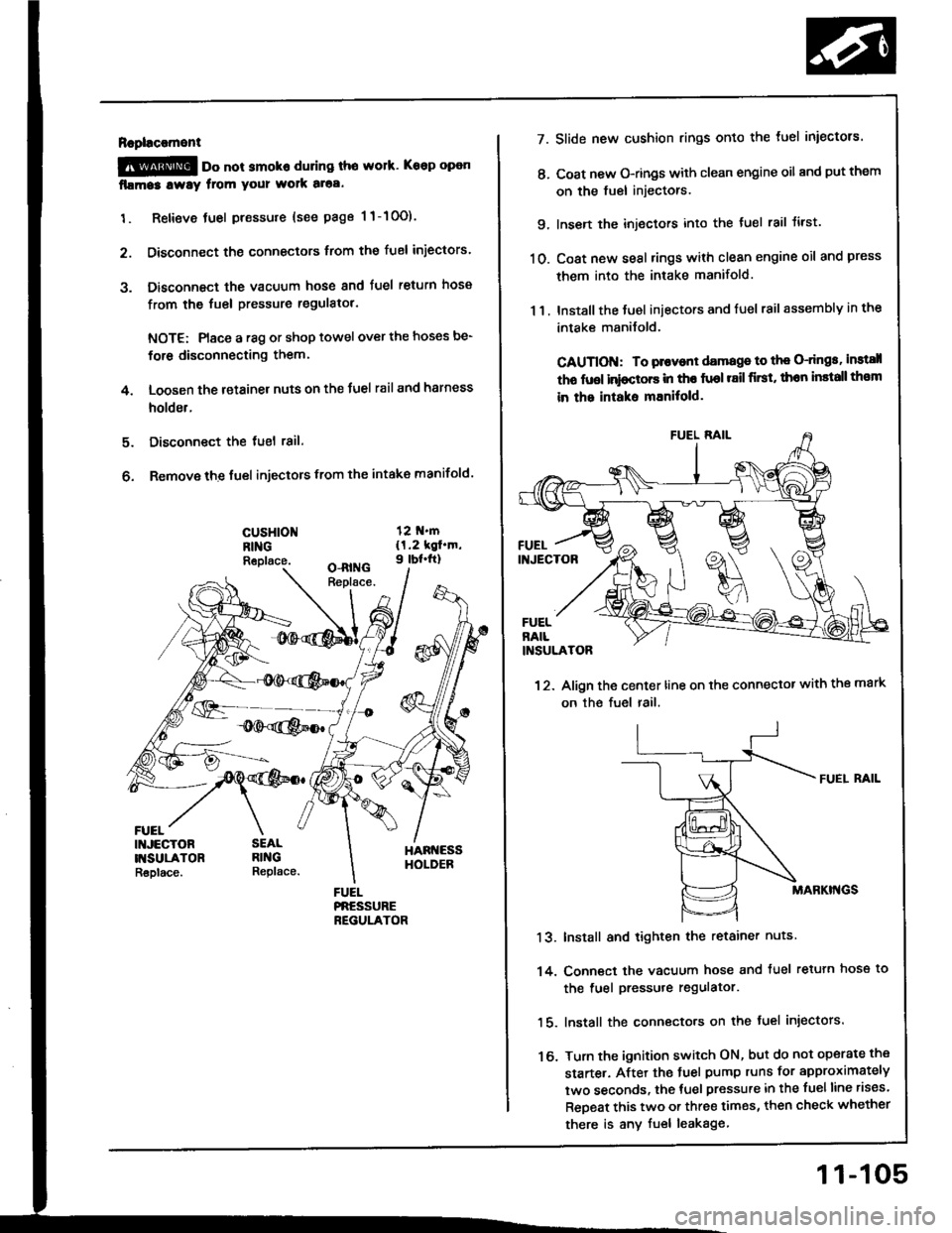

Rapl!c!ment

@ oo not smoko during tho work. Keep open

fllma3 lway from your wolk aloa.

1. Retieve tuel pressure {see page 1 1-10O).

2. Disconnect the connectors trom the fuel iniectors.

3. Disconnect the vacuum hose and fuel return hosa

from the fuel pressure regulatol.

NOTE: Place a r8g or shop towel over the hoses be-

for6 disconnecting them.

4. Loosen the retainer nuts on the Juel rail and harness

holder.

Disconnect the tuel 18il.

Remove the fuel injectors from the intake manifold.

5.

6.

cusHloNRINGReplace.

FUEL

7.

t'.

9.

10.

13.

14.

16.

11.

Slide new cushion rings onto the luel iniectors.

Coat new O-rings with clean engine oil and put them

on the fuel injectors.

Insen the injectors into the tuel rail tirst.

Coat new seal rings with clean engine oil and press

them into the intake manifold.

Install the Juel iniectors and fuel rail assembly in the

intake manilold.

CAUTION: To plovont damage to th€ O-dngs, instsll

tho fuol inioctors in tho fuol r8il first, thon install th€m

in the intaks mEnitold.

12. Align the center line on the connector with the mark

on the fuel rail.

FUEI. RAIL

MABKI'{GS

Install and tighten the retainer nuts

Conn€ct the vacuum hose and tuel retuln hose to

the fuel pressure regulator.

lnstall the connecto.s on the fuel injectors.

Turn the ignition switch ON, but do not operate the

starte.. After the tuel pump runs for approximately

two seconds, the tuel pressure in the fuelline rises.

ReDeat this two or three times, then check whether

there is any fuel leakage

11-105

Page 299 of 1413

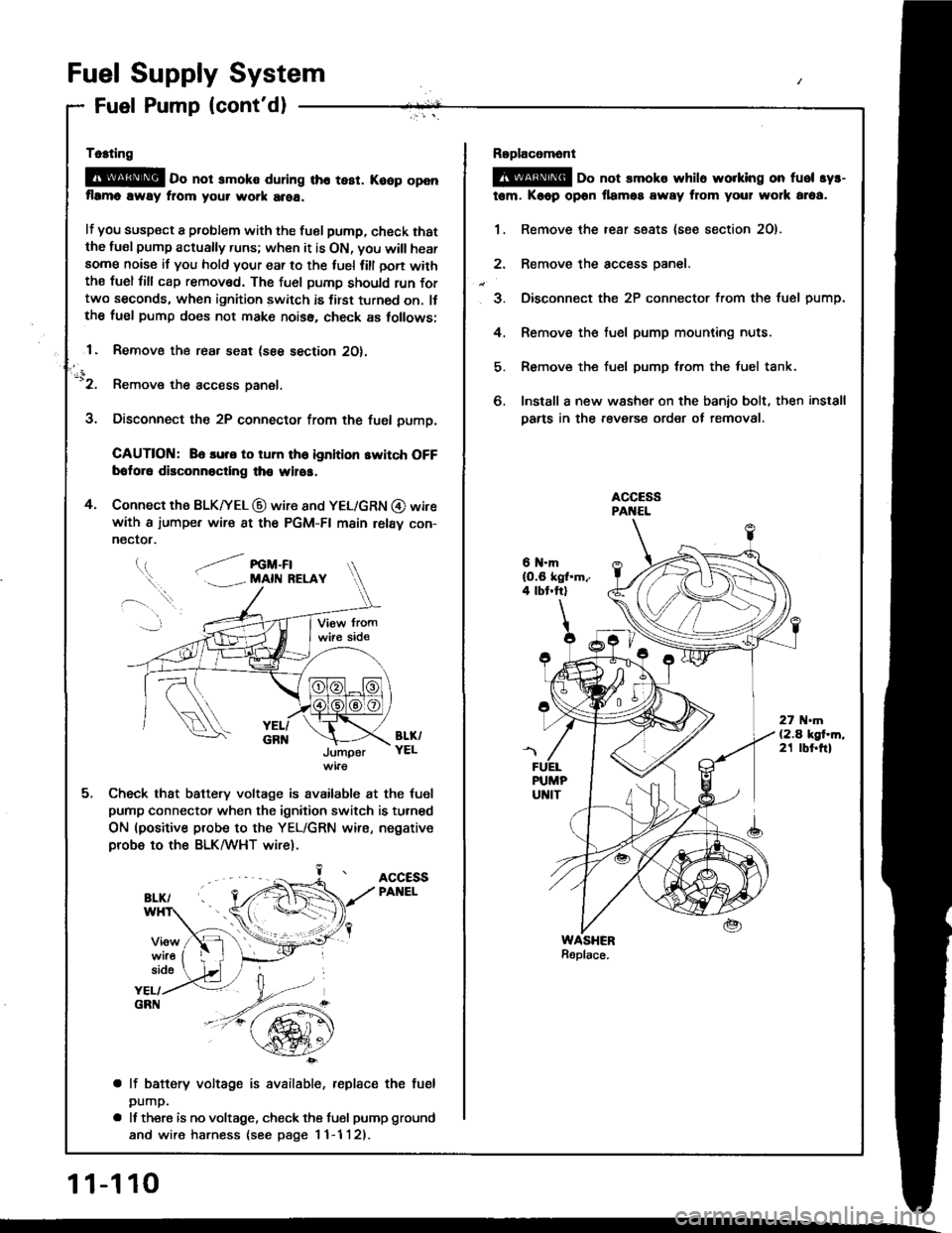

Fuel Supply System

Fuel Pump (cont'dl

Tc.ting

@E o" not smoko during tho tesr. Koop openflrmo away fiom your work area.

lf you susp€ct a problem with the tuel pump, check thatthe lusl pump actually runs; when it is ON, you will hearsome noise if you hold your ear to the luel lill oon withthe fuel fill cap remov6d. The fuel pumD should run fortwo seconds, when ignition switch is first turned on. llthe fuel pump does not make noiss, check as tollows;

1. Removo the rear seat (see section 2O).

-'2. Remove the access panel.

3. Disconnect the 2P connector from the fuel pump.

CAUTION: 86 lure to tum th6 ignition switch OFFbotor6 disconnoctlng th€ wilos,

4. Connect the BLK|yEL @ wire 8nd YEL/GRN @ wirewith a iumpe. wire 8t the PGM-FI main relav con-

nectot.

l.t, .--/ re -Fl. . MAll{ RELAY

BL&YELJumper

Check that battery voltage is available at the tuel

pump connector when the ignition switch is turned

ON (positive probe to the YEL/GRN wire, negativeprobe to ths BLK/WHT wire).

ACCESSPANEL

side

YEL/GRN

a lf battery voltage is available, replace the fuel

pump.

a It there is no voltage, check the tusl pump ground

and wire harness {see page I 1-1 l2).

11-110

Roplacomont

@ oo not smoks whilo worklng on fuel syr-

tem. Kaop opon llamos away from your wolk araa.

1. Remove the rear ssats {soe section 2O).

2. Remove the access oanel.

3. Disconnect the 2P connector from the fuel pump.

4. Remove the fuel pump mounting nuts.

5. Remove the fuel pump trom the luel tank.

6. Install a new washer on the banio bolt, then install

Darts in the revers€ order of removal.

6 N.mlO.6 kgl.m,.4 tbt.ftl

27 .m(2.4 kgt.m,21 tbt.ftl

Page 302 of 1413

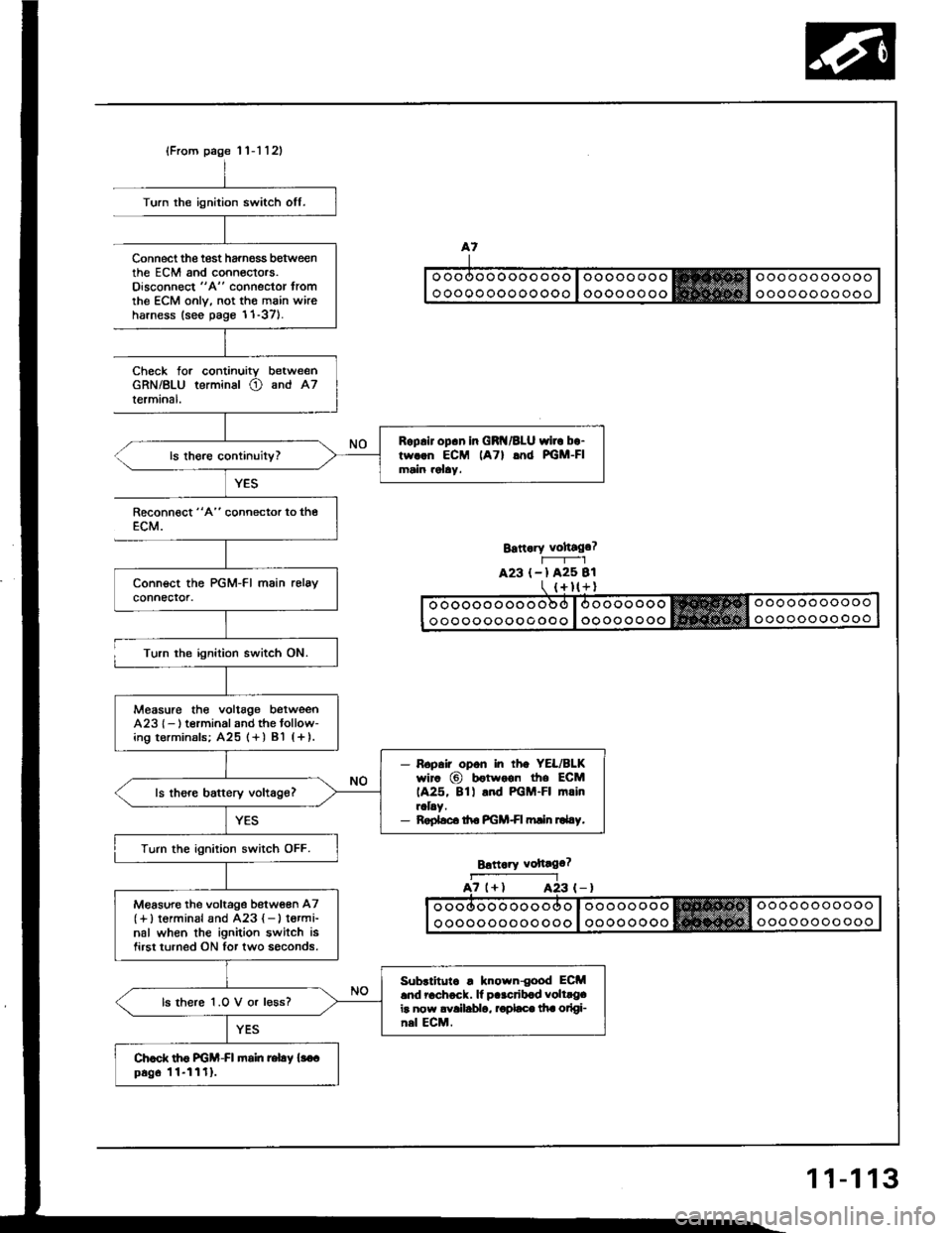

(From page 'l'l-1121

Roplir op.n in GRI{/BLU wirc bo-tw..n ECM lATl lnd PGM-FImain rolay.

Measure the voltag€ betweenA23l- ) t€rminal and the tollow-ing t€rminals; A25 (+ ) Bl (+ ).

- Ropair opon in rh. YEL/BLKwir. @ b€twoon the ECM1A25, 8tl .nd PGM-FI mrinraLy.- Roplsc. ttro PGM+I min ru4.y.

Turn the ignition switch OFF.

M€asure the voltage betw€en A7(+)torminal and A23 { - } t€rmi-nal when the ignition switch isfirst turned ON for two soconds.

Subrlitutc . known{ood ECM.nd 6chock. lf p..crib.d volt.g.ir now avallablo, rodaco lha otlgi-nsl ECM.

ls there 1.O V or l€ss?

Chod. th6 FGM-FI fioin relay {3o.p6g6 11-1111.

Turn the ignition switch off.

Connect the test harnoss b€tweenthe EcM and conneclors.Oisconnect "A" connector tromthe ECM onlv. not the main wireharness (see page 1'1-37).

Check forGRN/BLUlermrnal.

continuity betweenterminal O and A7

YES

Reconn€ct "4" connector to theECM.

Turn the ignition switch ON.

Bstt.ry vohago?r-----r_-lA23 (-l A25 Bl

Brttaiy voftago?

a7 (+l A23A23 (-)

11-113

Page 303 of 1413

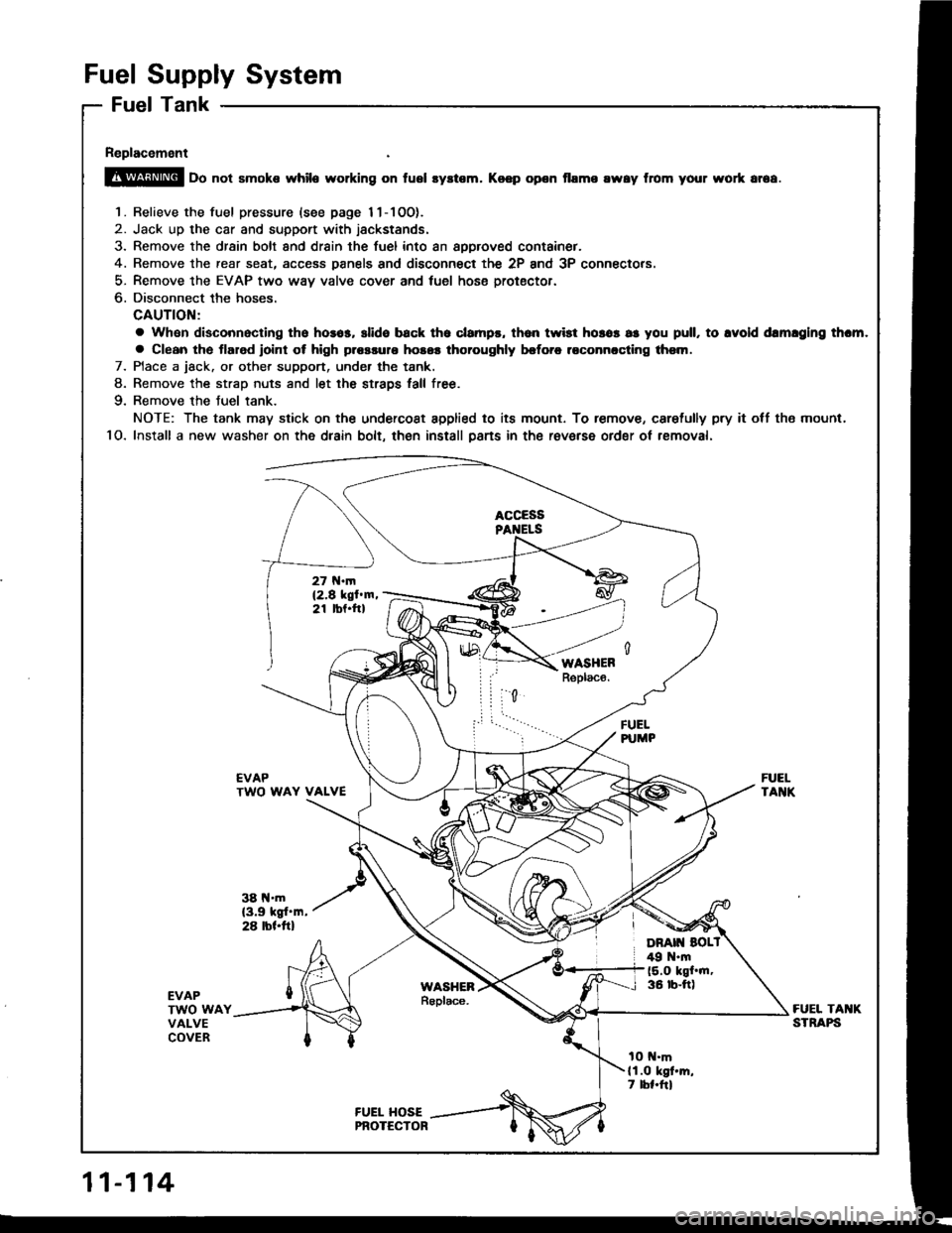

Fuel Supply System

Fuel Tank

Replacement

@ oo not smoke while working on fusl syltem. Koep opon flame rway from your wort ar6a.

1. Relieve the fuel pressure {see page 11-1OO).

2. Jack up the car and support with jackstands.

3. Remove the drsin bolt and drain the fuel into an approved container.

4. Remove the rear seat, access Danels and disconnect the 2P and 3P connectors.

5- Remove the EVAP two way valve cover and tuel hose protector.

6. Disconnect the hoses.

CAUTION:

a Whan disconnacling tho hosos, slide back tho clampr, th6n twist horos as you pull, to lvold drmlglng thcm.

a Clean the tlarod roint ot high plossulo hosos thoroughly brforc roconnccling thsm.

7. Place a jack. or other support, under the tank.

8. Remove the strao nuts and let the straDs tall free.

9. Remove the Juel tank.

NOTE: The tank may stick on the undercoat applied to its mount. To remove, caretully pry it off tho mount,

1O. Install a new washer on the dlain bolt, then install psns in the raverse ordgr ot rsmoval.

FUELPUMP

EVAPTWO WAY VALVE

38 l{.m(3.9 kgt'm,28 rbl.ftl

FUELTANK

EVAPTWO WAYVALVECOVER

FUEL TAI{KSTRAPS

tO t{.mll.O kgt'm,7 lbl.frl

11-114

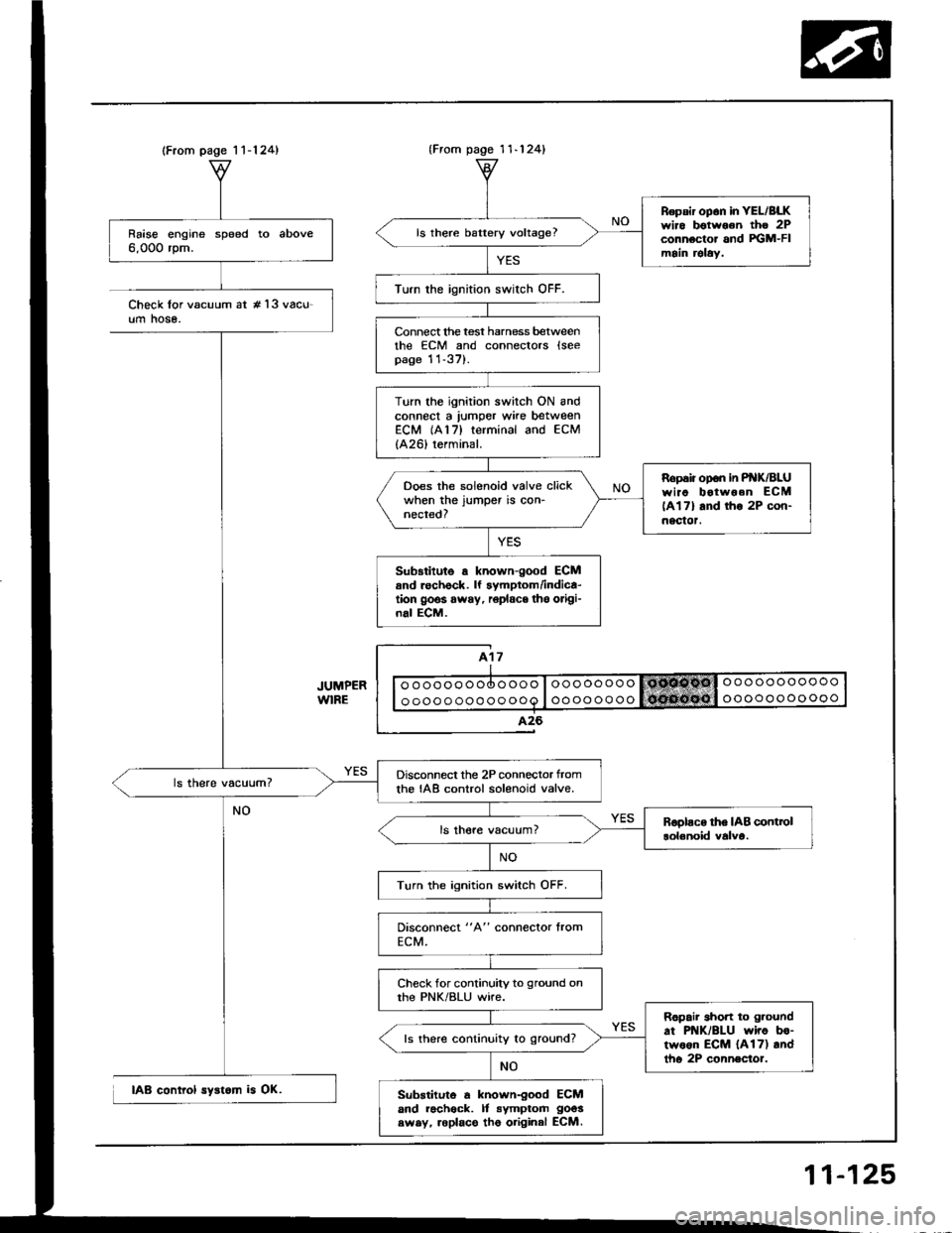

Page 314 of 1413

(From page 1 1-124)

Raise engine speed to above6,000 rpm.

Disconnect the 2P connector tromthe IAB control solenoid valve.

Turn the ignition switch OFF.

Check for continuity to ground onthe PNK/BLU wire.

Ropair short to g.ound

at PNK/BLU wiro bo-two6n ECM {A17) andtho 2P connector.

ls there continuity to ground?

Substituto a known-good ECMand racheck. It symptom goos

swsy, roplace tho original ECM.

{From pago 1 1-124}

Repsir op6n in YEL/BLKwiro botwoon tho 2Pconnector and FGM-FImain relaY.

ls there battery voltage?

Turn the ignition swirch OFF.

Connect lhe test harness betweenthe ECM and connectors lseepage 11-37).

Turn the ignition switch ON andconnect a lumper wke betweenECM (A17) terminal and ECM

{A26) terminal.

Ropaiiopon inP K/BLUwiao botwoen ECM

lAl7l and tho 2P con-nectot.

Ooes the solenoid valve clickwhen the jumper is con-nected?

Sub3titute a known-good ECMand rechock. lf symptom/indica-tion goos away, r6place tho origi-nal ECM.

Check lor vacuum at #'l3 vacu-um hose.

IAB control syst6m is OK.

11-125

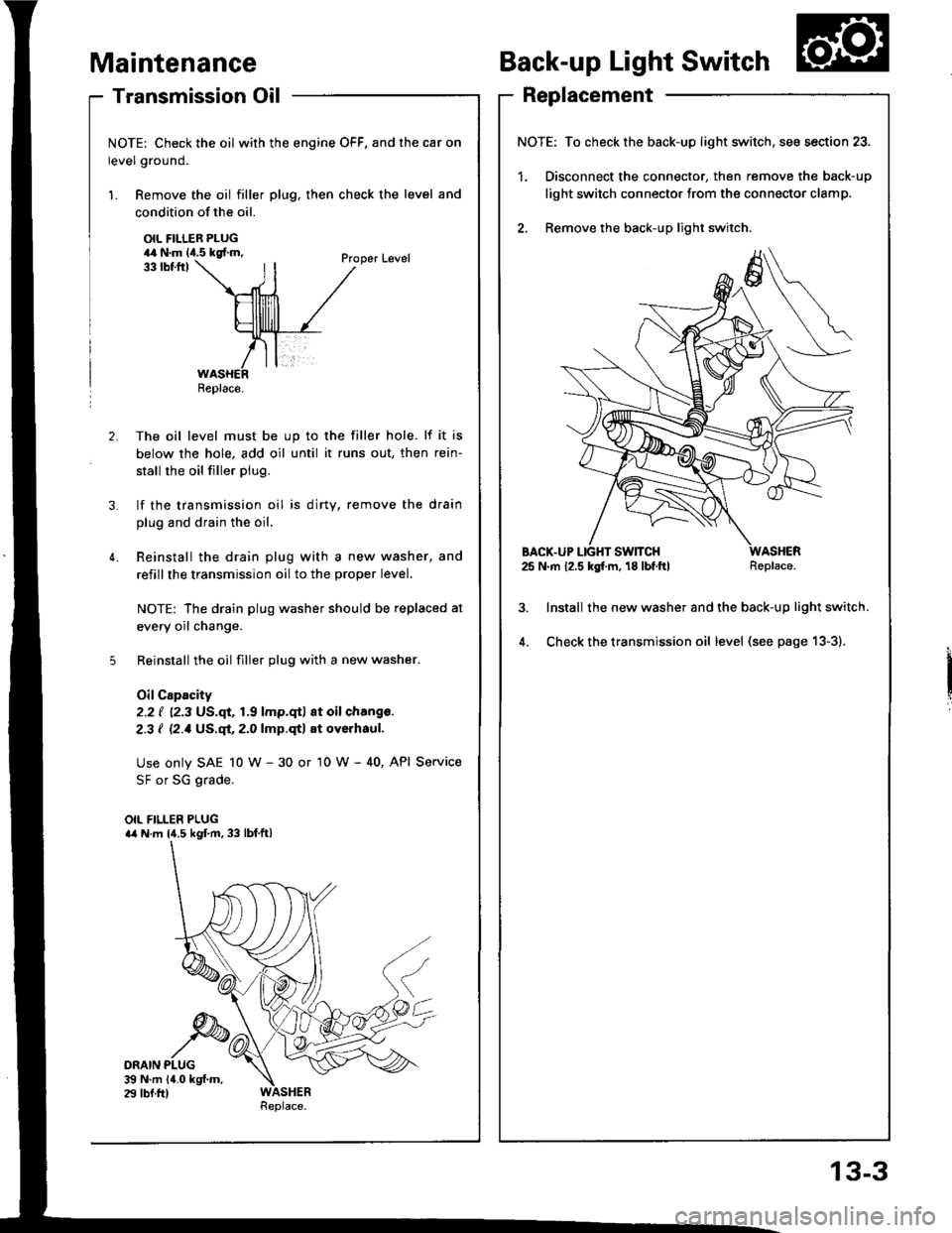

Page 345 of 1413

- Transmission Oil

NOTE: Check the oil with the engine OFF, and the car on

level ground.

1. Remove the oil filler plug, then check the level and

Maintenance

condition of the oil.

OIL FILLER PLUG44 N.m lia.5 kgf.m,

ORAIN PLUG$ N.m 14.0 kgf.m.29 lbf.fr)

33 tbtftlProper Level

2. The oil level must be up to the filler hole. lf it is

below the hole. add oil until it runs out, then rein-

stall rhe oil filler plug.

3. lf the transmission oil is dirty, remove the drain

plug and drain the oil.

4. Reinstall the drain plug with a new washer, and

refillthe transmission oil to the proper level.

NOTE: The drain plug washer should be replaced at

every oil change.

5 Reinstall the oil filler plug with a new washer.

OilCapacity

2.2 ( ''2.3 US.qt,1.9 lmp.qt) at oil chang€.

2-3 I l2.1Us.ql,2.0lmp.qtl at oyerhaul.

Use only SAE 10 w - 30 or '10 W - 40, API Service

SF or SG grade.

OIL FILLER PLUGa4 N.m l{.5 kgf.m, 33 lbf.ftl

Back-up Light Switch

Replacement

NOTE: To check the back-up light switch,

1. Disconnect the connector, then rem(

light switch connector trom the conn

2. Remove the back-up light switch.

BACX-UP LIGHT SWITCH25 N.m 12.5 kg[.m, 18 lbf.ftl

lnstall the new washer and the back-

Check the transmission oil level (see

Replace.

/itch, see section 23.

remove the back-up

]onnector clamp.

-up light switch.

) page 13-3).

Replace.

13-3

Page 346 of 1413

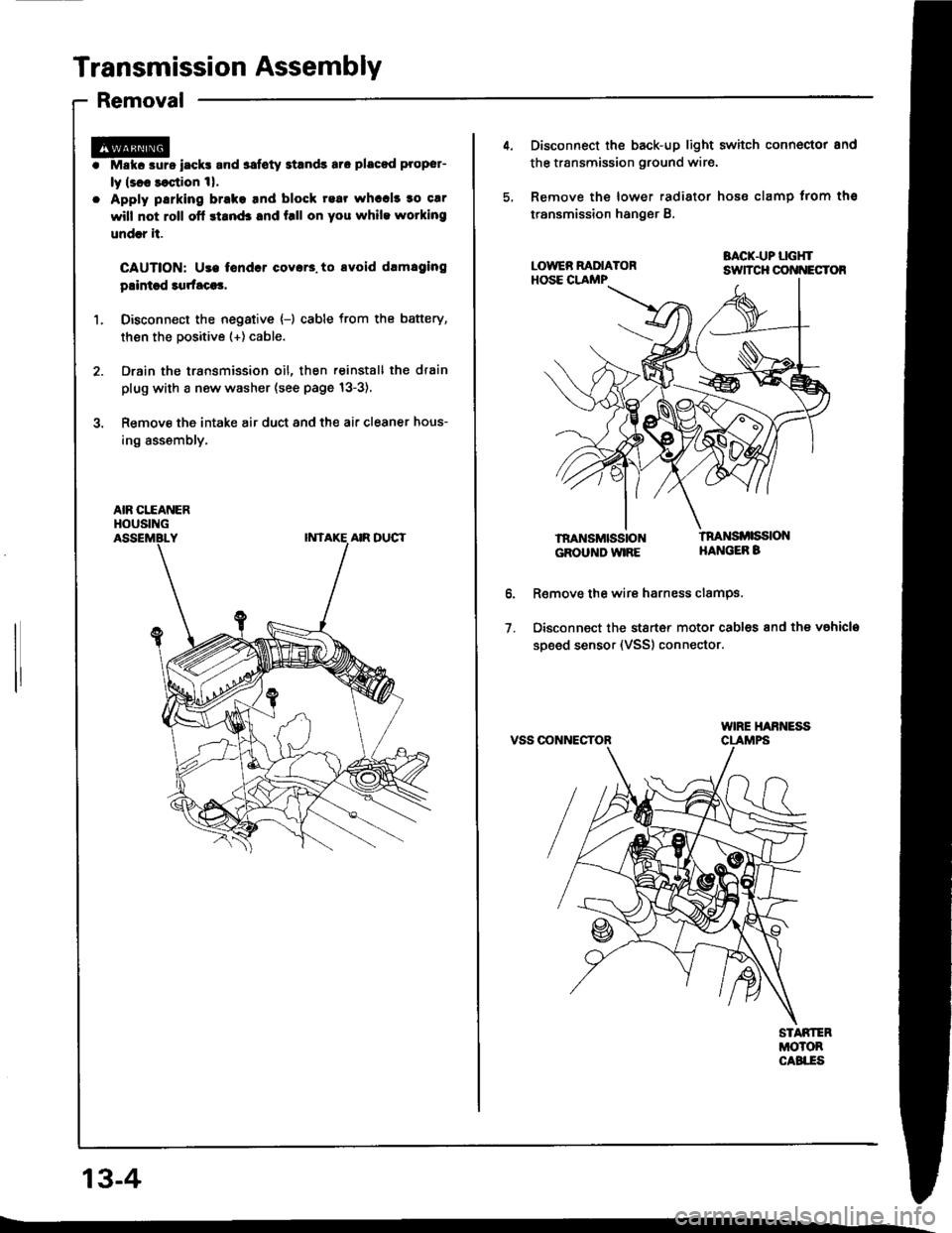

Transmission Assembly

Removal

Mskc aurs iack! and safoty Etands aro placod proper-

ly lsl8 saqtion 1|.

Apply parking brake tnd block rear whccl! to car

will not roll ofl stand3 and f.ll on you while wotking

undrr it.

CAUTION: Use tondcr coyar3. to avoid drmlging

plintsd 3qrfaca3,

Disconn€ct the negative {-) cable from the battery,

then the positive (+) cable.

Drain the transmission oil, then reinstall the drain

plug with a new washer (see page 13-3),

Remove the intake air duct and the air cleaner hous-

ing assembly,

AIR CITANERHOUSING

13-4

4. Disconnect the back-up light switch connoctor and

the transmission ground wir€.

5, Remove the lower radiator hose clamp trom ths

transmission hanger B.

BACK.UP LGHTsuTcH cot{t{EcToR

lnaNsMttistoNGROUND WIRE

tnaNsi ssloNHANGEB B

o.

1.

R€move the wire harness clamPs.

Disconnect the stsrt€r motor cables and the vahicla

soeed sensor (VSS) connector.

VSS OONNECTOR