indicator HONDA INTEGRA 1994 4.G Manual PDF

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 1239 of 1413

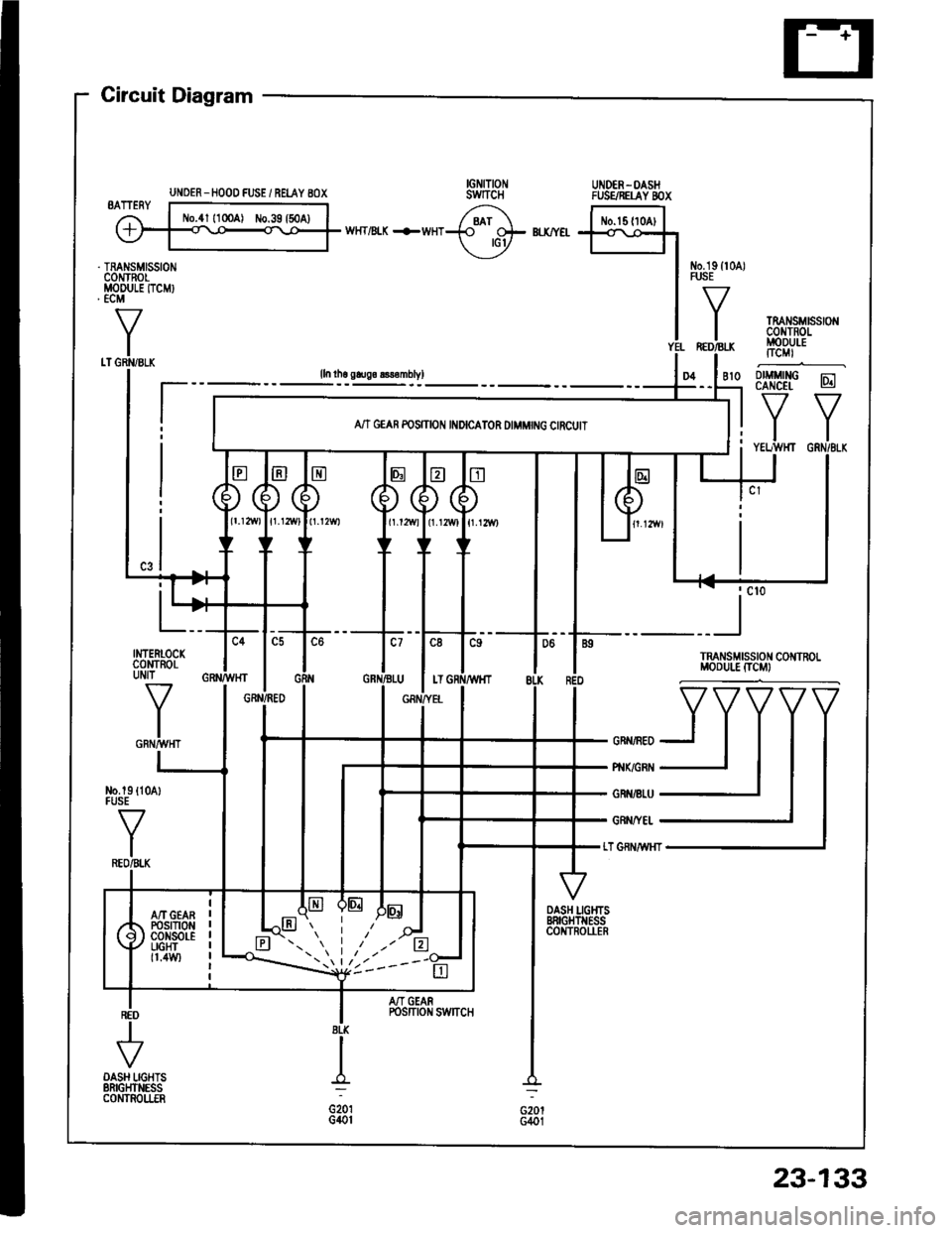

UNOER_HOOD FUSE / REI.AY 8OX

Circuit Diagram

IGNITIONswrTcHUNOER-OASHFUSSREI-AY 8OX

No.19ll0A)FUSE

TMI{SMrSSr0r,lc0IJTRori.IODULEITCMI

fitMritc-;-CANCEL lgll

tlYELTWHT GRN/8L|(

D4

II._l

TRANSMISSIONMODU|.! [TCM}

t

INTERLOCKcoMtRotUNJ]_

IGRT'IMHTo*nn,o_yTT

pr{x/cR1 -J

IGR €|-U -l

GRiITYEt

LT GNNiW{T

No.19 {lFUSE

V

I

I

DASH I-IGHTSBRIGHTNESSCONTROI.IERG2o lG401

I

G201G40t

/-?t ftrt*lwHT/BLX +wHT+ CH- Bl.x/Y€t -+<.\-o+!

y "l

IYEL

lln tho gtugo 8ls€mbvl

AN GEAR POSITION INDICATOR DIMMING CIRCUIT

A/T GEANPOStTt0NcoNsot-ELIGHT0.4w)

M GEARPosrTroN swncH

23-133

Page 1240 of 1413

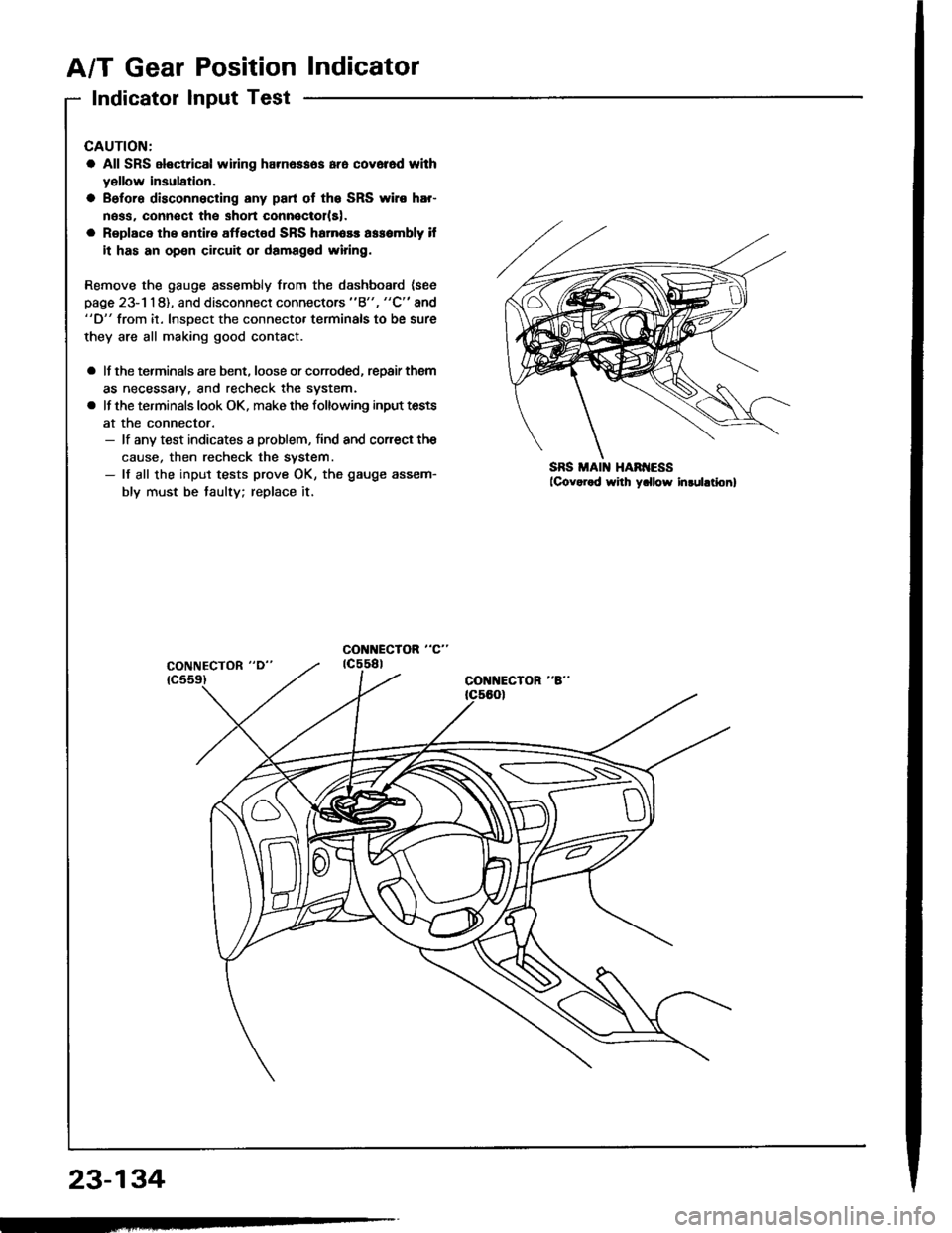

A/T Gear Position Indicator

Indicator Input Test

CAUTION:

a All SRS electrical widng harn6ssos ara cov6r6d whh

yellow insulation.

a Before disconnecting any part ot the SRS wiro hEr-

ness. connect the shon connoctolls).

a Replace the entire affectod SRS harnosr assombly il

it has an op€n circuit or damaged wiring.

Remove the gauge assembly from the dashboard (see

page 23- l 1 8), and disconnect connectors "8", "C" and"D" from it. lnsoect the connecto. terminals to be sure

they are all making good contact.

a lf the terminals are bent. loose or corroded, repair them

as necessary, and recheck the system.

a lf the terminals look OK, make the following input tests

at the connector.- lf any test indicates a problem, find and corect the

cause, then recheck the system.- lf all the input tests prove OK, the gauge assem-

bly must be taulty; replace it.

CONI{ECTOR "8"

SS

23-134

Page 1242 of 1413

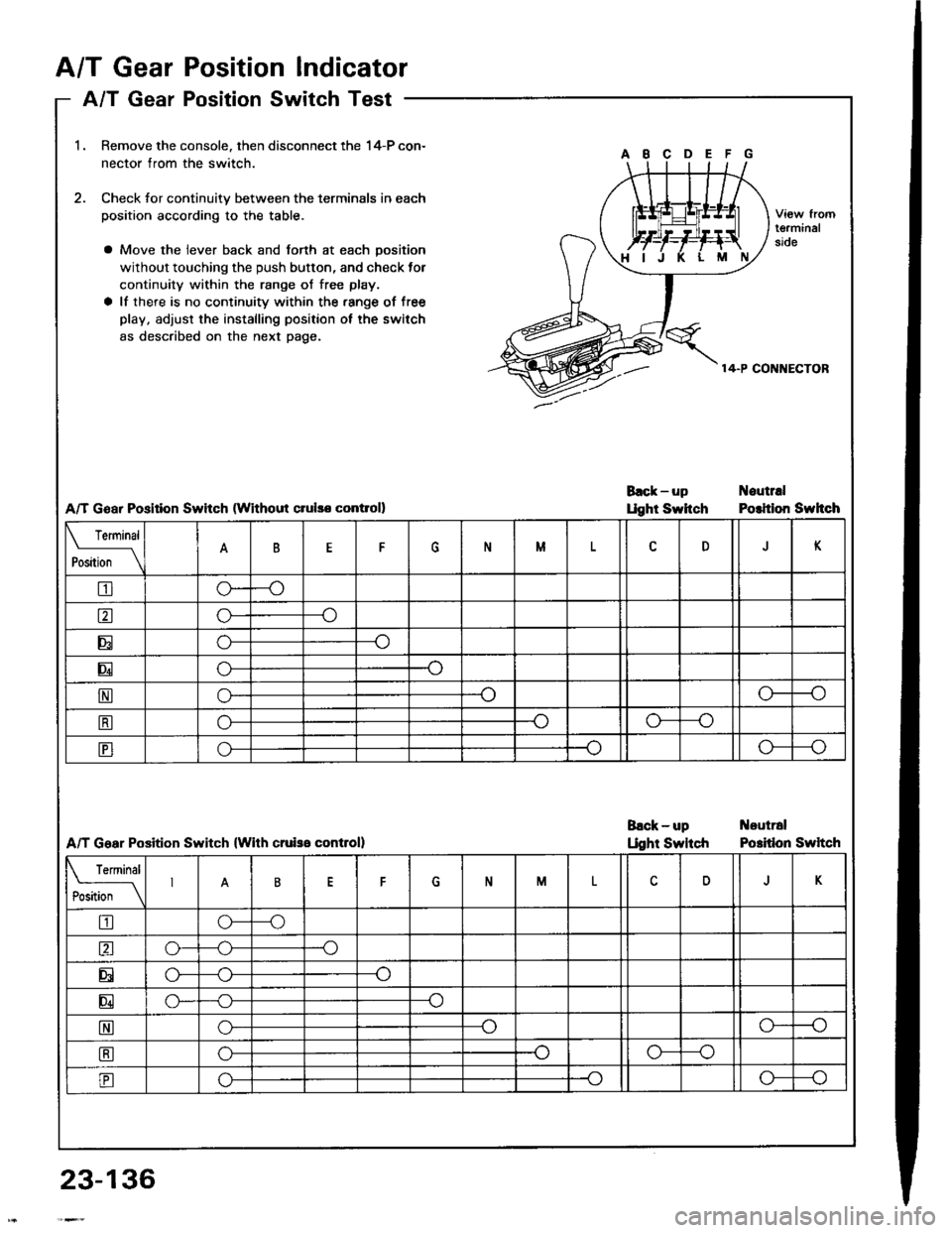

A/T GearPosition Indicator

A/T GeaPosition Switch Test

23-136

1.

2.

I I gear Fosluon Dwtrcn I esr -

Remove the console. then disconnect the 14-P con-

nector from the switch.

Check for continuitv between the terminals in each

position according to the table.

a Move the lever back and forth at each position

without touching the push button, and check tor

continuity within the range of free play.

a lf there is no continuity within the.ange of free

play, adjust the installing position ol the switch

as described on the next page.

A/T Goar Position Swhch (Without crulso contloll

A/T Goar Position Switch (With cruiss controll

tgrminal90e

14-P CONI{ECTOR

Back-up Noutrrl

Ught Swhch Polition Swhch

Back-up t{outral

Llght Swltch Potidon Swltch

Terminal

P*ii-_\BFNMDK

tro-

ao---o

Eo---o

Eo-

No--.oo-

tro--oo---o

tro---oo---o

Terminal

P*,i-

_\6NMDJK

tro---o

ao---.o

Eo---o

E--o

EG_o-

Eo-o---o

Eo---oo---o

Page 1250 of 1413

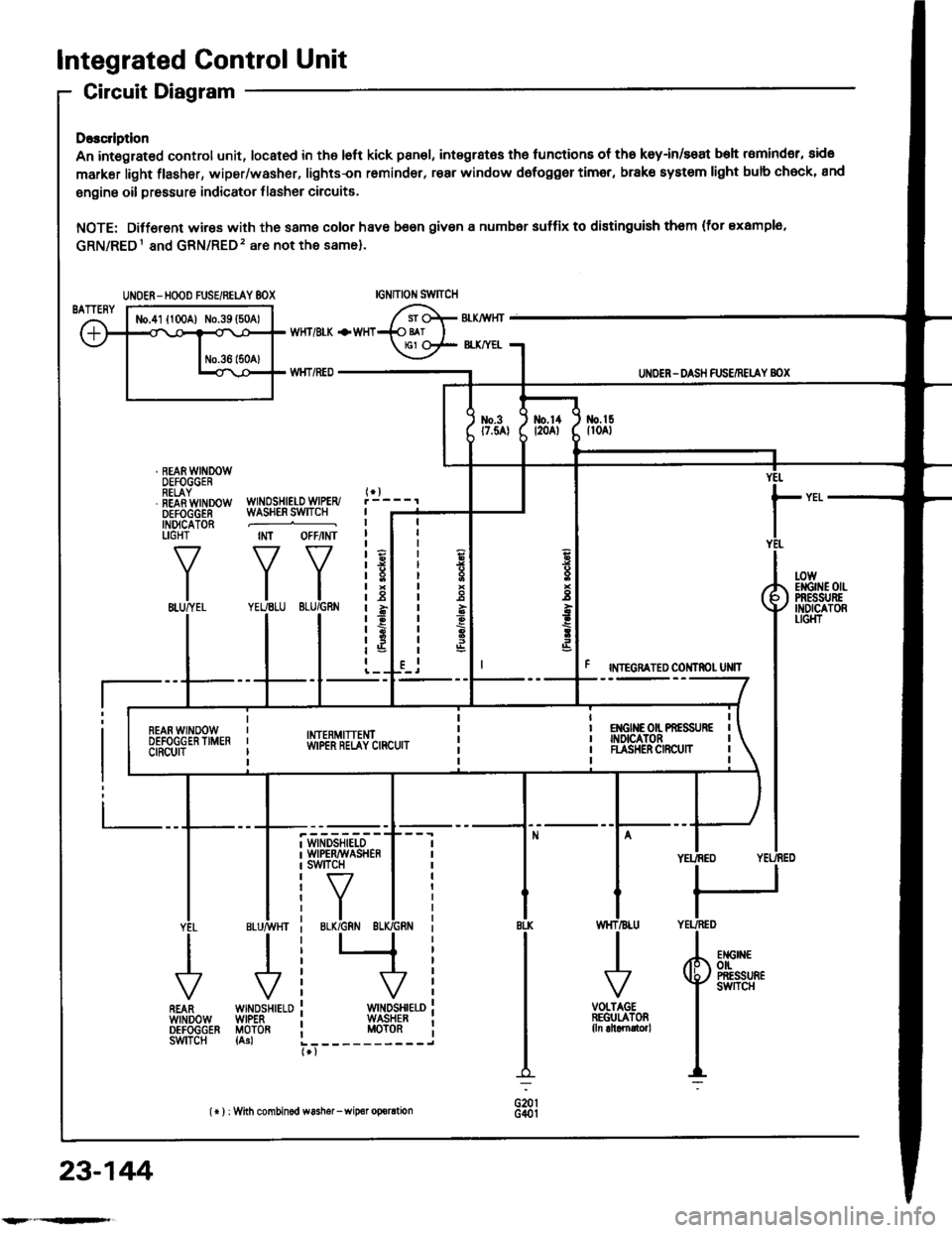

Integrated Control Unit

Circuit Diagram

D.3c ptlon

An integrat€d control unit, located in the left kick panel, integratss the functions of tho keyin/seat beh r6mind€r, sido

markar light {lasher, wiper/washer, lights-on r6minder, rear window dsfogger timer, brak€ system light bulb check, and

enging oil pressure indicator flasher circuitE,

NOTE: Difforent wires with the same color have be6n given a numbor suffix to distinguish them (for Example,

GRN/RED1 and GRN/RED'� are not the same).

WNOSHIELD WIPER/WASHER SWITCH

IMT OFFiINT

I

II

IIIIIIIIIIII

YEUEE

rl

t

P

UNOER - DASH FUS€/RETAY BOX

r NTEGRATED COI{TROI UNIT

t-0wErGrilE 0|lPRESSI'REINDICATORLIGI{T

WINDSHIELOWIPERAVASHERswtTcH

tr-/

IBLK/GRN BI

WINDSHIELOWIPERMOTOR{Asl

VOLTAGEREGULATOR{ln ahamator,

UNOER- HOOD FUSE/RELAY 8OX

I

r3

r8relit;rBt5I

23-144

lr ) : With combinod washef-wip€r oporation

Page 1254 of 1413

Integrated Control Unit

Input Test (cont'd)

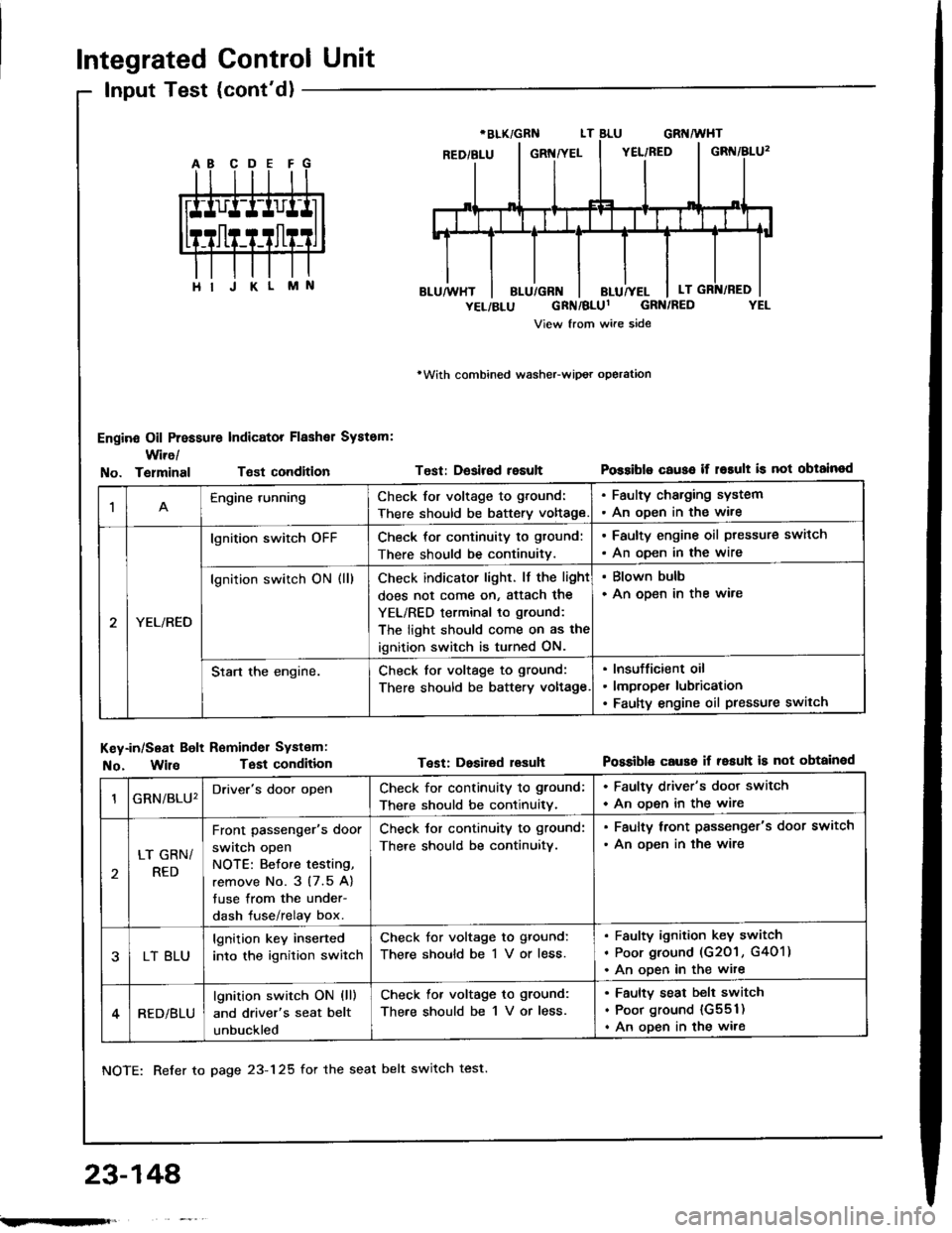

Engine Oil Pressure Indicator Flashal System:

Wire/

rWith combined washeFwipot operation

Test: Desired resultPossiblo c€use if r6rult is not obtainodNo. TelminalTsst condition

M

1Engine runningCheck for voltage to ground:

There should be battery voltage

. Faulty charging system. An oDen in the wire

YEL/RED

lgnition switch oFFCheck for continuity to gtound:

There should be continuitv.

. Faulty engine oil ptessure switch

. An oDen in the wire

lgnition switch ON (ll)Check indicator light. lf the light

does not come on, Sttach the

YEL/RED terminal to ground:

The light should come on as the

ignition switch is turned ON.

. Blown bulb. An open in the ware

Start the engine.Check for voltage to ground:

There should be battery voltage

Insufficient oil

lmproper lubrication

Faulty engine oil pressure switch

Key-in/Seat Bolt Reminder Systam:

No. WilaTest condition

NOTE: Refer to page 23-125 for the seat belt switch test.

Test: Dosired lesuhPossible causo if resuh is not obtainod

23-148'

GRN/BLU'Driver's door openCheck for continuity to ground;

There should be continuitv.

. Faulty driver's door switch

. An ooen in the wire

LT GRN/

RED

Front passenger's door

switch open

NOTE: Betore testing,

remove No. 3 (7.5 A)

tuse from the under-

dash fuse/relay box.

Check tor continuity to ground:

There should be continuitv.

. Faulty lront passenger's door switch

. An ooen in the wire

LT BLU

lgnition key inserted

into the ignition switch

Check for voltage to ground:

There should be 1 V or less.

Faulty ignition key switch

Poor ground (G201 , G401)

An ooen in the wite

RED/BLU

lgnition switch ON (ll)

and driver's seat belt

unbuckled

Check lor voltage to ground:

There should be 1 V or less.

Faulty seat belt switch

Poor ground {G551)

An open in the wire

;.rqFft,

Page 1257 of 1413

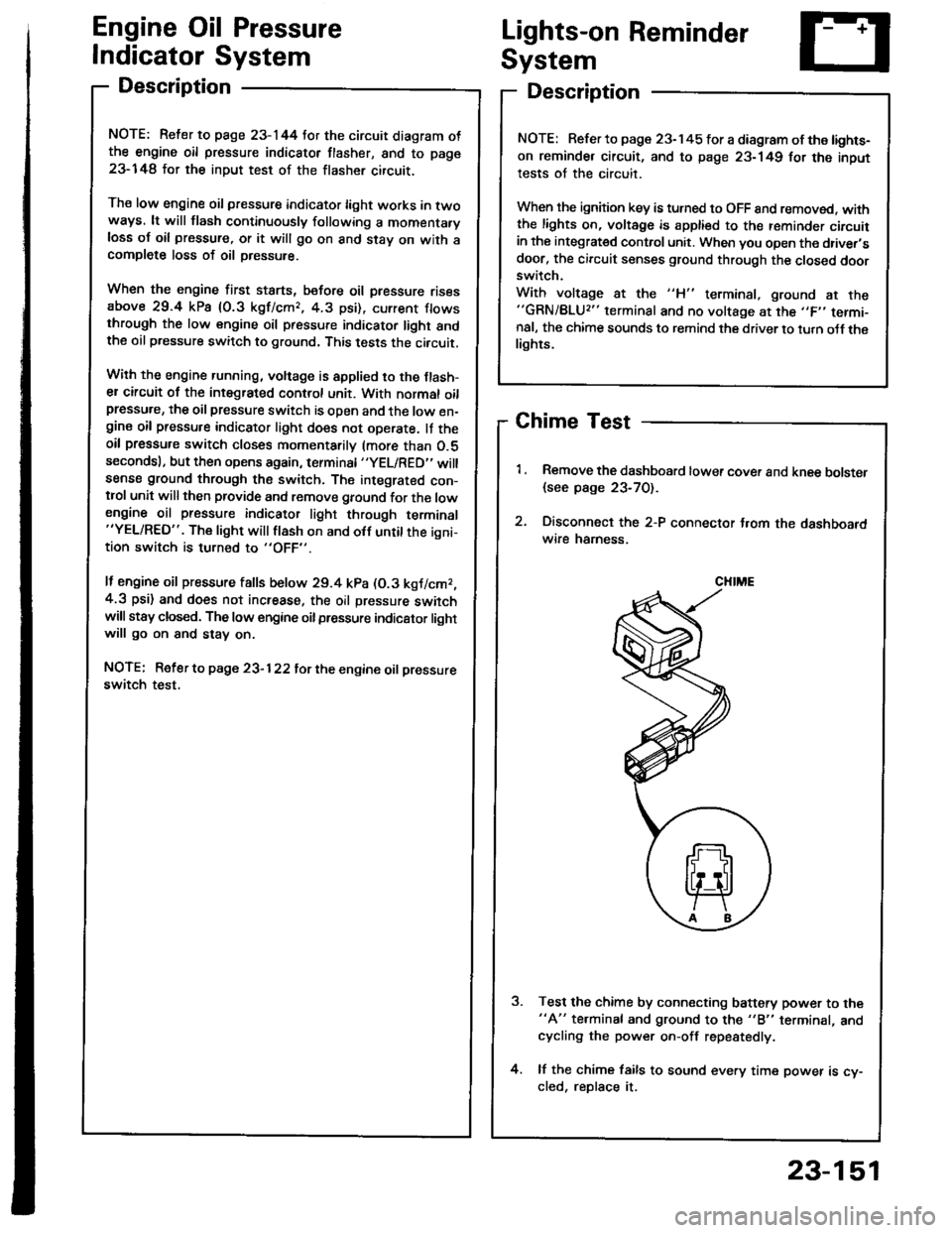

Engine Oil Pressure

Indicator System

Description

NOTE: Reter to page 23-144 tor the circuit diagram otthe engine oil pressure indicator flasher, snd to page

23-148 lor the input test of the flasher circuit.

The low engine oil pressure indicator tight works in twoways. lt will flash continuously following a momentaryloss of oil pressure, or it will go on and stay on with acomplete loss of oil pressure.

When the engine first starts, before oil Dressure risesabove 29.4 kP8 10.3 kgf/cmr, 4.3 psi), current flowsthrough the low engine oil pressure indicator light andthe oil pressure switch to ground. This tests the circuit.

Wilh the engine running, voltage is applied ro the ftash-er circuit of the integrated control unit. With normal oilpressure, the oil pressure switch is open and the low en-gine oil pressure indicator light does not operate. lf theoil pressure switch closes momentarily (more than O.5secondsl, but then opens again, terminal "yEL/RED,'will

sense ground through the switch. The integrated con-trol unit willthen provide and remove ground for th€ lowengine oil pressure indicator light through terminal"YEL/RED". The light will flash on and olf until the igni-tion switch is turned to "OFF".

lf engine oil pressure falls below 29.4 kPa (O.3 kgJ/cmr,4.3 psi) and does not increase, the oil pressure switchwillstsy closed. The low engine oilpressure indicator lightwill go on and stav on.

NOTE; Refer to page 23-122lot the engine oil pressure

switch test.

Lights-on Reminder

System

Description

Chime Test

Remove the dashboard lower cover and knee bolster

{see page 23-70).

Disconnect the 2-P connector t.om the dashboardwire hamess.

Test the chime by connecting battery power to the"A" te.minal and ground to the "B" terminal, andcycling the power on-off repestedly.

lf the chime fails to sound every time power is cy-cled, reDlace it.

NOTE: Refer to page 23-145 tor a diagram of the lights-

on reminder circuit, and to page 23-149 for the input

tests of the circuit.

When the ignition key is turned to OFF 8nd removed. withthe lights on, voltage is apptied to the reminder circuitin the integrat€d control unit. When you open the driver,sdoor, the circuit senses ground through the closed doorswitch.

With voltage at the "H" terminal, ground at the"GRN/BLU2" terminal and no voltage at the ,,F,' termi-nal, the chime sounds to remind the driver to turn oJf thelights.

CHIME

23-151

Page 1258 of 1413

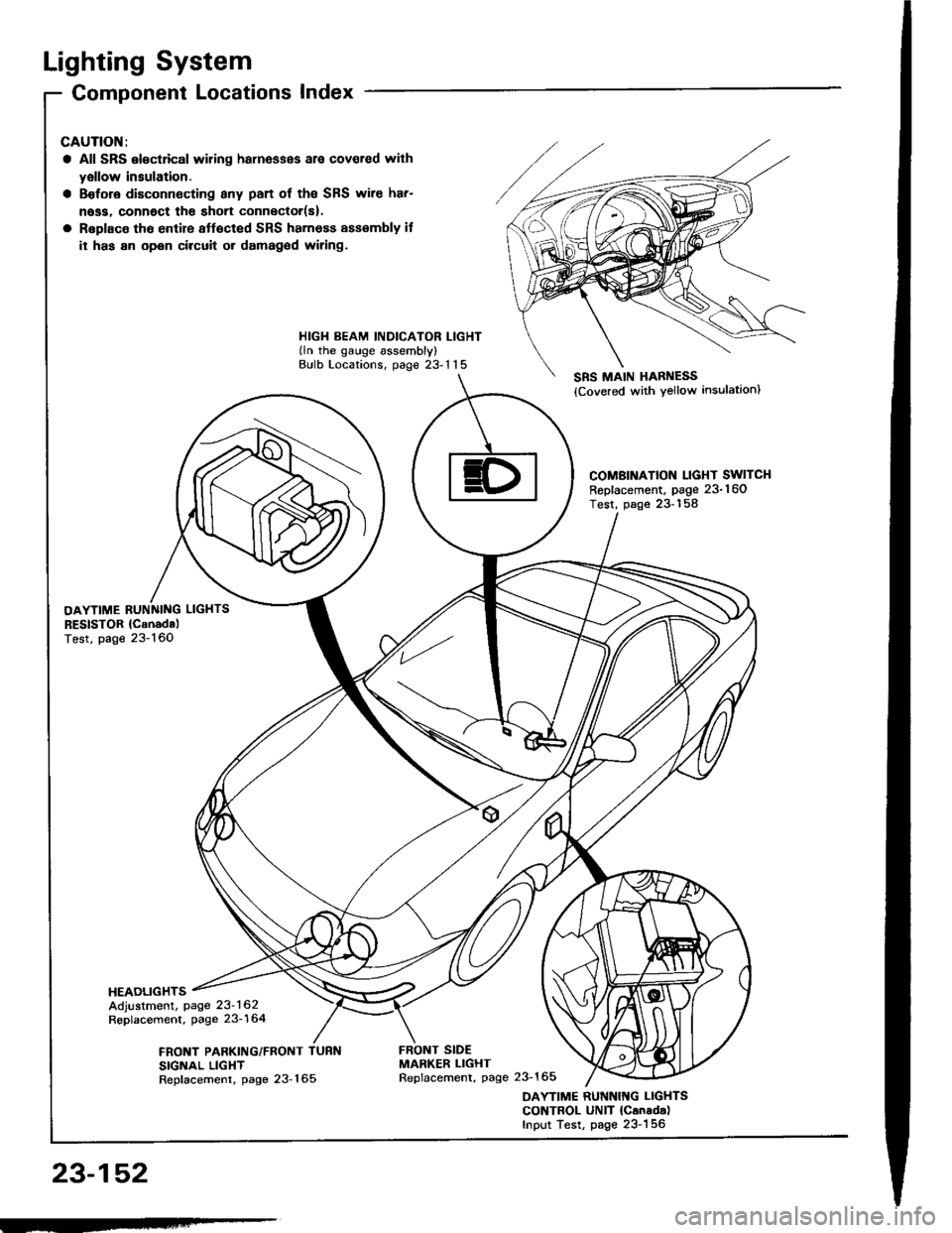

Lighting System

OAYTIMERESISTOR lC.nodalTest, page 23-160

HEAOLIGHTSAdjustment, page 23-162Replacement, page 23-164

Component Locations Index

All SRS el€ctrical wiring harnesses ale covered with

yallow insulation.

B€fore disconnocting any pan of th€ SBS wire har-

ness, connect the short connactor(sl.

Replac€ th6 entire affocted SRS harness assembly it

it has an open circuit or damagod wiring.

HIGI{ BEAM INDICATOR LIGHT(ln the gauge assembly)Bulb Locations, page 23-1 15

COMBINATION LIGHT SWITCHReplacement, page 23-160Test, page 23- l58

FRONT PARKING/FRONT TURNSIGNAL LIGHTReplacement, page 23-165

FRONT SIDEMARKER LIGHTReplacement, page 23-165

DAYTIME RUNNIT{G LIGHTSCONTROL UNIT {C6nada)Input Test, page 23-156

23-152

-

Page 1263 of 1413

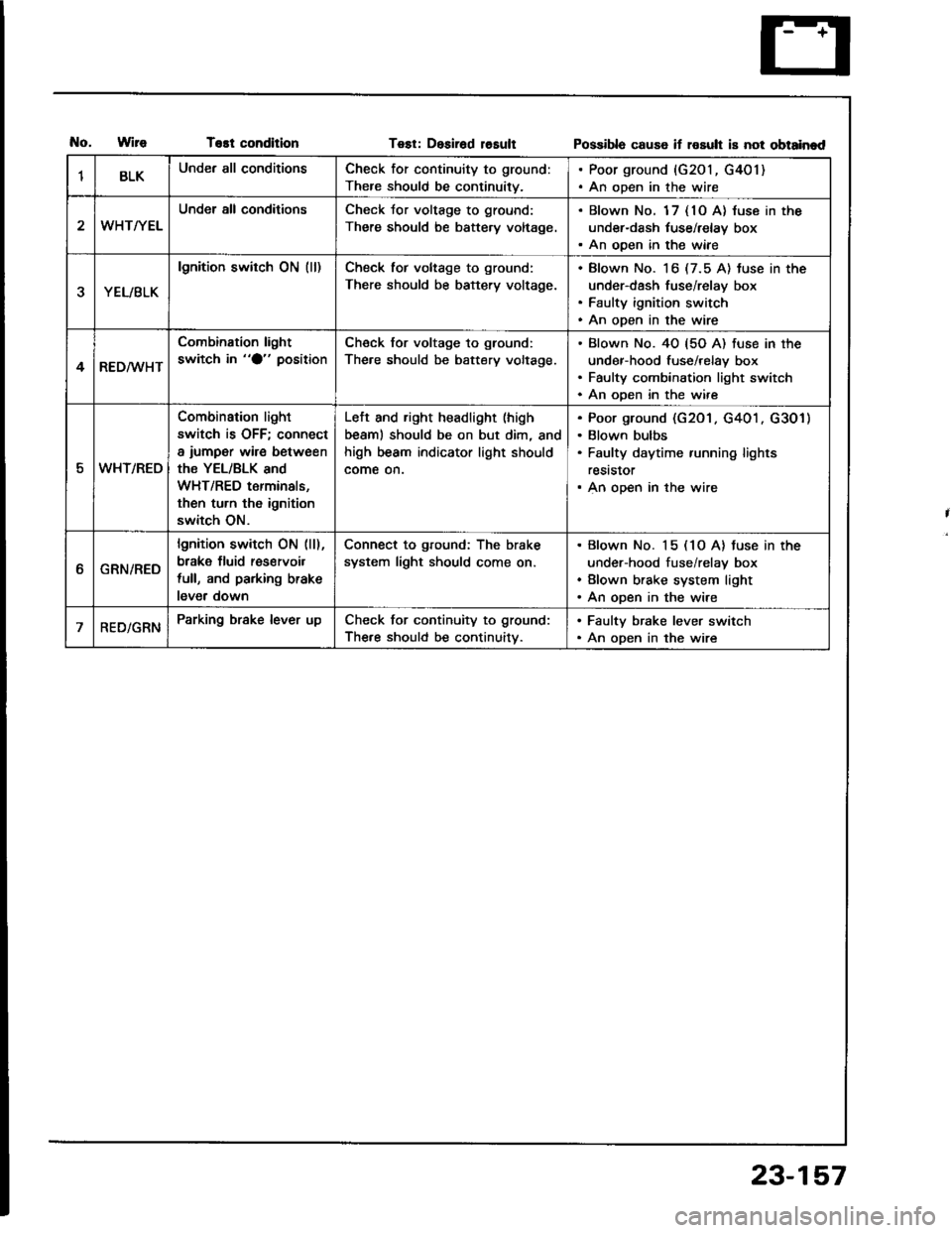

T€st conditionTest: Desirad losultPossibla cause if rosult is not obtainad

1BLKUnder all conditionsCheck for continuity to ground:

There should be continuity.

. Poor ground {G201, G401). An open in the wire

WHT/YEL

Under all conditionsCheck Jor voltage to ground:

There should be battery voltage.

. Blown No. 1 7 { 10 A} luse in the

under-dash tuse/relay box. An ooen in the wiae

YEL/BLK

lgnition switch ON (ll)Check tor voltage to ground:

There should be battery voltage.

Blown No. 16 (7.5 A) tuse in the

under-dash fuse/relay box

Faulty ignition switch

An open in the wire

4RED/WHT

Combination light

switch in "O" positionCheck for voltage to ground:

The.e should be battery voltage.

Blown No. 40 {5O A) fuse in the

under-hood fuse/relay box

Faulty combination light switch

An ooen in the wire

5WHT/REO

Combination light

switch is OFF; connect

a iumper wire between

the YEL/BLK and

WHT/RED terminals,

then turn th6 ignition

switch ON.

Left and right headlight (high

beaml should be on but dim, and

high beam indicator light should

come on.

Poor ground (G201 . G401 . G301)

Blown bulbs

Faulty daytime running lights

reststor

An open in the wire

ttGRN/RED

lgnition switch ON (ll),

brake fluid res€rvoil

full, and parking brake

lever down

Connect to ground: The brake

system light should come on.

Blown No. 15 (1O A) tuse in the

under-hood fuse/relay box

Blown brake system light

An open in the wire

RED/GRNParking brake lever upCheck for continuity to ground:

The.e should be continuitv.

. Faulty brake lever switch. An open in the wire

23-157

Page 1268 of 1413

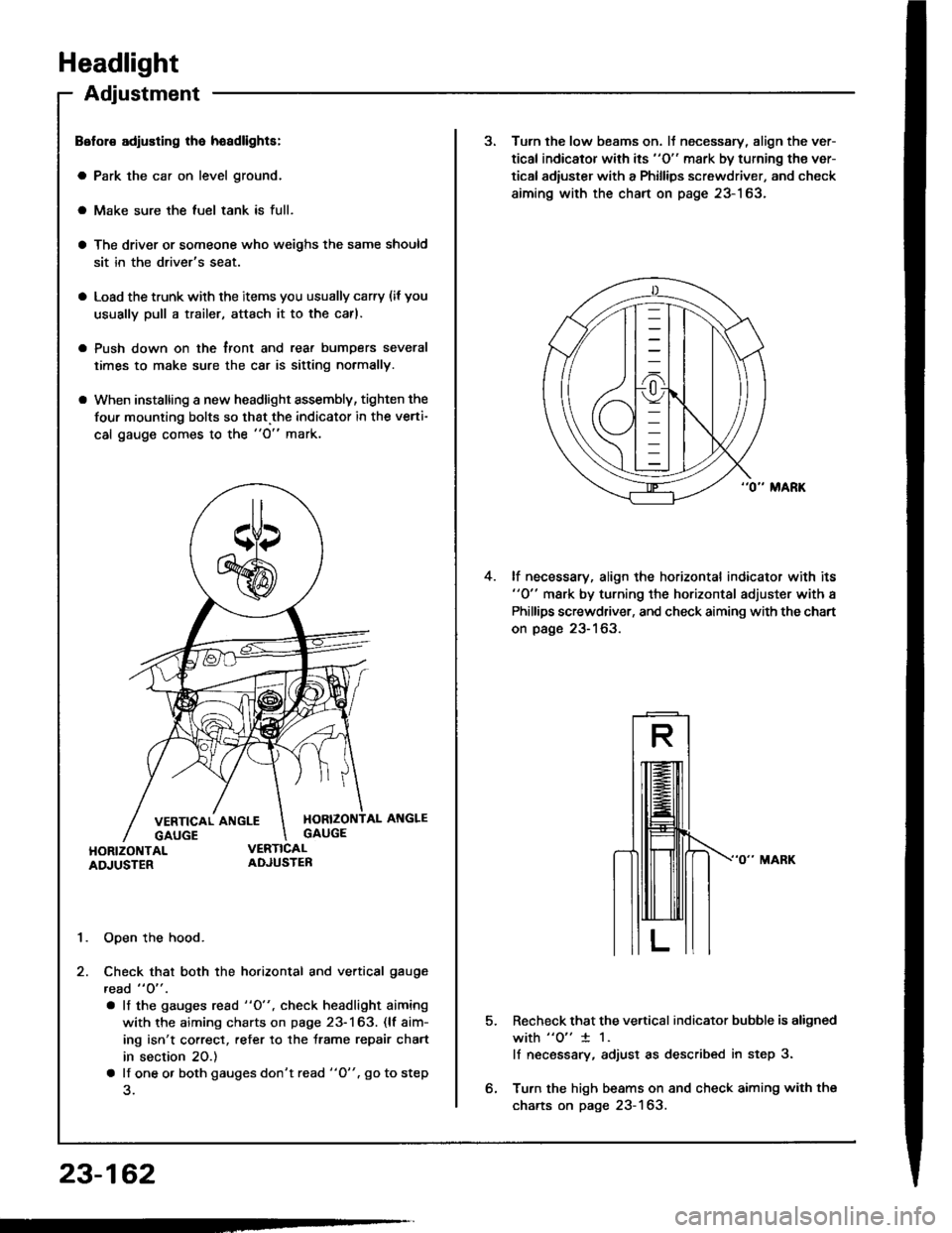

Headlight

Adjustment

Belol€ adiusting lha hoadlights:

a Park the car on level ground.

a Make sure the luel tank is full.

a The driver or someone who weighs the same should

sit in the driver's seat.

a Load the trunk with the items you usually carry (if you

usually pull a trailer, attach it to the carl.

a Push down on the tront and rear bumDers several

times to make sure the car is sitting normally.

a When installing a new headlight assembly, tighten the

four mounting bolts so that.the indicator in the verti-

cal gauge comes to the "O" mark.

1. Open the hood.

2. Check that both the horizontal and vertical gauge

read " O" .

. lf the gauges rcad "O", check headlight aiming

with the aiming charts on page 23-163. (lf aim-

ing isn't correct, refer to the trame repair chart

in section 20.)

a lf one o. both gauges don't read "O". go to step

23-162

3. Turn the low beams on. lJ necessary, align the ver-

tical indicator with its "O" mark by turning the ver-

tical adiuster with a Phillips screwdriver, and check

aiming with the chart on page 23-163.

lf necessary, align the horizontal indicator with its"0" mark by turning the horizontal adjuster with a

Phillips screwdriver, and check aiming with the chart

on page 23-163.

4.

5.Recheck that the vertical indicator bubble is aligned

with "o" 1 1.

lf necsssary, adjust as described in step 3.

Turn the high beams on and check aiming with the

charts on page 23-163.

Page 1290 of 1413

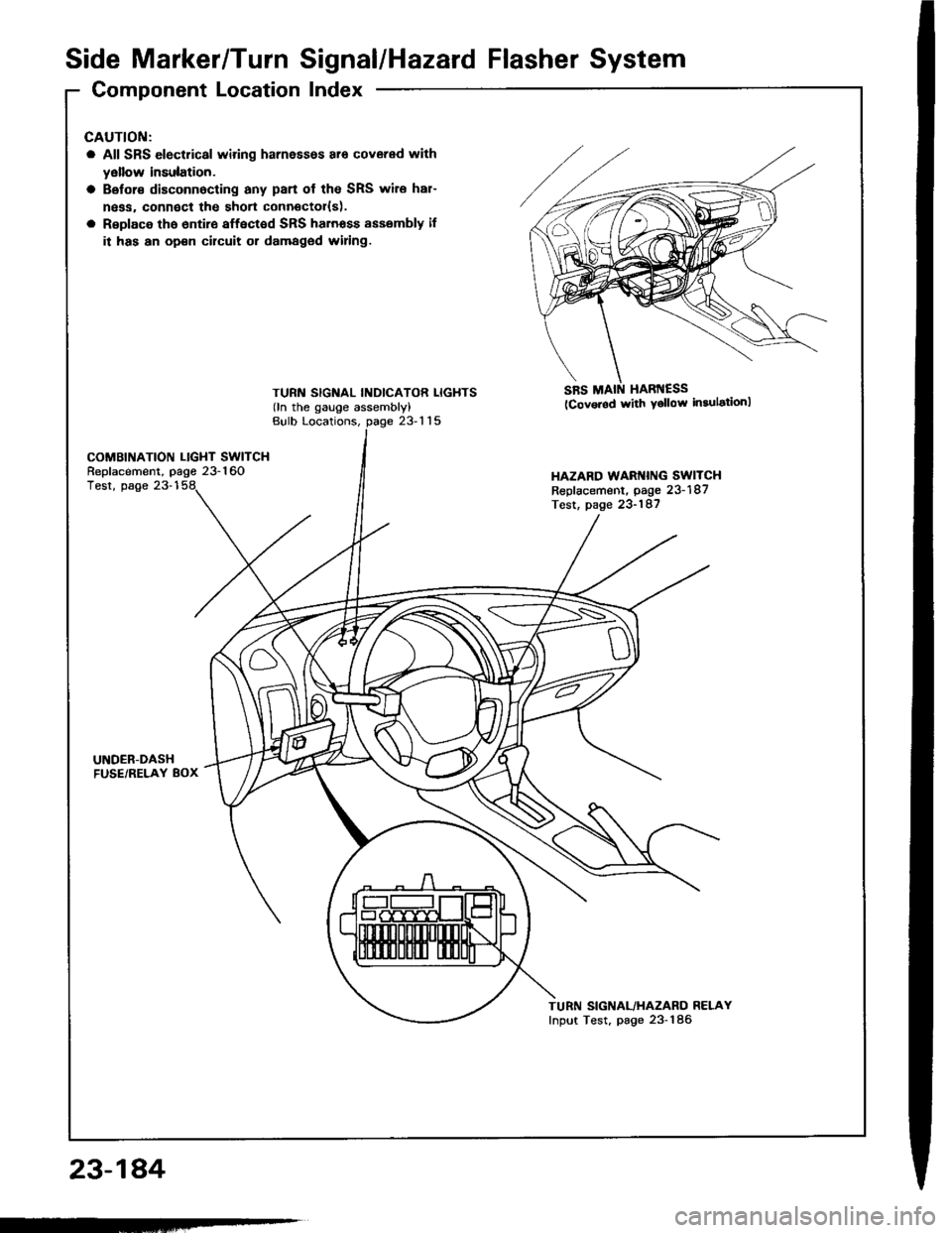

Side Marker/TurnSignal/Hazard Flasher System

Component LocationIndex

23-184

GAUTION:

a All SRS electrical wiring harnessos ar6 covered with

yellow insulation.

a Belor€ disconnocting any pan of the SRS wire har-

ngss, connoct the short connector{s).

a Rsplace tho 6ntir€ affect€d SRS harnoss sssembly il

it has an op€n cilcuit or damaged widng.

TURN SIGNAL INDICATOR LIGHTS(ln the gauge assembly)

SRS MAIN HARI{ESS(Cov.rod with Ysllow in3ulationl

Bulb Locations,23-115

COMBINATION LIGHT SWITCHReplacement, page 23-160HAZARD WARI{ING SWITCHReplacement, page 23-187Test, page 23-187

Test, page 23-1

UNDER-DASHFUSE/RELAY 8OX

TURN SIGNAL/HAZARO RELAYInput Test, page 23-186

-