boot HONDA INTEGRA 1998 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 636 of 1681

Disassembly

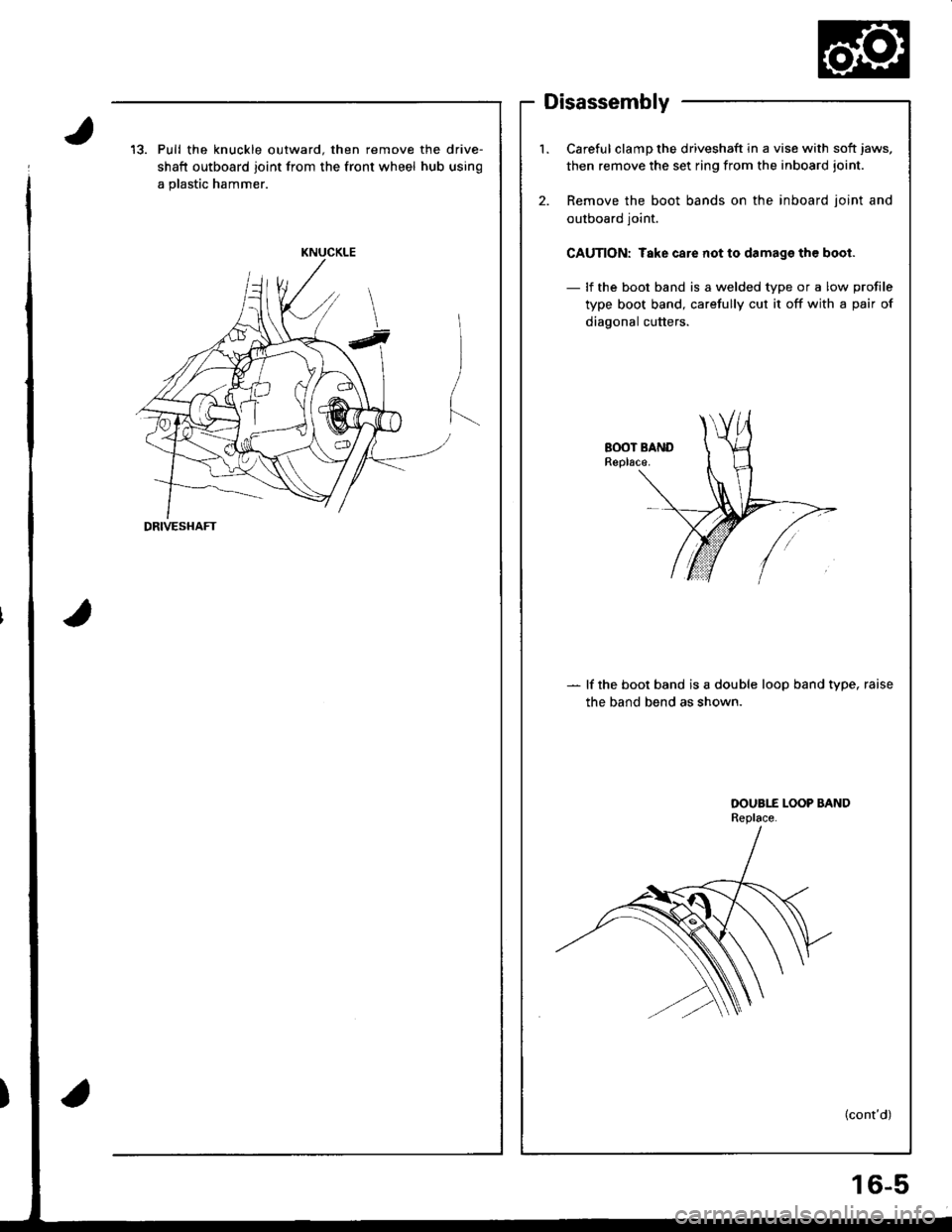

13. Pull the knuckle outward. then remove the drive-

shaft outboard joint from the front wheel hub using

a plastic hammer.

KNUCKLE

DRIVESHAFT

l.Careful clamp the driveshaft in a vise with soft jaws,

then remove the set ring from the inboard joint.

Remove the boot bands on the inboard ioint and

outboard joint.

CAUTION: Take care not to damags th€ boot.

- lf the boot band is a welded type or a low profile

type boot band, carefully cut it off with a pair of

diagonal cutters.

2.

- lf the boot band is a double loop band type, raise

the band bend as shown.

OOUBI-E LOOP BANDReplace.

(cont'd)

16-5

Page 637 of 1681

Driveshafts

Removal lcont'd)

- lf the boot band is an ear clamp

board joint on the Canada mode

tabs with a screwdriver.

type {for out-

raise the three

EAR CLAMP BAND

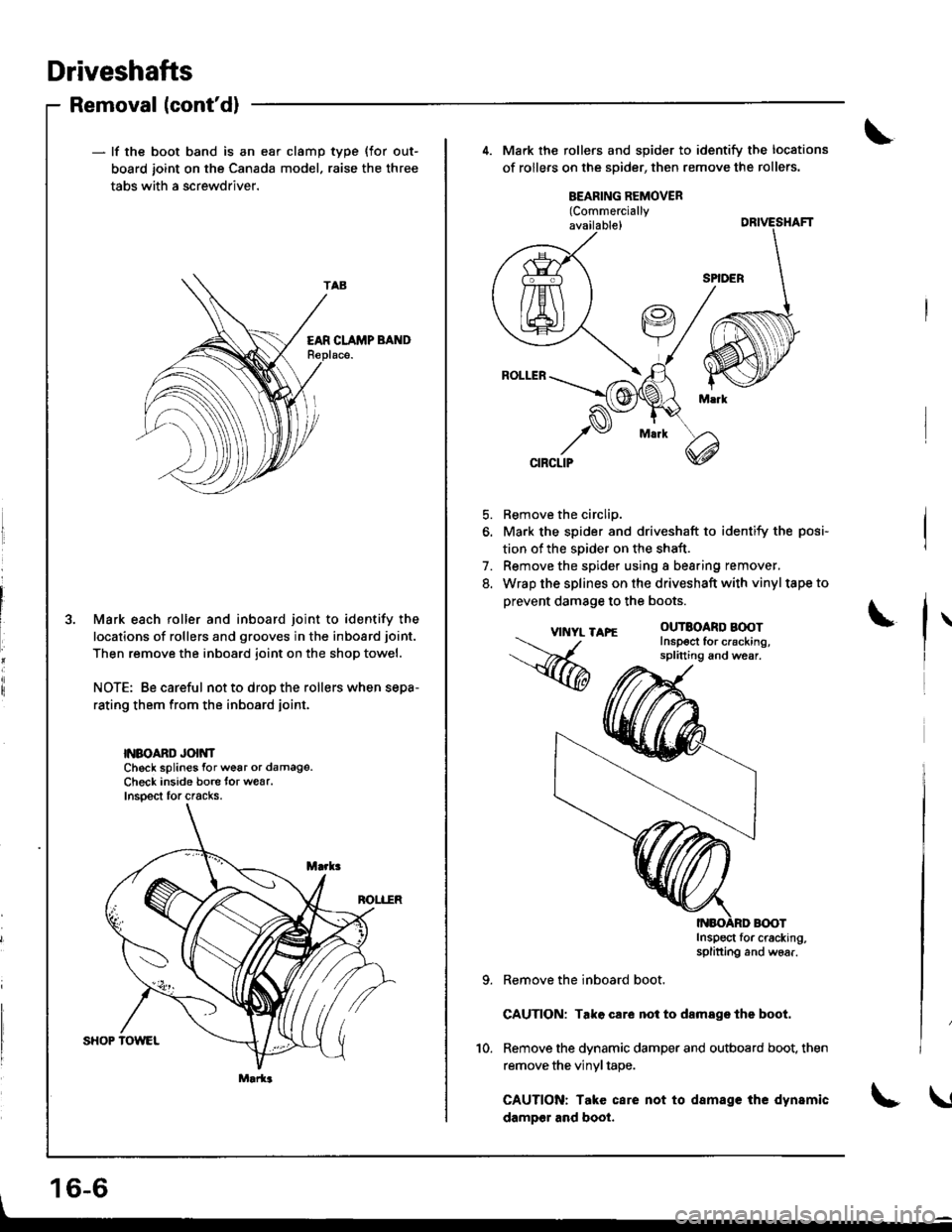

3. Mark each roller and inboard joint to identify the

locations of rollers and grooves in the inboard joint.

Then remove the inboard joint on the shop towel.

NOTE: Be careful not to drop the rollers when sepa-

rating them from the inboard joint.

NBOAND Jo|NNCheck splines for wear or damage.Check inside bore lor wear.lnsoect for cracks.

Marla

4. Mark the rollers and spider to identify the locations

of rollers on the spider, then remove the rollers.

VI'{YL T

,%

BEARING REMOVER(Commercially

available)

5. Remove the circlip.

6. Mark the spider and driveshaft to identify the posi-

tion of the soider on the shaft.

7. Remove the spider using a bearing remover,

8. Wrap the splines on the driveshaft with vinyltape to

prevent damage to the boots.

APE ouTBoaRD BOOTInsp€ct ror crackrng,splitting and wear.

Inspect for cracking,splitting and woar.

Remove the inboard boot.

GAUTION: Tako care noi to damsge the boot.

Remove the dynamic damper and outboard boot. then

remove the vinyl tape.

CAUTION: Take care not to damage the dynamic

dampor and boot.

10.

16-6

\

Page 639 of 1681

Driveshafts

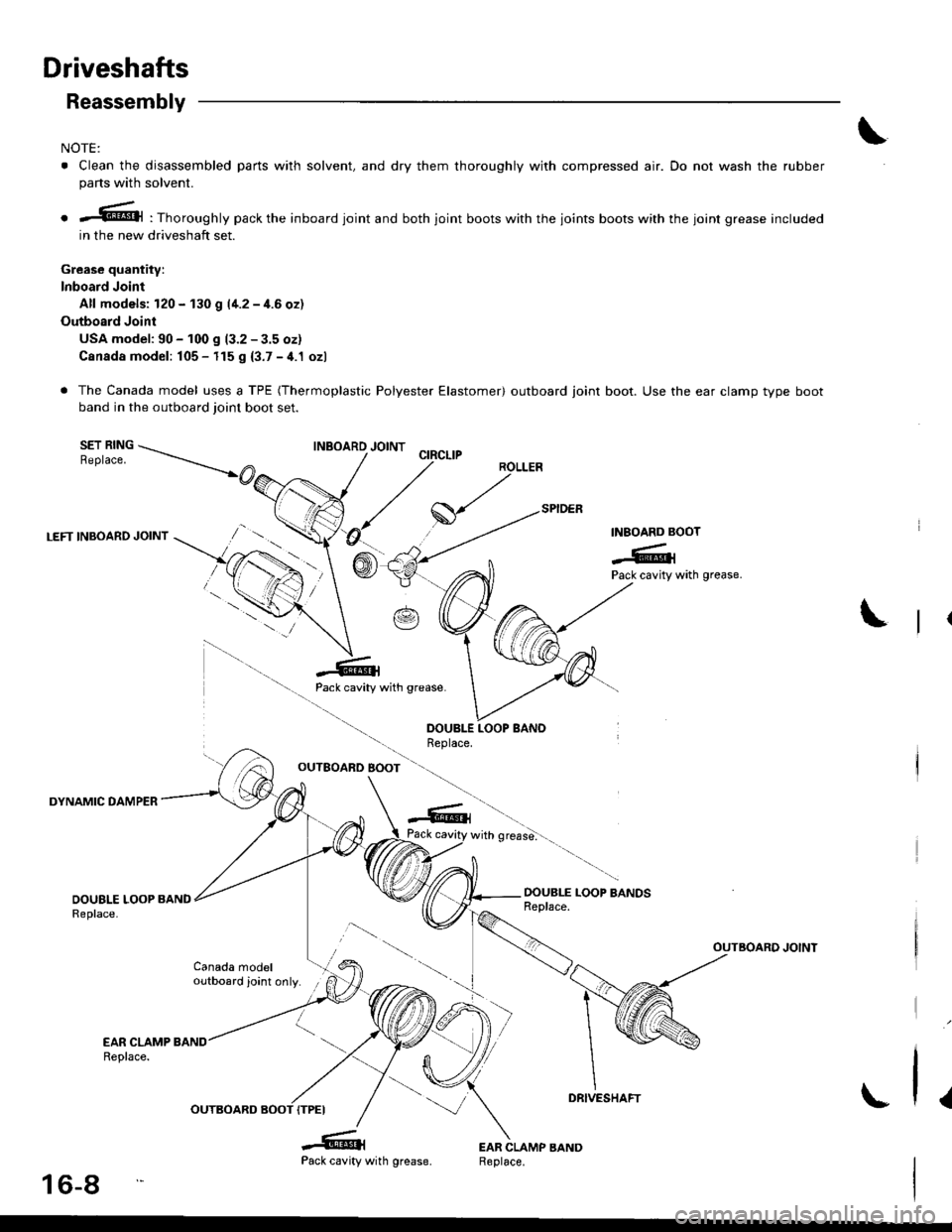

LEFT INBOARD JOINT

DYNAMIC DAMPER

Reassembly

NOTE:

. Clean the disassembled parts with solvent, and dry them thoroughly with compressed air. Do not wash the rubber

parts with solvent.

o -@l : Thoroughly pack the inboard joint and both joint boots with the joints boots with the joint grease included

in the new driveshaft set.

Grease quantity:

lnboard Joint

Alf models: 120 - 130 g l1-2 - 1.6 ozl

Outboard Joint

USA model: 90 - 100 S 13.2 - 3.5 oz)

Canada model: 105 - 115 g {3.7 - 4.1 ozl

. The Canada model uses a TPE (Thermoplastic Polyester Elastomer) outboard joint boot. Use the ear clamp type boot

band in the outboard joint boot set.

SET RINGReplace.

INBOARD BOOT

-#,1Pack cavity with grease.

Pack cavity with grease.

OUTEOARD BOOT

with grease''

OOUBLE LOOP BANDSReplace.

OUTBOARD JOINT

Canada modeloutboard joint only.

l.

-6{Pack cavity

INBOARD JOINT

DRIVESHAFT

16-8

OUTBOARD

wrln grease,

Page 640 of 1681

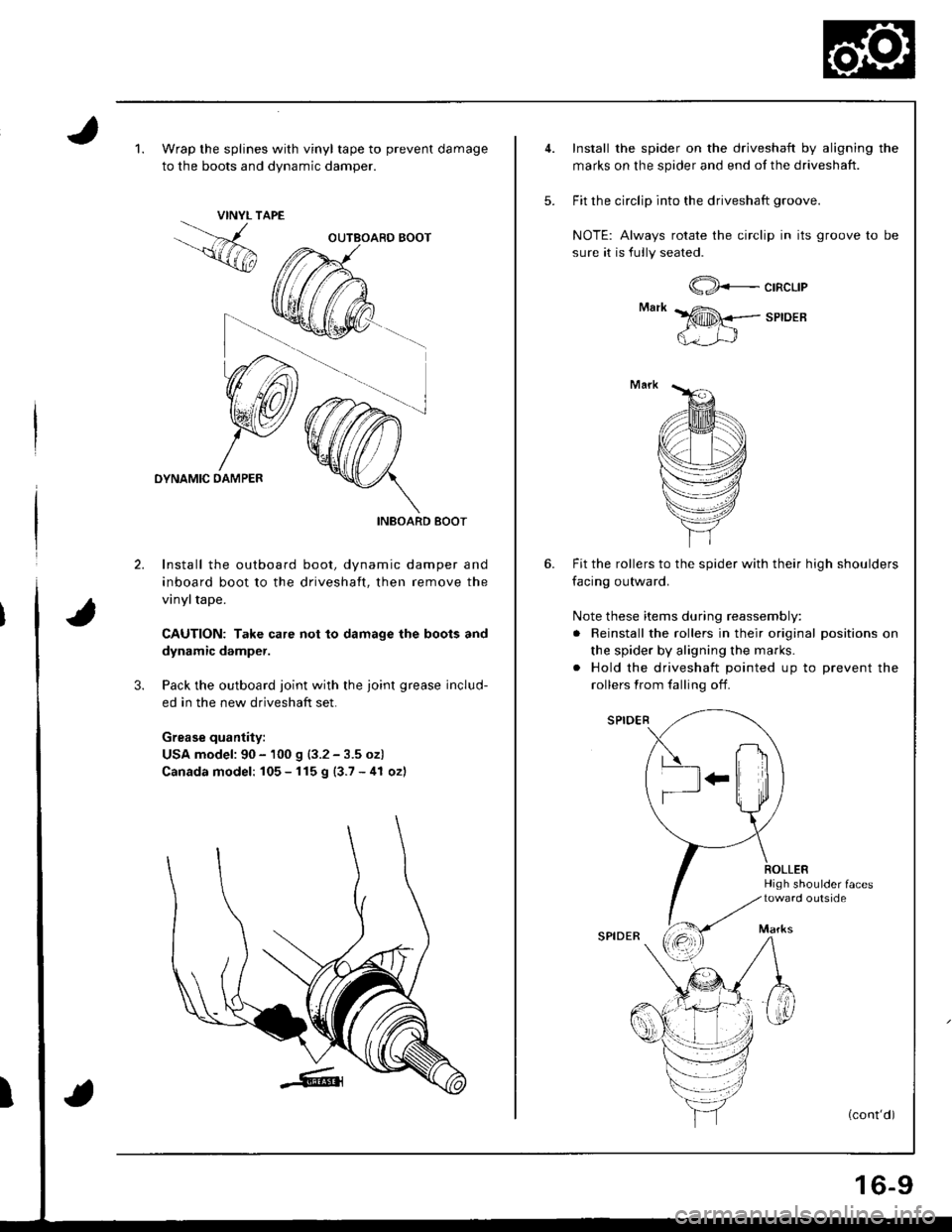

1.Wrap the splines with vinyl tape to prevent damage

to the boots and dvnamic damoer.

VINYL TAPE

OYNAMIC DAMPER

INBOARD BOOT

2. Install the outboard boot, dynamic damper and

inboard boot to the driveshaft, then remove the

vinyltape.

CAUTION: Take care not to damage the boots and

dynamic damper.

3. Pack the outboard joint with the joint grease includ-

ed in the new driveshaft set.

Grease quantily:

USA model: 90 - 100 g (3.2 - 3.5 oz)

Canada model: 105 - 115 g (3.7 - 41 oz)

I

5.

Install the spider on the driveshaft by aligning the

marks on the spider and end of the driveshaft.

Fit the circlip into the driveshaft groove.

NOTE: Always rotate the circlip in its groove to be

sure it is fully seated.

@*c'nc'-'t

SPIDEB

6. Fit the rollers to the spider with their high shoulders

facing outward.

Note these items during reassembly:

. Reinstall the rollers in their original positions on

the spider by aligning the marks.

. Hold the driveshaft pointed up to prevent the

rollers from falling off.

High shoulder {aces

Marks

(cont'd)

SPIOER

16-9

Page 641 of 1681

Driveshafts

Reassembly (cont'd)

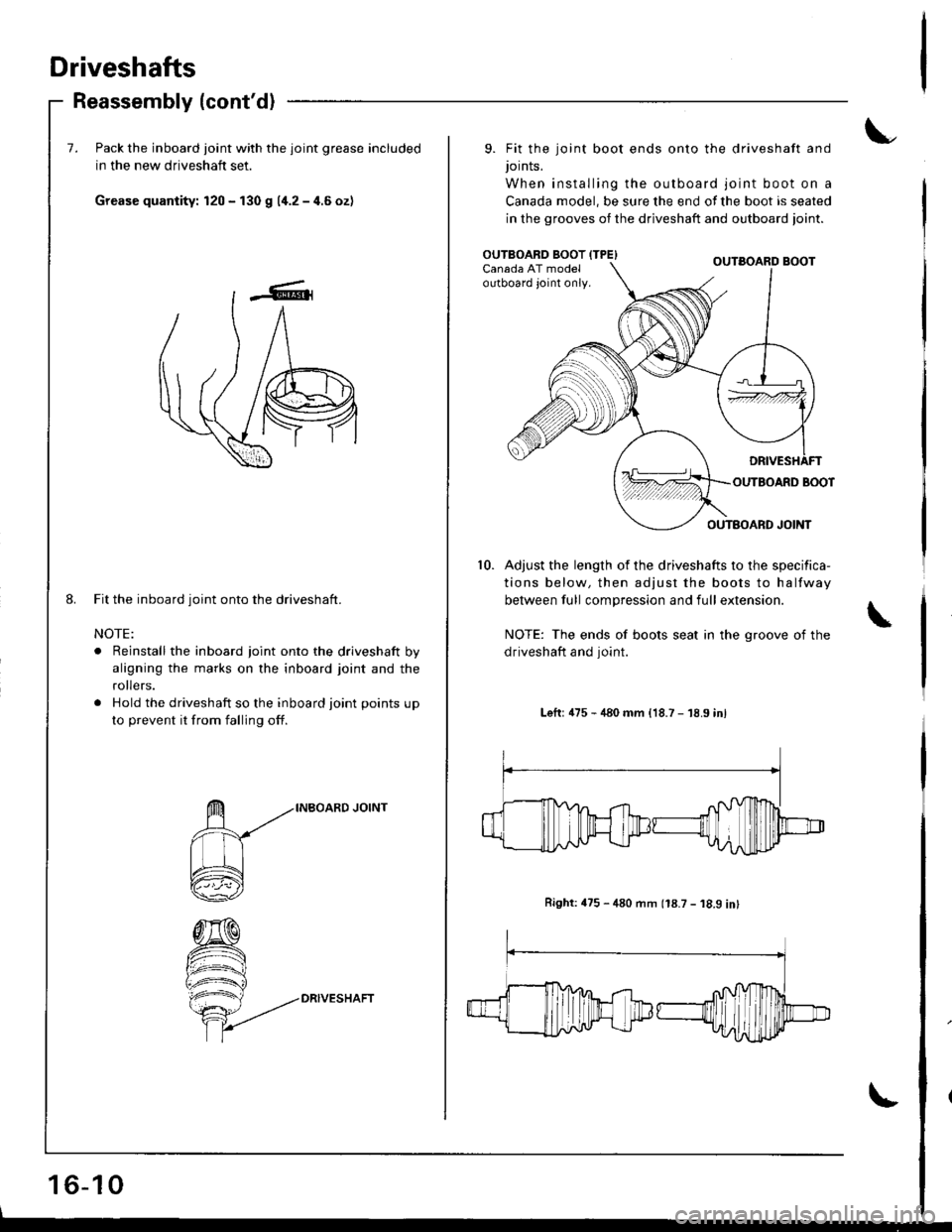

7. Pack the inboard joint with the joint grease included

in the new driveshaft set.

Grease quantity: 120 - f30 g 11.2-4.6ozl

Fit the inboard joint onto the driveshaft.

NOTE:

. Reinstall the inboard joint onto the driveshaft by

aligning the marks on the inboard joint and the

ro ers.

. Hold the driveshaft so the inboard joint points up

to p.event it from falling off.

DRIVESHAFT

16-10

8.

9. Fit the joint boot ends onto the driveshaft and

Jornts.

When installing the outboard joint boot on a

Canada model, be sure the end of the boot is seated

in the grooves of the driveshaft and outboard ioint.

Adjust the length of the driveshafts to the specifica-

tions below, then adjust the boots to halfway

between full compression and full extension.

NOTE: The ends of boots seat in the groove of the

driveshaft and joint.

Lefr: 475 - 480 mm {18.7 - 18.9 inl

Right:475 - 480 rnm (18.7 - 18.9 int

10.

OUTBOARD BOOT {TPE)Canada AT modeloutboard joint only.

Page 642 of 1681

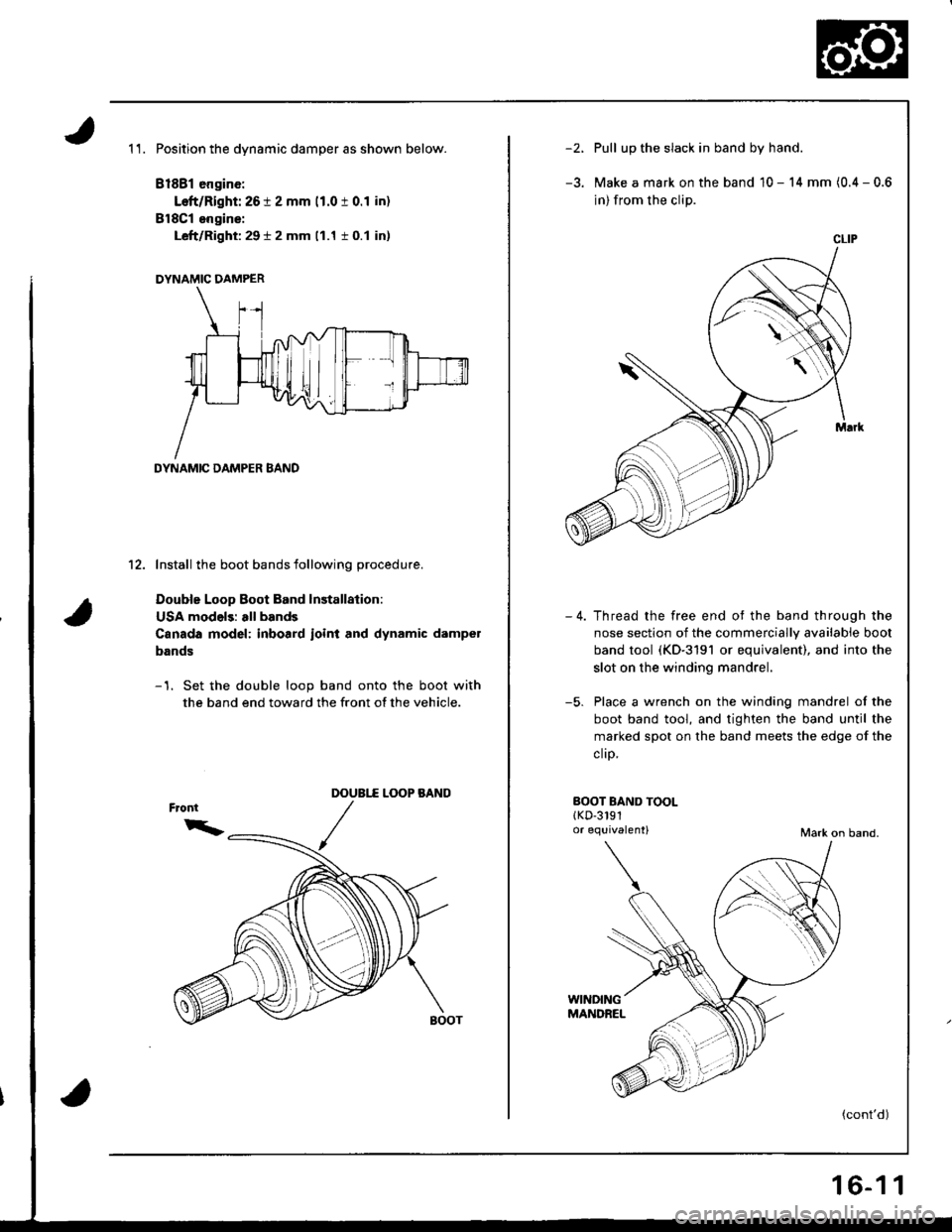

1 1. Position the dynamic damper as shown below.

81881 engine:

Left/Right: 26 t 2 mm 11.0 t 0.1 in)

BlSCl engins:

Left/Right: 29 t 2 mm (1.1 i 0.1 in)

DYNAMIC DAMPER

DYNAMIC DAMPER BAND

12. Install the boot bands following procedure.

Double Loop Boot Band lnstallalion:

USA models: all bands

Canada model: inboard ioint and dynamic dampel

bands

-1. Set the double loop band onto the boot with

the band end toward the front of the vehicle.

L(X)P BANODOUBI.f

/

-')Pull up the slack in band by hand.

Make a mark on the band 10 - 14 mm (0.4 - 0.6

in) from the clip.

Thread the free end ot the band through the

nose section of the commercially available boot

band tool (KD-3191 or equivalent), and into the

slot on the winding mandrel.

Place a wrench on the winding mandrel of the

boot band tool, and tighten the band until the

marked spot on the band meets the edge of the

clrp,

-5.

BOOT BAND TOOLlKD-3191o. equivalent)Mark on band.

(cont'd)

CLIP

16-1 1

Page 643 of 1681

Driveshafts

Reassembly (cont'dl

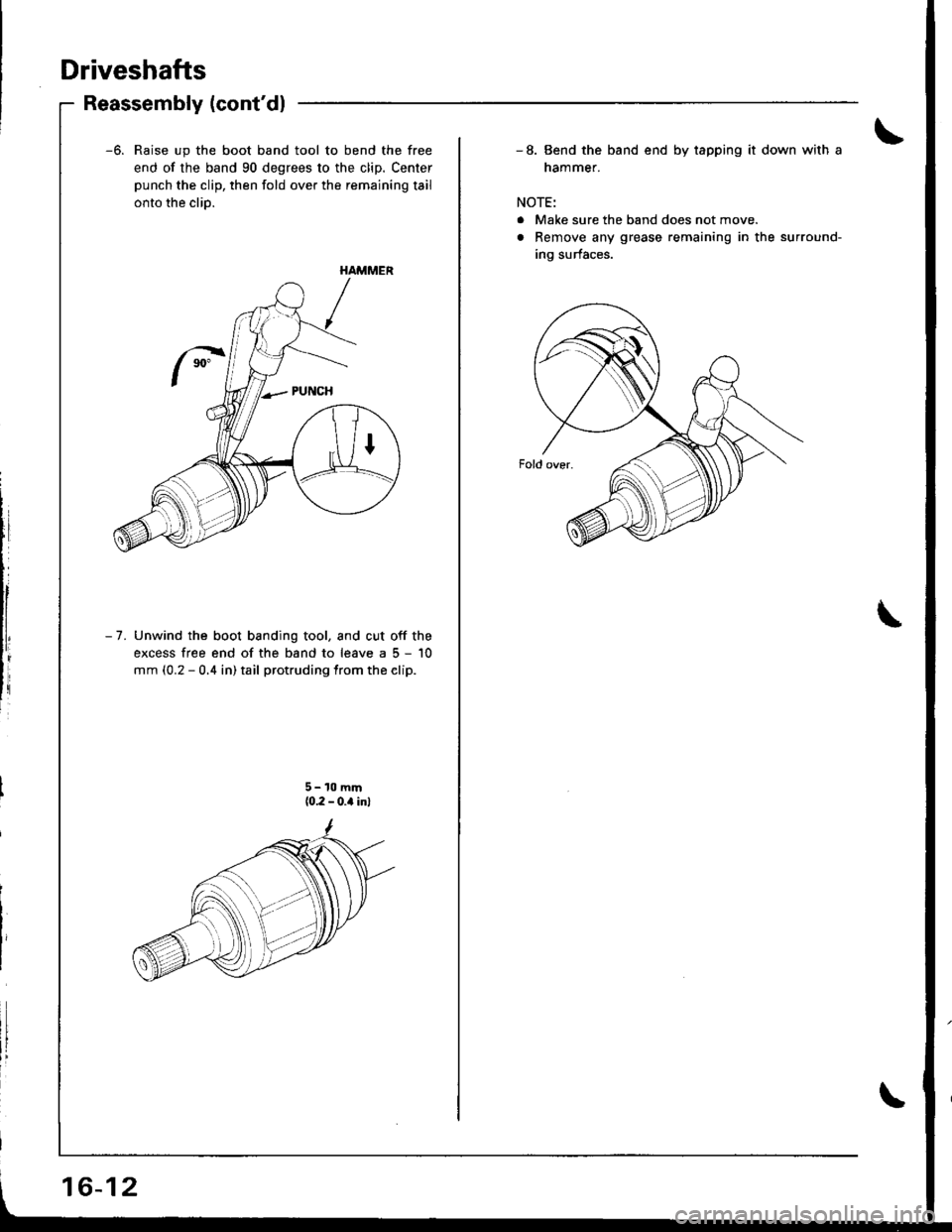

-6. Raise up the boot band tool to bend the free

end of the band 90 degrees to the clip. Center

punch the clip, then fold over the remaining tail

onto the clio.

- 7. Unwind the boot banding tool, and cut off the

excess free end of the band to leave a 5 - '10

mm (0.2 - 0.4 in) tail protruding from the elip.

HAMMER

5- 10 mm(0.2 - 0.a inl

16-12

- 8. Bend the band end by tapping it down with a

nammer.

NOTE:

. Make sure the band does not move.

. Remove any grease remaining in the surround-

ing surfaces.

Page 644 of 1681

![HONDA INTEGRA 1998 4.G User Guide E8r Clamp Type Boot Eand Installation:

Csnada model outboard joi]|t bands

-1. Install the ear clamp boot band by aligning the

tabs with holes in the band.

EAR CLAMP BANDReplace.

Close the ear portion HONDA INTEGRA 1998 4.G User Guide E8r Clamp Type Boot Eand Installation:

Csnada model outboard joi]|t bands

-1. Install the ear clamp boot band by aligning the

tabs with holes in the band.

EAR CLAMP BANDReplace.

Close the ear portion](/img/13/6069/w960_6069-643.png)

E8r Clamp Type Boot Eand Installation:

Csnada model outboard joi]|t bands

-1. Install the ear clamp boot band by aligning the

tabs with holes in the band.

EAR CLAMP BANDReplace.

Close the ear portion of the band with a com-

mercially available boot band pincers.

BOOT AAND PINCERS(Commercially available)Oetiker 1098 or equivalent

POSTION

Measure the clearance between the closed ear

portion of the band.

Siandard:0-3 mm (0 - 0.12 in)

lf the band's, clearance is not within the standard,

close the ear portion of the band further.

NOTE:

. Make sure the band does not move.

. Remove any grease remaining in the surround-

ing surfaces.

16-13

Page 646 of 1681

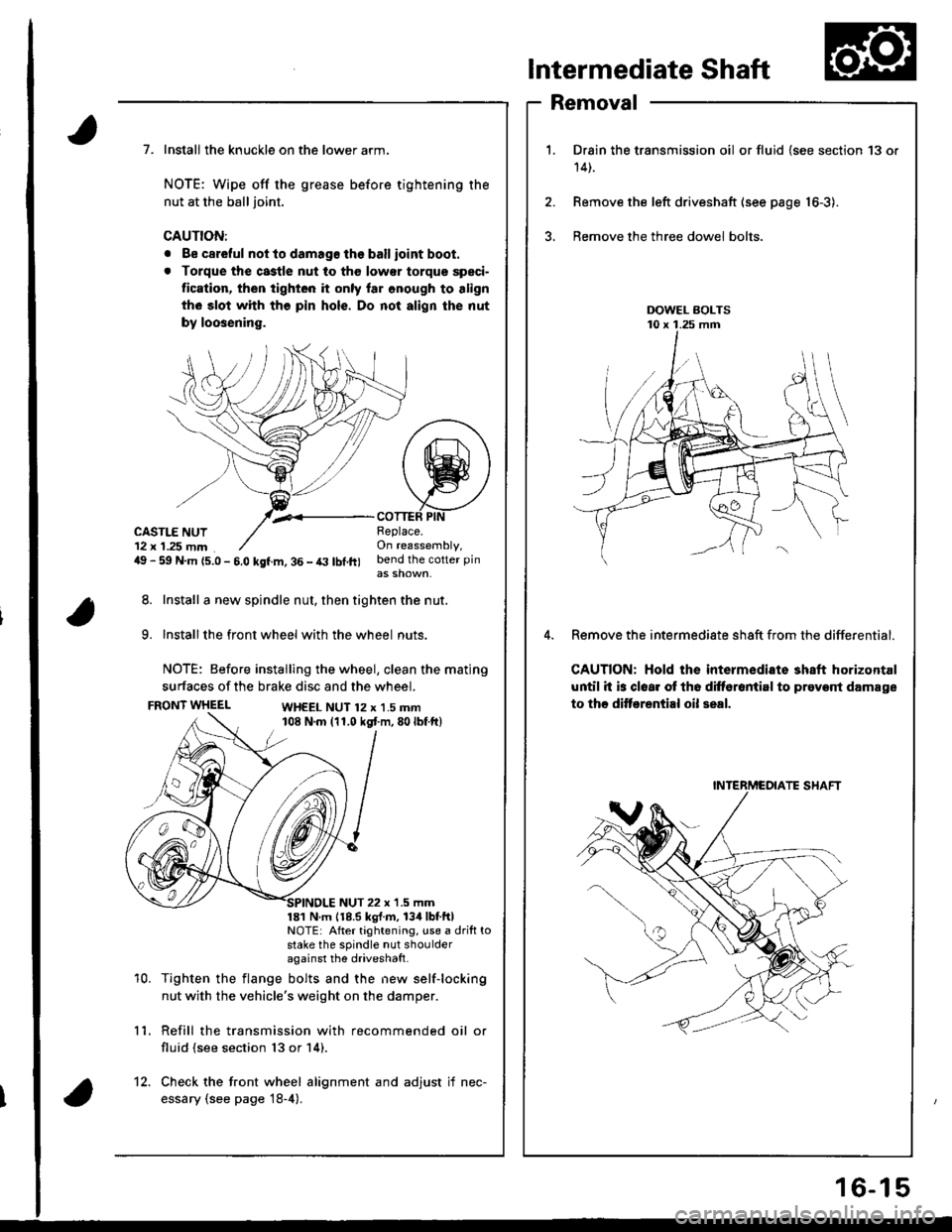

Intermediate Shaft

Removal

Drain the transmission oil or fluid {see section 13 or

14t.

Remove the left driveshaft (see page 16-3).

Bemove the three dowel bolts.

Remove the intermediate sh8ft from the differential.

CAUTION: Hold the intermediate shaft horizontal

until it is clear ot th6 difforantirl to prevont damage

to thc ditf€rential oil seal.

7. Install the knuckle on the lower arm.

NOTE: Wipe off the grease before tightening the

nut at the ball joint.

CAUTION:

. Be careful not to damago the ballioint boot.

. Torque the castle nut to tho low€r torque speci-

tication, then tighten it only lar onough to align

th6 slot whh tho pin hols. Do not align the nut

by loosening.

,.<__coTTEF PtNCASTLE NUT12 x 1.25 mm49 - 59 N.m {5.0 - 5.0 kgf.m, 36 - t3 lbl.ft)

Beplace.On reassembly,bend the cotter pin

8. Install a new spindle nut, then tighten the nut.

9. Installthe front wheel with the wheel nuts.

NOTE: Before installing the wheel, clean the mating

surfaces of the brake disc and the wheel.

FRONT WHEELWH€EL NUT 12 x 1.5 mm108 N.m (11.0 kgt m,80lbf ft)

10.

NUT 22 x '1.5 mm181 N m 118.5 kgl.m, 134lbtftlNOTE: After tightening, use a drift tostake the spindle nut shoulderagainst the driveshatt.

Tighten the flange bolts and the new self-locking

nut with the vehicle's weight on the damper.

Refill the transmission with recommended oil or

fluid (see section 13 or 14).

11.

12. Check the front wheel alignment and adjust if nec-

essary (see page 18-4).

INTERMCOIATE SHAFT

16-15

Page 650 of 1681

Steering

Componsnt Location

lndox

*Stooring Wheel

Removal ....

Disassombly/Ro8$.mbly

Disassombly ......

F08$€mbly

Powcr Stosring Gosrbox

R6moval

............................ 17-3

............. 17 -1

................ 17-16

............................. 17_25

17-30

17.31

.......17-21

Sy3tom DGcription

Fluid Flow Disgram

Steering Pump .............. 17-5

Stocring Goarbox ...17.8

Troublorhooting

Gonoral Troubleshooting .............................. 17.10

Noiso lnd Vibration ...... 17-1i[

Fluid Losk3

lnspoction

Installation

Powor Steering Hos6, Lino3

Roplacom€nt .................. 17.34

Powor Steoring Pump

RGplac6montlolpeqtion lnd Adiu3tm6nl

Stoo.ing Operation

Powor A$bi Chock

with v.hiclo Parked

Stcering Linkage 6nd Goarbox

Pump Bolt

17.18

17.18

17.19

17-20

17.35

t7-36

17 -37

r7-39

Inspoction

................... 17.41

Rack Guide Adiustmont ..........................-.-.-. 17 -21

Ffuid Rcplacemont ........17-21

Pump Prc&suro Chock ...,........................,..,..., 17 -22

Fluid Leakage Inrpection ............................... 17-23

Dissssembly

R€aEs€mbly

In3tallation........... 17_58

Ball Joint Boot Replacem.ni ........................ 17-61

17-U

17.49

J ,urrar*TNTAL REsrRArNr sysrEM (sRsr

The Integra SRS includes a driver's airbag located in the steering wheel hub and a passenger's airbag located inthe dashboard above the glove box,

Information necessary to safely service the SRS is included in this Service Manual. ltems marked with an asterisk(*) on the contents page include, or are located near, SRS components. Servicing, dissssembling or replacing

these items will require special pr6cautions and tools, and should therefore be done by an authorized Acura dealer.

. To avoid rondoring ths SRS inoparstivo. which could |rad to parsonal iniury or doath in the ov€nt of ! sev6.o

trontal collision, all SRS sarvice work must be perto.med by an authorizod Acura dsalor.. lmpropor 3orvic€ procadures, including inco[6ql rgmoval and inrtallation of the SRS, could l6ad to pgrsonal

iniury clus€d by unintentional doployment of the airbags,. Do nol bump tho SRS unh, (Xherwise, th6 3ystom may fail in cas€ ol a collision, or the airbags may d€ploy

when ths ignition switch is ON {ll).. All SRS electrical wiring harness€s aro covered with yallow insulation. Related component3 are located in ths

stcaring column. tront con3ol6, dashboard, d.shbolrd lower panel, and in the dashboard above ths glove box.

Do not u3o electrical test oquipm€nt on the3e circuii3.

NOTE: The original radio has a coded theft protection circuit. Be sure to get the customer's code number before- disconn€cting the battery.- removing the No. 47 (7.5 A) fuse from the under-hood fuse/relay box,- removing the radio.

After service, reconnect power to the radio and turn it on. When the word "CODE" is displayed. enter the cus-

tomer's 5-digit code to restore radio operation.