boot HONDA INTEGRA 1998 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 363 of 1681

T

fi

;ill

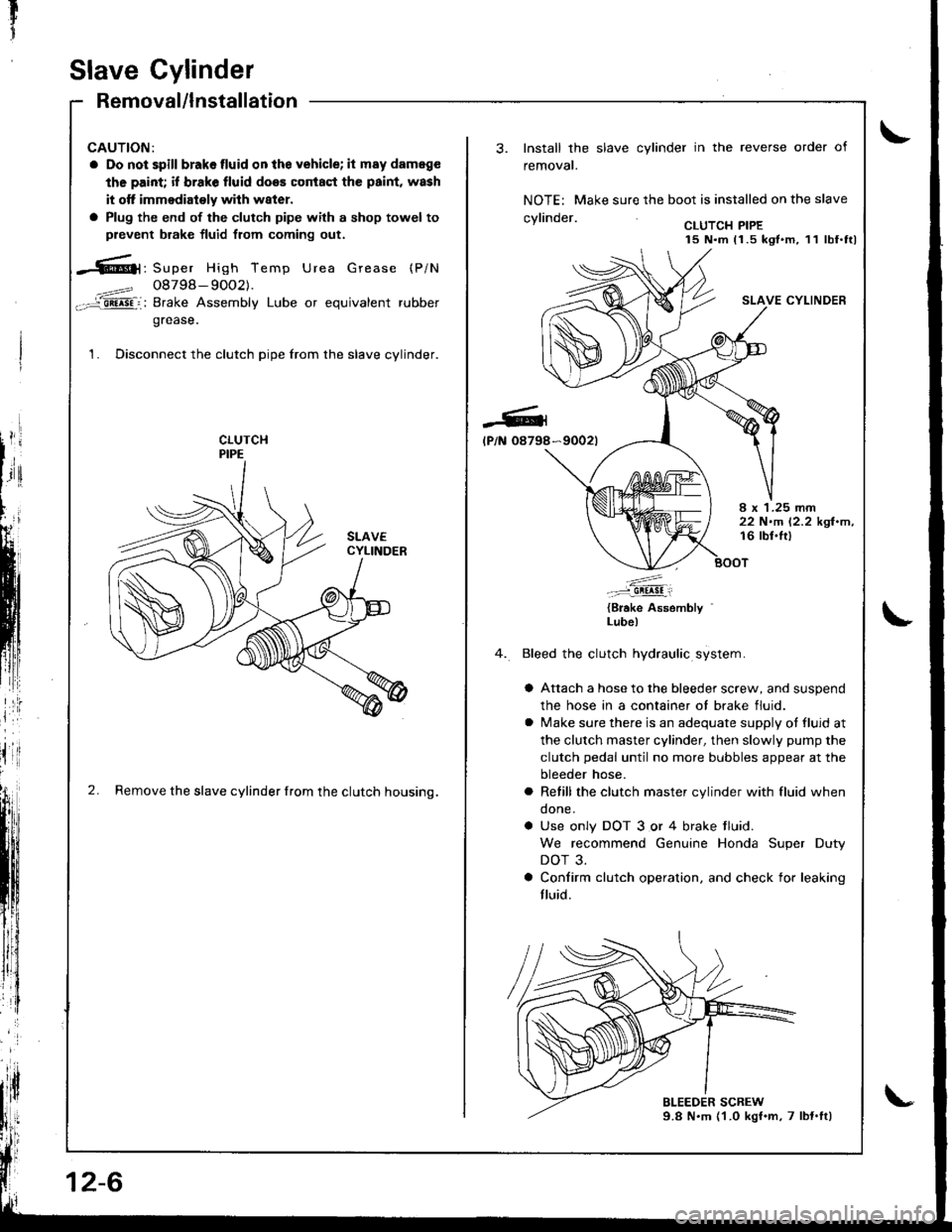

Slave Cylinder

Removal/lnstallation

CAUTION:

a Do not spill brakelluid onthe vehicle; it may dameg€

the paint; if brake fluid does coniaqt the paint, wash

it otf immodiaioly wilh w8ter.

a Plug the end of the clutch pipe with a shop towel to

prevent brake fluid from coming out.

-6|1, Super High Temp Urea Grease (P/N

4==? 08798- 9OO2).-='aii^5Fi: Brake Assembly Lube or equivalent rubber

grease.

1. Disconnect the clutch pipe from the slave cylinder.

2. Remove the slave cylinder from the clutch housing.

12-6

-Gl

lP/N 08798

Install the slave cylinder in the reverse order of

removal.

NOTE: Make sure the boot is installed on the slave

.wlin.larCLUTCH PIPE15 N.m 11.5 kgt.m, 11 lbf.ttl

SLAVE CYLINDER

*9002t

I x 1.25 rnm22 N.m 12.2 kgl.m,16 lbl.lt)

.'....-..-:::-9!!!!!i

{Brake Assembly '

Lube)

Bleed the clutch hydraulic system.

a Attach a hose to the bleeder screw, and suspend

the hose in a container ot brake fluid.

a lvlake sure there is an adequate supply ot fluid at

the clutch master cylinder, then slowly pump the

clutch pedal until no more bubbles appear at the

bleeder hose.

a Refill the clutch master cylinder with fluid when

done.

a Use only DOT 3 or 4 brake tluid.

We recommend Genuine Honda Super Duty

DOT 3.

a Confirm clutch operation. and check for leaking

fluid.

Page 368 of 1681

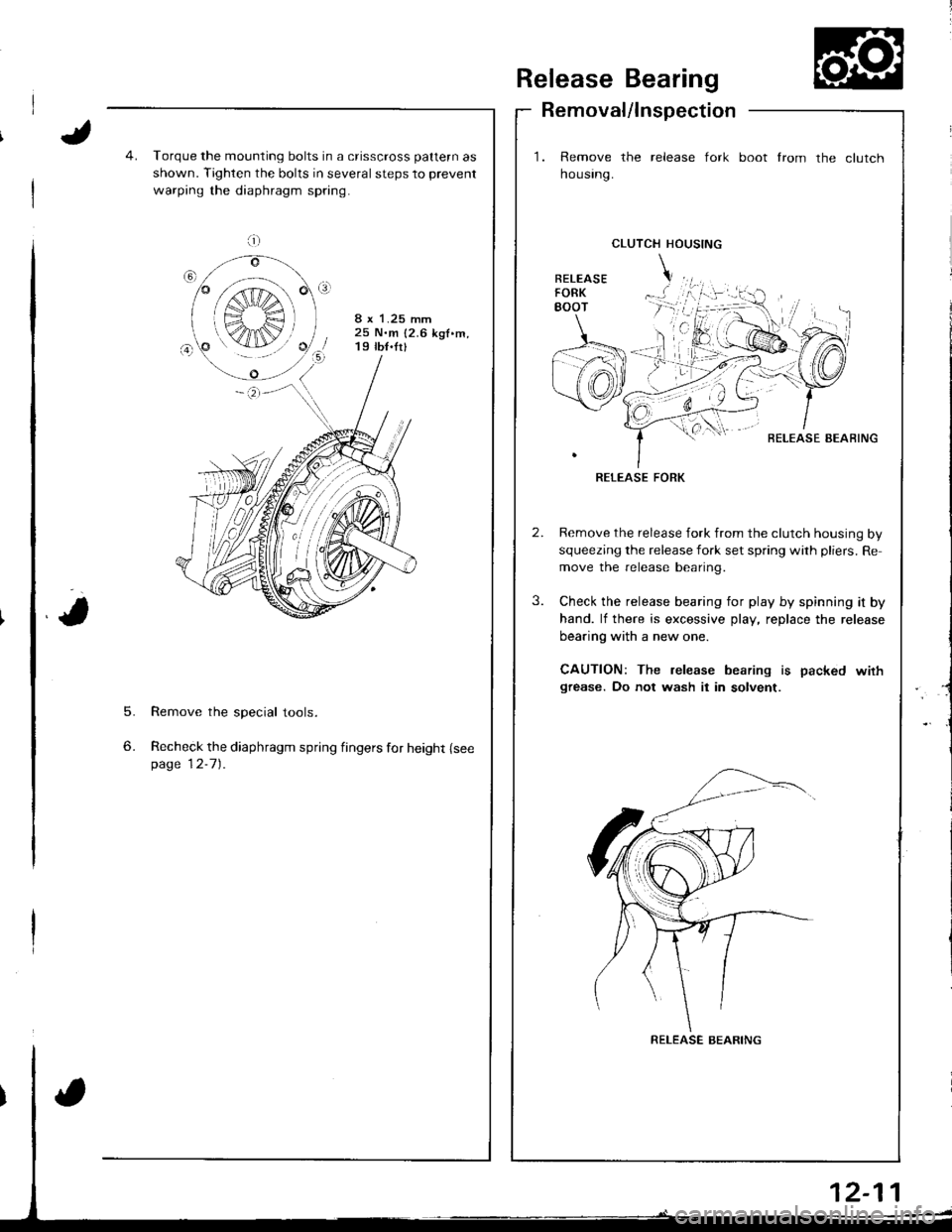

Release Bearing

Removal/lnspection

1. Remove the release fork

housrng.

boot from the clutch

5.

6.

Torque the mounting bolts in a crisscross pattern as

shown. Tighten the bolts in several steps to prevent

warping the diaphragm spring.

8 x 1.25 mm25 N.m {2.6 kgf.m,19 tb{.fr}

Remove the special tools.

Recheck the diaphragm spring fingers for height {seepage 12-7).

CLUTCH HOUSING

BELEASE AEAFING

RELEASE FORK

Remove the release fork from the clutch housing by

squeezing the release fork set spring with pliers. Re

move the release bearing.

Check the release bearing for play by spinning it by

hand. lf there is excessive play, replace the release

bearing with a new one.

CAUTION: The release bearing is packed wirhgrease. Do not wash it in solvent.

a;;;:

S",€ r

K4IN/

RELEASE BEARING

Page 369 of 1681

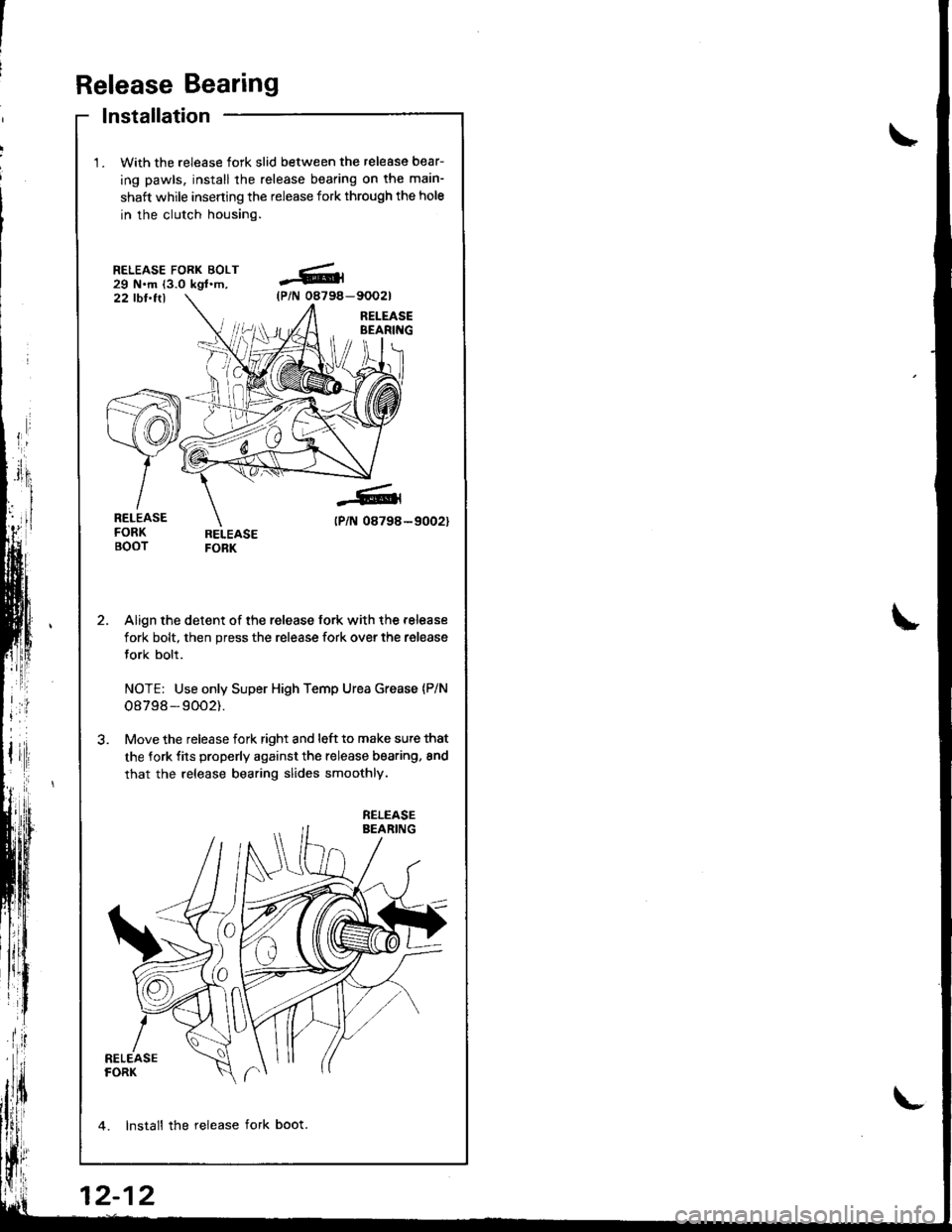

Release Bearing

lnstallation

With the release fork slid between the release bear-

ing pawls, install the release bearing on tha main-

shaft while inserting the release fork through the hole

in the clutch housing.

RELEASE FORK BOLT29 N.m (3.0 kgl.m,22 tbt.ttl

Align the detent of the release fork with the release

fork bolt, then press the release fork over the release

fork bolt.

NOTE: Use only Super High Temp Urea Grease {P/N

o8798 - 9002).

Move the release fork right and l6ft to make sute that

the fork fits properly against the release bearing, 8nd

that the release bearing slides smoothly.

4. lnstall the release fork boot.

-6(P/N 08794-

-6

tPlN 08798-

RELEASE

12-12

Page 384 of 1681

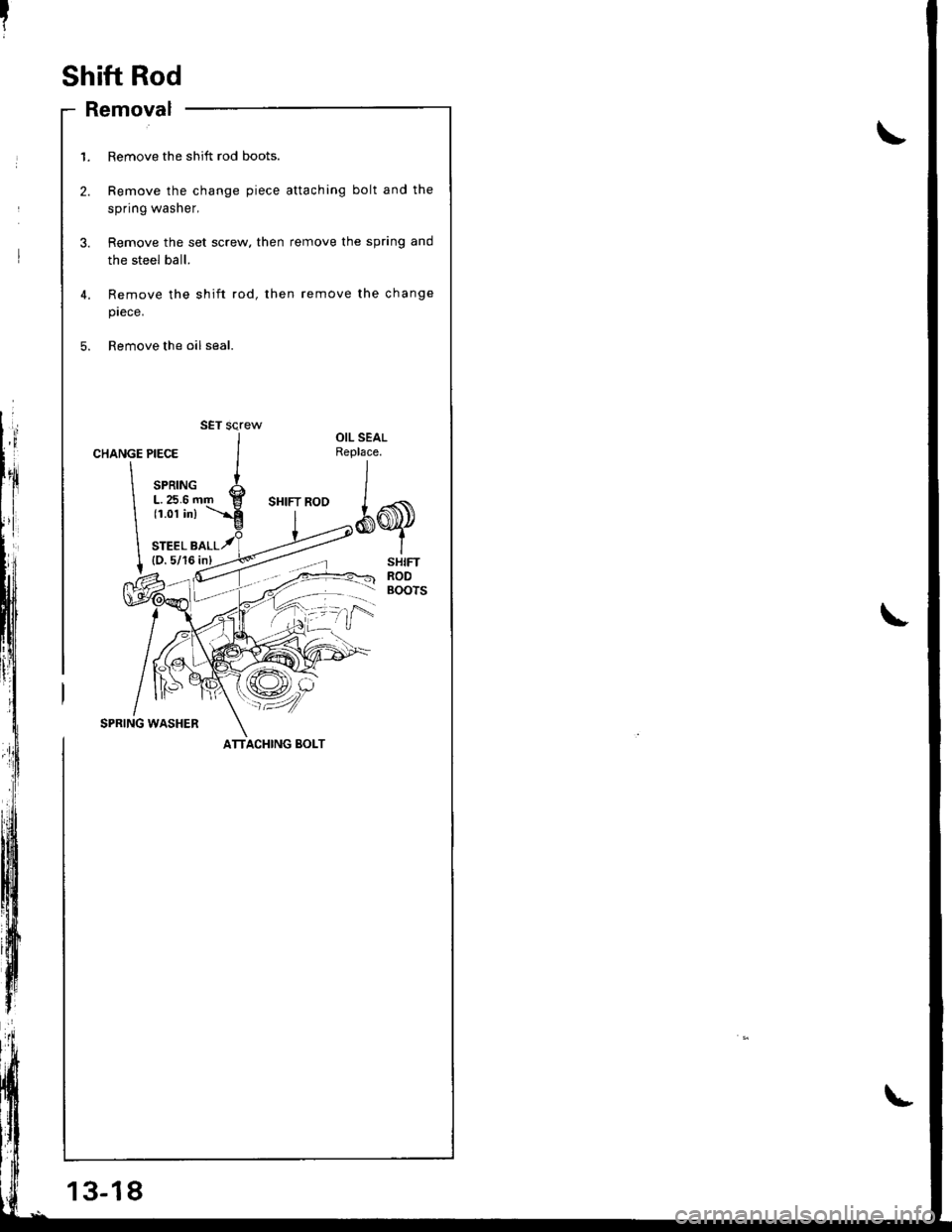

Shift Rod

- Removal

13-18

1. Remove the shift rod boots.

2. Remove the change piece attaching bolt and the

spring washer,

3. Remove the set screw. then remove the spring and

the steel ball.

4,

5.

Remove the shift rod, then remove the change

prece.

Remove the oil seal.

CHANGE

\

\

I

PIECE

SPRINGL.25.6 r(1.01 in)

STEEL B(D.5/16

OIL SEALReplace.

*q

SHIFTRODBOOTS

SPRING WASHER

SET screw

ATTACHING BOLT

Page 407 of 1681

I

t

\

Transmission

Reassembly

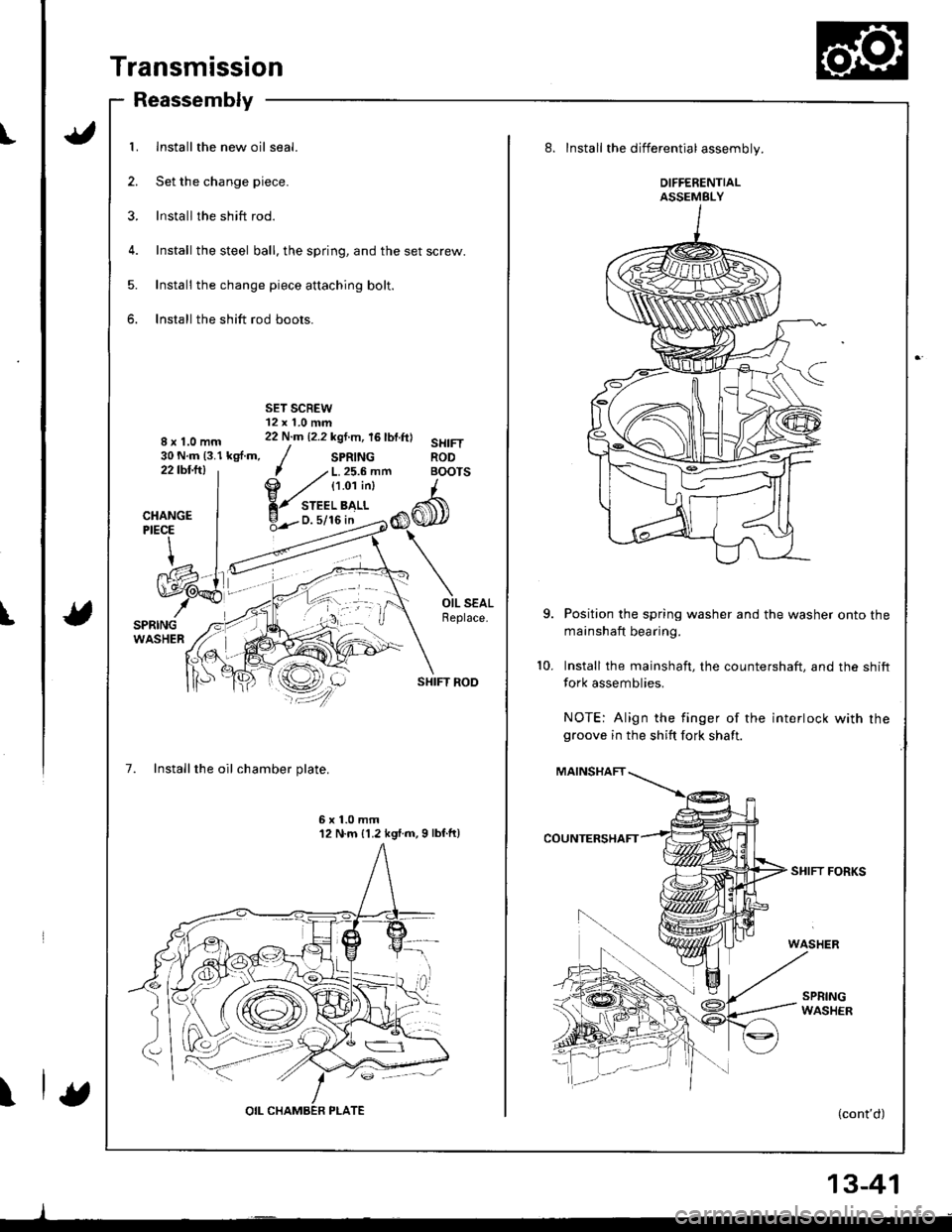

1. Install the new oil seal.

2. Set the change piece.

3. lnstall the shift rod.

4. Install the steel ball, the spring, and the set screw.

5. Install the change piece attaching bolt.

6. Install the shift rod boots.

8x1.0mm30 N.m (3.1 kgf.m,22tbfitl

SHIFT ROD

7. Installthe oil chamber plate.

7 .' L. 25.6 mfi BOI

@ ,zt tt.o'ti"t I

Y-",:'b>,",CI

6x1.0mm12 N.m {1.2 kgl.m,9 lbf.ft)

8. Install the differential assembly.

DIFFERENTIALASSEMBLY

Position the spring washer and the washer onto the

mainshaft bearing.

Install the mainshaft, the countershaft. and the shift

fork assemblies.

NOTE: Align the finger of the interlock with rhegroove in the shift fork shaft.

MAINSHAFT

SHIFT FORKS

(cont'd)

10.

13-41

Page 412 of 1681

I

Transmission Assembly

1.

2.

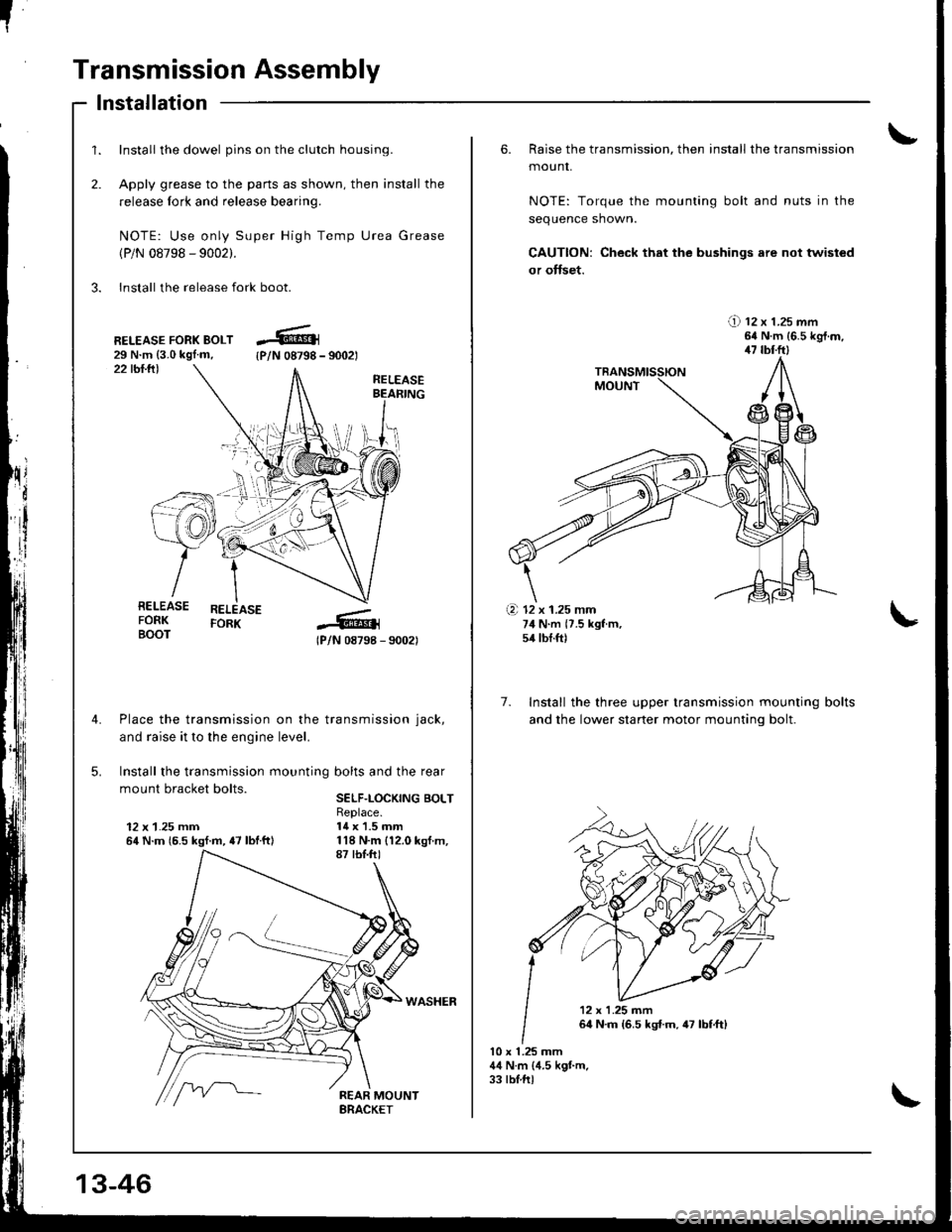

Install the dowel pins on the clutch housing.

Apply grease to the parts as shown, then install the

release fork and release bearing.

NOTE: Use only Super High Temp Urea Grease

(P/N 08798 - 9002).

3. Install the release fork boot.

lnstallation

22 tbl.lll

RELEASE FORK BOLT29 N.m {3.0 kgl.m,{P/N 08798 - 9002t

RELEASEBEAFING

RELEASEFORK

lPlN 08798 - 90021

Place the transmission on the transmission jack,

and raise it to the engine level.

Install the transmission mounting bolts and the rear

mount bracket bolts.SELF.LOCKING BOLT

12 x 1.25 mm64 N.m {6.5 kgf.m, {7 lbtftl

Replace.14 x 1.5 mm

RELEASEFORKBOOT

\i'l-r )i-

.+.i

13-46

6. Raise the transmission, then install the transmission

mounr,

NOTE: Torque the mounting bolt and nuts in the

sequence shown.

CAUTION: Check that the bushings are not twisted

or offset.

!) tz x t.zs mm64 N.m {6.5 kgt.m,47 tbl.ftl

7. Install the three upper transmission mounting

and the lower staner motor mountinq bolt.

bolts

10 x 1.25 mm44 N.m (4.5 kgt m.33 tblftl

(a 12 x 1.25 mm74 N.m {7.5 kgf m,54 tbf.ft)

'12x1.25m�n

64 N.m {6.5 kst.m,47 lbf,ft)

Page 414 of 1681

[!

"

Transmission Assembly

Installation (cont'd)

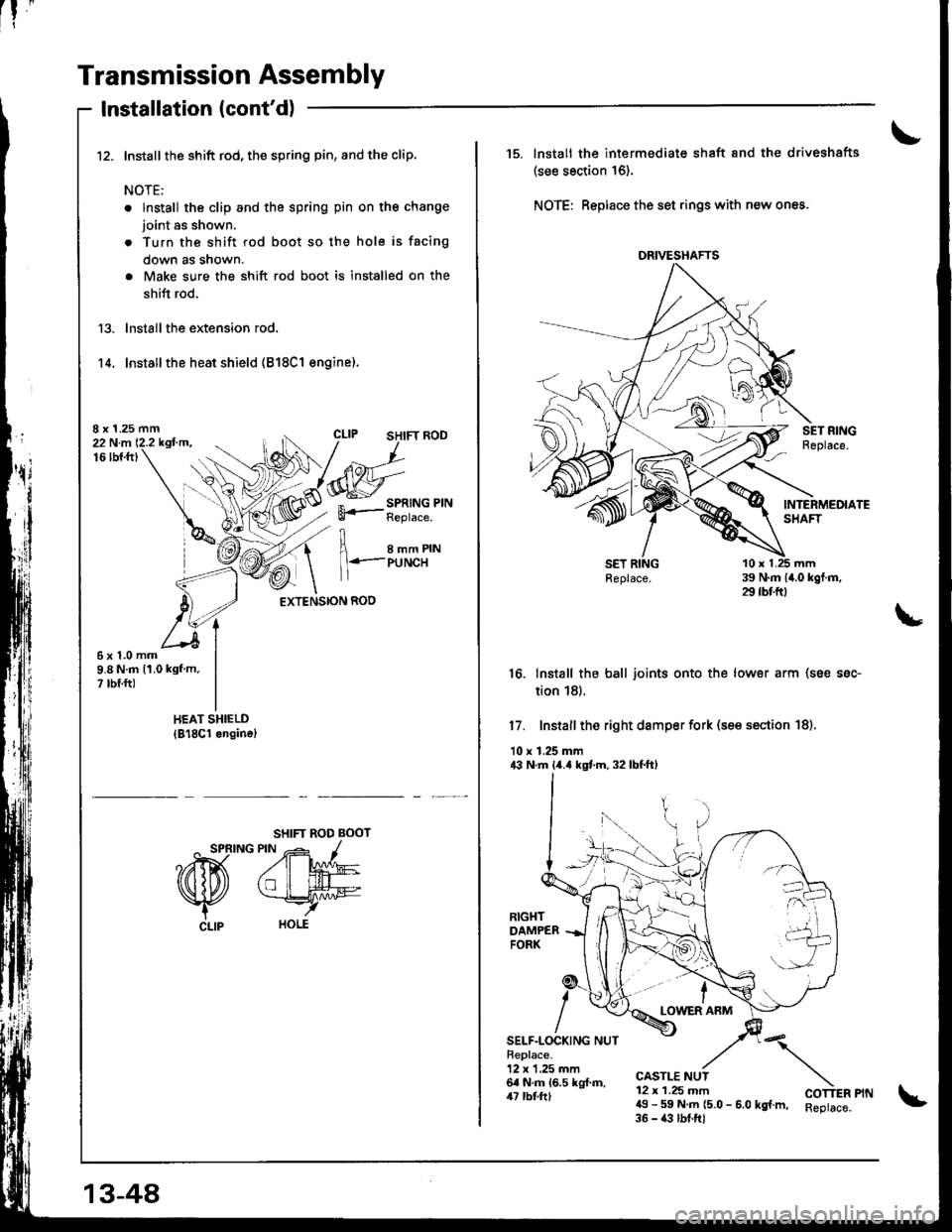

Install the shift rod, the spring pin, and the clip.

NOTE:

. lnstall the clip and the spring pin on the change

joint as shown.

. Turn the shift rod boot so the hole is facing

down as snown.

. Make sure the shift rod boot is installed on the

shift rod.

lnstall the extension rod.

Installthe heat shield (818C1 engine).'t 4.

8 x 1.25 mm22 N.m 12.2 kgfm.16lbt.ft)

I e--erru

1 l+.-PUNCH

EXTENSION ROD

6x1.0mm9.8 N.m 11.0 kgf m,? rbf.ft)

SHIFT ROD BOOT

^ SPRING PIN -- -1

?ffi A'W

Nfu *rry

CLlp HOLE

13-48

DRIVESHAFTS

15. lnstall the intermediate shaft 8nd the driveshafts

(see section 16).

NOTE: Beplace the set rings with new ones.

16. Install the ball joints onto the lower arm (soe ssc-

tion 18).

17. Install the right damper fork (see ssction 18).

10 r 1.25 mm43 N.m lir.a kgt m. 32 lbtftl

LOWER ARM

SELF.LOCKING NUTReplace.12 x 1,25 mm6a N.m 16.5 kg{.ft,/u rbl.tt)

CASTLE NUT12 x 1.25 mm49 - 59 N.m (5.0 - 6.0 kgf.m, Reptace.35 - 43 lbf.ftl

"\

COTTER PIN

Page 417 of 1681

Gearshift Mechanism

Overhaul

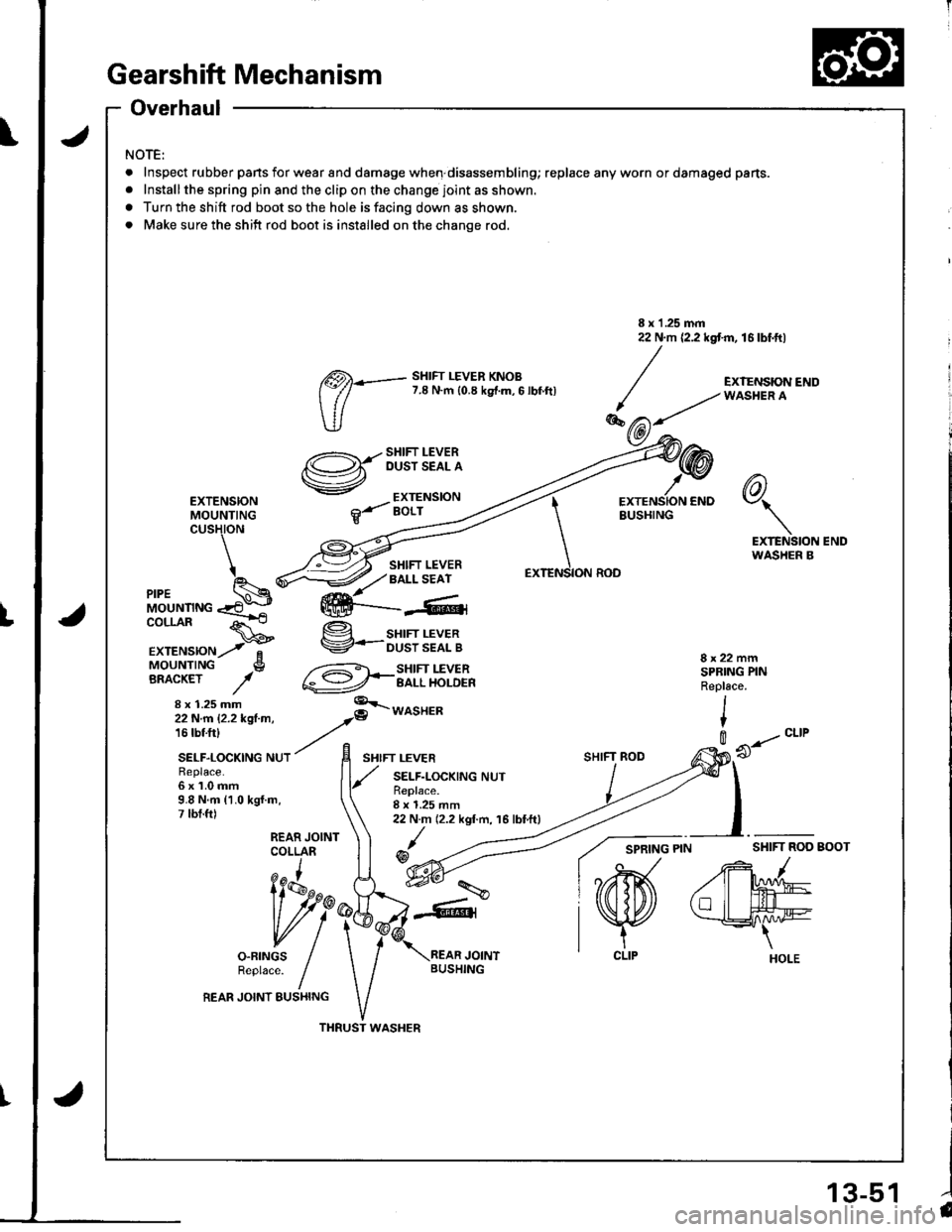

NOTE:

.Inspe(

.lnstall

a Turn t

. Make

Inspect rubber pans for wear and damage when disassembling; replace any worn or damaged pans.

Installthe spring pin and the clip on the change joint as shown.

Turn the shift rod boot so the hole is facing down as shown.

Make sure the shift rod boot is installed on the change rod.

\

tu

<:;s\-

-,-"Ye/

R€place.6x1.0mm9.8 N.m {1.0 kgl.m,7 lbt.ft)

liAru^

vll

o-FTNGS /Reptace. fREAR JOINT EUSHING

I x 1 .25 mm22 N.m {2.2 kgt m, 16 lbf.ft)

EXTENSIONMOUNTINGcusHtoN

6)\7\

EXTENSION ENDWASHER B

MOUNTINGCOLLAR

EXTENSIONMOUNTINGBRACKET

x 1.25 mm

SHIFT LEVERBALL SEAT

g sHrFr LEVERV-ousrssflg

@*3li.T'lib'l'

8x22mmSPBING PINRepl6ce.

I

t

SHIFT ROD

0 --..- "ttt

REAR JOINTCOLLARSHIFI ROD BOOT/

/rM

tllL#e

THRUST WASHER

@)*- sHtFr LEVER KNoB

(:// 7.8 N.m {0.8 ks{.m,6 lbf.ftl

SHIFT LEVEROUST SEAL A

EXTENSIONBOLT

8 x 1.25 mm22 N.m (2.2 kgf.m, 16 lbtft)

/@

EXTENSION CNDBUSHING

ION ROD

-\

\

\EXTENS

ffi---4,

l'a13-51

Page 634 of 1681

t

Driveshafts

Inspection

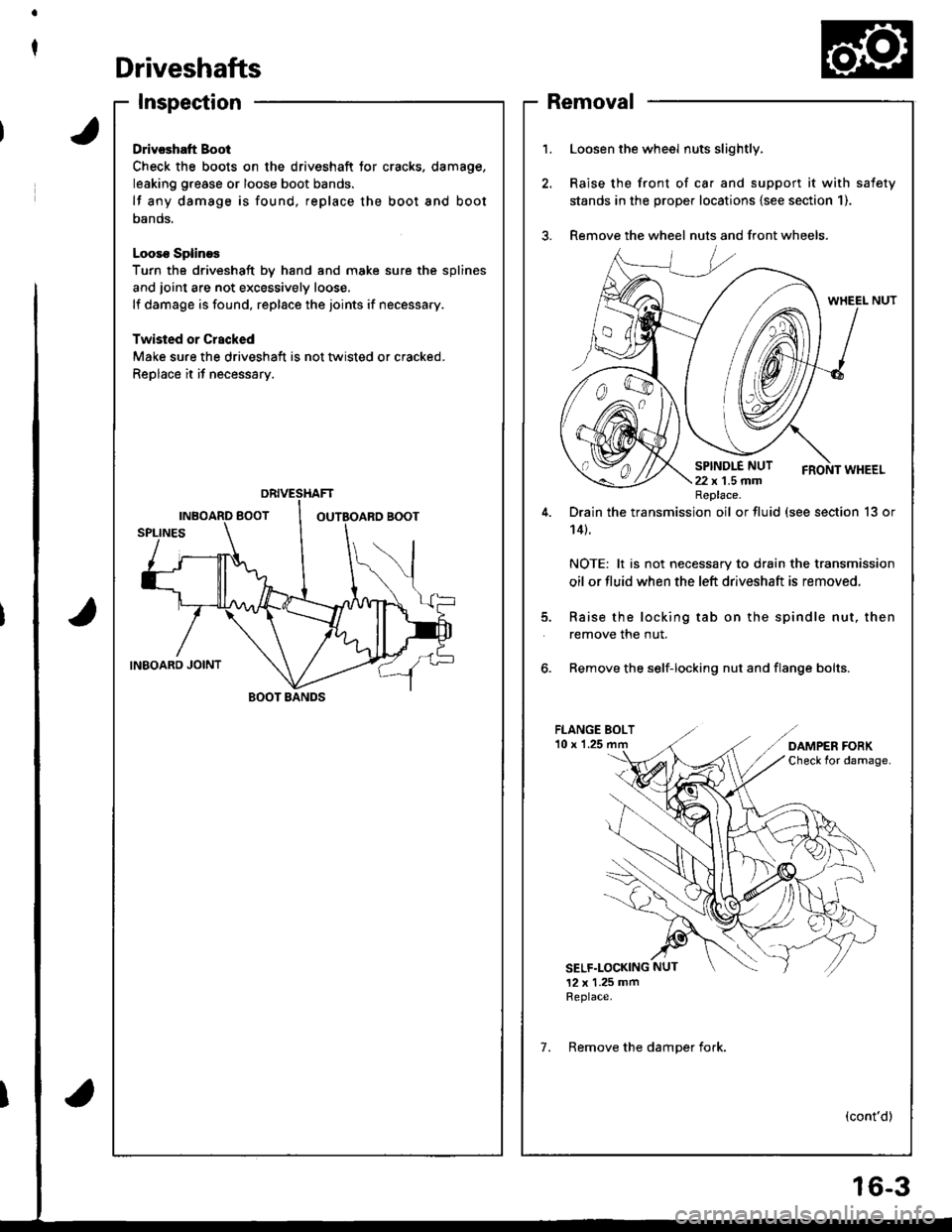

Drivcshatt Boot

Check the boots on the driveshaft tor cracks. damage,

leaking grease or loose boot bands.

lf any damage is found, replace the boot and boot

oanos.

Looso SplineE

Turn the driveshaft by hand and moke sure the splines

and joint are not excessively loose.

lf damage is found, replace the joints if necessary.

Twisled or Crscked

Make sure the driveshaft is not tlvisted or cracked.

Replace it if necessary.

BOOT BANDS

1.Loosen the wheel nuts slightly,

Raise the front of ca. and support it with safety

stands in the prope. locations {see section 1).

Remove the wheel nuts and front wheels.

5.

Drain the transmission oil or fluid (see section 13 or

14t.

NOTE: lt is not necessary to drain the transmission

oil or fluid when the left driveshaft is removed.

Raise the locking tab on the spindle nut, then

remove the nut.

6. Remove the self-locking nut and flange bolts.

FLANGE BOLT'10 x 1.25

SELF.LOCKING NUT

12 x 1.25 mmReplace.

(cont'd)

Replace.

7. Remove the damoer fork.

Removal

6-3

Page 635 of 1681

Driveshafts

Removal (cont'dl

11.

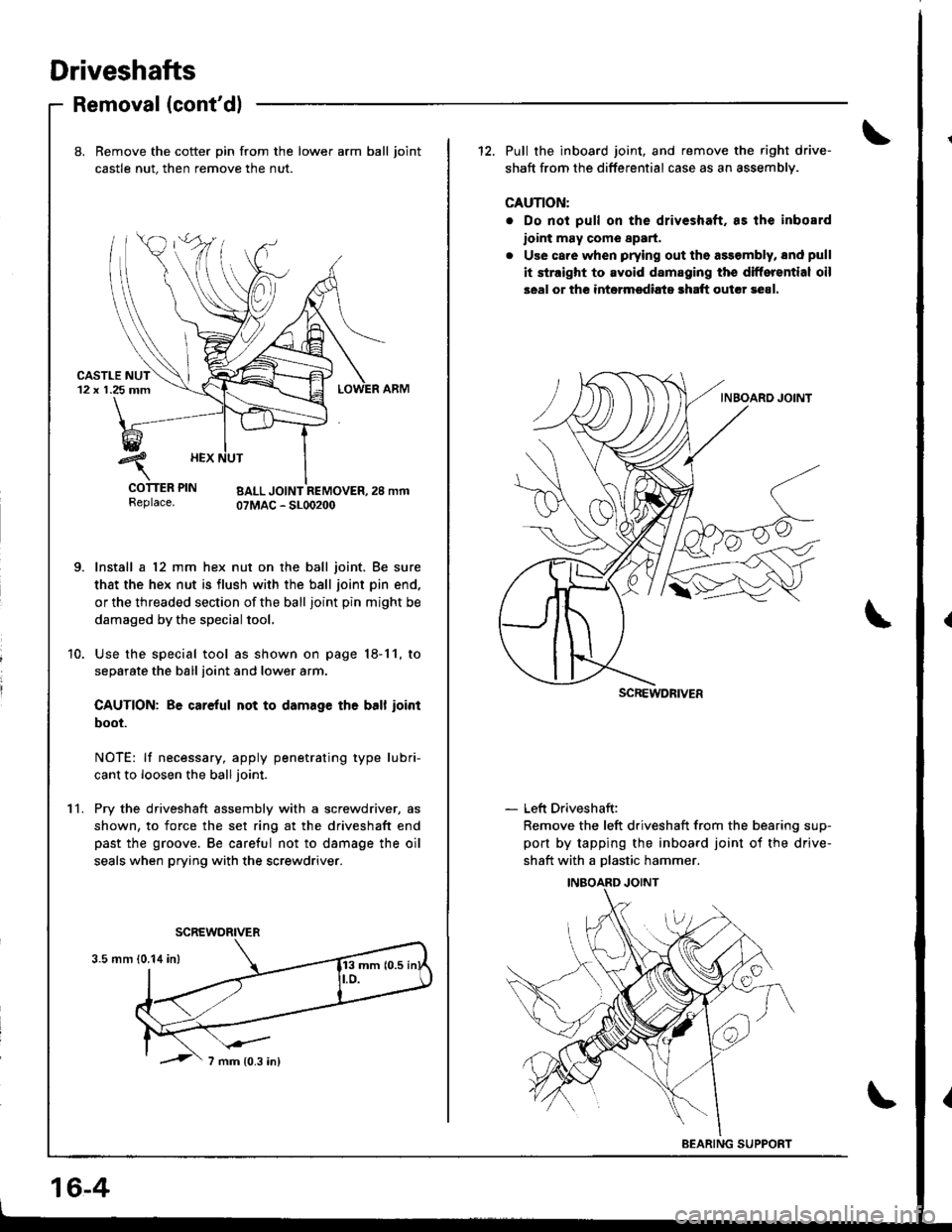

8. Bemove the cotter pin from the lower arm ball joint

castle nut. then remove the nut.

urJr rEr rrN BALL JOINT REMOVER,2S mmReplace. OTMAC - SLOO2OO

Install a 12 mm hex nut on the ball joint. Be sure

that the hex nut is flush with the ball joint pin end.

or the threaded section of the ball joint pin might be

damaged by the special tool.

Use the special tool as shown on page 18-11, to

separate the ball ioint and lower arm.

CAUTION: Be careful not to damage th6 ball ioint

boot.

NOTE: lf necessary, apply penetrating type lubri-

cant to loosen the ball joint.

Pry the driveshaft assembly with a screwdriver, as

shown, to force the set ring at the driveshaft end

past the groove. Be careful not to damage the oil

seals when prying with the screwdriver.

12. Pull the inboard joint, and remove the right drive-

shaft from the differential case as an assemblv.

CAUTION:

. Do not pull on the driveshaft. as lhe inbosrd

ioint may come 8p8rt.

. Use care when prying out the assembly, snd pull

it straight to avoid damaging the differential oil

seal or the intermsdiats rhaft outcr 3e81.

- Left Driveshaft:

Remove the left driveshaft from the bearing sup-

port by tapping the inboard joint of the drive-

shaft with a Dlastic hammer.

SCREWDRIVER

BEARING SUPPORT

16-4