brake HONDA INTEGRA 1998 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 343 of 1681

t"iI

Emission Gontrol System

System Description

Three Way Catalytic Converter (TWCI

\

t

The emission control system includes a Three Way

Catalytic Converter (TWC), Positive Crankcase Ventilation

(PCV) system and Evaporative Emission (EVAP) Control

system. The emission control system is designed to meet

tederal and state emission standards.

InsDeciion

!@@ Do not smoke during this procedure. Keep

any open llame away from your work area.

1. Start the engine. Hold the engine at 3,000 rpm with

no load {in Park or neutral) until the radiator fan

comes on, then let it idle.

2. Connect a tachometer.

Check and adjust the idle speed, if necessary (see

page '11-11 ! ).

Warm up and calibrate the CO meter according to the

meter manufacturer's instructions.

Check idle CO with rhe headlights, heater blower,

rear window defogger, cooling fan, and air condition-

er off.

NOTE: {Canada) Pull the parking brake lever up.

Start the engine, then check that the headlights are

olf.

CO meter should indicste 0.17o maximum.

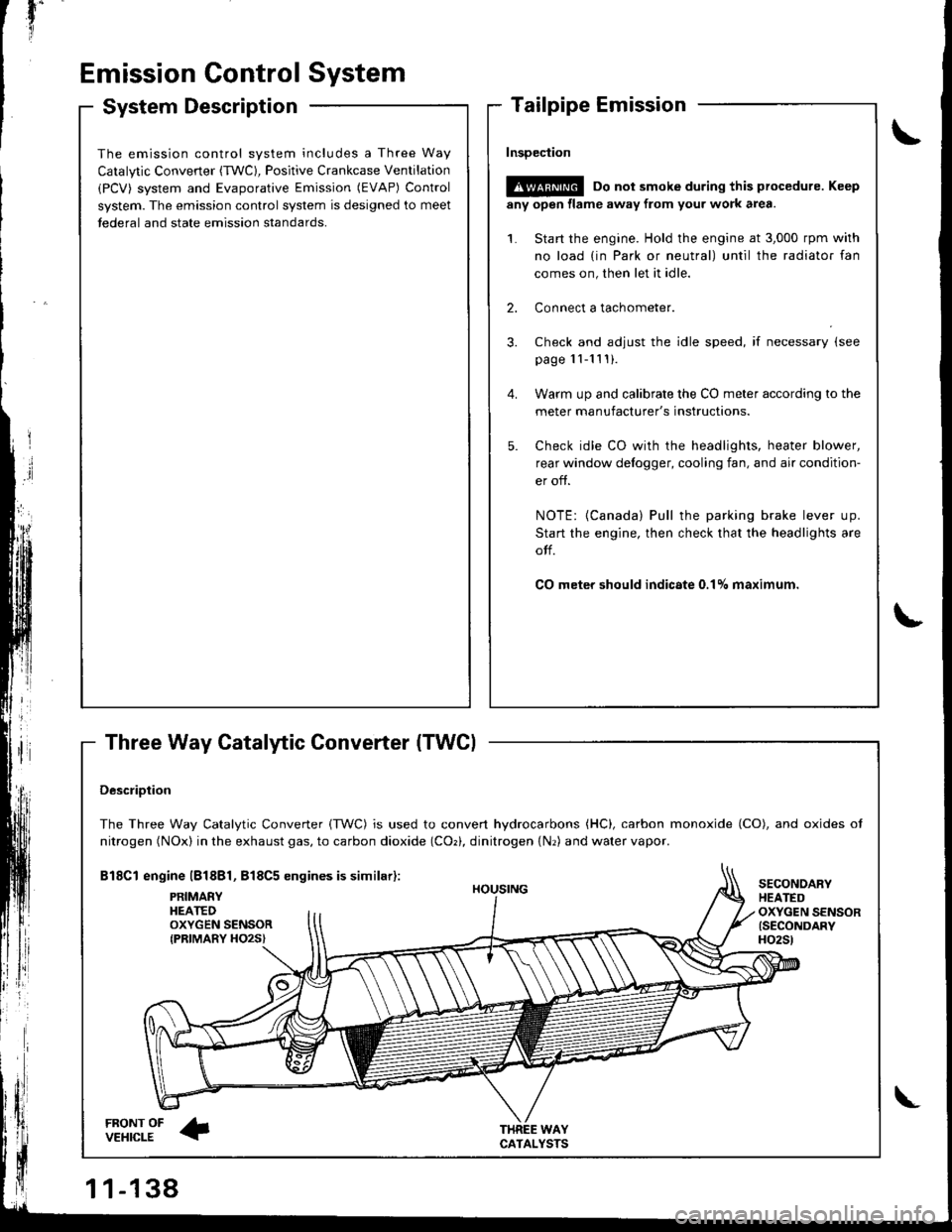

DescriDtion

The Three Way Catalytic Converter {TWC) is used to convert hydrocarbons (HC), carbon monoxide (CO), and oxides of

nitrogen (NOx) in the exhaust gas, to carbon dioxide (COr), dinitrogen {Nr) and water vapor.

Bl8Cl engine l818Bl, 818C5 engines is similar):

FRONT OFVEHICLE

PRIMAEYHEATEDOXYGEN SENSORIPRIMARY HO2S}

HOUSING

WAYCATALYSTS

SECONOARYHEATEDOXYGEN SENSOR{SECONDARYH02St

\

Page 353 of 1681

Emission Control System

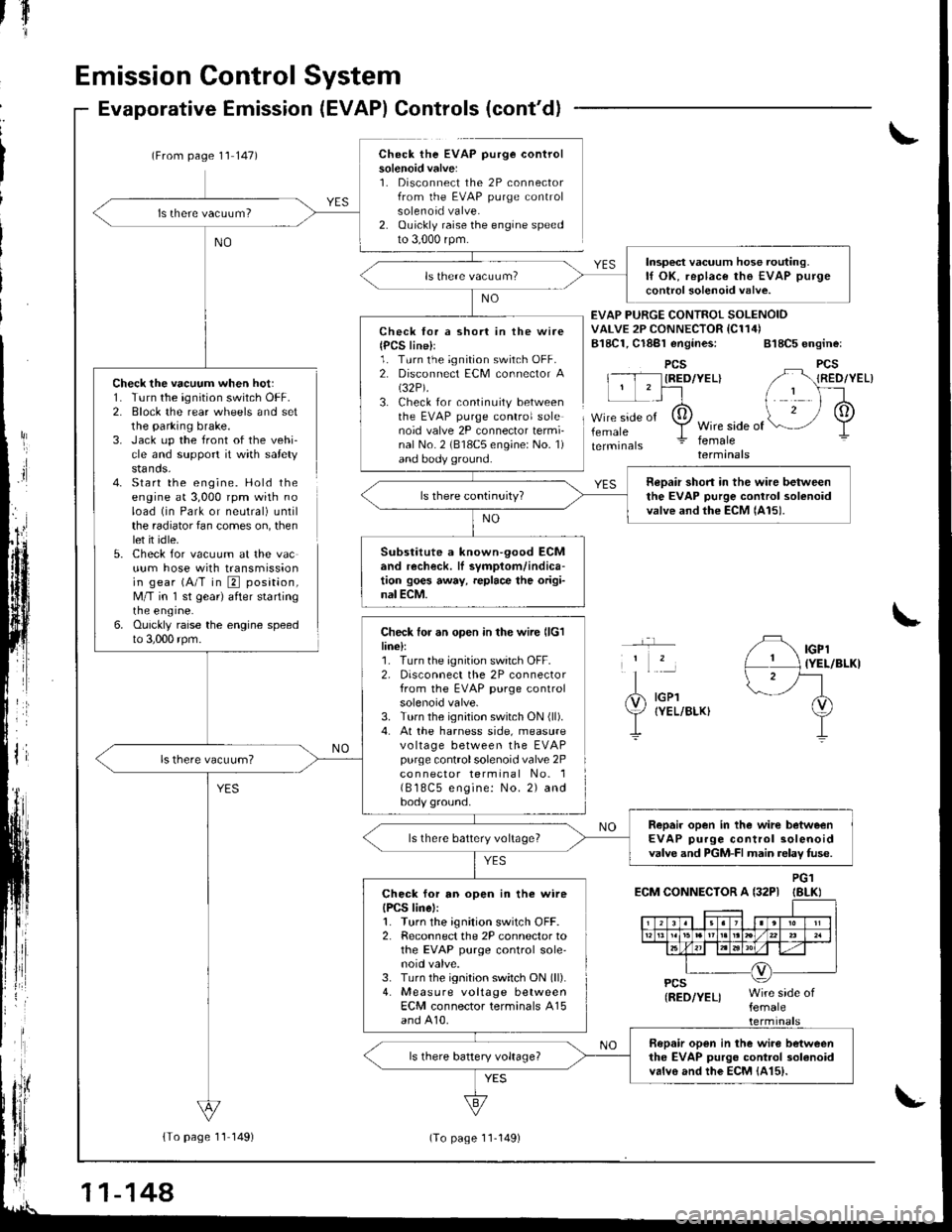

Check the vacuum when hot:1. Turn the ignition switch OFF.2. Block the rear wheels and setthe parking brake.3. Jack up the front of the vehi-cle and support it with safetystands.4- Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator fan comes on, thenlet it idle.5. Check for vacuum at the vacuum hose with transmissionin gear (A/T in E position,M/T in 'l st gear) after startingrne engrne.6. Ouickly raise the engine speedto 3,000 rpm.

Evaporative Emission (EVAP) Controls (cont'd)

(From page 1'l 147)Check the EVAP purge controlsolenoid valve:1. Disconnect the 2P connectorfrom the EVAP purge controlsolenoid valve.2. Ouickly raise the engine speedto 3,000 rpm.

{To page 11 149)

tfl'I

Check lor a short in the wire{PCS line}l1. Turn the ignition switch OFF.2. Disconnect ECM connector A(32P).

3. Check for continuity betweenthe EVAP purge control solenoid valve 2P connector termi-nal No. 2 (818C5 engine: No. 1)and body ground.

Check for an open in the wire llclline):1. Turn the ignition switch OFF.2, Disconnect the 2P connectorfrom the EVAP purge controlsolenoid valve.3. Turn the ignition switch ON (ll).

4. At the harness side, measurevo ltage between the EVAPpurge controlsolenoid valve 2Pco n nector terminal No. 1( B 18C5 engine: No. 2) andbody ground.

EVAP PURGE CONTROI SOLENOIDVALVE 2P CONNECTOR IC114)B18C1, Cl8Bl engines: 818C5 engine:

PCSIRED/YEL}

femaleWire side offemaleterminals

YES

IGPl{YEL/BLKI

IGPlIYEL/BLKI

ECM CONNECTOR A {32PIPG1IBLKI

Insp€ct vacuum hose routing.lf OK, replace the EVAP purge

control solenoid valve.

neDair short in the wire betweenthe EVAP purge control solenoidvalve and the ECM lAl5).

Substitute a known-90od ECMand recheck. lI symptom/indica-tion goes away, replace the origi-nal ECM.

Repair open in the wirc betweenEVAP purge control solenoidvalve and PGM-FI main relav fuse.ls there battery voltage?

Check for an open in the wireIPCS linel:1. Turn the ignition switch OFF.2. Reconnect the 2P connector tothe EVAP purge control sole'noid valve.3. Turn the ignition switch ON (ll).

4. Measure voltage betweenECM connector terminals A15and A10.

Bopair open in the wiro betweenthe EVAP purgo control 3olanoidvalvo and the EcM {415).

11-144

(To page 11-149)

Page 362 of 1681

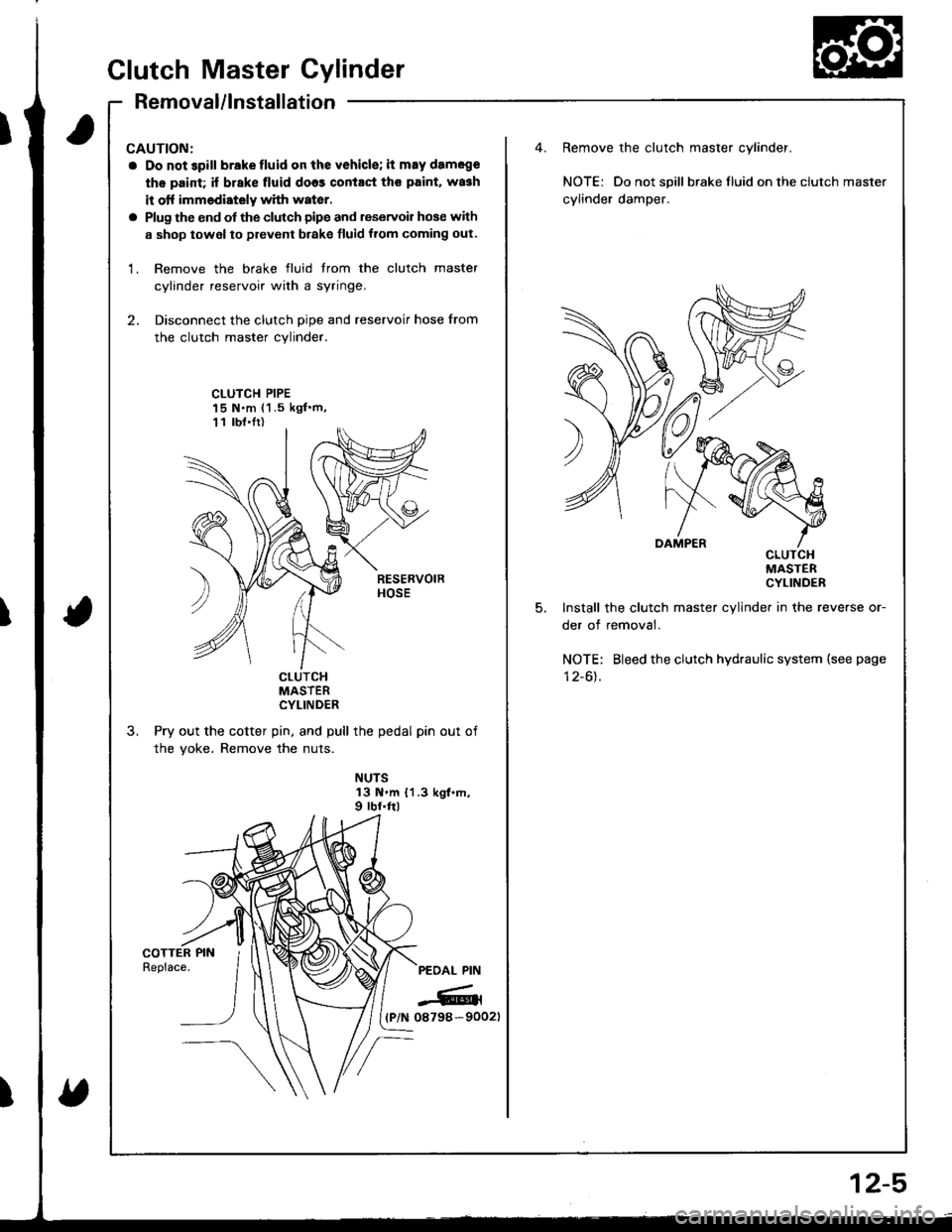

CAUTION:

a Do not 3pill brakefluid on the vehicle; it may damege

th€ paid; if brake fluid do63 contact th€ paint. wa3h

it otf immediately with water.

a Plug the end of the clutch pipe and reservoir hose with

a shop towel to prevent brake fluid from coming out.

1. Remove the brake fluid trom the clutch master

cylinder reservoir with a syringe,

2. Disconnect the clutch pipe and reservoir hose from

the clutch master cylinder.

Remove the clutch master cylinder.

NOTE: Do not spill braketluid ontheclutch master

cylinder damper.

CLUTCH PIPE15 N.m {1 .5 kgf'm,11 lbt.Ir)

5.

cLulcHMASTERCYLINDER

Install the clutch master cylinder in the reverse or-

der of removal.

NOTE: Bleed the clutch hydraulic system {see page

I z-ol.cturcHMASTERCYLINDER

Pry out the cotter pin, and pull the pedal pin out of

the yoke. Remove the nuts.

NUTS13 N.m {1.3 kgt.m,9 rbf.ftl

PEOAL PIN

-6rl(P/N 08798-90021

Clutch Master Cylinder

Removal/lnstallation

2-5

Page 363 of 1681

T

fi

;ill

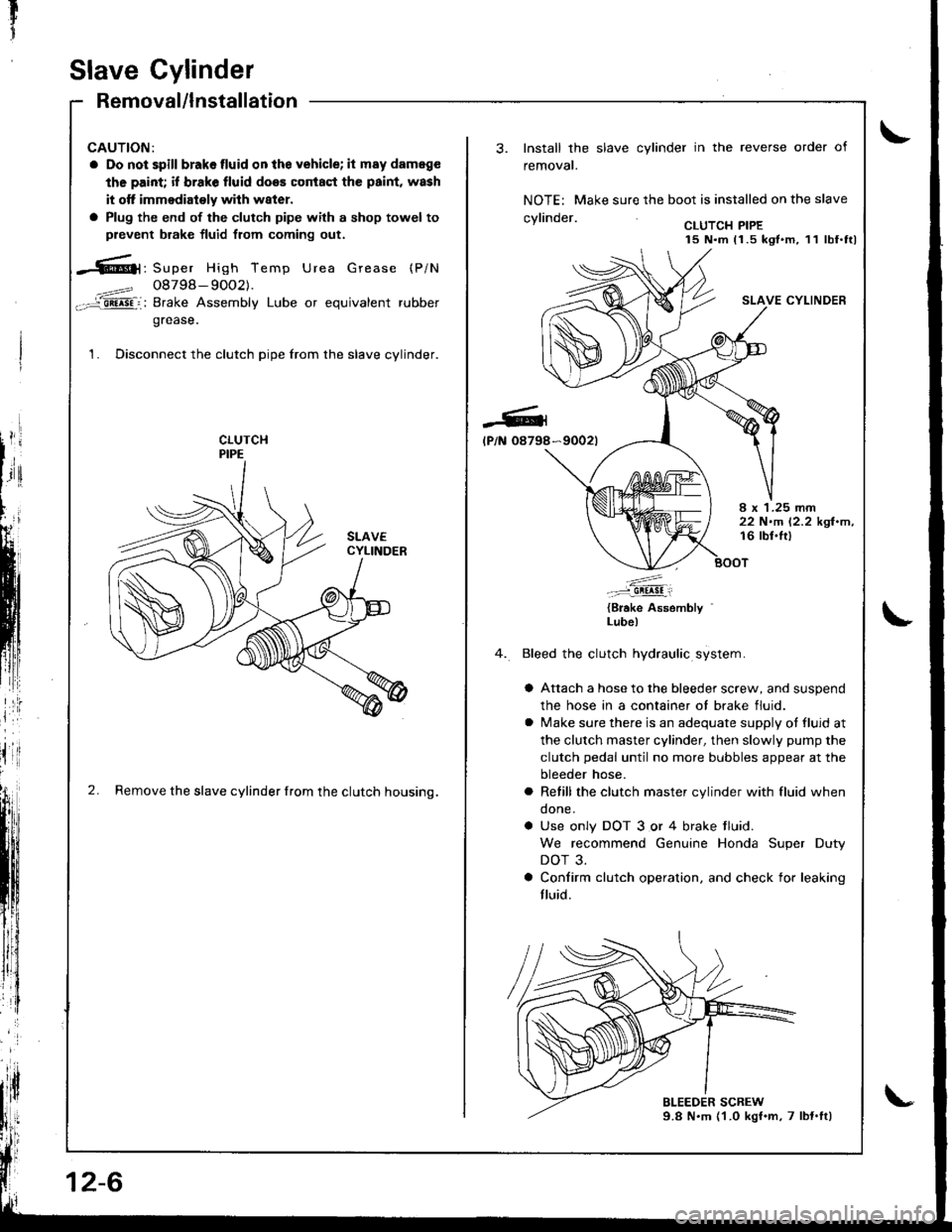

Slave Cylinder

Removal/lnstallation

CAUTION:

a Do not spill brakelluid onthe vehicle; it may dameg€

the paint; if brake fluid does coniaqt the paint, wash

it otf immodiaioly wilh w8ter.

a Plug the end of the clutch pipe with a shop towel to

prevent brake fluid from coming out.

-6|1, Super High Temp Urea Grease (P/N

4==? 08798- 9OO2).-='aii^5Fi: Brake Assembly Lube or equivalent rubber

grease.

1. Disconnect the clutch pipe from the slave cylinder.

2. Remove the slave cylinder from the clutch housing.

12-6

-Gl

lP/N 08798

Install the slave cylinder in the reverse order of

removal.

NOTE: Make sure the boot is installed on the slave

.wlin.larCLUTCH PIPE15 N.m 11.5 kgt.m, 11 lbf.ttl

SLAVE CYLINDER

*9002t

I x 1.25 rnm22 N.m 12.2 kgl.m,16 lbl.lt)

.'....-..-:::-9!!!!!i

{Brake Assembly '

Lube)

Bleed the clutch hydraulic system.

a Attach a hose to the bleeder screw, and suspend

the hose in a container ot brake fluid.

a lvlake sure there is an adequate supply ot fluid at

the clutch master cylinder, then slowly pump the

clutch pedal until no more bubbles appear at the

bleeder hose.

a Refill the clutch master cylinder with fluid when

done.

a Use only DOT 3 or 4 brake tluid.

We recommend Genuine Honda Super Duty

DOT 3.

a Confirm clutch operation. and check for leaking

fluid.

Page 373 of 1681

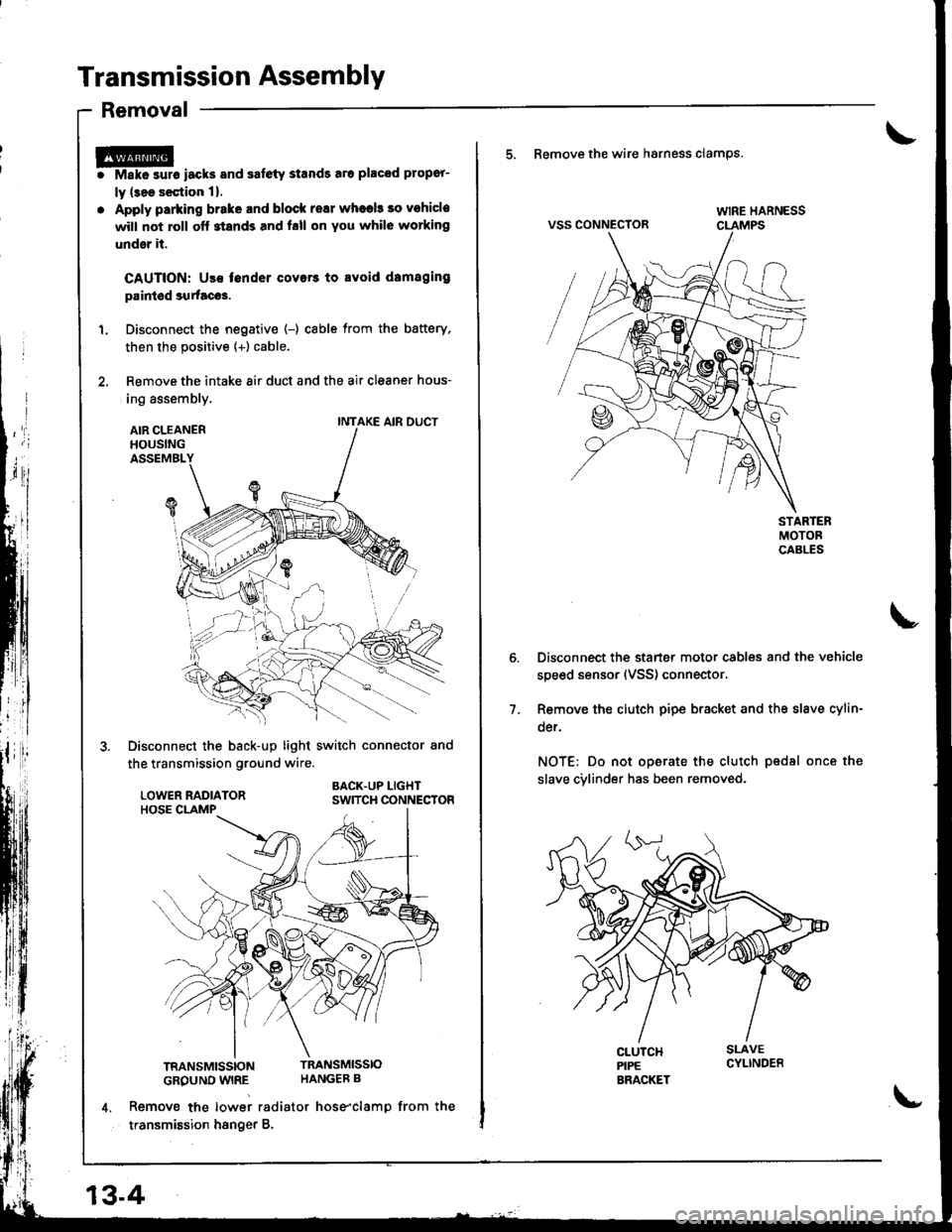

Transmission Assembly

Removal

r@i Make surs iacks and safety stands sro placod propor-

ly (3ee s€ction 1).

. Apply parking brake and block resr whaeb 30 vohicle

will not roll off stands and hll on You whil6 working

under it.

CAUTION: Use fender covers to svoid damaging

paintod surtacos.

1. Disconnect the negative (-) cable from the battery,

then the positive {+) cable.

2. Remove the intake 8ir duct and the air cleaner hous-

ing assembly,

AIR CLEANERHOUSINGASSEMBL

Disconnect the back-up light switch connector and

the transmission ground wire.

BACK.UP LIGHTSWITCH CONNECTOR

TRANSMISSIONTRANSMISSIO

GROUND WIRE HANGEB B

4. Remove tne lowei radiator hose"clamp from the

transmission hsnger B.

INTAKE AIR DUCT

13-4

\-

5. Remove the wire hsrness clamps.

VSS CONNECTOR

Disconnect the starter motor cables and the vehicle

speed sensor (VSS) connector.

Remove the clutch pipe bracket and the slave cylin-

der.

NOT€: Do not operate the clutch pedsl once the

slave cvlinder has been removed.

7.

Page 418 of 1681

Automatic Transmission

Special Tools ................ '14-2

Descraption .................... 14-3

Clutches ............ ...... 14-6

Power Flow ..,........... 14-8

Electronic Control System ..................... 1 4-1 8

Hydraulic Control ...... 14-23

Hydraulic Flow .........- 14-28

Lock-up System ........ 14-38

Electrical System

Component Location -................................ 1 4-45

Circuit Diagram ............. 14-46

TCM Terminal Voltage/

Measuring Conditions ......,.................... 1 4-48

Troubleshooting Procedures .. . ... ........ ...... ... 14-50

Symptom-to-Component Chart

Electrical System ...... 14-54

Electrical Troubleshooting

Troubleshooting Flowcharts .......... ... ...,.. 14-56

Lock-up Control Solenoid Valve A/B Assembly

Test .................. ...... 14-A7

Replacement ............. 14-a7

Shilt Control Solenoid Valve A/B Assembly

Test .................. ...... '14-88

Replacement .,..,........ 14-88

lvlainshaf t/Countershaft Speed Sensors

Replacement ....-......,. 14-89

Transmission Control Module (TCM)

Replacement ............. 14-89

Hydraulic System

Symptom-to-Component Chart

Hydraulic System ...... 14-90

Road Test ,................... 14-94

Stall Speed

Test .................. ...... 14-97

Fluid Level

Checking/Changing .... 14-98

Pressure Testing ........... 14-99

Transmission

Transmission

Removal ............. ...... 14-10�4

lllustrated lndex

Transmission/Right Side Cover ............... 1 4-1 08

Transmission Housin9 ................,..,....... 1 4-1'1 O

Torque Converter Housing/ValveBody .................. .. 14-112

Right Side Cover

Removal ............. ...... 14-114

Transmission Housing

Removal ............. ...... 14-1 l6

Torque Converter Housing/Valve Body

Removal ............. ...... l4-1 18

Valve Caps

Description ...........-... 14-120

Valve Body

Repair ................ ...... 14-12'l

Valve

Assembly

ATF Pump

Inspeclton

Main Valve Body

Disassembly/lnspection/Reassembly

Regulator Valve Body

Disassembly/lnspection/Reassembly

Lock-up Valve Body

Disassembly/lnspection/Reassembly

Secondary Valve Body

Disassembly/lnspection/Reassembly

Servo Body

....... 14-124

....... 14-126

....... 14-127

....... 14 124

Disassembly/lnspection/Reassembly .......

1st-hold Accumulator/Right Side Cover

Disassembly/lnspection/Reassembly .......

Mainsha{t

14-130

14-132

Disassembly/lnspection/Reassembly ....... 14-133

Inspection ................. 14-134

Countershaft

Disassembly/lnspection/Reassembly,..,.., l4-136

Disassembly/Reassembly ..,...,..,.........,,.. 1 4-1 37

Inspection ......,...,..,... 14-138

One-way Clutch

Disassembly/lnspection/Reassembly ....,.. 14-141

Sub-shaft

Disassembly/lnspection/Reassembly ...,,..'14-142

Disassembly/Reassembly ....................... 1 4- l 43

Sub-shaft Bearings

Replacement ,..,,.,,..,.. 14-144

Clutch

lllustrated Index ................................... I 4-1 45

Disassembly ............. 14-144

Reassembly .............. 14-150

Torque Converter Housing Bearings

Mainshaft Bearing/Oil Seal

Replacement ......... 14-154

Countershaft Bearing Replacement ......... 1 4- 1 55

Transmission Housing Bearings

Mainshaft/Countershaft BearingReplacement ......,.. 14-'156

Sub-shaft Bearing Replacement .,............ 1 4-1 57

Reverse ldler Gear

Installation .........-..... 14-158

Parking Brake Stop

Inspection/Adjustment .......................... 1 4-1 58

Transmission

Reassembly .............. 14-160

Torque Converler/Drive Plate ..............,.,,.,, 1 4-1 67

Transmission

Installation ............... 14-168

Cooler Flushing ......... 14-172

ATF Cooler Hoses

Connection ,..,,,....,,.,, '14-'174

*shift cable

Removal/lnstallation . . .. .... ... .... ... .... .. . ... .. 14-'l75

Adjustment ,..,...,,,,.,, 14-'116*Shilt lever

Disassembly/Reassembly ....................... 1 4-'17 7'Shift Indicator Panel

Adjustment .............. 14-178

\l

)g

Page 421 of 1681

Description

{cont'd)

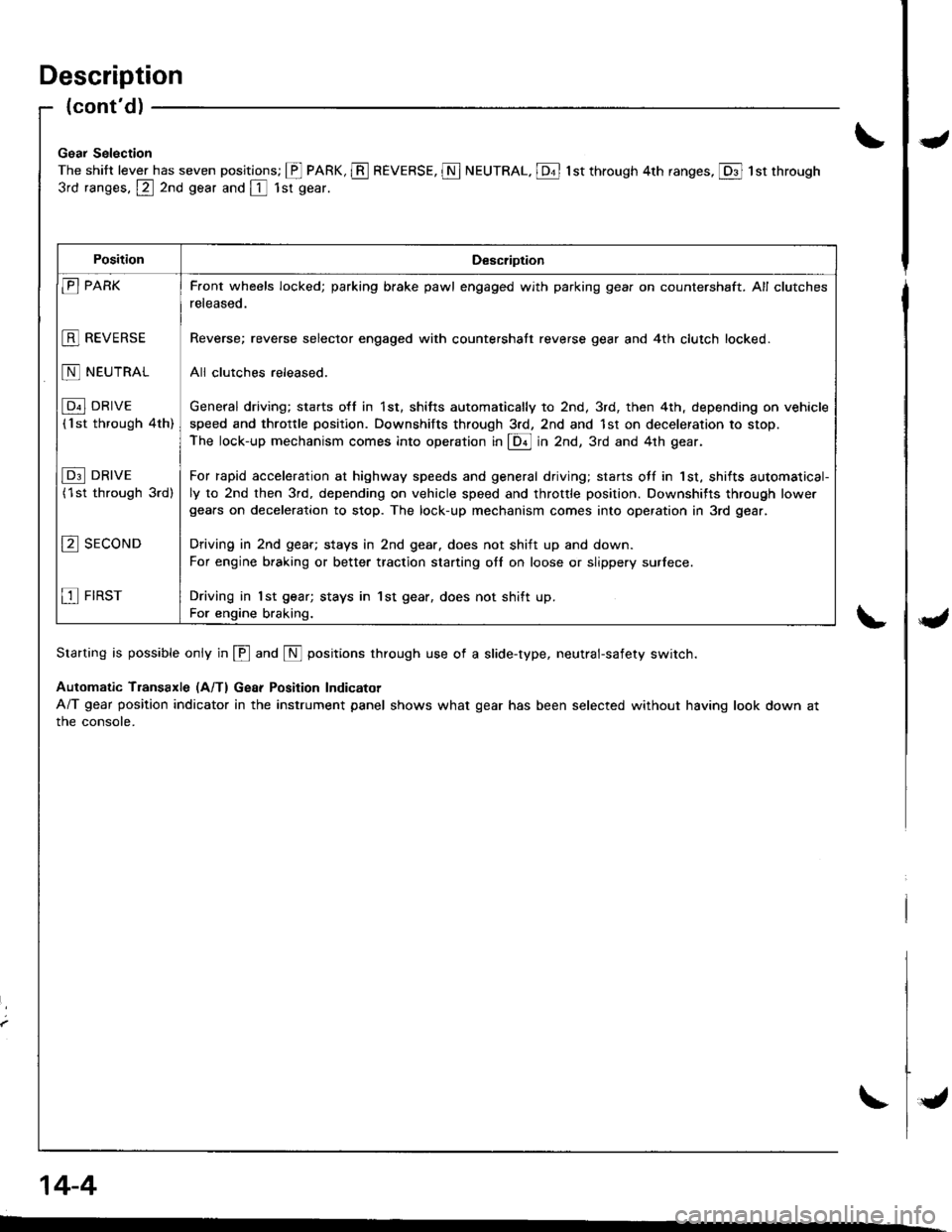

Gsar Selection

The shift lever has seven positions; @ PARK, E REVERSE, N NEUTRAL. [Dt l st through 4th ranges, @ 1st through

3rd ranges, @ 2nd gear and [ 1sr gear.

Starting is possible only in @ and N positions through use of a slide-type, neutral-safety switch.

Automatic Transaxle (A/T) Gear Position Indicator

A/T gear position indicator in the instrument panel shows what gear has been selected without having look down at

the console.

PositionDescription

E PARK

E REVERSE

N NEUTRAL

[p"l DRrvE

('lst through 4th)

I p3l DRrvE

(1st through 3rd)

E sEcoND

E FIRST

F.ont wheels locked; parking brake pawl engaged with parking gear on countershaft. All clutches

released.

Reverse; reverse selector engaged with countershatt reverse gear and 4th clutch locked.

All clulches released.

General driving; sta.ts o{f in 1st, shitts automatically to 2nd, 3rd, then 4th, depending on vehicle

speed and throttle positlon. Downshifts through 3rd, 2nd and 1st on deceleration to stop.

The lock-up mechanism comes into operation in @ in Zna, 3rd and 4th gear.

For rapid acceleration at highway speeds and general driving; starts otf in 1st, shifts automatical-

ly to 2nd then 3rd, depending on vehicle speed and throttle position. Downshifts through lowe.gears on deceleration to stop. The lock-up mechanism comes into operation in 3rd gear.

Driving in 2nd geat; stays in 2nd gear. does not shift up and down.

For engine braking or better traction starting otl on loose or slippery surlece.

Driving in 1st gear; stays in 1st gear, does not shift up.

For engine braking.

14-4

{

Page 426 of 1681

![HONDA INTEGRA 1998 4.G User Guide l

t

LNI Position

Hydraulic pressure is not applied to the clutches. Power is not transmitted to the countershaft.

[] Position

Hydrsulic pressure is not applied 10 the clutches. Power is not transmitt HONDA INTEGRA 1998 4.G User Guide l

t

LNI Position

Hydraulic pressure is not applied to the clutches. Power is not transmitted to the countershaft.

[] Position

Hydrsulic pressure is not applied 10 the clutches. Power is not transmitt](/img/13/6069/w960_6069-425.png)

l'

t

LNI Position

Hydraulic pressure is not applied to the clutches. Power is not transmitted to the countershaft.

[] Position

Hydrsulic pressure is not applied 10 the clutches. Power is not transmitted to the countershaft.

The countershaft is locked by the parking brake pawl interlocking the parking gear.

TOROUE CONVERTEB

PARKING GEAR

REVERSE SELECTOR

REVERSE GEAR

REVERSE SEI.ECTORHUB

SERVO VALVE/SHIFT FORK SHAFT

{cont'd)

14-9

Page 438 of 1681

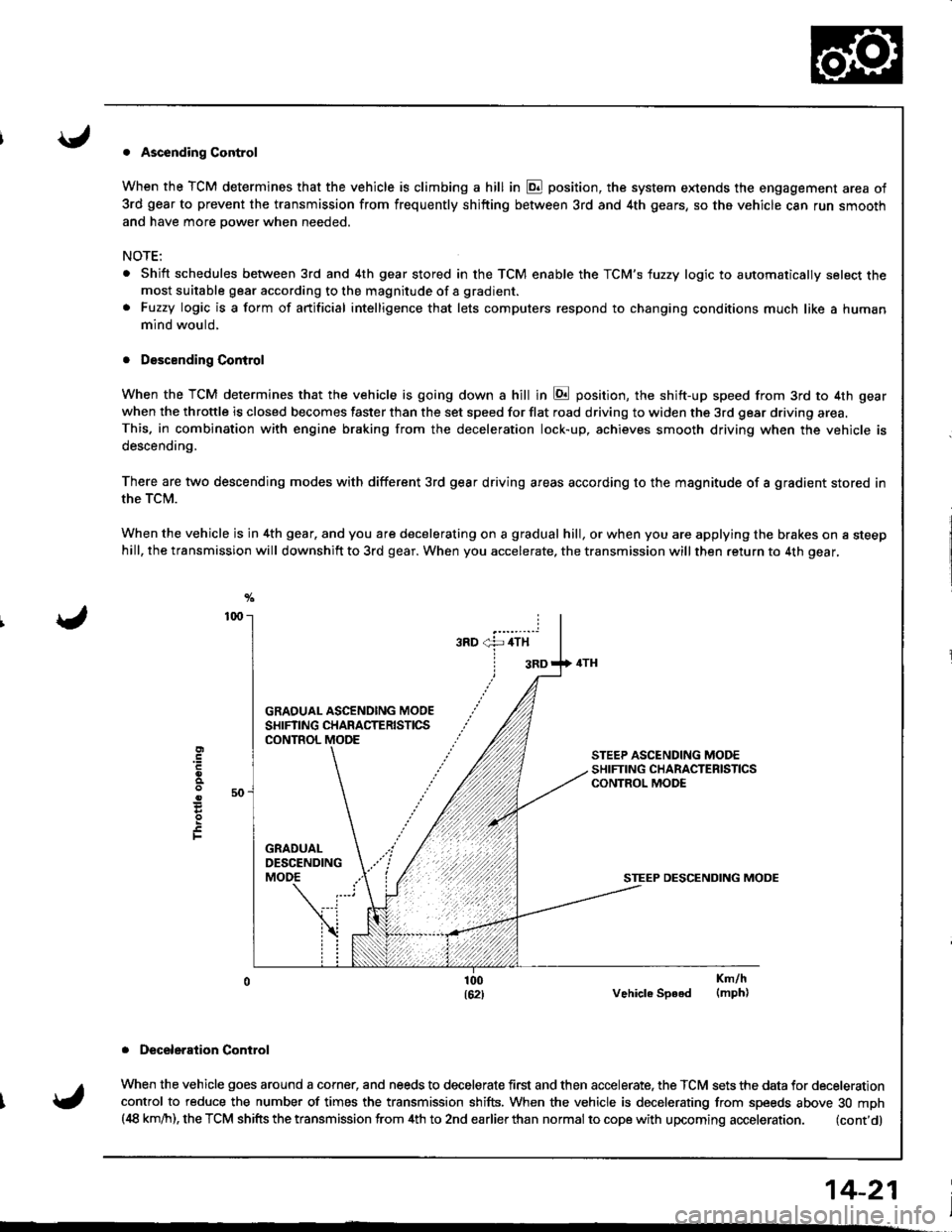

. Ascending Control

When the TCM determines that the vehicle is climbing a hill in E position, the system extends the engagement area of

3rd gear to prevent the transmission from frequently shifting between 3rd and 4th gears, so the vehicle can run smooth

and have more power when needed,

NOTE:

Shift schedules between 3rd and 4th gear stored in the TCM enable the TCM'S fuzzy logic to automatically select themost suitable gear according to the magnitude of a gradient.

Fuzzy logic is a form of artificial intelligence that lets computers respond to changing conditions much like a human

mind would,

. Descending Control

When the TCM determines that the vehicle is going down a hill in E position, the shift-up speed from 3rd to 4th gear

when the throttle is closed becomes faster than the set speed for flat road driving to widen the 3rd gear driving area.This. in combination with engine braking from the deceleration lock-up, achieves smooth driving when the vehicle is

descending,

There are two descending modes with different 3rd gear driving areas according to the magnitude of a gradient stored in

the TCM.

When the vehicle js in 4th gear, and you are decelerating on a gradual hill, or when you are applying the brakes on a steephill, the transmission will downshift to 3rd gear. When you accelerate, the transmission will then return to 4th gear,

GRAOUAL ASCENOING MOOESHIFTING CHARACTERISTICSCONTROL

STEEP DESCENDING MODE

Vehicle Speed

. Deceleraiion Control

When the vehicle goes around a corner, and needs to decelerate first and then accelerate. the TCM sets the data for deceleration

control to reduce the number of times the transmission shifts. When the vehicle is decelerating from speeds above 30 mph(,18 km/h), the TCM shifts the transmission from 4th to 2nd earlierthan normal to cope with upcoming acceleration. (cont'd)

E

F

Km/h(mph)

14-21

Page 465 of 1681

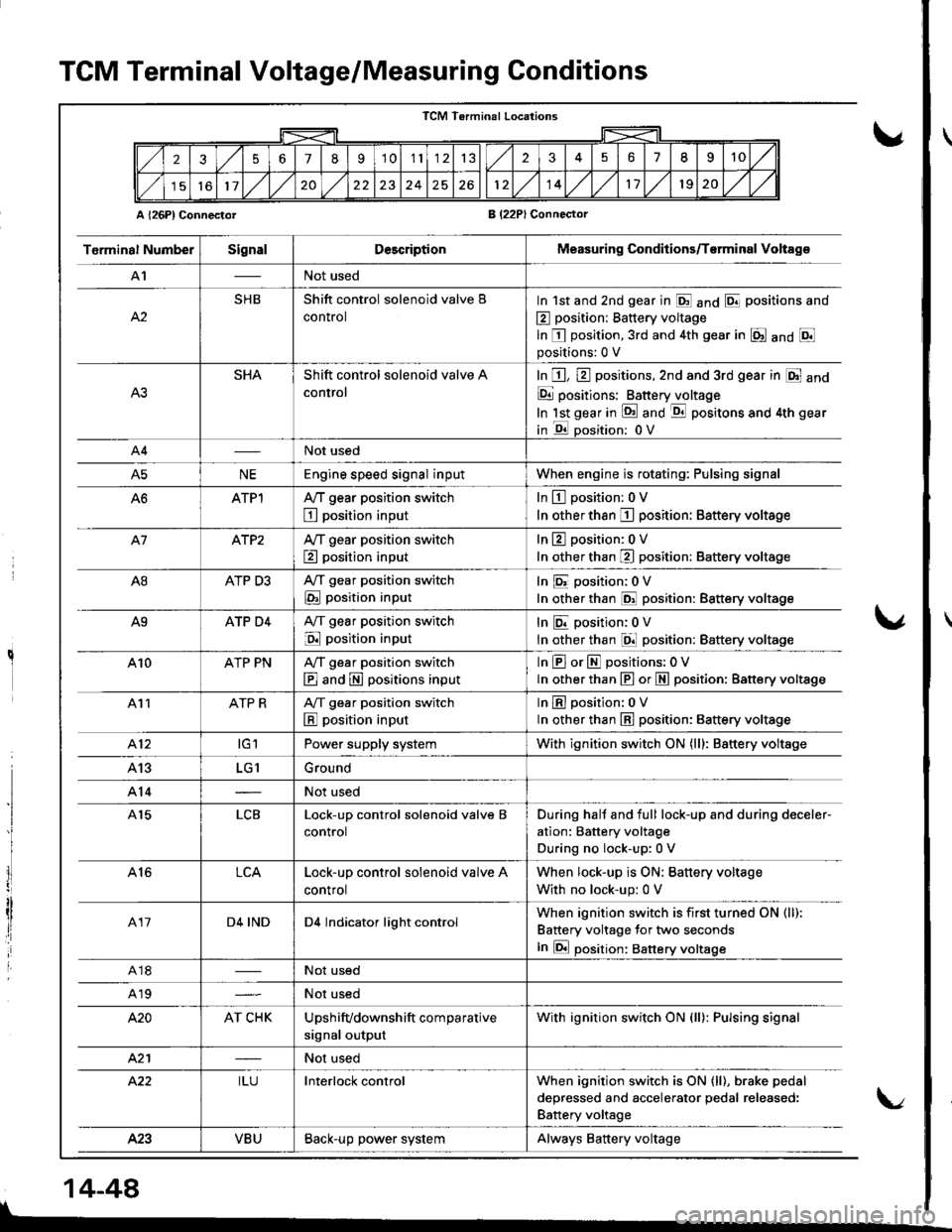

TCM Terminal Voltage/Measuring Conditions

A l26Pl ConnectorB (22PlConnector

TCM Terminal Locations

256789'1011132351II10

11,/l/2024261214,/l/1120,/1,/

T6rminal NumberSignalDescriptionMeasuring Conditions/T€rminal Voltag€

A'INot used

A2

SHBShift control solenoid valve B

control

In 1st and 2nd gear in E anO E positions and

E position: Battery voltage

ln E position,3rd and 4th gear in E anO Epositions:0 V

SHAShift control solenoid valve A

control

In E, E positions,2nd and 3rd gear in E and

E positions: Batteryjloltage

In lst gear in !d and -qtl positons and 4th gear

in E oosition: 0V

A4Not used

A5NEEngine speed signal inputWhen engine is rotating: Pulsing signal

ATPlA,/T gear position switch

E position input

In L!-l position: 0 V

In other than I position: Battery voltage

A7ATP2Ay'T gear position switch

E position input

In 13 position:0 V

In other than E position: Battery voltage

A8ATP D3A,/T gear position switch

E position input

In E position:0V

In other than @ position: Battery voltage

A9ATP D4A,/T gear position switch

E position input

InEposition;0V

In other than El position: Battery voltage

410ATP PNA,/T gear position switch

E and E positions input

InEorEpositions:OV

In other than E or N position: Battery vottage

411ATP RA/T gear position switch

E position input

lnEposition: oV

ln other than E position: 8attery voltage

412tGlPower supply systemWith ignition switch ON (lll: Battery voltage

413LG1Ground

A14Not used

A15LCBLock-up control solenoid valve B

control

During hall and full lock-up and during deceler-

ation: Battery voltage

During no lock-up:0 V

A16LCALock-up control solenoid valve A

control

When lock-up is ON; Battery voltage

With no lock-up: 0 V

417D4 INDD4 Indicator light controlWhen ignition switch is first turned ON (ll):

Battery voltage for two seconds

In E position: Battery voltsge

A18Not used

A19Not used

420AT CHKUpshifvdownshift comparative

signal output

With ignition switch ON (ll): Pulsing signal

421Not used

422ILUInterlock controlWhen ignition switch is ON (ll), brake pedal

deoressed and accelerator oedal released:

Battery voltage

423VBUBack-up power systemAlways Battery voltage

I

lI

I

14-44

\/