heater HONDA INTEGRA 1998 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 248 of 1681

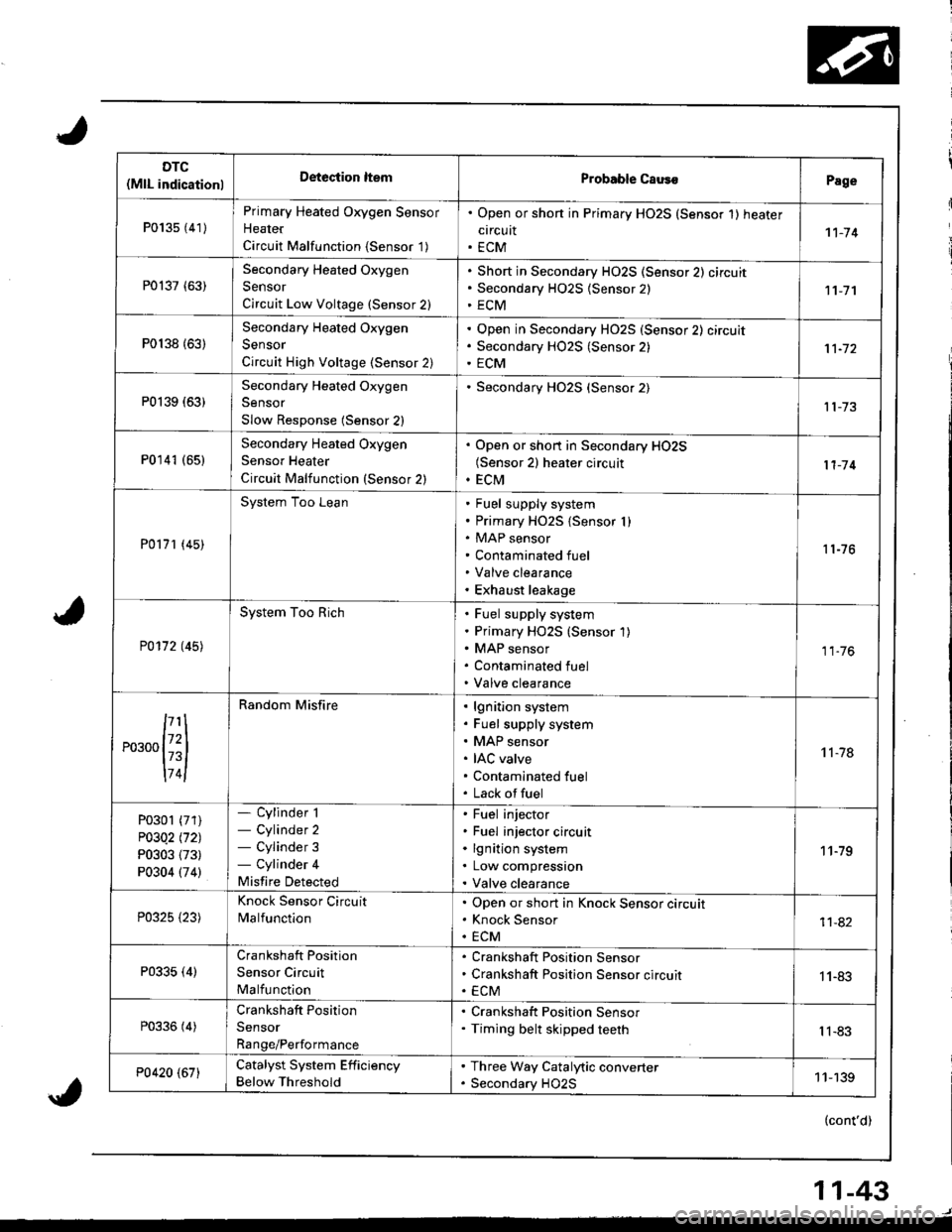

DTC(MlL indicationlDeteciion ltemProbable CausoPage

P013s {41)

Primary Heated Oxygen Sensor

Heater

Circuit Malfunction {Sensor '1)

. Open or shon in Primary HO2S (Sensor 1) heater

circuit. ECM1't-74

P0137 (63)Secondary Heated Oxygen

Sensor

Circuit Low Voltage (Sensor 2)

Short in Secondary HO2S (Sensor 2) circuit

Secondary H02S {Sensor 2)

ECM11-7'l

P0138 {63)

Secondary Heated Oxygen

Sensor

Circuit High Voltage (Sensor 2)

Open in Secondary HO2S (Sensor 2) circuit

Secondary HO2S (Sensor 2)

ECM

P0139 (63)Secondary Heated Oxygen

Sensor

Slow Response (Sensor 2)

Secondary HO2S (Sensor 2)

P0141 (651Secondary Heated Oxygen

Sensor Heater

Circuit Malfunction (Sensor 2)

. Open or short in Secondary HO2S(Sensor 2) heater circuit. ECM11-'14

P0171 (45)

System Too LeanFuel supply system

Primary HO2S {Sensor I )MAP sensor

Contaminated fuel

Valve clearance

Exhaust leakage

11-76

P0172 t45l

System Too RichFuel supply system

Primary HO2S (Sensor 1)

MAP sensor

Contaminated fuel

Valve clearance

11.76

,...,{iil

174l

Random Misfirelgnition system

Fuel supply system

MAP sensor

IAC valve

Contaminated fuel

Lack offuel

't 1-78

P0301 (71)

P03Q2 l'121

P0303 (73)

P0304 (74)

- Cylinder 1- Cylinder 2- Cylinder 3- Cylinder 4

Misfire Detected

Fuel injector

Fuel injector circuit

lgnition system

Low compression

Valve clearance

11-79

P0325 {23)

Knock Sensor Circuit

MalfunctionOpen or short in Knock Sensor circuit

Knock Sensor

ECM11-82

P0335 (4)Crankshaft Position

Sensor Circuit

Malfunction

Crankshaft Position Sensor

Crankshaft Position Sensor circuit

ECM1 1-83

P0336 (4)Crankshaft Position

Sensor

Range/Performance

. Crankshaft Position Sensor. Timing belt skipped teethIl-83

P0420 (67)Catalyst System Efficiency

Below Threshold

. Three Way Catalytic converter. Secondary HO2S11-139

(cont'd)

11-43

Page 253 of 1681

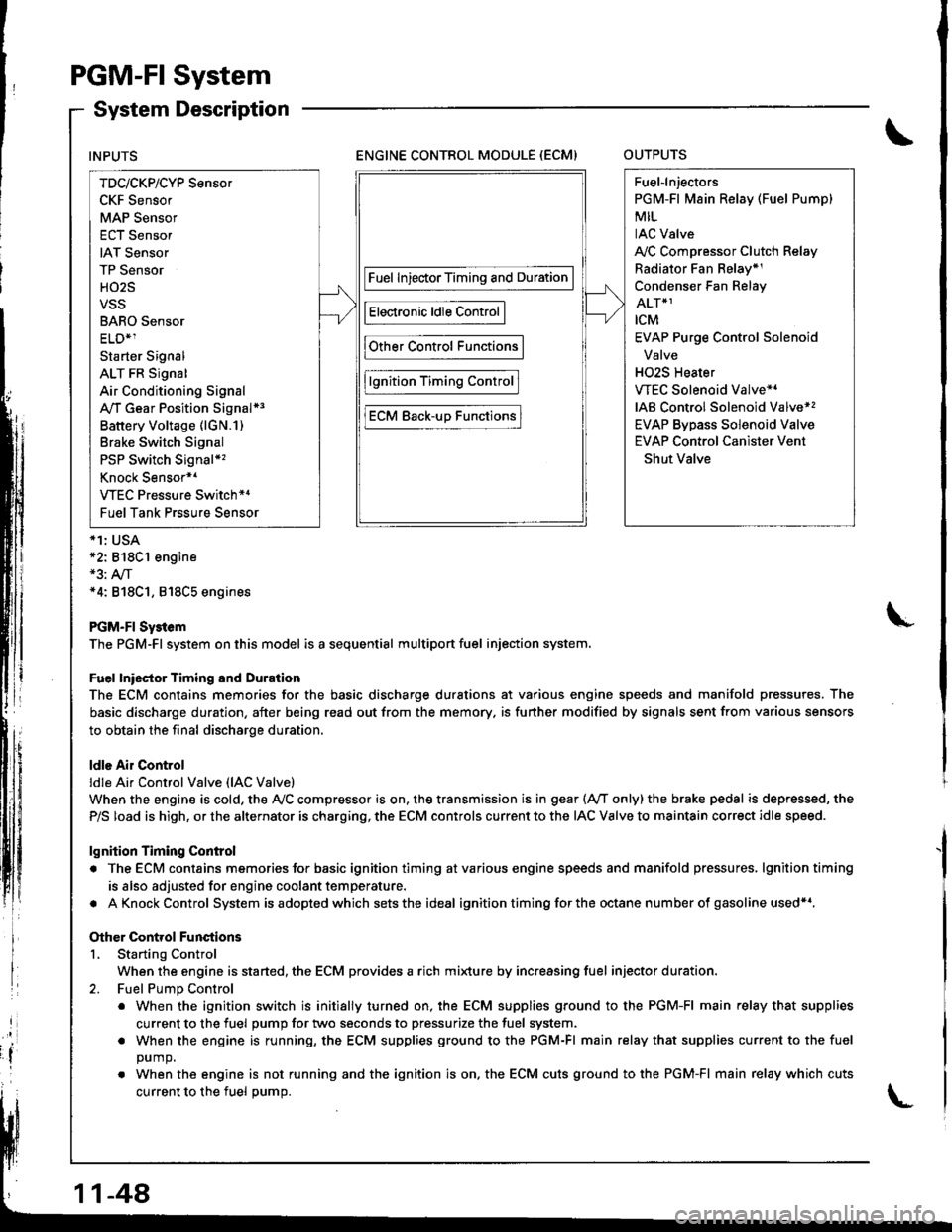

PGM-FI System

System Description

ENGINE CONTROL MODULE (ECM)OUTPUTS

*1: USA*2: 818C1 engine*3: A,/T*4: 818C1, 818C5 engines

PGM-FI Sy3tem

The PGM-Fl system on this model is a sequential multiport fuel injection system.

Fuel lniector Timing and Duration

The ECM contains memories for the basic discharge durations at various engine speeds and manifold pressures. The

basic discharge duration, after being read out from the memory. is further modified by signals sent from various sensors

to obtain the final discharge duration.

ldle Air Control

ldle Ai. Control Valve (lAC Valve)

When the engine is cold, the Ay'C compressor is on. the transmission is in gear (Ay'T only)the brake pedal is depressed, the

P/S load is high, or the alternator is charging, the ECM controls current to the IAC Valve to maintain correct idle speed.

lgnition Timing Control

. The ECM contains memories for basic ignition timing atvarious engine speeds and manifold pressures, lgnitiontiming

is also adjusted for engine coolant temperature.

. AKnockControl System isadoptedwhich sets the ideal ignition timing for the octane n um ber of gasoline used*r,

Other Control Functions

L Starting Control

When the engine is started, the ECM provides a rich mi{ure by increasing fuel injector duration.

2. Fuel PumD Control

. When the ignition switch is initially turned on, the ECM supplies ground to the PGM-FI main relay that supplies

current to the fuel pump for two seconds to pressurize the fuel system.

. When the engine is running, the ECM supplies ground to the PGM-FI main relay that supplies current to the fuel

DUmO.

. When the engine is not running and the ignition is on. the ECM cuts ground to the PGM-FI main relay which cuts

current to the fuel oumo.

INPUTS

TDc/CKP/CYP Sensor

CKF Sensor

MAP Sensor

ECT Sensor

IAT Sensor

TP Sensor

HO2S

VSS

BARO Sensor

ELD*1

Starter Signal

ALT FR Signal

Air Conditioning Signal

A,/T Gear Position Signal*3

Battery Voltage (lGN.1)

Brake Switch Signal

PSP Switch Signal*'�

Knock Sensor*1

VTEC Pressure Switch*4

Fuel Tank Prssure Sensor

Fuel InjectorTiming and Duration

Electronic ldle Control

Other Control Functions

lgnition Timing Control

ECM Back-uD Functions

Fuel-lnjectors

PGM-Fl Main Relay (Fuel Pump)

MIL

IAC Valve

A,/C Compressor Clutch Relay

Radiator Fan Belay*1

Condenser Fan Relay

ALT*1

rcM

EVAP Purge Control Solenoid

Valve

H02S Heater

VTEC Solenoid Valve*'

IAB Control Solenoid Valve*,

EVAP Bypass Solenoid Valve

EVAP Control Canister Vent

Shut Valve

11-48

Page 272 of 1681

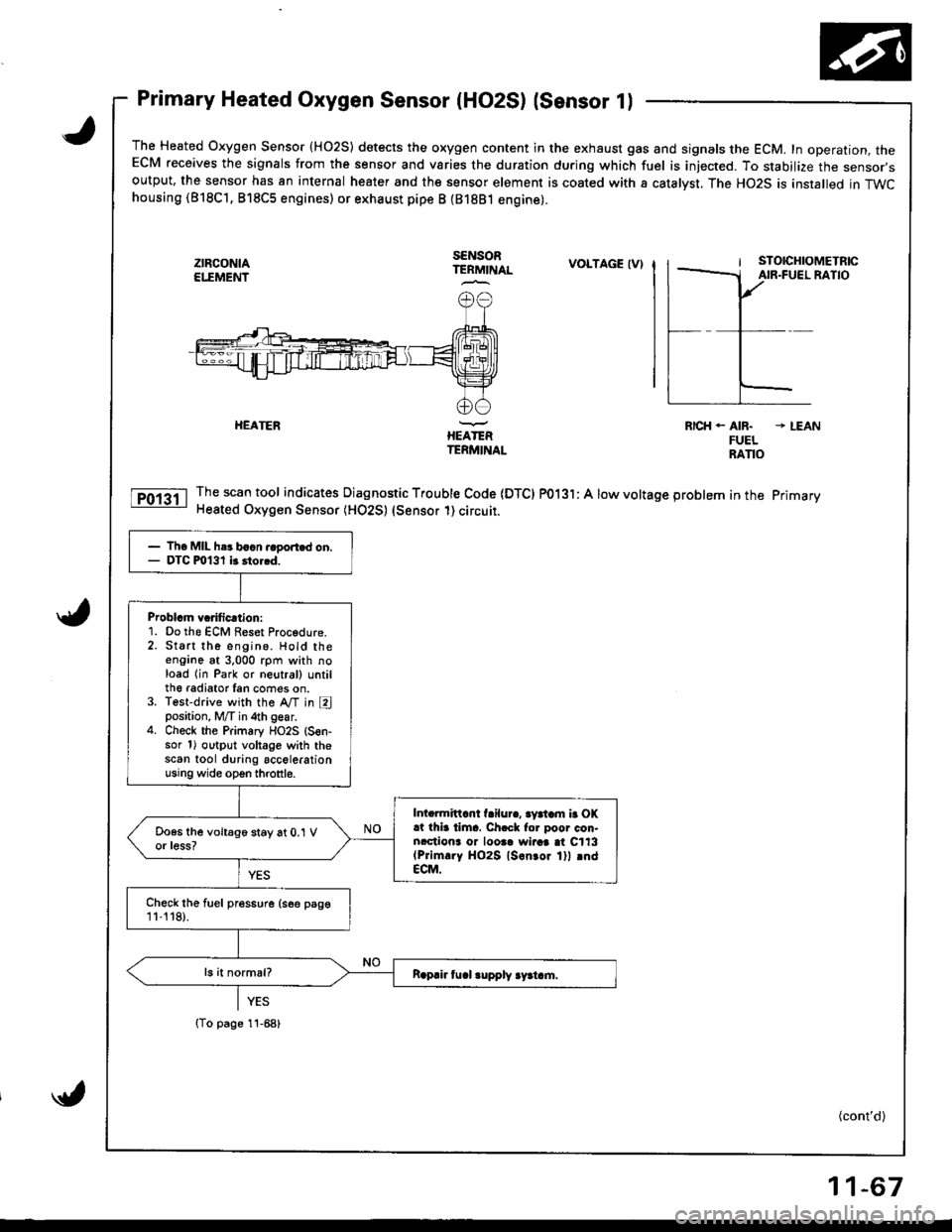

Primary Heated Oxygen Sensor (HO2S) lsensor 1l

The Heated Oxygen Sensor {HO2S) detects the oxygen content in the exhaust gas and signals the ECM. In operation, theECM receives the signals from the sensor and varies the duration during which fuel is iniected. To stabilize the sensor,soutput, the sensor has an internal heater and the sensor element is coated with a catalyst. The HO2S is installed in TWChousing (818C'1, 818C5 engines) or exhaust pipe B {81881 engine).

ztFcoNtAEI."EMEI'IT

SENSORTERMINALVOLTAGE IV)

HEATERIIEATERTERMINAL

RICH. AIR. * LEANFUELRANO

Thescantool indicates Diagnostic Trouble Code IDTCI PO13l: A low voltage problem in the primary

Heated Oxygen Sensor (HO2S) (Sensor 1) circuit.

- Th6 MIL h.r baan.ago.t.d on.- DTC m131 it 3to..d.

Problcm vcrificrtion:1. Do the ECM Reset Procedure.2. Start the engino. Hold theengane at 3,000 rpm with noload lin Park or neutral) untilth€ radiator Ian cofies on.3. Test-drive with the A,/T in Eposition, M/T in 4th gear.4. Check the Primary flO2S {S€n-sor 1) output voltage with thescan tool during accelerationusing wide open throttle.

Intarmittcnt f.ilur., 3yatam b OK.t thia tima. Ch.ck for poor con.nrctiona or loosa wiraa at C113(Prim.ry HO2S ls.n.or lll rndECM.

Chock the fuel pres6ure (see psge11-'t 18).

{To page 11-68)

(cont'd)

11-67

Page 275 of 1681

PGM-FI System

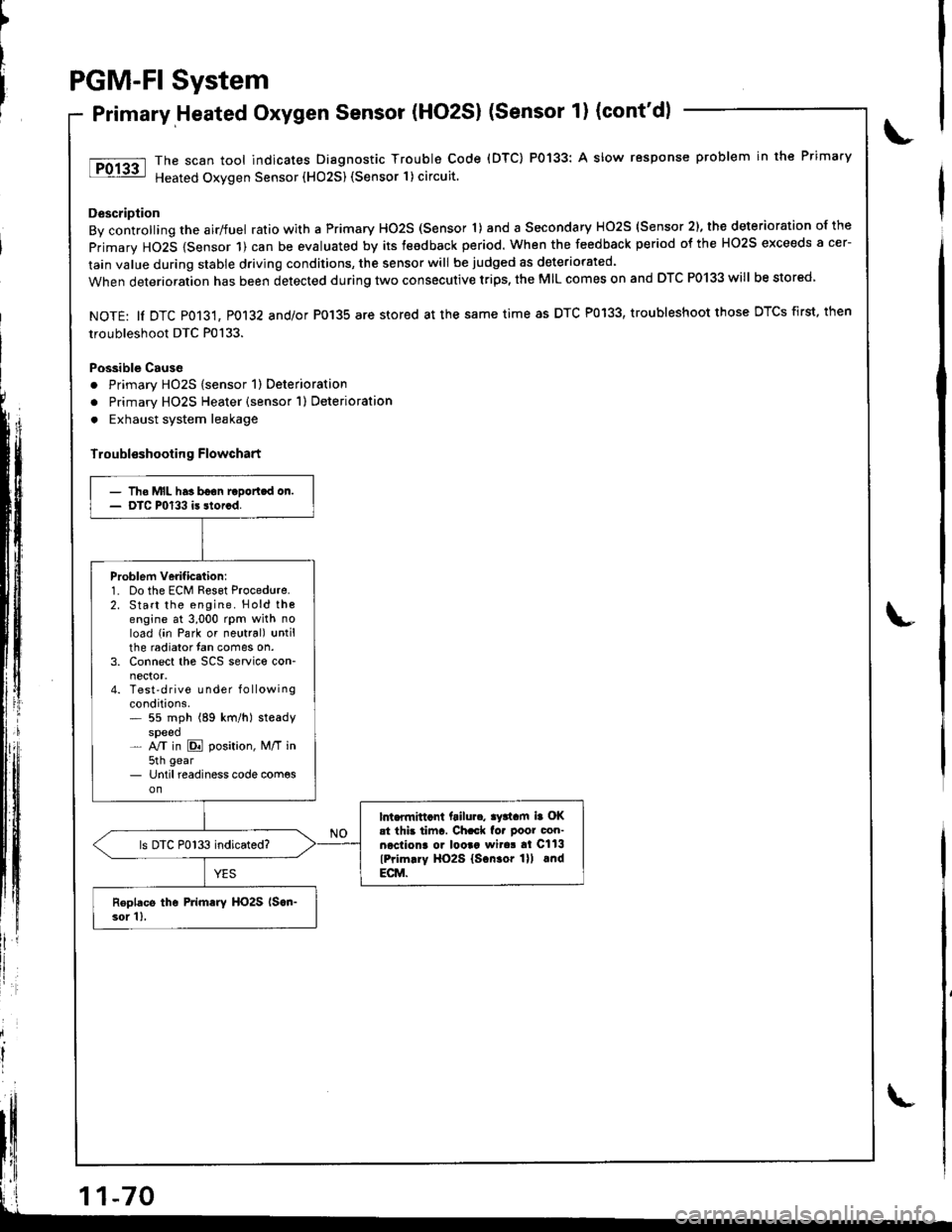

Primary,Heated Oxygen Sensor (HO2S) (Sensor 1) (cont'dl

The scan tool indicates Diagnostic Trouble Code (DTC) P0133: A slow response problem in the Primary

Heated Oxygen Sensor (HO25) (Sensor 1) circuit.

Description

By controlling the airlfuel ratio with a Primary HO2S (Sensor 'l) and a Secondary HO2S (Sensor 2), the deterioration of the

primary HO2S {Sensor 1) can be evaluated by its teedback period. When the feedback period of the HO2S exceeds a cer-

lain value during stable driving conditions, the sensor will be judged as deteriorated.

When deterioration has been detected during two consecutive trips, the MIL comes on and DTC P0133 will be stored

NOTE: ll DTC P013't, P0132 and/or P0'135 are stored at the same time as DTC P0133, troubleshoot those DTCS first, then

troubleshoot DTC P0133.

Possible Cause

. Primary HO2S (sensor 1) Deterioration

o Primary HO2S Heater (sensor 1) Deterioration

. Exhaust system leakage

Troubl€shooting Flowchart

')

litll r

- Tho MIL has boon raDortcd on.- DTC P0133 is storcd.

Problem verificttion:1. Do the ECM Reset Procedure.2. Start the engine. Hold thoengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator fan comes on.3. Connect the SCS service con-

4. Test'drive Lrnder f o llowingconditions.* 55 mph (89 km/h) steadyspeed- NT in E position, M/T in5th gear- Until readiness code com€son

lnt.flnittcnt ftilu... ay3tam ia OKat thb tiinr. Ch.ck fo. poor con-necliona o. looaa wita! al Cll3

lPrim.ry HO2S lscn.or lll lndECM.

ls DTC P0133 indicated?

Roplacs the Primary HO2S lscn-3or 1),

Page 279 of 1681

PGM-FI System

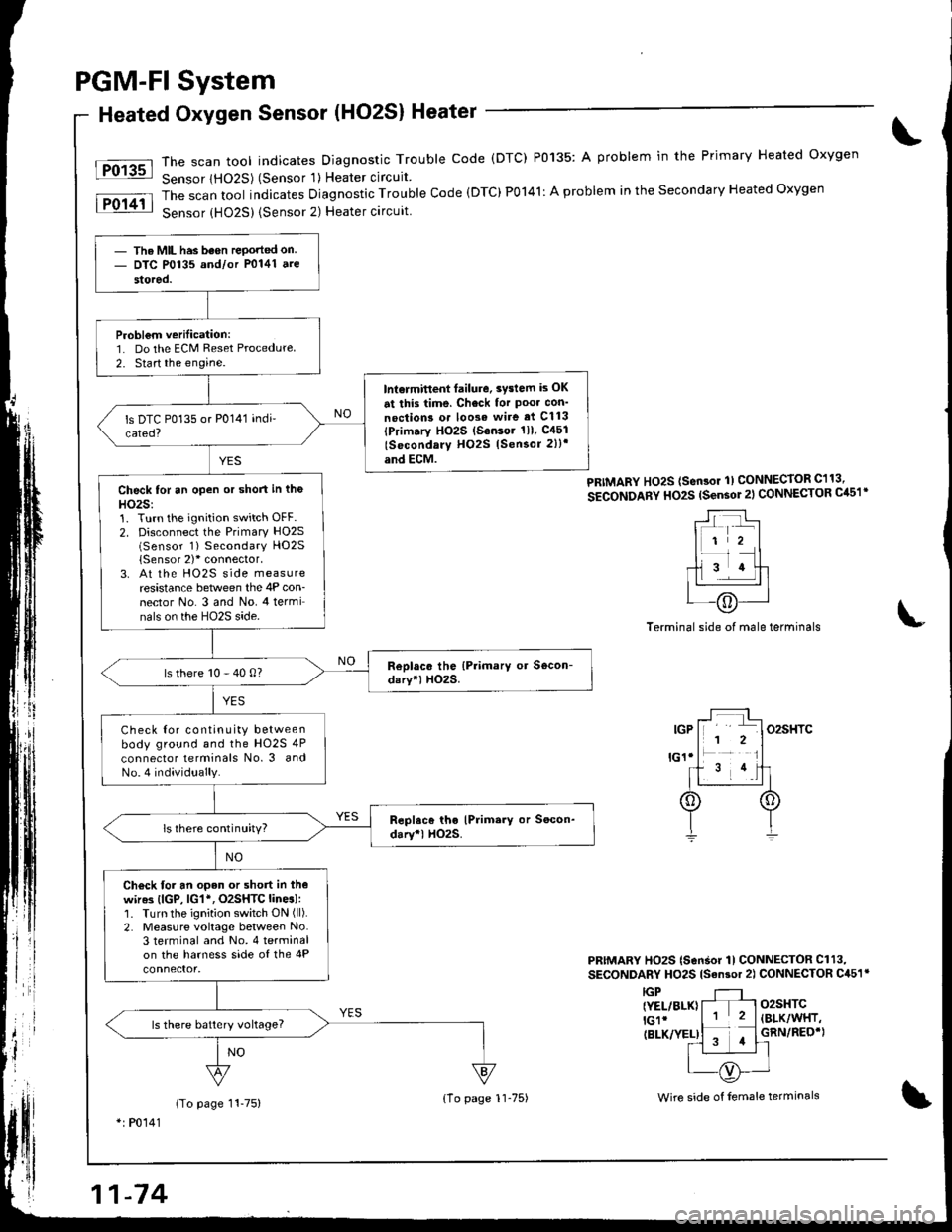

Heated Oxygen Sensor (HO2S) Heater

The scan tool indicates Diagnostic Trouble code (DTC) P0135: A problem in the Primary Heated oxygen

Sensor lHO2S) (Sensor 'l) Heater circuit

The scan tool indicates Diagnostic Trouble Code (DTC)P0141: A problem in the Secondary Heated Oxygen

Sensor {HO25) {Sensor 2) Heater circuit

Fo13sl

lFol4il

PRIMARY Ho2S (sen3or 1) CONNECToR C113,

SECONDARY HO2S (sensor 2l CONNECTOR Cil51'

Terminal side of male terminals

PRIMARY HO2S (SonSor 1l CONNECTOR Cl13,

SECONDARY HO2S lsan3or 2) CONNECTOR C451r

o2sHTC(BLK/WHT,

GRN/REO'}

IGP{YEL/BLK}lGlr(BLK/YEL)

(To page 11-75)*: P0141

- The MIL has been rePorted on- DTC P0135 and/or P0141 ate

stored.

Probl€m verilication:1. Do the ECM Reset Procedure

2. Start the engine.

lnt€rmitlent failure. 3vslem is OK

at this time. Check for Poo. con'

noction3 o. loose wire ai Cl13(Primary HO2S (S.nsor 1ll. gl51

lSocondary H02S lSensor 2))'

and ECM.

Check for an open or short in tho

HO2S:1. Turn the ignition switch OFF.2. Disconnect the Primary HO2S(Sensor 1) Secondary HO2S

{Sensor 2)'connector,3. At the HO2S side measureresistance between the 4P con-nector No. 3 and No. 4 terminals on the HO2S side.

ls there 10 - 40 0?

Check Ior continuity betweenbody ground and the HO2S 4P

connector lerminals No. 3 andNo.4 individually.

ls there continuity?

Ch€ck for an open or short in thewir63 (lGP, lG1*, O2SHTC lines):1. Turn the ignition switch ON (ll).

2. Measure voltage between No.3 terminal and No. 4 terminalon the harness side of the 4P

ls there batlery vohage?

{1o page 1l-75)Wire side of female terminals

Page 281 of 1681

PGM-Fl System

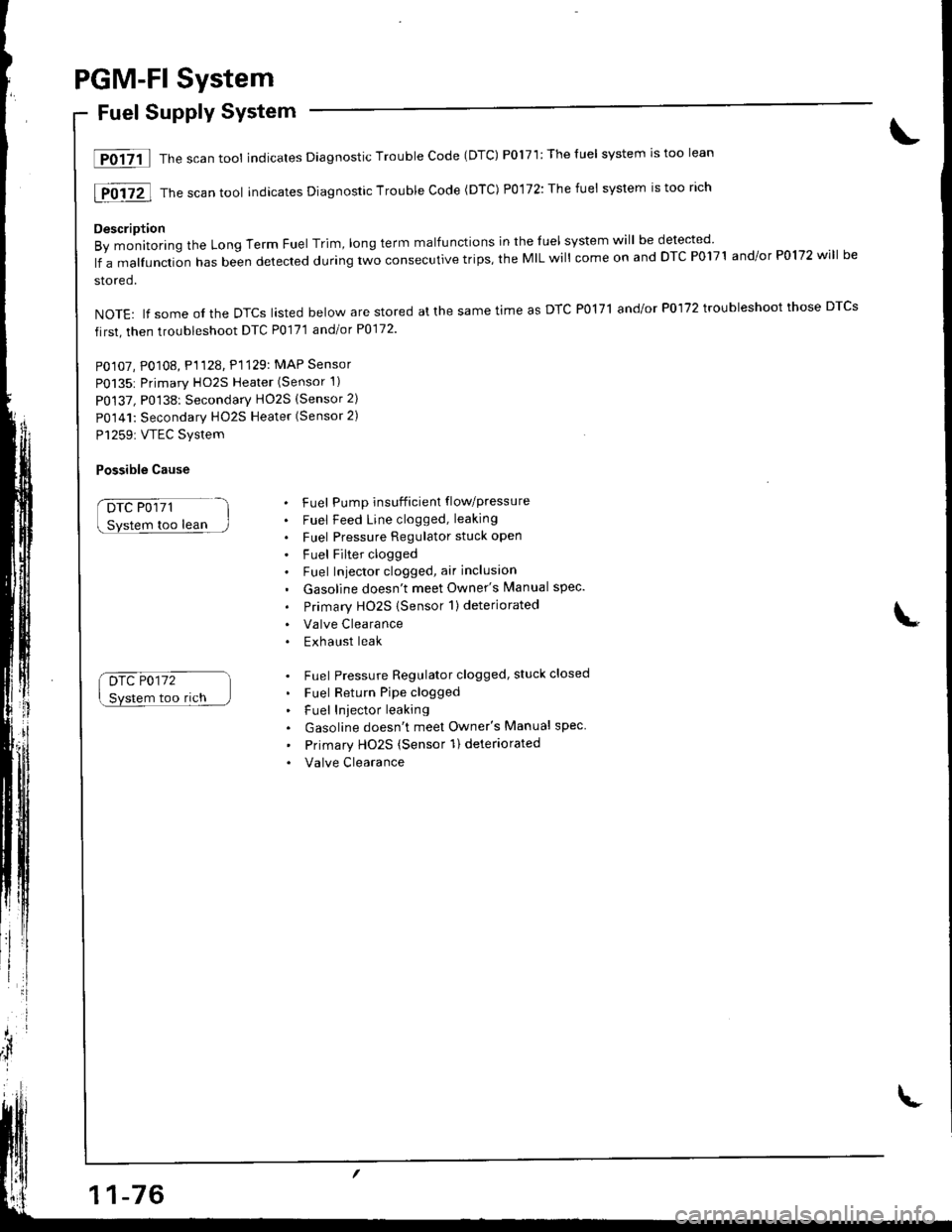

Fuel Supply System

lF0{7il Thescantool indicates Diagnostic Trouble Code (DTC) P0171:Theluel system rstoo lean

[F0i72l Th" ""un tool indicates Diagnosric Trouble code (DTc) p0,172: The fuet system is too rich

Description

By monitoring the Long Term Fuel Trim, long term malfunctions in the luel system will be detected

lf a malfunction has been detected during two consecutive trips, the MIL will come on and DTC P0171 and/or P0172 will be

stored.

NOTE: lf some ol the DTCS lasted below are stored at the same time as DTC PolTl and/or P0172 troubleshoot those DTCS

first, then troubleshoot DTC P0171 andlot P0172

PO107, P0108, P1128. P1129: MAP Sensor

P0135: Primary HO2S Heater (Sensor 1)

P0137, P0138: Secondarv HO2S (Sensor 2)

P0141: Secondary HO2S Heater (Sensor 2)

P1259: VTEC Svstem

Possible Cause

DTC P0171

too lean

Drc P0172

Svstem too rich

. Fuel Pump insufficient flowpressure

. Fuel Feed Line clogged, leaking

. Fuel Pressure Regulator stuck open

. Fuel Filter clogged. Fuel Iniector clogged, air inclusion

. Gasoline doesn't meet Owner's Manual spec.

. Primary HO2S (Sensor 1)deteriorated

. Valve Clearance. Exhaust leak

. Fuel Pressure Regulator clogged, stuck closed

. Fuel Return Pipe clogged

. Fuel Iniector leaking

. Gasoline doesn't meet Owner's Manual spec

' Primary Ho2s (Sensor 1) deteriorated

. Valve Clearance

Page 317 of 1681

ldle Control System

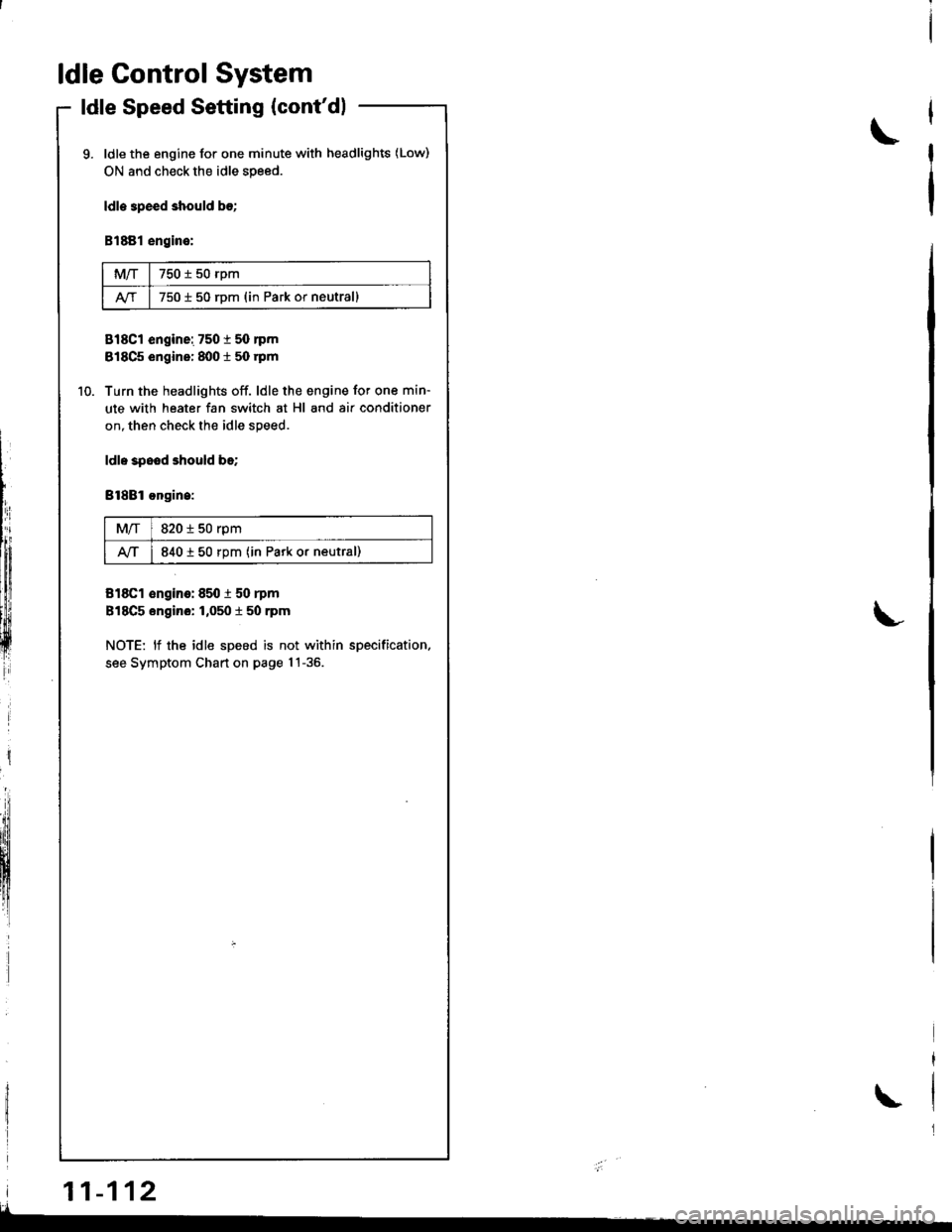

ldle Speed Setting (cont'dl

ldle the engine for one minute with headlights (Low)

ON and check the idle speed.

ldle 3peed should b€;

B1881 engine:

MIT750 t 50 rpm

750 i 50 rDm (in Park or neutrall

818C1 engine: 7501 50 nm

818C5 engine: 8001 50 rpm

Turn the headlights off. ldle the engine for one min-

ute with heater fan switch at Hl and air conditioner

on, then check the idle speed.

ldl. spood should be;

Bl8Bl ongin.:

M/T820 i 50 rpm

lvT840 t 50 rpm (in Park or neutral)

818C1 €ngino: 850 i 50 rpm

818C5 engino: 1,050 t 50 rpm

NOTE: lf the idle speed is not within specification.

see Symptom Chart on page 1!-36.

\

L

i

lIh:

lffiiltfl!

ffi

| 11-112

\

I

Page 343 of 1681

t"iI

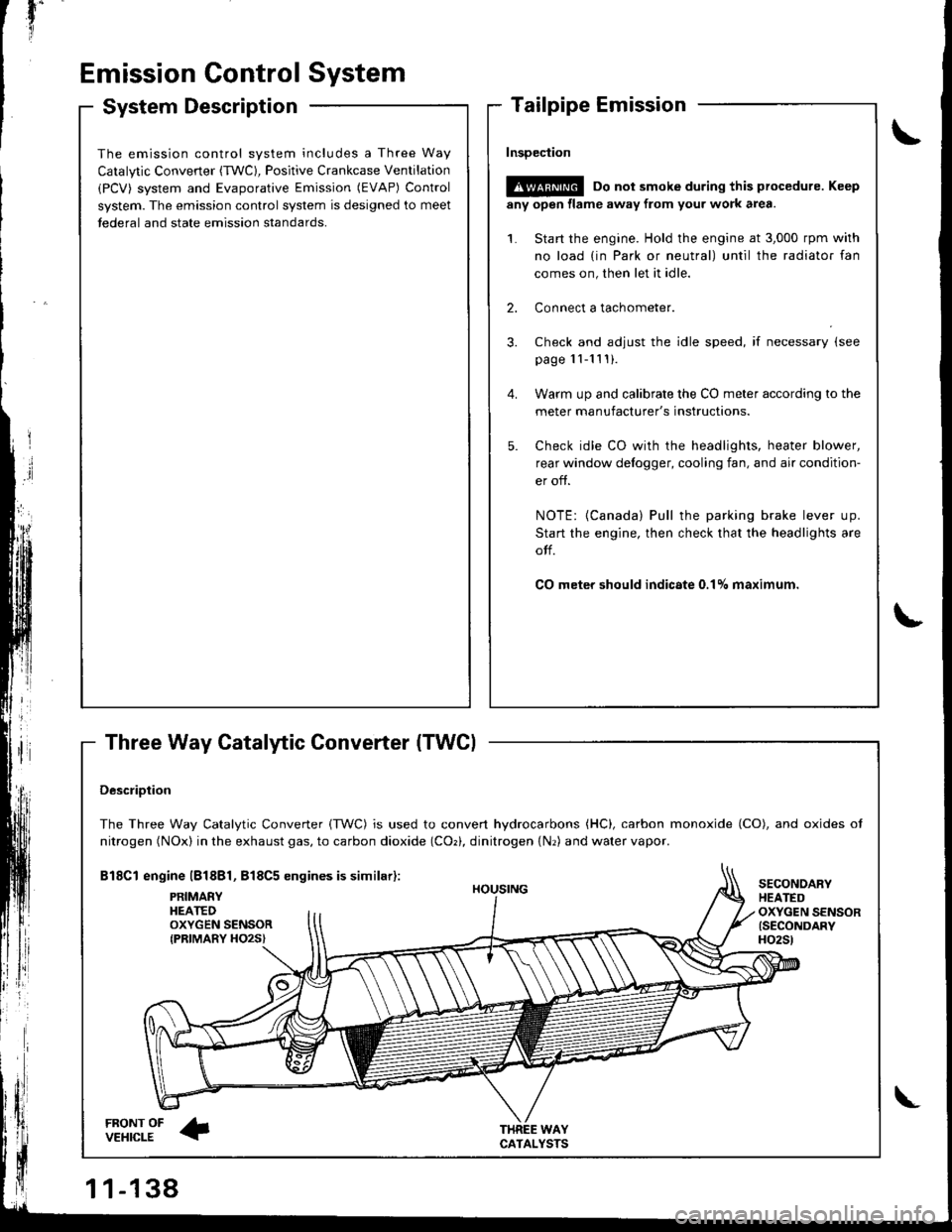

Emission Gontrol System

System Description

Three Way Catalytic Converter (TWCI

\

t

The emission control system includes a Three Way

Catalytic Converter (TWC), Positive Crankcase Ventilation

(PCV) system and Evaporative Emission (EVAP) Control

system. The emission control system is designed to meet

tederal and state emission standards.

InsDeciion

!@@ Do not smoke during this procedure. Keep

any open llame away from your work area.

1. Start the engine. Hold the engine at 3,000 rpm with

no load {in Park or neutral) until the radiator fan

comes on, then let it idle.

2. Connect a tachometer.

Check and adjust the idle speed, if necessary (see

page '11-11 ! ).

Warm up and calibrate the CO meter according to the

meter manufacturer's instructions.

Check idle CO with rhe headlights, heater blower,

rear window defogger, cooling fan, and air condition-

er off.

NOTE: {Canada) Pull the parking brake lever up.

Start the engine, then check that the headlights are

olf.

CO meter should indicste 0.17o maximum.

DescriDtion

The Three Way Catalytic Converter {TWC) is used to convert hydrocarbons (HC), carbon monoxide (CO), and oxides of

nitrogen (NOx) in the exhaust gas, to carbon dioxide (COr), dinitrogen {Nr) and water vapor.

Bl8Cl engine l818Bl, 818C5 engines is similar):

FRONT OFVEHICLE

PRIMAEYHEATEDOXYGEN SENSORIPRIMARY HO2S}

HOUSING

WAYCATALYSTS

SECONOARYHEATEDOXYGEN SENSOR{SECONDARYH02St

\

Page 344 of 1681

Three Way Catalytic Converter (TWC)

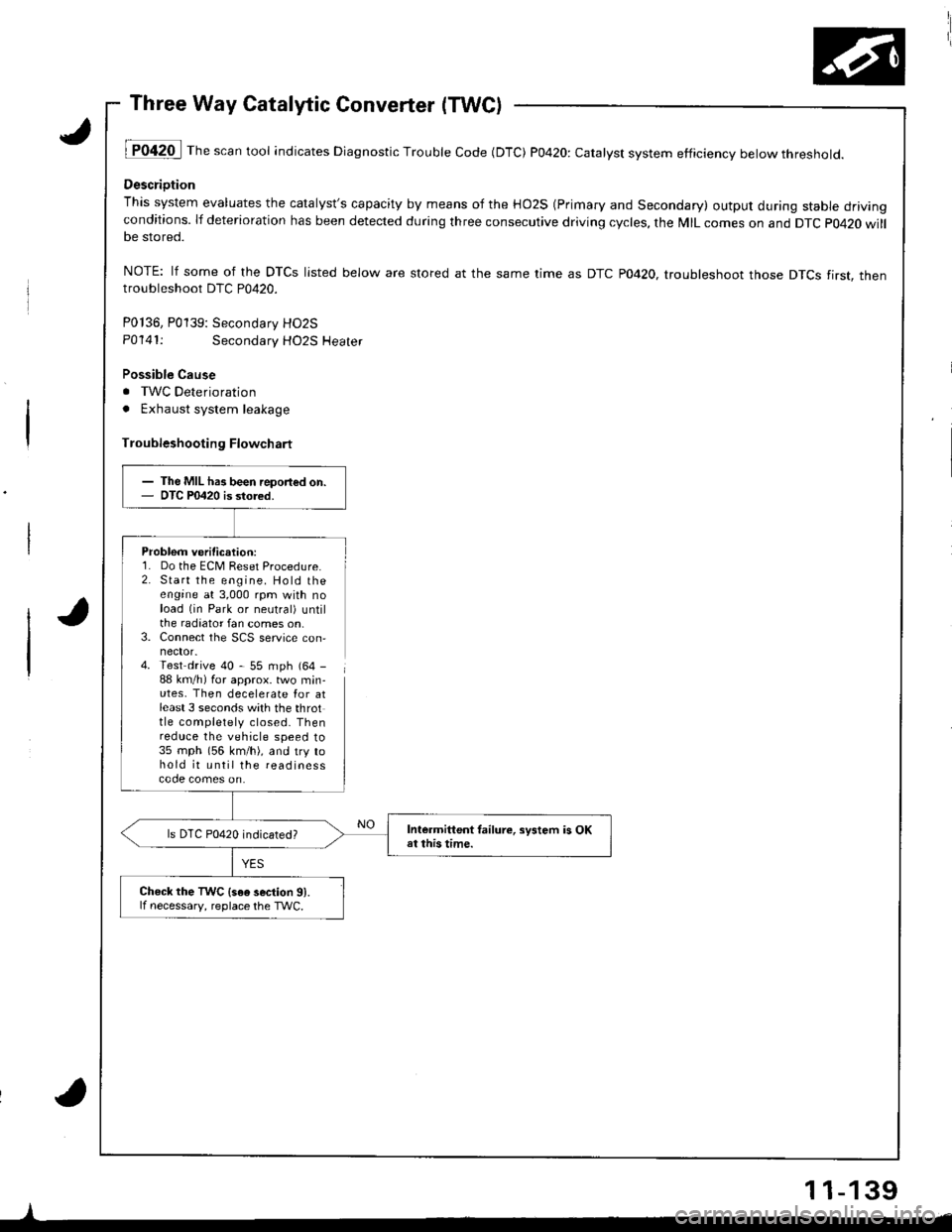

lT042O I Th" """n tool indicates Diagnostic Trouble Code (DTC) P0420: catatyst system efficiency below threshold.

Descriotion

This system evaluates the catalyst's capacity by means of the HO2S (Primary and Secondary) output during stable drivingconditions. lf deterioration has been detected during three consecutive driving cycles, the MIL comes on and DTC p0420 willbe stored.

NOTE: lf some of the DTCS listed below are stored at the same time as DTC PO42O. troubleshoot those DTCS tirst. thentroubleshoot DTC P0420.

P0136, P0139: Secondarv HO2S

P0141:Secondary HO2S Heater

Possible Cause

. TWC Deterioration

. Exhaust system leakage

Troubleshooting Flowchart

Problem verification:1. Do the ECM Reset Procedure.2. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator fan comes on,3. Connect the SCS service con,

4. Test drive 40 - 55 mph (64 -

88 km/h) for approx. two min-utes, Then decelerate Ior atleast 3 seconds with the throttle completely closed. Thenreduce the vehicle speed to35 mph (56 km/h), and try tohold it until the readinesscode comes on.

I

- The MIL has been report€d on.- OTC P0420 is stored.

Intermittent tailure, sFtem is OKat this time.ls DTC P0420 indicated?

Check the TWC {s6e 3ection 91.lf necessary, reolace the TWC.

11-139

Page 949 of 1681

Dashboard

Component Removal/lnstallation (cont'dl

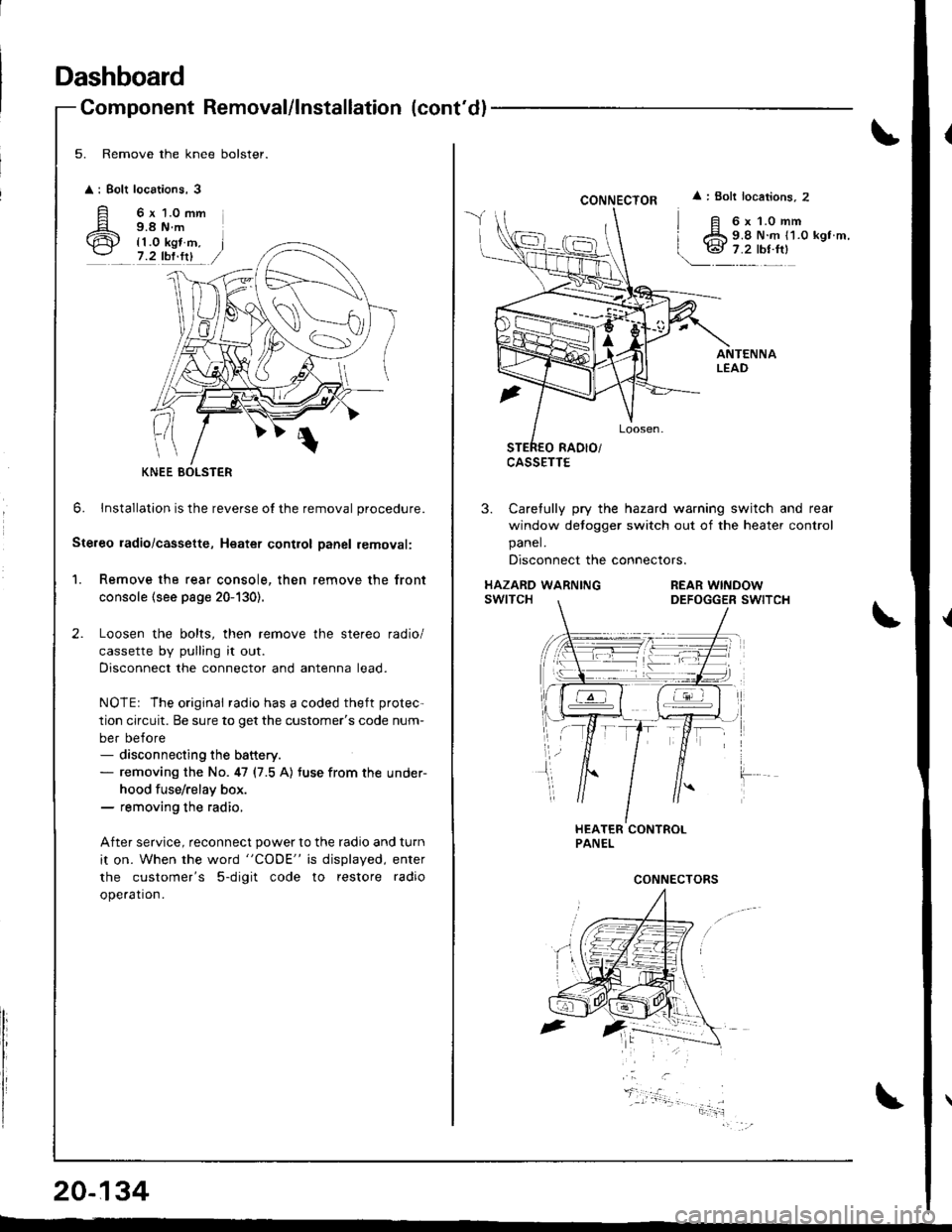

5. Remove the knee bolster.

: Bolt

A'ir

locations,3

6 x 1.0 mm9.8 N.m

{1.0 kgt m,7.2 tbf.fit

0

6. lnstallation is the reverse o{ the removal procedure.

Ste.eo ladio/cassette, Heatet contlol Danel removal:

1. Remove the rear console, then remove the front

console (see page 20-130).

Loosen the bolts, then remove the stereo radio/

cassette by pulling it out.

Disconnect the connector and antenna lead.

NOTEr The original radio has a coded theft protec-

tion circuit. Be sure to get the customer's code num-

ber before- disconnecting the battery.- removing the No. 47 (7.5 A) tuse from the under-

hood fuse/relay box.- removing the radio,

After service, reconnect power to the radio and turn

it on. When the word "CODE" is displayed, enter

the customer's 5-digit code to restore radio

ope.ation.

KNEE BOLSTER

20-134

CONNECTOR

CASSETTE

: Bolt locations, 2

6x1.0mm9.8 N.m {1.0 kgt m,

3. Carefully pry the hazard warning switch and rear

window detogger switch out of the heater control

panel.

Disconnect the connectors.

HAZARD WARNINGswtTcHREAR WINDOWDEFOGGER SWITCH

CONNECTORS