oil temperature HONDA INTEGRA 1998 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 1479 of 1681

A/C Gompressor Controls (conrd)

- How the Circuit Works

Battery voltage is supplied through fuse 56 to the

A,/C compressor clutch relay contacts at all times.

With the ignition switch in ON (ll), voltage is applied

to the coil of the A,/C compressor clutch relay

through fuse 17. When you push the A,/C switch

ON, and the heater fan switch is in posation 1, 2, 3,

or 4, a "ground" input is provided to the engine or

powertrain control module (ECM or PCM) through

the A,/C thermostat and the A,/C pressure switch.

The A,/C compressor clutch relay is grounded by the

engine or powertrain control module (ECM or PCM).

When energized, the A,/C compressor clutch relay

allows battery voltage to turn on the A,/C

comDressor clutch,

The A,/C ON indicator light comes on when the A"/C

system is requested.

A,/C Thermostat

The A,/C thermostat is located on the evaoorator

housing. The AJC thermostat turns off the A,/C

compressor clutch if the temperature at the

evaporator goes below 3'C (37'F). This prevents

condensation from freezing on the evaporator fins

and blocking the air delivery into the passenger

compartment. The blower motor will keep running

when the sensor lurns off the compressor.

A,/C Pressure Switch

The A,/C pressure switch is located in the condenser

outlet line where refrigerant is in a high

temperature/high pressure liquid state. The switch

will sense abnormally high or low pressure, and

open the circuit. This removes ground, and the

compressor will stop running.

Refer to the Service Manual (Section 22,

Air Conditioning) for specific tests or

troubleshooting procedures.

62-2

Page 1483 of 1681

Fans (cont'd)

- How the Gircuit Works

When the ignition switch is in ON (ll), voltage is

applied to the coils of the radiator fan relay and the

condenser fan relay (with A,/C) through fuse 17.

Whenever a ground is provided to the radiator fan

relay and condenser fan relay, the relays are

energized, turning on the radiator fan motor and

condenser fan motor. The relays can be grounded

by the radiator fan switch, engine or powertrain

control module (ECM or PCM) (USA), or the A,/C

and heater lan switches via the A'lC pressure switch

and the A,/C lhermostat.

A,/C Thermostat

The A,/C thermostat is located on the evaporator

housing. The A/C thermostat turns oft the A/C

compressor clutch it the temperature at the

evaporator goes below 3'C (37"F). This prevents

condensalion from freezing on the evaporator fins

and blocking the air delivery into the passenger

compartment. lt the temperature goes below 3'C

(37'F) turning off the A"/C thermostat, and the

BLU/RED wire at the A,/C diode was the only wire

providing ground to the condenser and radiator

fan relays (A,/C switch on, heater fans switch on,

radiator fan switch open, and ECM or PCM fan

controi output not grounded), the relay will

deenergize removing voltage from the condenser

and radiator fan motors causing them to stop

running.

A,/C Pressure Switch

The AJC oressure switch is located in the condenser

outlet line where refrigerant is in a high

temperature/high pressure liquid state. The A,/C

switch turns off the A,/C compressor clutch if it

senses abnormally high or low pressure. lf the A'lC

pressure switch opens, and the BLU/RED wire at

the A/C diode was the only wire providing ground

to the condenser and radiator fan relays (L/C switch

on, heater fans switch on, radiator lan switch open'

and ECM or PCM fan control output not grounded),

the relay will deenergize removing voltage from the

condenser and radiator fan motors causing them to

stop running.

A./C Diode

This diode orevents the radiator fan switch f rom

grounding the "A'lC ON" input to the engine or

powertrain control module (ECM or PCM).

Refer to the Service Manual (Section 23, Electrical)

for specific tests or troubleshooting procedures.

63-3

Page 1500 of 1681

Gauges (cont'd)

- How the Circuit Works

When the ignition switch is in ON (ll) or START (lll),

battery voltage is supplied through fuse 25 to the

gauges in the gauge assembly.

Speedometer and Odometer

The odometer and speedometer drive circuits

receive pulses lrom the vehicle speed sensor

(VSS). The pulse rate increases as the car

accelerates. The frequency and duration of these

input pulses are measured and displayed by the

speedometer, odometer and tripmeter.

Tachometer ('98-'99 Models)

The tachometer drive circuit receives oulses from

the ignition control module (lCM) in the distributor

assembly. The solid-state tachometer then displays

these pulses as engine speed. For each 200 pulses

per minute from the ignition control module (lCM),

the tachometer displays 100 RPM.

Tachometer ('00 Model)

The tachometer drive circuit receives pulses f rom

the PCM or ECM. The solid-state tachometer then

displays these pulses as engine speed. For each

200 oulses oer minute trom the PCM or ECM the

tachometer displays 1 00 RPM.

Engine Coolant Temperature Gauge and Fuel

Gauge

The engine coolant temperature gauge has two

intersecting coils wound around a permanent

magnet rotor. Voltage applied to the coils, through

fuse 25, generates a magnetic field. The magnetic

field, controlled by the engine coolant temperature

gauge sending unit, causes the rotor to rotate and

the gauge needle to move. As the resistance in the

sending unit varies, current through the gauge coils

changes. The gauge needle moves toward the coil

with the strongest magnetic tield. The fuel gauge

works the same way.

The engine coolant temperature gauge sending

unit's resistance varies from about 137 ohms at low

engine temperature to between 30-46 ohms at high

temperature (radiator fan running).

The fuel gauge sending unit's resistance varies from

about 2-5 ohms at full, to about 110 ohms at empty.

When you turn the ignition switch to LOCK (0), the

gauge remains at the last reading until you turn lhe

ignition switch to ON (ll) or START (lll) again.

Refer to the Service Manual (Section 23, Electrical)

for specific tests or troubleshooting procedures.

81'2

Page 1598 of 1681

Connector ldentification and Wire Harness Routing (cont,d)

Connector

or

Terminal

Number ot

Cavities/

Color

LocationConnects toNotes

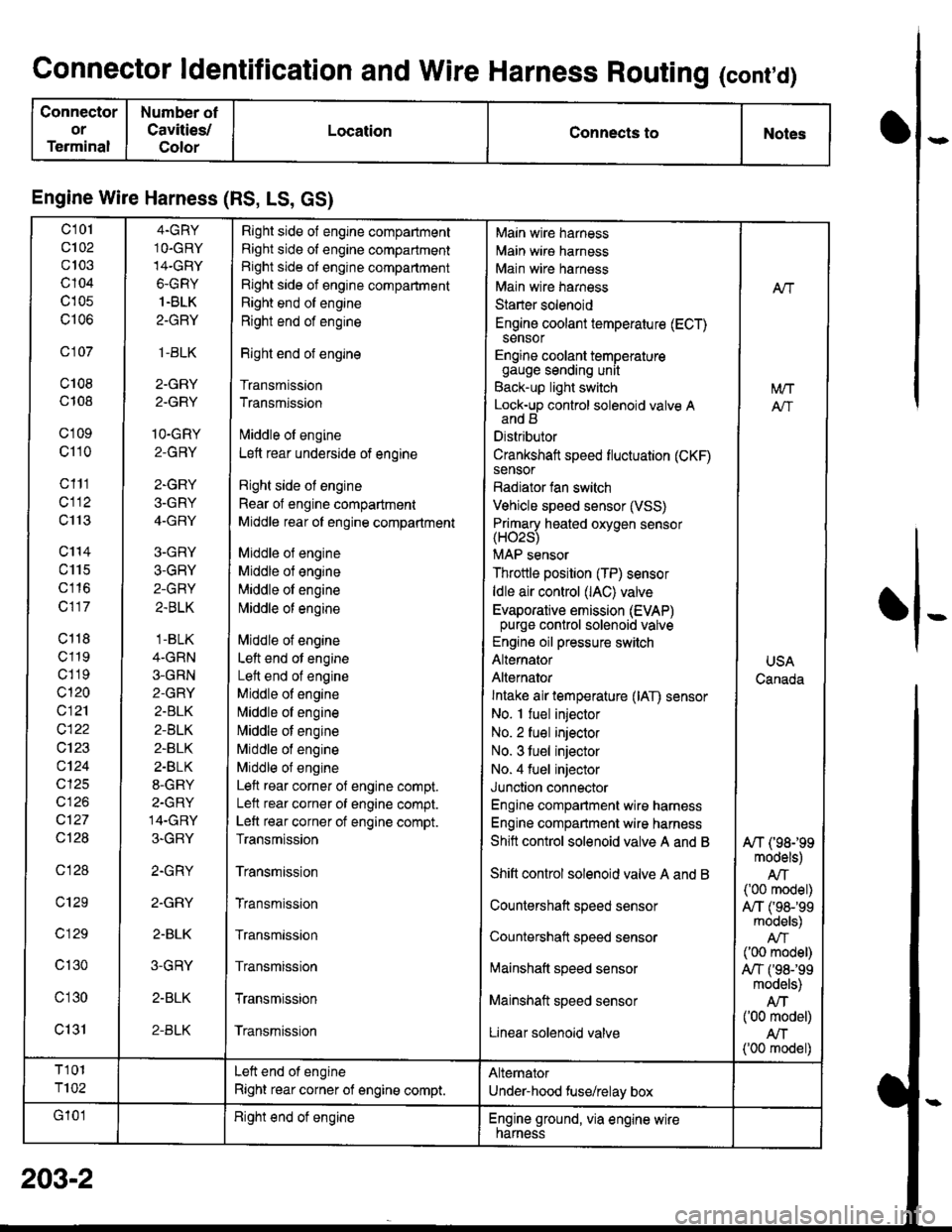

Engine Wire Harness (RS, LS, GS)

c101

c102

c103

c104

c105

c106

c 107

c108

c108

c'1 09

c110

c111

cl12

c113

c'114

c115

c116

c117

c118

c119

c1 19

c120

c121

c122

c123

c124

cl25

cl26

c127

Ql28

c128

c129

c 129

c130

c'l30

c131

4.GRY

1O.GRY

14-GRY

6-GRY

1.BLK

2-GRY

,1-BLK

2-GRY

2.GRY

1O-GRY

2-GRY

2-GRY

3-GRY

4-GRY

3-GRY

3-GRY

2-GRY

2.BLK

.1-BLK

4-GRN

3-GRN

2-GRY

2.BLK

2-BLK

2-BLK

2.BLK

8-GRY

2-GRY

14-GRY

3-GRY

2.GRY

2.GRY

2-BLK

3-GRY

2-BLK

2-BLK

Right side of engine compartment

Right side of engine compartment

Right side ot engine compartment

Right side of engine compartment

Right end of engine

Right end of engine

Right end of engine

Transmission

Transmission

lvliddle ol engine

Lett rear underside of engine

Right side ol engine

Rear of engine compartment

Middle rear ol engine compartment

Middle ol engine

Middle of engine

Middle ol engine

l\4iddle of engine

Middle of engine

Left end ot engine

Lett end of engine

Middle of engine

N,liddle ol engine

Middle of engine

Middle of engine

Middle of engine

Left rear corner of engine compt.

Lelt rear corner of engine compt.

Left rear corner of engine compt.

Transmission

Transmission

Transmission

Transmission

Transmission

Transmission

Transmission

Main wire harness

Main wire harness

Main wire harness

Main wire harness

Starter solenoid

Engine coolant temperature (ECT)sensor

Engine coolant temperaturegauge sending unit

Back-up light switch

Lock-up control solenoid valve Aand B

Distributor

Crankshaft speed fluctuation (CKF)sensor

Radiator fan switch

Vehicle speed sensor (VSS)

Primary heated oxvoen sensor(H02s)

MAP sensor

Throttle position (TP) sensor

ldle air control (lAC) valve

Evaporative emission (EVAP)purge control solenoid valve

Engine oil pressure switch

Alternator

Alternator

Intake air temperature (lAT) sensor

No. I fuel injector

No. 2 fuel injector

No. 3 tuel injector

No. 4 fuel injector

Junction connector

Engine compartment wire harness

Engine compartment wire harness

Shitt control solenoid valve A and B

Shift control solenoid valve A and B

Countershaft speed sensor

Countershatt speed sensor

lvtainshatt speed sensor

Mainshaft speed sensor

Linear solenoid valve

NT

[/VT

A"/T

USA

Canada

A/T (98199models)

AIT('00 model)

A,/T ('98-'�99models)

('00 model)

A,/T f98-'99models)

Atf('00 model)

AN('00 model)

T101

T102

Left end of engine

Right rear corner of engine compt.

Alternator

Under-hood fuse/relay box

G'101Right end ot engineEngine ground, via engine wirenarness

o

I

203-2

Page 1600 of 1681

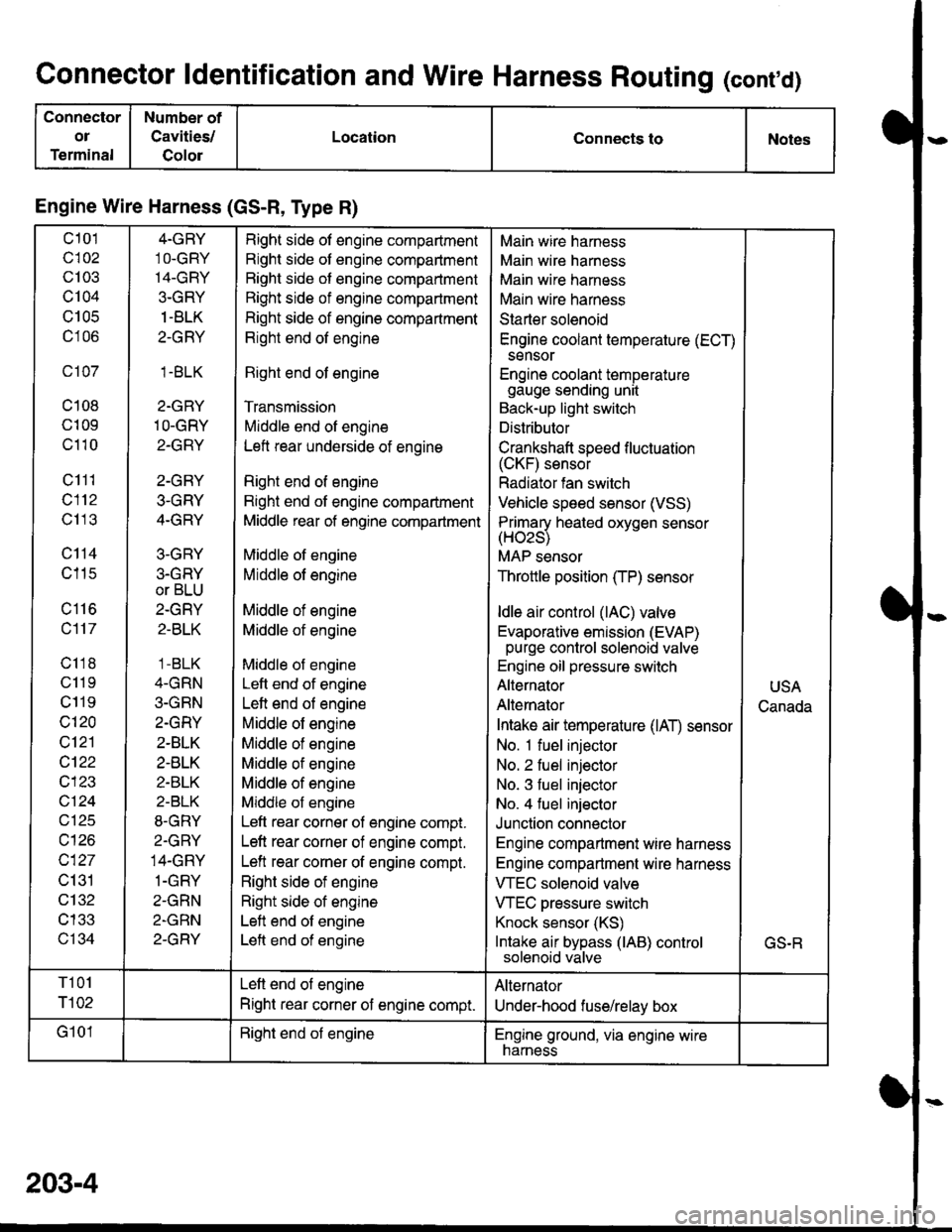

Connector ldentification and Wire Harness Routing (conrd)

Connector

ol

Terminal

Number of

Cavities/

Golor

LocationConnects toNotes

Engine Wire Harness (GS-R, Type R)

c101

c102

c103

c104

U IUC

c106

c107

c108

c109

c110

c111

c112

c113

c114

c115

c116

c117

c118

c11 9

c119

c120

c121

cl22

c123

vtzl

wt10

c127

c131

c132

c133

c134

4-GRY

1O-GRY'I4-GRY

3-GRY

1 -BLK

2-GRY

1.BLK

2-GRY

1O-GRY

2-GRY

2-GRY

3-GRY

4-GRY

3-GRY

3.GRY

or BLU

2-GRY

2-BLK

1 -BLK

4-GRN

3-GRN

2.GRY

2-BLK

2-BLK

2-BLK

2-BLK

8-GRY

2.GRY

14-GRY

1-GRY

2-GRN

2-GRN

2-GRY

Right side of engine compartment

Right side of engine compartment

Bight side of engine compartment

Right side of engine compartment

Right side of engine compartment

Right end of engine

Right end of engine

Transmission

Middle end of engine

Left rear underside of engine

Right end of engine

Right end of engine compartment

Middle rear of engine compartment

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Left end of engine

Left end of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Left rear corner of engine compt.

Left rear corner of engine compt.

Left rear corner of engine compt.

Right side of engine

Right side of engine

Left end of engine

Left end of engine

Main wire harness

Main wire harness

Main wire harness

Main wire harness

Starter solenoid

Engine coolant temperature (ECT)

sensor

Engine coolant temperaturegauge sending unit

Back-up light switch

Distributor

Crankshaft speed f luctuation(CKF) sensor

Radiator fan switch

Vehicle speed sensor (VSS)

Primarv heated oxvoen sensor(Hozs)

MAP sensor

Throttle position (TP) sensor

ldle air control (lAC) valve

Evaporative emission (EVAP)purge control solenoid valve

Engine oil pressure switch

Alternator

Alternator

Intake air temperature (lAT) sensor

No. 1 fuel injector

No. 2 fuel injector

No. 3 fuel injector

No. 4 fuel injector

Junction connector

Engine compartment wire harness

Engine compartment wire harness

VTEC solenoid valve

VTEC pressure switch

Knock sensor (KS)

Intake air bypass (lAB) controlsolenoid valve

USA

Canada

GS.R

T101

r102

Left end of engine

Right rear corner of engine compt.

Alternator

Under-hood fuse/relay box

G101Right end of engineEngine ground, via engine wirenarness

203-4

Page 1656 of 1681

ng

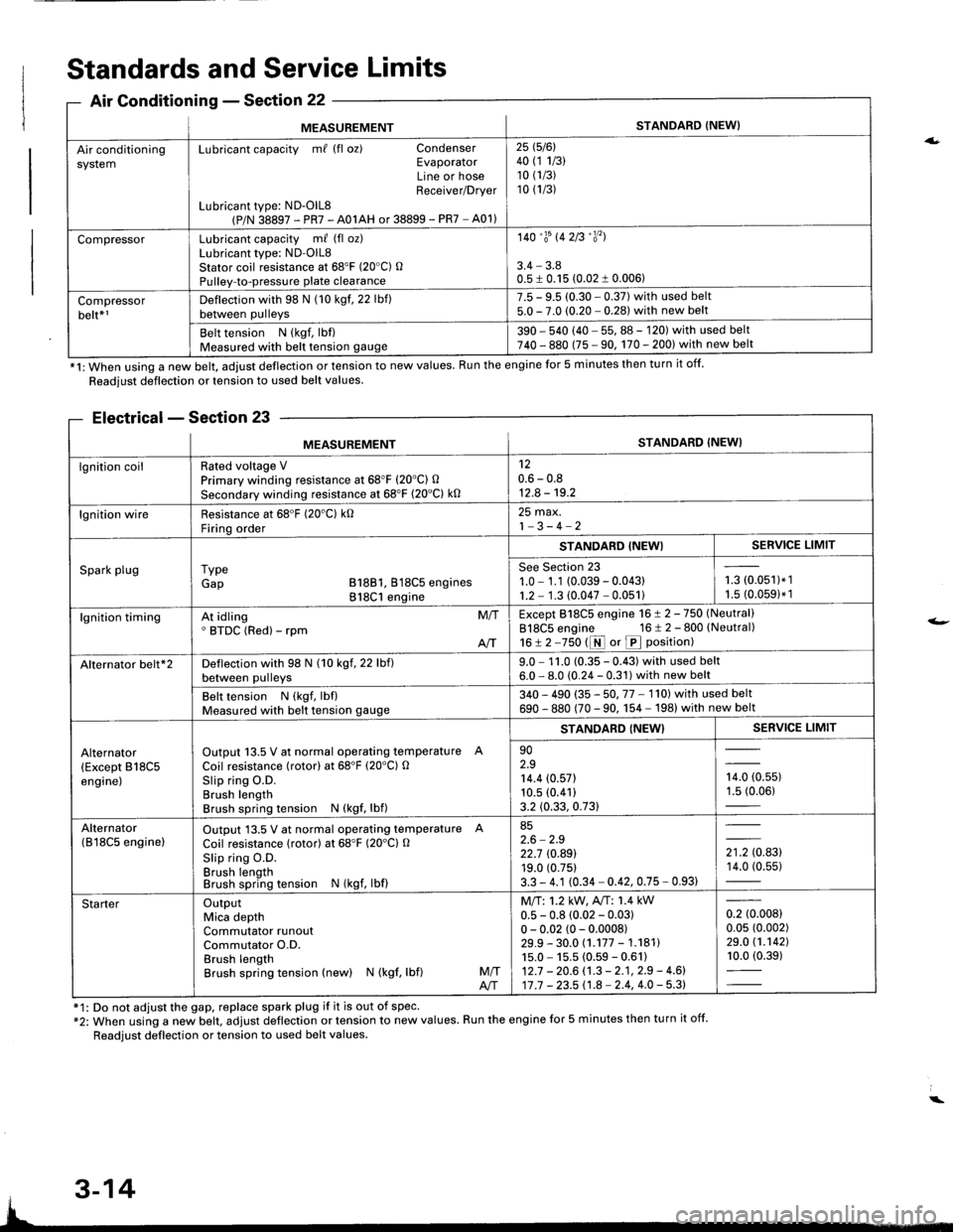

MEASUREMENTSTANDARD {NEW}

Air conditioningsystemLubricant capacity m/ (fl oz) CondenserEvaporatorLine or hoseReceiver/Drver

Lubricant type: ND-OlL8(P/N 38897 - PR7 - A01AH or 38899 - PR7 - A01)

25 1516l40 (1 1/3)10 (1/3)

10 (1/3)

CompressorLubricant capacity m/ (fl oz)Lubricant type: ND-OlL8Stator coil resistance at 68'F (20"C) OPulley-to-pressure plate clearance

140'�trs 142B'�y'�l

3.4 - 3.80.5 I 0.15 (0.02 1 0.006)

Compressorbelt*rDeflection with 98 N (10 kgf. 22 lbf)between pulleys

7.5 - 9.5 (0.30 - 0.37) with used belt5.0 - 7.0 (0.20 - 0.281 with new belt

Belt tension N (kgf, lbf)Measured with belt tension gauge390 - 540 (40 - 55, 88 - 120) with used belt740 - 880 (75 - 90, 170 - 200) with new belt

*1: When using a new belt, adjust deflection or tension to new values. Run the engine for 5 minutes then turn it off.

Standards and Service Limits

Air Conditionins - Section 22

Readjust deflection or tension to used belt values.

Electrical - Section 23

f1: Do not adjust the gap, replace spark plug if it is out of spec'*2: When using a new belt. adjust deflection or tension to new values. Run the engine for 5 minutes then turn it off.

Readjust deflection or tension to used belt values.

a.

t-

MEASUREMENTSTANDARD (NEW}

lgnition coilRated voltage VPrimary winding resistance at 68"F (20'C) O

Secondary winding resistance at 68'F (20"C) k0

120.6 - 0.812.8 - 19.2

lgnition wireResistance at 68'F (20'C) k0Firinq order

25 max.1-3-4-2

Spark plugI ypeGap B18B1, 818C5 engines818C1 engine

STANDABD {NEWISERVICE LIMIT

See Section 231.0 - 1.1 (0.039 - 0.04311.2 - 1.3 (0.047 - 0.051)i-= roru',t.',1.5 (0.0591* 1

lgnition timingAt idling' BTDC (Red) - rpmM/T

AIT

Except 818C5 engine 16 ! 2 -750 (Neutral)

818C5 engine 16 t 2 - 800 (Neutral)

16!2-750 t1r{ or p position)

Alternator belt*2Deflection with 98 N (10 kgf, 22 lbf)between pulleys9.0 - 1 1.0 (0.35 - 0.43) with used belt6.0 - 8.0 (0.24 - 0.31) with new belt

Belt tension N (kgf, lbflMeasured with belt tension gauge340 - 490 (35 - 50. 77 - 1'l0l with used belt

690 - 880 (70 - 90. 1 54 - 198) with new belt

Alternator(Except B18C5engine)

Output 13.5 V at normal operating temperature A

Coil resistance (rotor) at 68'F (20'C) OSlip ring O.D.Brush lengthBrush spring tension N (kgf, lbf)

STANDARD {NEW}SERVICE LIMIT

902.914.4 (0.571

10.5 (0.41)

3.2 (0.33, 0.73)

,0, to.uur1.5 (0.06)

Alternator(B l8C5 enginelOutput 13.5 V at normal operating temperature A

Coil resistance (rotor) at 68"F (20'Cl O

Slip ring O.D.Brush lengthBrush spring tension N (kgf, lbf)

852.6 - 2.922.7 rc.89119.0 (0.75)

3.3 - 4.1 (0.34 - 0.42, 0.75 - 0.93)

',to.tg14.0 (0.55)

StarterOutputMica depthCommutator runoutCommutator O.D.Brush lengthBrush spring tension (new) N (kgf, lbf)M/TA/T

Mll:1.2 kW, A"rT: 1.4 kW0.5 - 0.8 (0.02 - 0.03)0 - 0.02 (0 - 0.0008)29.9 - 30.0 (.177 - 1.18111s.0 - 15.5 (0.59 - 0.61)12.7 - 20.6 (.3 - 2.1, 2.9 - 4.6)17 .7 - 23.5 11.8 - 2.4, 4.0 - 5.3)

0.2 (0.008)

0.05 (0.002)

29.0 (1.1421

10.0 (0.39)

3-14

Page 1658 of 1681

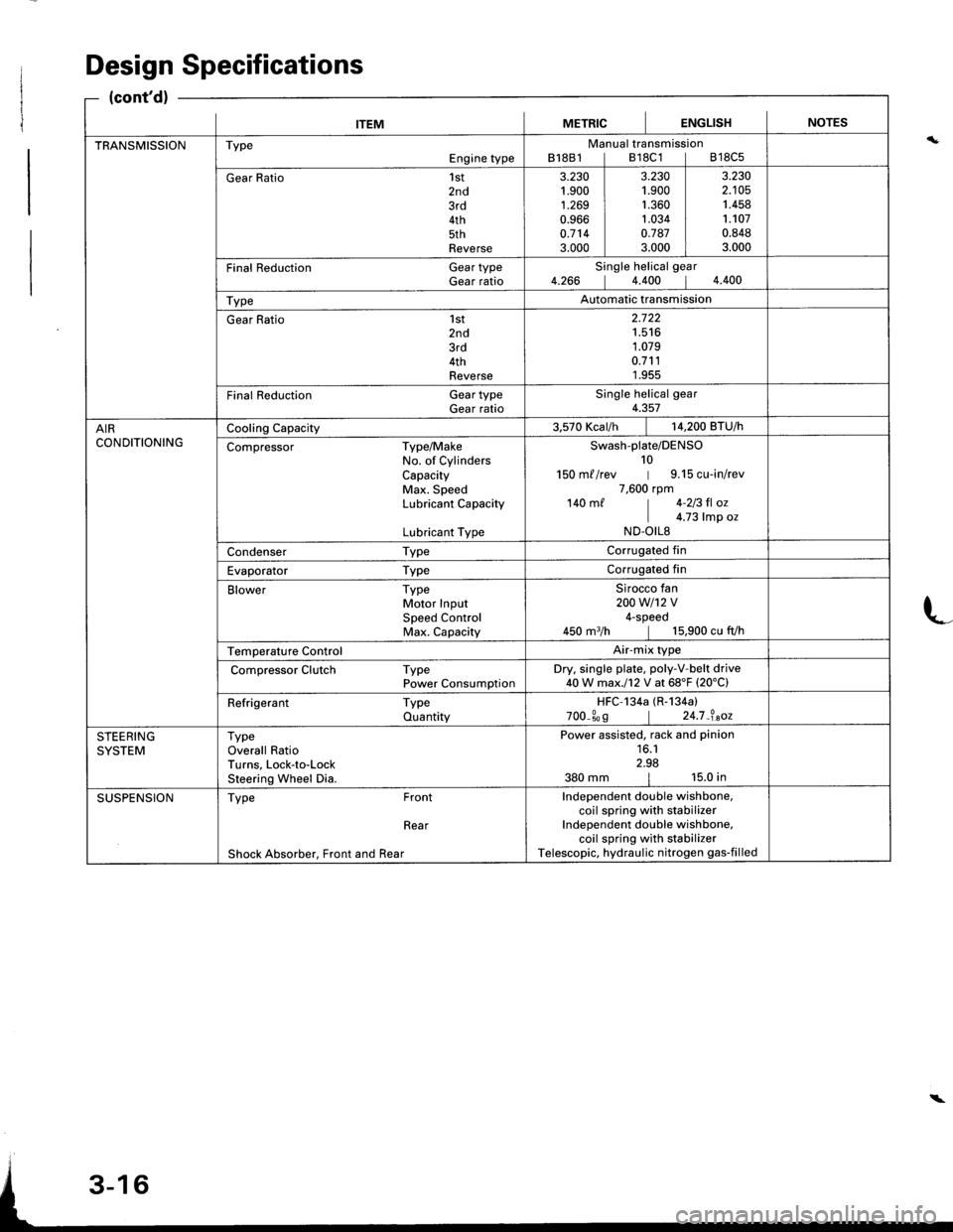

ITEMMETRICIENGLISHINOTES

TRANSMISSIONTypeEngine typeManual transmissionB18B1lB18C1lB18C5

Gear Ratio1st2nd3rd4th5thReverse

3.230't.900

1.2690.9660.7143.000

3.2301.9001.3601.0340.7873.000

3.2302.1051.4581.1070.8483.000

Final Reduction Gear typeGear ratioSingle helical gear4.266 14.400 14.400

TypeAutomatic transmission

Gear Ratio 1st2nd3rd4thReverse

2.722't.516

1.0790.7111.955

Final Reduction GeartypeGear ratioSingle helical gear4.357

AIRCONDITIONINGCooling Capacity3.570 Kcar/h | 14,200 BTU/h

Compressor Type/MakeNo. of CylindersCapacityMax. SpeedLubricant Capacity

Lubricant Type

Swash-plate/DENSO10150 m//rev | 9.15 cu-in/rev7,600 rpm140 m/ | 4-213 fl oz

I c.z3 |rp o.ND.OILS

Condenser TypeCorrugated fin

Evaporator TypeCorrugated fin

Blower TypeMotor InputSpeed ControlMax. Capacity

Sirocco fan200w1't2v4-speed450 m3/h | 15,900 cu fVh

Temperature ControlAir-mix type

Compressor Clutch TypePower ConsumptionDry. single plate, poly-V-belt drive40W max.l12 V at 68'F (20'C)

Refrigerant TypeQuantityHFC-134a (R-134a)

700_309 | 24.7_?.aoz

STEERINGSYSTEMTypeOverall RatioTurns, Lock-to-LockSteering Wheel Dia.

Power assisted, rack and pinion16.12.98380 mm | 15.0 in

SUSPENSIONType Front

Rear

Shock Absorber, Front and Rear

Independent double wishbone,coil spring with stabilizerIndependent double wishbone,coil spring with stabilizerTelescopic, hydraulic nitrogen gas-filled

Design Specifications

(cont'd)

L

\

Page 1664 of 1681

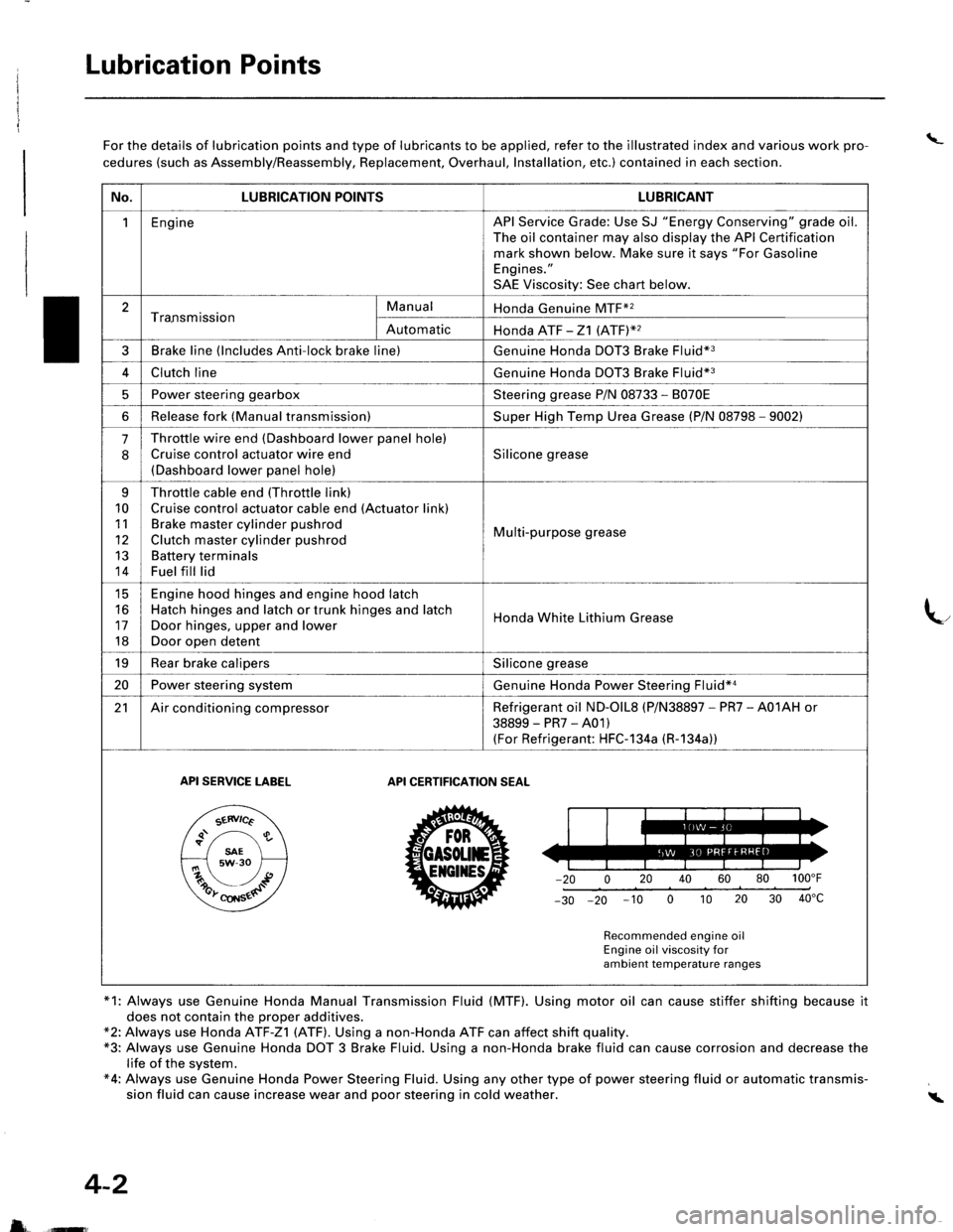

Lubrication Points

\_For the details of lubrication points and type of lubricants to be applied, refer to the illustrated index and various work pro-

cedures (such as Assembly/Reassembly, Replacement, Overhaul, Installation, etc.) contained in each section.

*1: Always use Genuine Honda Manual Transmission Fluid (MTF). Using motor oil can cause stiffer shifting because it

does not contain the proper additives.*2: Always use Honda ATF-Z1 (ATF). Using a non-Honda ATF can affect shift quality.*3: Always use Genuine Honda DOT 3 Brake Fluid. Using a non-Honda brake fluid can cause corrosion and decrease thelife of the system.*4: Always use Genuine Honda Power Steering Fluid. Using any other type of power steering fluid or automatic transmis-sion fluid can cause increase wear and poor steering in cold weather.i

4-2

5 ffi

No.LUBRICATION POINTSLUBRICANT

1EngineAPI Service Grade: Use SJ "Energy Conserving" grade oil.The oil container may also display the API Certificationmark shown below. Make sure it says "For GasolineEngines."

SAE Viscosity: See chart below.

2Tra.nsmissionManualHonda Genuine MTF*2

AutomaticHonda ATF -21 (ATFY2

3Brake line (lncludes Anti-lock brake line)Genuine Honda DOT3 Brake Fluid*3

4Clutch lineGenuine Honda DOT3 Brake Fluid*3

5Power steering gearboxSteering grease P/N 08733 - 8070E

6Release fork (Manual transmission)Super High Temp Urea Grease (P/N 08798 - 9002)

.J

Throttle wire end (Dashboard lower panel hole)

Cruise control actuator wire end(Dashboard lower panel hole)

Silicone grease

q

10

11

12

13

14

Throttle cable end (Throttle link)

Cruise control actuator cable end (Actuator link)Brake master cylinder pushrod

Clutch master cylinder pushrod

Battery terminalsFuel fill lid

Multi-purpose grease

tc

16

17

18

Engine hood hinges and engine hood latchHatch hinges and latch or trunk hinges and latch

Door hinges, upper and lower

Door open detent

Honda White Lithium Grease

19Rear brake calipersSilicone grease

20Power steering systemGenuine Honda Power Steering Fluid*a

21Air conditioning compressorRefrigerant oil ND-olL8 (P/N38897 - PR7 - A01AH or

38899-PR7-A01)(For Refrigerant: HFC-1 34a (R-1 34a))

API SERVICE TABELAPI CERTIFICATION SEAT

ZU30

Recommended engine oilEngine oil viscosity forambient temperature ranges