wheel alignment HONDA INTEGRA 1998 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 715 of 1681

\

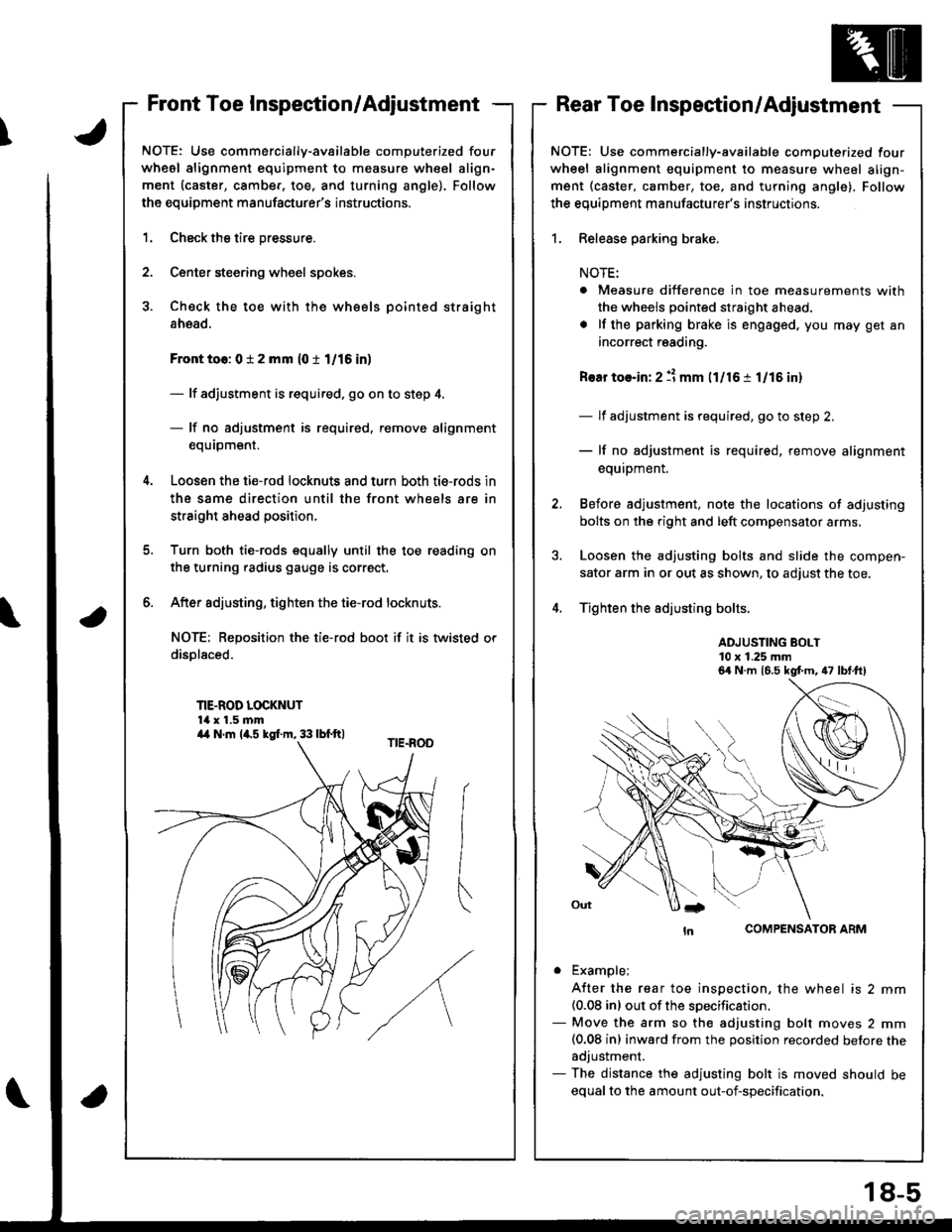

Front Toe Inspection/AdjustmentRear Toe Inspection/Adjustment

NOTE: Use commercially-available computerized four

whesl alignment equipment to measure wheel align-

ment (caster, camber, toe. and turning angle). Follow

the equipment manufacturer's instructions.

1.

2.

Check the tire pressure.

C€nter steering wheel spokes.

Check the toe with the wh€els pointed straight

ahead.

Front to6: 0 i 2 mm (0 t 1/16 in)

- lf adjustment is required. go on to step 4.

- lf no adjustment is required, remove alignment

equrpm€nr,

Loosen the ti€-rod locknuts and turn both tie-rods in

the same direction until the front wheels are in

straight ahead position.

Turn both tie-rods equally until the toe reading on

the turning radius gauge is correct.

After sdjusting, tighten the tie-rod locknuts.

NOT€: Reposition the tie-rod boot if it is twisted or

displaced.

TIE-ROD LOCKNUT14 x 1.5 mm

6.

a

NOTE: Use commercially-available computerized four

wheel alignment equipment to measure wheel align-

ment (caster, camber, toe, and turning angle), Follow

the equiDment manufacturer's instructions.

1. Release parking brake.

NOTE:

. Measure difference in toe measurements with

the wheels pointed straight ahead.

. lf the parking brake is engaged. you may get an

incorrect reading.

Rear toe-in: 2 11 mm l1l16 i 1/15 in)

- lf adjustment is required, go to step 2.

- lf no adjustment is required, remove alignment

equipment.

Before adjustment, note the locations of adjusting

bolts on the right and left compensator arms.

Loosen the adjusting bolts and slide the compen-

sator arm in or out as shown, to adjust the toe.

Tighten the adjusting bolts.

ADJUSTING BOLT10 x 1.25 mm

COMPENSATOR ARM

. Example;

A{ter the rear toe inspection, the wheel is 2 mm(0.08 inl out of the soecification.- Move the arm so the adjusting bolt moves 2 mm(0.08 inl inward from the position recorded betore theadjustment.- The distance the adjusting bolt is moved should be

equal to the amount out-of-specification.

6a N.m 16.5 kgt m, 47 lbt.ft)

a4 N.m la.s kgI.m, 33 lbf.ft)

18-5

Page 716 of 1681

l,

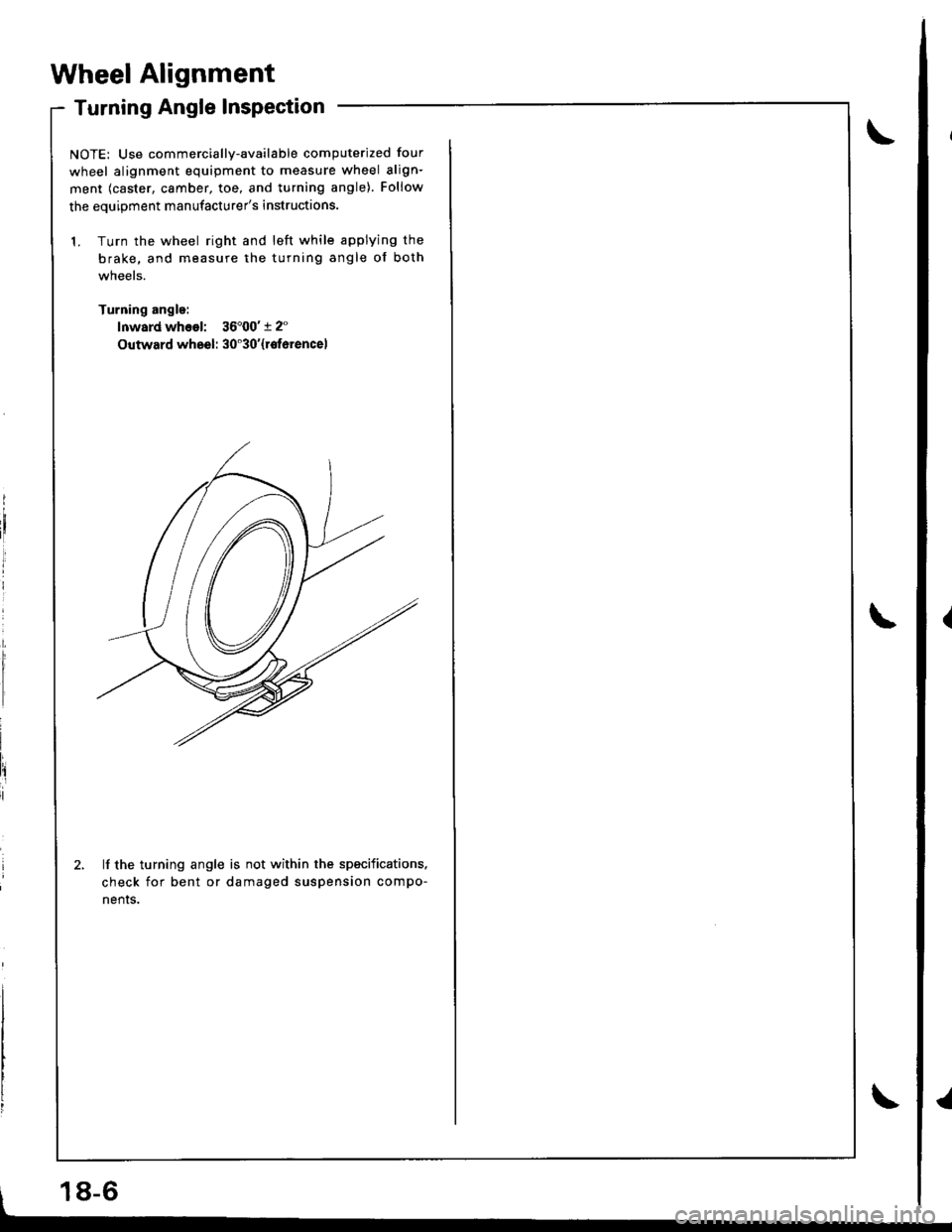

Wheel Alignment

Turning Angle Inspection

NOTE: Use commercially-available computerized four

wheel alignment equipment to measure wheel align-

ment (caster, camber, toe, and turning angle). Follow

the equioment manufacturer's instructions.

1. Turn the wheel right and left while applying the

brake, and measure the turning angle of both

wneels.

Turning angle:

lnward whsol: 36'00't 2"

Outward wheel: 30'30'{rotorencel

lf the turning angle is not within the specifications.

check for bent or damaged suspension compo-

nenrs.

18-6

Page 727 of 1681

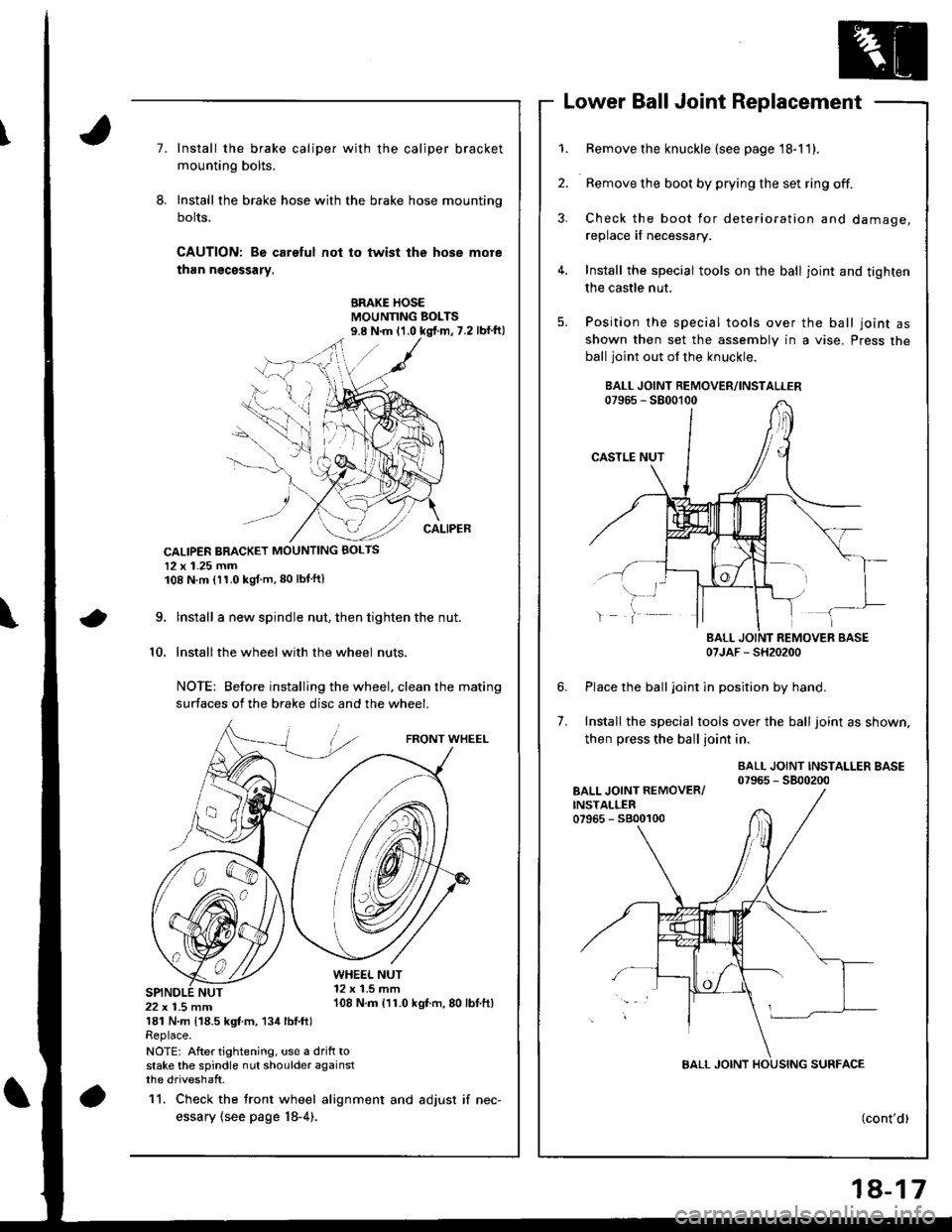

Lower Ball Joint Replacement

7.Install the brake caliper with the caliper bracket

mounting bolts.

Install the brake hose with the brake hose mounting

bolts.

CAUTION: Bo careful not to twist the hose more

than ngcsssary.

BRAKE HOSEMOUNNNG BOLTS

CALIPER BRACKET MOUNTING BOLTS

12 x 1.25 mm108 N.m (11.0 kgf m,80 lbtftl

\9.

10.

lnstall a new spindle nut, then tighten the nut.

Installthe wheel with the wheel nuts

NOTE: Before installing the wheel, clean the mating

surfaces of the brake disc and the wheel.

FRONT WHEEL

WHE€L NUT12 x 1.5 mm108 N.m {11.0 kgf.m,80 lbtft)22 x 1.5 mm181 N.m 118.5 kgt m, 134 lbl.ftlReplace.

NOTE: After tightening, us€ a drift tostake the spindle nut shoulder againstthe driveshaft.

11. Check the tront wheel alignment and adjust if nec-

essary (see page l8-4).

1.

2.

4.

5.

Remove the knuckle (see page 18-11).

Remove the boot by prying the set ring off.

Check the boot for deterioration and damage,

replace if necessary.

Install the special tools on the ball joint and tighten

the castle nut.

Position the special tools over the ball joint asshown then set the assembly in a vise. Press the

ball joint out of the knuckle.

07JAF - SH20200

Place the balljoint in position by hand.

Install the special tools over the ball joint as shown,

then press the ball joint in.

BALL JOINT INSTALLER BASE07965 - 5800200

6.

7.

(cont'd)

18-17

Page 728 of 1681

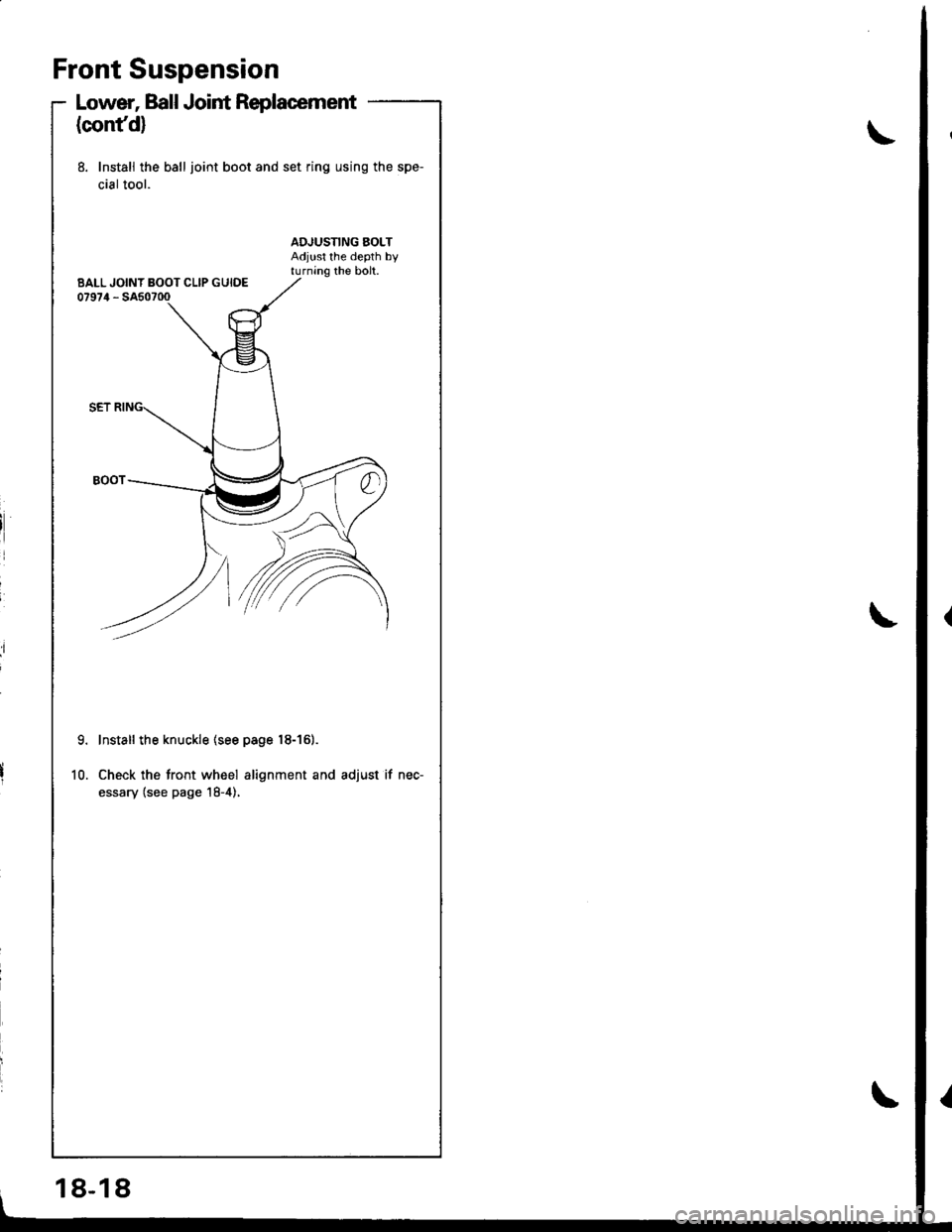

Front Suspension

Lower, Ball Joint Replacement

(confd)

8. Install the ball joint boot and set ring using the spe-

cial tool.

9.

10.

Install the knuckle (see page 18-161.

Check the tront wheel alignment and adjust if nec-

essary (see page 18-4),

BALL JOINT BOOT CLIP GUIDE

18-18

Page 731 of 1681

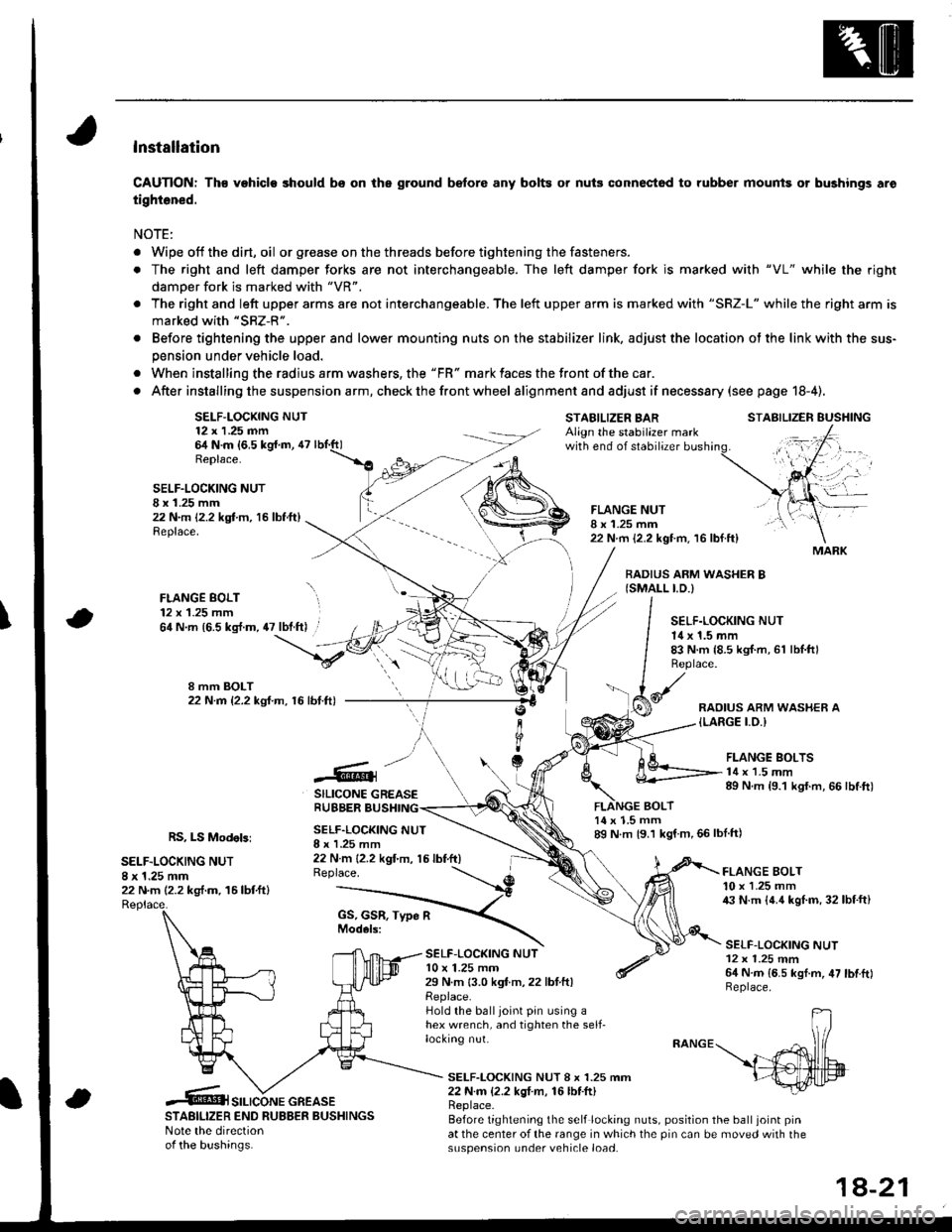

lnstallation

CAUTION: Th€ vehiclo should bs on the ground b€fore any bolts or nuis connectod to rubber mounis or bushings aro

tightened.

NOTE:

. Wipe off thedirt,oil or gr€ase on the threads before tightening the fasteners.

. The right and left damper forks are not interchangeable. The left damper fork is ma.ked with "VL" while the righr

damoer fork is marked with "VR".

. The right and left upper arms are not interchangeable. The left upper arm is marked with "SRZ-L" while the right arm is

marked with "SRZ-R".

. Before tightening the upper and lower mounting nuts on the stabilizer link, adjust the location ot the link with the sus-

pension under vehicle load.

. When installing the radius arm washers, the "FR" mark faces the front ofthe car.

. After installing the suspension a rm, check the front wheel alignmentand adjust if necesssry (see page 18-4).

SELF-LOCKING NUT12 x 1.25 nn64 N.m {6,5 kg{.m, 47Replace.

STABILIZER BARAlign the stabilazer markwith end of stabilizer

BOLT

STABILIZER EUSHING

SELF.LOCKING NUTI x 1.25 mm22 N.m 12.2 kgt m, 16 lbf.ft)Replace.

FLANGE BOLT12 x 1.25 mm

FLANGE NUTI x 1.25 mm22 N.m {2.2 kgt m. 16 lbf.ft}

BADIUS ARM WASHER B{SMALL I.D.)

\64 N.m {6.5 kg{.m, 47 lbt.ft) .SELF.LOCKING NUT14 x 1.5 mm83 N.m {8.5 kgI.m, 61 lbl.ftlReplace.

RAOIUS ARM WASHER A{LARGE I.O.I

.@]

SILICONE GREASERUBBER BUSHING

FLANGE BOLTS14 x 1.5 mm89 N.m {9.1 kgf.m, 66 lbtft)

RS, LS Modebi

SELF.LOCKING NUT8 x 1.25 mm22 N.m (2.2 kg,f.m. 16lbtftl

SELF.LOCKING NUTI x I .25 mm22 N m {2.2 kgt'm, 15 lbf.ft)Replace.

14 x 1.5 mm89 N m {9.1 kgf m,66lblft)

SELF-LOC(ING NUTl0 x 1.25 mm29 N.m 13.0 kgf.m,22 lbtftlReplace.Hold the balljoint pin using ahex wrench, and tighten the self-locking nut.

FLANGE BOLT10 x 1.25 mm43 N.m {4.4 kgl.m, 32lbf.ft}

SELF-LOCKING NUT12 x 1.25 mm64 N.m {6.5 kgf.m, 47 lbtftlReplace.

SELF-LOCKING NUT 8 x 1.25 mm22 N.m {2.2 kgI m, 16lbf.ft)

STABILIZER END RUBBER BUSHINGSNote the directionof the bushinas.

Replace.Before tightening the self locking nuts, position the ball joint pinat the center of the range in which the pin can be moved with thesuspension under vehicle load.

MARK

SILICONE GREASE

1A-21

Page 744 of 1681

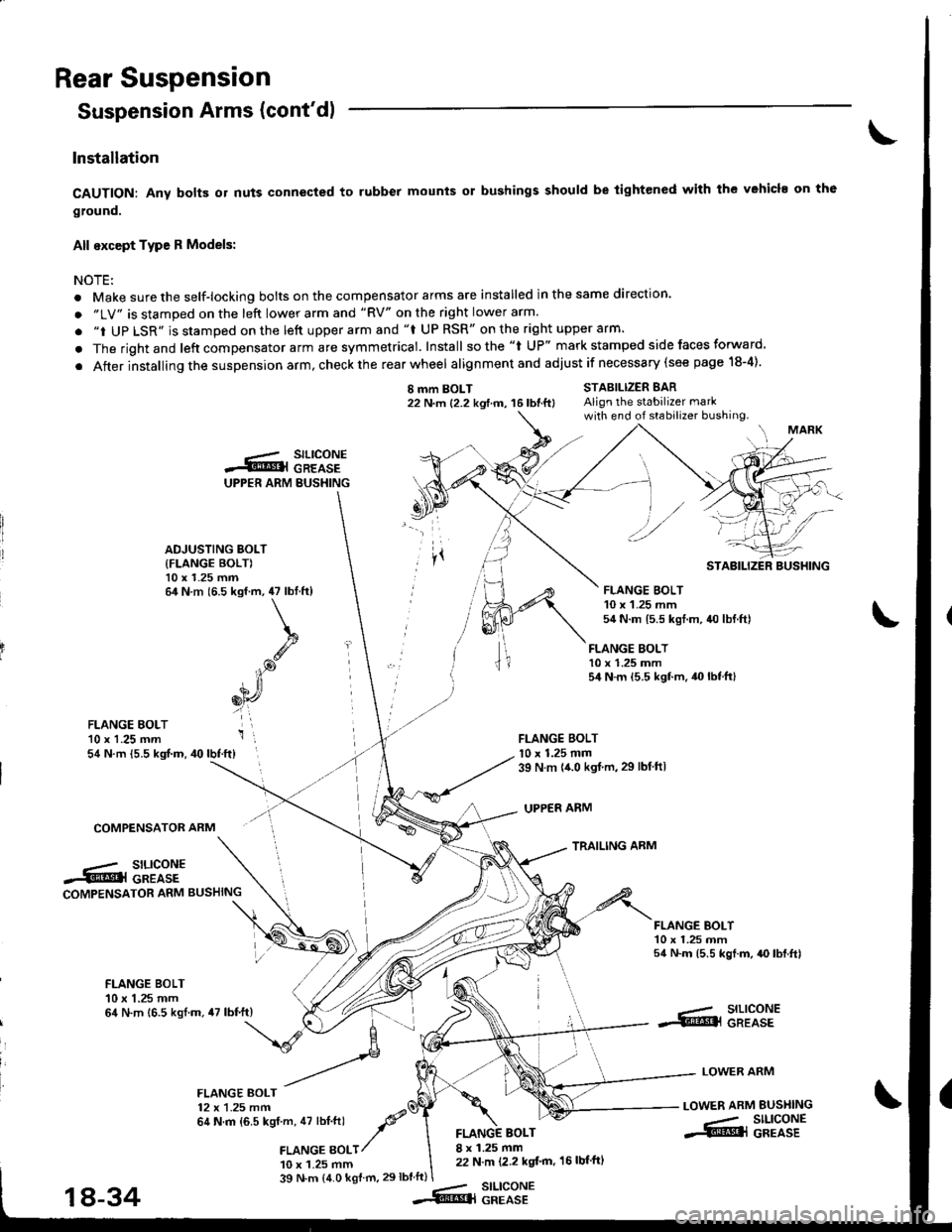

Rear Suspension

Suspension Arms (cont'dl

Installation

CAUTION: Any bolB or nuts connected to rubber mounts or bushings should be tightened with the vehicl. on th6

ground.

All except Type R Models:

NOTEi

. Make sure the self-locking bolts on the compensator arms are installed in the same direction.

. "LV" is stamped on the left lower arm and "RV" on the right lower arm.

. "i UP LSR" is stamped on the lett upper arm and "f UP RSR" on the right upper arm.

. The rightand left compensator arm are symmetrical. Install sothe "l UP" mark stamped side faces forward.

. After installing the suspension arm, check the rear wheel alignmentand adjust if necessary (see page 18-4).

I mm BOLT22 N.m {2.2 kgtm, 16lbtft}STABILIZER BARAlign the stabilizer markwith end of stabilizer bushing.

FLANGE BOLT10 x 1.25 mm54 N.m {5.5 kgf.m.40lbtft}

FLANGE BOLTl0 x 1.25 mm39 N m {{.0 kgt.m,29 lbtftl

UPPER ARM

TRAILING ARM

FLANGE EOLT'10 x 1.25 mm54 N.m {5.5 kgf.m, 40lbf.ft}

COMPENSATOR ARM

.-/ SILICONE.5tr@l GREASECOMPENSATOR ARM BUSHING

FLANGE BOI-T10 x 1.25 mm54 N.m (5.5 kgf.m, {O lbf.ft)

FLANGE BOLT10 x 1.25 mm64 N.m 16.5 kgl.m.47 lbf.ft)--- SILICONE.S!@l GREASE

LOWER ARM

LOWER ARM BUSI{ING

-- SILIGONE.S@l GREASE

FLANGE BOLT12 x 1.25 mm64 N.m {6.5 kgf m, 47 lbt.ftl -P'a

,amce gotr/

10 x 1.25 mm

BOLT8 x 1.25 mm22 N.m (2.2 kgt'm, 16 lbf'ftl

39 N.m (4.0 kgf m.29lbtft)stLtcoNEGREASE

UPPER ARM BUSHING

.-.- SILICONES@l GREASE

ADJUSTING BOLT

{FLANGE BOLT)10 x 1.25 mm64 N.m (6.5 kgf.m, 47 lbtft)

k

.g

iP

6[r,

i',

STABILIZER BUSHING

FLANGE BOLT10 x 1.25 mm54 N.m 15.5 kgt.m, 40 lbf.ftl

18-34--Rq

Page 745 of 1681

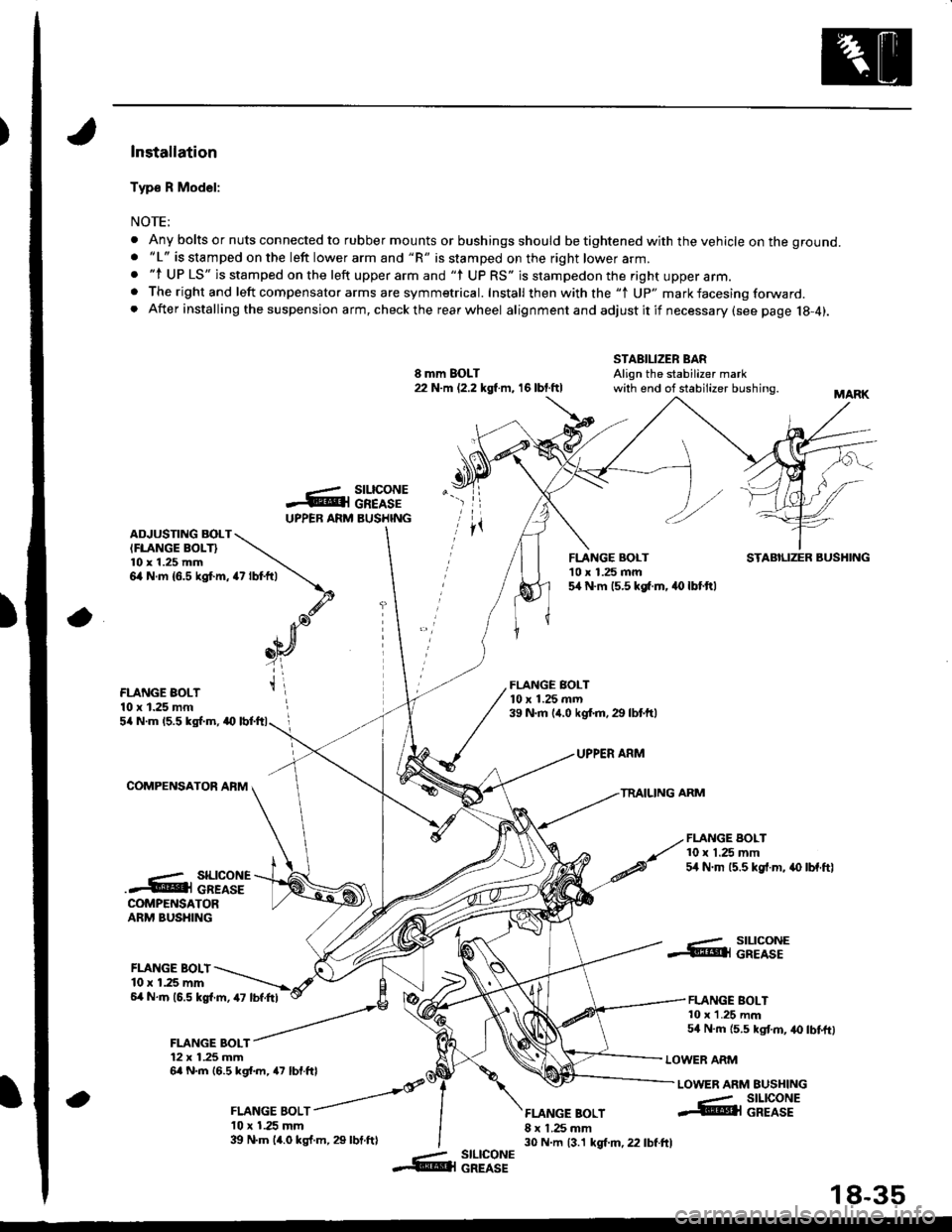

)Installation

Typ€ R Model:

NOTE;

. Any bolts or nuts connected to rubber mounts or bushings should be tightened with the vehicle on the ground.. "L" is stamped on the left lower arm and "R" is stamped on the right lower arm.. "l UP LS" is stamped on the left upper arm and "l UP RS" is stampedon the right upper arm.. The right and left compensator arms are symmetrical. Install then with the "1 Up" mark facesing forward. After installing the suspension arm, checkthe rearwheel alignmentand adjustitif necessary(see page 18-4).

8 mm BOLT22 N.m (2.2 kgl m, 16 lbt.ftl

STABILIZER BARAlign the stabilizer markwith end of stabilizer bushing.

-ArUPPEB ARM

rz tot+,t \

\.d'. Ja),n[

_oY

t\

a

stLtcoNEGREASEBUSHINGADJUSTING BOLTIFLANGE BOLT}l0 x 1.25 mm6,4 N.m {6.5 kgt m,

FLANGE BOLT'10 x 1.25 mm5,[ N.m 15.5 kg[.m. 40 lbt.ftl

STABILIZER BUSHING

FLANGE BOLT10 x 1.25 mm

FLANGE BOLT10 x 1.25 mrn39 N.m (,r.0 kgf.m.29 lbtftl5/a N.m 15.5 kgl.m, a0

COMPENSATOR AFM

UPPER ARM

TRAILING ARM

FLANGE BOLT10 x 1.25 mm54 N.m 15.5 kgf.m, .{) lbf.ftl..- SILICONE.4@i cREAsECOMPENSATORARM BUSHING

FLANGE BOLI10 r 1.25 mm6,4 N.m (6.5 kgl.m, 47 lbf.Itl

FLANGE BOLT12 x 1.25 mm6a N.m 16.5 kgl.m, a7 lbf.ftl

, ror"orr /

l0 x 1.25 mm39 N.m 14.0 kgf.m, 29 lbt.ftl

FLANGE BOLT8 x 1.25 mm30 N.m 13.1 kgt m, 22 lbf.ftl

..- SILICONE.@ll GREASE

FLANGE BOLT10 x 1.25 mm54 N.m {5.5 kgt m, 40 lbtftl

LOWER ARM

LOWER ARM EUSHING

a

--- SILICONE@l GREASE

-- slLlcoNE&l GREASE

18-35

Page 1340 of 1681

Precautions/Procedures

Steering-related Precautions

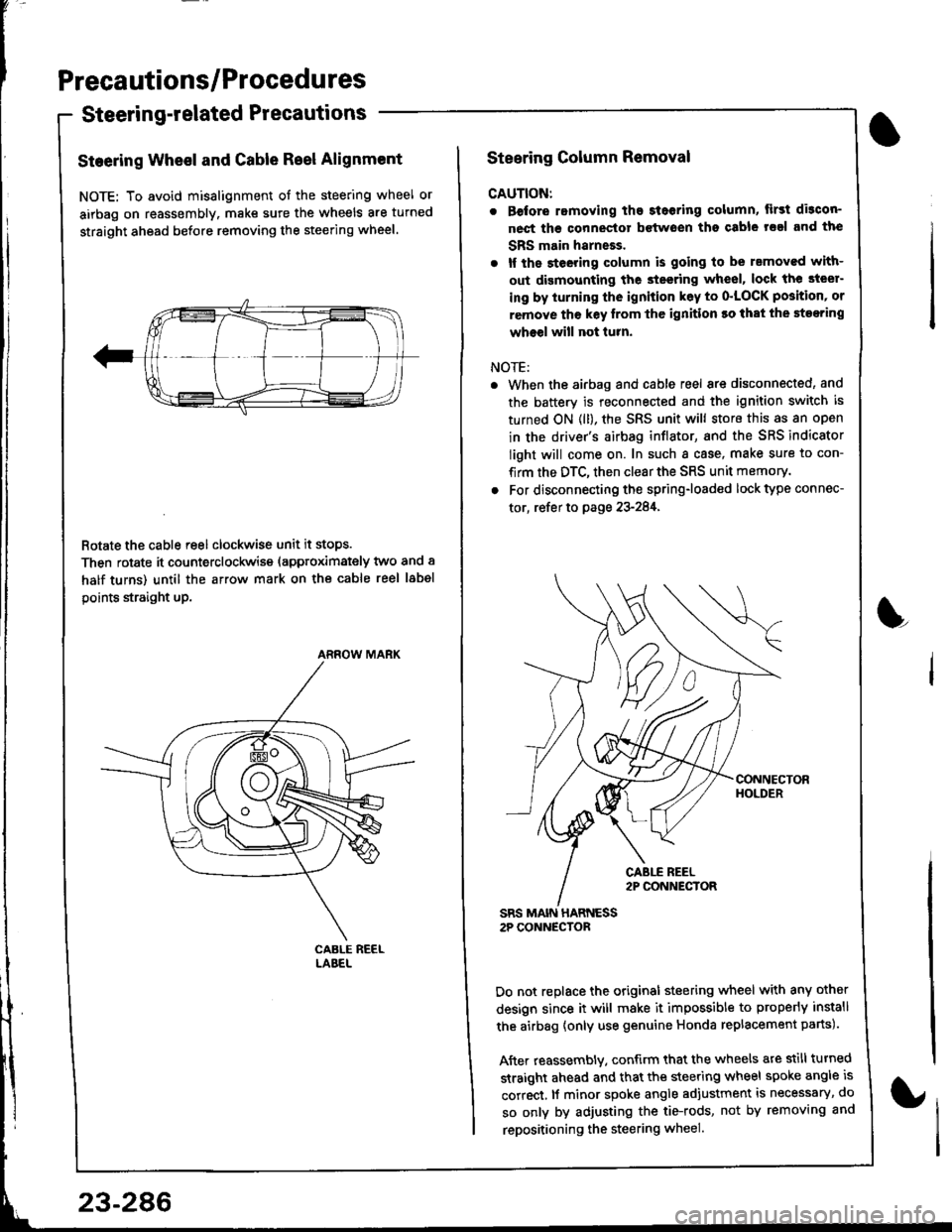

Steering Wheel and Gable Reel Alignment

NOTE: To avoid misalignment of the steering wheel or

airbag on reassembly. make sure the wheels are turned

straight ahead before removing the steering wheel.

Rotate the cable reel clockwise unit it stops.

Then rotate it counterclockwise (approximately two and a

half turns) until the arrow mark on the cable reel label

points straight up.

ARROW MARK

23-286

Steering Column Removal

CAUTION:

. Before romoving the steoring column, lirst di3con-

nect ths connector bctwoen tho csble rsal and the

SBS main harneEs.

. lf the steeting column is going to be rsmoved with-

out dismounting the steering wheel, lock the steer-

ing by iurning the ignition k6y to o'LOCK position' or

remove tho key lrom thc ignition ro that the steering

wheel will not turn.

NOTE:

When the airbag and cable reel are disconnected, and

the battery is reconnected and the ignition switch is

turned ON (ll), the SRS unit will store this as an open

in the driver's airbag inflator, and the SRS indicator

light will come on. In such a case, make sure to con-

firm the DTC, then clear the SRS unit memory.

For disconnecting the spring-loaded lock type connec-

tor, refer to page 23-284,

SRS MAIN HARNESS2P CONNECTOR

Do not replace the original steering wheel with any other

design since it will make it impossible to properly install

the airbag {only use genuine Honda replacement parts).

After reassembly. confirm that the wheels are still turned

straight ahead and that the steering wheel spoke angle is

correct, lf minor spoke angle adjustment is necessary, do

so only by adjusting the tie-rods, not by removing and

repositioning the steering wheel.

L

Page 1655 of 1681

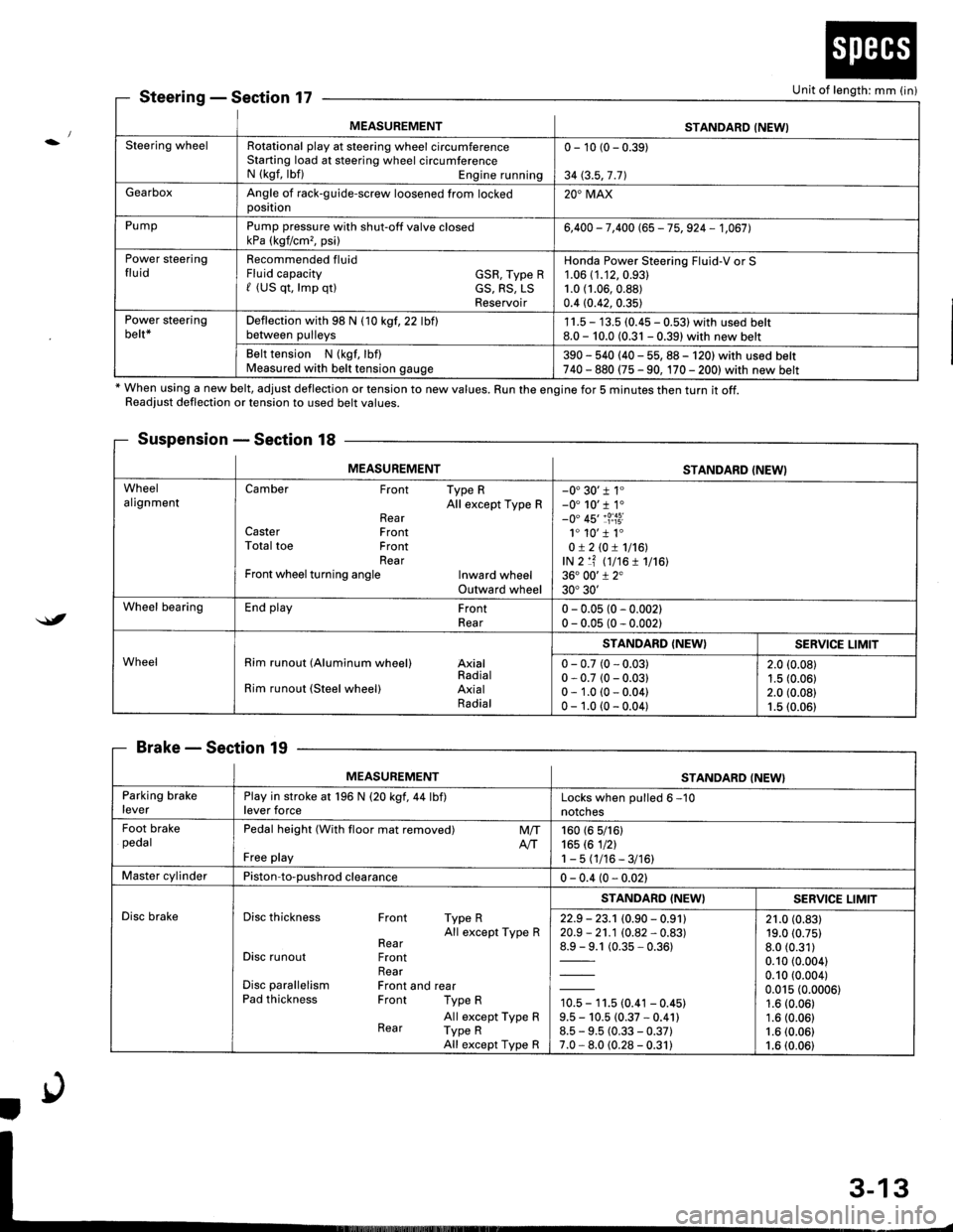

MEASUREMENTSTANDARD (NEWI

Steering wheelRotational play at steering wheel circumferenceStarting load at steering wheel circumferenceN (kgf, lbf) Engine running

0 - 10 (0 - 0.39)

34 (3.5,7 .71

GearboxAngle of rack-guide-screw loosened from lockedoosition20'MAX

PumpPump pressure with shut-off valve closedkPa (kgf/cm,, psi)6,400 - 7,400 (65 - 75, 924 - 1,067],

Power steeringfluidRecommended fluidFluid capacity GSR, Type Rf (US qt, lmp qtl cS, RS, LSReservoir

Honda Power Steering Fluid-V or S1.06 (1.12,0.93)

1.0 (1.06,0.88)

0.4 (0.42, 0.35)

Power steeringbelt*Deflection with 98 N (10 kgf,22 lbflbetween pulleys1 1.5 - 13.5 (0.45 - 0.531 with used belt8.0 - 10.0 (0.31 - 0.39) with new belt

Belt tension N (kgf, lbf)Measured with belt tension gauge390 - 540 (40 - 55, 88 - 120) with used belt740 - 880 (75 - 90, 170 - 2001with new belt

SteeringSection 17

* When using a new belt, adjust deflection or tension to new values. Run the engine for 5 minutes then turn it off.Readiust deflection or tension to used belt values.

Suspension - Section 18

BrakeSection 19

Unit of length: mm (in)

$t

MEASUREMENTSTANDARD (NEWI

WheelalignmentCamber Front Type RAll except Type RRearCaster FrontTotal toe FrontRearFront wheel turning angle Inward wheelOutward wheel

-0'30'r 1"-0' 10'r 1.-0" 45'�1?:i3i1. 10'�1 1.0!210!1116!,lN 2 lf (t7t6 1 1716136. 00'1 2"30'30'

Wheel bearingEnd play FrontRear0 - 0.05 (0 - 0.002)0 - 0.05 (0 - 0.002)

WheelRim runout (Aluminum wheel) AxialRadialRim runout (Steel wheel) AxialRadial

STANDARD (NEW}SERVICE LIMIT

0 - 0.7 (0 - 0.03)0 - 0.7 (0 - 0.03)0 - 1.0 (0 - 0.04)0 - 1.0 (0 - 0.04)

2.0 (0.08)

1.5 (0.06)2.0 (0.08)1.5 (0.06)

MEASUREMENTSTANDARD (NEW}

Parking brakeleverPlay in stroke at 196 N (20 kgf,44 lbf)lever forceLocks when oulled 6 -10

notches

Foot brakepedalPedal height (With floor mat removed)

Free play

M/TAtT160 (6 5/161165 rc 1nl1-5(1/16-3/16)

Master cylinderPiston-to-oushrod clearance0 - 0.4 (0 - 0.021

Disc brakeDisc thickness Front Type RAll except Type RRearDisc runout FrontRearDisc parallelism Front and rearPad thickness Front Type R

All except Type RRear Type RAll except Type R

STANDARD (NEWISERV]CE LIMIT

22.9 - 23.1 (0.90 - 0.91120.9 - 21.1 (0.82 - 0.83)

1= t (0.35-0.361

10.5 - 11.5 (0.41 - 0.45)9.5 - 10.5 (0.37 * 0.41)8.5 - 9.5 (0.33 - 0.37)7.0 - 8.0 (0.28 - 0.31)

21.0 (0.83)19.0 (0.75)

8.0 (0.31)

0.10 (0.004)

0.10 (0.004)

0.015 (0.0006)1.6 (0.06)

1.6 (0.06)1.6 (0.06)

1.6 (0.06)

Page 1659 of 1681

:/

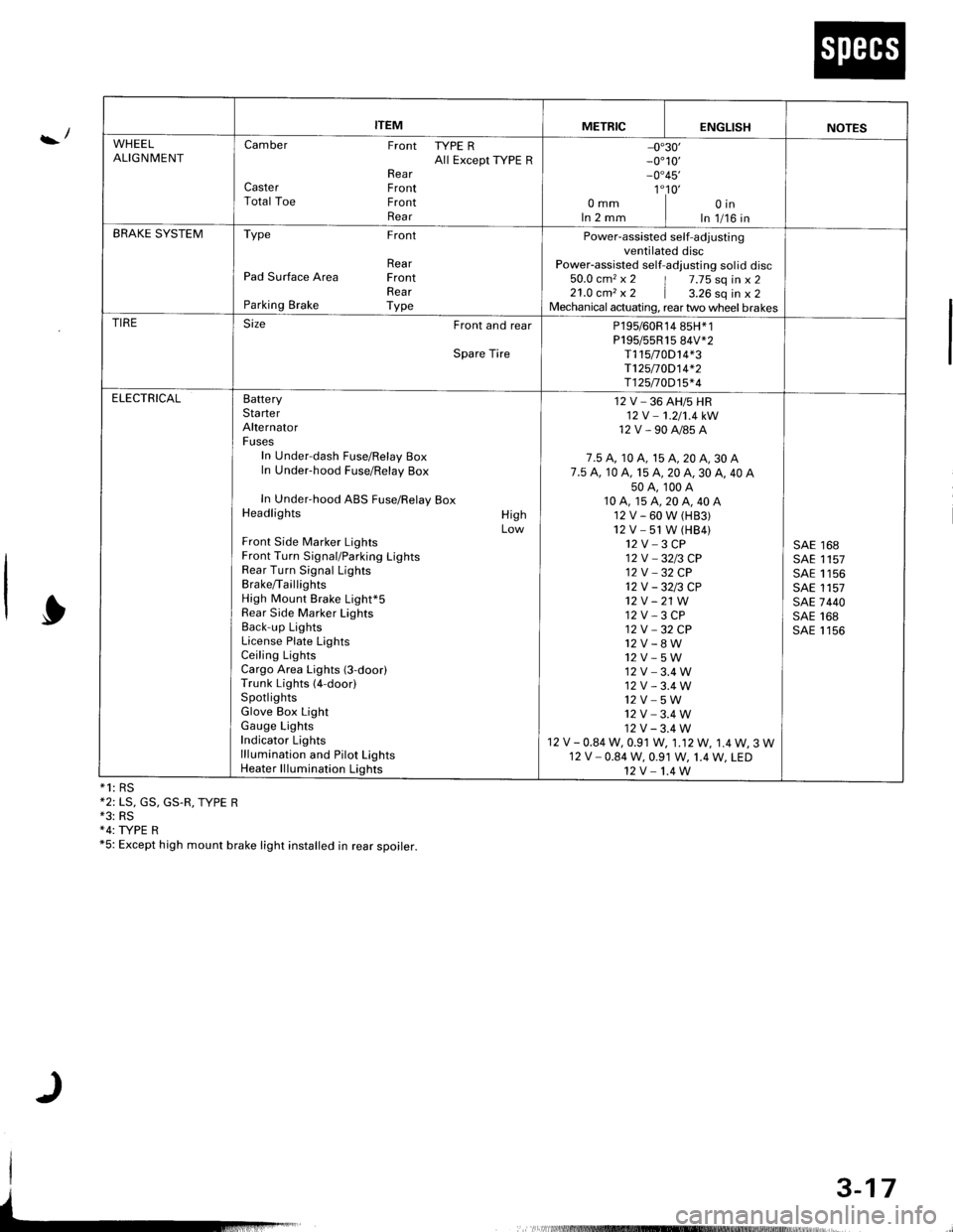

*1: RS*2: LS, GS, GS.R, TYPE R*3: RS+4: TYPE R*5: Except high mount brake light installed in rear spoirer.

ITEMMETRICENGLISHNOTES

WHEELALIGNMENTCamber Front TYPE RAll Except ryPE RRearCaster FrontTotal Toe FrontRear

-0"30'_0"10,_0"45'

1"10'omm I oinIn 2 mm I In 1/16 inBRAKE SYSTEMType Front

RearPad Surface Area FrontRearParking Brake Type

Power-assisted self-adjustingventilated discPower-assisted self-adlusting sol id disc50.0 cm2 x 2 | 7.75 sq in x 221.0 cm, x 2 | a.ZO sq in x 2Mechanical actuating, rear two wheel brakesTIRESize Front and rear

Spare Tire

P195/60R14 85H*1P195/55R15 84V*2T115t0D14*3T125/70D14*2T125n0D15*4

ELECTRICALBatteryStarterAlternatorFusesIn Under-dash Fuse/Relay BoxIn Under-hood Fuse/Relay Box

In Under-hood ABS Fuse/Relay BoxHeadlights

Front Side Marker LightsFront Turn Signal/Parking LightsRear Turn Signal LightsBrake/TaillightsHigh Mount Brake Light*5Rear Side Marker LightsBack-up LightsLicense Plate LightsCeiling LightsCargo Area Lights (3-door)Trunk Lights (4-door)SpotlightsGlove Box LightGauge LightsIndicator Lightslllumination and Pilot LightsHeater lllumination Lights

HighLow

12 V _ 36 AH/5 HR12V -1.2/'t.4kW

12V-90A/85A

7.5 A, 10 A, 15 A, 20 A, 30 A7.5 A. 10 A, 15 A, 20 A, 30 A, 40 A50A,100A10A,15A,20A,40A12V-60W(H83)12V -51 W (HB4)12V-3CP12V _3213 CP12V _32 CP12V-3213CP't2v -21 W12 V - 3 CP12V -32CP

12V_8W12V-5W12V-3.4W12V-3.4W12V_5W12V-3.4W12V-3.4W12 V - 0.84 W, 0.91 W, 1.12W, 1.4W, 3 W12 V - 0.84 W, 0.91 W, 1.4 W, LED12V-1.4W

SAE 168SAE 1157SAE 1156SAE 1157SAE 7440SAE 168SAE 1156

3-17