ECU HONDA INTEGRA 1998 4.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 506 of 1681

uJ

14-89

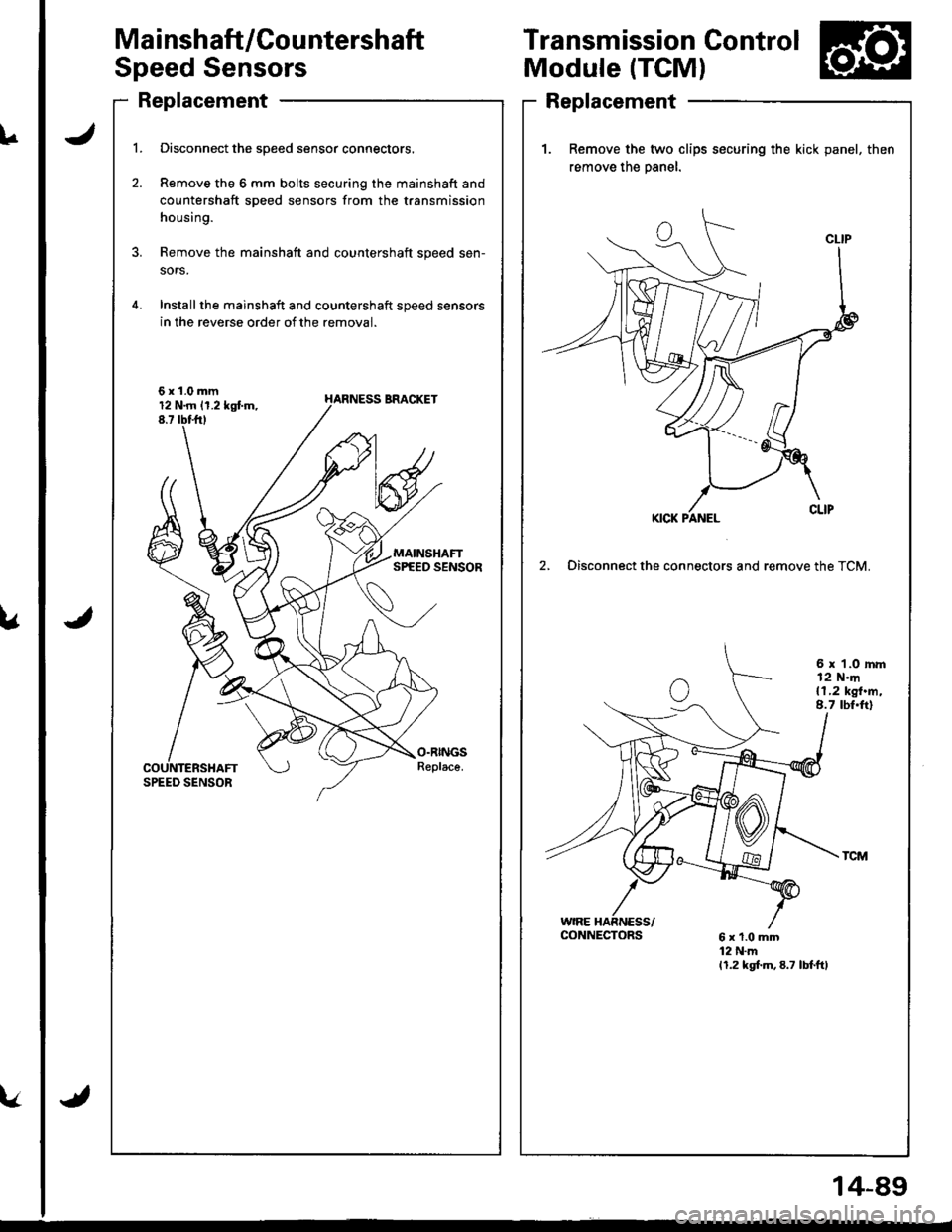

Ma i nshaft/Cou ntershaft

Speed Sensors

Replacement

l.

2.

Disconnect the speed sensor connectors.

Remove the 6 mm bolts securing the mainshaft and

countershaft speed sensors from the transmission

housing.

Remove the mainshaft and countershaft speed sen-

sors.

Installthe mainshaft and countershaft speed sensors

in the reverse order of the removal.

6x1.0mm12 N.rn 11.2 kgtm,8.7 tbttrt

Transmission Control

Module (TCM)

Replacement

1. Remove the two clips socuring the kick panel, then

remove the oanel.

2, Disconnect the connectors and remove the TCM.

6 x 1.0 rnm12 N.m{1,2 kgt.m,8.7 tbt.ft)

CONNECTORS

Page 516 of 1681

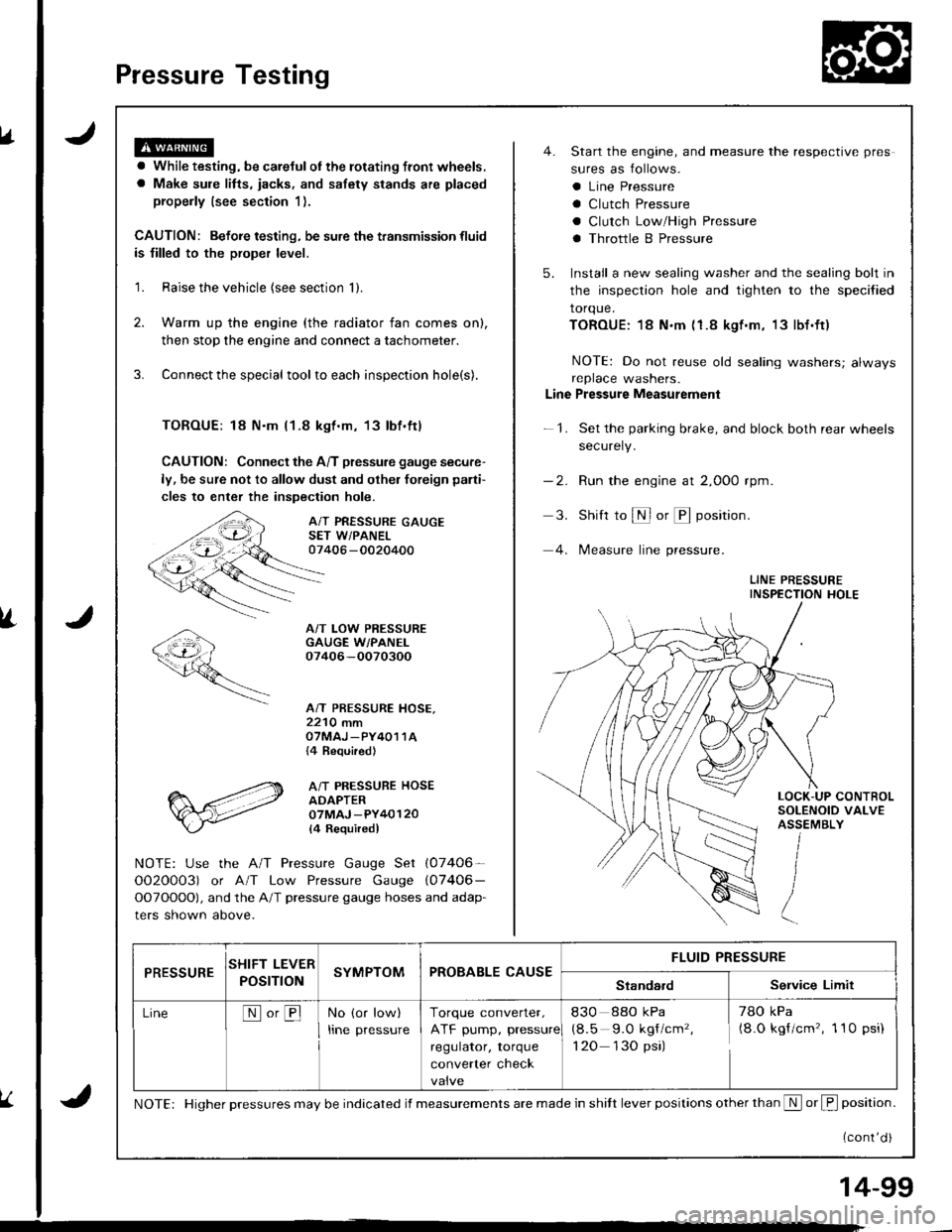

Pressure Testing

a While testing, be careJulot the rotating front wheels.

a Make sule litts, iacks, and safety stands are placed

properly (see section 1).

CAUTION: Befoie testing, be sure the transmission fluid

is filled to the proper level.

'1. Raise the vehicle {see section 'll.

2. Warm up the engine (the radiator fan comes on),

then stop the engine and connect a tachometer.

3. Connect the special tool to each inspection hole(s).

TOROUE: 18 N.m l1-8 kgt.m, 13lbf.ftl

CAUTION: Connect the A/T pressure gauge secure-

ly, be sure not to allow dust and olher foreign pani-

cles to enter the inspection hole.

A/T PRESSURE GAUGESET W/PANEL07406 -0020400

A/T LOW PRESSUREGAUGE W/PANEI.07406-OO70300

A/T PRESSURE HOSE,2210 mmOTMAJ _PY4O1 1A{4 Required}

A/T PRESSURE HOSEADAPTER07MAJ -PY40120

l4 Requiredl

NOTE: Use the A/T Pressure Gauge Set (07406-

OO2O0O3) or A/T Low Pressure Gauge (07406-

OOTOOOO), and the A/T pressure gauge hoses and adap-

ters shown above.

4. Start the engine, and measure the respective pres

sures as follows.

a Line Pressure

a Clutch Pressure

a Clutch Low/High Pressure

a Throttle B Pressure

5. Install a new sealing washer and the sealing bolt in

the inspection hole and tighten to the specified

torque.

TOROUE:18 N.m (1.8 kgf.m, 13lbf.ft)

NOTE: Do not reuse old sealing washers; alwaysreplace washers.

Line Pressure Measurement

-1. Set the parking brake, and block both rear wheels

securely.

-2. Run the engine at 2,000 rpm

3. Shift to S or @ position.

4. lMeasure line pressure.

LINE PRESSUREINSPECTION HOLE

LOCK-UP CONTROLSOLENOID VALVEASSEMBLY

PRESSURESHIFT LEVER

POST ONSYMPTOMPROBABLE CAUSEFLUID PRESSURE

StandardService Limit

LineNo,BNo (or low)

Irne pressure

Torque converter,

ATF pump, pressure

regulator, torque

converter check

830 88o kPa

(8.5 9.O kgf/cm'�,

1 20 130 psi)

78O kPa(8.O kgf/cm'�, 1 10 psi)

NOTE: Higher pressures may be indicated if measurements are made in shitt lever positions other than S or f, position.

{cont'd )

14-99

Page 517 of 1681

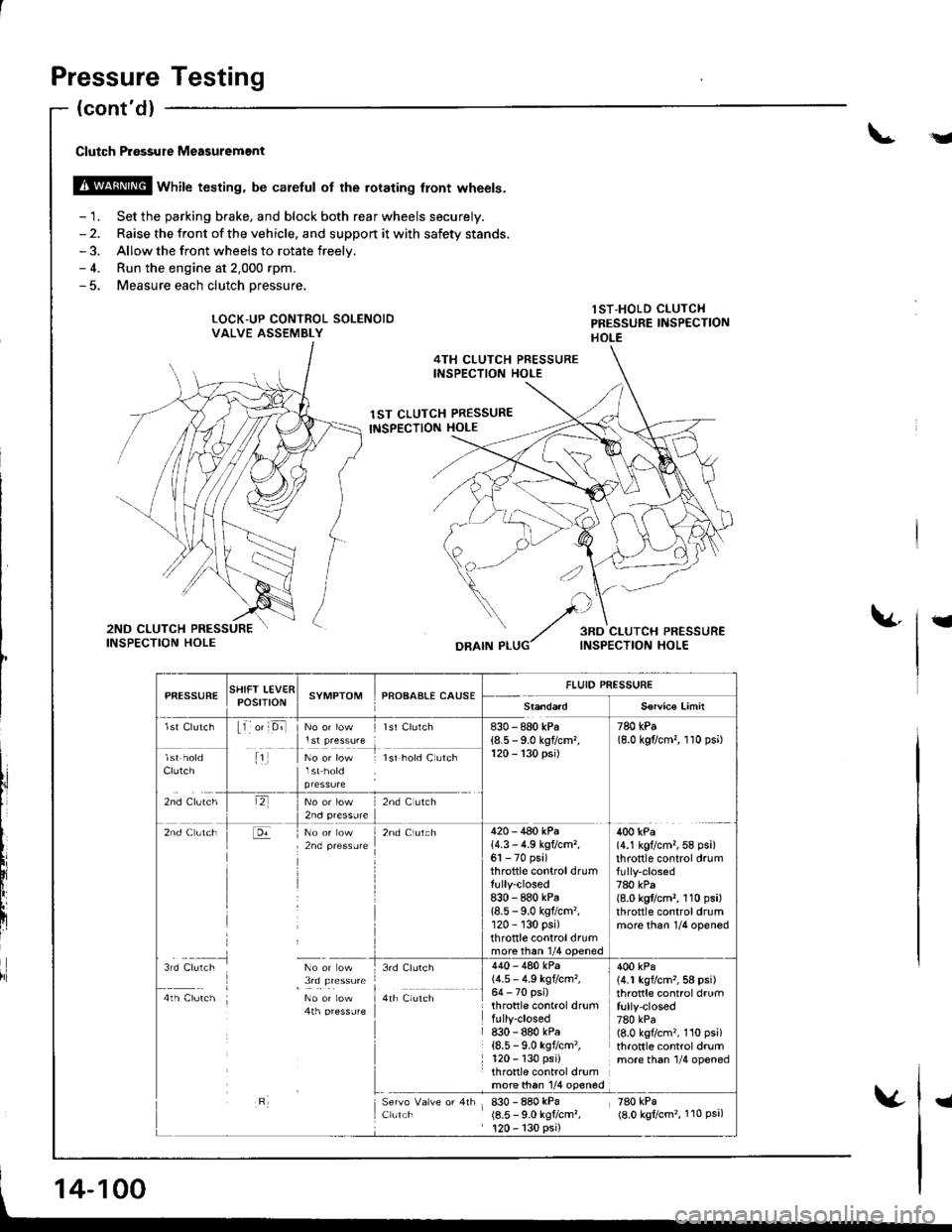

Pressure Testing

.Y

Clutch P.6ssure Measuremgnt

@ wnirc testing. be caretul ot the rorating tront wheels.

- 1. Set the parking brake, and block both rear wheels securely.- 2. Raise the front of the vehicle, and support it with safety stands.- 3. Allow the front wheels to rotate freelv.- 4. Run the engine at 2.000 rpm.- 5. Measure each clutch oressure.

LOCK"UP CONTROL SOLENOIDVALVE ASSEMBLY

lST-HOLD CLUTCHPRESSURE IiISPECTIONHOLE

4TH CLUTCH PRESSUREINSPECTION HOLE

1ST CLUTCH PRESSURE

INSPECTION HOLE

t

DRAIN P

l,i

PfiESSURESTIIFT LEV€RPOStTtONSYMPTOMPROAAALE CAUSEFLUID PRESSURE

S€rvico Limit

lst Clutch11 o' D;llst Clurch830 - 880 kPa(8.5 - 9.0 kgflcm,120 - 130 psi)

780 kPa(8.0 kgflcm,, 1 10 psi)

Clutch

zno cruiltr

1No or low lsr hold C utch

lr,2nd C ltch

2nd Clutch420 - 440 kPa14.3 - 4.9 kg?cm,,61 - 70 psi)throttle controldrumtully-closed8:|0 - 880 kPa18.5 - 9.0 kgflcm'�,120 - 130 psi)throttle controldrummore than 1/4 ooened

400 kPa(4.1 kg?cm,,58 psi)throttle control drum

780 kPa(8.0 kgflcm,, 110 psi)throttle controldrummore than 1/4 opened

3rd Clulch No or ow

I , !,q !le"**4th Clutch No or Low4th pressufe

3rd Clurch

a,r il","r,

Clulch

440 - 480 kPa(4.5 - 4.9 kgtcm,,64 - 70 psi)throttle control drumfully-closed830 - 880 kPa{8.5 - 9.0 ksf/cm'�,120 - 130 psi)throttle control drumrn9l9!q l/4 olqg

830 - 880 kPa(8.5 - 9.0 kgtcm?,120 - 130 psi)

400 kPa14.1 kgvcm,,58 psi)throttle control drumfully-closed780 kPa(8.0 kgflcm'�, 110 psi)throttle control drummore th6n 1/4 opened

zeo rpi(8.0 kgtcm'�, 110 Psa,

14-100

I

Page 532 of 1681

I

t

I

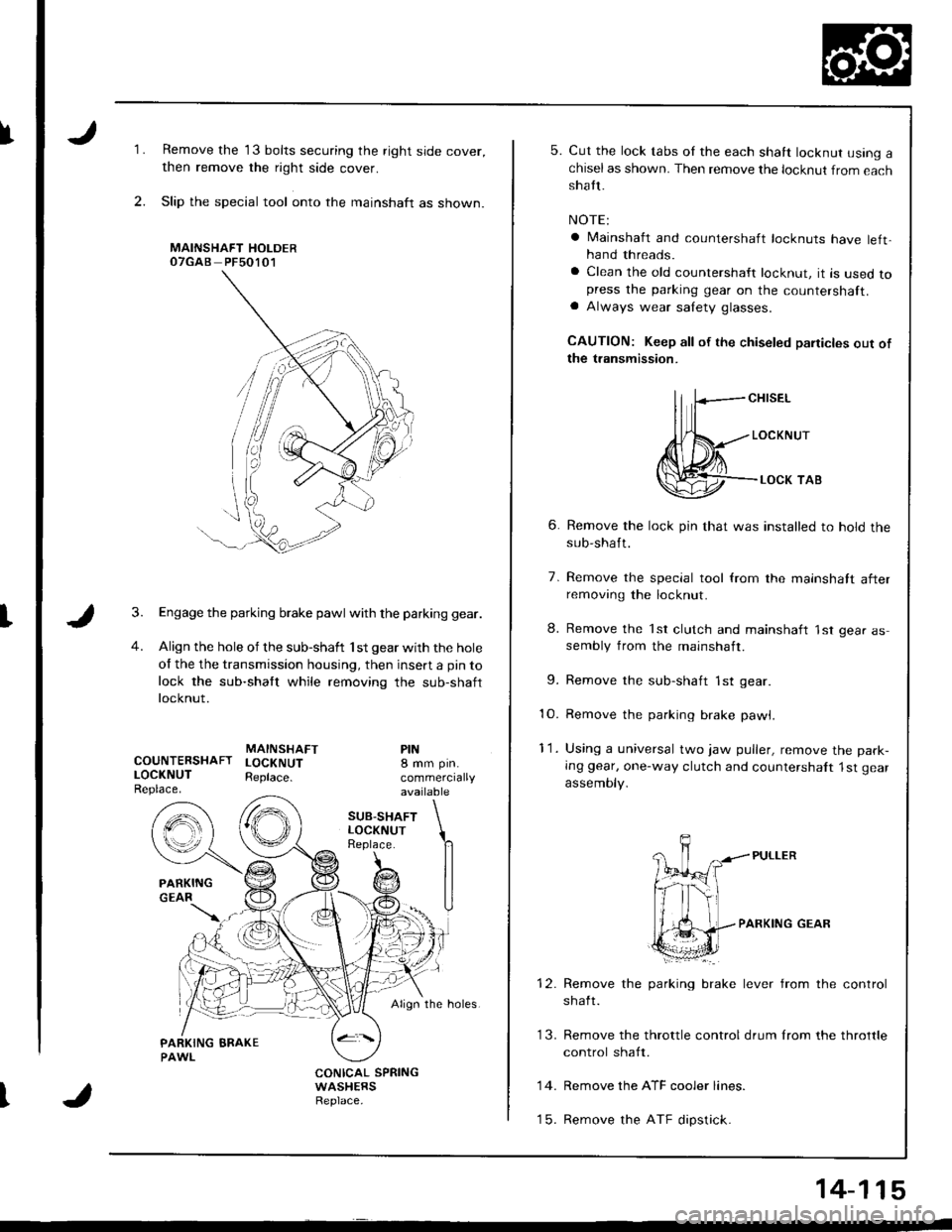

1.

2.

Remove the 13 bolts securing the right side cover,

then remove the right side cover.

Slip the special tool onto the mainshaft as shown.

MAINSHAFT HOLDEROTGAB PFsO1O1

Engage the parking brake pawl with the parking gear.

Align the hole of the sub-shaft 'lst gear with the hole

of the the transmission housing, then insert a pin to

lock the sub-shaft while removing the sub-shaft

locknut.

MAINSHAFTCOUNTERSHAFT LOCKNUTLOCKNUT Reptace.Replace.

PIN8 mm pin.

commerciallyavailable

SUB.SHAFTLOCKNUTReplace.

Align the holes.

CONICAL SPRINGWASHERSReplace.

5. Cut the lock tabs oI the each shaft locknut using achiselas shown. Then remove the locknut from eachshatt.

NOTE:

a lvlainshaft and countershaft locknuts have left,hand threads.

a Clean the old countershaft locknut, it is used topress the parking gear on the countershaft.a Always wear salety glasses.

CAUTION: Keep all of the chiseled paiticles out ofthe transmission.

ll fcH,sEL

Jl{*---,o"*",r

@--.**,o,

6. Remove the lock pin that was installed to hold thesub-shaft.

7. Remove the special tool from the mainshatt afterremoving the locknut.

8. Remove the 'lst clutch and mainshaft 'lst gear assembly from the mainshaft.

9. Remove the sub-shaft 1st gear

10. Remove the parking brake pawl,

11. Using a universal two jaw puller, remove the park-

Ing gear, one-way clutch and countershalt 1st gear

assemoty.

PARKING GEAR

brake lever from the controlRemove the parking

shaft.

Remove the ATF cooler lines.

Remove the ATF dipstick.

13. Remove the throttle control drum lrom the throttle

control shaft.

14.

t5.

14-115

Page 534 of 1681

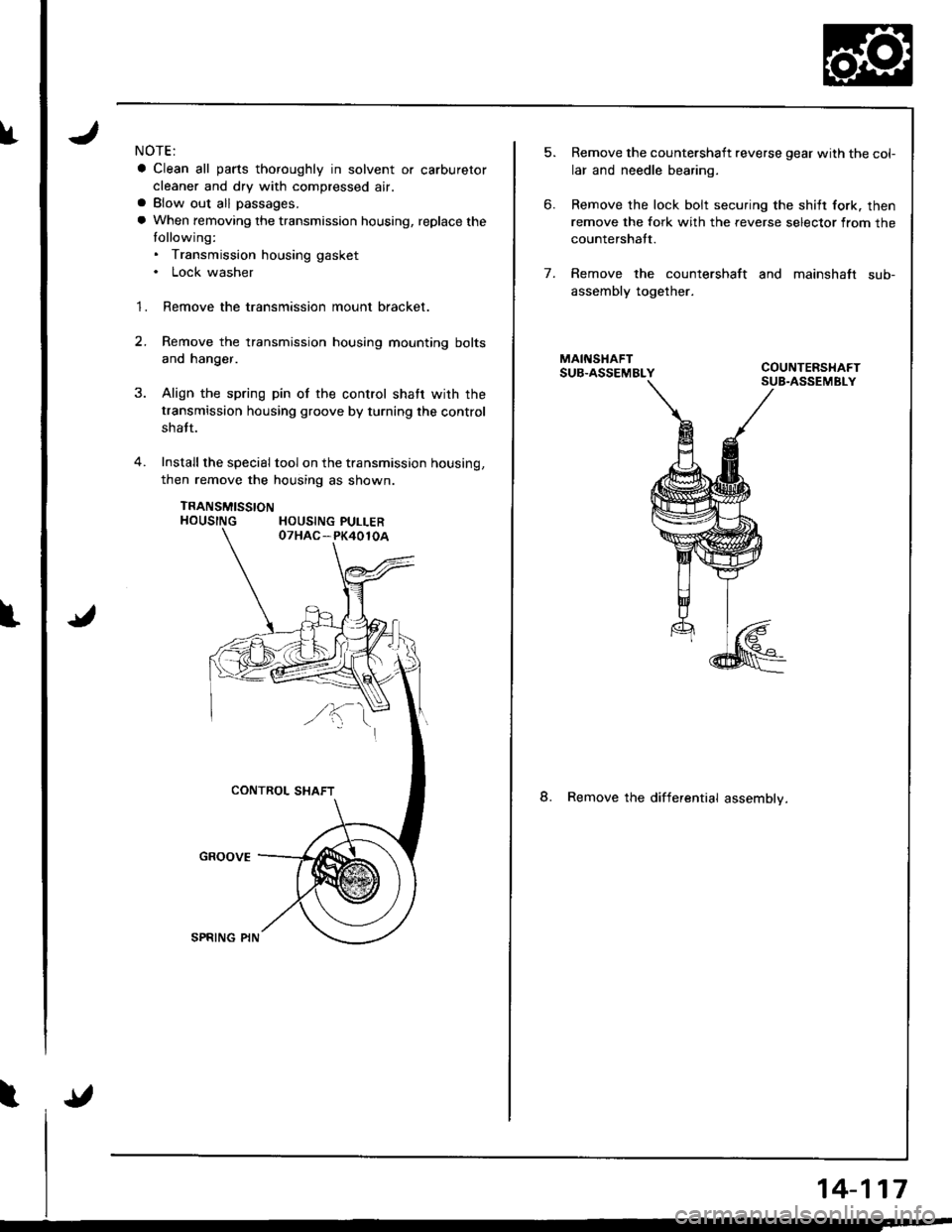

fNOTE:

a Clean all parts thoroughly in solvent or carburetor

cleaner and dry with compressed air.a Blow out all passages.

a When removing the transmission housing, replace the

tollowing:. Transmission housing gasket. Lock washer

1. Remove the transmission mount bracket.

2.Remove the transmission housing mounting bolts

and hanger.

Align the spring pin of the control shatr wirh the

transmission housing groove by turning the control

shatt.

Install the special tool on the transmission housing,

then remove the housing as shown.

TRANSMISSTONHOUSING HOUSING PULLER

5.

6.

Remove the countershaft reverse gear with the col-

lar and needle bearing.

Remove the lock bolt securing the shilt fork. then

remove the fork with the reverse selector from the

countershatt.

Remove the countershaft and mainshaft sub-

assembly together.

8. Remove the differential assemblv.

7.

14-117

Page 536 of 1681

I

l"

I

J

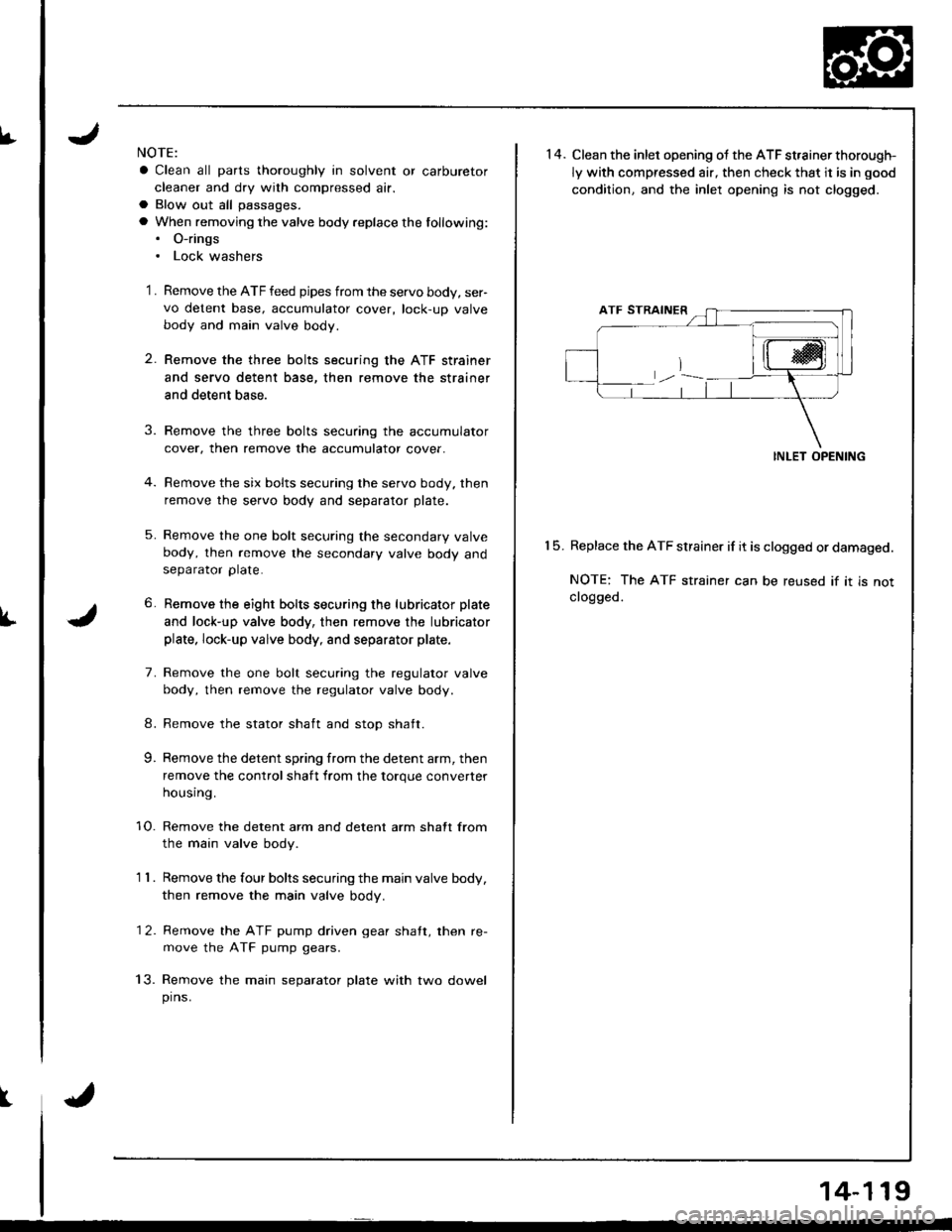

NOTE:

a Clean all parts thoroughly in solvent or carburetor

cleaner and dry with compressed air.

a Blow out all passages.

a When removing the valve body replace the lollowing:. O-rings. Lock washers

1 . Remove the ATF feed pipes from the servo body, ser-vo detent base, accumulator cover, lock-up valve

body and main valve body.

2. Remove the three bolts securing the ATF strainer

and servo detent base, then remove the strainer

and detent base.

3. Remove the three bolts securing the accumulator

cover, then remove the accumulator cover.

4. Remove the six bolts securing the servo body. then

remove the servo body and separator plate.

5. Remove the one bolt securing the secondary valvebody, then remove lhe secondary valve body andseparator plate.

6. Remove the eight bolts securing the lubricator plate

and lock-up valve body, then remov€ th€ lubricator

plate. Iock-up valve body, and separator plate.

7. Remove the one bolt securing the regulator valve

body, then remove the regulator valve body.

8. Remove the stator shaft and stop shaft.

9. Remove the detent spring from the detent arm, then

remove the control shaft from the torque converter

housrng.

1O. Remove the detent arm and detent arm shatt from

the main valve body.

1 'l . Remove the four bolts securing the main valve body,

then remove the main valve body.

'I2. Remove the ATF pump driven gear shatt, then re-

move the ATF pump gears.

13. Remove the main separator plate with two dowel

pins.

15.

14. Clean the inlet opening ot the ATF st,ainer thorough-

ly with compressed air, then check that it is in good

condition. and the inlet opening is not clogged.

INLET OPENING

Replace the ATF strainer if it is clogged or damaged.

NOTE: The ATF strainer can be reused if it is notclogged.

14-119

Page 539 of 1681

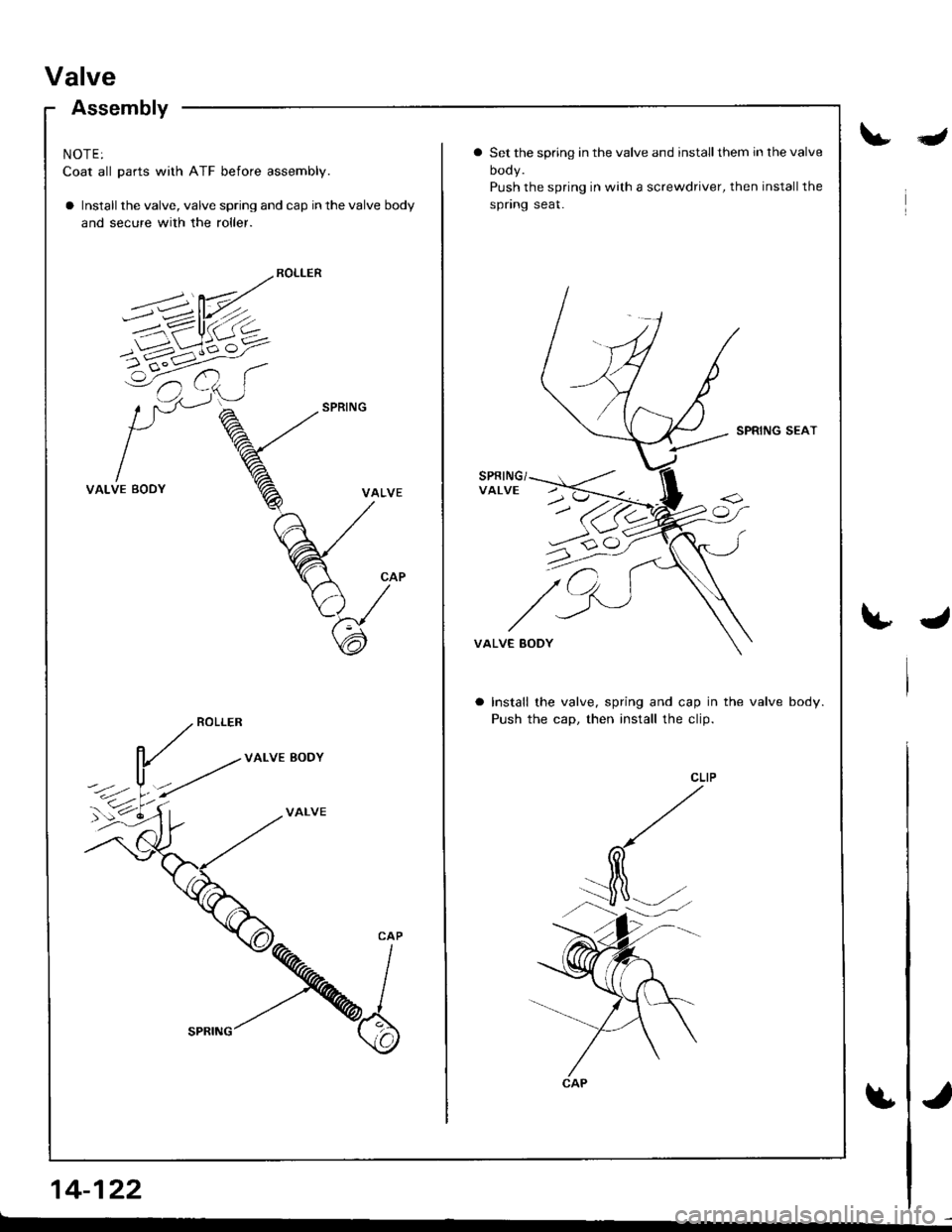

Valve

Assembly

NOTE:

Coat all parts with ATF before assembly.

a Install the valve, valve spring and cap in the valve body

and secure with the roller.

VALVE BODY

VALVE

14-122

Ia Set the spring in the valve and installthem in the valve

oooy.

Push the spring in with a screwdriver, then installthe

spnng seat.

SPRING SEAT

VALVE EODY

Install the valve, spring and cap in the valve body.

Push the cap, then install the clip.

Page 584 of 1681

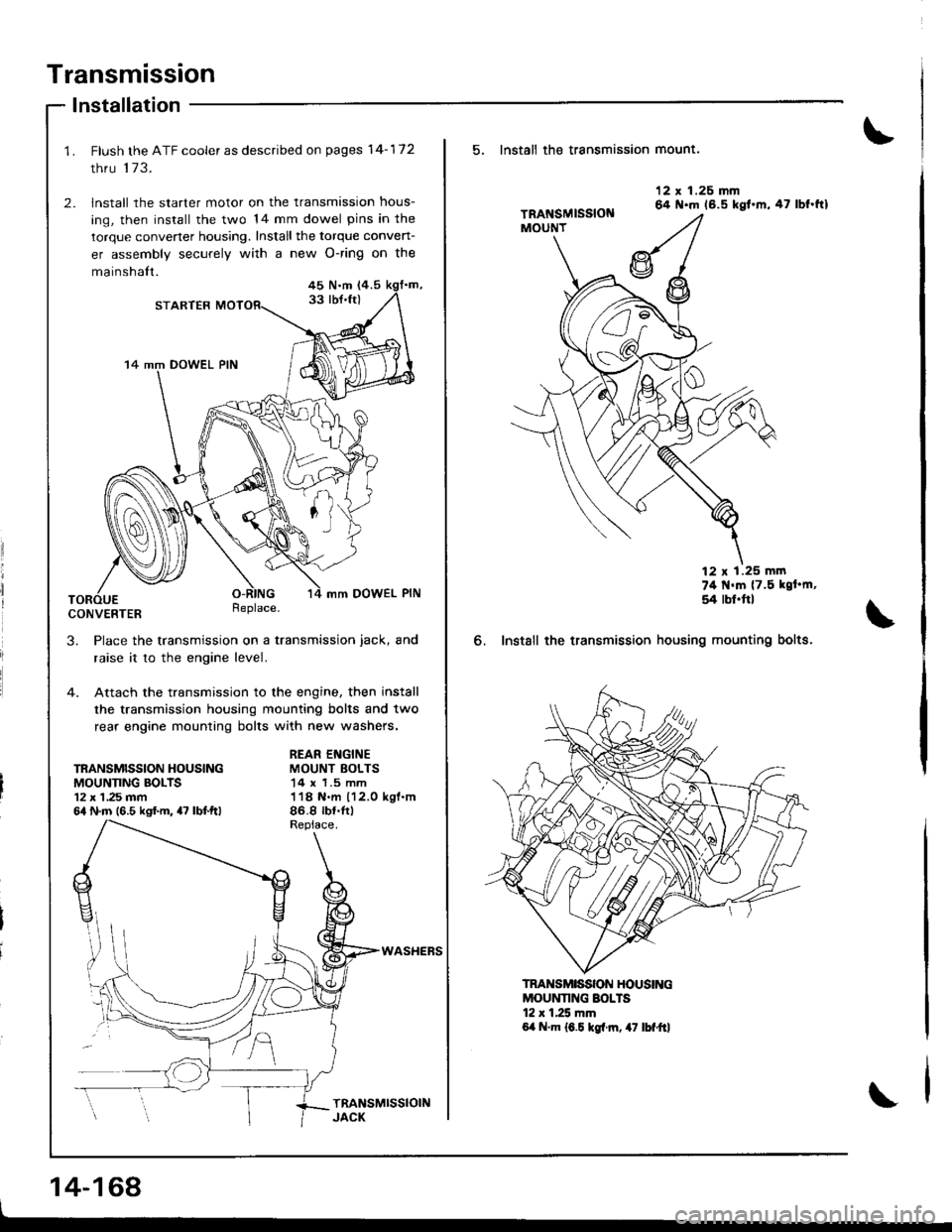

Transmission

lnstallation

Flush the ATF cooler as described on pages 14-172

thru 173.

lnstall the starter motor on the transmission hous-

ing, then install the two 14 mm dowel pins in the

torque convener housing. Install the torque conven-

er assembly securely with a new O-ring on the

mainshalt.45 N.m (4.5

33 lbJ.ft)STARTER

14 mm DOWEL PIN

mm DOWEL PIN

CONVERTERReplace.

3. Place the transmission on a transmission jack, and

raise it to the engine level.

4. Attach the transmission to the engine, then install

the transmission housing mounting bolts and two

rear engine mounting bolts with new washers.

TRANSMISSION HOUSINGMOUNNNG BOLTS12 x 1 ,25 mm64 N.m (6.5 kgf.m, 47 lbf.ftl

REAR ENGINEMOUNT BOLTS14 x 1.5 mm118 N.m 112.0 kgl.m86.8 rb{.tr)

WASHEFS

14-168

5. Install th€ transmission mount.

6. Instsll the transmission

12 x 1.26 mm64 N.m 16.5 kgt.m,47 lbf.ftl

74 t{'m {7.5 kgt'm,

54 rbl.ftl

housing mounting bolts.

MOUNNNG SOLTS12 r 1.25 mm6,t N.m 16.5 kgl.rn, 47 lbf"ftl

TRANSMISSON HOUSING

Page 588 of 1681

Transmission

Cooler Flushing

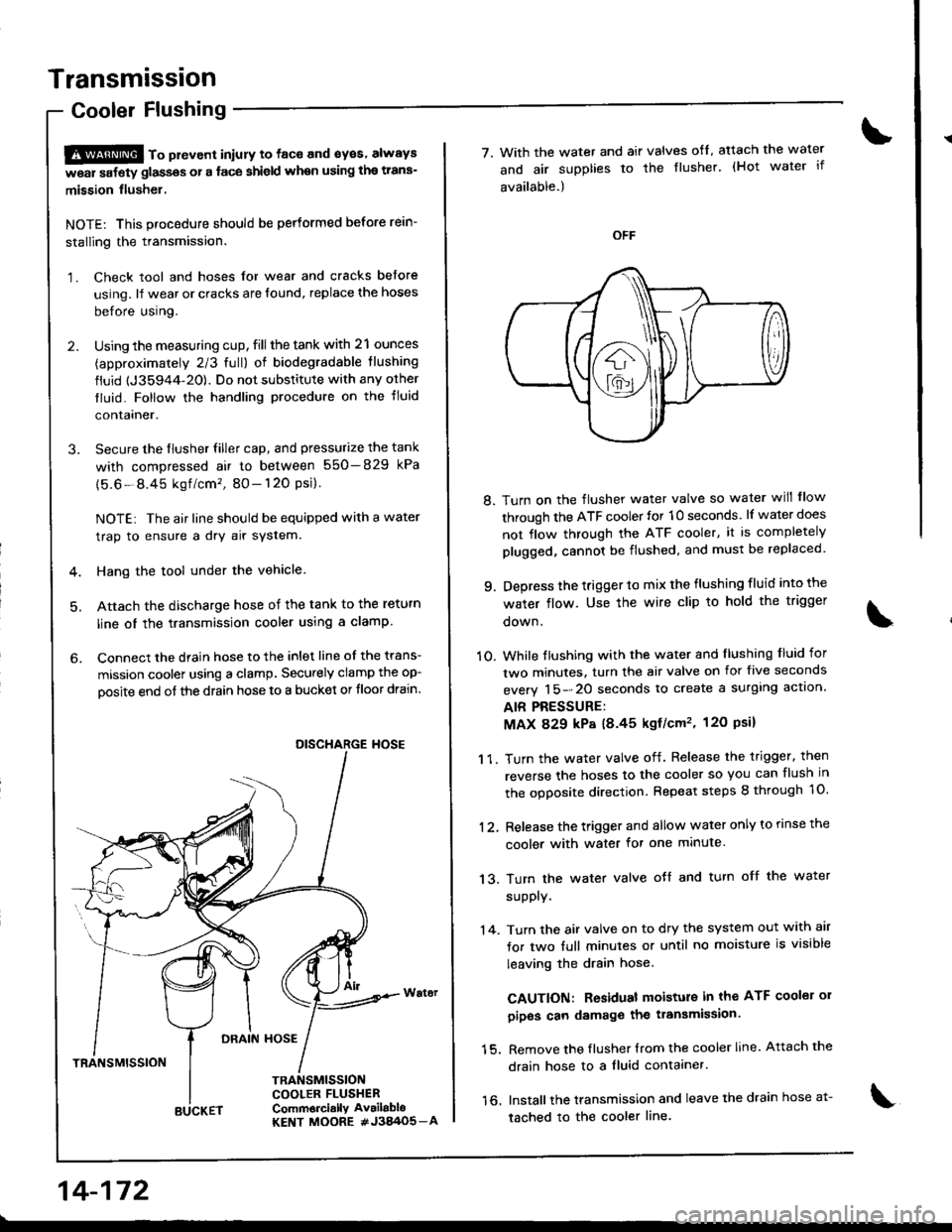

S@ to pttvont iniury to face and syes' always

w6ar safety glassos or a face shield when using the trans-

mission flusher.

NOTE: This procedure should be performed before rein-

stalling the transmission.

1. Check tool and hoses for wear and cracks before

using. lf wear or cracks are found, replace the hoses

before using.

2. Using the measuring cup, fill the tank with 21 ounces

(approximately 2/3 full) of biodegradable tlushing

fluid {J35944-20). Do not substitute with any orher

tluid. Follow the handling procedure on the tluid

contalner.

3. Secure the flusher filler cap, and pressurize the tank

with compressed air to between 550-829 kPa

{5.6-8.45 kgf /cm'�, 80- 120 Psi}.

NOTE: The air line should be equipped with a water

trap to ensure a dry air system.

4. Hang the tool under the vehicle

5. Attach the discharge hose of the tank to the return

line oI the transmission cooler using a clamp

6. Connect the drain hose to the inlet line of the trans-

mission coolel using a clamp. Securely clamp the op-

oosite end of the drain hose to a bucket or tloor drain.

DRAIN HOSE

TRANSMISSION

TRANSMISSIONCOOLER FLUSHERComm6rci.llY Av.ilabloKENT MOORE #J3A/O5_A

DISCHARGE HOSE

14-172

BUCKET

7. With the water and air valves ofl, atach the water

and air supplies to the flusher. (Hot water if

available.)

8. Turn on the flusher water valve so water will flow

through the ATF cooler for 10 seconds. lf water does

not flow through the ATF cooler, it is completely

plugged, cannot be flushed, and must be replaced

9. Depress the trigger to mix the flushing fluid into the

water flow. Use the wire clip to hold the trigger

oown.

1O. While tlushing with the water and llushing f luid for

two minutes. turn the air valve on for five seconds

everv 15-20 seconds to create a surglng actlon.

AIR PRESSURE:

MAX 829 kP8 18.45 kgf/cm'�, 120 Psil

1 1. Turn the water valve off. Release the trigger. then

reverse the hoses to the cooler so you can flush in

the ooDosite direction. Repeat steps 8 through 1O.

12, Release the trigger and allow water only to rinse the

cooler with water for one minute.

13. Turn the water valve oJf and turn off the water

supply.

'14. Turn the air valve on to dry the system out with air

for two full minutes or until no moisture is visible

leaving the drain hose.

CAUTION: Residual moisture in the ATF coolei 01

pipos can damage the transmission.

15. Remove the flusher {rom the cooler line. Attach the

drain hose to a fluid contaaner.

16. Installthe transmission and leave the drain hose a1-

tached to the cooler line.

Page 589 of 1681

![HONDA INTEGRA 1998 4.G Owners Manual 17. Make sure the transmission is in E] position.

Fill the transmission with ATF, and run the engineJor 30 seconds or until approximately one quart isdischarged.

18. Remove the drain hose, and reconn HONDA INTEGRA 1998 4.G Owners Manual 17. Make sure the transmission is in E] position.

Fill the transmission with ATF, and run the engineJor 30 seconds or until approximately one quart isdischarged.

18. Remove the drain hose, and reconn](/img/13/6069/w960_6069-588.png)

17. Make sure the transmission is in E] position.

Fill the transmission with ATF, and run the engineJor 30 seconds or until approximately one quart isdischarged.

'18. Remove the drain hose, and reconnect the coolerreturn hose to the transmission.

19. Refillthe tiansmission with ATF to the propef level.

FILLER CAP

TOOL MAINTENANCE

1. Empty and rinse after each use. Fill the can withwater and pressurize the can. Flush the dischargeline to ensure that the unit is clean.

2. lf discharge liquid does not foam, the orifice may beblocked.

3, To clean, disconnect the plumbing from the tank atthe large coupling nut,

4. Remove the in-line filter trom the discharge side andclean if necessary.

5. The fluid oritice is located behind the filter.

Clean it with the pick stored in the bottom of the tankhandle or blow it clean with air. Securely reassem-

ble all parts.

COUPLING NUT

FILTER

\

IO-RINGORIFICE

14-173