cruise control HONDA INTEGRA 1998 4.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 1311 of 1681

t

t;

i'l

I

dil

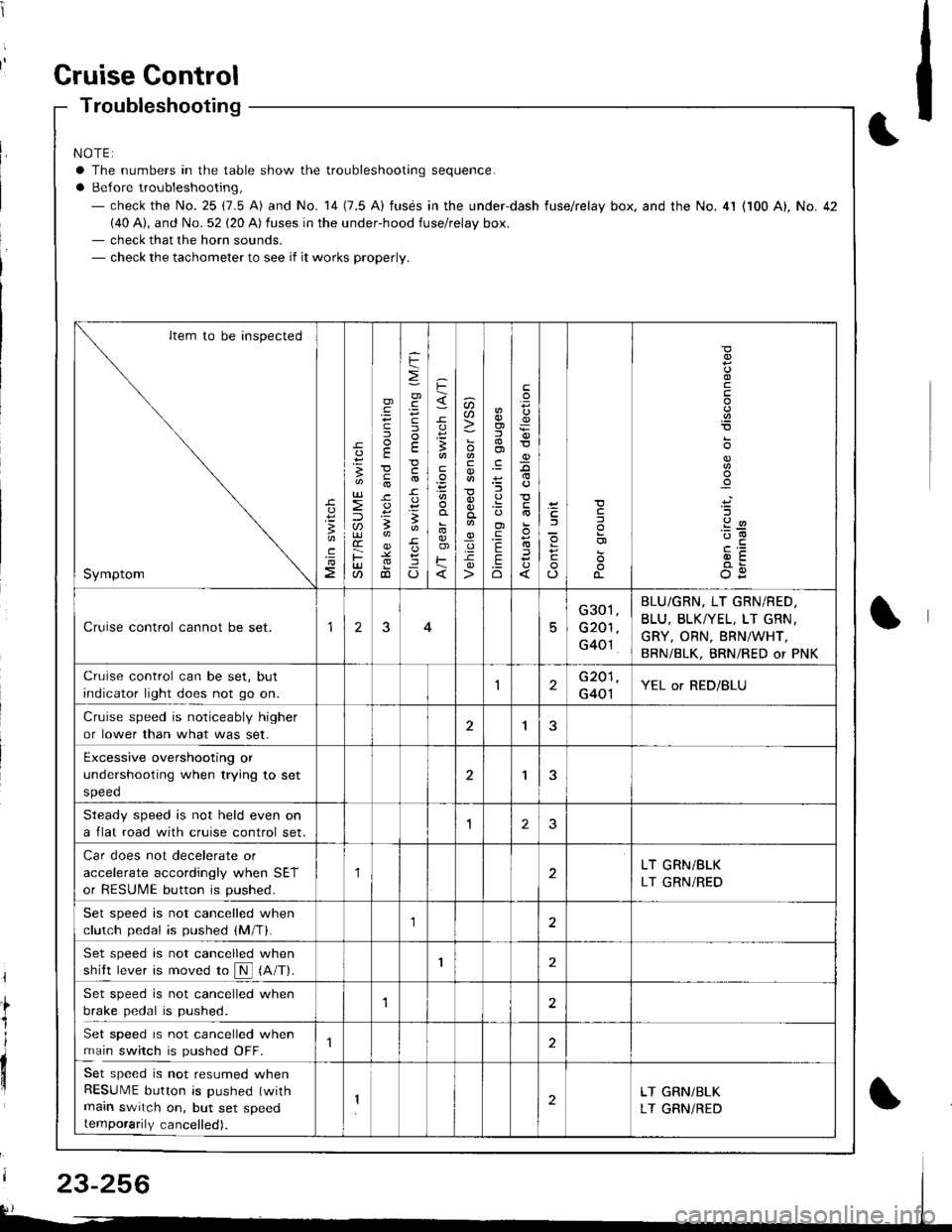

Gruise Gontrol

Troubleshooting

NOTE:

a The numbers in the table show the troubleshooting sequence.

a Belore troubleshooting,- check the No. 25 (7.5 A) and No. 14 (7.5 A) fusds in the under-dash fuse/relay box. and the No. 4l (100 A), No. 42(40 A), and No. 52 (20 A) fuses in the under-hood fuse/relay box.- check that the horn sounds.- check the tachometer to see if it works properly.

Item to be inspected

Symptom

c

:3

UJ

lU)(r

F(t

)

E

c

.

F

=

.g

E

-c

!-

Io

F

3

E

o)F

u)U'

co

_q.9-c

o)f,

ol

;l

E

.Eo

F

E

_9

)a

o

o-

o

c

.2

'::-c

OE

Cruise control cannot be set.15

G301

G201

G40't

BLU/GRN, LT GRN/RED.

BLU, BLKTYEL, LT GRN.

GRY, ORN, BRNiWHT,

BRN/BLK, BRNi RED or PNK

Cruise control can be set, but

indicator light does not go on.1G201

G401YEL or RED/BLU

Cruise speed is noticeably higher

or lower than what was set.1

Excessive overshooting or

undershooting when trying to set

speed

'I

Steadv soeed is not held even on

a flat road with cruise control set.1J

Car does not decelerate or

accelerate accordingly when SET

or RESUME button is pushed.

1LT GRN/BLK

LT GRN/RED

Set speed is not cancelled when

clutch pedal is pushed (M/T).1

Set speed is not cancelled when

shift lever is moved ro N (A/T).I

Set speed is not cancelled when

brake pedal is pushed.12

Set speed is not cancelled when

main switch is pushed OFF.

Set speed is not resumed whenRESUME button is pushed (with

main switch on, but set speedtemporarily cancelled).

2LT GRN/BLK

LT GRNiRED

23-256

Page 1312 of 1681

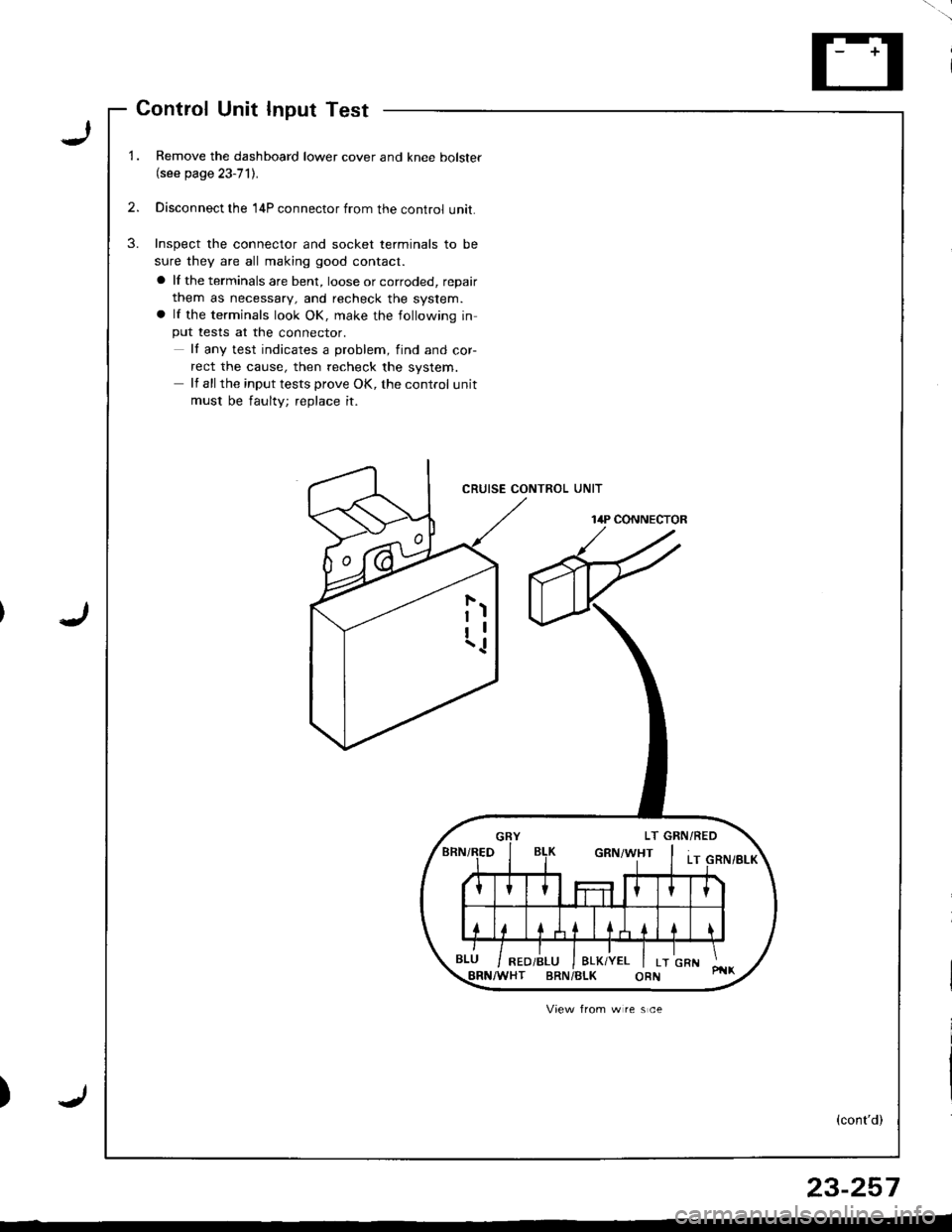

ControlInputTestUnit

'LRemove the dashboard lower cover and knee bolster(see page 23-71).

Disconnect the 14P connector from the control unit.

Inspect the connector and socket terminals to be

sure they are all making good contact.

a lf the terminals are bent, loose or corroded, repair

them as necessary, and recheck the system.a lf the terminals look OK, make the following input tests at the connector.

It any test indicates a problem, find and cor-

rect the cause, then recheck the system.

lf allthe input tests prove OK, the control unit

must be faulty; replace it.

3.

CRUISE CONTROL UNIT

View from w re s ce

(cont'd)

LT GRN/RED

14P CONNECTOR

)

23-257

Page 1313 of 1681

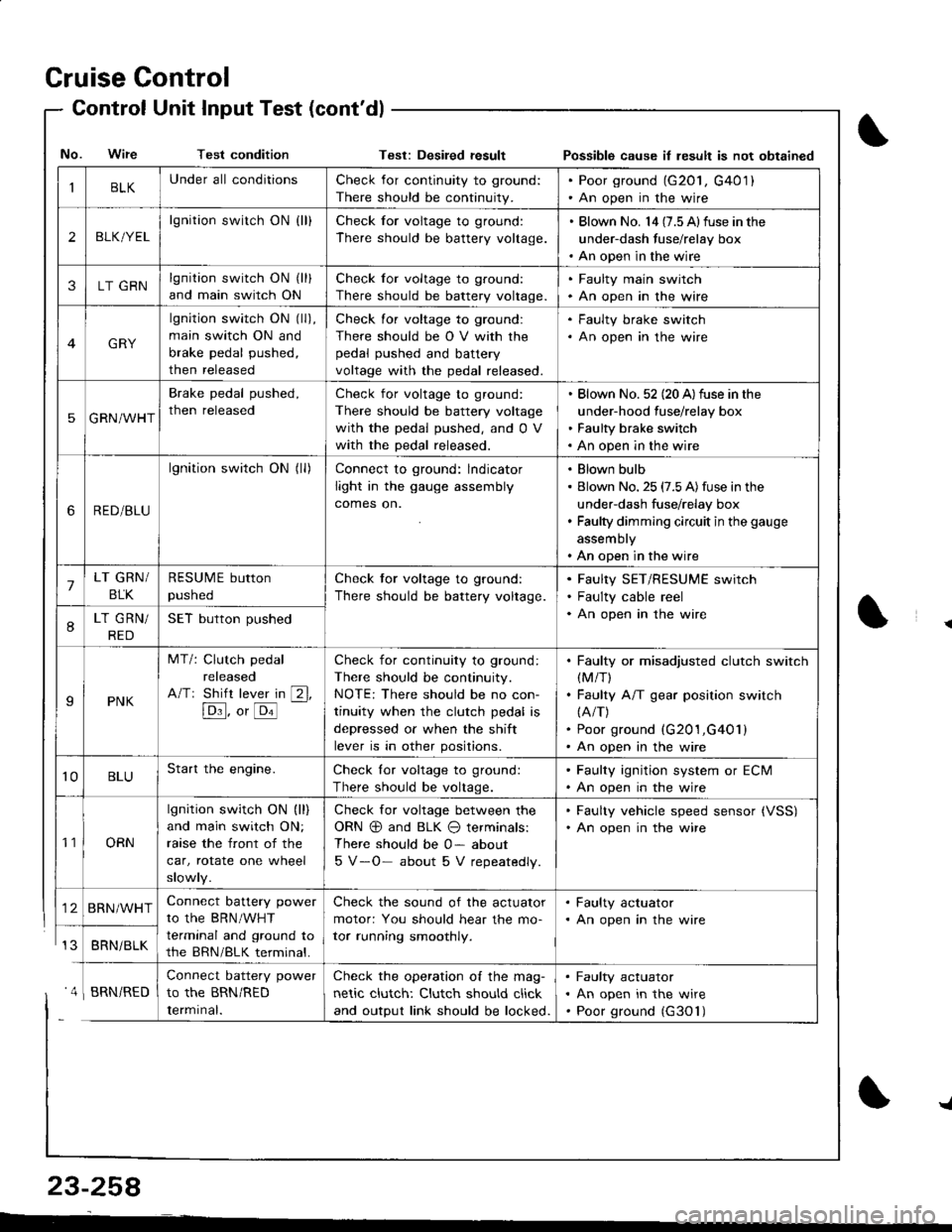

Cruise Control

- Control Unit InputTest(cont'dl

IBLKUnder all conditionsCheck for continuity to ground:

There should be continuity.

. Poor ground (G20l, G401). An open in the wire

2BLK/YEL

lgnition switch ON {ll}Check for voltage to ground:

There should be battery voltage.

. Blown No. l4 (7.5 Alfuse in the

under-dash fuse/relay box. An open in the wire

3LT GRNlgnition switch ON (ll)

and main switch ON

Check for voltage to ground:

There should be battery voltage.

. Faulty main swjtch. An open in the wire

GRY

lgnition switch ON (ll),

main switch ON and

brake pedal pushed,

then released

Check for voltage to ground:

There should be O V with the

pedal pushed and battery

voltage with the pedal released.

. Faulty brake switch. An open in the wire

5GRN/WHT

Brake pedal pushed,

then released

Check for voltage to ground:

There should be battery voltage

with the pedal pushed, and 0 V

with the pedal released.

Blown No. 52 (20 A)fuse in the

under-hood fuse/relay box

Faulty brake switch

An open in the wire

6RED/BLU

lgnition switch ON (ll)Connect to ground: lndicator

light in the gauge assembly

comes on.

Blown bulb

Blown No. 25 (7.5 A)fuse in the

under-dash fuse/relay box

Faulty dimming circuit in the gauge

assembly

An open in the wire

7LT GRN/

BLK

RESUME button

pushed

Check tor voltage to ground:

There should be battery voltage.

Faulty SET/RESUME switch

Faulty cable reel

An open in the wire8LT GRN/

RED

SET button pushed

IPNK

MT/: Clutch pedal

released

A/Tr Shift lever in [2l,

[Dl]. o, [o'l

-

Check for continuity to ground:

There should be continuity.

NOTE: There should be no con-

tinuity when the clutch pedal is

depressed or when the shift

lever is in other positions.

Faulty or misadjusted clutch switch(M/T)

Faulty A/T gear position switch(A/T)

Poor ground (G201,G401)

An open in the wire

't0BLUStart the engine.Check lor voltage to ground:

There should be voltage.

. Faulty ignition system or ECM. An open in the wire

't1ORN

lgnition switch ON (ll)

and main switch ON;

raase the front of the

car, rotate one wheel

slowly.

Check for voltage between the

ORN @ and BLK O terminals:

There should be 0- about

5 V-O- about 5 V repeatedly.

. Faulty vehicle speed sensor {VSS). An open in the wire

BRN/WHTConnect battery power

to the BRN/WHT

terminal and ground to

the BRN/BLK terminal.

Check the sound of the actuator

motor: You should hear the mo-

tor running smoothly.

. Faulty actuator. An open in the wire

BRNi BLK

Connect battery power

to the BRN/RED

Iermrnal.

Check the operation of the mag-

netic clutch: Clutch should click

and output link should be locked.

Faulty actuator

An open in the wire

Poor ground (G30'l)

No. Wire Test conditionTest: Desiled result Possible cause il lesult is not obtained

' 4 I BRN/RED

{

{

23-258

-L

Page 1318 of 1681

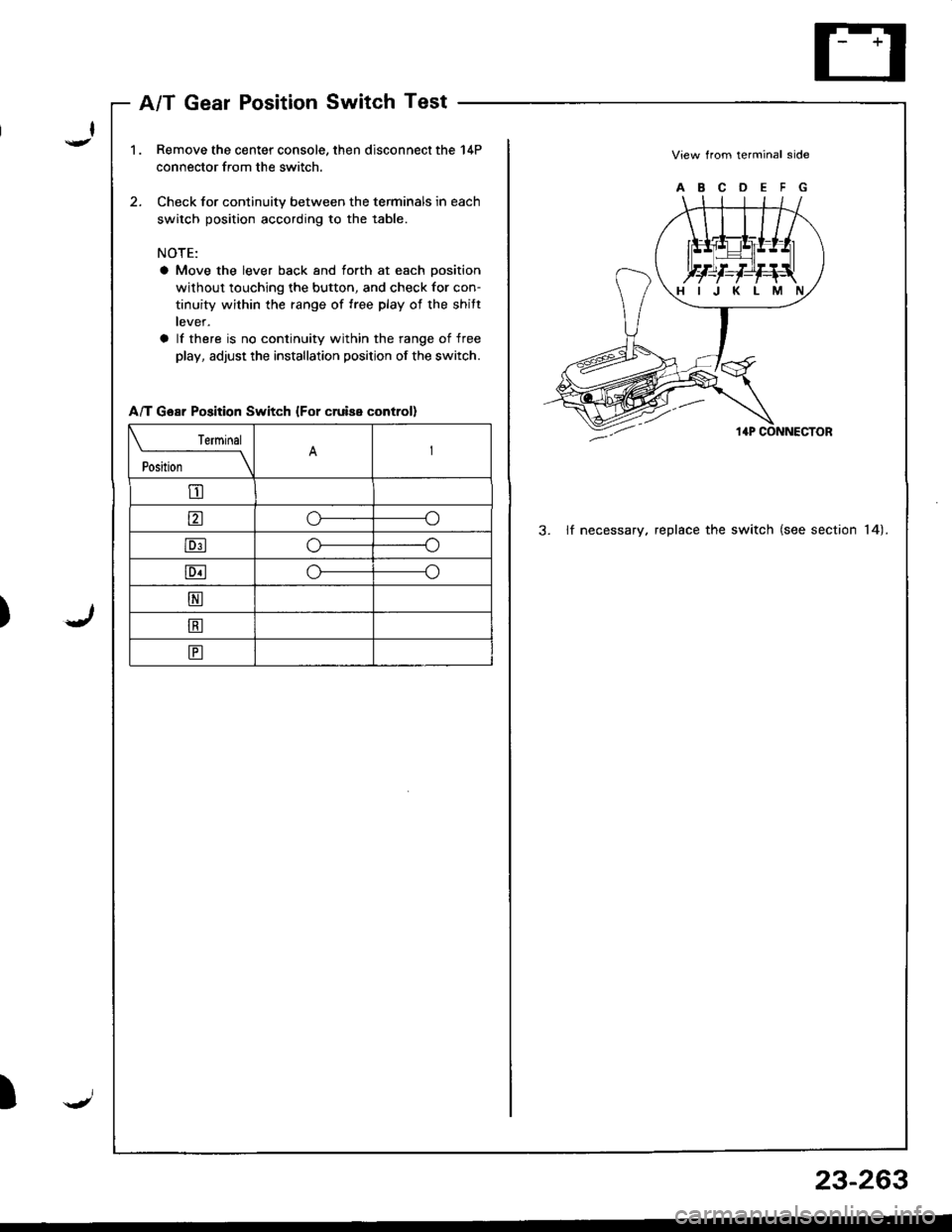

A/T Gear Position Switch Test

1.Remove the center console, then disconnect the 14P

connector from the switch.

Check for continuity between the terminals in each

switch position according to the table.

NOTE:

a Move the lever back and forth at each position

without touching the button, and check for con-

tinuity within the range of free play of the shitt

lever-

a lf there is no continuity within the range of free

play, adjust the installation positjon of the switch.

View lrom terrninal side

ABCDEFG

3. lf necessary. replace the switch (see section 14).

HIJKLM

A/T Goar Position Switch {For cruise control}

Terminal

'*';----_\

n

aoo

@oo

Eoo

E

tr

tr

I

J)

)

23-263

Page 1335 of 1681

)

Precautions/Procedures

General Precautions

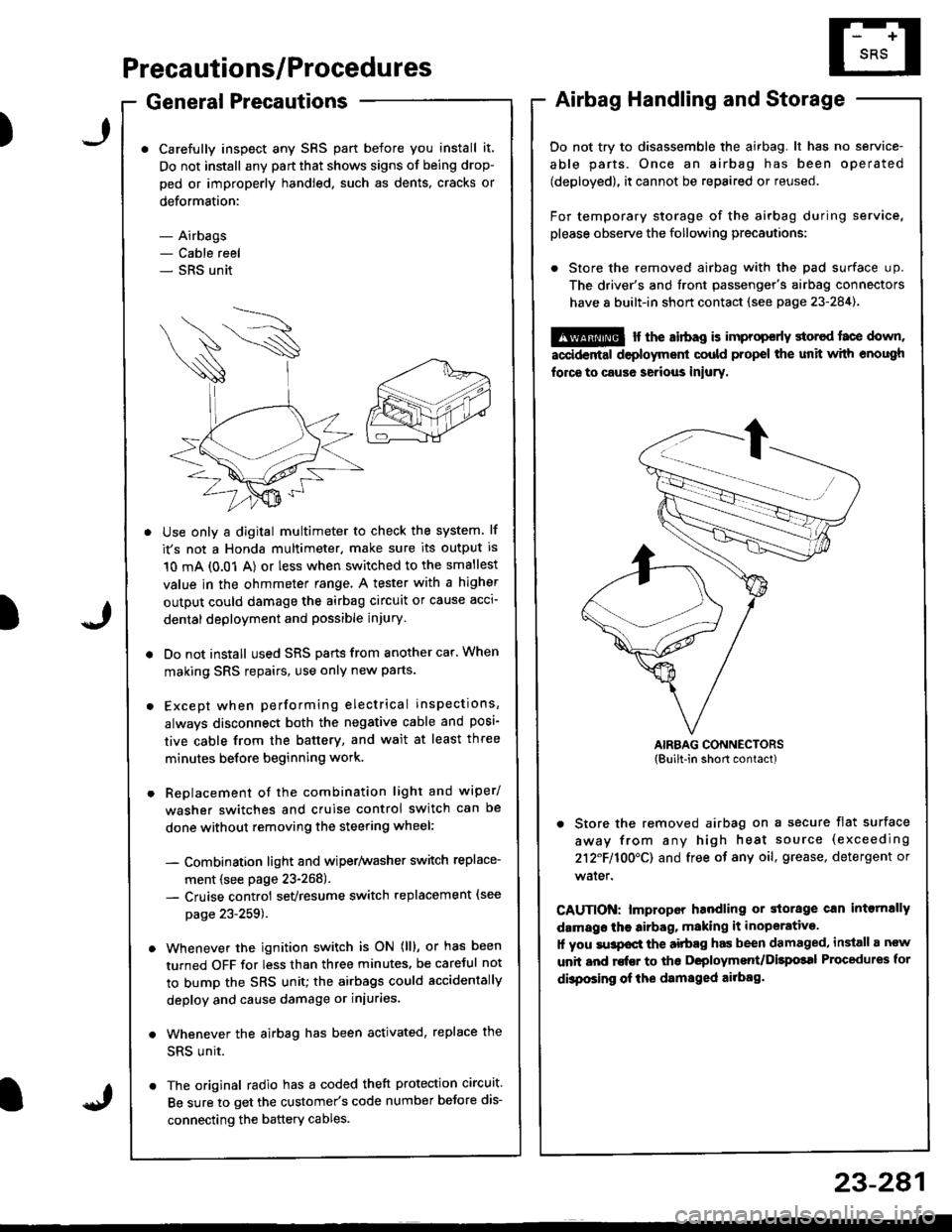

Carefully inspect any SRS part before you install it,

Do not install any part that shows signs of being drop-

ped or improperly handled. such as dents, cracks or

deformstion:

- Airbags- Cable reel- SRS unit

' Use only a digital multimeter to check the system lf

it's not a Honda multimeter. make sure its output is

10 mA (0.01 A) or less when switched to the smallest

value in the ohmmeter range. A tester with a higher

output could damage the airbag circuit or cause acci-

dental deployment and possible injury.

r Do not install used SRS parts from anothercar.When

making SRS repairs, use only new parts.

r Except when performing electrical inspections,

always disconnect both the negative cable and posl-

tive cable from the batterY, and wait at least three

minutes before beginning work.

r Replacement of the combination light and wiper/

washer switches and cruise control switch can be

done without removing the steering wheel:

- Combination light and wiperlwasher switch replace-

ment (see page 23-268).- Cruise controi sevresume switch replacement (see

page 23-259t�.

. Whenever the ignition switch is ON (ll), or has been

turned OFF for less than three minutes, be caretul not

to bump the SRS unit; the airbags could accidentally

deploy and cause damage or iniuries.

. Whenever the airbag has been activated, replace the

SRS unit.

. The original radio has a coded theft protection circuit.

Be sure to get the customer's code number beJore dis-

connecting the battery cables.

23-281

Airbag Handling and Storage

Do not try to disassemble the airbag. lt has no service-

able parts. Once an airbag has been operated

(deployed), it cannot be repaired or reused.

For temporary storage of the airbag during service,

please observe the following precautions:

. Store the removed airbag with the pad surface up.

The driver's and tront passenger's airbag connectors

have 8 built-in short contact (see page 23-284).

@ r the airbag is improp€rly storcd face down,

accidental deployment could propel the unit with enough

force to caus6 serious iniury.

AIRBAG CONNECTORS(Built-in short contact)

. Store the removed airbag on a secure flat surface

away from any high heat source (exceeding

212F110O'CI and free of any oil, grease, detergent or

water.

CAUTION: lmproper handling or storage can intornally

damags the airbag, making it inoperative.

1l you su3pocl the aitbag has been damaged, install a ncw

unit and rofEr to ths Deployment/Dilpolal Procedures for

dbposing of ihe damsged ailbag.

)

Page 1377 of 1681

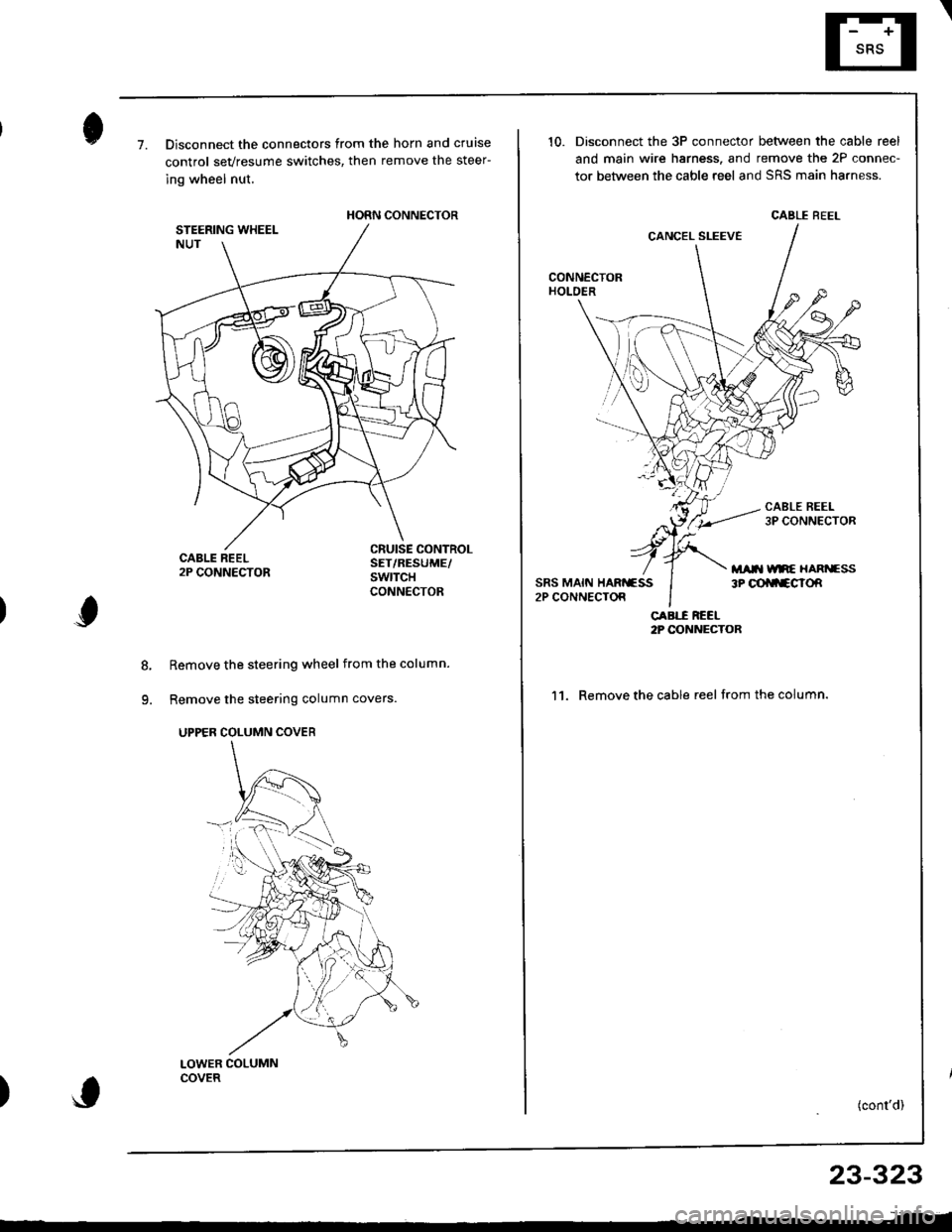

7.Disconnect the connectors from the horn and cruise

control sevresume switches, then remove the steer-

ing wheel nut.

Remove the steering wheel from the column.

Remove the steering column covers

UPPER COLUMN COVER

8.

)

HORN CONNECTOR

\

10.Disconnect the 3P connector between the cable reel

and main wire harness. and remove the 2P connec-

tor between the cable reel and SRS main harness.

CABLE BEEL

CABE R€EL2P CONNECTOR

'11. Remove the cable reel fromthecolumn.

(cont'd)

23-323

Page 1378 of 1681

Cable Reel

Replacement (cont'dl

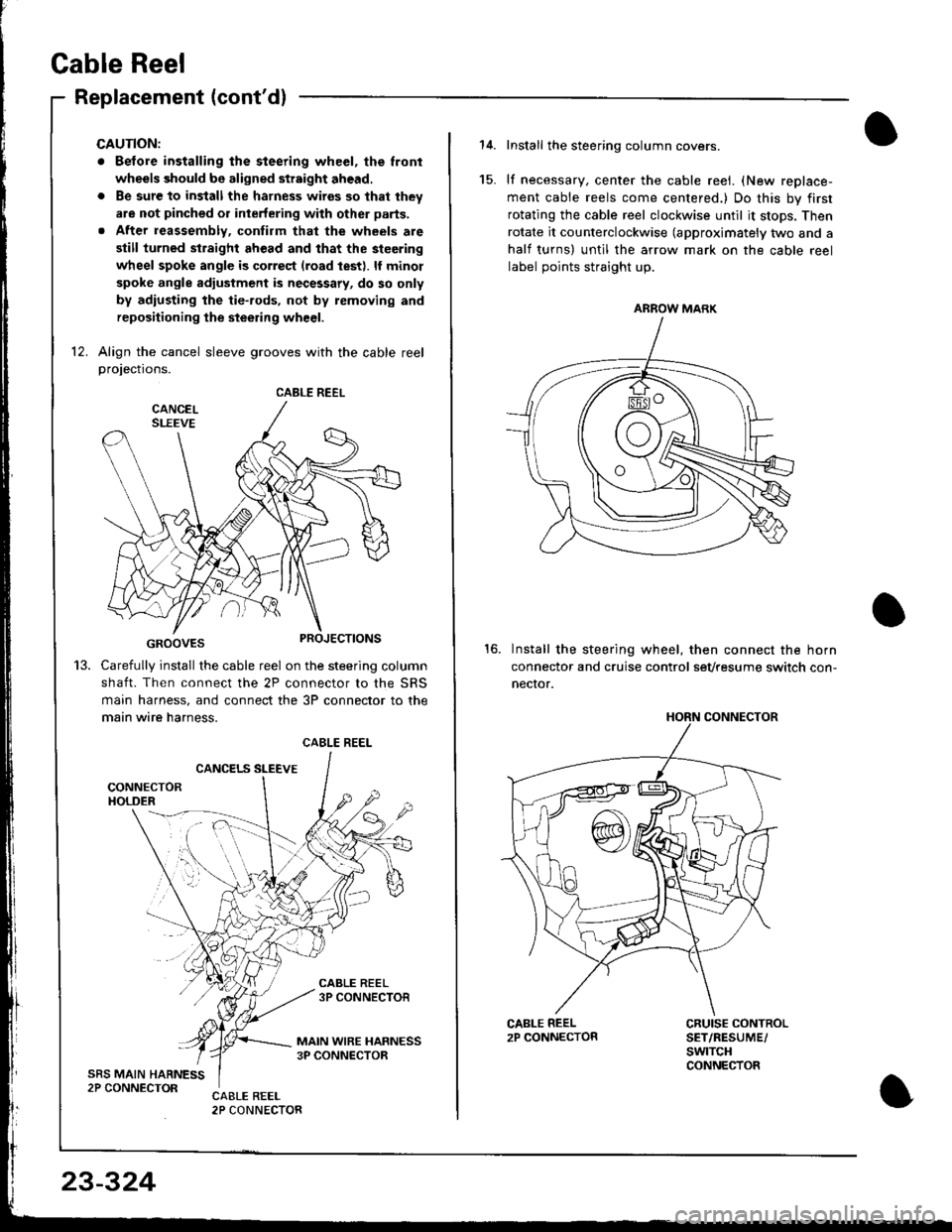

CAUTION:

. Before installing the steering wheel, the lront

wheels should be aligned str8ight ahead.

. Be sure to install the harness wires so that they

are not pinched or interfering with other parts.

. After reassembly, confirm thal the wheels are

slill turned str8ight ahead and that the steering

wheel spoke angle is correst (road test). lf minol

spoke angle adjustment is necessary, do so only

by adiusting the tie-.ods, not by removing and

repositioning the steering wheel.

12. Align the cancel sleeve grooves with the cable reelprojections.

GROOVES

Carefully install the cable reel on the steering column

shaft. Then connect the 2P connector to the SRS

main harness, and connect the 3P connector to the

main wire harness.

CANCELS SLEEVE

CABLE REEL

13.

CABLE REEL

23-324

Install the steering column covers.

lf necessary, center the cable reei. (New replace-

ment cable reels come centered.) Do this by first

rotating the cable reel clockwise until it stops. Then

rotate it counterclockwise (approximately two and a

half turns) untll the arrow mark on the cable reel

label points straight up.

Install the steering wheel, then connect the horn

connector and cruise control sevtesume switch con-

necror.

15.

16.

CRUISE CONTROLSET/RESUME/swtTcHCONNECTOR

ARROW MARK

HORN CONNECTOR

Page 1383 of 1681

).1

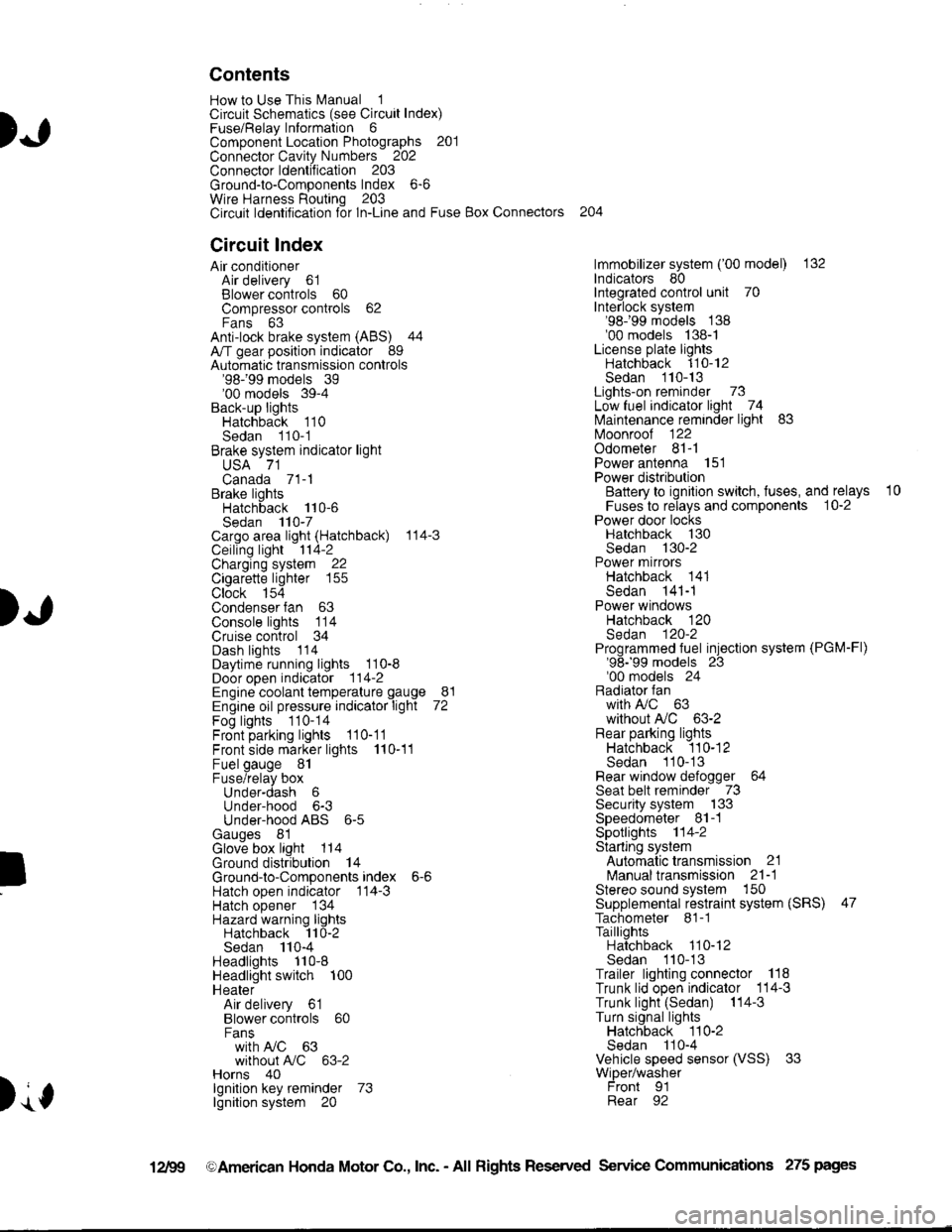

Contents

How to Use This l\.4anual 1Circuit Schematics (see Circuit Index)Fuse/Relaylnformation 6ComponentLocation Photographs 201

Connector Cavity Numbers 202Connectorldentification 203

Ground-to-Components Index 6-6Wire Harness Routing 203Circuit ldentification lor ln-Line and Fuse Box Connectors

Circuit Index

Air conditionerAir delivery 61Blower controls 60Compressor controls 62Fans 63Anti-lock brake system (ABS) 44A/T gear position indicator 89Automatic transmission controls'98199 models 39'00 models 39-4Back-up lightsHatchback 110Sedan 110- 1Brake system indicator light

USA 71Canada 71-1Brake lightsHatchback 110-6Sedan 110-7Cargo area light (Hatchback) 114-3Ceiling light 114-2Charging system 22Cigarette lighter 155

Clock 154Condenser fan 63Console lights 114Cruise control 34Dash lights 1 14Daytime running lights 110-8Door open indicator 114-2Engine coolant temperature gauge 81Engine oil pressure indicator light 72Fog lights 110-14Front parking lights 110-11Front side marker lights 110-11Fuel gauge 81Fuse/relay boxUnder-dash 6Under-hood 6-3Under-hood ABS 6-5Gauges 81Glove box light 114Ground distribution 14Ground-to-Componentsindex 6-6Hatch open indicator '114-3

Hatch opener '134

Hazard warning lightsHatchback 'l l0-2Sedan 110-4Headlights 1'10-8Headlight switch 100HeaterAir delivery 61Blower controls 60Fanswith A,/C 63without A,/C 63-2Horns 40lgnilion key reminder 73lgnition system 20

204

lmmobilizer system ('00 model) 132lndicators 80Integrated control unit 70Interlock system'98199 models 138'00 models 138-1License plate lightsHatchback 110-12Sedan 110-13Lights-on reminder 73Low fuel indicator light 74l\,4aintenance reminder light 83l\iloonroof 122Odometer 81-1Power antenna 151Power distributionBattery to ignilion switch, fuses, and relays

Fuses to relays and components 10-2Power door locksHatchback '130

Sedan 130-2Power mirrorsHatchback 141Sedan 141-1Power windowsHatchback 120Sedan 120-2Programmed fuel injection system (PGM-Fl)'98199 models 23'00 models 24Radiator fanwith tuC 63without A,/C 63-2Rear parking lightsHatchback 110-12Sedan 110- 13Rear window defogger 64Seat belt reminder 73Security system 133Speedometer Il-1Spotlights 114-2Starting syslemAutomalictransmission 21l\.4anualtransmission 21-1Stereo sound system 150Supplemental restraint system (SRS) 47Tachometer 81- 1TaillightsHatchback 110-12Sedan 110-13Trailer lighting conneclor 118Trunk lid open indicator 114-3Trunk light (Sedan) 114-3Turn signal lightsHatchback 110-2Sedan 110-4Vehicle speed sensor (VSS) 33Wiper/washerFront 91Rear 92

10

).1

I

Xr

12Fg oAmerican Honda Motor Co., Inc. - All Rights Reserved Service Communications 275 pages

Page 1389 of 1681

How To Use This Manual

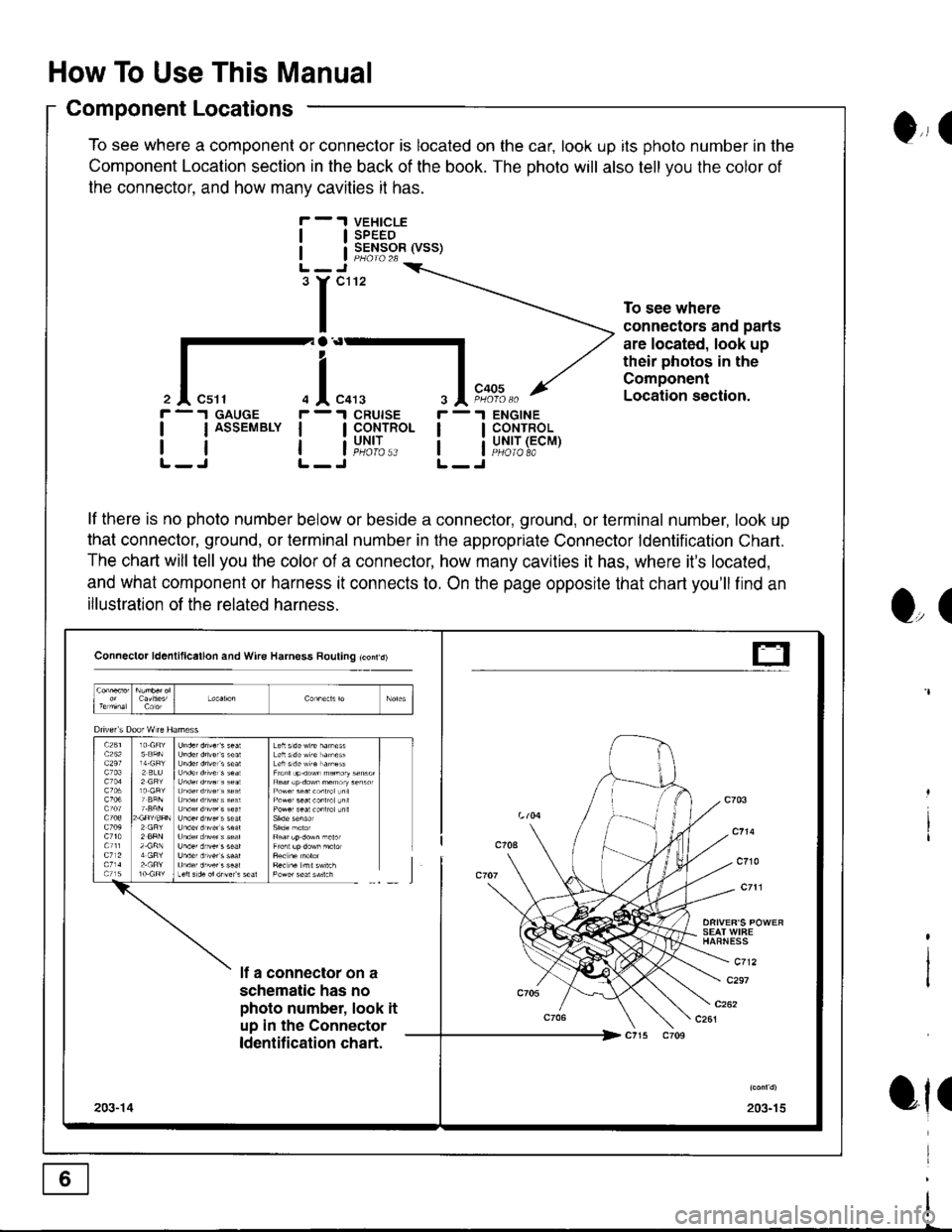

Component Locations

To see where a component or connector is located on the car, look up its photo number in the

Component Location section in the back of the book. The photo will also tell you the color of

the connector. and how manv cavities it has.

VEHICLESPEEDSENSOR (VSS)

ENGINECONTROLUNIT (ECMPHOIO 8A

0,, I

tl

tl

'r"'

To see where

connectors and parts

are located, look up

their photos in the

Component

Location section.

r -.I GAUGE

| | ASSEMBLY I

rtlL-J L-

r -'l

ll

ll

O,(

ot(

il"l,*.I CRUISE

I CoNTROL

i"u,t',:..

lf there is no photo number below or beside a connector, ground, or terminal number, look up

that connector, ground, or terminal number in the appropriate Connector ldentification Chart.

The chart will tell you the color of a connector, how many cavities it has, where it's located,

and what component or harness it connects to. On the page opposite that chart you'll find an

illustration of the related harness.

Connector ld6nlillcallon and Wire Harness Rouling tconrd)

SEAT WIFEHAFNESS

c712lf a connector on a

schematic has no

photo number, look it

up in the Connector

ldentification chart.

c297

203-15203-14

t-

Page 1390 of 1681

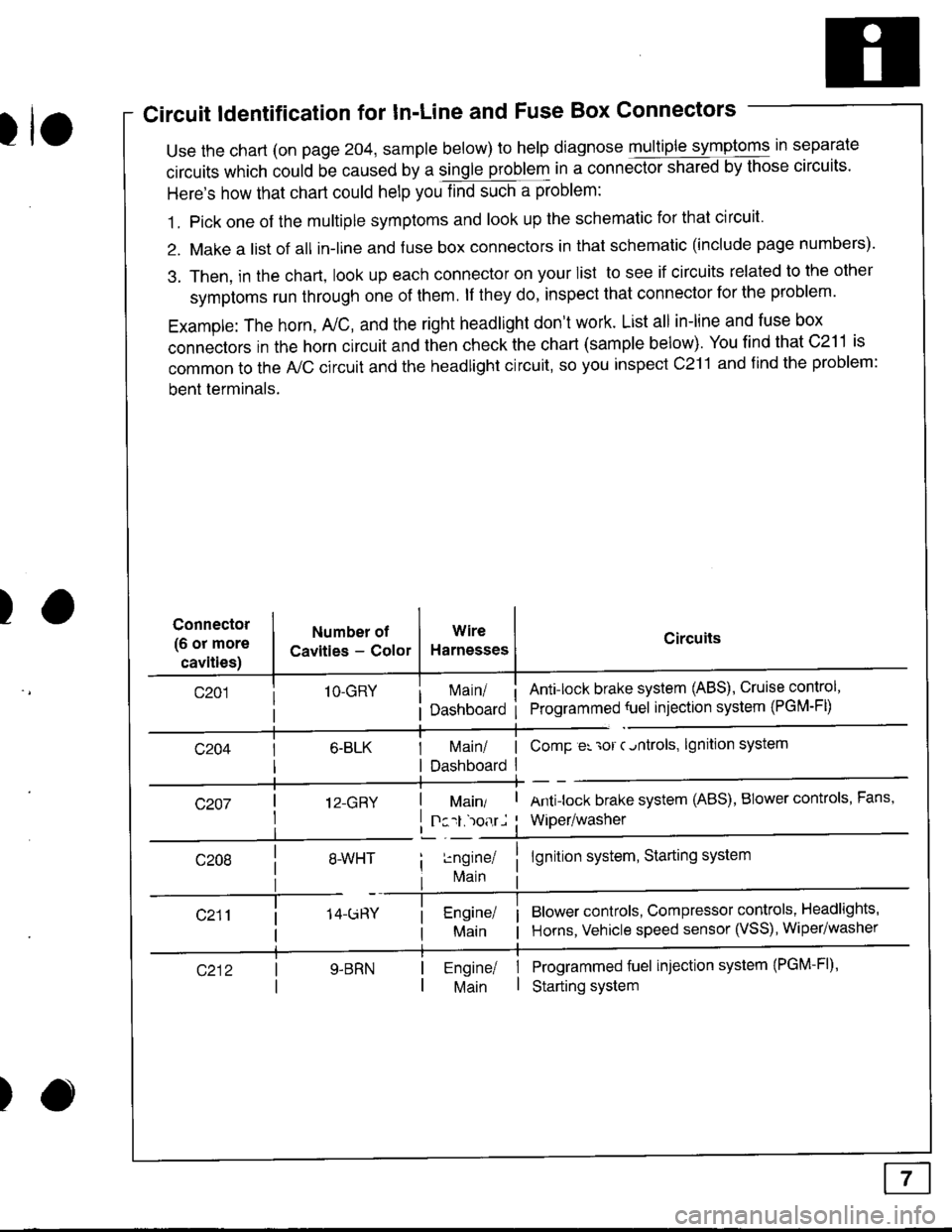

Circuit ldentification for In'Line and Fuse Box Connectors

tuse the chart (on page 204, sample below) to help diagnose multiple symptoms in separate

circuits which could be caused by a single problem in a connect,oishared by those circuits'

Here's how that chart could help you find such a problem:

1. Pick one of the multiple symptoms and look up the schematic for that circuit'

2. Make a list of all in-lrne and fuse box connectors in that schematic (include page numbers).

3. Then, in the chart, look up each connector on your list to see if circuits related to the other

symptoms run through one of them. lf they do, inspect that connector for the problem.

Example: The horn, A,/C, and the right headlight don't work. List all in-line and fuse box

connectors in the horn circuit and then check the chart (sample below). You find that C211 is

common to the A,/C circuit and the headlight circuit, so you inspect c211 and find the problem:

bent terminals.

)Connector

(6 or more

cavities)

Numbel of

Cavities - Color

1O-GRY

I 12-GRY

I

Wire

Harnesses

I Main/ | ComP er 'ror c.ntrols,

I Dashboard I

Circuits

Ant!lock brake system (ABS), Cruise control,

Programmed {uel injection system (PGM-FD

!ngrnei

lvlain

lgnition system

Antilock brake system (ABS), BIower controls, Fans,

Wiper/washer

lgnition system, Starting system

Blower controls, Compressor controls, Headlights'

Horns, Vehicle speed sensor (VSS), Wiper/washer

Programmed fuel injection system (PGM-Fl)'

Starting system

Engine/ |Main I

)