turn signal HONDA INTEGRA 1998 4.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 465 of 1681

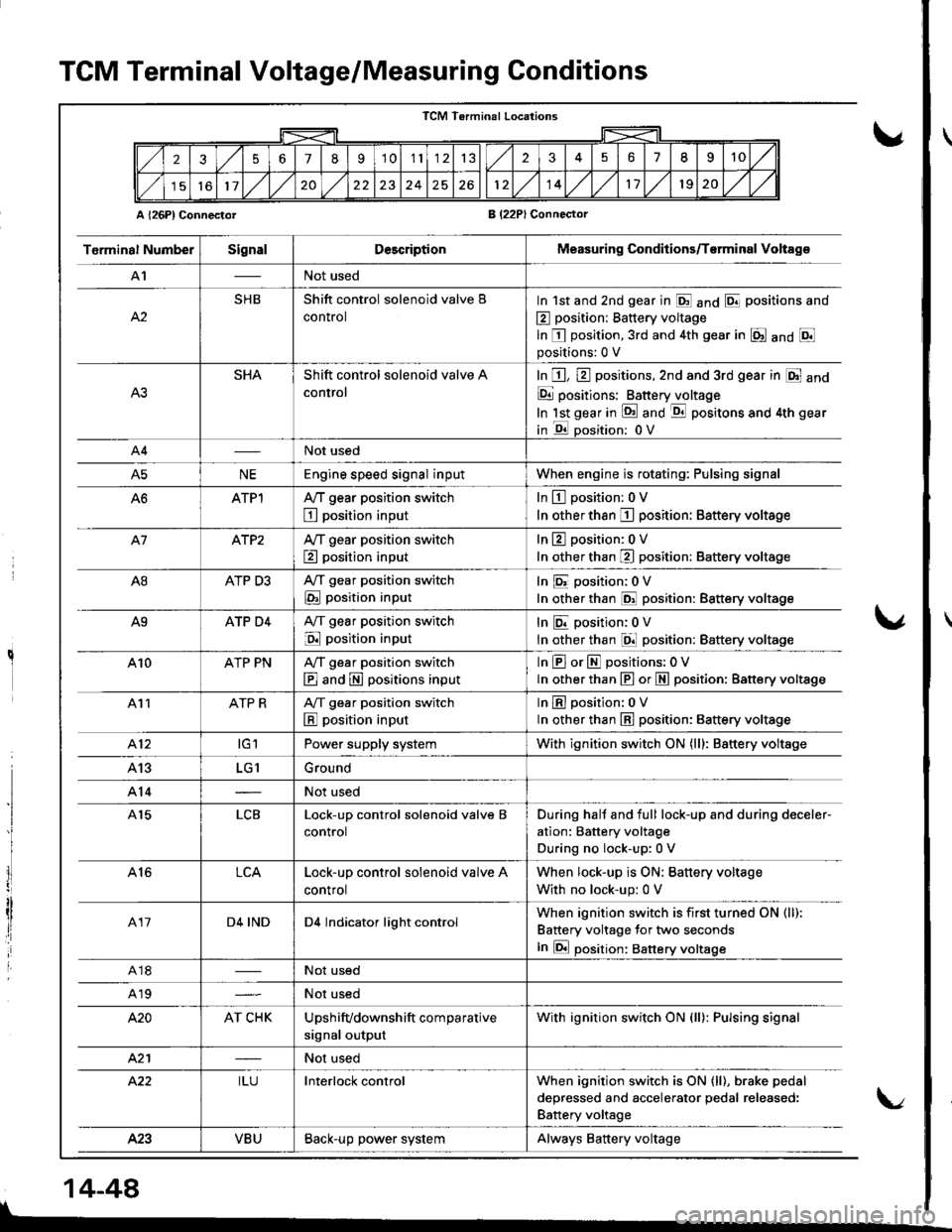

TCM Terminal Voltage/Measuring Conditions

A l26Pl ConnectorB (22PlConnector

TCM Terminal Locations

256789'1011132351II10

11,/l/2024261214,/l/1120,/1,/

T6rminal NumberSignalDescriptionMeasuring Conditions/T€rminal Voltag€

A'INot used

A2

SHBShift control solenoid valve B

control

In 1st and 2nd gear in E anO E positions and

E position: Battery voltage

ln E position,3rd and 4th gear in E anO Epositions:0 V

SHAShift control solenoid valve A

control

In E, E positions,2nd and 3rd gear in E and

E positions: Batteryjloltage

In lst gear in !d and -qtl positons and 4th gear

in E oosition: 0V

A4Not used

A5NEEngine speed signal inputWhen engine is rotating: Pulsing signal

ATPlA,/T gear position switch

E position input

In L!-l position: 0 V

In other than I position: Battery voltage

A7ATP2Ay'T gear position switch

E position input

In 13 position:0 V

In other than E position: Battery voltage

A8ATP D3A,/T gear position switch

E position input

In E position:0V

In other than @ position: Battery voltage

A9ATP D4A,/T gear position switch

E position input

InEposition;0V

In other than El position: Battery voltage

410ATP PNA,/T gear position switch

E and E positions input

InEorEpositions:OV

In other than E or N position: Battery vottage

411ATP RA/T gear position switch

E position input

lnEposition: oV

ln other than E position: 8attery voltage

412tGlPower supply systemWith ignition switch ON (lll: Battery voltage

413LG1Ground

A14Not used

A15LCBLock-up control solenoid valve B

control

During hall and full lock-up and during deceler-

ation: Battery voltage

During no lock-up:0 V

A16LCALock-up control solenoid valve A

control

When lock-up is ON; Battery voltage

With no lock-up: 0 V

417D4 INDD4 Indicator light controlWhen ignition switch is first turned ON (ll):

Battery voltage for two seconds

In E position: Battery voltsge

A18Not used

A19Not used

420AT CHKUpshifvdownshift comparative

signal output

With ignition switch ON (ll): Pulsing signal

421Not used

422ILUInterlock controlWhen ignition switch is ON (ll), brake pedal

deoressed and accelerator oedal released:

Battery voltage

423VBUBack-up power systemAlways Battery voltage

I

lI

I

14-44

\/

Page 472 of 1681

u.drrf,,

J

J

J

14-55

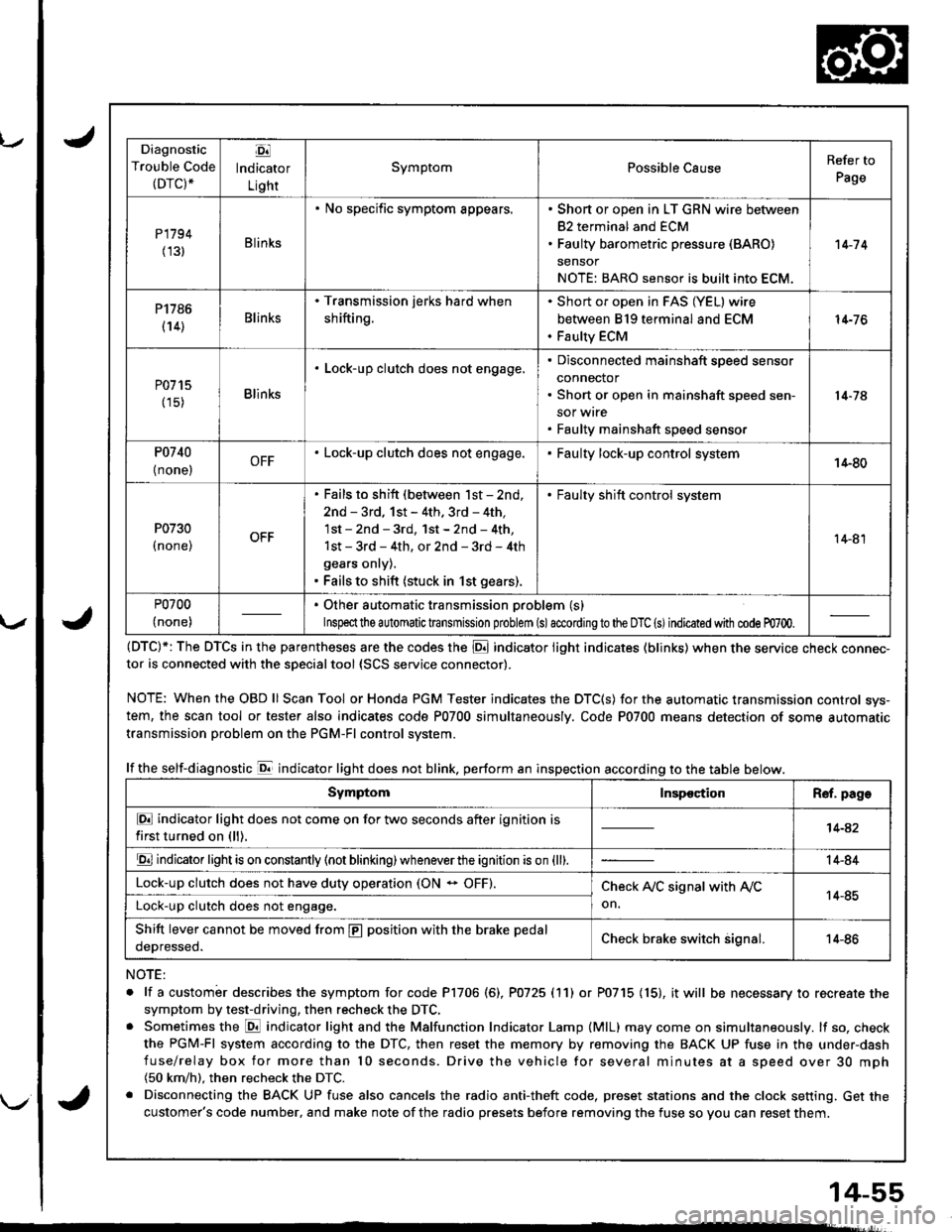

Diagnostic

Trouble Code(DTC).

Ej

lndicator

Light

SymptomPossible CauseRefer to

Page

P1794

(131Blinks

. No specific symptom appears.. Short or open in LT GRN wire between

82 terminal and ECM. Faulty barometric pressure (BARO)

sensor

NOTE: BARO sensor is built into ECM.

't 4-7 4

P1786

(14)Blinks

. Transmission jerks hard when

shifting.

Short or open in FAS (YEL) wire

between 819 terminal and ECM

Faulty ECM

14-76

P0715

(15)Blinks

. Lock-up clutch does not engage,Disconnected mainshaft speed sensor

connector

Short or open in mainshaft speed sen-

sor wrre

Faulty mainshaft speed senso.

14-74

P0740

{ none,OFF. Lock-up clutch does not engage.Faulty lock-up control system14-80

P0730

I none,

. Fails to shift (between lst - 2nd,

2nd - 3rd, 1st - 4th. 3rd - 4th,

1st - 2nd - 3rd, 1st - 2nd - 4th,

1st - 3rd - 4th, or 2nd - 3rd - 4th

gears onry).. Fails to shift (stuck in 1st gears).

. Faulty shift control system

14-81

P0700

(none)

. Other automatic transmission problem (s)

Inspeclthe a utomatic transmission problem (s)accordingto the DTC (s)indicated with code m700.

(DTC)*: The DTCS in the parentheses are the codes the E indicator light indicates (blinks) when the service cnecK connec-tor is connected with the sDecialtool {SCS service connector).

NOTE: WhentheOBDll Scan Tool orHonda PGM Tester indicates the DTC(S) for the automatic transmission control sys-

tem, the scan tool or tester also indicates code P0700 simultaneously. Code P0700 means detection of some automatic

transmission problem on the PGM-Fl control system.

lf the self-diagnostic E indicator light does not blink. perform an inspection according to the table below.

NOTE:

. lf a custombr describes the symptom for code P1706 (6), P0725 (11) or P0715 (15), it will be necessary to recreate the

symptom by test-driving, then recheck the DTC,. Sometimes the E indicator light and the Malfunction Indicator Lamp (MlL) may come on simultaneously. lf so, check

the PGM-Fl system according to the DTC, then reset the memory by removing the BACK UP fuse in the under-dash

fuse/relay box for more than l0 seconds. Drive the vehicle for several minutes at a speed over 30 mph(50 km/h). then recheck the DTC.

. Disconnecting the BACK UP fuse also cancels the radio anti-theft code, preset stations and the clock setting. Get the

customer's code number, and make note of the radio presets before removing the fuse so you can reset them.

SymptomInspectionR€f. page

E indicator light does not come on for two seconds after ignition is

first turned on (ll).14-42

E indicator light is on constantly (not blinking) wheneverthe ignition is on {ll).14-84

Lock-up clutch does not have duty operation (ON - OFF).Check A,/C signal with Ay'C

on.14-85Lock-up clutch does not engage.

Shift lever cannot be moved from E position with the brake pedal

oeDresseo.Check brake switch signal.14-86

Page 493 of 1681

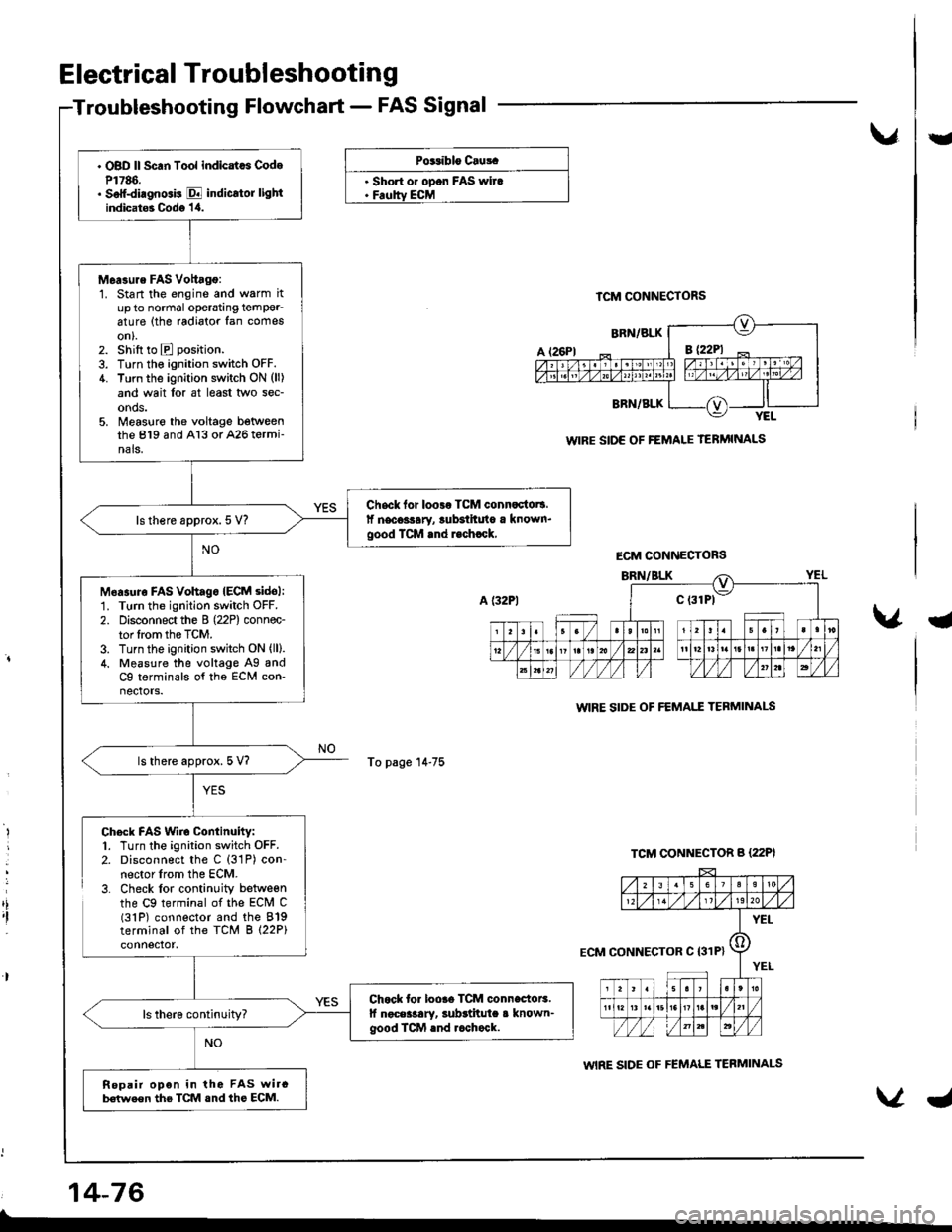

. OBD ll Scan Tool indicatcs CodeP1786.. Soff-diagnGis E indicrtor lightindicat6 Codo '1,0.

M6a3ure FAS Vottago:1. Start the engine and warm itup to normal operatang temPer_6ture (the radiator fan comeson).2. shift to E position.

3. Turn the ignition switch OFF.4. Turn the ignition switch ON (ll)

and wait lor at least two sec-onds.5. Measlre the voltage betweenthe 819 and A13 or A26 termi-nals.

Chsck for loo3r TCM connactot!.lf necoslary, lubsihuto a known.good TCM rnd r.chrck,ls there approx. 5 V?

M6asuro FAs vohagoIECM sidol:1. Turn the ignition switch OFF.

2. Disconnect the B (22P) connec-tor lrom the TCM.3. Turn the ignition switch ON (ll).

4. Measure the voltage Ag andC9 terminals of tho ECM con-nectors.

ls there approx. 5 V?

Chock for loore TCM connectoE.lf noceilary, subrtitula a known-good ICM rnd rcchock.

Repair opon in the FAS wircb€(we€n the TCM snd ths ECM.

Electrical Troubleshooting

Troubleshooting Flowchart - FAS Signal

vU

PG.iblo Cru!.

. Short o. opon FAS wira. Feoltv ECM

To page 14-75

TCM CONNECTORS

WIRE SIDE OF FEMALE TERMINALS

WIRE SIDE OF FEMAI.T TEBMINAI-S

WIRE SIDE OF FEMALE TERMINALS

a

,i,I

Chock FAS Wiro Continuity:1. Turn the ignition switch OFF.2. Disconnect the C (31P) con-nector lrom the ECM.3. Check lor continuity betweenthe C9 terminal of the ECM C(31P) connector and the 819terminal of the TCM B (22P)

14-76

ECM CONNECTORS

ECM CONNECTOR C I31P}

Page 503 of 1681

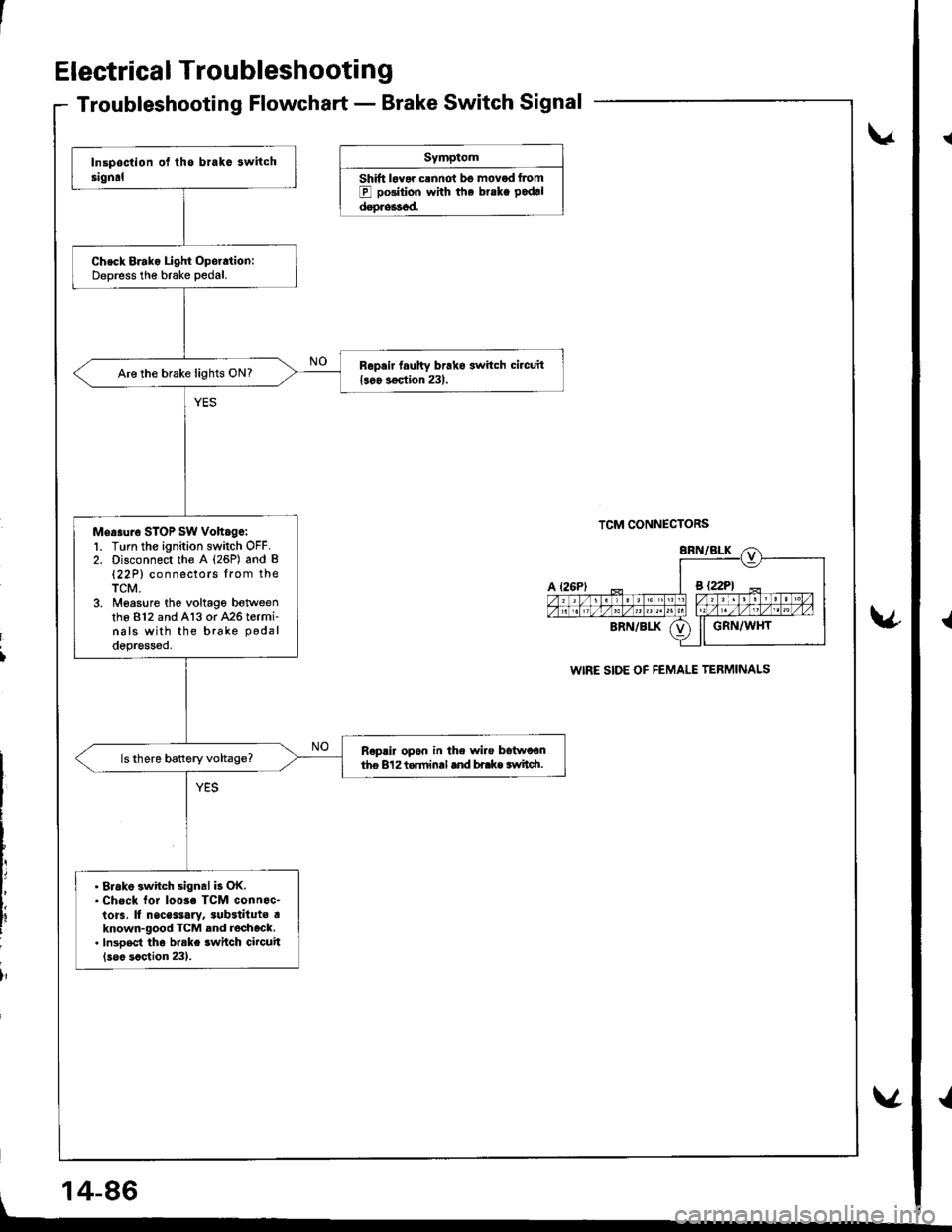

Electrica I Troubleshooti n g

Troubleshooting Flowchart - Brake Switch Signal

Symptom

Shift lovar clnnot bo moved Itom

E pGition with the brske pod.l

dsoressod.

v

TCM CONNECTORS

WIRE SIDE OF FEMALE TERMINALS

v

i

lr

Check Brako Light Oporation:Deoress the brake Dedal.

Repair taulty brako switch circuit{soo 3€qtion 231.Are the brake lights ON?

Mea.ur6 STOP sw voh.ge:1. Turn the ignition switch OFF.2. Disconnect the A (26P) and B(22P) connectors lrom theTCM.3. Moasure the voltage botweenthe 812 and A13 or 426 termi-nals with the brake podal

depressed.

R€plir opon in the wire Itstwoonth€ 8'l2 torminal and bi.ke svtidt.

. 8rak6 switch signal b OK.. check lor loose TcM connoc-to]s, lf nsce$ary, sub3tituts aknown-good TcM and rochock.. lnsooct tho brake swilch circuit(soo scction 231.

, 14-86

v

{

{

Page 677 of 1681

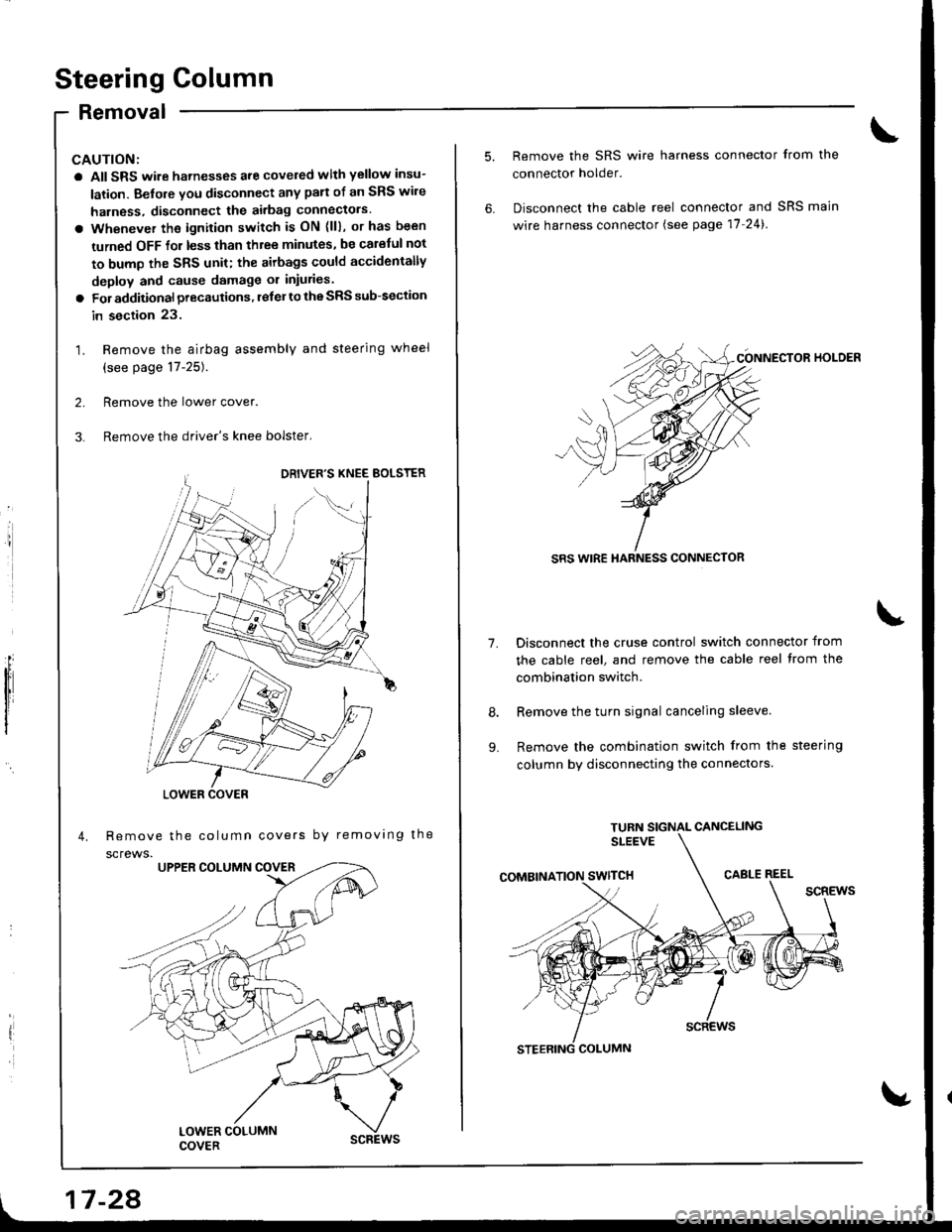

Steering Golumn

Removal

I

a All SRS wire harnesses are covered with yellow insu-

lation. Before vou disconnect any pan of an SRS wire

harness, disconnect the airbag Gonnectors.

a Whenever the ignition switch is ON (lll, or has been

turned OFF for less than three minutes, be carelul not

to bump the SRS unit; the airbags could accidentally

deploy and cause damage or iniuries.

a For additional precautions, lelel to the SRS sub-section

in section 23.

1. Remove the airbag assembly and steering wheel

(see page 17-25).

2. Remove the lower cover.

3. Remove the driver's knee bolster,

Remove the column covers by removing the

screws.

'//

,,1G

LOWER COVER

17 -28

1.

9.

Remove the SRS wire harness connector from the

connector holder.

Disconnect the cable reel connector and SRS main

wire harness connector (see page 17-24).

CONNECTOR HOI-DER

SRS WIRE HARNESS CONNECTOR

Disconnect the cruse control switch connector from

the cable reel, and remove the cable reel trom the

combination switch.

Remove the turn signal canceling sleeve.

Remove the combination switch from the steering

column by disconnecting the connectors.

Page 682 of 1681

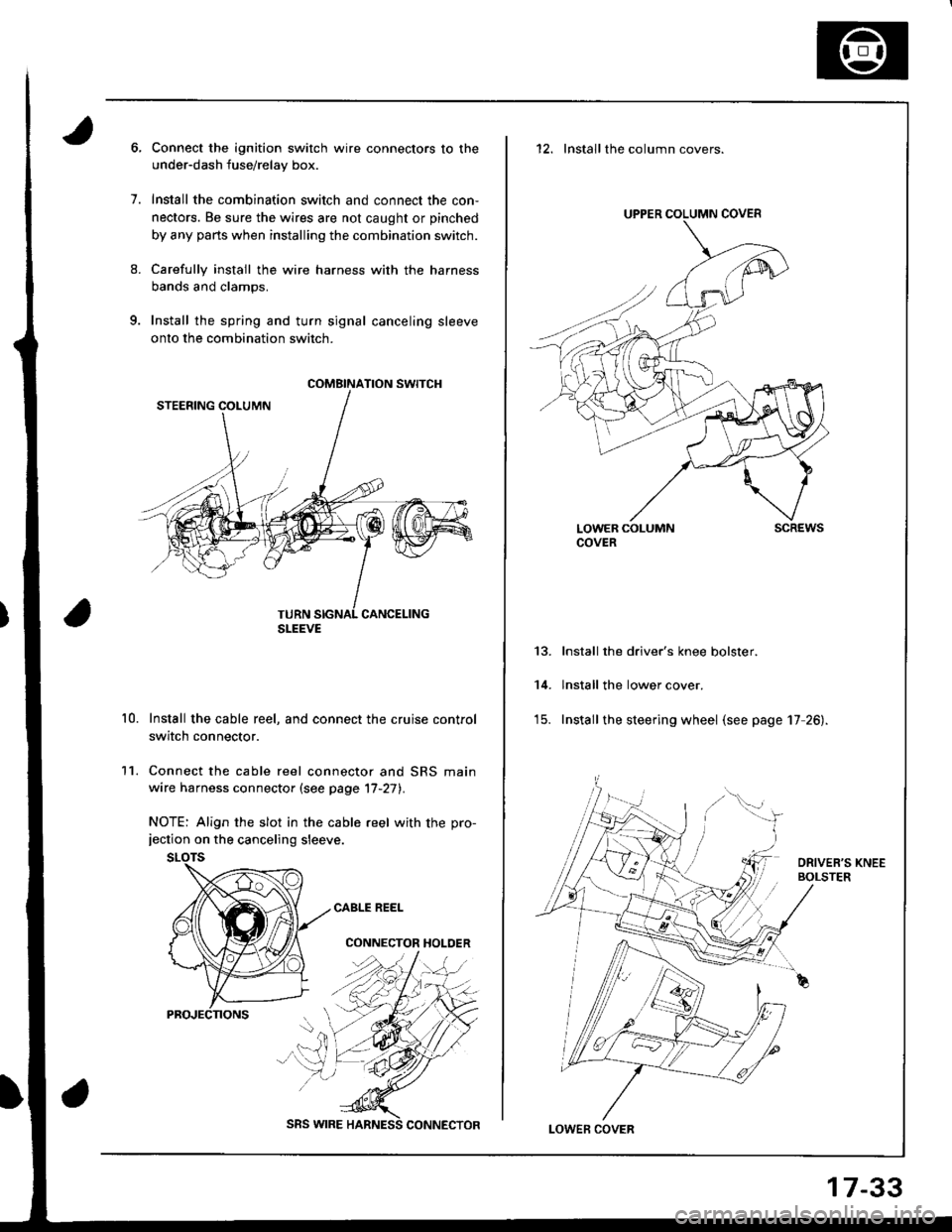

9.

1.

8.

11.

10.

Connect the ignition switch wire connectors to the

under-dash fuse/relay box.

Install the combination switch and connect the con,

nectors. Be sure the wires are not caught or pinched

by any parts when installing the combination switch.

Carefully install the wire harness with the harness

bands and clamps.

Install the spring and turn signal canceling sleeve

onto the combination switch.

Install the cable reel, and connect the cruise control

switch connector.

Connect the cable reel connector and SRS main

wire harness connector (see page '17-27).

NOTE: Align the slot in the cable reel with the pro-jection on the canceling sleeve.

CABLE REEL

CONNECTOR HOLDER

COMBINATION SWITCH

SLEEVE

SRS WIRE

17-33

12. Installthe column covers.

UPPER COLUMN COVER

LOWER COLUMNCOVERscREws

13.

14.

Install the driver's knee bolster.

lnstall the lower cover.

Install the steering wheel (see page 17 26).

LOWEF COVER

Page 779 of 1681

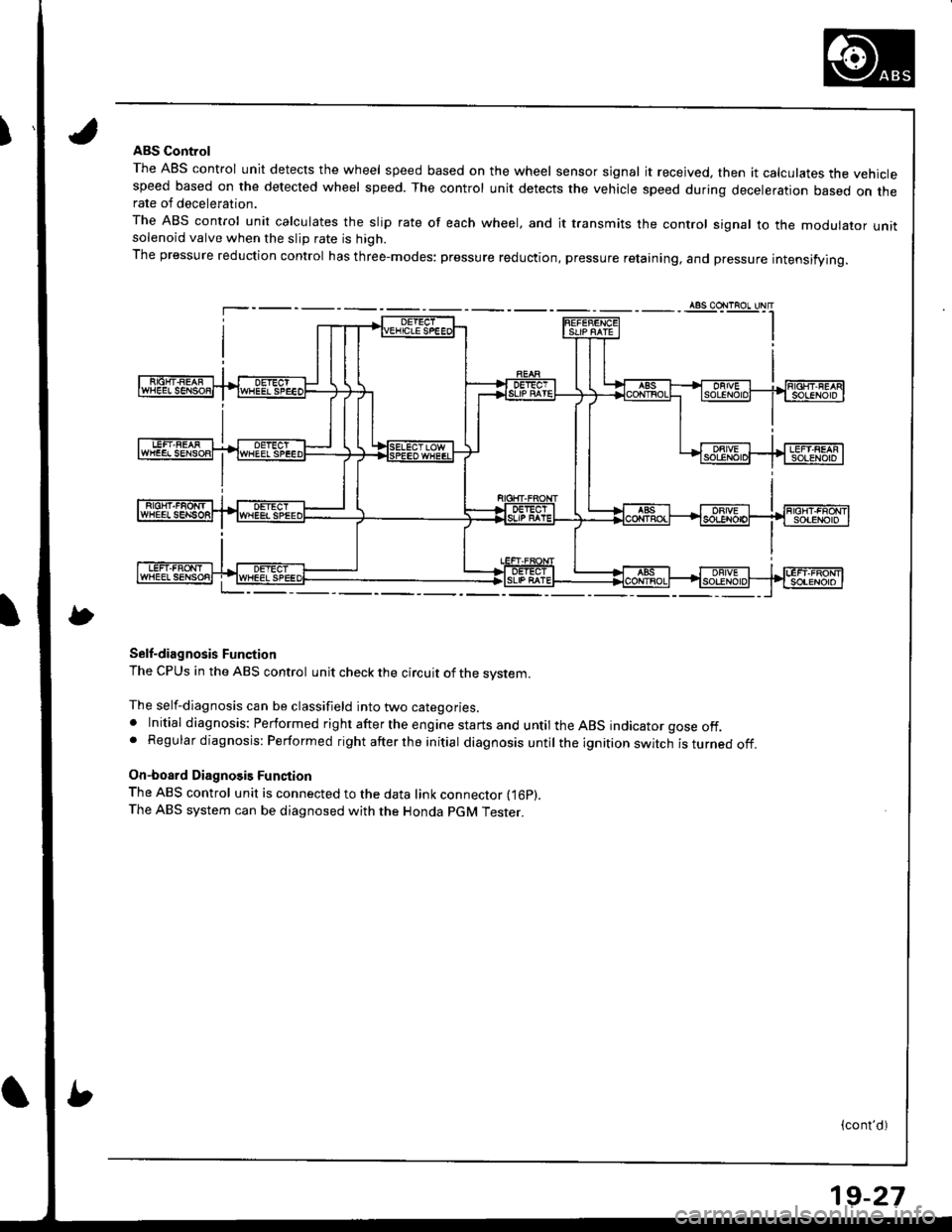

IABS Control

The ABS control unit detects the wheel speed based on the wheel sensor signal it received, then it calculates the vehiclespeed based on the detected wheel speed. The control unit detects the vehicle speed during deceleration based on therate of deceleration.

The ABS control unit calculates the slip rate of each wheel, and it transmits the control signal to the modulator unitsolenoid valve when the slip rate is high.

The pressure reduction control has three-modes: pressure reduction, pressure retaining, and pressure intensifying.

Self-diagnosis Function

The CPUS in the ABS control unit check the circuit of the system.

The self-diagnosis can be classifield into two categories.. Initial diagnosis: Performed right after the engine starts and until the ABS indicator gose off.. Regular diagnosis: Performed right after the initial diagnosis until the ignition switch isturnedoff.

On-board Diagnosis Function

The ABS control unit is connected to the data link connector fi6p).The ABS system can be diagnosed with the Honda PGM Tester.

(cont'd)

19-27

Page 784 of 1681

![HONDA INTEGRA 1998 4.G Owners Manual ABS Gontrol Unit Terminal Arrangement

ABS CONTROL UN]T 22P CONNECTOR

Wire side oI female t6rminals

Terminal

numbel

Wire

Golor

Terminsl sign

{Terminal

namet

Description

Measurgmgnt

TerminalConditions

{ HONDA INTEGRA 1998 4.G Owners Manual ABS Gontrol Unit Terminal Arrangement

ABS CONTROL UN]T 22P CONNECTOR

Wire side oI female t6rminals

Terminal

numbel

Wire

Golor

Terminsl sign

{Terminal

namet

Description

Measurgmgnt

TerminalConditions

{](/img/13/6069/w960_6069-783.png)

ABS Gontrol Unit Terminal Arrangement

ABS CONTROL UN]T 22P CONNECTOR

Wire side oI female t6rminals

Terminal

numbel

Wire

Golor

Terminsl sign

{Terminal

namet

Description

Measurgmgnt

TerminalConditions

{lgnition swhch ON {ll}}Voltage

1BLK/WHTGND3(Ground 3)

Ground1.GNDBelow 0.3 V

4GRN/REDPARK

{Parking)

Detects parking brake

switch signal4-GNDParking

brake

PulledBelow 0.3 V

Battery voltage

LT GRN/

BLK

FLW (-)

{FronLleft

wheel negative)

Detects left-front wheel

sensor srgnal

0.053 V or

above

0sci\oscope:

0.15 Vp-p or

above

7GBN/ORN

FLW (+)

(Front-left

wheel positive)- | Turn wheel at

E

1 turntsecona

l'GRN

FRW (-)

(Front-right

wheel negative)

Detects right-f ront wheel

sensor slgnal

8-9

1 FR\N (+)

I \GRN/BLK (Front-right

I I wheelpositiveStops0.25 - 1.15 V

10GRN/WHTSTOPDetects brake switch signal1O.GNDBrake pedalDepressedBaftery voltage

ReleasedBelow 0.3 V

11BLK/TELtG2

(lgnition 2)

Power source for activating

the system11-GNDlgnition

switch

oN {I)Battery voltage

Start (lll)Below 0.3 V

19-32

Page 785 of 1681

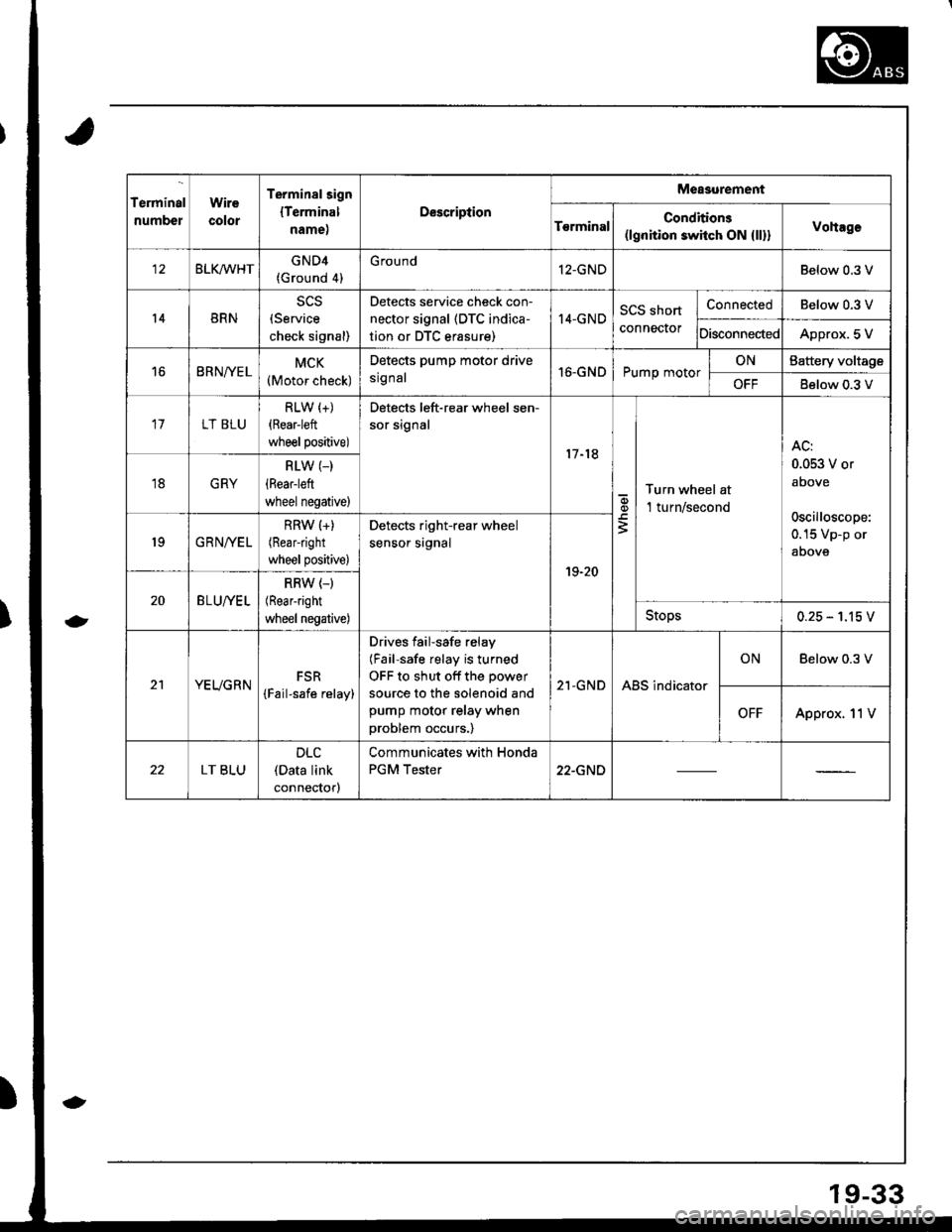

Terminal

numbel

Wire

color

Terminalsign

lTerminal

name,

Description

Measurement

T€rminalConditions(lgnition switch ON {ll}}Vohage

BLKMHTGND4(Ground 4)

G round12-GNDBelow 0.3 V

14BRN(Service

check signal)

Detects service check con-

nector signal (DTC indica-

tion or DTC erasure)

I4-GNDSCS short

connector

ConnectedBelow 0.3 V

DisconnectedApprox. 5 V

16BRNfYELMCK(Motor check)

Detects pump motor drive

srg nal16-GNDPump motorONBattery voltage

OFFBelow 0.3 V

17LT BLU

RLW (+)

{Rear-left

wheel positive)

Detects left-rear wheel sen-

sor signal

17-18

q,

3

Turn wheel at

l turn/second

AC:

0.053 V or

above

oscilloscope:

0.15 Vp-p or

aoove

18GRY

RLW (_)

(Rear-left

wheel negative)

19GRNIVEL

RRW (+)

(Rearright

wheel positive)

Detects right-rear wheel

sensor srgnal

19-20

20BLU//EL

RRW (-)

(Rear-right

wheel negative)Stops0.25 - 1.15 V

21YEUGRNFSR

{Fail-safe relay)

Drives failsafe relay

(Fail-safe relay is turned

OFF to shut off the power

source to the solenoid and

pump motor relay when

problem occurs.)

21-GNDABS indicator

ONBelow 0.3 V

OFFApprox. 11V

LT BLU

DLC(Data link

connectorl

Communicates with Honda

PGM Tester22-GND

19-33

Page 787 of 1681

Troubleshooting Precautions

ABS lndicator

1. lf the system is OK. the ABS indicator goes off two seconds after turning the ignition switch ON (ll) without starting

the engine, and then comes on again and goes off after two seconds. This occurs because the ABS control unit is

turned on bv the lG2 oower source.

2. The ABS indicator comes on when the ABS control unit detects a problem in the system. However, even though the

system is operating properly, the ABS indicator will come on under the following conditions.. Onlv drive wheels rotate

. One drive wheel is stuck

. Vehicle spin

. ABS continues to operate for a long time

. Signal disturbance

To determine the actual cause of problem. question the customer about the problem, taking these conditions into

consideration.

3. When a problem is detected and the ABS indicator comes on, there are cases when the indicator stays on until the

ignition switch is turned OFF, and cases when the indicator goes off automatically when the system returns to nor-

mal. For DTCS 61 and 62, the indicator goes off automatically when the system returns normal. For all other codes.

the indicator stays on until the ignition switch is turned OFF.

4. For DTCS 12, 14, 16, '18, 2'1,22, 23, 24,51,52 and 53, the indicator goes off when the vehicle is driven again and the

system is OK after the ignition switch is turned from OFF to ON (ll). However, if the DTC is erased, the CPU is reset

and the indicator goes off right after the engine is started if the system is OK.

Diagnostic Trouble Code (DTC)

1. lf the CPU cannot be actlvated and the indicator comes on, the DTC is not memorized.

2. The memory can hold any number of DTCS. However, when the same DTC is detected more than once, the later one

is written over the old one. Therefore, when the same problem is detected repeatedly, it is memorized as one DTC.

3. The DTCs are indicated in the order of ascending number, not in the order they occur.

4, The DTCS are memorized in the EEPROM (non-volatile memory). Therefore, the memorized DTCS cannot be canceled

by disconnecting the battery. Perform the specified procedures to erase the DTCS,

S6lt-dirgnosis

1. Self-diagnosis can be classifield into two categories.

. Initial diagnosis: Performed right afterthe enginestansand untiltheABS indicator goes off.. Regular diagnosis: Performed rightafterthe initial diagnosis untilthe ignition switch isturned OFF.

2. When a problem is detected by self-diagnosis, the system

. Turns the fail-safe relay OFF

. Turns the solenoid valve OFF

. Turns the oumo motor OFF

. Turns the ABS indicator ON