engine HONDA INTEGRA 1998 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 1161 of 1681

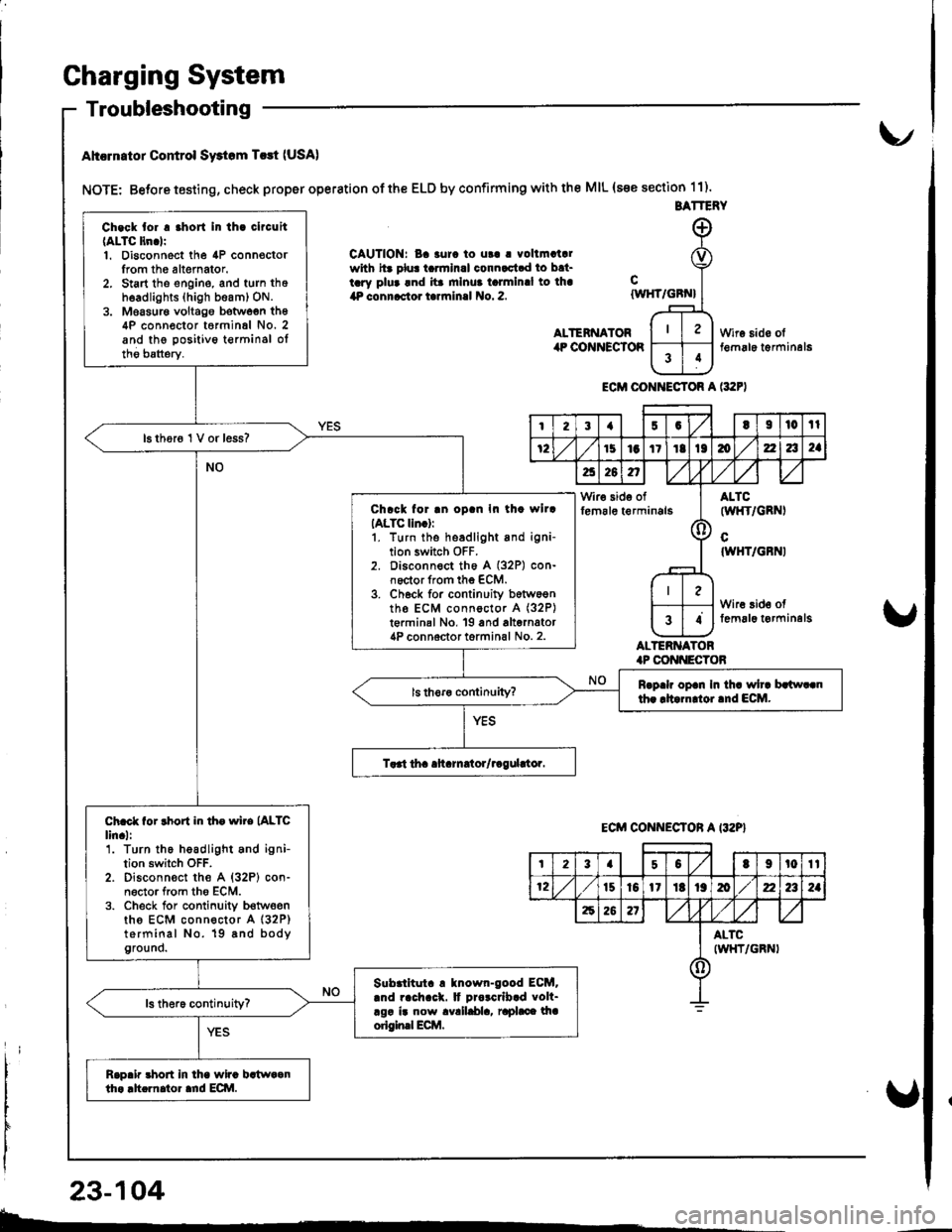

Gharging System

Troubleshooting

Ahcrn.tor Control Swtom T.rt (USA)

NOTE: Betore testing, check proper operation of the ELD by confirming with the MIL (s€e section 11).

CAUTION: Ba 3urc to ut! | vollmatalwith hr plu! tarmlnal connactad to bat-tary plua and ita mlnua talmlnal to lha4P connactor tarrninal No. 2.

ALTENNATORilP COiINECTOR

cIWHT/GBN}

ALTERNATOR.P CONI{ECTOB

Wire sido olt€m6le t€rminal6

ECM CONI{ECTOR A l:t2F)

BATTERY

Ch.ck tor . .hort In th. clrcuit(ALTC ltn.lr1. Disconnect the 4P connoctorIrom th6 altemator.2. Start tho engine, and turn thoh6adlights (high beam) ON.3. Moasur€ voltago botwoen th64P conn€ctor t6rminal No. 2and the positivo t€rminsl oltho batterv.

16 thor6 1 V or less?

Chrck for .n oD.n In th. wllrIALTC lln.):1. turn the headlight and igni-tion switch OFF.2. Disconnect th6 A (32P) con-noctor from the ECM.3. Ch6ck for continuity b6tw6entho ECM connoctor A (32P)

t€rminal No, 19 and alternator4P connoctor torminal No. 2.

Rrp.h op.n In th. wh. brlw..nth. rltarn oi.nd ECM.

Ch.ct for rhort in th. wire (ALTC

lin.l:'1. Turn the headlight and ignition switch OFF.2. Disconn€ct the A {32P} con-n6ctor from tho ECM.3. Check for conlinuity b€twoenths ECM connector A (32P)

terminal No. 19 8nd bodyground.

Slbrlltut. ! tnown-good ECM..nd rach.ck. It Drorcrlb.d volt-rgr ir now avalldla, raphce lhaorigin.l Ecilt.

Rap.ir 3hort in lha wira bstwaanth. .h.rnator ard ECI\|.

I23{5GtI|l0tl

72151aItIt136zla2a

a26n,/,V

Wir€ side offem6le t€rminals(l

ALTC(wl{T/GRNI

cIWHT/GBNI

Wire 3id€ offemal6 t€rminelg34

ECM CONNECTON A I32P}

t23a50t9t0tt

12t510l1Itt9mz2a2a

62621

ALTCIWHT/GRNI()

23-104

b-.

Page 1162 of 1681

{

t

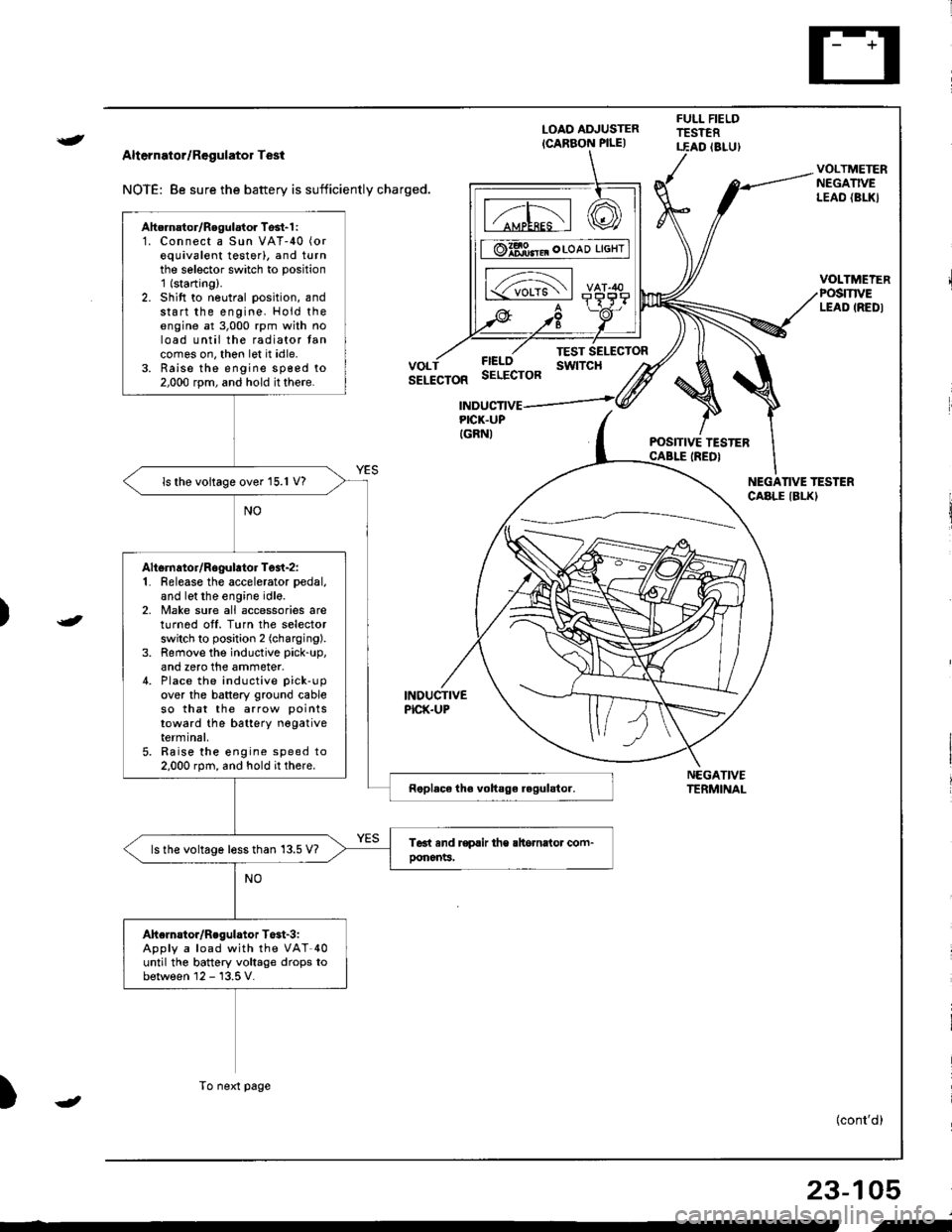

Alternator/Regulator Test

NOTE: 8e sure the battery is sufficiently charged.

LOAO ADJUSTER

ICARBON PILE)

FULL FIELDTESTERT.EAD (8LU)

POSITIVE TESTERCABLE IREDI

NEGATIVETERMINAL

VOLTMETERNEGATIVELEAO {BL|(}

VOLTMEIERPOSmVELEAD IREDI

FIELOSELECTOR

TEST SELECTORswtTcHVOLTSELECTOR

INDUCTIVEPICK.UP

INDUCTIVEPICK.UPIGRNI

NEGANVE TESTERCABLE IBLKI

)

)

{cont'd)

23-105

Ahernator/Regulator Tosl-1 :1. Connect a Sun VAT-40 (or

equivalent testerl, and turnthe selector switch to position'1 (starting).

2. Shift to neutral position, andstart the engine. Hold theengine at 3,000 rpm with noload until the radiator tancomes on, thon let it idle.3. Raise the engine sp€ed to2,000 rpm, and hold it there.

ls the voltage over 15.1 V?

Altsrnator/Rogulator Test-z:1. Release the accelerator pedal,

and let the engine idle.2, Make sure all accessories areturnod off. Turn the selectorswitch to position 2 (charging).

3. Remove the inductive pick-up,

and zero the ammeter.4. Place the inductive pick-up

over the battery ground cableso that the arrow points

toward the batterY negativeterminal,5. Raise the engine speed to2.000 rpm, and hold it there.

ls the voltage less than 13.5 V?

Ahelnstor/Regulator T$t-3iApply a load with the VAT-40until the battery voltage drops tobetween 12 - 13.5 V.

To next page

-

i-

Page 1163 of 1681

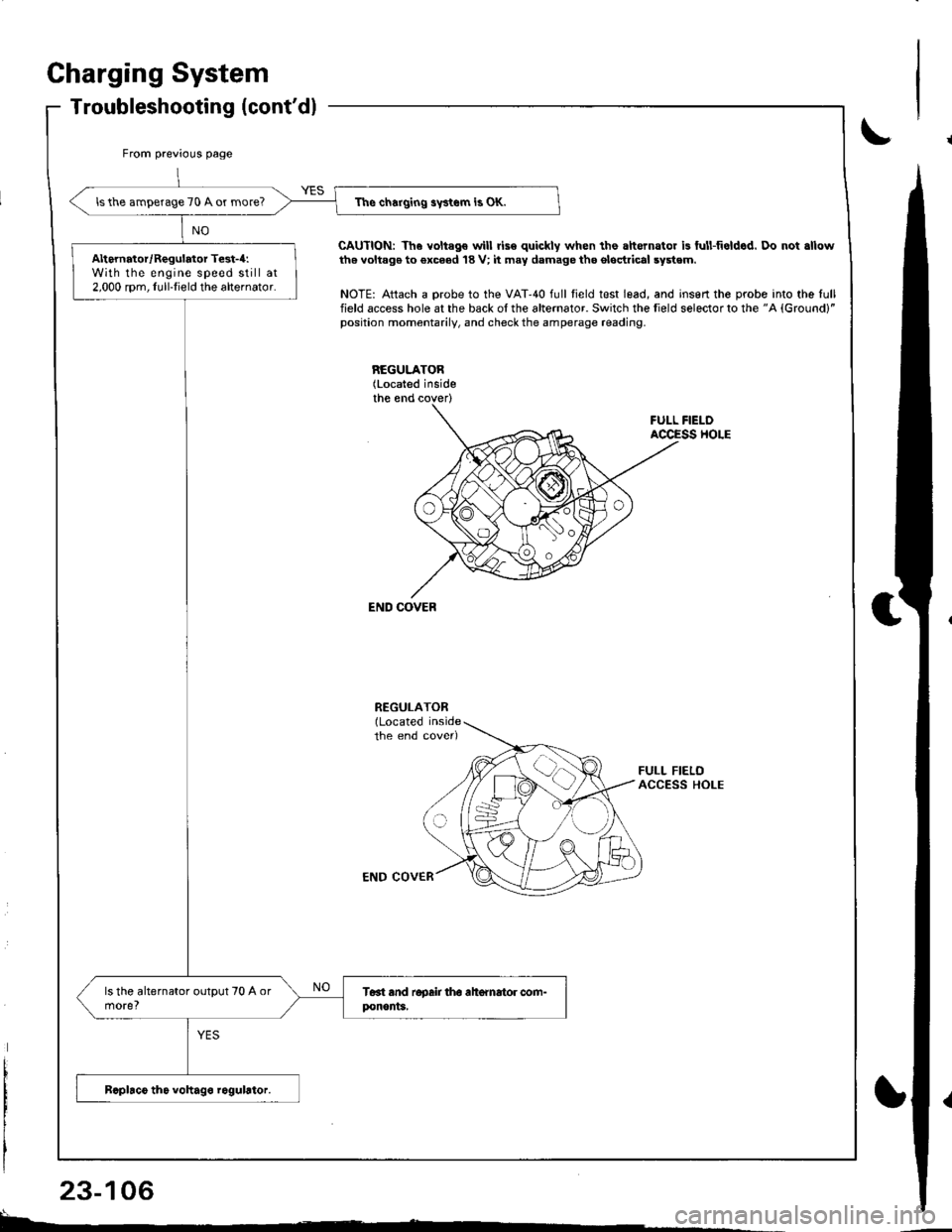

From previol.rs page

The charging swtem is OK.lsthe amperage 70 A or more?

Alternator/Regulator Test-4:With the engine speed still at2,000 rpm, Iull-Iield the alternator.

Charging System

Troubleshooting (cont'dl

CAUTION: Th6 voltago will rise quickly when the ahernator is ful!fieldcd. Do not .llowth6 voltag€ to €xc6ed 18 V; it may damage tho ol6drical system.

NOTE: Attach a probe to the VAT'40 full field test lead, and insert the probe into the lullfield access hole at the back of the alternator. Switch the field selector to the "A {Ground}"position momentarily, and check the amperage reading.

REGULATOB(Located inside

FULL FIELOACCESS HOLE

END COVEB

END COVER

FULL FIELDACCESS HOLE

L^

23-106

Page 1172 of 1681

)

t

J

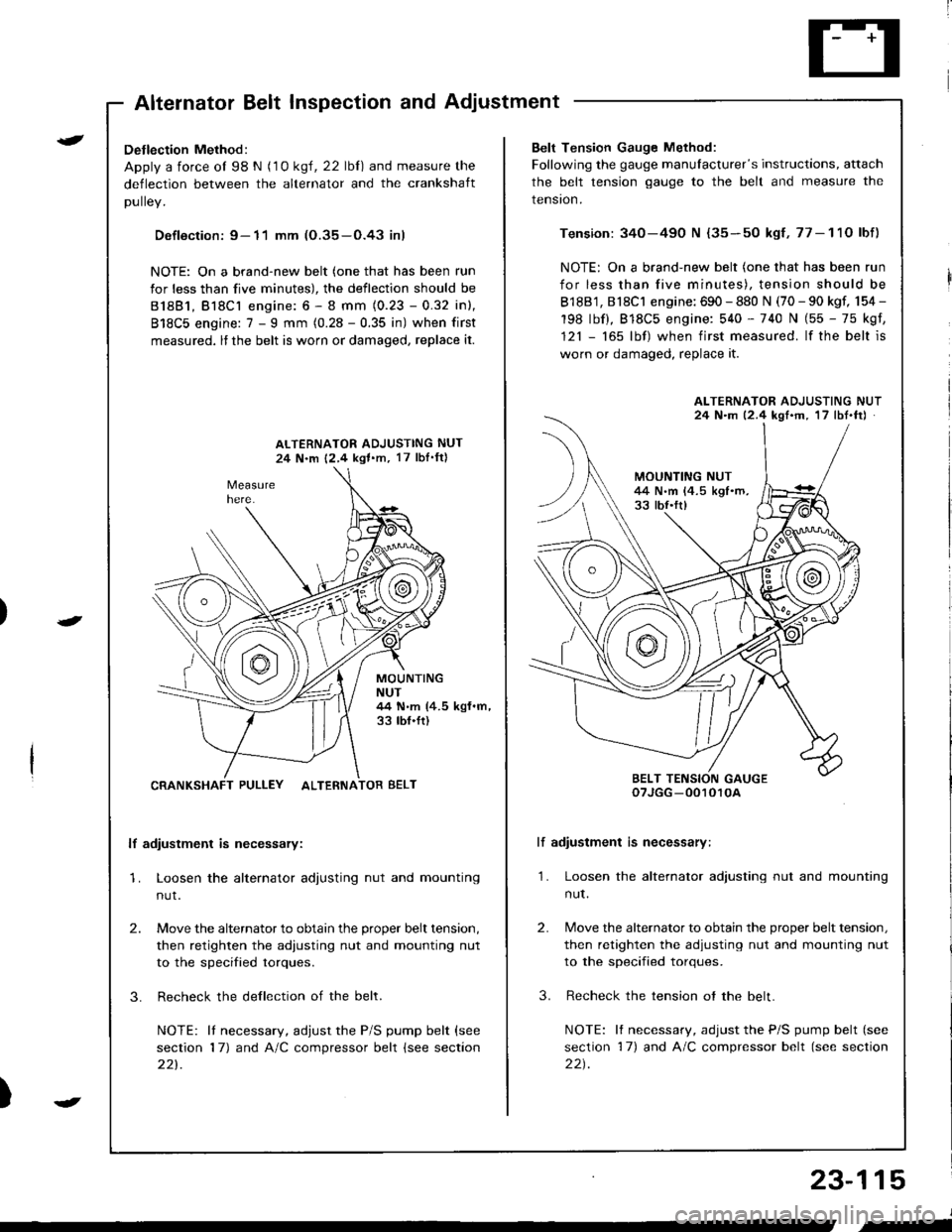

Altelnator ttelr Inspecuon ano Aol

Detlection Method:

Apply a force ol 98 N (1 0 ksl, 22 lbl) and measure the

deflection between the alternator and the crankshaft

DUllev,

Defloction: 9- 11 mm (O.35-O.43 inl

NOTE: On a brand-new belt (one that has been run

for less than five minutes), the deflection should be

81881, Bl8Cl engine: 6 - 8 mm (0.23 - 0.32 inl,

818C5 engine: 7 - I mm (0.28 - 0.35 in) when first

measured, lf the belt is worn or damaged, replace it.

ALTERNATOR ADJUSTING NUT

24 N.m 12,4 kgl.m, 17 lbI'ftl

MOUNTINGNUT44 N.m (4.5 kgf.m,33 tbf.ft)

CRANKSHAFT PULLEY ALTERNATOR BELT

lf adiustment is necessary:

1. Loosen the alternator adjusting nut and mounting

nut.

2.

3.

Move the alternator to obtain the proper belt tension,

then retighten the adiusting nut and mounting nut

to the specified torques.

Recheck the dellection of the belt.

NOTE: lI necessary, adjust the P/S pump belt (see

section 17) and A/C compressor belt (see section

221.

Belt Tension Gauge Method:

Following the gauge manulacturer's instructions, attach

the belt tension gauge to the belt and measure the

tension.

Tension: 340-490 N {35-50 kgf,77-11O lbf)

NOTE: On a brand-new belt (one that has been run

for less than five minutes), tension should be

818B1, 818C1 engine: 690 - 880 N (70 - 90 kgf, 154 -

198 lbf), 818C5 engine: 540 - 740 N (55 - 75 kgf,

121 - 165 lbf) when first measured. lf the belt is

worn or damaged, replace it.

lf adiustment is necessary:

1. Loosen the alternator adjusting nut and mounting

nut.

2.

3.

Move the alternator to obtain the proper belt tension,

then retighten the adjusting nut and mounting nut

to the specified torques.

Recheck the tension ot the belt.

NOTE: It necessary, adjust the P/S pump belt (see

section 17) and A/C compressor belt (see section

22t.

ALTERNATOR ADJUSTING NUT24 N.m 12.4 kgf'm, 17 lbt.ftJ

BELT TENSION GAUGEoTJGG -0010r0A

23-115

J

,-

Page 1176 of 1681

)

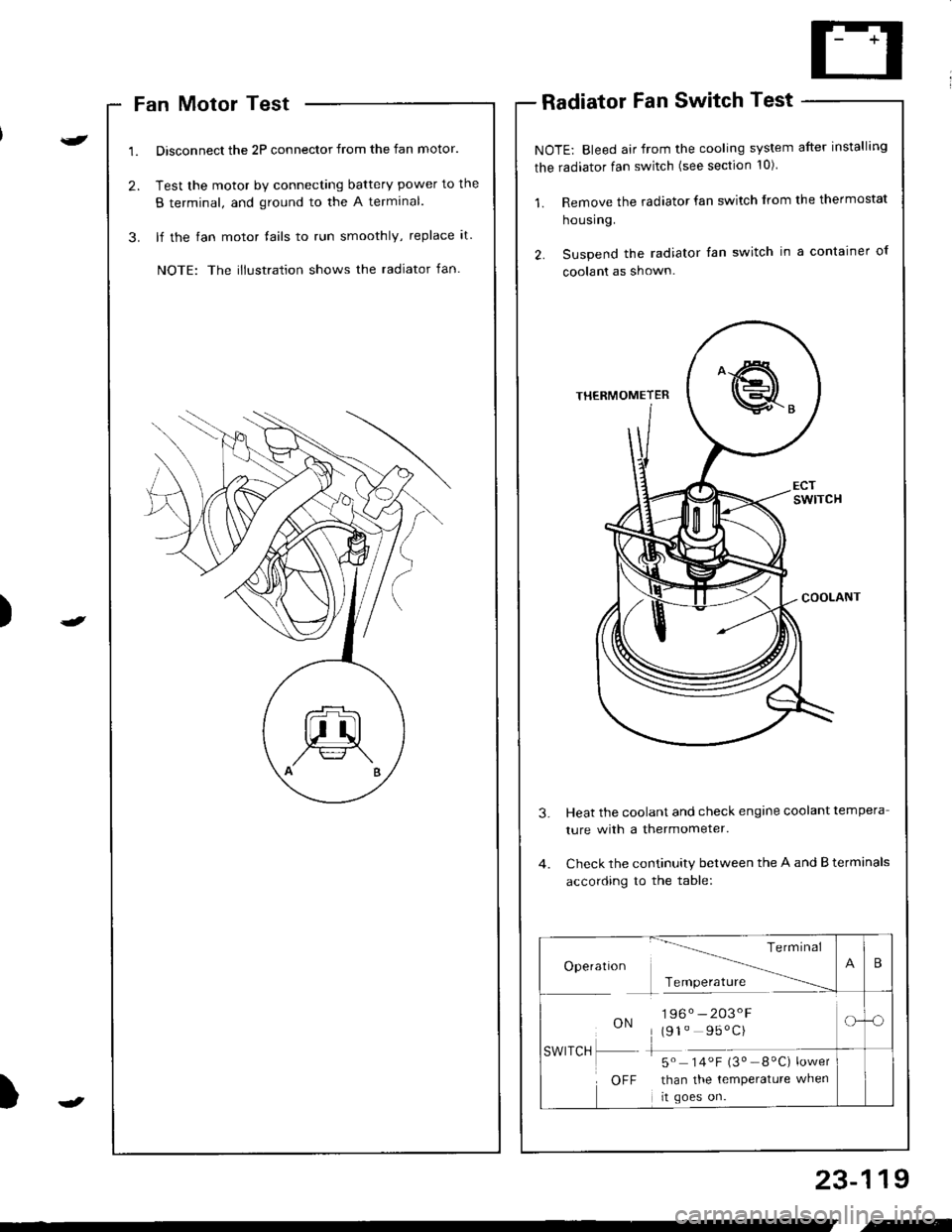

Fan Motor Test

Disconnect the 2P connector from the fan motor.

Test the motor by connecting battery power to the

B terminal, and ground to the A termlnal.

lf the fan motor fails to run smoothly, replace it.

NOTE: The illustration shows the radiator fan.

Radiator Fan Switch Test

NOTE: Bleed air from the cooling system after installing

the radiator fan switch (see section 10)

1. Remove the radiator fan switch from the thermostat

housing.

2. Suspend the radiator fan switch in a container ol

coolanl as shown.

Heat the coolant and check engine coolant tempera

ture with a thermometer.

Check the continuity between the A and B terminals

according to the table:

23-119

Te rm Inal

Operatlon -------\

Tcmoerature ------

ON196. -203'F

(91" 95'C)

-5" 14.F i3" _8"C) ;*,*

than the temperature when

rt goes on.

SWITCH

OFF

B

-o

.-

Page 1177 of 1681

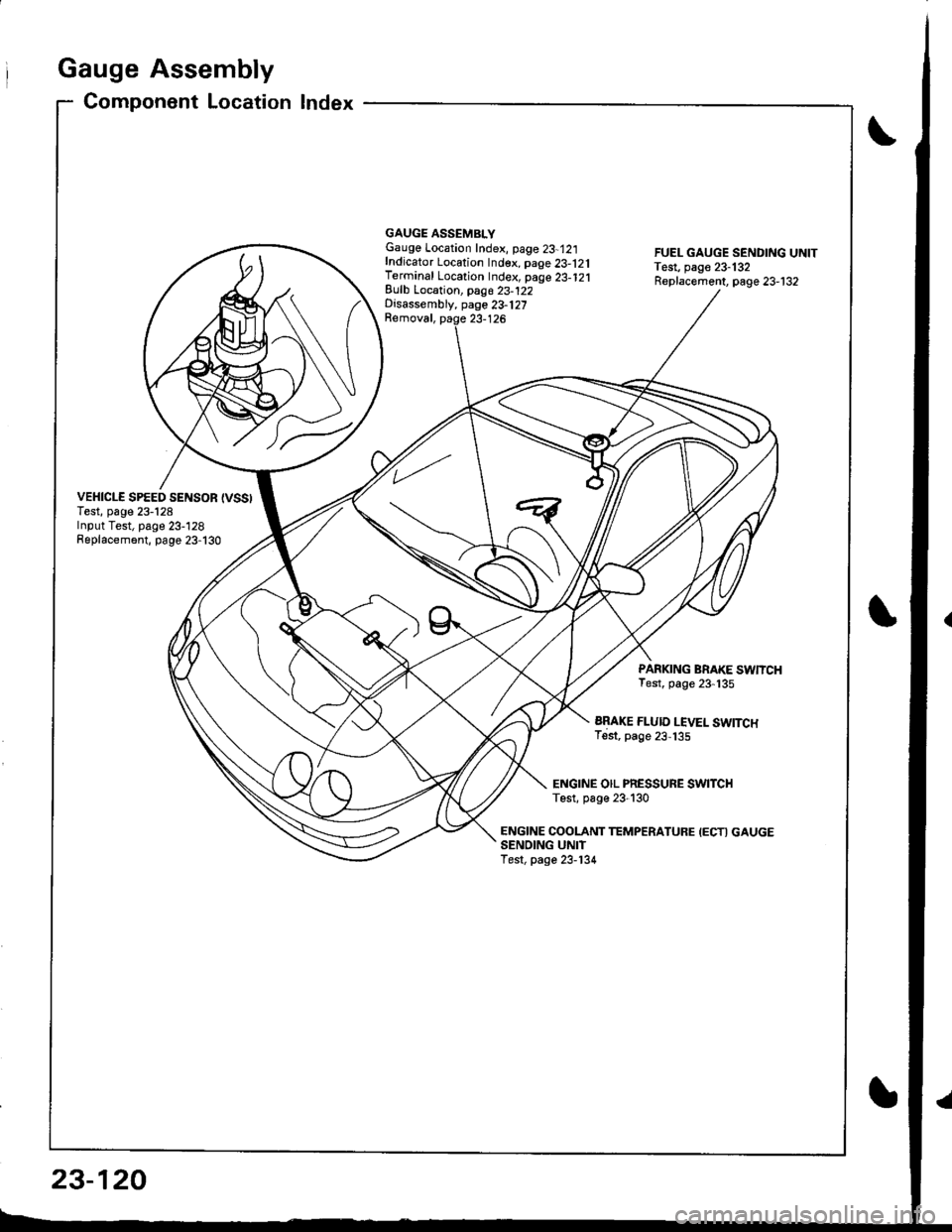

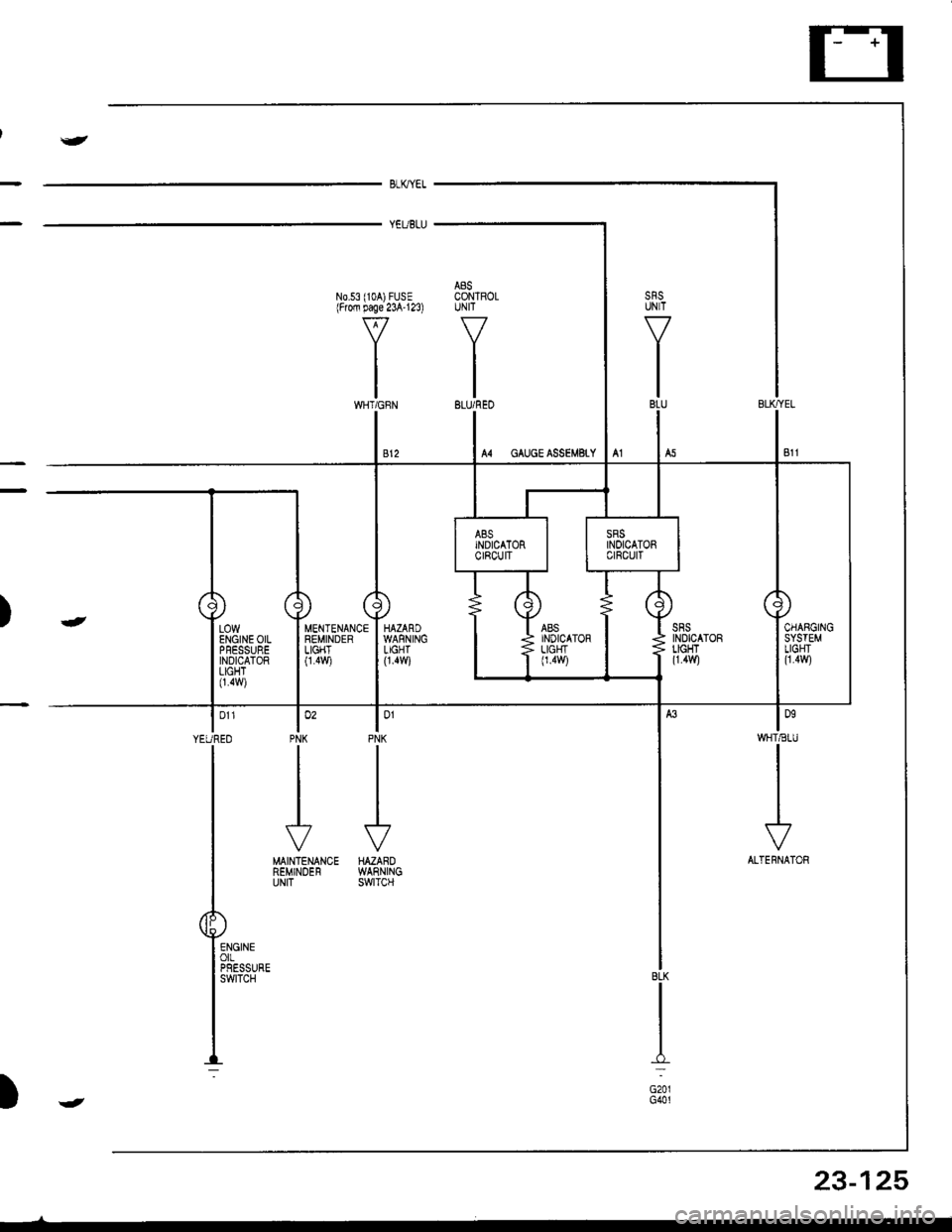

Gauge Assembly

Component Location Index

VEHICLE SPEED SENSOR {VSSITest, page 23-128Input Test, page 23-128Replacement, page 23-130

GAUGE ASSEMBLYGauge Location Index, page 23-12:|fndicator Location Index. page 23-121Terminal Location Index, page 23-121Eulb Location, pag6 23-122Disassembly, page 23-127Removal, paqe 23-126

FUEL GAUGE SENDING UNITTest, page 23-132Replacement, page 23-132

PARKING BRAKE SWNCHTest, page 23-135

ARAKE FLUID LEVEL SWITCHTest, page 23,135

ENGINE OIL PRESSURE SWITCHTest, p6ge 23-130

ENGINE COOLANT TEMPERATUFE IECTI GAUGESENOING UNITTest, page 23-134

23-120

Page 1178 of 1681

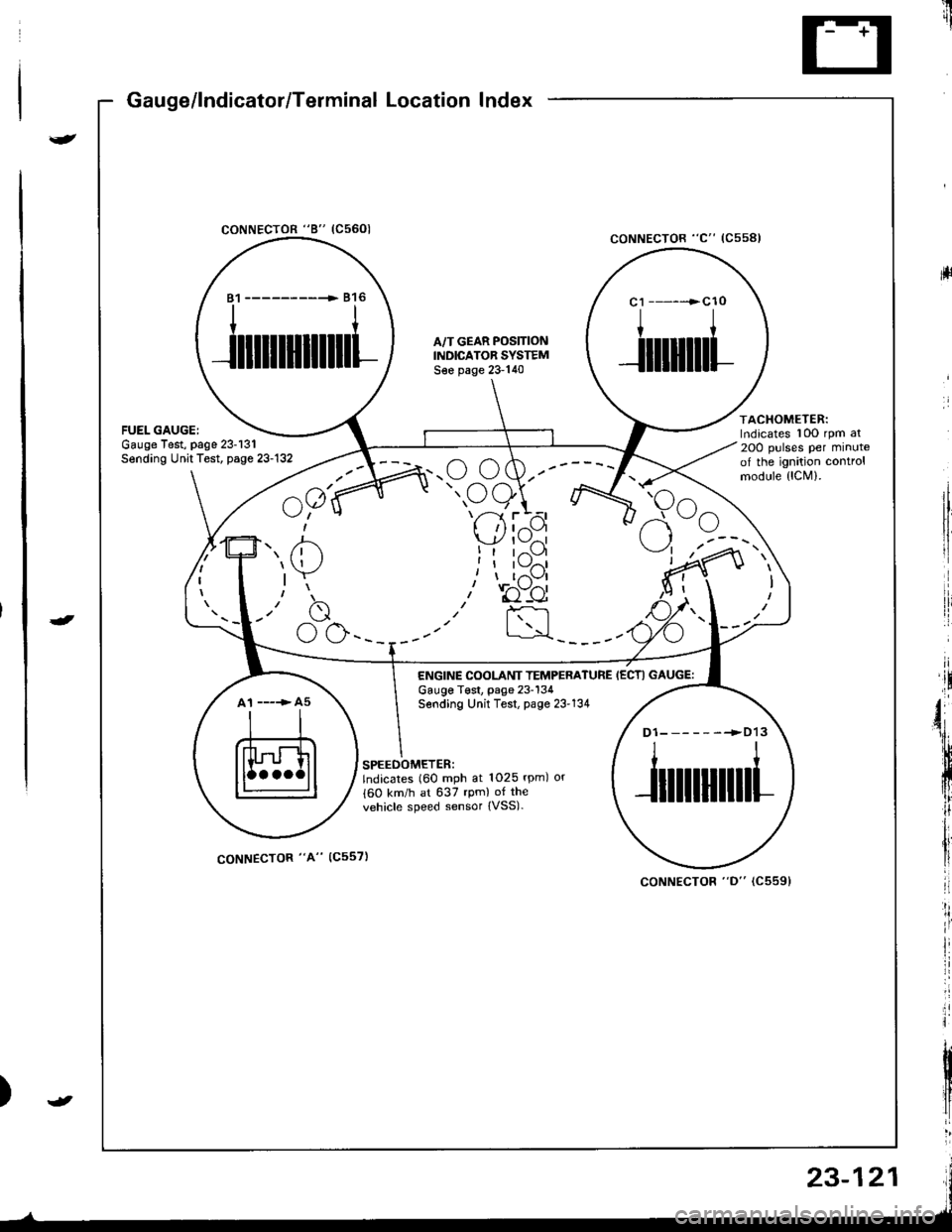

Gauge/lndicator/Terminal Location Index

coNNECTOR "8" (C5601

ltrii

rll

coNNECTOR "C" (Css8l

ACHOMETER:rdicates 10O rpm al

OO pulses per minutef the ignition controlrodule {lCM).

81 ------------ 816

ililllllilll

A,/T GEAR POS]TIONINDICATOR SYSTEMS€e page 23-140

c1 ------>cl0

I

Jilliltl

atespage 23-131t Test, page 23-132

^a1(

u;" u

7' /'- /n.u (,w.--

" oe)\r- -7 ttt'-1 r --

I 'l I z{.-a\y' | \-./^l

!t tr--',9I I l\-//11, I t,-\Jl

.r' to"-ei

I :rl

F<

elrle

ENGINE COOLANT TEMPERATUREGauge T€st, page 23-134Sending Unit Test, page 23'134

IECTI GAUGE:

A1 ----> A5

D1-------->D13

ililtl|illl

SPEEOOMETER:lndicates (60 mph at 1025 rpm) or

{60 km/h at 637 rpm) of the

vehicle speed sensor {VSS).

coNNECTOR "A" (C557)

coNNECTOR "D" (C5591

23-121

Page 1179 of 1681

I

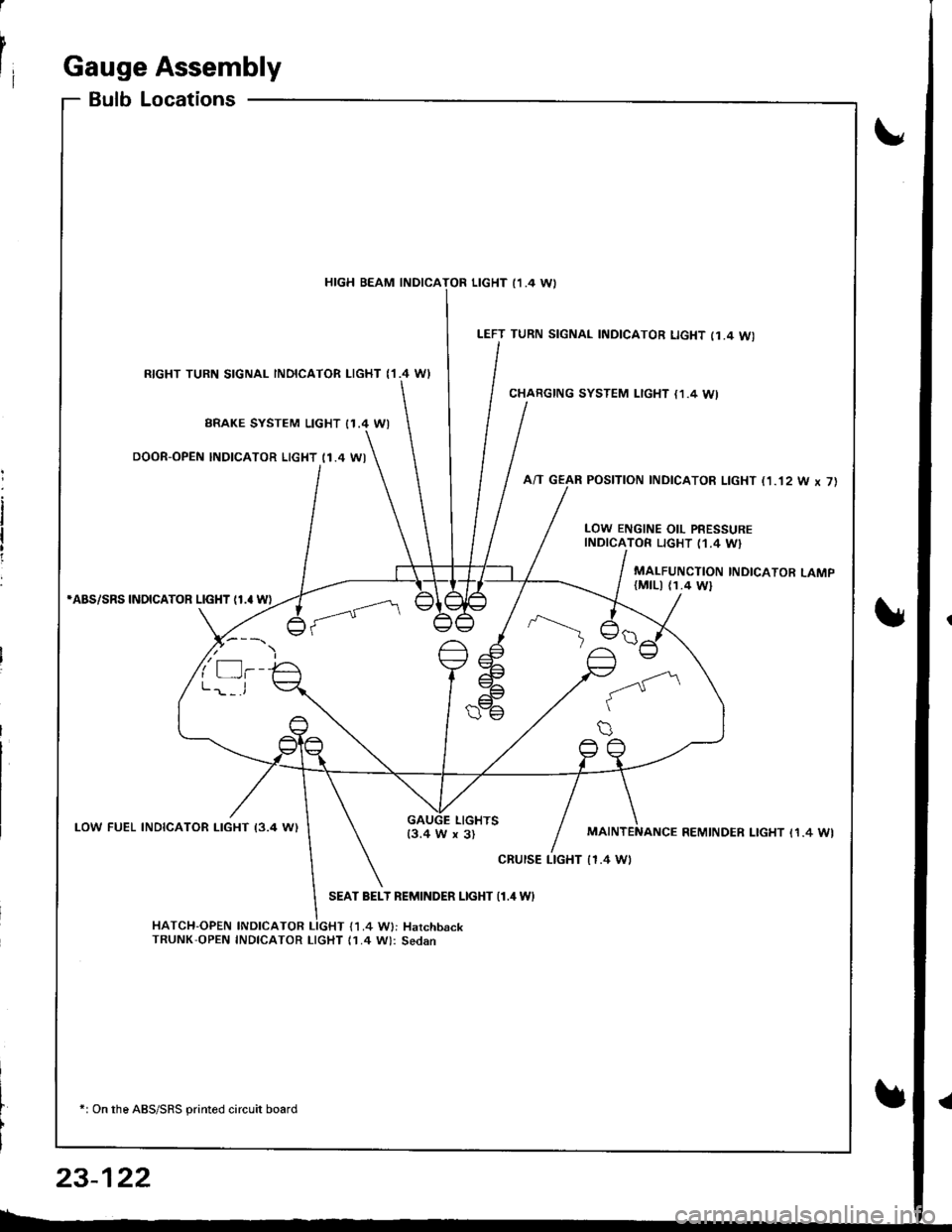

rIGauge Assembly

BulbLocations

RIGHT TURN SIGNAL INOICATOR LIGHT ('I.4 WI

BRAKE SYSTEM LIGHT I1.4 WI

DOOR-OPEN INDICATOR LIGHT (1.4 WI

*ABS/SRS INOICATOR LIGHT (1.' W)

LOW FUEL INDICATOR I-IGHT I3.4 W)

SEAT BELT REMINDER LIGHT {1.4 WI

HATCH-OPEN INDICATOR LIGHT {1.4 W}: HarchbackTRUNK'OPEN INDICATOR LIcHT (1.4 W): Sedan

+: On the ABS/SRS printed circuit board

LEFT TURN SIGNAL INDICATOR LIGHT (1.4 WI

CHARGING SYSTEM LIGHT {1,4 WI

A/T GEAR POSITION INDICATOR LIGHT (1.'t2 W x 7)

HIGH BEAM INDICATOR LIGHT I1 .4 \A,

LOW ENGINE OIL PRESSUREINDICATOR LIGHT (1.4 W}

MALFUNCTION INDICATOR LAMP(MtLl (1.4 Wl

LIGHTS13.4 W x 3)REMINDER LIGHT I1.4 WI

cRursE LTGHT | 1.4 Wt

23-122

Page 1182 of 1681

J

BLKYEL

YEUBLU

A8SN0.53 (104) FUSE CONTROLlFrofi page 23A'123) UNIT

VV

II

tltlWHT/GFN BLU/REO

lonWHT€IU

I

I

I

\?

ALTERNATOR

lo'PNK

J

HAZAROWARNINGswtTcH

MENTENANCEREMINDERLIGHT0.4v,/i

lo'PNK

II

I

J

MAINTENANCEREMINDERUNIT

| 011

YEUREO

I

T

P"-:

)-

BLK

I:

G201G401

LOWENGINE OILPFESSUREINDICATORLIGHT0.4w)

23-125

)J

Page 1184 of 1681

{

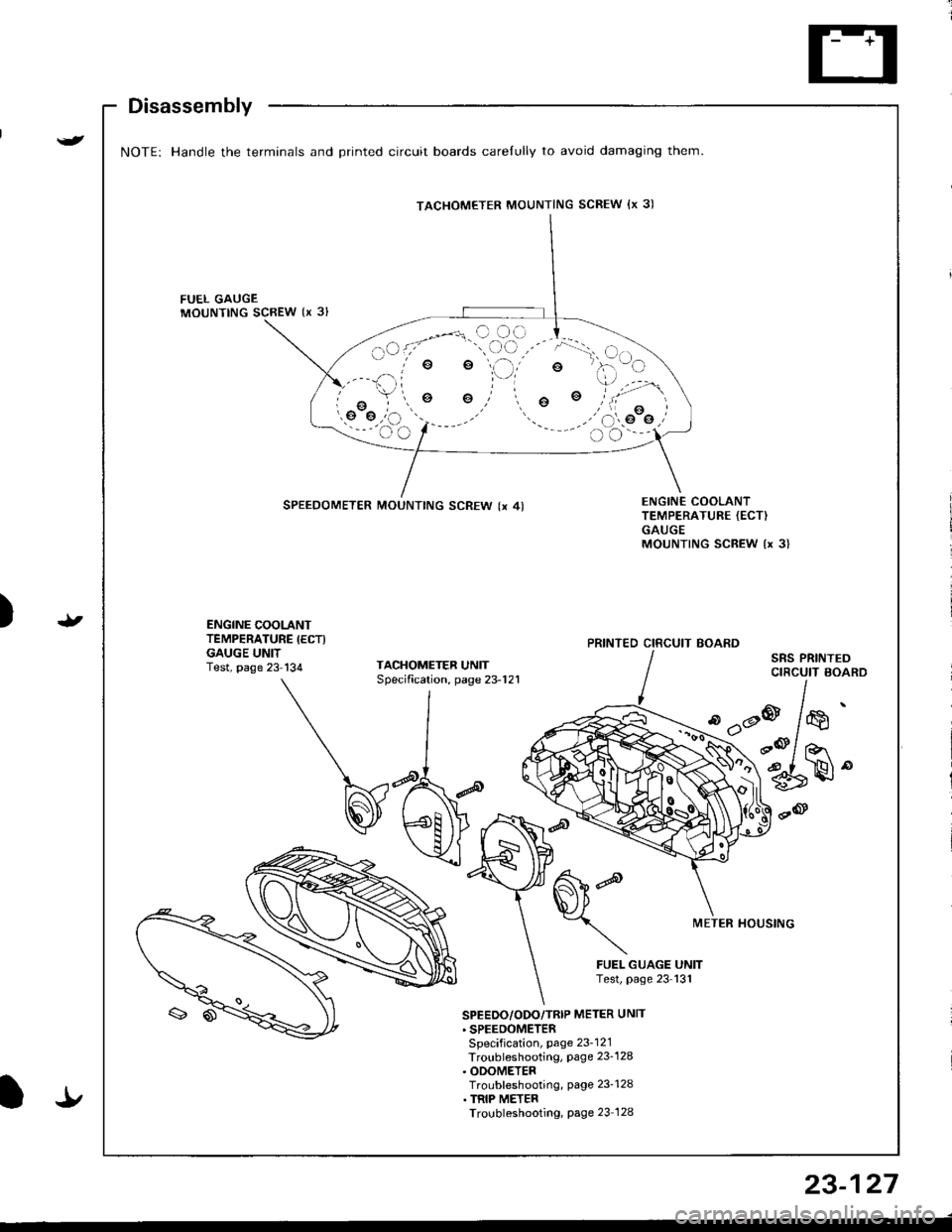

Disassembly

NOTE: Handle the terminals and Drinted circuit boards carelully to avoid damaging them.

FUEL GAUGEMOUNTING SCBEW {x 3l

e

o

SPEEDOMETER MOUNTING SCREW (x 4)ENGINE COOLANTTEMPERATURE {ECT)GAUGEMOUNTING SCREW {x 3}

t)ENGINE COOLANTTEMPERATURE IECTIGAUGE UNITTest, page 23-134TACHOMETEF UNITSpecification, page 23-121

SRS PRINTEDCIRCUIT BOARD

d'dP

METER HOUSTNG

FUEL GUAGE UNITTest, page 23 131

'

/*'

r@/ ror

6rH"

SPEEDO/ODO/TRIP METER UNTT' SPEEDOMETERSpecification, page 23-121Troubleshooting, Page 23_128. ODOMETERTroubleshooting, page 23-128. TRIP METERTroubleshooting, Page 23 128

TACHOMETER MOUNTING SCREW {x 3)

PRINTED CIRCUIT BOARD

It

23-127