engine HONDA INTEGRA 1998 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 995 of 1681

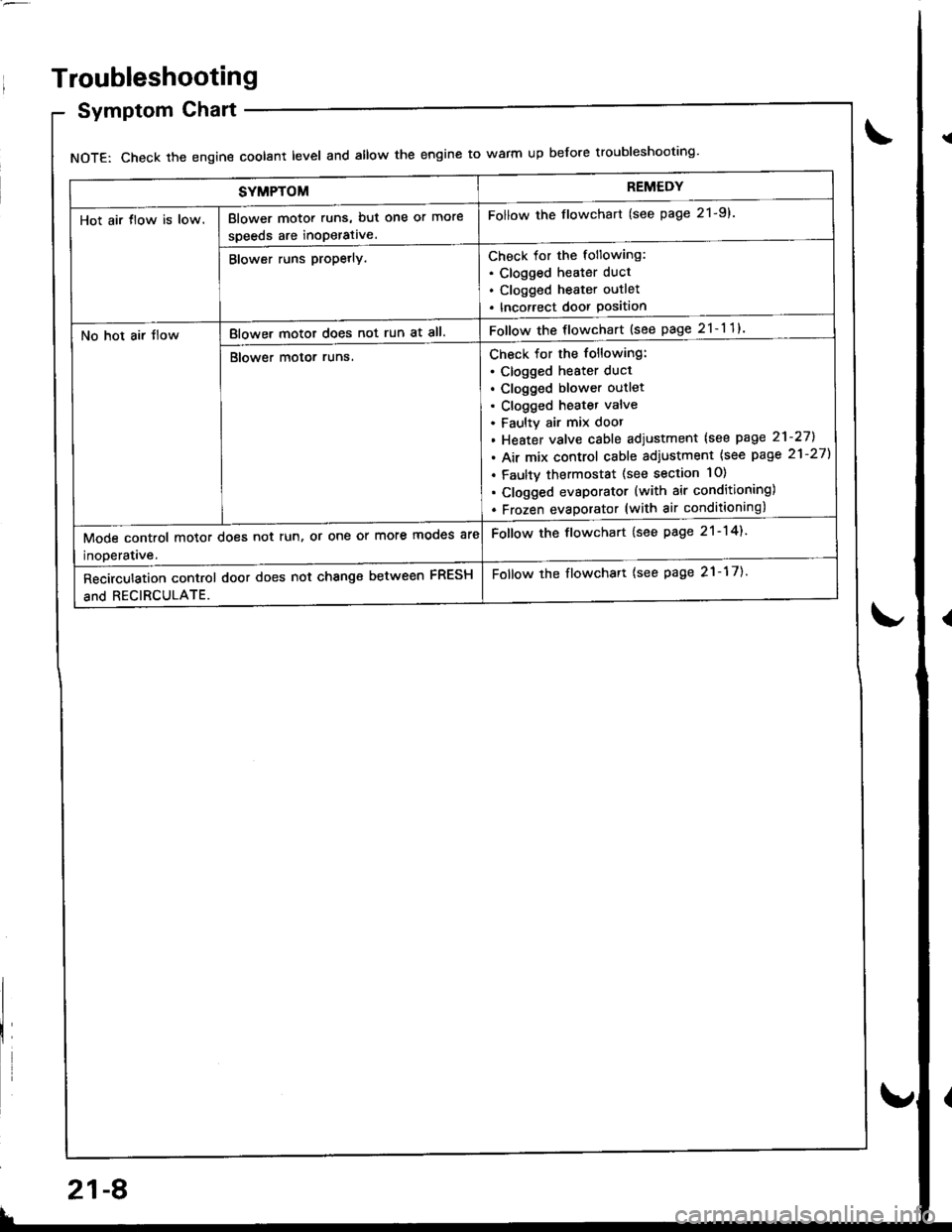

SYMPTOMREMEDY

Hot air tlow is low.Blower motor runs, but one or more

speeds are inoperative.

Follow the flowchart (see page 21-9).

Blower runs propetly.Check for the following:. Clogged heater duct

. Clogged heater outlet

. Incorrect door Position

No hot air tlowBlower motor does not run at all.Follow the flowchart {see page 21-11}

Blower motor runs.Check for the following:

. clogged heater duct

. Clogged blower outlet. Clogged heatet valve

. Faultv air mix door

. Heater valve cable adjustment lsee page 21-27].

. Air mix control cable adiustment {see page 21-27)

. Faulty thermostat (see section 10)

. Clogged evsporator (with air conditioning)

. Frozen evaDorator (with air conditioning)

Mode control motor does not run, or one or more mooes are

inoDeratave.

Follow the flowchart (see page 21-14).

Recirculation control door does not change between FRESH

and RECIRCULATE.

Follow the flowchart {see page 21-17).

Troubleshooting

Symptom Chart

NOTE: Check the engin€ coolant level and allow the engine to warm up before troubleshooting'

21-8

v

Page 1009 of 1681

Heater Unit

Replacement

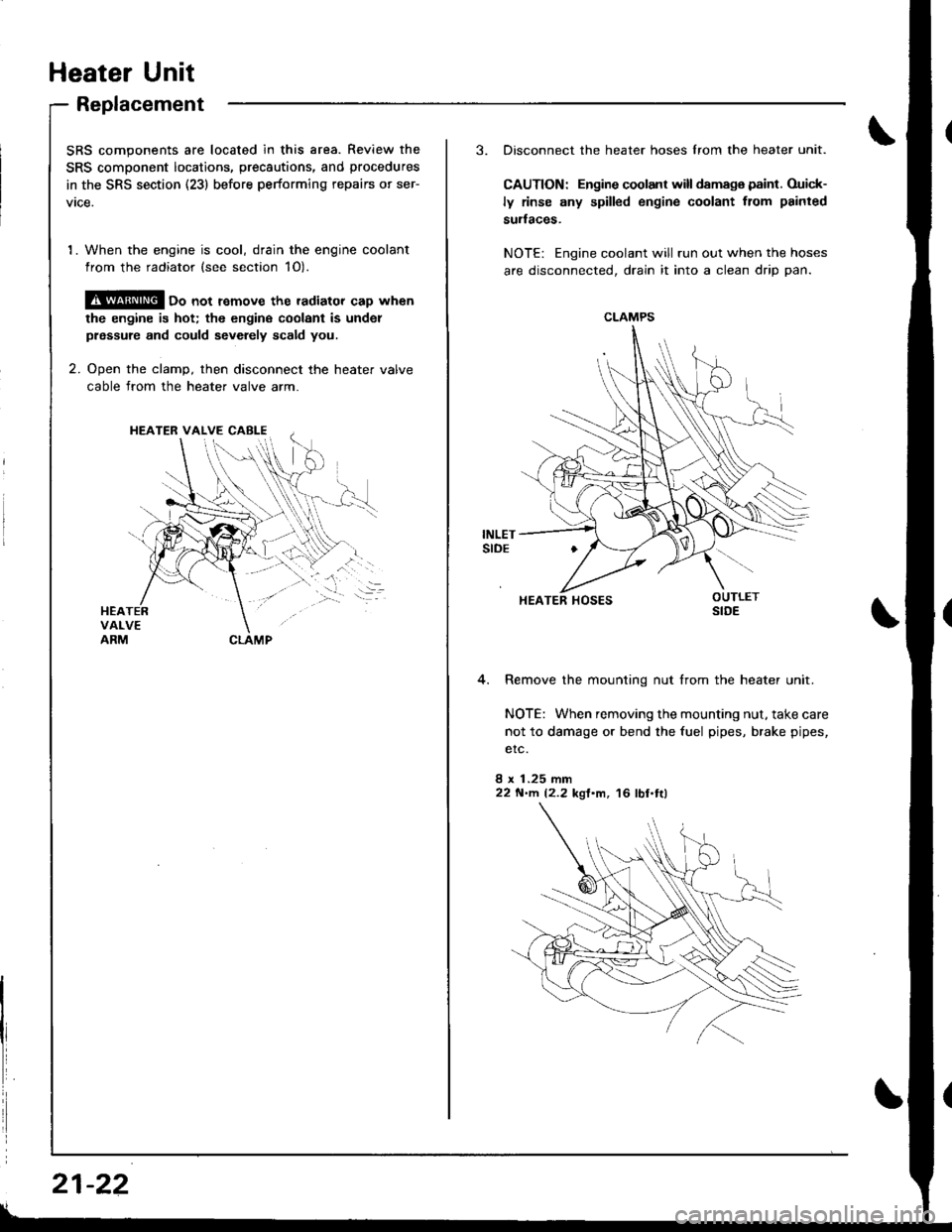

SRS components are located in this area. Review the

SRS component locatio.s, precautions, and procedures

in the SRS section (23) before performing repairs or ser-

vtce.

1. When the engine is cool, drain the engine coolant

from the radiator (see section 1O).

@ oo not remove the radiator cap when

the engine is hot; the engine coolant is undol

prsssure and could sevdely scald you.

2. Ooen the clamD, then disconnect the heater valve

cable from the heater valve arm.

HEATER VALVE CABI-E

I

i

21-22

3. Disconnect the heater hoses lrom the heater unit.

CAUTION: Engine coolant will damaga paint. Ouick-

ly rinse any spilled engine coolant from painted

sudaces.

NOTE: Engine coolant will run out when the hoses

are disconnected, drain it into a clean drip pan.

4. Remove the mounting nut from the heater unit.

NOTE: When removing the mounting nut, take care

not to damage or bend the fuel pipes, brake pipes,

etc.

8 x 1.25 mm22 N'llt. 12.2 kgl'm, 16 lbl.tl)

CLAMPS

HEATER HOSES

Page 1010 of 1681

.J

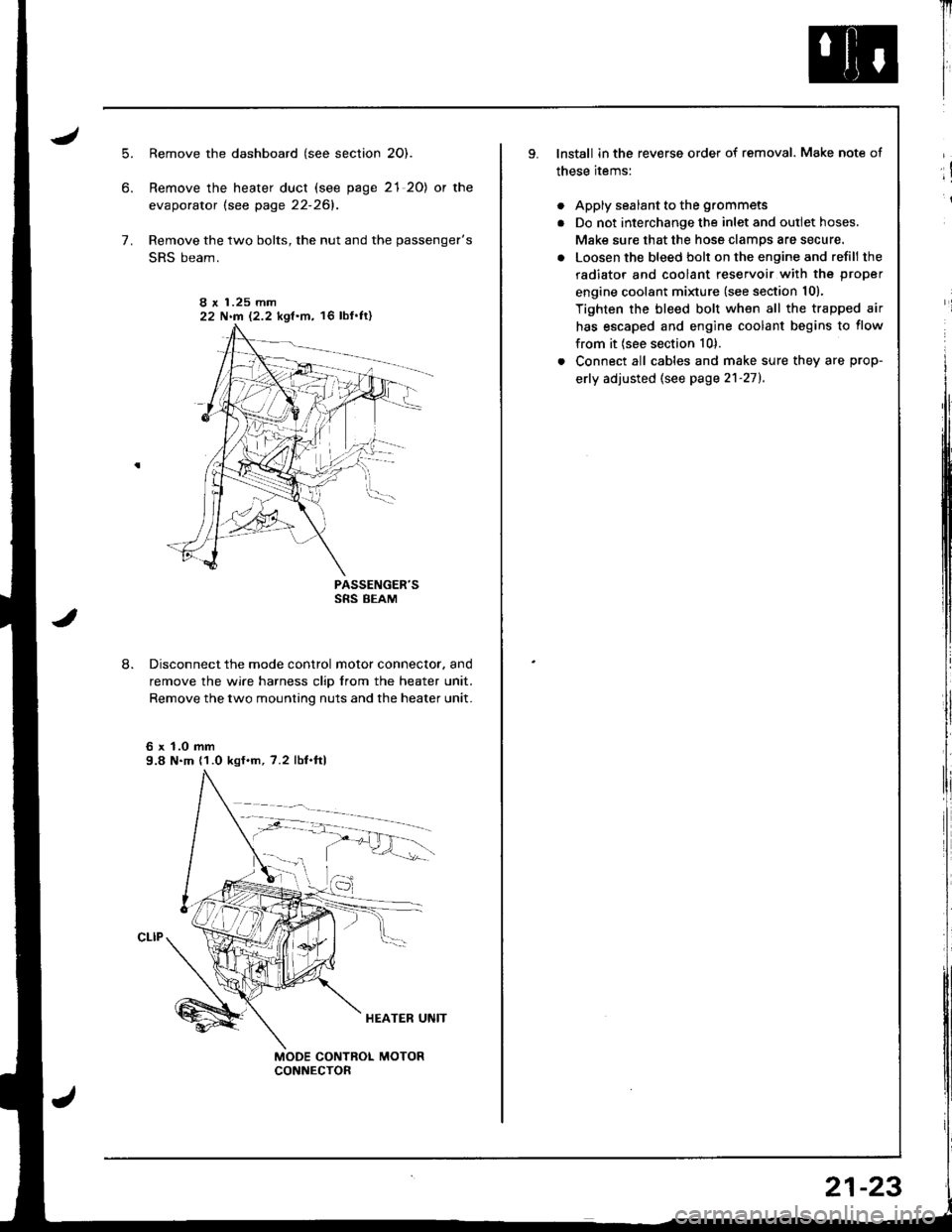

5.

6.

7.

8.

Remove the dashboard (see section 2O).

Remove the heater duct (see page 21 20) or the

evaporator lsee page 22-261.

Remove the two bolts, the nut and the passenger's

SRS beam.

PASSENGER'SSRS BEAM

Disconnect the mode control motor connector. and

remove the wire harness clip from the heater unit.

Remove the two mounting nuts and the heater unit.

6 x 1.0 mm9.8 N.m (1.0 kgf.m, 7.2 lbf.ftl

I r 1.25 mm22 N.m 12.2 kgf.m, 16 lbf'ft)

Il

I

I

lnstall in the reverse order of removal. Make note of

these items:

. Apply sealant to the grommets

. Do not interchange the inlet and outlet hoses.

Make sure that the hose clamps are secure.

. Loosen the bleed bolt on the engine and refill the

radiator and coolant reservoir with the proper

engine coolant minure (see section 10).

Tighten the bleed bolt when all the trapped air

has escaped and engine coolant begins to flow

from it (see section 10).

. Connect all cables and make sure they are prop-

erly adjusted (see page 2'l-271.

;!

i

21-23

Page 1025 of 1681

J

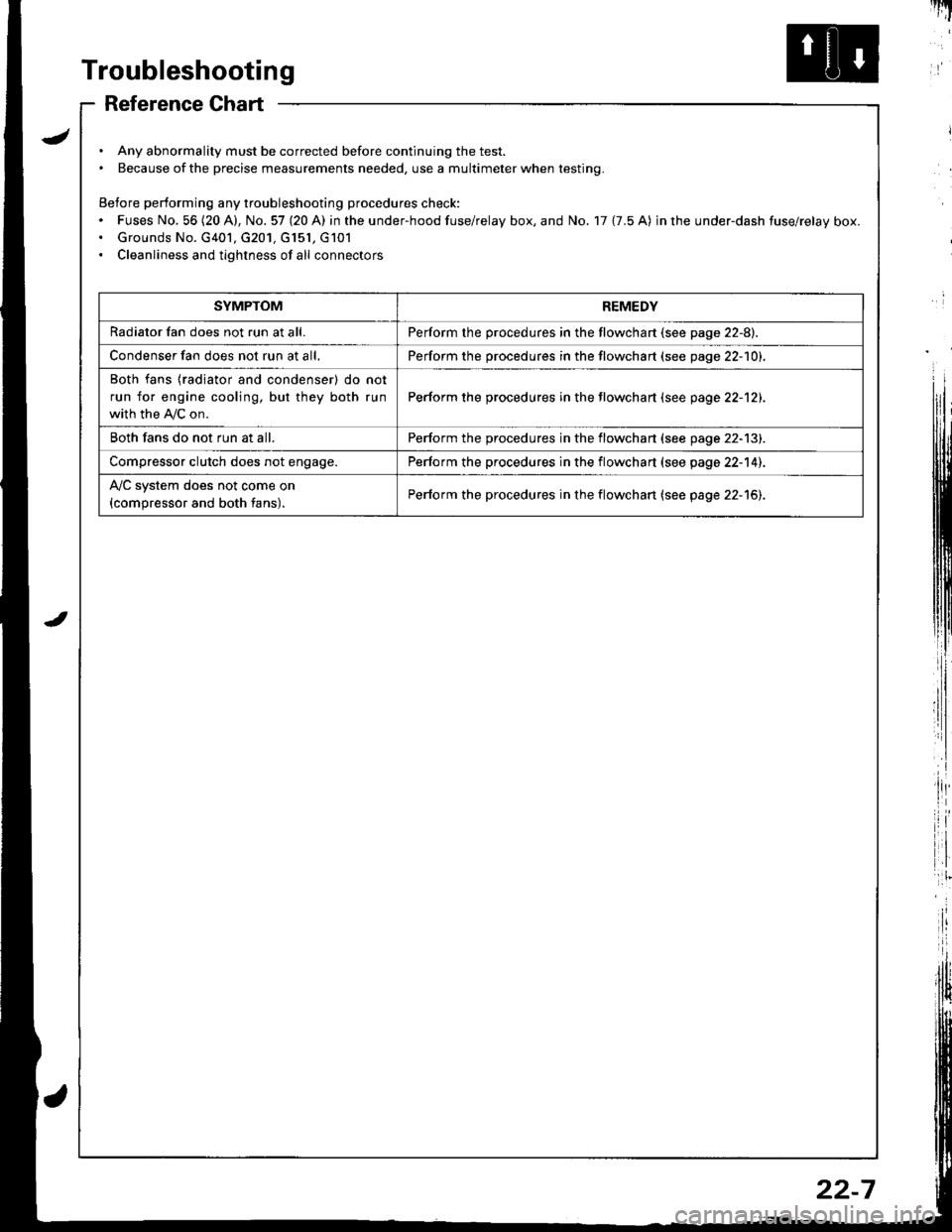

Troubleshooting

Reference Chart

. Any abnormality must be corrected before continuing the test.. Because of the precise measurements needed, use a multimeter when testing.

Before performing any troubleshooting procedures check:. Fuses No, 56 (20 A), No. 57 (20 A) in the under-hood fuse/relay box, and No. 17 {7.5 A) in rhe under-dash fuse/relay box.. Grounds No. G401, G201, G151, G101. Cleanliness and tightness of all connectors

I'IT

I

I

SYMPTOMREMEDY

Radiator fan does not run at all.Perform the procedures in the flowchart {see page 22-8).

Condenser fan does not run at all,Perform the procedures in the flowchart (see page 22-1O1.

Both fans {radiator and condenser) do not

run for engine cooling, but they both run

with the IVC on.

Perform the procedures in the tlowchart (see page 22-12).

Both fans do not run at all.Perform the procedures in the flowchart (see page 22-13).

Compressor clutch does not engage.Perform the procedures in the flowchart (see page 22-14).

l'lc system does not come on

{compressor and both fans).Perform the procedures in the flowchart (see page 22-15).

22-7

Page 1030 of 1681

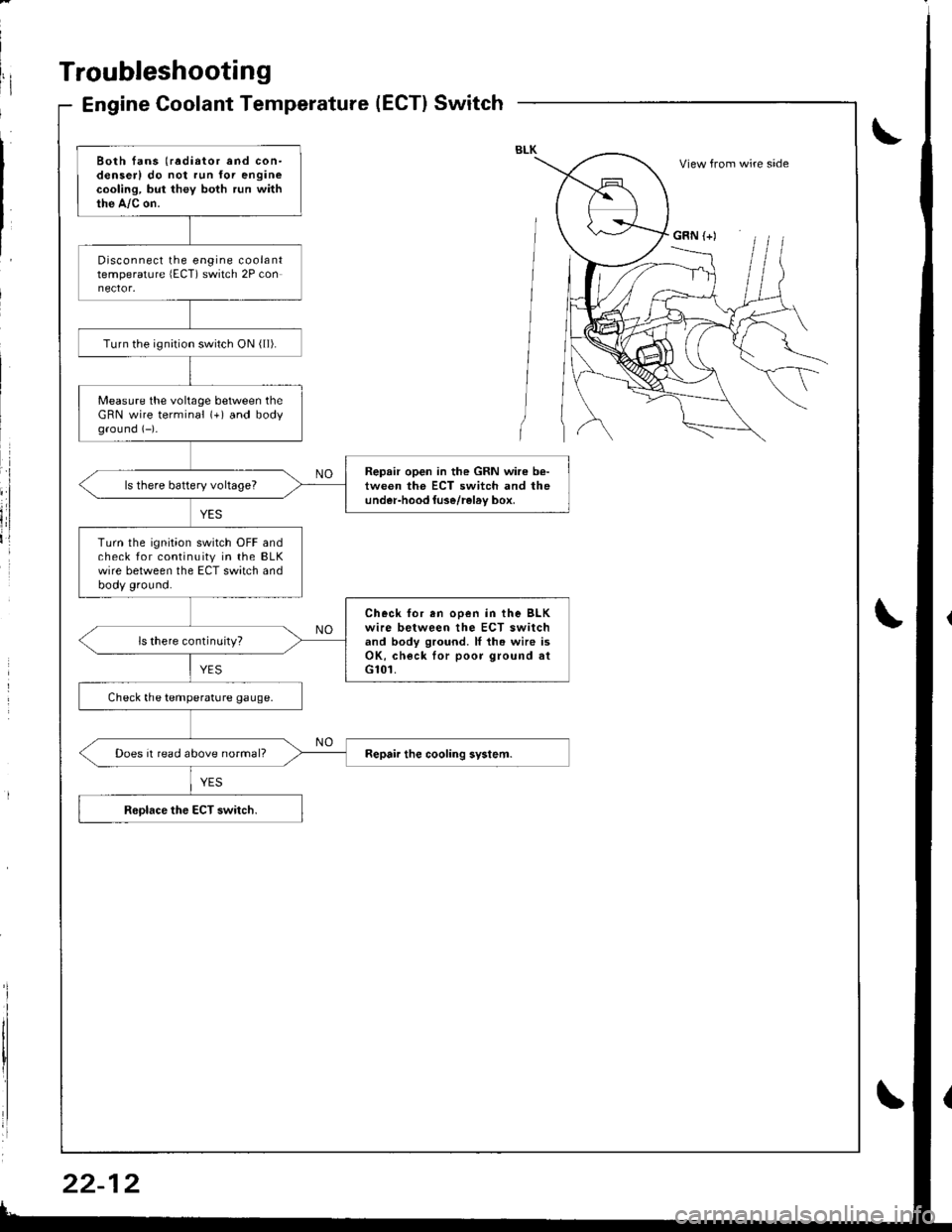

Troubleshooting

Engine Coolant Temperature(ECT}Switch

Both fans (radiator and con-denserl do not run for enginecooling, but they both run withthe A,/c on.

Disconnect the engine coolanttemperature lECT) switch 2P con

Turn the ignirion switch ON ( ll).

Measure the voltage between theGRN wire terminal (+) and bodyground (-)-

Repair open in the GRN wire b€-tween the ECT switch and theunder-hood luse/rel6v box,ls there battery voltageT

Turn the ignition switch OFF andcheck for continuity in the BLKwire between the ECT switch andbody ground.

Check for en ooen in the BLKwire between the ECT switchand body ground. ll th. wire isOK, check lor poor ground atG101.

ls there continuity?

Check the temperature gauge.

Does it read above normal?

View from wire side

GRN (+)

Page 1042 of 1681

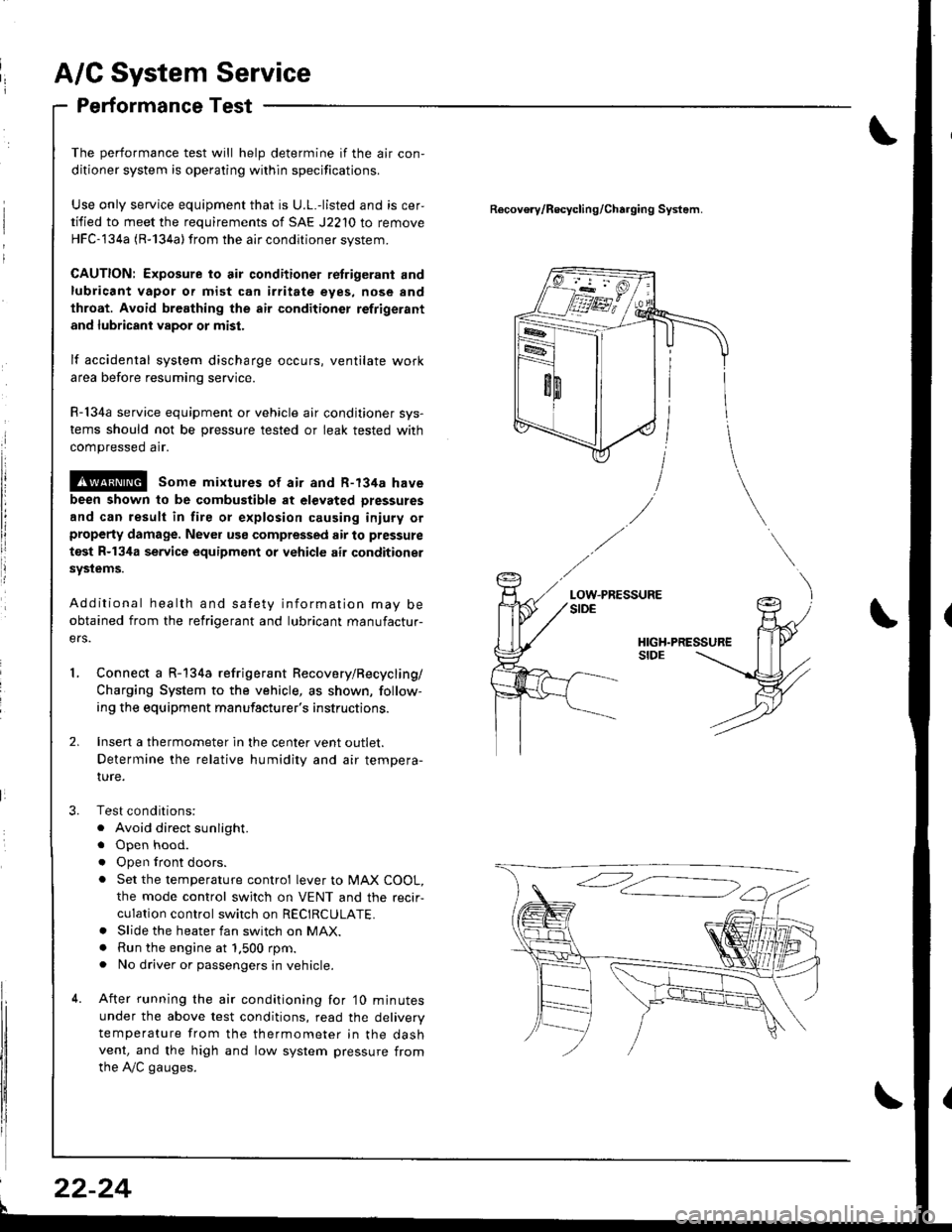

A/C System Service

Performance Test

The performance test will help determine if the air con,

ditioner system is operating within specifications.

Use only service equipment that is U.L.-listed and is cer,

tified to meet the requirements of SAE J2210 to remove

HFC-134a (R-134a) from the air conditioner svstem.

CAUTION: Exposure to air conditioner retrigerant and

lubricant vapor or mist can irritate eyes, nose and

throat. Avoid breathing the air conditioner refrigerant

and lubricant vapor or mist.

lf accidental system discharge occurs, ventilate work

area before resuming service.

R-134a service equipment or vehicle air conditioner sys-

tems should not be pressure tested or leak tested with

compressed arr.

@ some mixtures of air and R-134a have

been shown to be combustible at elevated Dressures

and can result in fire or explosion causing iniury orproperty damage. Never use compressed air to pressure

test R-134a service equipment or vehicle air conditioner

systems.

Additional health and safety information may be

obtained from the refrigerant and lubricant manufactur-

ers.

Connect a R-134a refrigerant Recovery/Recycling/

Charging System to the vehicle, as shown, follow-

ing the equipment manufacturer's instructions.

Insen a thermometer in the center vent outlet.

Determine the relative humidity and air tempera-

IUre.

Test conditions:

. Avoid direct sunlight.

. Open hood.

. Open lront doors.

. Set the temperature control lever to MAX COOL,

the mode control switch on VENT and the recir-

culation control switch on RECIRCULATE.. Slide the heater fan switch on MAX.. Run the engine at 1.500 rpm.. No driver or passengers in vehicle.

After running the air conditioning for'10 minutes

under the above test conditions, read the delivery

temperature from the thermometer in the dashvent, and the high and low system pressure from

the A,/C gauges.

Recovo.v/Recycling/Charging System.

LOW.PRESSURE

l

22-24

Page 1048 of 1681

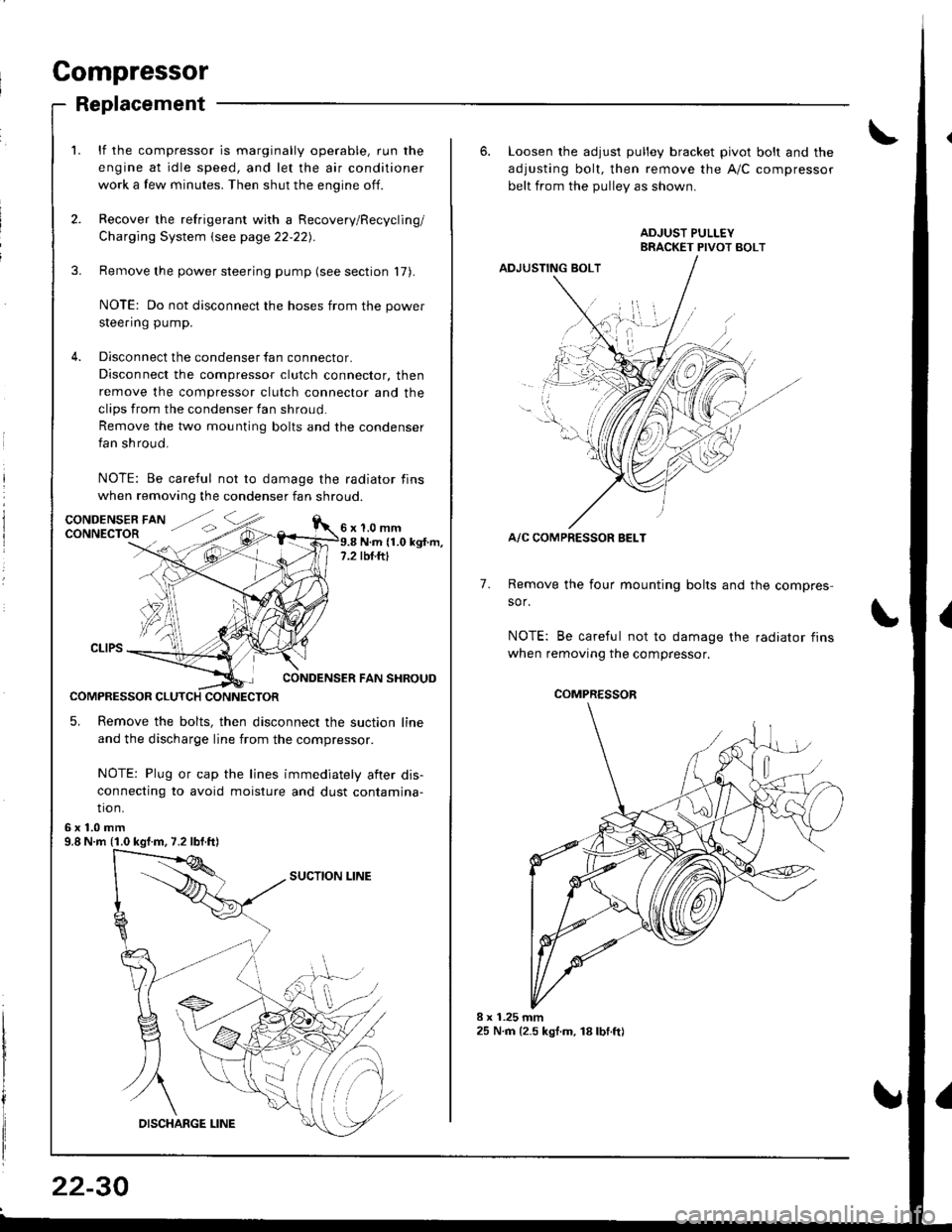

Compressor

Replacement

lf the compressor is marginally operable, run the

engine at idle speed, and let the air conditioner

work a few minutes. Then shut the engine off.

Recover the refrigerant with a Recovery/Recycling/

Charging System \see page 22-22).

Remove the power steering pump (see section 17).

NOTE: Do not disconnect the hoses from the power

steering pump.

Disconnect the condenser fan connector.

Disconnect the compressor clutch connector, then

remove the compressor clutch connector and the

clips from the condenser fan shroud

Remove the two mounting bolts and the condenser

fan shroud.

NOTE: Be careful not to damage the radiator fins

when removing the condenser fan shroud.

1.0 mmN.m (1.0 kgt.m,rbf.ftt

CONDENSER FAN SHROUD

COMPRESSOR CLUTCH CONNECTOR

5. Remove the bolts, then disconnect the suction line

and the discharge line from the compressor.

NOTE: Plug or cap the lines immediately aiter dis-

connecting to avoid moisture and dust contamina-

tio n.

6x1.0mm9.8 N.m (1.0 kgf.m, 7.2 lbf.ft)

22-30

6. Loosen the adjusl pulley bracket pivot bolt and the

adjusting bolt, then remove the A/C compressor

belt from the Dullev as shown.

ADJUSTING BOLT

A/C COMPRESSOR BELT

Remove the four mounting bolts and the compres-

sor.

NOTE: Be careful not to damage the radiator fins

when removing the compressor.

7.

./.,

COMPRESSOR

Page 1049 of 1681

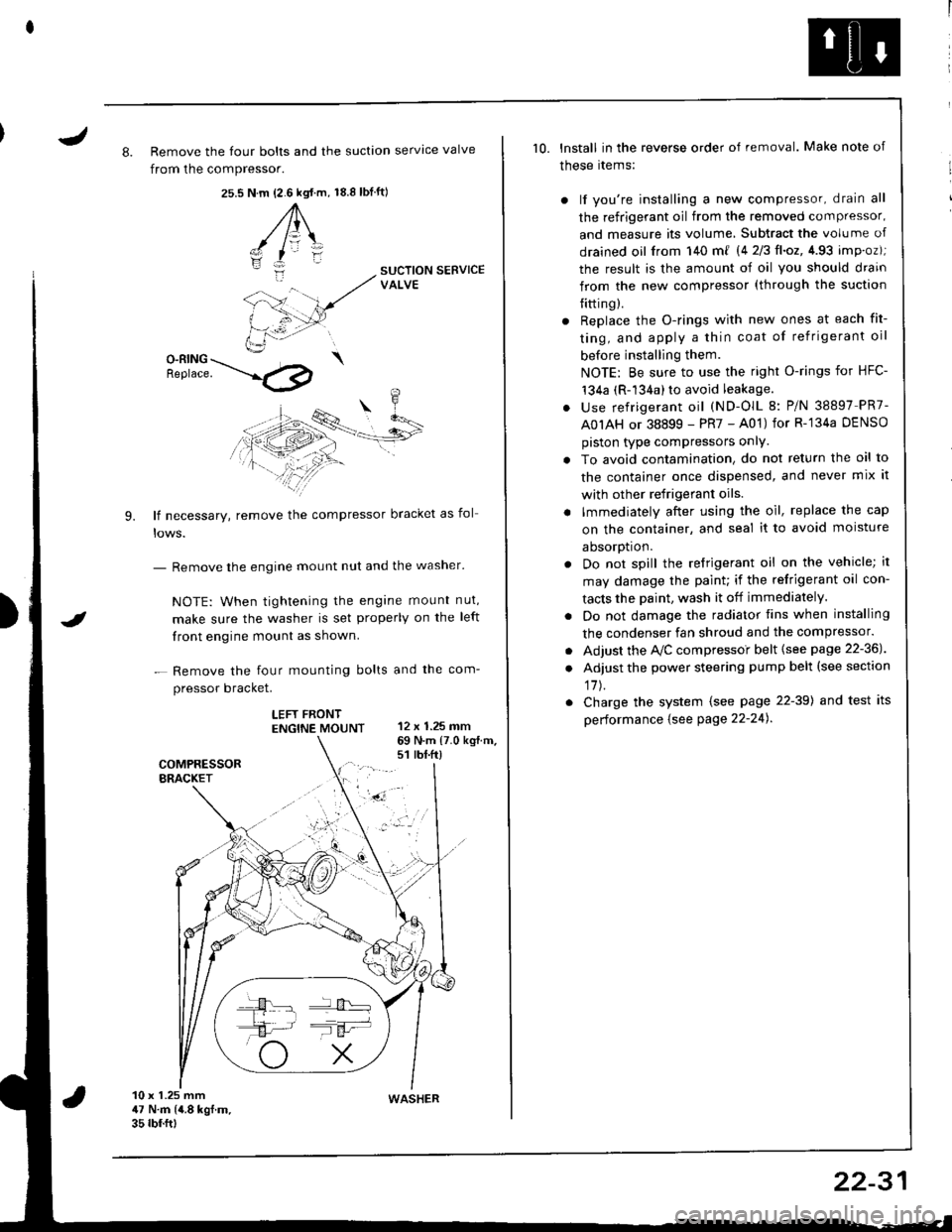

J8. Remove the four bolts and the suction servtce valve

from the compressor.

25.s18.8 tbf.ft)N.m {2.6 kgt.m,

A\

-/ l=\'zI

i:-

9.

SUCTION SERVICEVALVE

O-RING \Benrace. --'.l4p

lf necessary, remove the compressor bracket as fol

- Remove the engine mount nut and the washer'

NOTE: When tightening the engane mount nut,

make sure the washer is set properly on the left

front engine mount as shown.

- Remove the four mounting bolts and the com-

pressor bracket.

LEFT FRONTENGTNE MOUNT 12 x 1.25 mm

I

69 N.m {7.0 kg{.m.s1 rbt.ft)

10 x 1.25 mm47 N.m (4.8 kgf.m.35 rbf.ftt

10. lnstall in the reverse order of removal. Make note of

these rtems:

) lf you're installing a new compressor, drain all

the refrigerant oil from the removed compressor,

and measure its volume, Subtract the volume of

drained oil from 140 m{ 14 2/3ll.oz,4.93 imp.oz);

the result is the amount of oil you should drain

from the new compressor (through the suction

{itting).

r Replace the O-rings with new ones at each fit-

ting, and apply a thin coat of refrigerant oil

before installing them.

NOTE: Be sure to use the right O-rings for HFC-'t34a (R-134a) to avoid leakage.

. use refrigerant oil (ND-OlL 8: P/N 38897 PR7-

A0IAH or 38899 - PR7 - A01) for R-'134a DENSO

piston type compressors onlY.

. To avoid contamination, do not return the oil to

the container once dispensed, and never mix it

with other refrigerant oils.

. lmmediately after using the oil, replace the cap

on the container, and seal it to avoid moisture

aDsorDt|on.

. Do not spill the refrigerant oil on the vehicle; it

may damage the paint; if the refrigerant oil con-

tacts the Daint, wash it off immediately.

. Do not damage the radiator fins when installing

the condenser fan shroud and the compressor.

. Adjust the Ay'C compressoi belt {see page 22-36J

. Adjust the power steering pump belt (see section

17J.

. Charge the system (see page 22-39) and test its

performance {see Page 22-24).

WASHER

22-31

Page 1053 of 1681

J

A/G Compressor Belt

Replacement

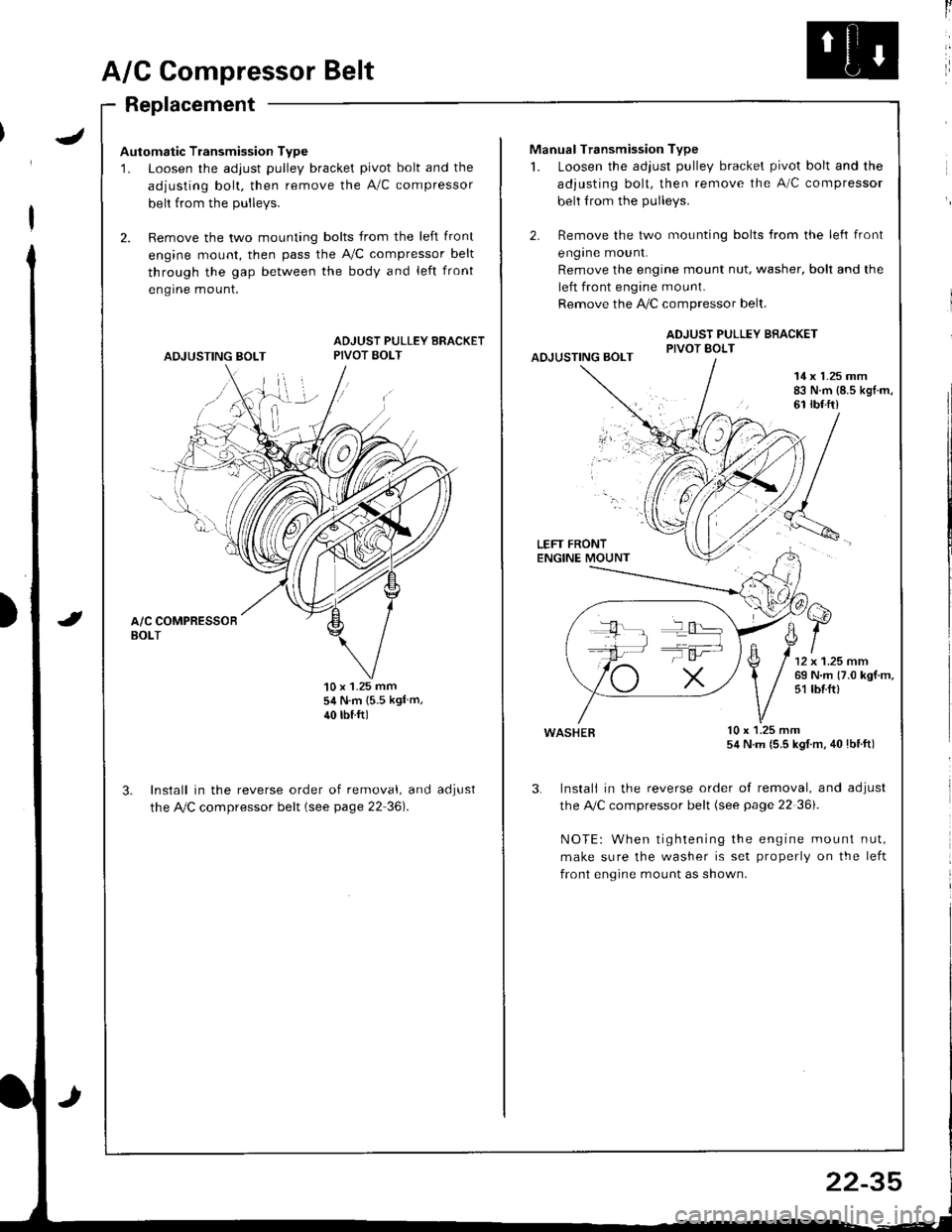

Automatic Transmission Type

1. Loosen the adjust pulley bracket pivot bolt and the

adjusting bolt. then remove the A/C compressor

belt from the Dullevs.

2. Remove the two mounting bolts from the left front

engine mount, then pass the A,/C compressor belt

through the gap between the body and left front

engrne mount.

ADJUSTING BOLT

ADJUST PULLEY BRACKETPIVOT BOLT

'10 x 1.25 mm54 N.m {5.5 kgl m,

40 rbtftl

Install in the reverse order of removal, and

the Ay'C compressor belt (see page 22 36).

aoJUsI

ll

Manual Transmission Type

1. Loosen the adjust pulley bracket pivot bolt and the

adjusting bolt, then remove the A/C compressor

belt from the pulleys.

2. Remove the two mounting bolts from the left front

engrne mount.

Remove the engine mount nut, washer, bolt and the

left front engine mount.

Remove the !i/C compressor belt.

ADJUST PULLEY BRACKETPIVOT BOLTAOJUSTING BOLT

14 x 1.25 mm83 N.m {8.5 kgl.m,61 rbf.ft)

LEFT FRONTENGINE MOUNT

wasHEB lu x l.z5 mm54 N.m (5.5 kgl m, 40lbtft)

3. Instali in the reverse order of removal, and adjust

the A,/C compressor belt (see page 22 36i.

NOTE: When tightening the engine mount nut,

make sure the washer is set properly on the left

front engine mount as shown.

T':

22-35

Page 1058 of 1681

J

Electrical

Speciaf Toofs ..........................23-2

Troubleshooting

Tips 8nd Precautions .......................,..,.,.,.,.,......,..., 23-3

Five-step Troubleshooting ............,......,.,.,...,..,....., 23-5

Schsmatic Svmbols ...............23-6

Wire Color Code3 .. ................. 23-6

Relay and Control Unit Locations

Engine Compartment ......,.,.................,.,.,.,.,.,,,, 23-7

Dashboard and Door .........,...........,.....,.,....,.,.... 23-8

Dashboard and Floor ......................................... 23-10

Ouarter Pan€f .,,.,...,.,..,...,,,23-12

Connector ldontification and WireHarness Routing ......,.,......23-'13

Index to Circuits and Systems

Airbag

* Integrated Control Unit .....,.,.,.....23-152* Interlock Sytem .,...,.,...........,. 23.146

Lights, Exterior

Eack-up LighB ..................23.187

Brake Ligh$ ......................23-190*Daytime Running Lights (Canada) ................... 23"164

Front Parking Lights .......................................... 23-173

Front Side Marker Lights .................................. 23-173

Front Turn Signal Lights ..................-.......,...,.,. 23-173* Hazard Warning Lights ....................,........,....... 23-192

Headlights.....23-169

23-253 powerDistribution..................... 23-5/r

Air Conditioning.....,....... Soction 21

Alternator ..........,................... 23.99

iCigarette Lighter .........23-212

*Cruise Control

Distributor

'.'.,.'.'.,.'...,,,,.,''.'.,.',.'''.' 23.277

.............................. 23.88

................... 23-90lgnition Timing ......

Indicator Lights

Key-in Reminder System

Maintenance Reminder System*Seat Belt R€mindor System .,...........................* Side Marker/Turn Signal/HazardFlashcr Svstem .................23-192

Spark Plugs ............................23-98

Starting System .....................23-74* Stereo Sound System ...,......,..........,...,......,.,.,.,..,., 23-196

Supplemental Restraint System (SRS) ................ 23-277

Vshicle Speed Sensor (VSS) ................................. 23.130r Wiper/Washer System .........................................., 23-265

*Read SRS precautions on Psge 23-283 before working

in those areas,

23-154

23.136

23"133