engine HONDA INTEGRA 1998 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 1078 of 1681

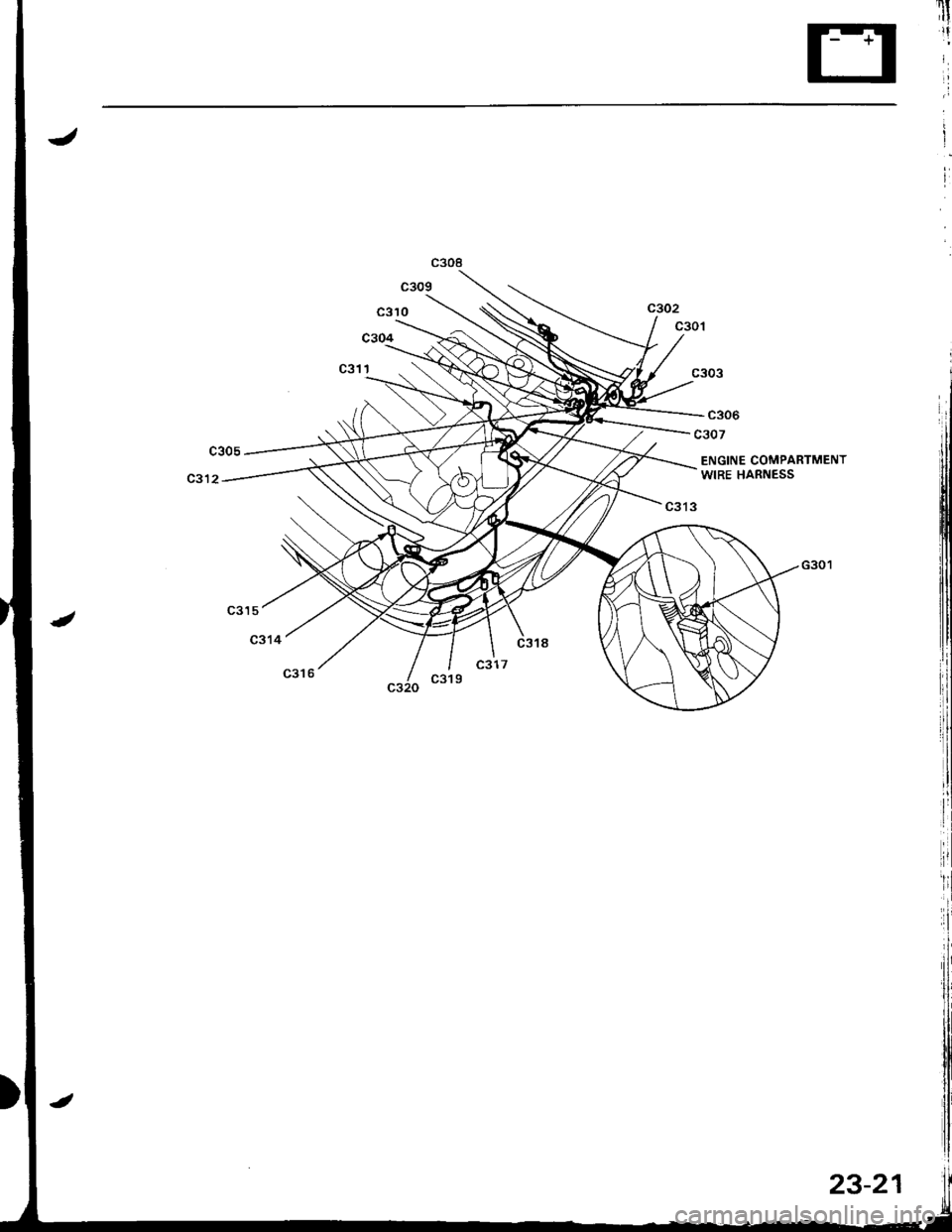

c306

c307

ENGINE COMPARTMENTWIRE HARNESS

G301

Page 1079 of 1681

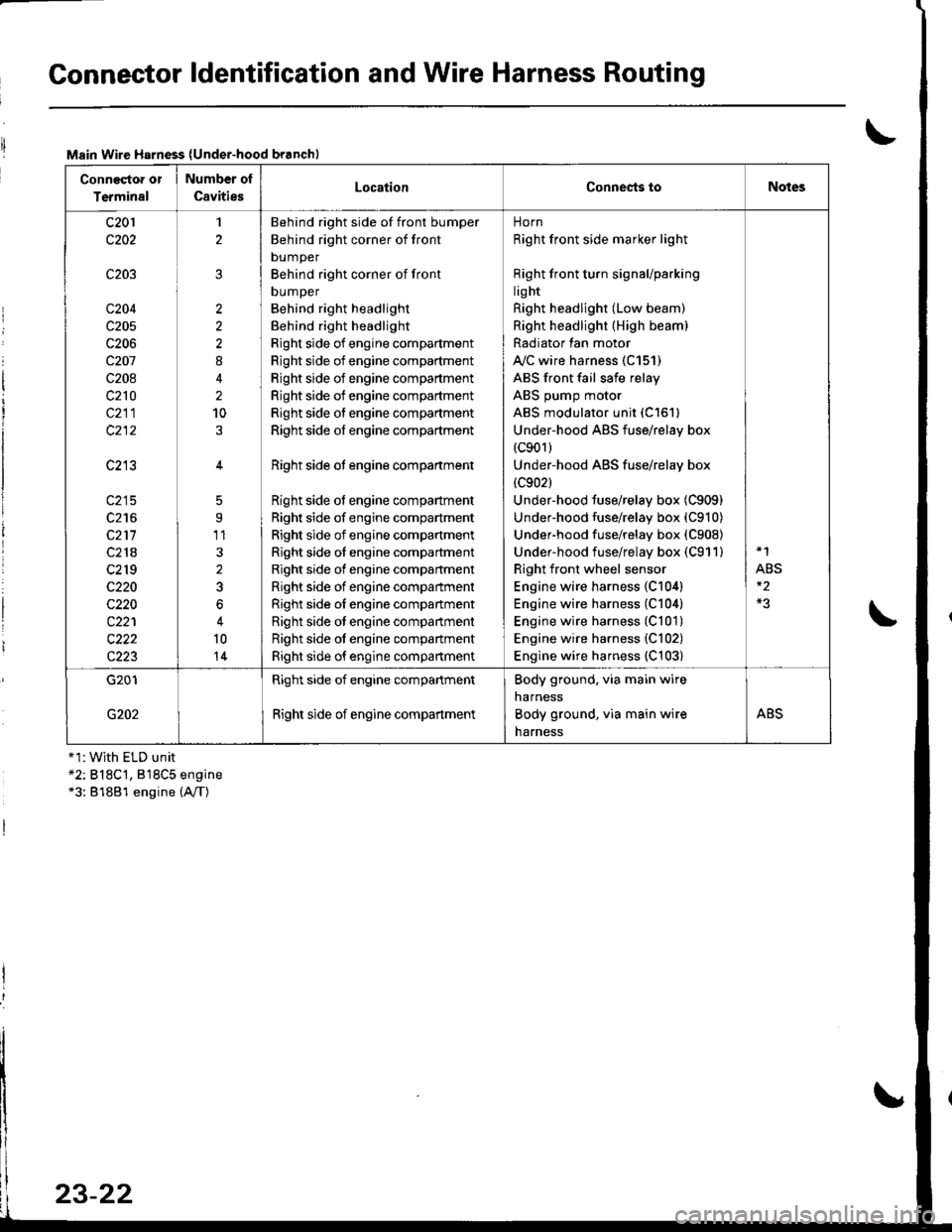

Connector ldentification and Wire Harness Routing

Main Wire Harness (Under-hood branchl

Conneqtor or

Terminal

Number ol

CavitiesLocationConnests toNotes

c201

c202

c203

c204

c205

c206

c207

c208

c210

c211

c213

c215

c216

c211

c218

c2r 9

c220

c220

c221

c222

c223

1

2

2

2

2

8

2

10

5

9'11

3

2

3

6

10

14

Behind right side of front bumper

Behind right corner of front

bumper

Behind right corner of front

DUmper

Behind right headlight

Behind right headlight

Right side of engine compartment

Right side of engine compartment

Right side of engine compartment

Right side of engine compartment

Right side of engine compartment

Right side of engine compartment

Right side ot engine compartment

Right side of engine compartment

Right side of engine compartment

Right side of engine compartment

Right side of engine compartment

Right side of engine compartment

Right side of engine compartment

Right side oI engine companment

Right side ot engine compartment

Right side ot engine compartment

Right side of engine compartment

norn

Right front side marker light

Right front turn signaUparking

lig ht

Right headlight (Low beam)

Right headlight (High beam)

Radiator lan motor

A"/C wire harness (C151)

ABS front fail safe relay

ABS pump motor

ABS modulator unit (C151)

Under-hood ABS fuse/relay box(c901)

Under-hood ABS fuse/relay box

{c902}

Under-hood fuse/relay box (C909)

Under-hood fuse/relay box (C910)

Underhood fuse/relay box (C908)

Under-hood fuse/relay box (C911)

Right front wheel sensor

Engine wire harness {C104)

Engine wire harness (C104)

Engine wire harness (C101)

Engine wire harness {C102)

Engine wire harness (C103)

*1

ABS

G201

G202

Right side of engine compartment

Right side of engine compartment

Body ground. via main wire

narness

Body ground, via main wire

harness

ABS

+1:With ELD unit*2: B18C't, 818C5 engine*3: 81881 engine (A,/T)

23-22

Page 1081 of 1681

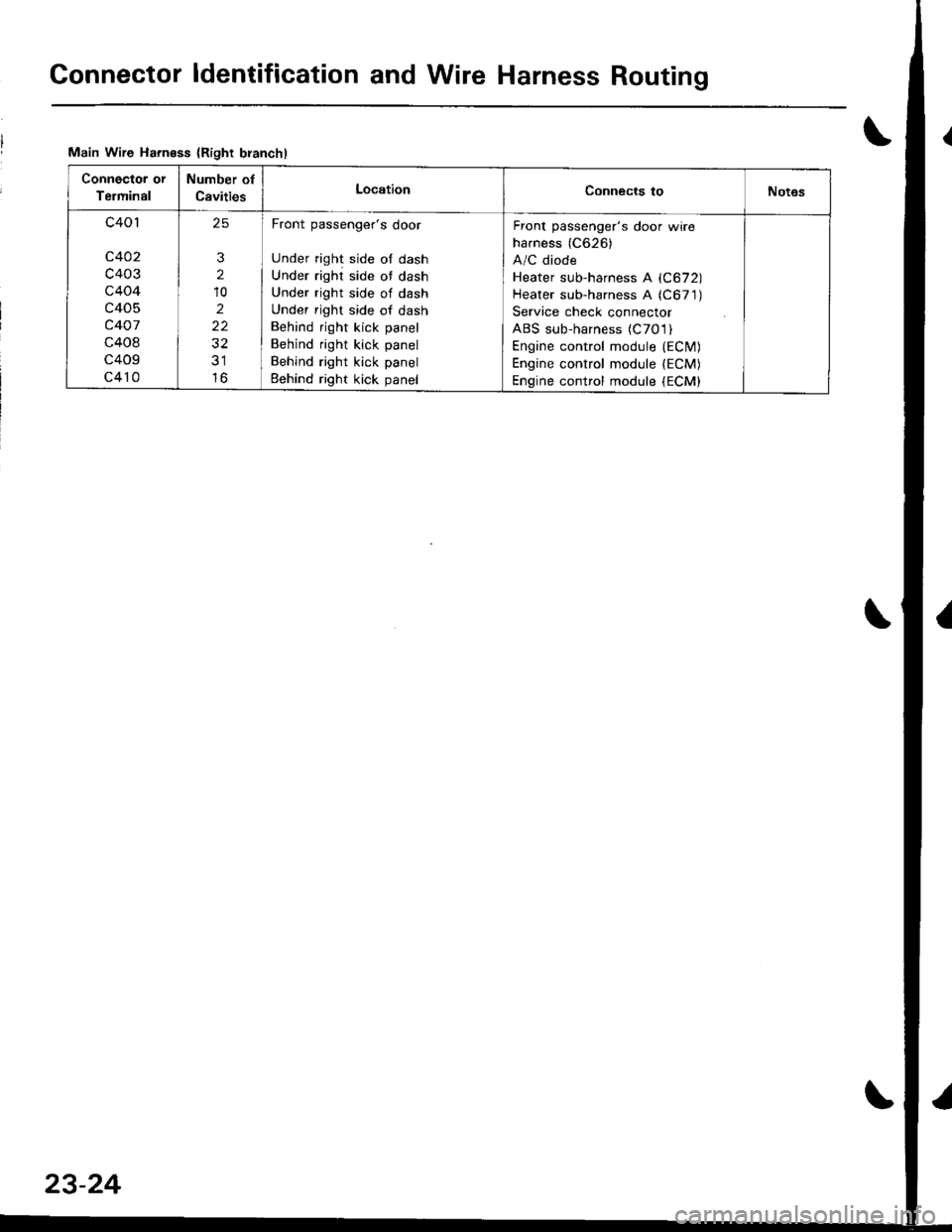

Gonnector ldentification and Wire Harness Routing

Main Wire Harness {Right branchl

Connector or

Terminal

Number of

CavitiesLocationConnects toNot6s

c401

c402

c403

c404

c405

c407

c408

c409

c410

25

3

2

10

2

22

32

lo

Front passenger's door

Under right side of dash

Under right side ot dash

Under right side of dash

Under right side of dash

Behind right kick panel

Behind right kick panel

Behind right kick panel

Eehind right kick panel

Front passenger's door wire

harness (C626)

A/C diode

Heater sub-harness A (C672)

Heater sub-harness A (C671)

Service check connector

ABS sub-harness (C7O l)

Engine control module {ECfM)Engine control module lECM)Engine contfol module (ECM)

23-24

Page 1083 of 1681

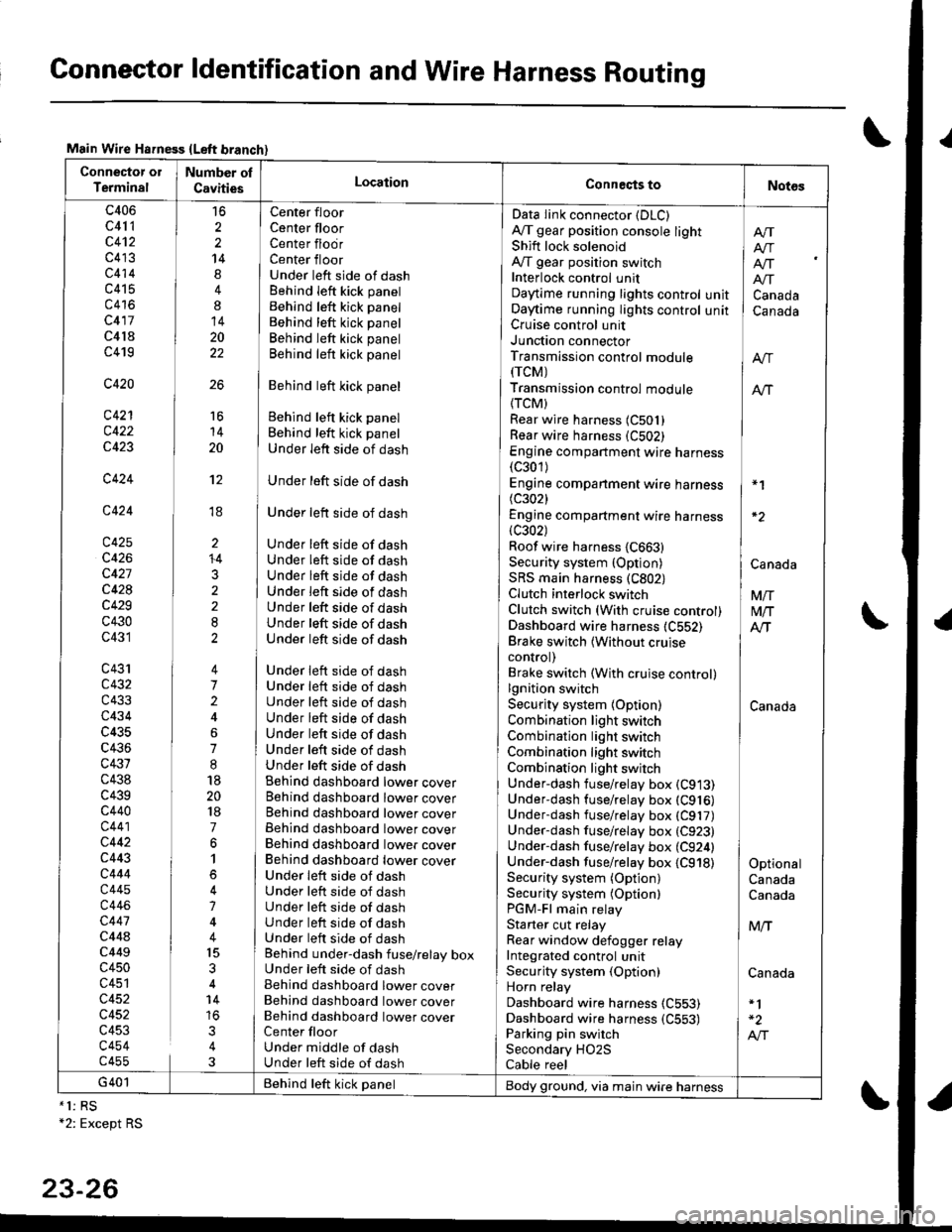

Connector ldentification and Wire Harness Routing

Main Wire Hsfness {Left branch}

Connector ol

TerminalNumber ol

CavitiesLocationConneqts toNot6s

c406

c41 1

c4't2

c413

c414

c415

c416

c417

c4l8

c419

c420

c421

c422

c423

c424

c424

c425

c426

c427

c428

c429

c430

c431

c43'rc432

c433

c434

c435

c436

c431

c438

c439c440

c441

c442

c443

c444

c445

c446

c447

c44ac449

c450

c451

c452

c452

c453

c454c455

16

2

2

14

4

8

14

20

22

26

Center floor

Center floorCenter flodrCenter floorUnder left side of dashBehind Ieft kick panel

Behind left kick panel

Behind left kick panel

Behind left kick panel

Behind left kick panel

Behind left kick panel

Behind left kick panel

Behind left kick panel

Under left side of dash

Under left side of dash

Under left side of dash

Under left side of dashUnder left side of dashUnder left side of dashUnder left side of dashUnder left side of dashUnder left side of dashUnder left side of dash

Under left side of dashUnder left side of dashUnder left side of dashUnder left side of dashUnder left side of dashUnder left side of dashUnder left side of dashBehind dashboard lower coverBehind dashboard lower coverBehind dashboard lower coverBehind dashboard lower coverBehind dashboard lower coverBehind dashboard lower coverUnder leit side of dashUnder left side of dashUnder left side of dashUnder left side of dashUnder left side of dashBehind under-dash fuse/relay boxUnder left side of dashBehind dashboard lower coverBehind dashboard lower coverBehind dashboard lower coverCenter floorUnder middle of dashUnder left side of dash

Data Iink connector (DLC)

A,/T gear position console lightShift lock solenoidAy'T gear position switchInterlock control unitDaytime running lights controlOaytime running lights controlCruise control unitJunction connectorTransmission control module(rcM)

Transmission control module

{TCM)Rear wire harness (C501)

Rear wire harness (C502)

Engine compartment wire harness(c301)

Engine companment wire harness I *1

(c3021 IEngine compartment wire harness(c302) lRoof wire harness {C663} |Security system {Option) | CanaAaSRS main harness (C802) |Clutch interlock switch I VnClutch switch (With cruise control) M/TDashboard wire harness (C552) AlTBrake switch lwithout cruise Icontrol) |Brake switch (With cruise control)lgnition switch ISecurity system {Option) CanadaCombination light switch /Combination light switch ICombination light switchCombination light switchUnder-dash fuse/relay box (C913)

Under-dash fuse/relay box (C916)

Underdash fuse/relay box (C917)

Under-dash fuse/relay box (C923)

Under-dash fuse/relay box (C924) |Under-dash fuse/relay box {C918) I OptionalSecurity system (Option) CanadaSecurity system (Optionl CanadaPGM-Fl main relayStarter cut relay ] M,.fRear window defogger relay IIntegrated control unitSecurity system (Option) CanadaHorn relay

Dashboard wire harness (C553)

Dashboard wire harness {C553) | -2

Parking pin switch I A,"ISecondary HO2S

Cable reel

Afi

I Atr

lf[

unit ] Canadaunit I Canada

16

14

20

't2

ti

I'

li

ll

li

+4

3

G401 Behind teft kick panelBody ground, via main wire harness*1: RS+2: Except RS

23-26

Page 1118 of 1681

l'

i'l

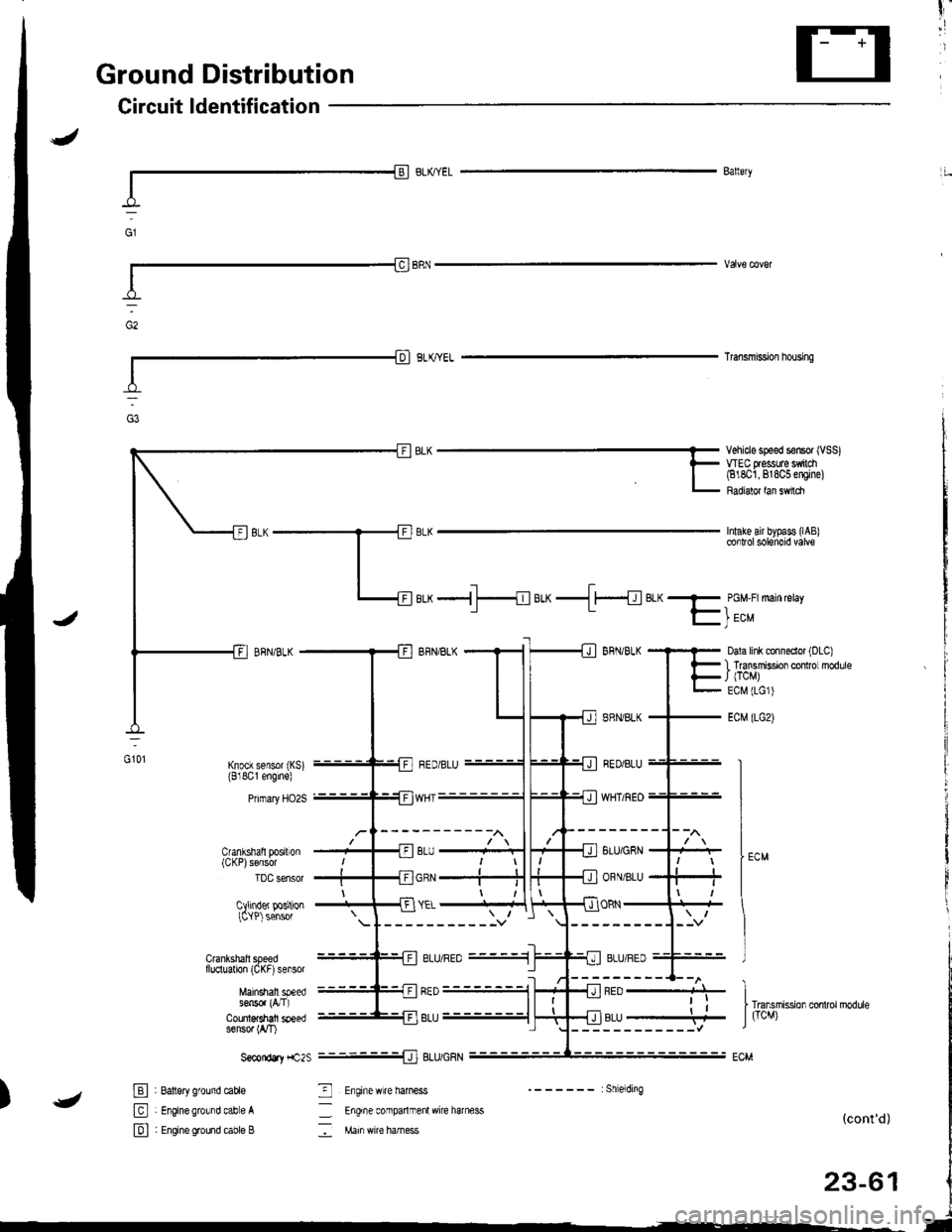

Ground Distribution

Circuit ldentification

I-l

Ballery

Transmi9slon housing

Intake air bypass (lAB

Vehicle speed sensor (VSS)WEC flessuae $ilch(818O1,818C5 engine)

Radialor lan sMch

Cranlshatl posrton(CKP)sensor

luu sensor

Cllinder positionICYP) sensor

d:

aLx -{ f---{eLx-.ll{el<- PGM-F:main retay

f- | ec"

Dala link clnneclor (DLC)

I lransmissDn cor ro modlleJ (TCM)

ECM (LG1)

ECM (LGz)

GOl

--------1--l\

8LU/GRN

ORN/BLU

vYflt/tlEU--

ORN

---------J--v

"J)

-{ neo ----+J-

------------l

.i

rr"n.rit ion *t,o,.oarb

J ficM)r,u----4

-------:Shielding

_ Engife conparlmenl wire harness

: Main wi€ harness(cont'd)

23-61

Crankshall speedf luclualion (CKF) sensor

Mainshall speeds6n5o. (a'I)

Counl$shafi speedsensor (rVT)

S€condtY f1c2s

E : Batlsry ground cable

El : Enginegrowd cabe A

E I Engineground cable B

_J] ELU/UHN

3 Enginewire haness

ELU/hEU_.1

I

Page 1134 of 1681

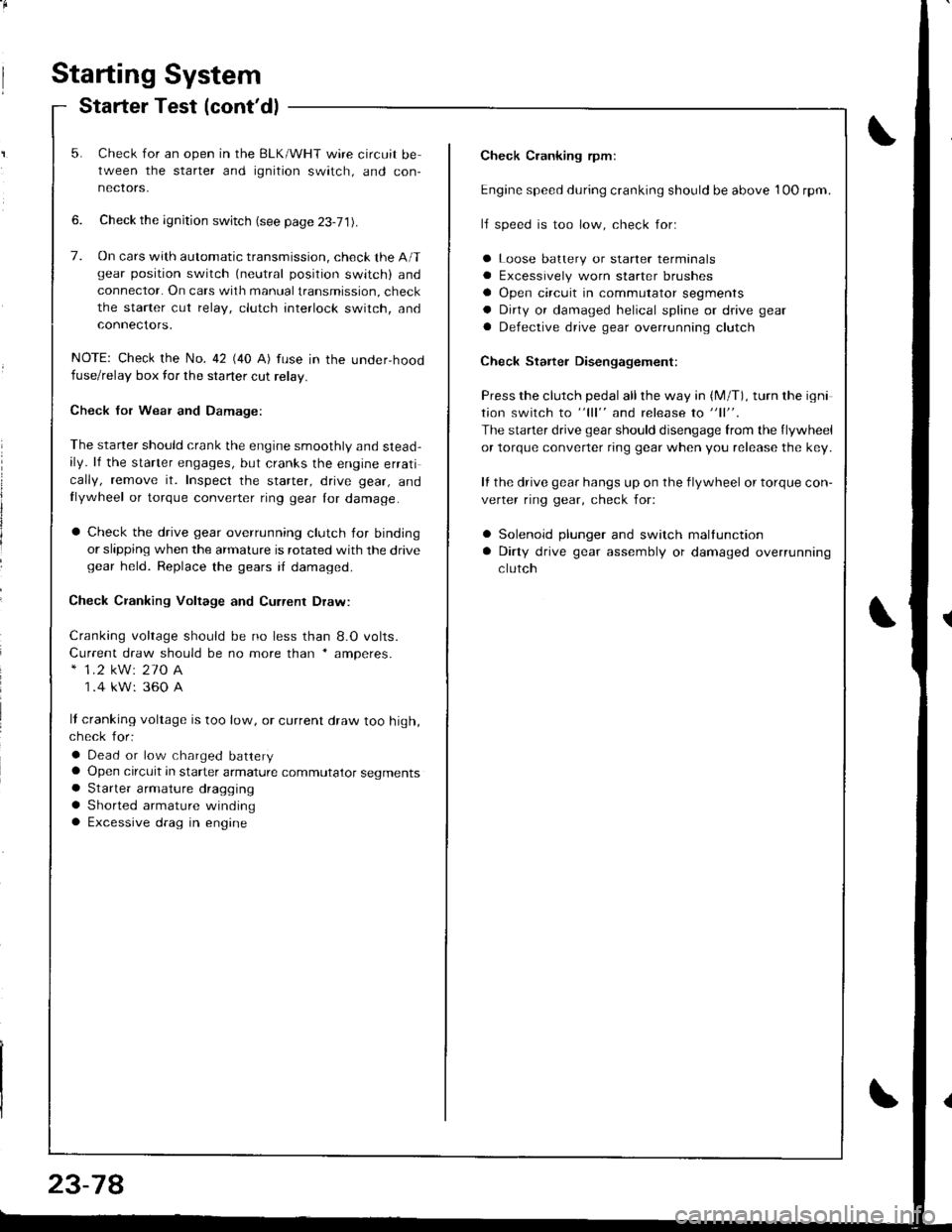

Ch6ck Starter Engag€mont;

1. Remove the No. 44 (15 A) fuse from the under-hood

fuse/relay box,

Press the clutch pedal all the way in (M/T), and turn

the ignition switch to "St8rt". The staner should

crank the engine,

NOTE: On cars equipped with manual transmission,

the engine will not crank unless the clutch pedal is

fully depressed.

lf the starter does not crank the engine, go to step 3.

Check the battery, battery positive cable, ground,

and the wire connections for looseness and cor-

rosion.

Test again. lf the stsner stilldoes not crank the en-

gine, go to step 4.

Bypass the ignition switch circuit as follows {make

sure the transmission is in neutral)

Unplug the connector (BLKMHT wire and solenoid

terminal) trom the staner. Then connect a jumper

wire from the batterv positive (+ ) terminal to the

solenoid terminal. The starter should crank the

engine.

a It the stsrter still does not crank the engine,

replace it and diagnose its internal problems,

a lf the starter cranks the engine. go to step 5.

(cont'd)

4.

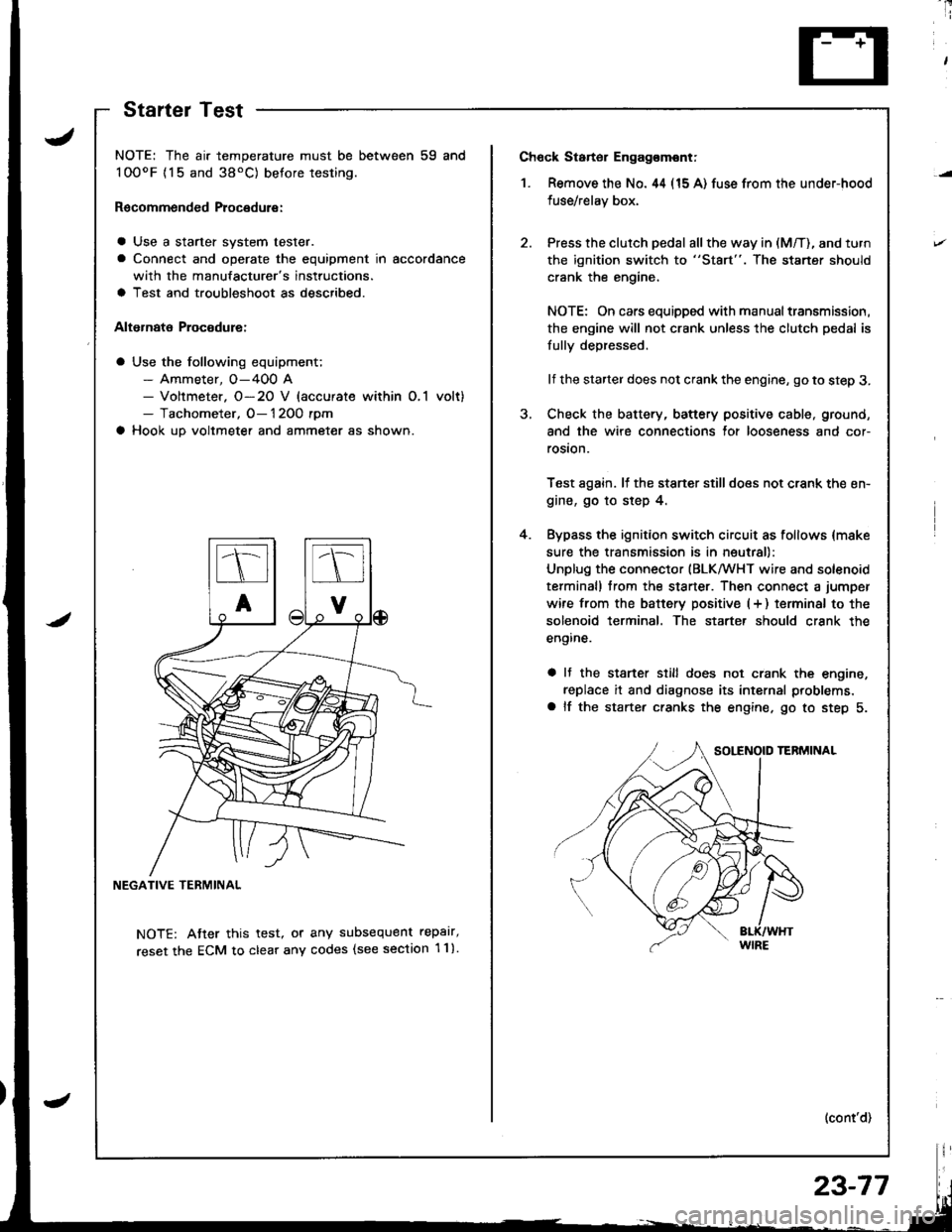

NOTE: The air temperature must be between 59 and

100oF {15 and 38'C) betore testing.

Recommended Procedure:

a Use a starter system tester.

a Connect and operate the equipment in accordance

with the manufacturer's instructions.

a Test and troubleshoot as described.

Alternate Procodure:

a Use the following equipment;- Ammeter, O-400 A- Voltmeter. O-20 V (accurate within O,1 volt)- Tachometer, O- 1 2OO rpm

a Hook up voltmeter and ammeter as shown.

NEGATIVE TERMINAL

NOTE: Atter this test, or any subsequent repalr,

reset the ECM to clear any codes (see section 1 1).

StartelTest

23-77

Page 1135 of 1681

Starting System

Starter Test (cont'dl

Check Cranking rpmr

Engine speed during cranking should be above 1OO rpm.

lJ speed is too low, check for:

a Loose batlery or starter terminals

a Excessively worn starter brushes

a Open circuit in commutator segments

a Dirty or damaged helical spline or drive gear

a Defective drive gear overrunning clutch

Check Starter Disengagement:

Press the clutch pedal all the way in (M/T), turn rhe igni

tion switch to "lll" and release to "11".

The starter drive gear should disengage from the flywheel

or torque converter ring gear when you release the key.

It the drive gear hangs up on the flywheel or torque con-

verter ring gear, check for:

a Solenoid plunger and switch mallunction

a Dirty drive gear assembly or damaged overrunning

clutch

5. Check for an open in the BLK/WHT wire circuit be

tween the starter and ignition switch, and con-

necrors,

6. Check the ignition switch (see page 23-71).

7. On cars with automatic transmission, check the A/Tgear position switch (neutral position switch) and

connector. On cars with manualtransmission, check

the starter cut relay, clutch interlock switch, and

connectors.

NOTE: Check the No. 42 (40 A) fuse in the under,hoodfuse/relay box for the starter cut relay.

Check Jor Wear and Damage:

The starter should crank the engine smoothly and stead,ily. lf the starter engages, but cranks the engine errati

cally, remove it. Inspect the starter, drive gear, andllywheel or torque converter ring gear lor damage.

a Check the drive gear overrunning clutch for binding

or slipping when the armature is rotated with the drivegear held. Replace the gears i{ damaged.

Check CJanking Voltage and Current Draw:

Cranking voltage should be no less than 8.O volts.

Current draw should be no more than * amperes.* 1.2 kW: 27O A

1 .4 kW: 360 A

It cranking voltage is too low, or current draw too high,check for:

a Dead or low charged batterya Open circuit in starter armature commutator segmentsa Starter armalure dragging

a Shorted armature windinga Excessive drag in engine

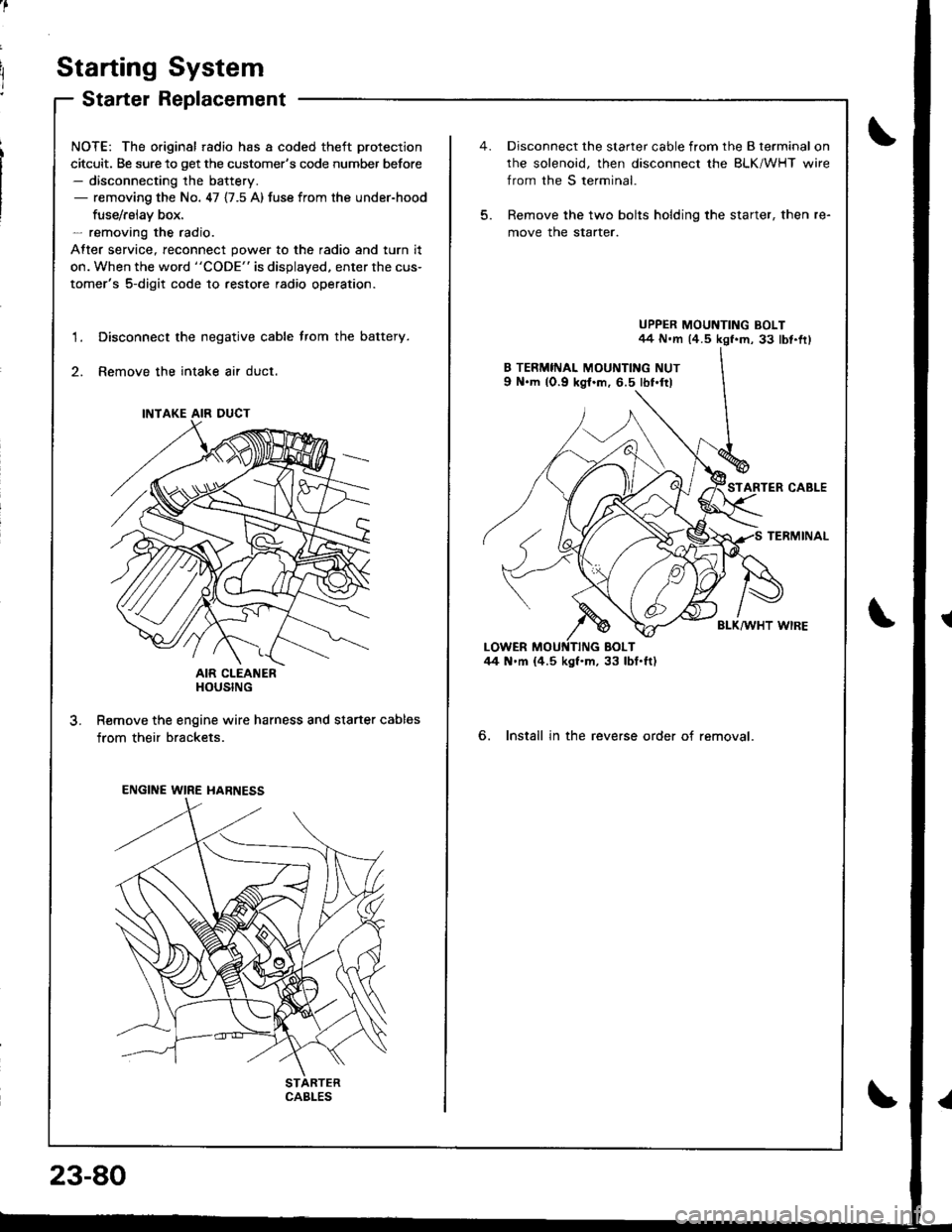

Page 1137 of 1681

Starting System

Starter Replacement

NOTE: The original radio has a coded theft protection

citcuit. Be sure to get the customer's code number before- disconnecting the battery.- removing the No. 47 {7.5 A) fuse from the under-hood

fuse/rslav box.- removing the radio.

After service, reconnect power to the radio and turn it

on. When the word "CODE" is displayed. enter the cus-

tomer's 5-digit code to restore radio operation.

Disconnect the negative cable trom the battery.

Remove the intake air duct.

AIR CLEANERHOUSING

R€move the engine wire harness and starter cables

from their brackets.

1.

3.

INTAKE AIR DUCT

ENGINE WIRE HARNESS

CABLES

23-80

5.

Disconnect the starter cable from the B terminal on

rhe solenoid, then disconnect the BLK/WHT wire

from the S terminal.

Remove the two bolts holding the starter, then re-

move the starter.

UPPER MOUNTING BOLT44 N.m (4.5 kgf.m, 33 lbt.fr)

STARTER CABLE

TERMINAL

BLK/WHT WIRE

6. Install in the reverse order of removal.

Page 1155 of 1681

lgnition System

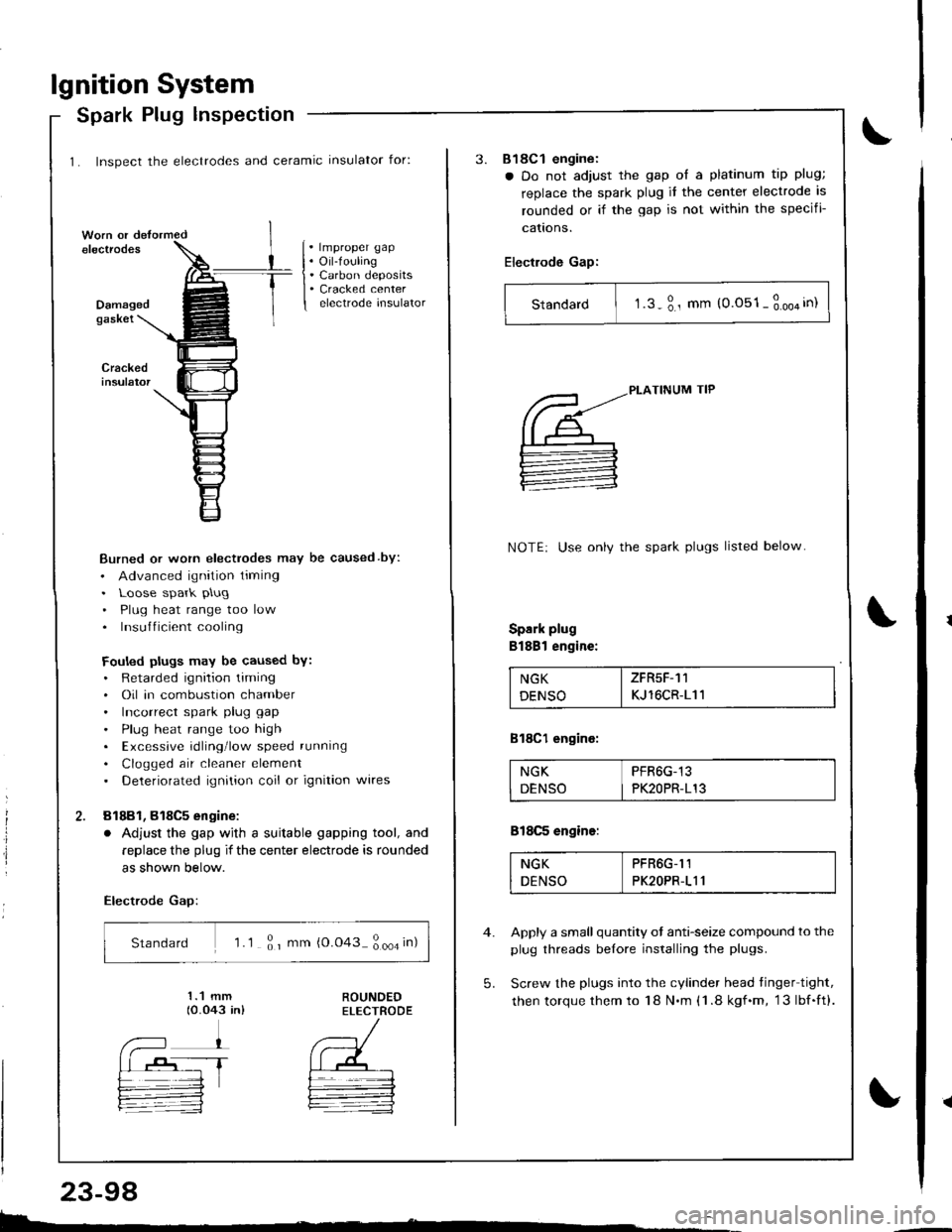

1. Inspect the electrodes and ceramic insulator for:

Spark Plug lnspection

. lmproper gap. Oil-fouling. Carbon deposits. Cracked centerelectrode insulatorDamagedgaskei

Burned or worn electrodes may be caused by:

. Advanced ignition timing. Loose spark plug

. Plug heat range too low. Insufficient cooling

Fouled plugs may be caused bY:. Retarded ignition liming. Oil in combustion chamber. Incorrect spark plug gap

. Plug heat range too high. Excessive rdling'low speed running

. Clogged air cleaner element. Deteriorated ignition coil or ignition wires

81881, 818C5 engine:

. Adjust the gap wjth a suitable gapping tool, and

replace the plug if the center electrode is rounded

as shown below.

Electrode Gap:

Standard 'l .1 ; r mm {0.043 ; ooa in)

E.

23-98

3.818C1 engine:

a Do not adjust the gap ol a platinum tip plug;

replace the spark plug it the center electrode is

rounded or if the gap is not within the specifi-

cattons.

Electrode Gap:

Standard I t.s-3., mm (0.051-3.oo4in)

5.

PLATINUM TIP

NOTE: Use onlv the spark plugs listed below

Spark plug

Bl88l engine:

NGK I ZFR5F-11

DENSO I KJ 16CR-111

818C1 engine:

NGK PFR6G-13

DENSO I PK2OPR-113

818C5 engine:

NGK PFR6G-I1

DENSO PK2OPR-111

Apply a small quantity ot anti-seize compound to the

plug threads belore installing the plugs.

Screw the plugs into the cylinder head tinger tight,

then torque them to 18 N.m (1 .8 kgf.m, 13lbf.ft).

Page 1159 of 1681

Charging System

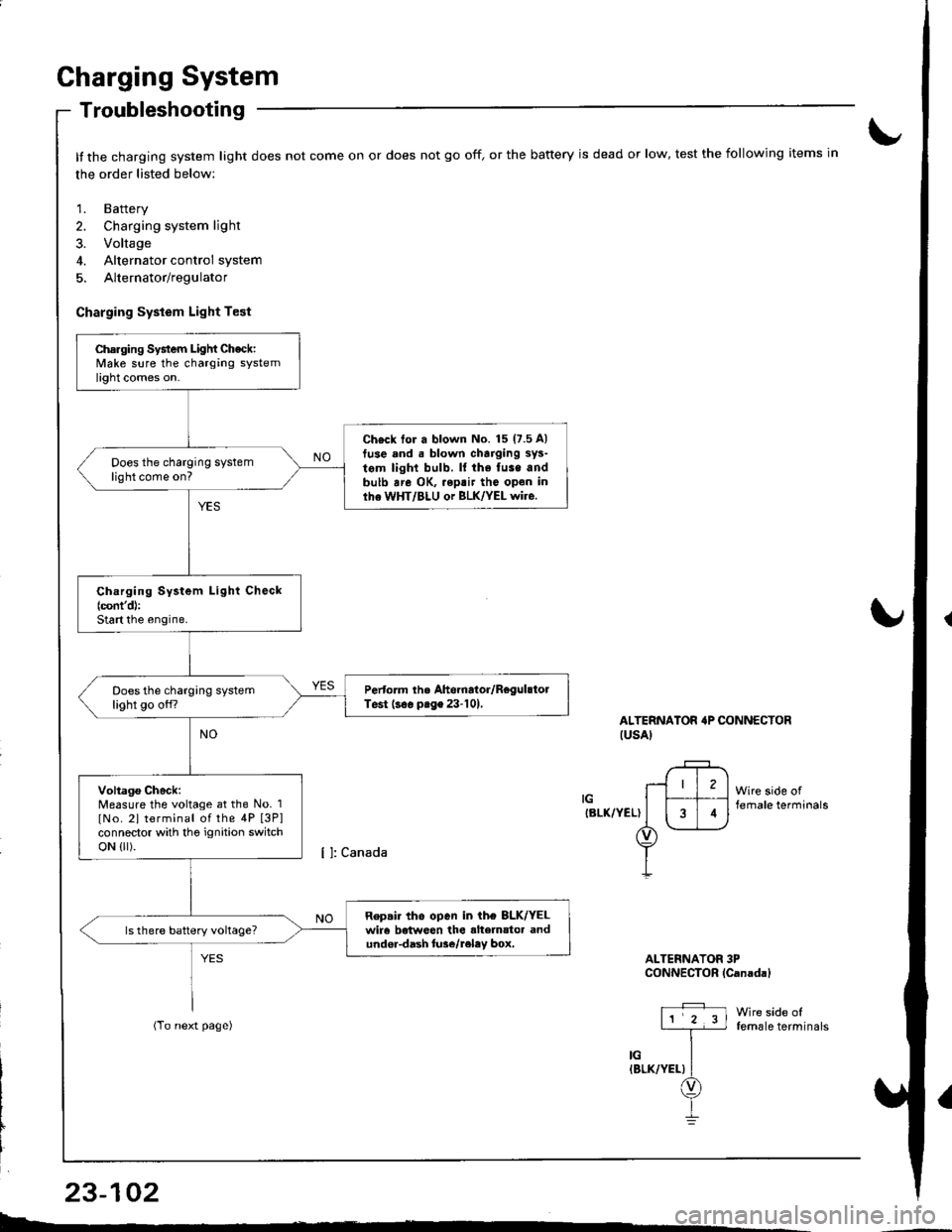

Troubleshooting

It the charging system light does not come on or does not go off, or the battery is dead or low, test the following items in

the order listed below:

1. Battery

2. Charging system light

3. Voltage

4. Alternator control system

5. Alternator/regulator

Charging System Light Test

ALTERNATOR'P CONNECTORIUSAI

IGIBLK/YEL)

Wire side offemale terminals

Wire side offemale terminals

ALTERNATOR 3PCONNECTOR lCanadal

Charging System Light Check:Make sure the charging systemlight comes on.

Ch€ck tor a blown No. 15 (7.5 A)

tuse and . blown charging sys-

tem light bulb. ll the fuse andbulb are OK, .eptir tho open inlhe WHT/BLU or BLK/YEL wire.

Does the charging systemlight come on?

Ch.rging System Light Check(cont'd):

Start the engine.

Pertorm the Ahernator/RegulstolTest (s€. prge 23-101,Does the charging systemlight go off?

Voltago Check:Measure the voltage at the No. 1

lNo. 2l terminal of the 4P [3P]connector with tho ignition switchoN {lr).

Repair tho open in ih€ 8LK/YELwir6 betweon the alte]nator andundor-dash lure/reley box.

I4

L-*

23-102