Timing HONDA INTEGRA 1998 4.G Owner's Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 1058 of 1681

J

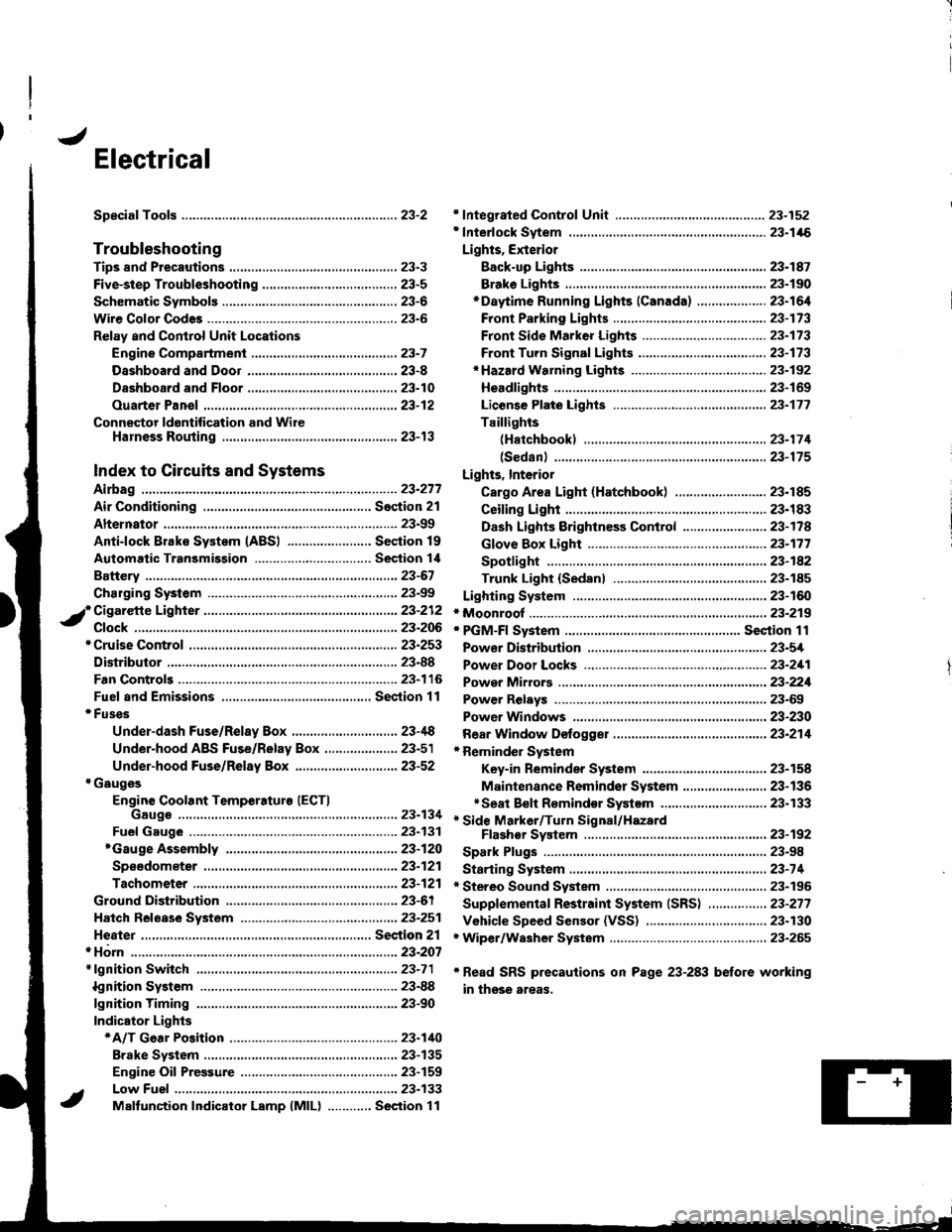

Electrical

Speciaf Toofs ..........................23-2

Troubleshooting

Tips 8nd Precautions .......................,..,.,.,.,.,......,..., 23-3

Five-step Troubleshooting ............,......,.,.,...,..,....., 23-5

Schsmatic Svmbols ...............23-6

Wire Color Code3 .. ................. 23-6

Relay and Control Unit Locations

Engine Compartment ......,.,.................,.,.,.,.,.,,,, 23-7

Dashboard and Door .........,...........,.....,.,....,.,.... 23-8

Dashboard and Floor ......................................... 23-10

Ouarter Pan€f .,,.,...,.,..,...,,,23-12

Connector ldontification and WireHarness Routing ......,.,......23-'13

Index to Circuits and Systems

Airbag

* Integrated Control Unit .....,.,.,.....23-152* Interlock Sytem .,...,.,...........,. 23.146

Lights, Exterior

Eack-up LighB ..................23.187

Brake Ligh$ ......................23-190*Daytime Running Lights (Canada) ................... 23"164

Front Parking Lights .......................................... 23-173

Front Side Marker Lights .................................. 23-173

Front Turn Signal Lights ..................-.......,...,.,. 23-173* Hazard Warning Lights ....................,........,....... 23-192

Headlights.....23-169

23-253 powerDistribution..................... 23-5/r

Air Conditioning.....,....... Soction 21

Alternator ..........,................... 23.99

iCigarette Lighter .........23-212

*Cruise Control

Distributor

'.'.,.'.'.,.'...,,,,.,''.'.,.',.'''.' 23.277

.............................. 23.88

................... 23-90lgnition Timing ......

Indicator Lights

Key-in Reminder System

Maintenance Reminder System*Seat Belt R€mindor System .,...........................* Side Marker/Turn Signal/HazardFlashcr Svstem .................23-192

Spark Plugs ............................23-98

Starting System .....................23-74* Stereo Sound System ...,......,..........,...,......,.,.,.,..,., 23-196

Supplemental Restraint System (SRS) ................ 23-277

Vshicle Speed Sensor (VSS) ................................. 23.130r Wiper/Washer System .........................................., 23-265

*Read SRS precautions on Psge 23-283 before working

in those areas,

23-154

23.136

23"133

Page 1155 of 1681

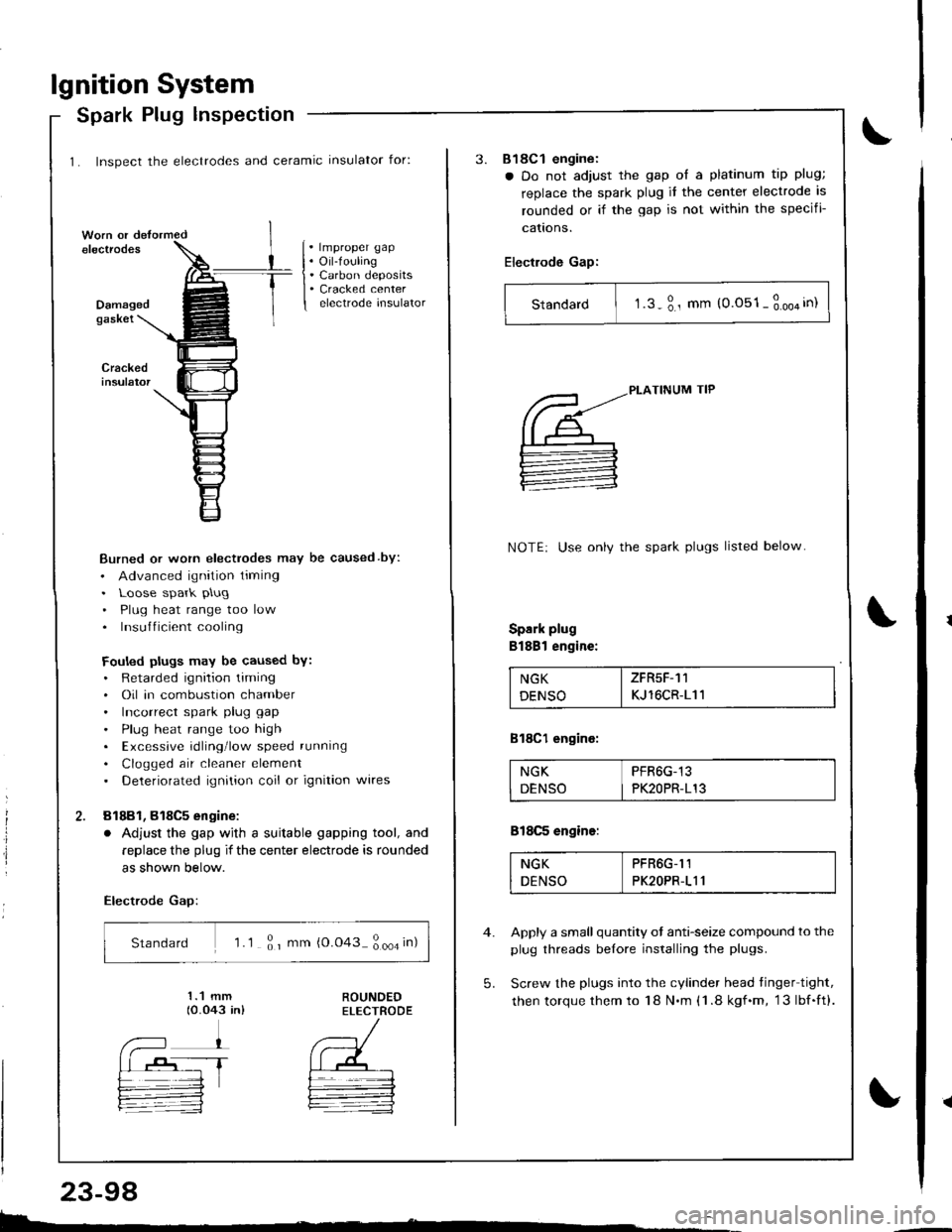

lgnition System

1. Inspect the electrodes and ceramic insulator for:

Spark Plug lnspection

. lmproper gap. Oil-fouling. Carbon deposits. Cracked centerelectrode insulatorDamagedgaskei

Burned or worn electrodes may be caused by:

. Advanced ignition timing. Loose spark plug

. Plug heat range too low. Insufficient cooling

Fouled plugs may be caused bY:. Retarded ignition liming. Oil in combustion chamber. Incorrect spark plug gap

. Plug heat range too high. Excessive rdling'low speed running

. Clogged air cleaner element. Deteriorated ignition coil or ignition wires

81881, 818C5 engine:

. Adjust the gap wjth a suitable gapping tool, and

replace the plug if the center electrode is rounded

as shown below.

Electrode Gap:

Standard 'l .1 ; r mm {0.043 ; ooa in)

E.

23-98

3.818C1 engine:

a Do not adjust the gap ol a platinum tip plug;

replace the spark plug it the center electrode is

rounded or if the gap is not within the specifi-

cattons.

Electrode Gap:

Standard I t.s-3., mm (0.051-3.oo4in)

5.

PLATINUM TIP

NOTE: Use onlv the spark plugs listed below

Spark plug

Bl88l engine:

NGK I ZFR5F-11

DENSO I KJ 16CR-111

818C1 engine:

NGK PFR6G-13

DENSO I PK2OPR-113

818C5 engine:

NGK PFR6G-I1

DENSO PK2OPR-111

Apply a small quantity ot anti-seize compound to the

plug threads belore installing the plugs.

Screw the plugs into the cylinder head tinger tight,

then torque them to 18 N.m (1 .8 kgf.m, 13lbf.ft).

Page 1642 of 1681

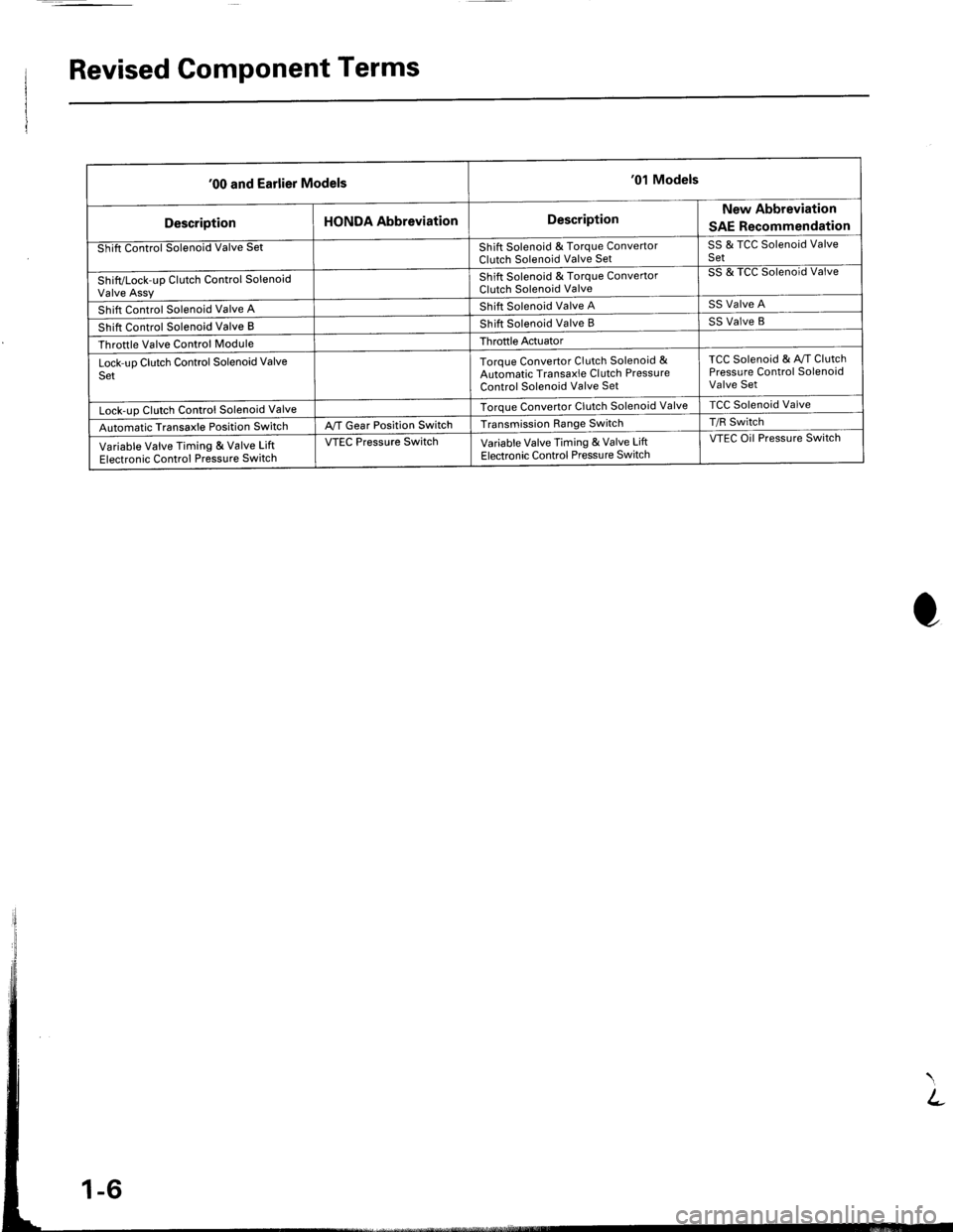

Revised Component Terms

'00 and Earlier Models'01 Models

DescriptionHONDA AbbreviationDescriptionNew Abbreviation

SAE Recommendation

Shift Control Solenoid Valve SetShift Solenoid & Torque ConvertorClutch Solenoid Valve SetSS & TCC Solenoid ValveSet

Shift/Lock-up Clutch Control SolenoidValve Assy

Shift Solenoid & Torque ConvertorClutch Solenoid Valve

SS & TCC Solenoid Valve

Shift Control Solenoid Valve AShift Solenoid Valve ASS Valve A

Shift Control Solenoid Valve BShift Solenoid Valve BSS Valve B

Throttle Valve Control ModuleThroftle Actuator

Lock-uo Clutch Control Solenoid ValveSetToroue Convertor Clutch Solenoid &Automatic Transaxle Cl utch PressureControl Solenoid Valve Set

TCC Solenoid & Av/T ClutchPressure Control SolenoidValve Set

Lock-uo Clutch Control Solenoid ValveTorque Convertor Clutch Solenoid ValveTCC Solenoid Valve

Automatic Transaxle Position SwitchA,/T Gear Position SwitchTransmission Range SwitchT/R Switch

Variable Valve Timing & Valve LiftElectronic Control Pressure Switch

VTEC Pressure SwitchVariable Valve Timing & Valve LiftElectronic Control Pressu re Switch

VTEC Oil Pressure Switch

Page 1654 of 1681

MFASIIREMENTSTANDARD (NEW}

Wire Dia.o.D.Free LengthNo. of Goils

SpringsRegulator valve spring ARegulator valve spring BStator reaction sPringModulator valve springTorque converter check valve springCooler relief valve springRelief valve spring2nd orifice control valve spring1-2 shift valve spring2-3 shift valve spring3-4 shift valve spring1st accumulator spring4th accumulator spring B4th accumulator spring A2nd accumulator spring A3rd accumulator spring A2nd accumulator spring B3rd accumulator spring B3rd sub accumulator spring2nd accumulator spring CLock-up shift valve springLock-up timing valve springLock-up control valve spring3-4 orifice control valve springServo control valve springCPB valve spring4th exhaust valve spring

1.8 (0.071)

1.8 (0.071)

4.5 rc.177].1.4 (0.05s)

1.2 10.047l.1.0 (0.039)

1.1 (0.043)

0.7 (0.0281

0.9 (0.035)

0.9 (0.035)

0.9 (0.035)

2.1 (0.083)

2.3 (0.091)

2.6 (0.102)

2.4 (0.094)

2.8 (0.110)

1.6 (0.063)

2.1 (0.083)

2.7 (0.106)

2.2 l0.o87l0.9 (0.035)

0.9 (0.035)

0.7 (0.028)

0.6 (0.024)

1.0 (0.039)

0.9 (0.0351

0.9 (0.035)

14.7 (0.5791

9.6 (0.378)

35.4 (1 .394)9.4 (0.370)

8.4 (0.331)

8.4 (0.331)

8.6 (0.339)

6.6 (0.260)

7.6 (0.299)

7.6 (0.299)

7.6 (0.299)

16.0 (0.630)

10.2 rc.402117.0 (0.669)

29.0 11.142117.5 (0.689)

9.0 (0.354)

31.0 (1 .220)17.0 (0.669)

14.5 (0.571)

7.6 (0.299)

8.1 (0.319)

6.6 (0.260)

6.6 (0.260)

8.1 (0.319)

8.1 (0.319)

6.1 (0.240)

87.8 (3.457)

44.0 (1.732\

30.3 (1.193)

35.0 (1.378)

32.4 (1.2761.

33.8 (1.331)

37.1 (1.461)

34.8 (1.370)

41.3 (1.626)

57.0 12.244157.0 12.244].89.1 (3.508)

s1.6 (2.0311

88.4 (3.480)

39.0 (1 .53s)94.3 (3.713)

20.7 (0.815)

38.2 (1.504)

39.0 (1.535)

68.0 (2.677)

73.7 (2.9021

81.4 (3.205)

38.0 (1.496)

37.9 (1.492)

52.1 (2.0511

47.2 (1 .858)36.4 (1.433)

16.51 1.01.910.912.78.213.422.01A ?

26.826.8't6.2

13.814.2z.J15.9o. l2.66.313.932.O47.814.1?1 A

20.8ttJ.JI v.5

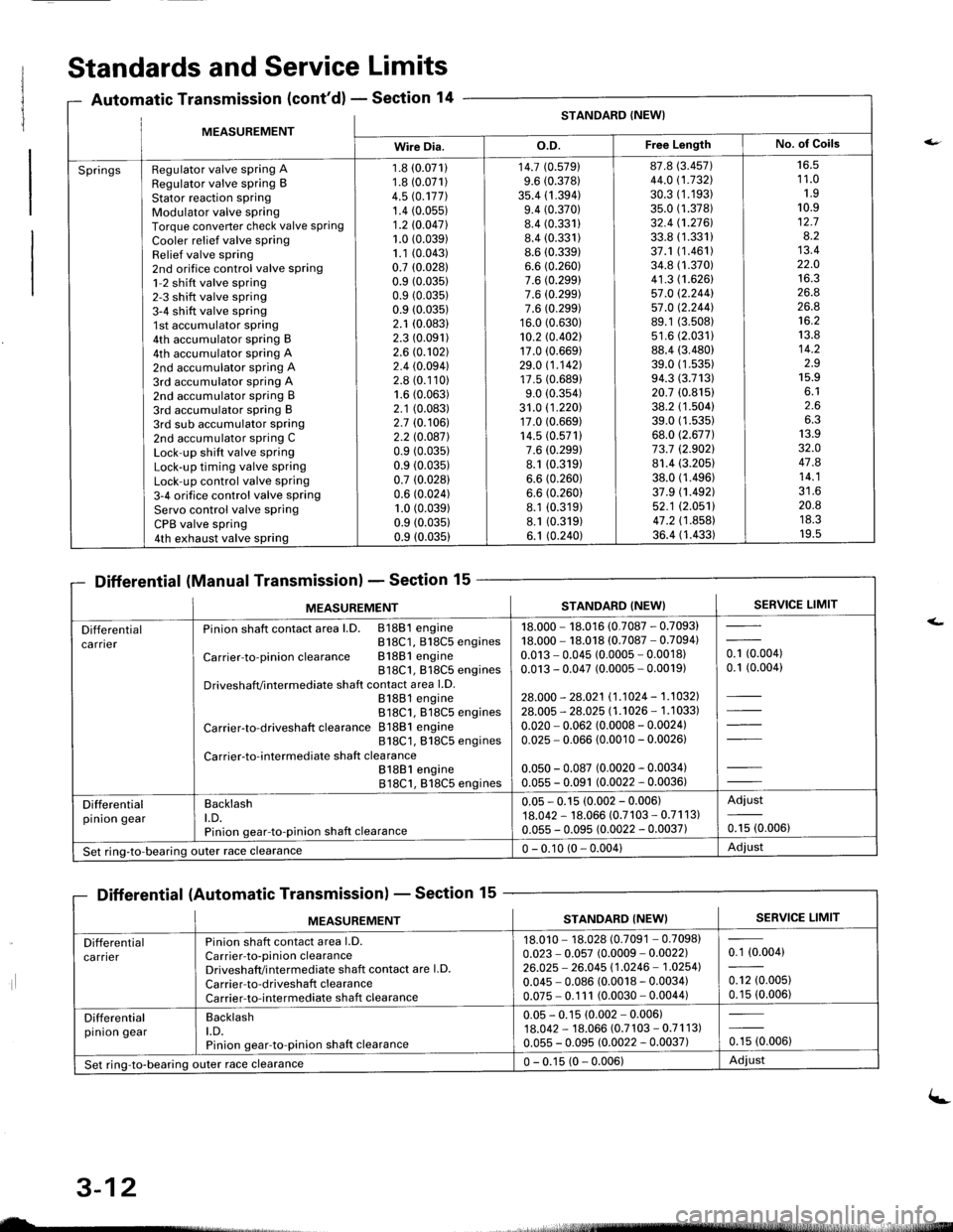

Standards and Service Limits

Automatic Transmission (cont'd) - Section 14

Differential (Manual Transmission) - Section 15

Differential (Automatic Transmission) - Section 15

ilt5stlrrr, - 4,

MEASUREMENTSTANDARD (NEW}SERVICE LIMIT

Differentialca rnerPinion shaft contact area l.D. 81881 engineB18C1, 818C5 engines

Carrier-to-pinionclearance Bl88lengine818C1, 818C5 enginesDriveshafVintermediate shaft contact area l.D.81881 engine818C1. 818C5 engines

Carrier-to-driveshaft clearance 81881 engine818C1, 818C5 engines

Carrier-to-intermediate shaft clea rance81881 engine818C1, 818C5 engines

18.000 - 18.016 (0.7087 - 0.7093)18.000 - 18.018 (0.7087 - 0.7094)0.013 - 0.045 (0.0005 - 0.0018)0.013 - 0.047 (0.0005 - 0.0019)

28.000 - 28.021 11.1024 - 1.1032].28.005 - 28.025 l1 .'�t026 - 1 .1 033)

0.020 - 0.062 (0.0008 - 0.0024)0.025 - 0.066 (0.0010 - 0.00261

0.050 - 0.087 (0.0020 - 0.0034)0.055 - 0.091 (0.0022 - 0.0036)

- toooot0.1 (0.004)

Differentialpinion gearBacklasht.D.Pinion gear-to-pinion shaft clearance

0.05 - 0.15 (0.002 - 0.006)18.042 - 18.066 (0.7103 - 0.71 1 3)0.055 - 0.095 (0.0022 - 0.0037)

Adjust

0.15 (0.006)

Set ring-to-bearing)uter race clearance0 - 0.10 (0 - 0.004)Adjust

nsmlssaonl - Sectton

MEASUREMENTSERVICE LIMITSTANDARD (NEW}

Differentialca rrierPinion shaft contact area l.D.Carrier-to-pinion clearanceDriveshaft/i ntermediate shaft contact are l.D.

Carrier-to-driveshaft clearanceCarrier-to-intermediate shaft clearance

18.010 - 18.028 (0.7091 - 0.7098)0.023 - 0.057 (0.0009 - 0.0022)26.025 - 26.045 11.0246 - 1.02541

0.045 - 0.086 (0.0018 - 0.0034)0.075 - 0.1 11 (0.0030 - 0.0044)

0.1 (0.004)

0.12 (0.005)

0.15 (0.006)

Differentialpinion gearBacklasht.D.Pinion gear-to-pinion shaft clearance

0.05 - 0.15 (0.002 - 0.006)18.042 - 18.066 (0.7 103 - 0.71 1 3)0.055 - 0.095 (0.0022 - 0.0037)0.15 (0.006)

Set ring-to-bearing outer race clearance0 - 0.15 (0 - 0.006)Adiust

uL-

3-12

(-

Page 1656 of 1681

ng

MEASUREMENTSTANDARD {NEW}

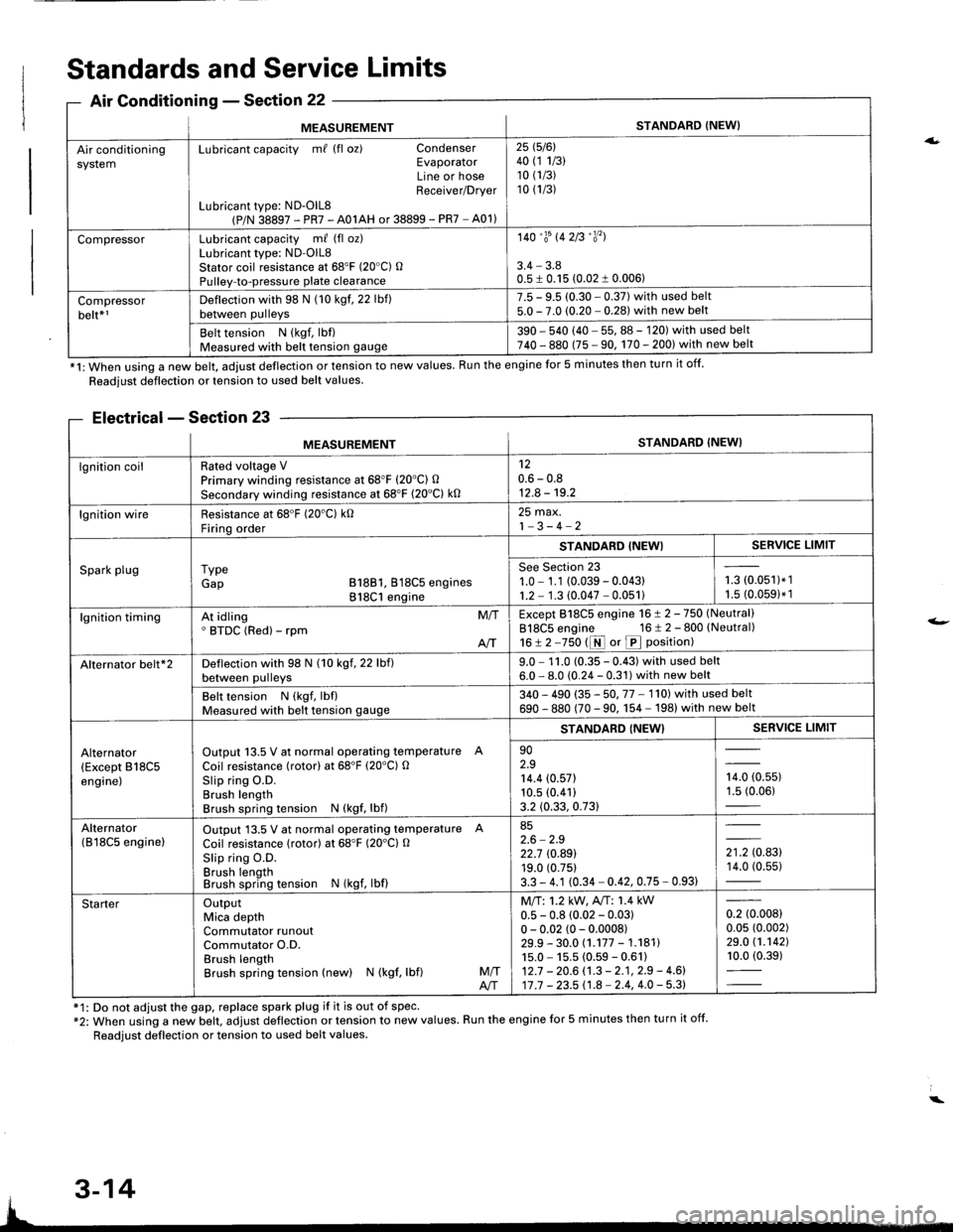

Air conditioningsystemLubricant capacity m/ (fl oz) CondenserEvaporatorLine or hoseReceiver/Drver

Lubricant type: ND-OlL8(P/N 38897 - PR7 - A01AH or 38899 - PR7 - A01)

25 1516l40 (1 1/3)10 (1/3)

10 (1/3)

CompressorLubricant capacity m/ (fl oz)Lubricant type: ND-OlL8Stator coil resistance at 68'F (20"C) OPulley-to-pressure plate clearance

140'�trs 142B'�y'�l

3.4 - 3.80.5 I 0.15 (0.02 1 0.006)

Compressorbelt*rDeflection with 98 N (10 kgf. 22 lbf)between pulleys

7.5 - 9.5 (0.30 - 0.37) with used belt5.0 - 7.0 (0.20 - 0.281 with new belt

Belt tension N (kgf, lbf)Measured with belt tension gauge390 - 540 (40 - 55, 88 - 120) with used belt740 - 880 (75 - 90, 170 - 200) with new belt

*1: When using a new belt, adjust deflection or tension to new values. Run the engine for 5 minutes then turn it off.

Standards and Service Limits

Air Conditionins - Section 22

Readjust deflection or tension to used belt values.

Electrical - Section 23

f1: Do not adjust the gap, replace spark plug if it is out of spec'*2: When using a new belt. adjust deflection or tension to new values. Run the engine for 5 minutes then turn it off.

Readjust deflection or tension to used belt values.

a.

t-

MEASUREMENTSTANDARD (NEW}

lgnition coilRated voltage VPrimary winding resistance at 68"F (20'C) O

Secondary winding resistance at 68'F (20"C) k0

120.6 - 0.812.8 - 19.2

lgnition wireResistance at 68'F (20'C) k0Firinq order

25 max.1-3-4-2

Spark plugI ypeGap B18B1, 818C5 engines818C1 engine

STANDABD {NEWISERVICE LIMIT

See Section 231.0 - 1.1 (0.039 - 0.04311.2 - 1.3 (0.047 - 0.051)i-= roru',t.',1.5 (0.0591* 1

lgnition timingAt idling' BTDC (Red) - rpmM/T

AIT

Except 818C5 engine 16 ! 2 -750 (Neutral)

818C5 engine 16 t 2 - 800 (Neutral)

16!2-750 t1r{ or p position)

Alternator belt*2Deflection with 98 N (10 kgf, 22 lbf)between pulleys9.0 - 1 1.0 (0.35 - 0.43) with used belt6.0 - 8.0 (0.24 - 0.31) with new belt

Belt tension N (kgf, lbflMeasured with belt tension gauge340 - 490 (35 - 50. 77 - 1'l0l with used belt

690 - 880 (70 - 90. 1 54 - 198) with new belt

Alternator(Except B18C5engine)

Output 13.5 V at normal operating temperature A

Coil resistance (rotor) at 68'F (20'C) OSlip ring O.D.Brush lengthBrush spring tension N (kgf, lbf)

STANDARD {NEW}SERVICE LIMIT

902.914.4 (0.571

10.5 (0.41)

3.2 (0.33, 0.73)

,0, to.uur1.5 (0.06)

Alternator(B l8C5 enginelOutput 13.5 V at normal operating temperature A

Coil resistance (rotor) at 68"F (20'Cl O

Slip ring O.D.Brush lengthBrush spring tension N (kgf, lbf)

852.6 - 2.922.7 rc.89119.0 (0.75)

3.3 - 4.1 (0.34 - 0.42, 0.75 - 0.93)

',to.tg14.0 (0.55)

StarterOutputMica depthCommutator runoutCommutator O.D.Brush lengthBrush spring tension (new) N (kgf, lbf)M/TA/T

Mll:1.2 kW, A"rT: 1.4 kW0.5 - 0.8 (0.02 - 0.03)0 - 0.02 (0 - 0.0008)29.9 - 30.0 (.177 - 1.18111s.0 - 15.5 (0.59 - 0.61)12.7 - 20.6 (.3 - 2.1, 2.9 - 4.6)17 .7 - 23.5 11.8 - 2.4, 4.0 - 5.3)

0.2 (0.008)

0.05 (0.002)

29.0 (1.1421

10.0 (0.39)

3-14