Timing HONDA INTEGRA 1998 4.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 441 of 1681

Description

Hydraulic Control (cont'd)

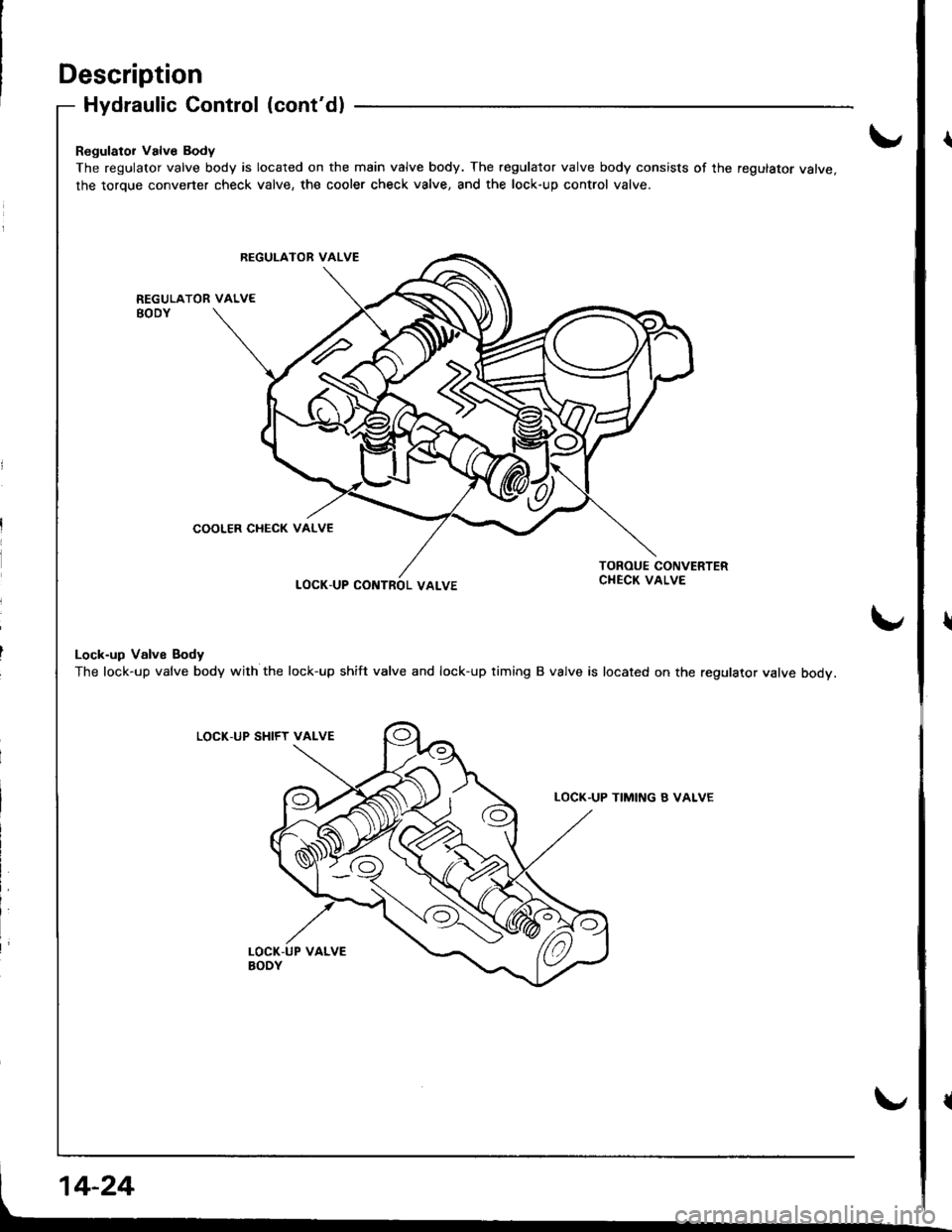

Regulator Valve Body

The regulator valve body is located on the main valve body. The regulator valve body consists of the regulator valve,

the torque converter check valve, the cooler check valve, and the lock-up control valve.

LOCK.UP CONTROL VALVE

Lock-up Valve Body

The lock-up valve body with the lock-up shift valve and lock-up timing B valve is located on the regulator valve body.

LOCK-UP SHIFY VALVE

TIMI[\'G B VALVE

REGUI-ATOR VALVE

COOLER CHECK VALVE

Page 456 of 1681

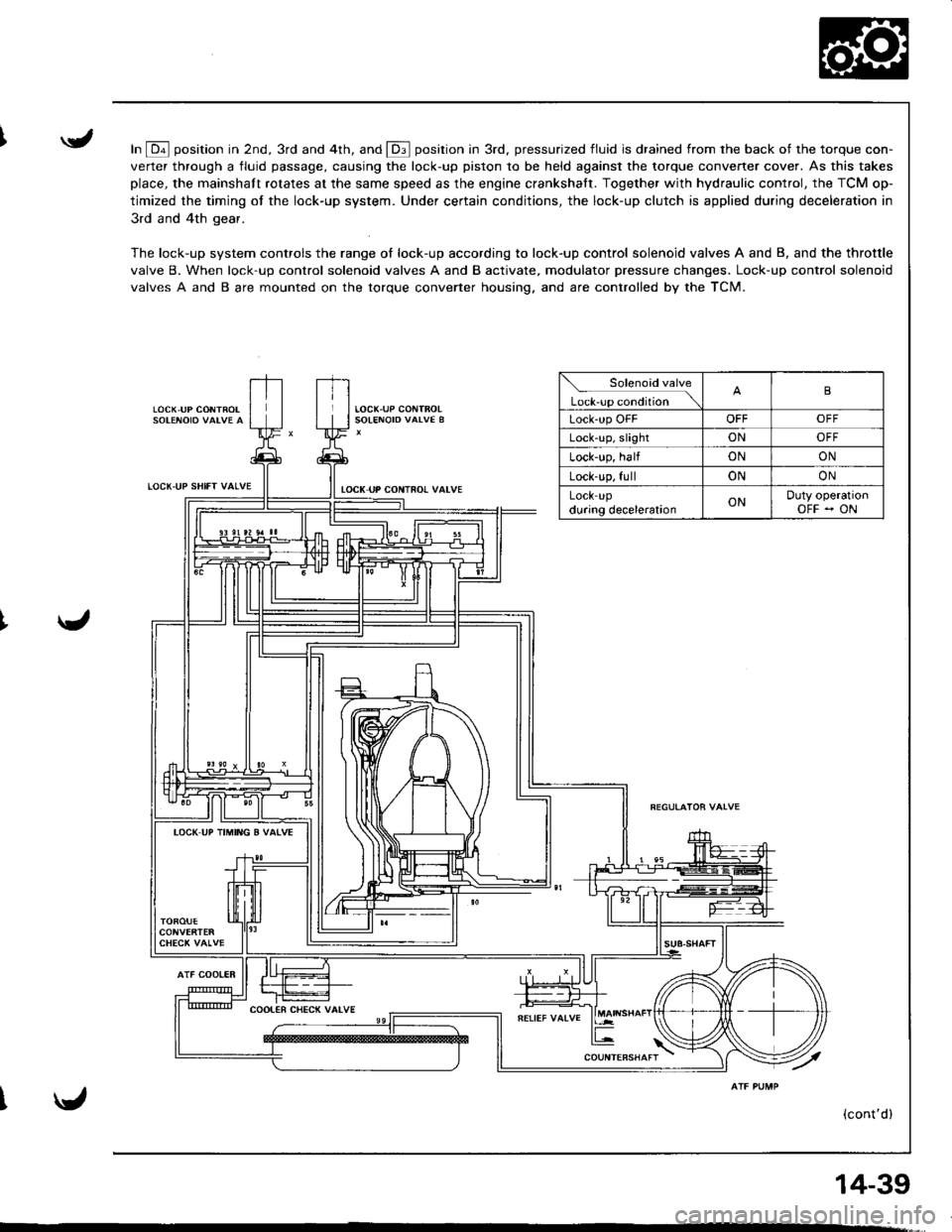

In E position in 2nd, 3rd and 4th, and E position in 3rd, pressurized fluid is drained from rhe back of the torque con-

verter through a fluid passage, causing the lock-up piston to be held against the torque converter cover. As this takes

place, the mainshaft rotates at the same speed as the engine crankshatt. Together with hydraulic control, the TCM op-

timized the timing of the lock-up system. Under certain conditions, the lock-up clutch is applied during deceleration in

3rd and 4th gear.

The lock-up system controls the range of lock-up according to lock-up control solenoid valves A and B, and the throttle

valve B. When lock-up control solenoid valves A and B activate, modulator pressure changes. Lock-up control solenoid

valves A and B are mounted on the torque converter housing. and are controlled by the TCM.

LOCK,UP CONTROL

LOCT.UP SHIfT VALVE

AlF COOIER

tocK uP coNTno! valvE

Solenoid valve

L*r""r "o.Jtio" \B

Lock'up OFFOFFOFF

Lock-up, slightONOFF

Lock-up, halfONON

Lock-up, fullONON

LOCK-Updu.ing decelerationONDuty operationOFF - ON

IOCK UP TIMING B VATVE

(cont'd)

14-39

Page 457 of 1681

Description

LOC(,UP SlllFT VATVE

Lock-up System (cont'd)

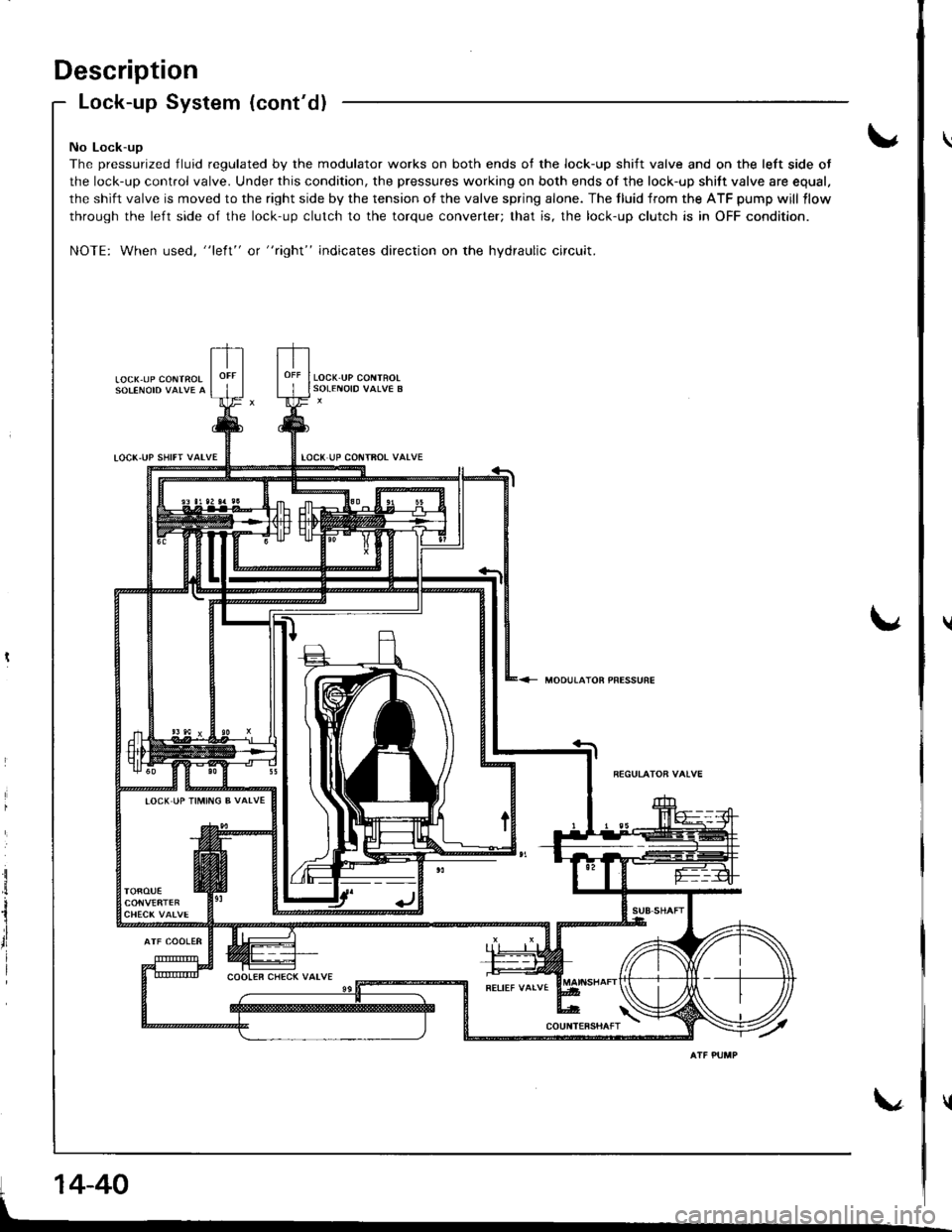

No Lock-ug

The pressurized fluid regulated by the modulator works on both ends of the lock-up shift valve and on the left side ot

the lock-up control valve. Under this condition, the pressures working on both ends of the lock-up shift valve are equal.

the shift valve is moved to the right side by the tension of the valve spring alone. The tluid from the ATF pump will llow

through the left side of the lock-up clutch to the torque converter; that is, the lock-up clutch is in OFF condition.

NOTE: When used, "left" or "right" indicates direction on the hydraulic circuit.

LOCX.UP CONTROI

LOCK.UP COITTFOT VATVE

MOOUTATOR PRESSURE

i

il

rl

I

IOCK IJP TIMING B VALVE

14-40

Page 458 of 1681

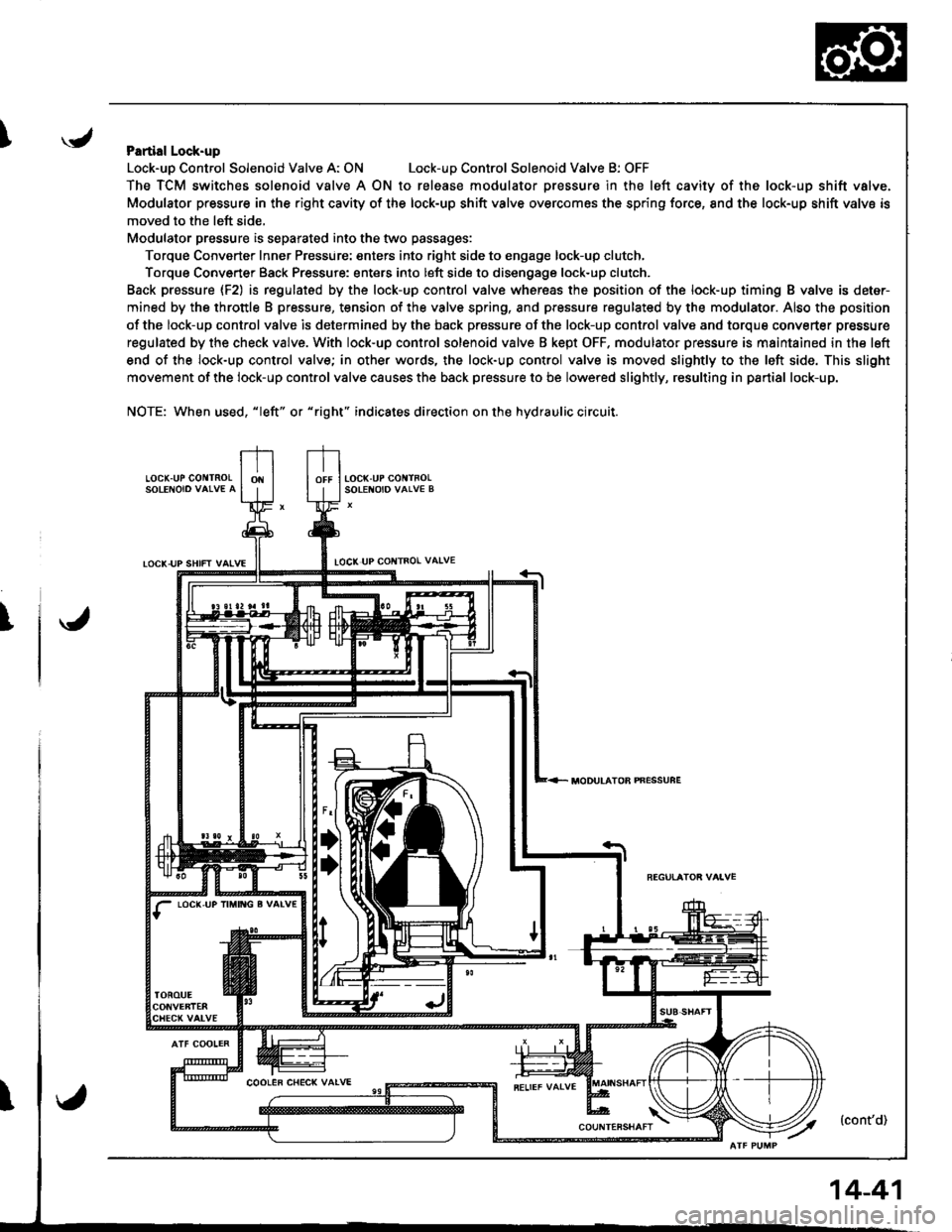

IPartial Lock-up

Lock-uo Control Solenoid Valve A: ONLock-uD Control Solenoid Valve B: OFF

The TCM switches solenoid valve A ON to release modulator Dressure in the left cavity of the lock-up shift valve.

Modulator pressure in the right cavity of the lock-up shift valve overcomes the spring force, 8nd the lock-up shift valve is

moved to the left side,

Modulator pressure is separated into the two passages:

Torque Converter Inner Pressure: enters into right side to engage lock-up clutch,

Torque Converter Back Pressure: enters into left side to disengage lock-up clutch.

Back prassure {F2) is regulated by the lock-up control valve whereas the position of the lock-up timing B valve is deter-

mined by the throttle B pressure, tension of the valve spring, and pressure regulated by the modulator. Also the position

of the lock-up control valve is determined by the back prossure of the lock-up control valve and torque converter pressure

regulated by the check valve. With lock-up control solenoid valve B kept OFF. modulator pressure is maintained in the left

end of the lock-up control valve; in other words, the lock-up control valve is moved slightly to the left side. This slight

movement of the lock-up control valve causes the back pressure to be lowered slightly, resulting in partial lock-up.

NOTE: When used, "|eft" or "right" indicates direction on the hydraulic circuit.

LOCK.UP GO TNOLSOLENOIO VAIVE A

TOCK-UP SHIFT VAIVELOCI( UP COI{TROL VAIVE

T

LOC(,UP IM TG g VALV€

MODULATOB PNESSUFE

14-41

Page 459 of 1681

Description

I,OCK UP SHIFT VALVE

Lock-up System (cont'dl

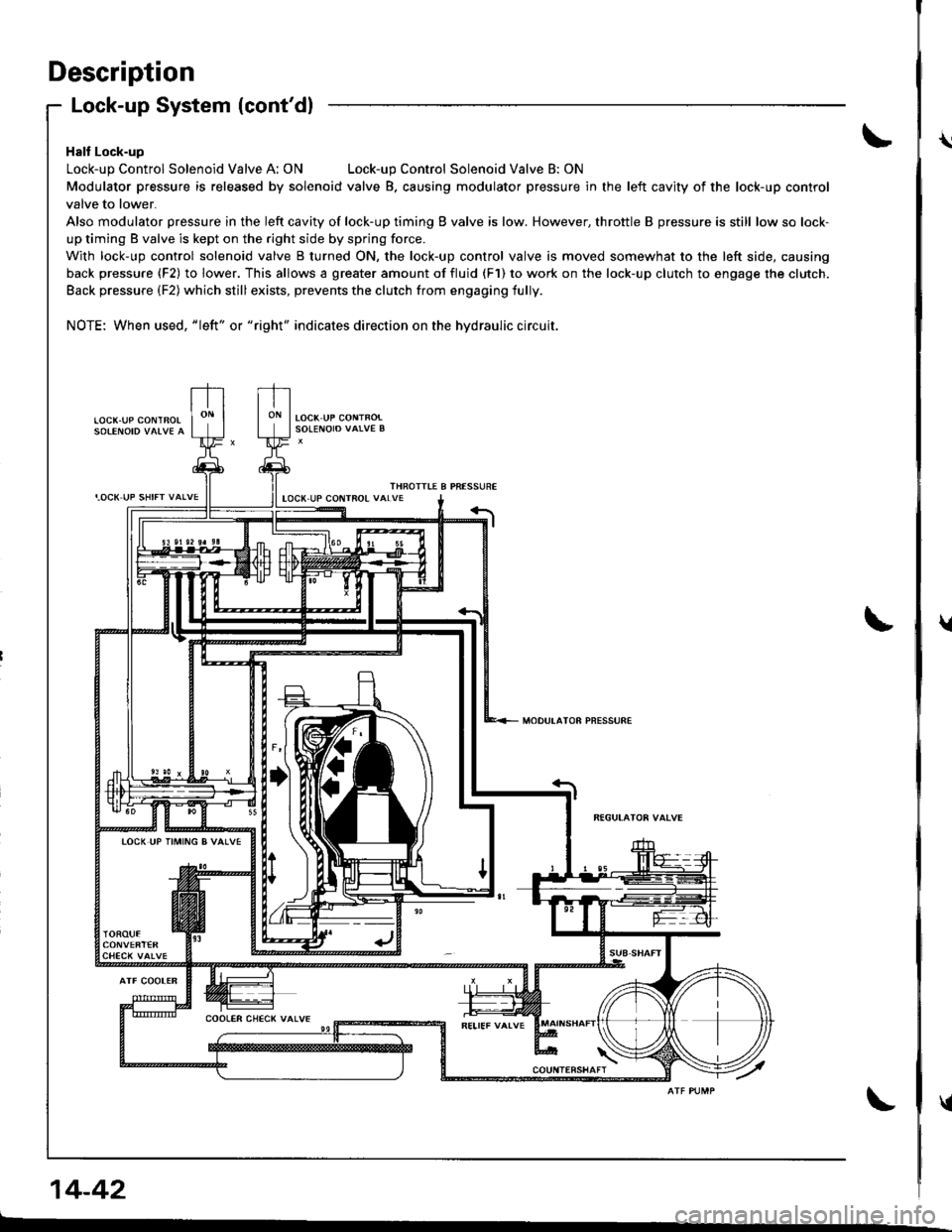

Halt Lock-up

Lock-up Control Solenoid Valve A: ONLock-up Control Solenoid Valve B: ON

Modulator pressure is released by solenoid valve B. causing modulator pressure in the left cavity of the lock-up control

valve to lower.

Also modulator pressure in the left cavity of lock-up timing B valve is low. However, throttle B pressure is still low so lock-

up timing B valve is kept on the right side by spring force.

With lock-up control solenoid valve B turned ON, the lock-up control valve is moved somewhat to the left side, causing

back pressure (F2) to lower. This allows a greater amount of fluid (F1) to work on the lock-up clutch to engage the clutch.

Back pressure (F2) which still exists, prevents the clutch from engaging fully.

NOTE: When used, "|eft" or "right" indicates direction on the hydraulic circuit.

LOCK.UP COI\ITBOL

THROITIE B PRESSUREIOCX UP COIITROL VALVE

MODULATOR PNESSURE

TOCK UP TIMING B VALVE

14-42

\

t

{

Page 460 of 1681

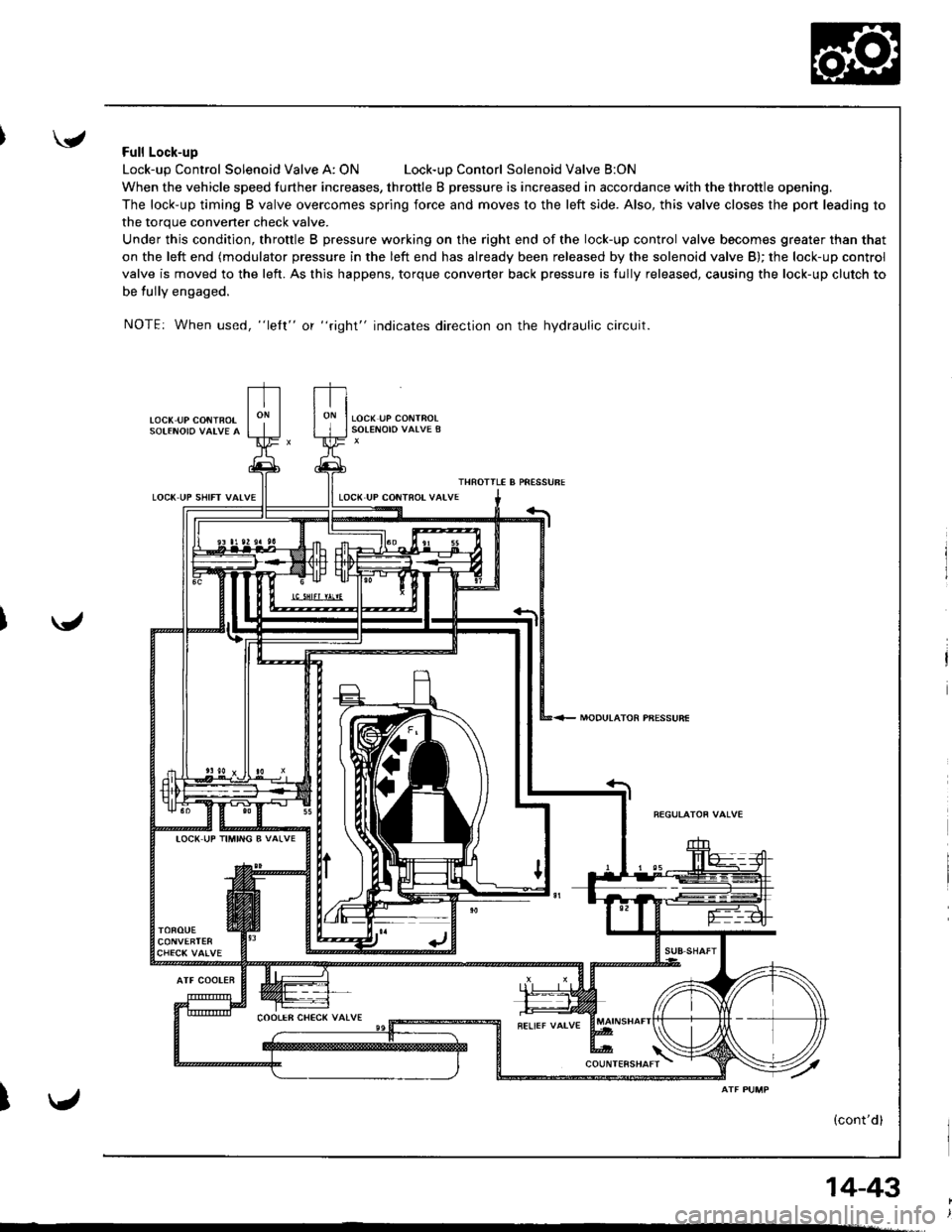

'Full Lock-up

Lock-up Control Solenoid Valve A: ONLock-uD Contorl Solenoid Valve B:ON

When the vehicle speed further increases, throttle B pressure is increased in accordance with the throttle opening.

The lock-up timing B valve overcomes spring force and moves to the left side. Also, this valve closes the port leading to

the torque convener check valve.

Under this condition, throttle B pressure working on the right end of the lock-up control valve becomes greater than that

on the left end (modulator pressure in the left end has already been released by the solenoid valve B); the lock-up control

valve is moved to the left. As this happens, torque converter back pressure is fully released, causing the lock-up clutch to

be tully engaged.

NOTE: When used, "lelt" or "right" indicates direction on the hydraulic circuit.

LOC( UP CONiBOT

LOCK UP SHIFT VAIVE

MODULATOR PBESSURE

ATF COOLER

I

IOC( UP TIMING B VALVE

14-43

Page 466 of 1681

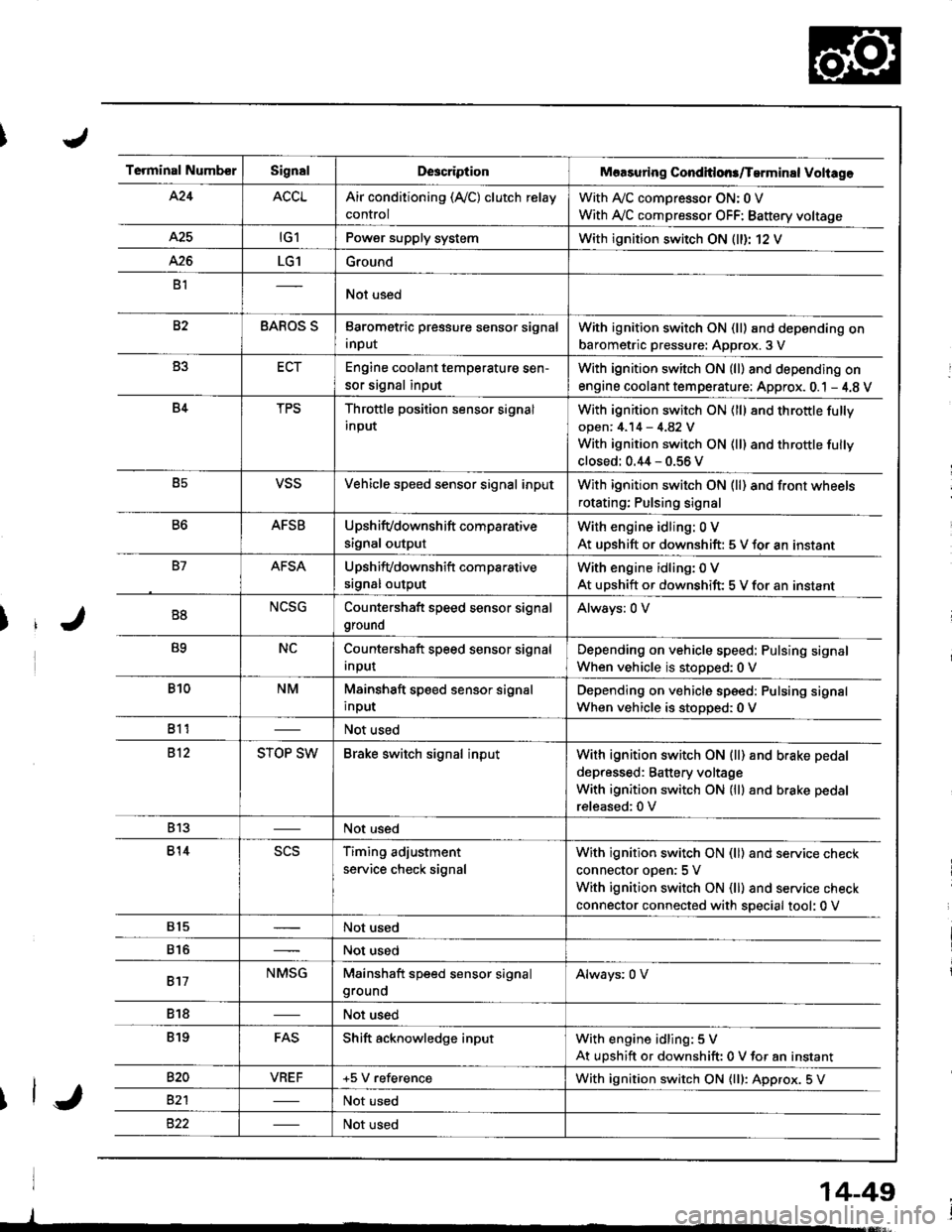

Terminal NumberSignalDescriptionMaasuring Conditlons/Tarminal Voliage

424ACCLAir conditioning (Ay'C) clutch relay

control

With A,/C comDressor ON: 0 V

With Ay'C compressor OFF: Battery voltage

A25tG1Power supply systemWith ignition switch ON (ll)r 12 V

426LG1Ground

B1Not used

82BAROS SBarometric pressure sensor signal

input

With ignition switch ON (ll) and depending on

barometric pressure: Approx. 3 V

B3ECTEngine coolant temperature sen-

sor signal input

With ignition switch ON (ll) and depending on

engine coolant tem perature: Approx. 0.1 - 4.8 V

B4TPSThrottle position sensor signal

input

With ignition switch ON (ll) 8nd throttle fully

open: 4.14 - 4.82 V

With ignition switch ON (ll) and throttle fully

closed: 0.44 - 0.56 V

B5VSSVehicle speed sensor signal inputWith ignition switch ON (ll) and front wheels

rotating; Pulsing signal

B6AFSBUpshifvdownshift comparative

signal output

With engine idling: 0 V

At uDshift or downshift: 5 V for an instant

B7AFSAUpshifvdownshift com parative

srgnal output

With engine idling: 0 V

At upshift or downshift: 5 V for an instant

B8NCSGCountershaft speed sensor signal

ground

Always: 0 V

B9NCCountershaft speed sensor signal

Input

Depending on vehicle speed: Pulsing signal

When vehicle is stopped:0 V

B10NMMainshaft speed sensor signal

input

Depending on vehicle speed: Pulsing signal

When vehicle is stoDoed: 0 V

811Not used

812STOP SWBrake switch signal inputWith ignition switch ON {ll) and b.ake pedal

depressed: Battery voltage

With ignition switch ON (lll and brake pedal

released:0 V

813Not used

814scsTiming adjustment

service check signal

With ignition switch ON (ll) and service check

connector oDen:5 V

With ignition switch ON (ll) and service check

connector connected with special tool: 0 V

815Not used

816Not used

817NMSGMainshaft speed sensor signalgroundAlways: 0 V

818Not used

819FASShift acknowledge inputWith engine idling: 5 V

At upshift or downshift: 0 V for an instant

820VBEF+5 V referenceWith ignition switch ON {lll: Approx. 5 V

82'lNot used

Not used

14-49

Page 508 of 1681

L

\a

\."tl

14-91

J

al

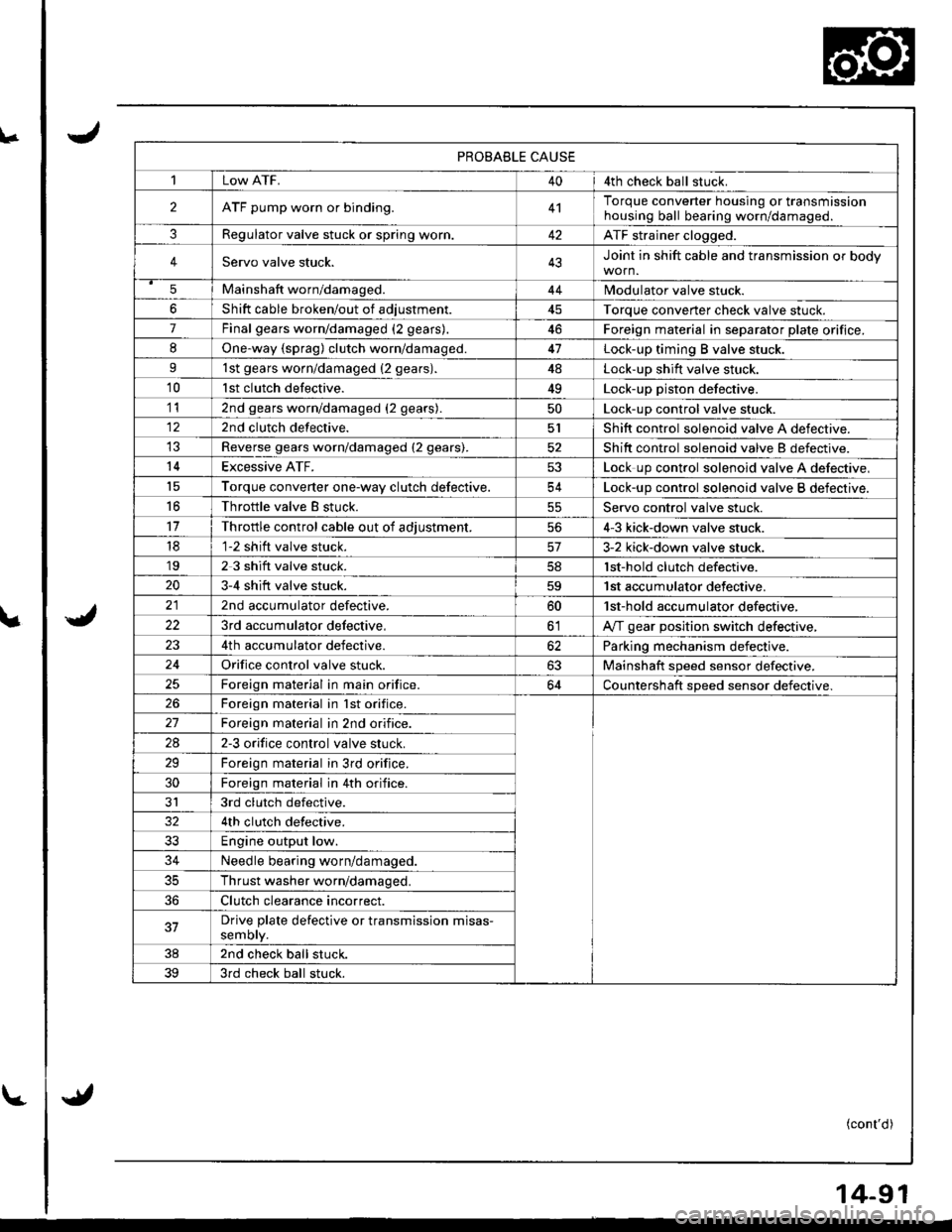

PROBABLE CAUSE

1Low ATF.404th check ball stuck.

2ATF pump worn or binding.4'lTorque converter housing or transmissionhousing ball bearing worn/damageo.

3Regulator valve stuck or spring worr..42ATF strainer clogged.

4Servo valve stuck.43Joint in shift cable and transmission or body

5Mainshaft worn/damaged.44Modulator valve stuck.

6Shift cable broken/out of adiustment45Torque converter check valve stuck.

7Final gears worn/damaged (2 gears).46Foreign material in separator plate orifice.

8One.way {sprag) clutch worn/damaged.47Lock-up timing B valve stuck.

91st gears worn/damaged {2 gears).4ALock-up shift valve stuck.

10lst clutch defective.49Lock-up piston defective.

112nd gears worn/damaged (2 gears).50Lock-up control valve stuck.

122nd clutch defective.5lShift control solenoid valve A defective.

Reverse gears worn/damaged (2 gears).52Shift control solenoid valve B defectrve.

14Excessive ATF.53Lock up control solenoid valve A defective,'t5Torque converter one-wav clutch defective.54Lock-up control solenoid valve B defective.

16Throttle valve B stuck.55Servo control valve stuck.

11Throttle control cable out of adiustment.564-3 kick-down valve stuck.

181-2 shift valve stuck.3-2 kick-down valve stuck.'192 3 shift valve stuck.lst-hold clutch defective.

203-4 shift valve stuck.59'| st accumulator defective.

2nd accumulator defective.60'lst-hold accumulator defective,

223rd accumulator delective,olA,rf gear position switch defective,

4th accumulator defective.62Parking mechanism defective.

24Orifice control valve stuck.63Mainshaft speed sensor defective.

Foreign material in main orifice.64Countershaft speed sensor defective.

26Foreign material in lst orifice.

Foreign material in 2nd orifice.

2A2-3 orifice control valve stuck.

29Foreign material in 3rd orifice.

30Foreign material in 4th orifice.

JI3rd clutch defective.

4th clutch defective.

33Engine output low.

34Needle bearing worn/damaged.

35Thrust washer worn/damaged.

36Clutch clearance incorrect.

37Drive plate defective or transmission misas-semory.

382nd check ball stuck.

393rd check ball stuck.

(cont'd)

Page 544 of 1681

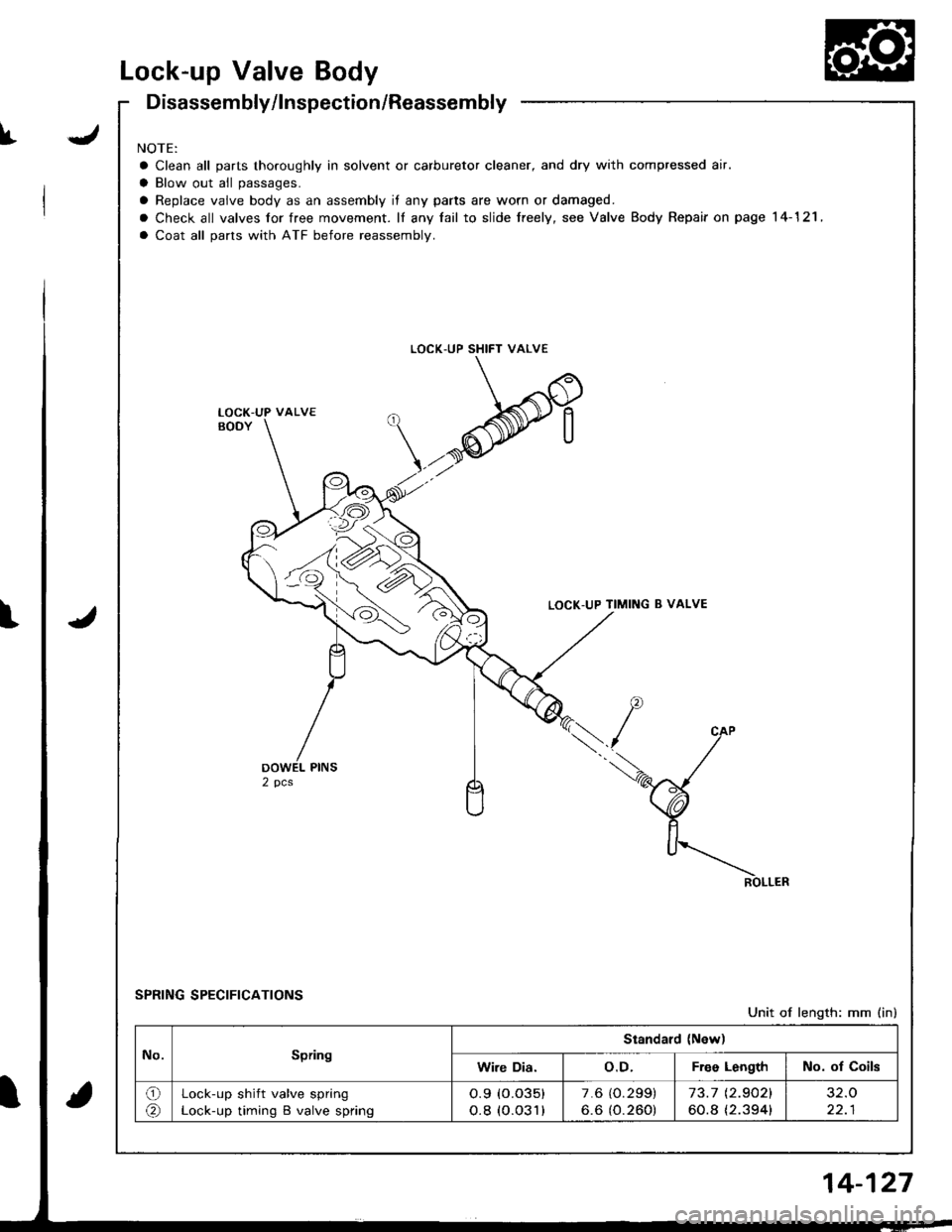

Lock-up Valve Body

JI

Disassembly/lnspection/Reassembly

NOTE:

a Clean all parts thoroughly in solvent or carburetor cleaner, and dry with compressed air.

a Blow out all passages.

a Replace vaive body as an assembly if any parts are worn or damaged.

o Check all valves for free movement. lf any fail to slide freely, see Valve Body Repair on page 14-121 ,

a Coat all parts with ATF before reassembly.

LOCK-UP SHIFT VALVE

LOCK-UP TIMING B VALVE

SPRING SPECIFICATIONS

Unit of length: mm (in)

LOCK-UP VALVE

No.Spring

Standard (New)

Wire Dia.o.D.Free LengthNo. of Coils

o(r\Lock-up shift valve spring

Lock-up timing B valve spring

o.9 (o.o35)

o.8 (o.o31)

7.6 (O.299)

6.6 (O.260)73.7 t2.9021

60.8 {2.394}

32.O

22.1

4-127

Page 791 of 1681

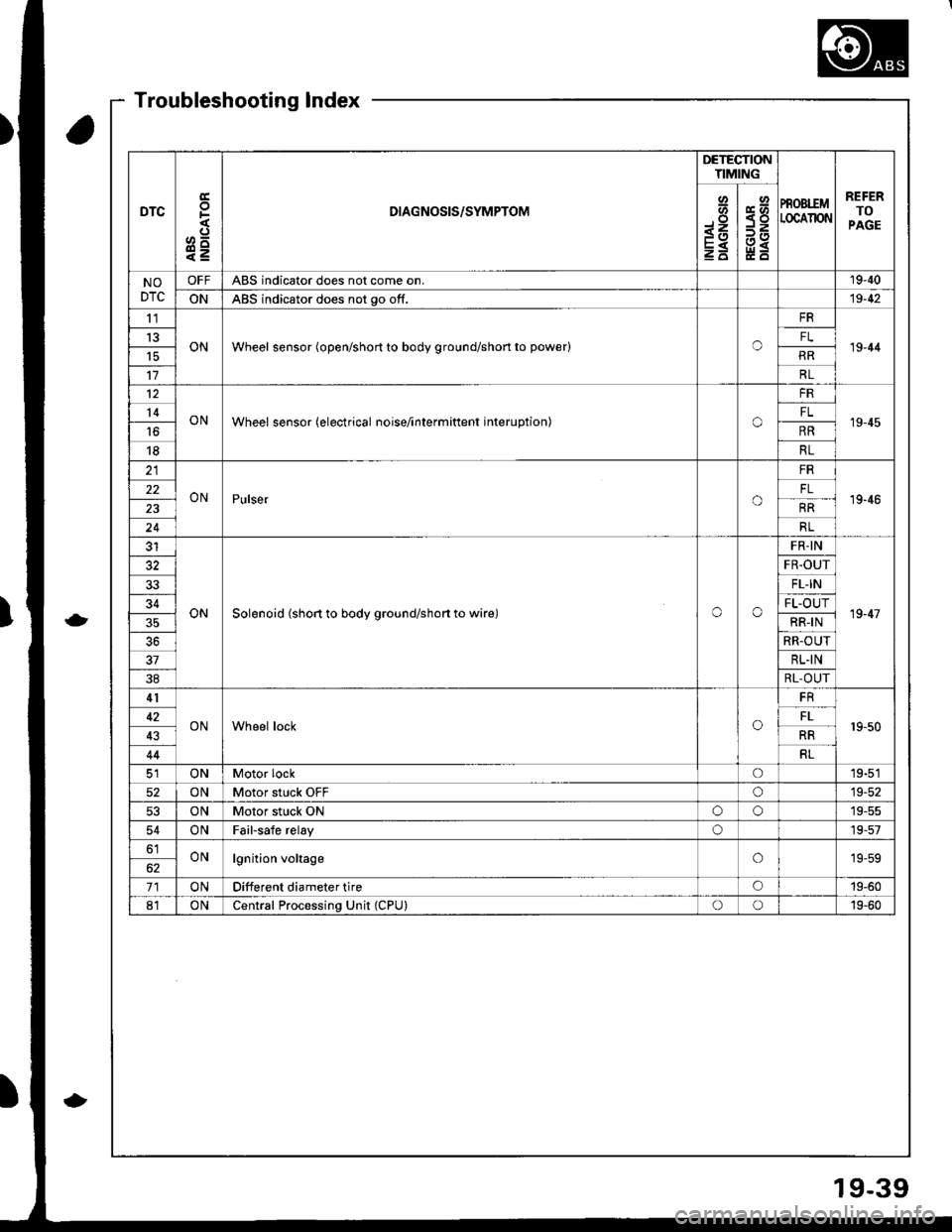

DTC

E

F

o^

e=

DIAGNOSIS/SYMPTOM

DETECTIONTIMING

PROBIEMLOCAIION

REFERTOPAGE

Io-<1

E

Y<

NODTC

OFFABS indicator does not come on.19-40

ONABS indicator does not go off.19-42

tl

ONWheel sensor (open/short to body ground/shon to power)o19-44t3FL

RR

17RL

12

ONWheel sensor (electrical noise/interminent interuption)o

FR

19-4514FL

16RR

18RL

ONPulsero

FR

19'4622

RR

24RL

ONSolenoid (short to body ground/shon to wire)oo

FR-IN

19-47

FR.OUT

33FL-IN

34FL-OUT

RR-IN

RR-OUT

37RL.IN

38RL-OUT

41

ONWheel locko19-5042FL

43RR

44RL

ONMotor locko19-51

52ONMotor stuck OFFo19-52

53ONMotor stuck ONoo19-55

54ONFailsafe relayo19-57

61ONlgnition voltageo19-59

71ONDifferent diameter tireo19-60

81ONCentral Processing Unit (CPU)oo19-60

Troubleshooting Index

19-39