steering HONDA INTEGRA 1998 4.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 710 of 1681

)

)

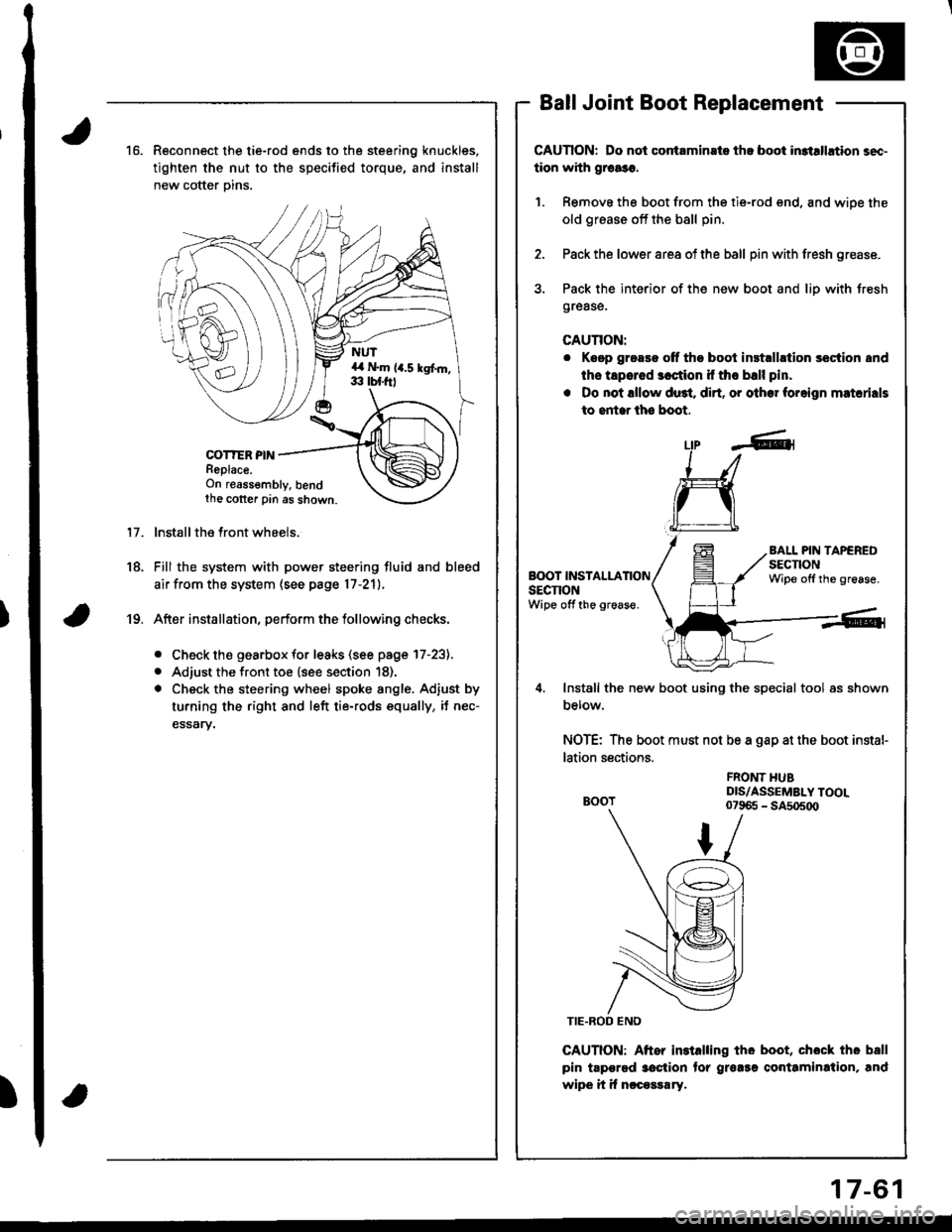

16.Reconnect the tie-rod ends to the steering knuckles,

tighten the nut to the specified torque, and install

new cotter Dins.

COT?ER PINReplace.On reassembly, bendthe cotter pin as shown.

lnstall the front wheels.

Fill the system with power steering fluid and bleed

air from the system (see page 17-21).

After installation, perform the tollowing checks.

. Check the gearbox for leaks (see page l7-23).

. Adjust the front toe (see section 18).

. Check the steering wheel spoke angle. Adjust by

turning the right and left tie-rods equally, it nec-

essary.

Ball Joint Boot Replacement

CAUTION: Do not contaminste th! boot in3tllhtion sec-

tion with grca3o.

1. Remove the boot from the tie-rod end, and wiDe the

old grease off the bsll pin.

2. Pack the lower area of the ball pin with fresh grease.

3. Pack the interior of the new boot and liD with Jresh

grease.

CAUTION:

r Keep grease off tho boot inst.llrtion section 8nd

ths tapered 3cction if tho ball pin.

. Do not lllow du3t. dirt. or other foreign matcrials

to entar lh6 boot.

17.

18.

Lfp -A-1

L:I

ru

Install the new boot using the special tool as shown

Derow.

NOTE: The boot must not be a gap at the boot instal-

lation sections.

CAUTION: Aftor installing tho boot, chock tho ball

pin tapgrgd 3oction tor grorsg conttmination, and

wipe it if nccossary.

BALL PIN TAPEREDsEcnoNWipe offthe grease.BOOT INSTALLATIONsEcnoNWipe off the groaso.

19.

FROI{T HUBDIS/ASSEMBLY TOOL07965 - SA5o5o0

17-61

Page 715 of 1681

\

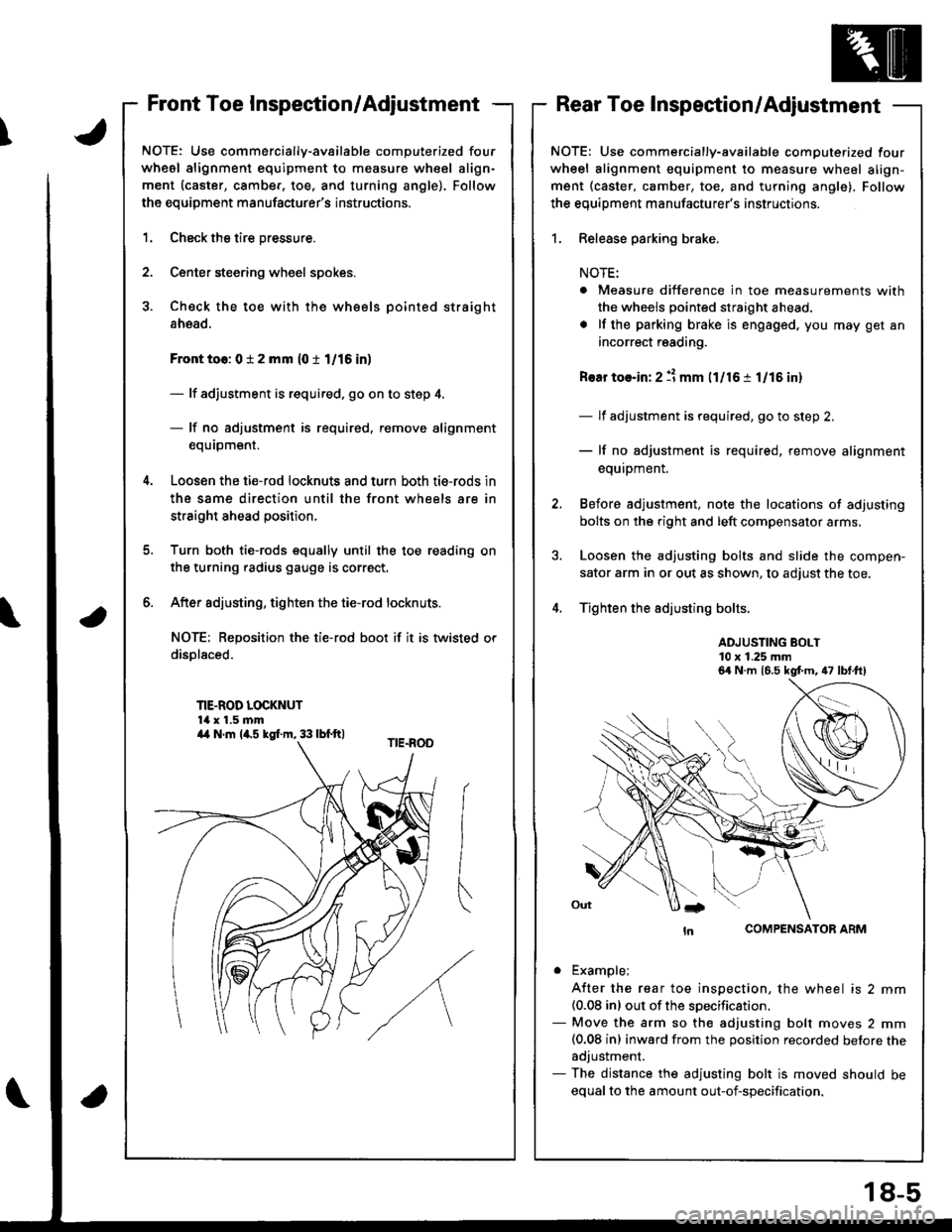

Front Toe Inspection/AdjustmentRear Toe Inspection/Adjustment

NOTE: Use commercially-available computerized four

whesl alignment equipment to measure wheel align-

ment (caster, camber, toe. and turning angle). Follow

the equipment manufacturer's instructions.

1.

2.

Check the tire pressure.

C€nter steering wheel spokes.

Check the toe with the wh€els pointed straight

ahead.

Front to6: 0 i 2 mm (0 t 1/16 in)

- lf adjustment is required. go on to step 4.

- lf no adjustment is required, remove alignment

equrpm€nr,

Loosen the ti€-rod locknuts and turn both tie-rods in

the same direction until the front wheels are in

straight ahead position.

Turn both tie-rods equally until the toe reading on

the turning radius gauge is correct.

After sdjusting, tighten the tie-rod locknuts.

NOT€: Reposition the tie-rod boot if it is twisted or

displaced.

TIE-ROD LOCKNUT14 x 1.5 mm

6.

a

NOTE: Use commercially-available computerized four

wheel alignment equipment to measure wheel align-

ment (caster, camber, toe, and turning angle), Follow

the equiDment manufacturer's instructions.

1. Release parking brake.

NOTE:

. Measure difference in toe measurements with

the wheels pointed straight ahead.

. lf the parking brake is engaged. you may get an

incorrect reading.

Rear toe-in: 2 11 mm l1l16 i 1/15 in)

- lf adjustment is required, go to step 2.

- lf no adjustment is required, remove alignment

equipment.

Before adjustment, note the locations of adjusting

bolts on the right and left compensator arms.

Loosen the adjusting bolts and slide the compen-

sator arm in or out as shown, to adjust the toe.

Tighten the adjusting bolts.

ADJUSTING BOLT10 x 1.25 mm

COMPENSATOR ARM

. Example;

A{ter the rear toe inspection, the wheel is 2 mm(0.08 inl out of the soecification.- Move the arm so the adjusting bolt moves 2 mm(0.08 inl inward from the position recorded betore theadjustment.- The distance the adjusting bolt is moved should be

equal to the amount out-of-specification.

6a N.m 16.5 kgt m, 47 lbt.ft)

a4 N.m la.s kgI.m, 33 lbf.ft)

18-5

Page 722 of 1681

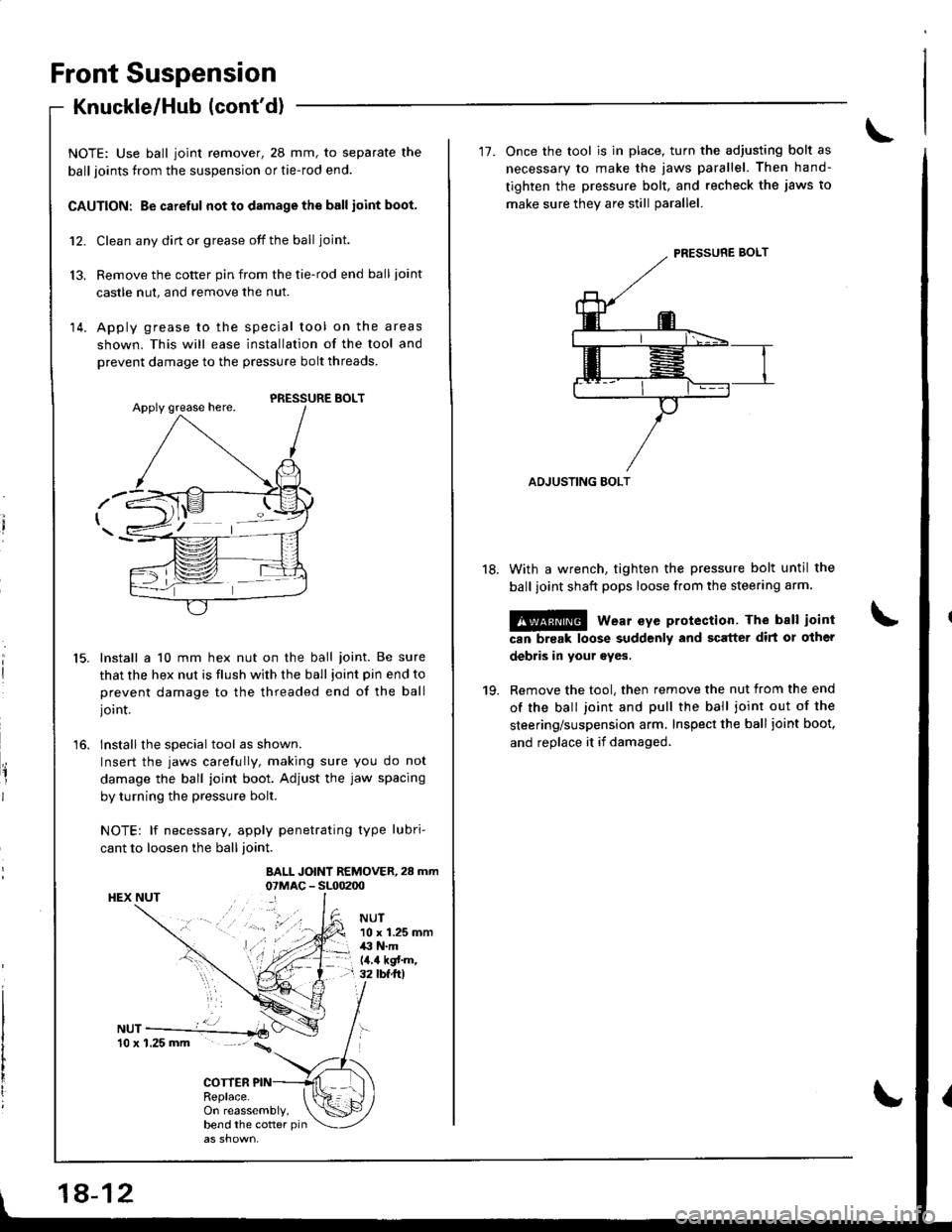

Front Suspension

Knuckle/Hub (cont'd)

13.

N-ur--------------*i10 x 1.25 mm \

COTTERReplace.

NOTE: Use ball joint remover, 28 mm, to separate the

ball joints from the suspension or tie-rod end.

CAUTIONT Be careful not to damage the ball ioint boot.

Clean any dirt or grease off the ball joint.

Remove the cotter pin from the tie-rod end balljoint

castle nut, and remove the nut.

Apply grease to the special tool on the areas

shown. This will ease installation of the tool and

prevent damage to the pressure bolt threads.

12.

14.

15.

'16.

PRESSURE BOLT

Install a 10 mm hex nut on the ball joint. Be sure

that the hex nut is flush with the ball joint pin end to

prevent damage to the threaded end of the ball

joint.

Installthe special tool as shown.

Insert the jaws carefully, making sure you do not

damage the ball joint boot. Adjust the jaw spacing

by turning the pressure bolt.

NOTE: lf necessary, apply penetrating type lubri-

cant to loosen the ball joint.

BALL JOINT REMOVER,28 mm07MAC - SL00200HEX NUT

NUT10 x 1.25 mm,li' N.mla.a kgf'm,32 tbf ft)

On reassembly,bend the cotter pin

18-12

'17. Once the tool is in place, turn the adiusting bolt as

necessary to make the jaws parallel. Then hand-

tighten the pressure bolt, and recheck the jaws to

make sure thev are still oarallel.

ADJUSTING BOLT

With a wrench, tighten the pressure bolt until the

ball ioint shaft pops loose from the steering arm.

@ wear eye protection. The ball ioint

can break loose suddenly and scrtter dirt or other

debris in your eyes.

Remove the tool, then remove the nut from the end

of the ball joint and pull the ball ioint out of the

steering/suspension arm, Inspect the ball joint boot,

and replace it if damaged.

18.

19.

Page 948 of 1681

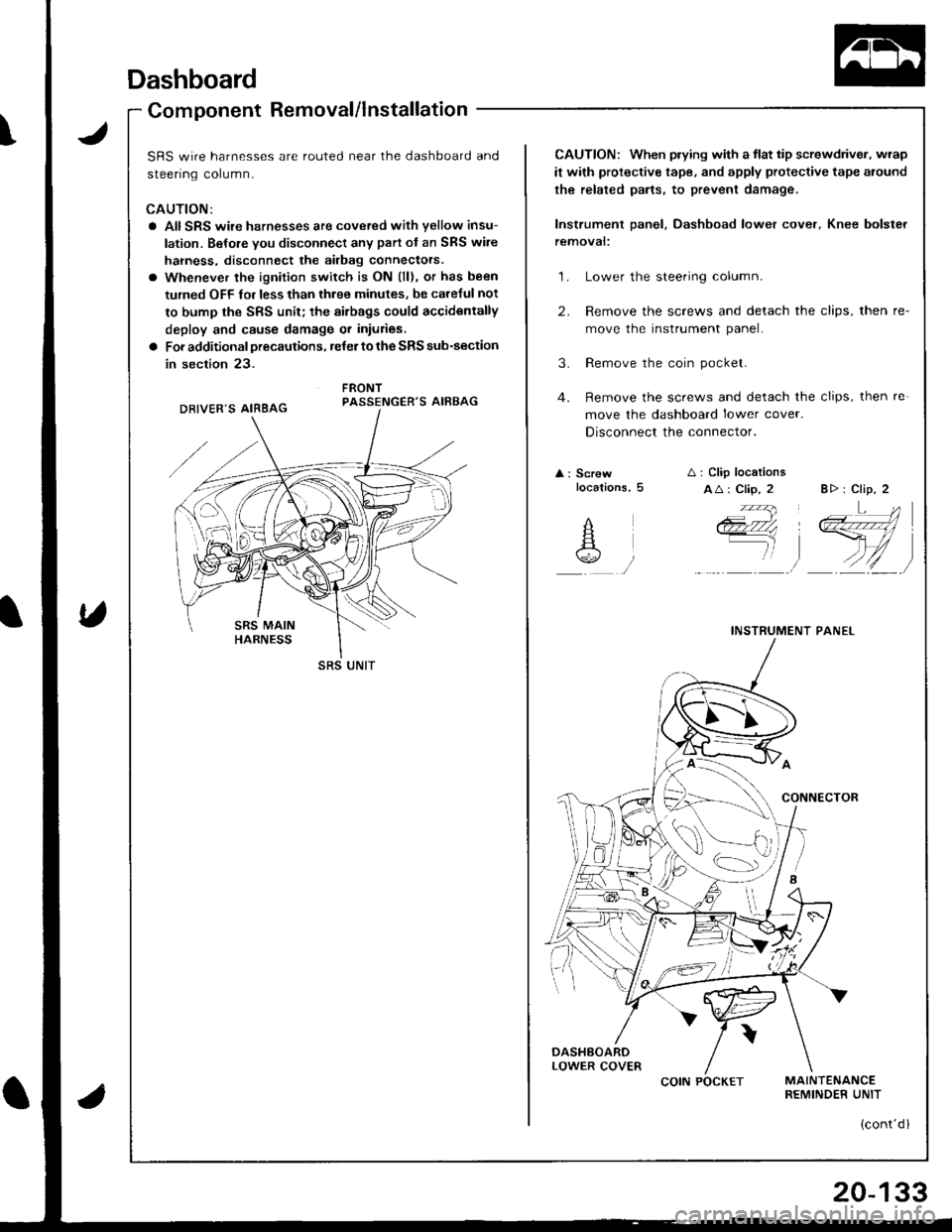

Dashboard

Component Removal/lnstallation

\J

U

uomponenl r{emoval/ Insrallarlon -

SRS wire harnesses are routed near the dashboard and

sreenng corumn.

CAUTION:

a AIISRS wire harnesses are cove.ed with yellow insu-

lation. Belore you disconnect any part of an SRS wire

hahess, disconnect the airbag connectors.

o Whenever the ignition switch is ON (ll), or has been

turned OFF fol less than three minutes, be caretul not

to bump the SRS unit; the airbags could accidentally

deploy and cause damage or inturies.

a For additional precautions, reJer to the SRS sub-section

in section 23.

FRONTPASSENGER'S AIRBAG

SRS UNIT

CAUTION: When prying with a flat tip screwdriver, wrap

it with protective tape, and apply proteclive tape around

the related parts, to prevent damage,

Instrument panel, Dashboad lower cover, Knee bolster

temovat:

1. Lower the steering column.

2. Remove the screws and detach the clips, then re-

move the instrument panel.

3. Remove the coin pocket.

4. Remove the screws and detach the clips, then re

move the dashboard lower cover.

Disconnect the connector.

A : Screwlocations,5A i Clip locations

AA: Clip, 2 B> : Clip, 2

INSTRUMENT PANEL

ii'- ' iq4'ii \Ll1

COIN POCKET

(cont'd l

20-133

Page 954 of 1681

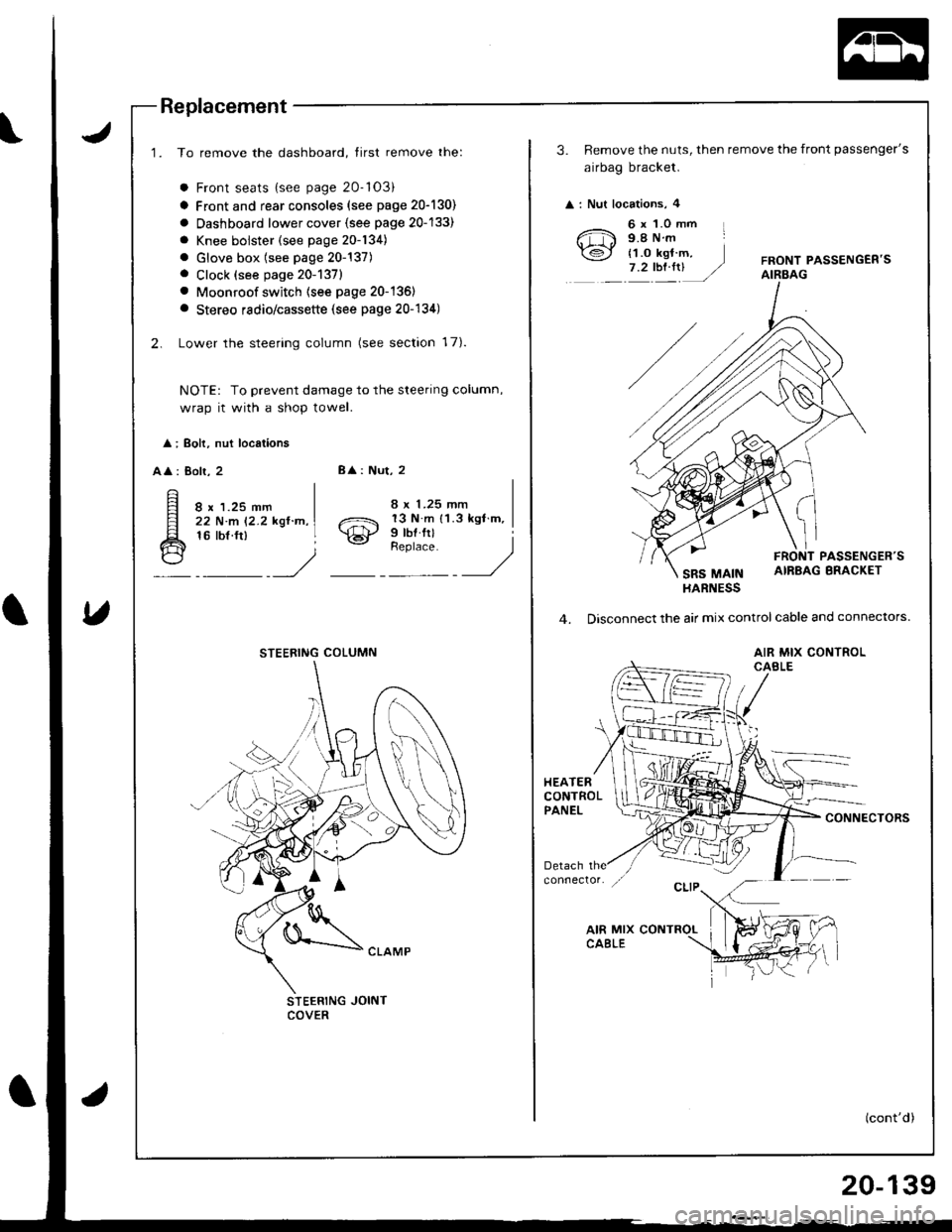

Replacement

1. To remove the dashboard, tirst remove the:

a Front seats {see page 20-'103)

a Front and rear consoles (see page 20-130)

a Oashboard lower cover {see page 20-133)

a Knee bolster (see page 20-134)

. Glove box (see page 20-137). Clock (see page 20-1371

. Moonroof switch (see page 20-136)

a Stereo radio/cassette (see page 20-134)

2. Lower the steering column (see section 17).

NOTE: To prevent damage to the steering column,

wrap it with a shop towel.

l ; Boh, nut locations

AA : Bolr, 28

: Nut, 2

8 x 1.25 mm22 N.m 12.2 kgl.n,16 tbf.ft)o21 13 N m 11.3 kgl m,

\€J' Prbl rll

_Urr'rr,t __)

STEERING JOINTCOVER

STEERING COLUMN

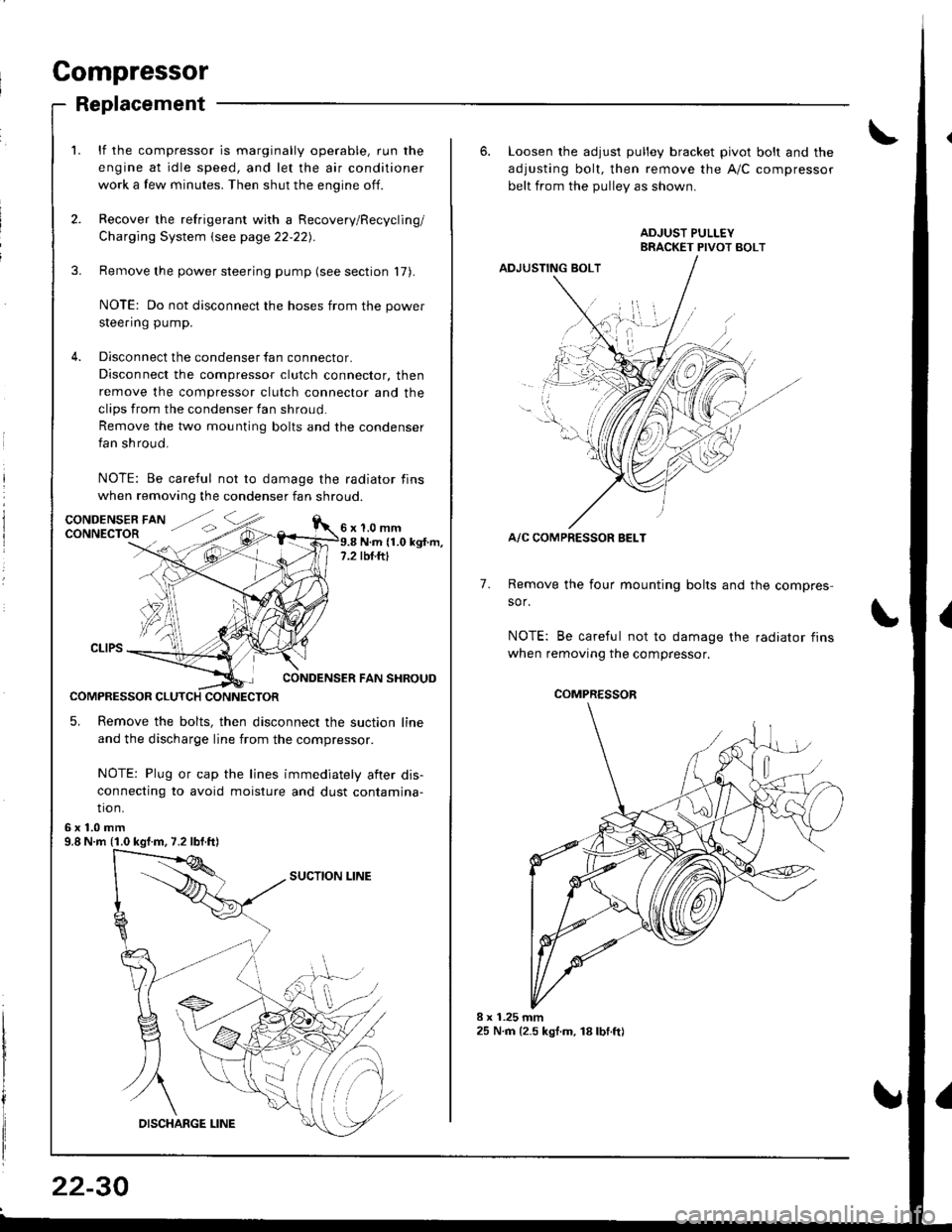

3. Remove the nuts, then remove the front passenger's

airbag bracket.

: Nut locations, 4

6 x 1.0 mm L9.8Nm

{1.o kgt m,7.2tbt.rrUFRONT PASSENGEB'SAIRBAG

PASSENGER'S

SRS MAINAIRBAG BRACKET

HARNESS

4. Disconnect the air mix control cable and connectors.

AIR MIX CONTROLCABLE

HEATERCONTROLPANELCONNECTORS

(cont'd)

20-139

Page 1048 of 1681

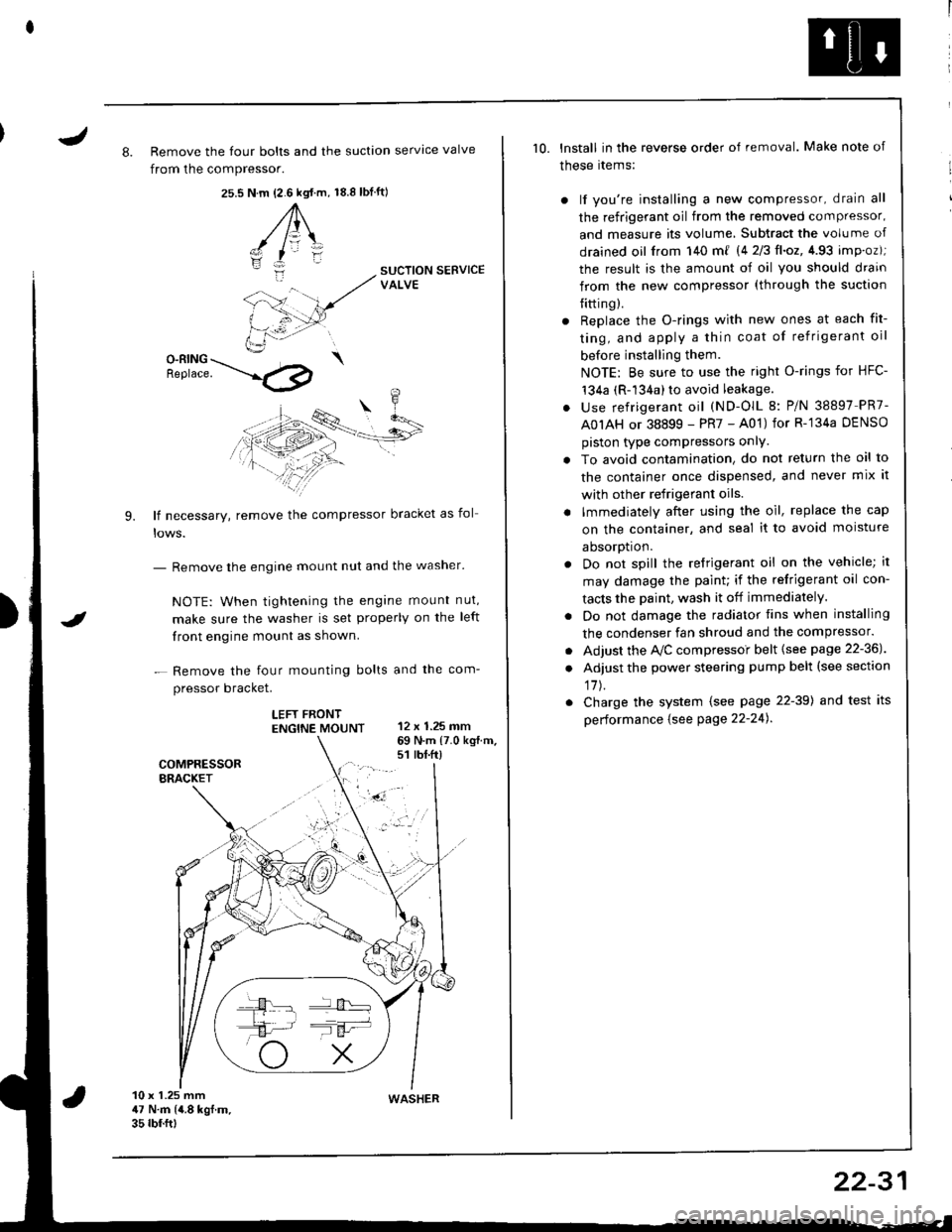

Compressor

Replacement

lf the compressor is marginally operable, run the

engine at idle speed, and let the air conditioner

work a few minutes. Then shut the engine off.

Recover the refrigerant with a Recovery/Recycling/

Charging System \see page 22-22).

Remove the power steering pump (see section 17).

NOTE: Do not disconnect the hoses from the power

steering pump.

Disconnect the condenser fan connector.

Disconnect the compressor clutch connector, then

remove the compressor clutch connector and the

clips from the condenser fan shroud

Remove the two mounting bolts and the condenser

fan shroud.

NOTE: Be careful not to damage the radiator fins

when removing the condenser fan shroud.

1.0 mmN.m (1.0 kgt.m,rbf.ftt

CONDENSER FAN SHROUD

COMPRESSOR CLUTCH CONNECTOR

5. Remove the bolts, then disconnect the suction line

and the discharge line from the compressor.

NOTE: Plug or cap the lines immediately aiter dis-

connecting to avoid moisture and dust contamina-

tio n.

6x1.0mm9.8 N.m (1.0 kgf.m, 7.2 lbf.ft)

22-30

6. Loosen the adjusl pulley bracket pivot bolt and the

adjusting bolt, then remove the A/C compressor

belt from the Dullev as shown.

ADJUSTING BOLT

A/C COMPRESSOR BELT

Remove the four mounting bolts and the compres-

sor.

NOTE: Be careful not to damage the radiator fins

when removing the compressor.

7.

./.,

COMPRESSOR

Page 1049 of 1681

J8. Remove the four bolts and the suction servtce valve

from the compressor.

25.s18.8 tbf.ft)N.m {2.6 kgt.m,

A\

-/ l=\'zI

i:-

9.

SUCTION SERVICEVALVE

O-RING \Benrace. --'.l4p

lf necessary, remove the compressor bracket as fol

- Remove the engine mount nut and the washer'

NOTE: When tightening the engane mount nut,

make sure the washer is set properly on the left

front engine mount as shown.

- Remove the four mounting bolts and the com-

pressor bracket.

LEFT FRONTENGTNE MOUNT 12 x 1.25 mm

I

69 N.m {7.0 kg{.m.s1 rbt.ft)

10 x 1.25 mm47 N.m (4.8 kgf.m.35 rbf.ftt

10. lnstall in the reverse order of removal. Make note of

these rtems:

) lf you're installing a new compressor, drain all

the refrigerant oil from the removed compressor,

and measure its volume, Subtract the volume of

drained oil from 140 m{ 14 2/3ll.oz,4.93 imp.oz);

the result is the amount of oil you should drain

from the new compressor (through the suction

{itting).

r Replace the O-rings with new ones at each fit-

ting, and apply a thin coat of refrigerant oil

before installing them.

NOTE: Be sure to use the right O-rings for HFC-'t34a (R-134a) to avoid leakage.

. use refrigerant oil (ND-OlL 8: P/N 38897 PR7-

A0IAH or 38899 - PR7 - A01) for R-'134a DENSO

piston type compressors onlY.

. To avoid contamination, do not return the oil to

the container once dispensed, and never mix it

with other refrigerant oils.

. lmmediately after using the oil, replace the cap

on the container, and seal it to avoid moisture

aDsorDt|on.

. Do not spill the refrigerant oil on the vehicle; it

may damage the paint; if the refrigerant oil con-

tacts the Daint, wash it off immediately.

. Do not damage the radiator fins when installing

the condenser fan shroud and the compressor.

. Adjust the Ay'C compressoi belt {see page 22-36J

. Adjust the power steering pump belt (see section

17J.

. Charge the system (see page 22-39) and test its

performance {see Page 22-24).

WASHER

22-31

Page 1054 of 1681

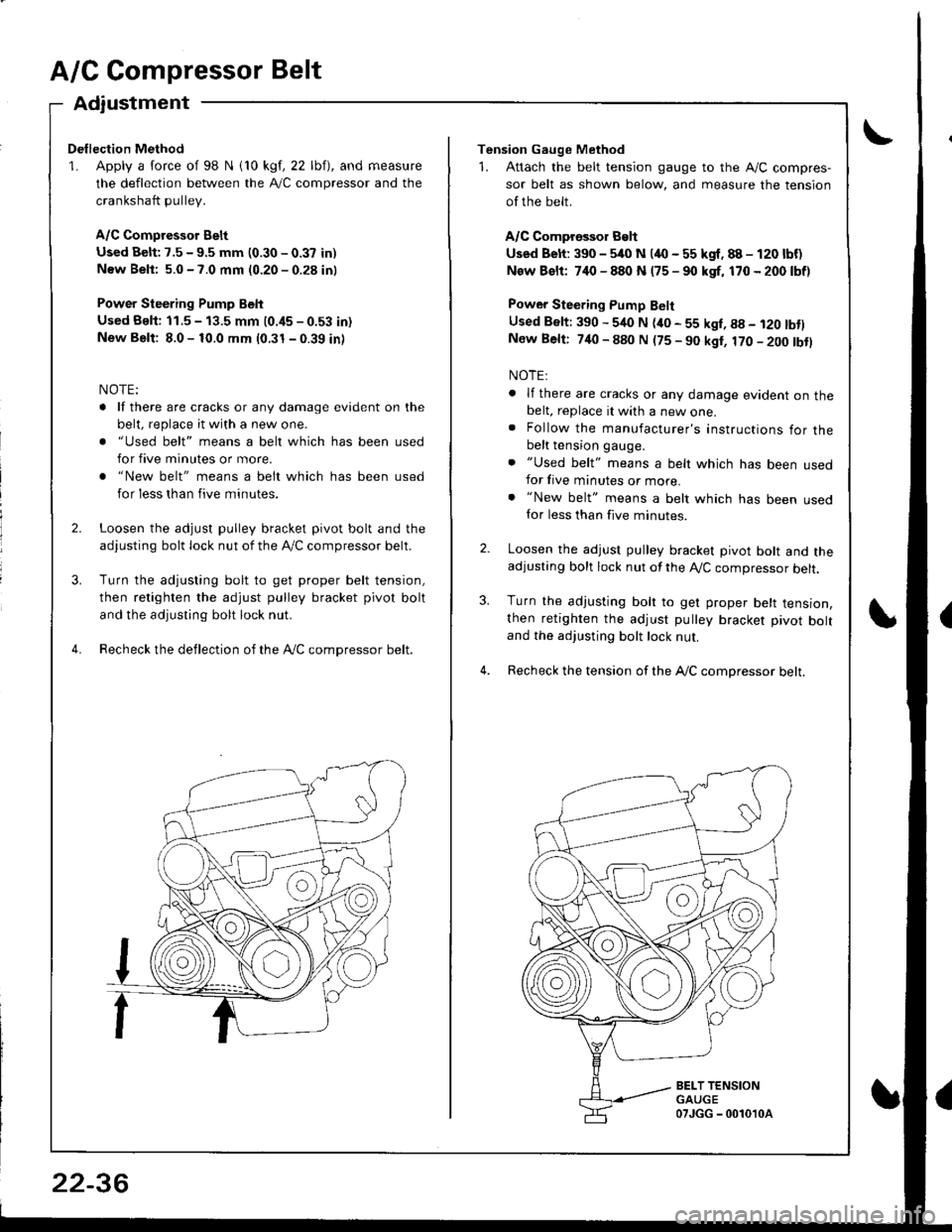

A/C Compressor Belt

Adiustment

Dellection Method

1. Apply a force of 98 N i10 kgf, 22 lbf), and measure

the deflection between the A,/C compressor and the

crankshaft pullev.

A/C Compressor Belt

Used Belt: 7.5 - 9.5 mm (0.30 - 0.37 in)

New Beli: 5.0 - 7.0 mm (0.20 - 0.28 in)

Power Steering Pump Belt

Used Bslt: 11.5 - 13.5 mm (0.i15 - 0.53 in)

New Belt: 8.0 - 10.0 mm (0.31 - 0.39 in)

NOTE:

. lf there are cracks or any damage evident on the

belt, replace it with a new one.

. "Used belt" means a belt which has been used

for five minutes or more.

. "New belt" means a belt which has been used

for less than five minutes.

Loosen the adjust pulley bracket pivot bolt and the

adjusting bolt lock nut of the lVC compressor belt.

Turn the adjusting bolt to get proper belt tension,

then retighten the adjust pulley bracket pivot bolt

and the adjusting bolt lock nut.

Recheck the deflection of the Ay'C compressor belt.

22-36

Tension Gauge Method

1. Attach the belt tension gauge to the Ay'C compres-

sor belt as shown below, and measure the tension

of the belt.

A/C Comprossor Belt

Used Belt: 390 - 5/rc N (4O - 55 kgf. 88 - 120 lbf)

New Bslt: 7,10 - 880 N (75 - 90 kgf, 170 - 200 lbf)

Power Steering Pump Belt

Used Belt: 390 - 540 N (ito - 55 kgl, g8 - i20 tbtlNew Belt: 740 - 880 N (75 - 90 kgt, 170 - 200 tbtl

NOTE:

. lf there are cracks or any damage evident on thebelt, replace it with a new one.. Follow the manufacturer's instructions for thebelt tension gauge.

. "Used belt" means a belt which has been usedfor five minutes or more.. "New belt" means a belt which has been usedfor less than five minutes.

Loosen the adjust pulley bracket pivot bolt and theadjusting bolt lock nut of the A,/C compressor belt.

Turn the adjusting bolt to get proper belt tension,then retighten the adjust pulley bracket pivot boltand the adjusting bolt lock nut.

Recheck the tension of the A,/C compressor belt.

3.

BELT TENSIONGAUGE07JGG - 0010'l0a

Page 1077 of 1681

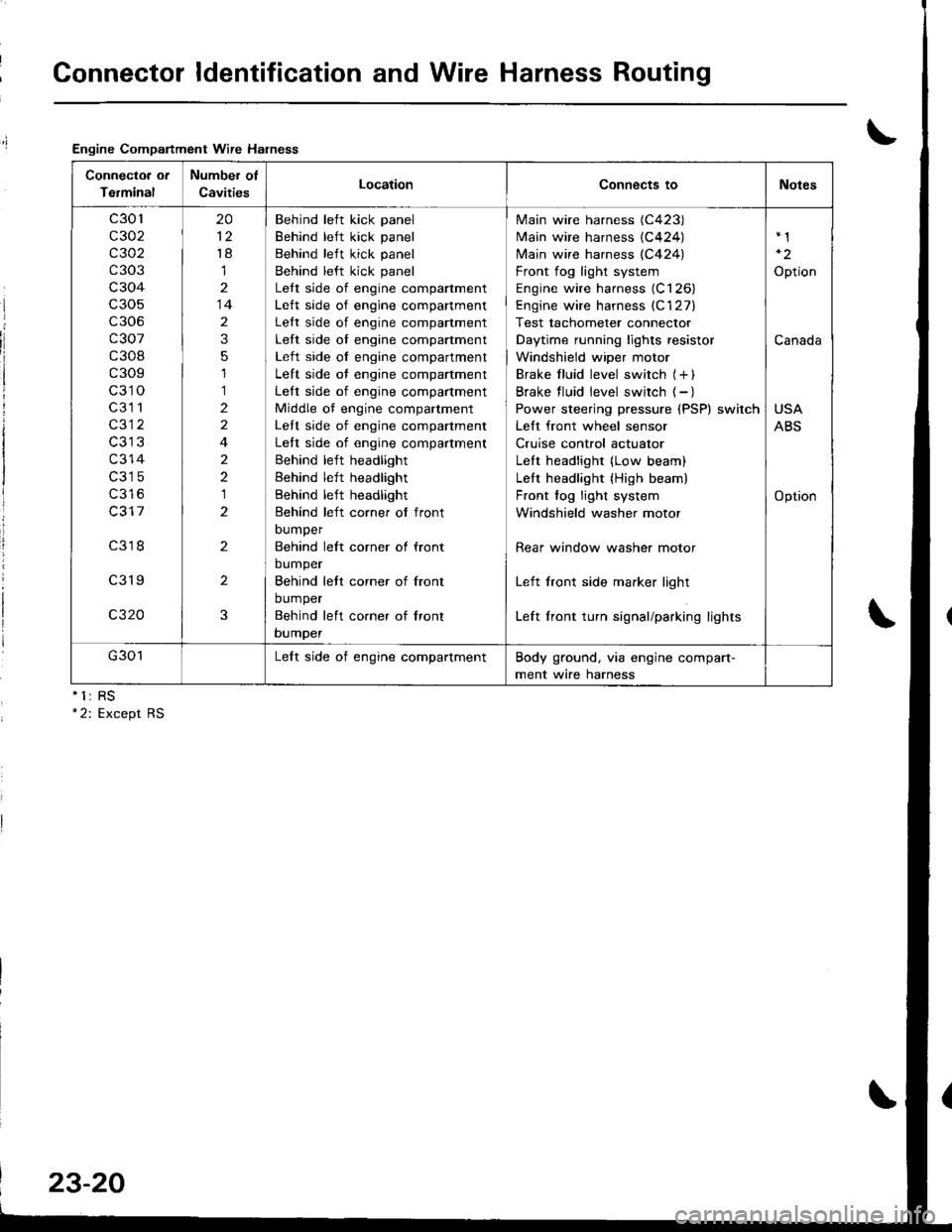

Connector ldentification and Wire Harness Routing

Engine Compartment Wire Halness

nll

Connectoa ot

Terminal

Number of

CavitiesLocationConnects toNotes

c301

c302

c 302

c303

c304

c306

c307

c308

c309

c310

c3l 1

c312

c314

c316

c317

c318

c319

c320

20

't8

1

14

2

3

5

1

1

2

2

4

2

2

1

2

2

2

3

Behind left kick panel

Behind left kick panel

Behind left kick panel

Behind left kick panel

Lett side of engine compartment

Lett side of engine companment

Lett side of engine compartment

Left side of engine compartment

Left side of engine compartment

Left side of engine compartment

Left side of engine compartment

Middle of engine compartment

Lett side of engine companment

Left side of engine compartment

Behind left headlight

Behind left headlight

Behind left headlight

Behind left corner of front

DUmper

Behind left corner ol front

bumper

Behind lett corner of front

bumper

Behind left co.ner of lront

bumper

Main wire harness (C423)

Main wire harness {C424)

N4ain wire harness (C424)

Front fog light system

Engine wire harness (C126)

Engine wire harness (C'127)

Test tachometer connector

Daytime running lights resistor

Windshield wiper motor

Brake f luid level switch (+ )

Brake f luid level switch ( - )

Power steering pressure (PSP) switch

Lett front wheel sensor

Cruise control actuator

LeIt headlight (Low beam)

Lett headlight {High beam)

Front fog light system

Windshield washer motor

Rear window washer motor

Left front side marker light

Left front turn signal/parking lights

Option

Canada

USA

ABS

Option

G301Lelt side of engine compartmentBody ground, via engine compart-

ment wire harness

23-20

Page 1129 of 1681

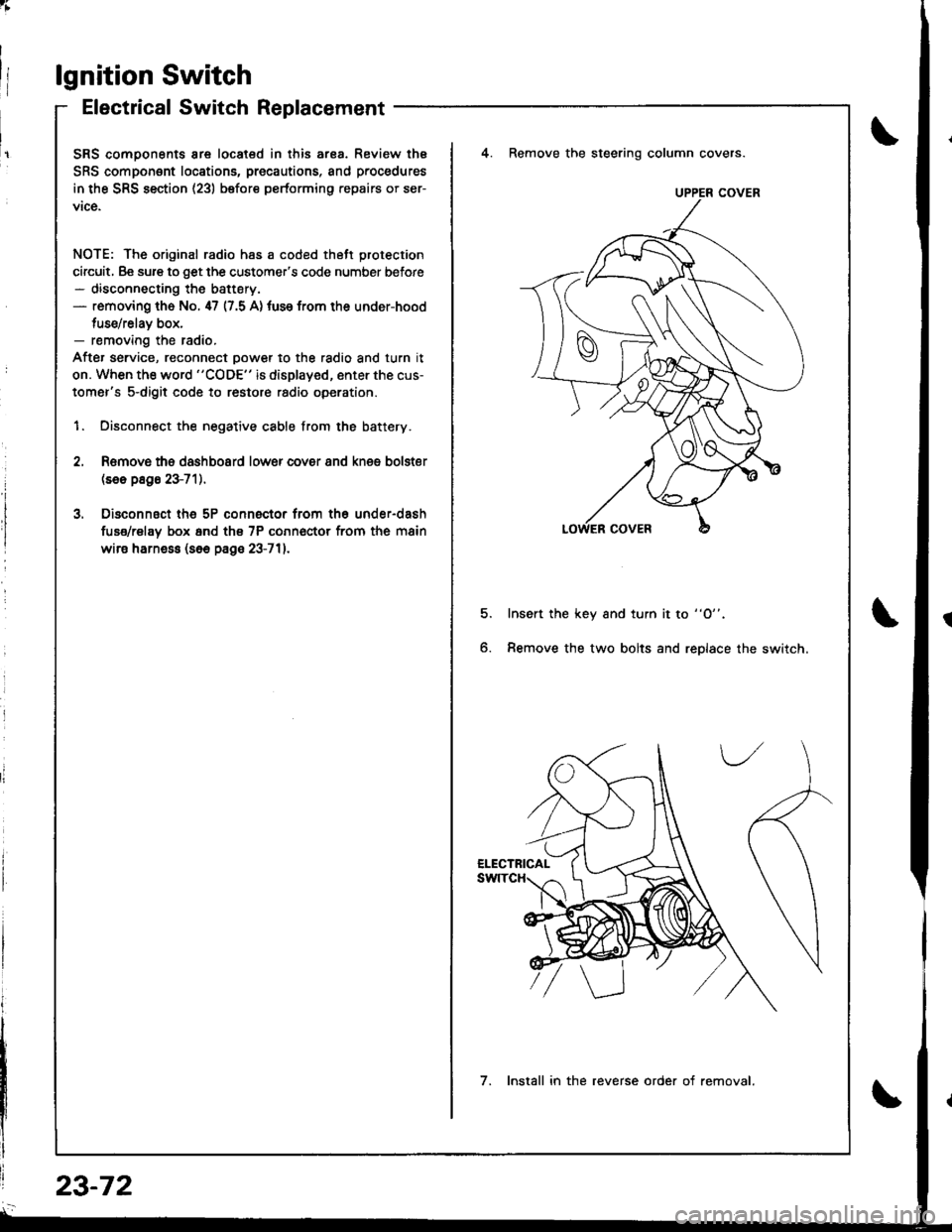

lgnition Switch

Electrical Switch Replacement

SRS comoonents are located in this ar8a. Review thE

SRS component locations, precautions, and procedures

in the SRS section (23) before performing repairs or ser-

vice.

NOTE: The original radio has a coded thett protection

circuit, Be sure to get the customer's code number before- disconnecting the battery.- removing th6 No. 47 (7.5 A) tuse from the under-hood

tuse/relav box,- removing the radio.

After service, reconnect oower to the radio and turn it

on. When the word "CODE" is displayed, enter the cus-

tomer's s-digit code to restore radio operation.

1. Disconnect the negative cable from the battery.

4. Remove the steering column covers.

Romovs ths dashboard lower cover 8nd knes bolster(se6 p8g6 23-71).

Disconnsct th6 5P connector from th6 under-dash

fuse/rel8y box 6nd th€ 7P conn€ctor from the main

wire harne$ (s6e page 23-711.

5.Insert the key and turn it to "O".

Remove the two bolts and replace the switch6.

UPPER COVER

7. Install in the reverse order of removal.

23-72