brake HONDA INTEGRA 1998 4.G Manual PDF

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 770 of 1681

Inspection

rrii tlmm {0.4 inl10

l.

Rear Brake Disc

Disc Runout Inspection

Loosen the rear wheel nuts slightly, then raise the

vehicle and support it on safety stands. Remove the

rear wneers.

Remove the brake pads (see page 19-16).

Inspect the disc surface for damage or cracks. Clean

the disc thoroughly and remove all rust.

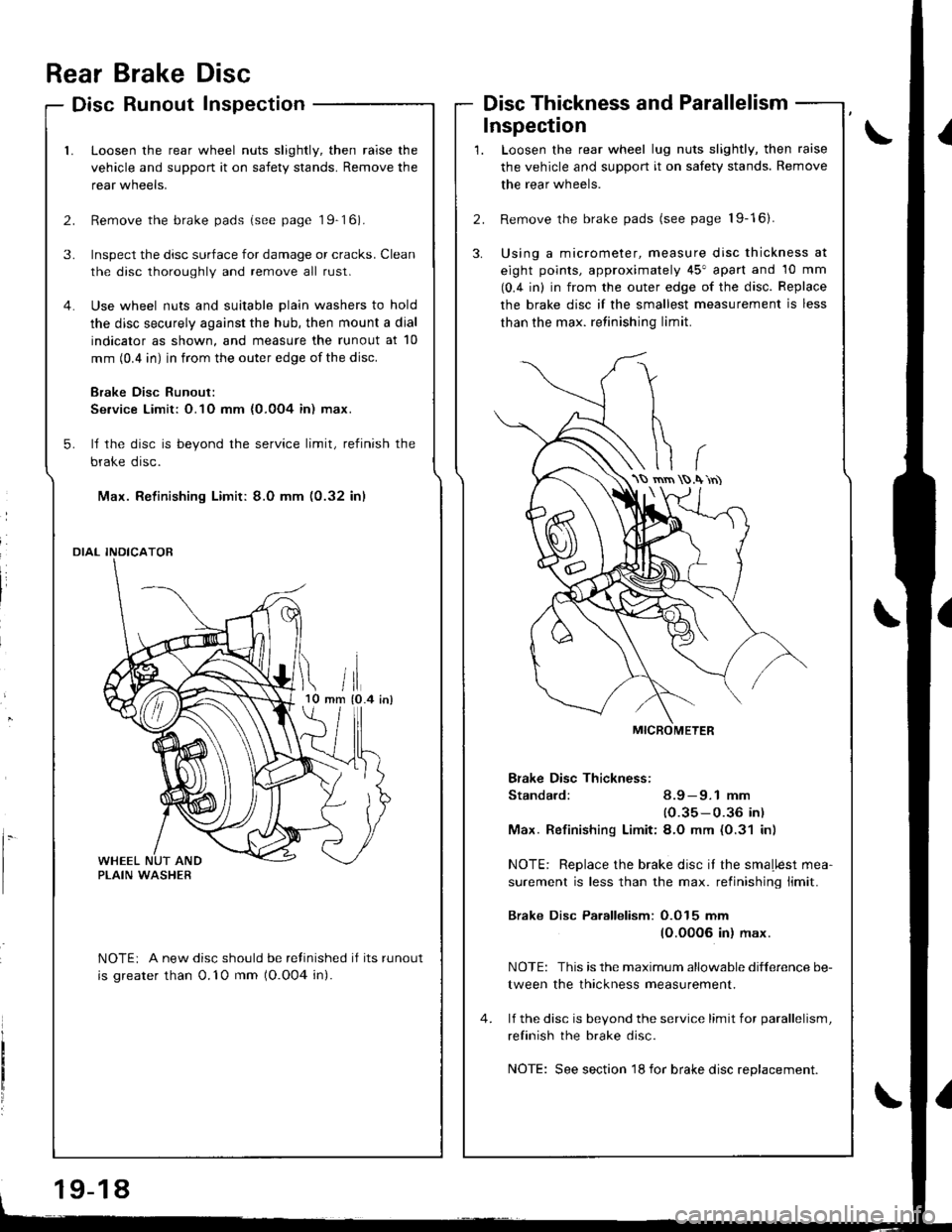

Use wheel nuts and suitable plain washers to hold

the disc securely against the hub, then mount a dial

indicator as shown, and measure the runout at 10

mm (0.4 in) in from the outer edge of the disc.

Brake Disc Runout:

Se.vice Limit: O.1O mm {0.0O4 in) max.

ll the disc is beyond the service limit, refinish the

brake disc.

Max. Refinishing Limit: 8.0 mm (0.32 in)

DIAL INDICATOR

NOTEi A new disc should be refinished if its runout

is greater than 0.'10 mm (O.O04 in).

Disc Thickness and Parallelism

Loosen the rear wheel lug nuts slightly, then raise

the vehicle and support it on safety stands. Remove

the rear wheels.

Remove the brake pads (see page 19-16).

Using a micrometer, measure disc thickness at

eight points, approximately 45" apart and 10 mm

(0.4 in) in from the outer edge of the disc. Replace

the brake disc if the smallest measurement is less

than the max. retinishing limit.

Bfake Disc Thickness:

Standard: 8.9 - 9.1 mm

(0.35-0.36 in)

Max. Refinishinq Limit:8.O mm (0.31 in)

NOTE: Replace the brake disc it the smaLlest mea-

surement is less than the max. retinishing limit.

Brake Disc Parallelism: O.O15 mm

(O.00O6 in) max.

NOTE: This is the maximum allowable difference be-

tween the thickness measurement.

lf the disc is bevond the service limit for parallelism,

refinish the brake disc.

NOTE: See section 18 for brake disc replacement.

\S rnrn .\'rn)

19-18

Page 771 of 1681

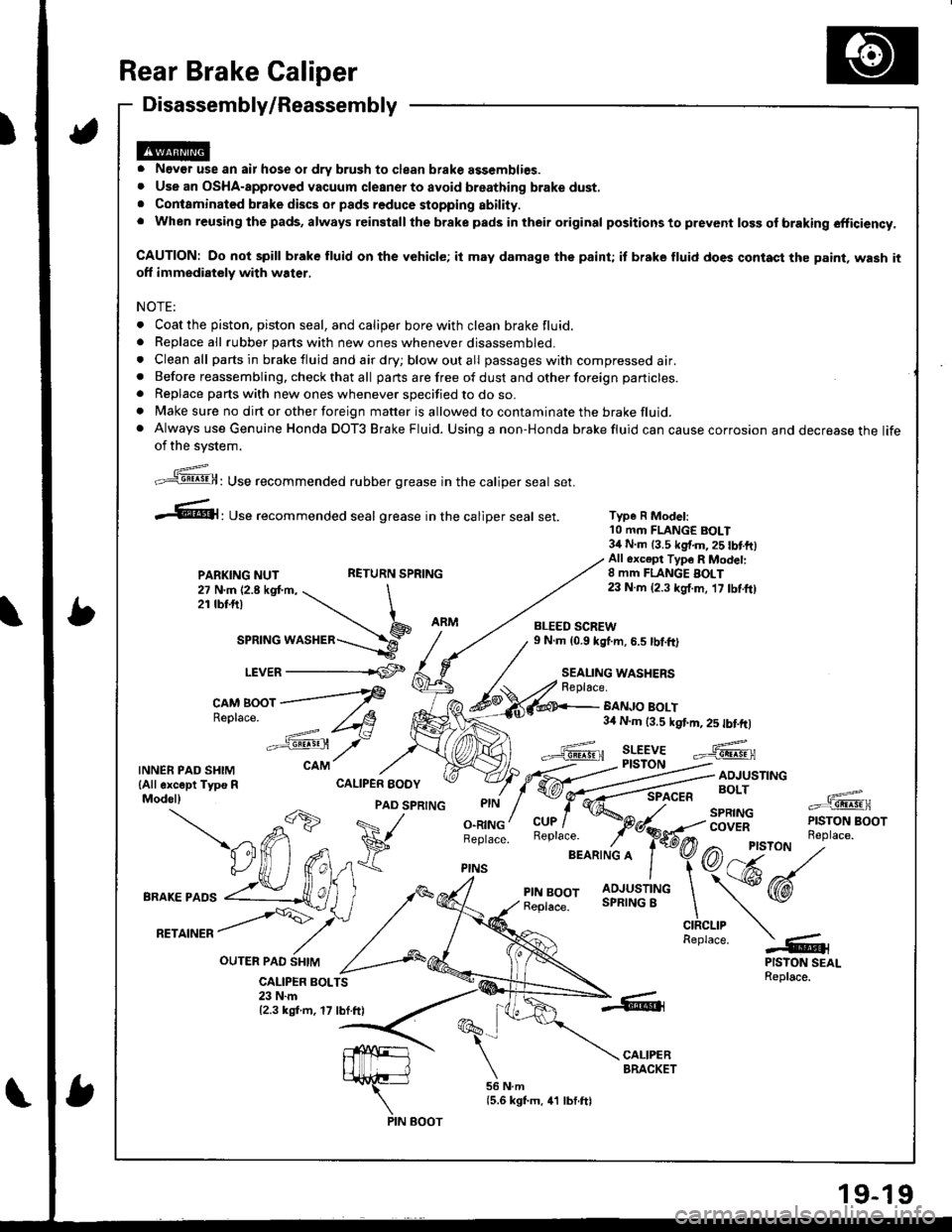

Rear Brake Caliper

Disassembly/Reassembly

o Never use an air hose or dry brush to clean brake assemblies.o Use an OSHA-approv€d vacuum cleaner to avoid breathing brake dust.. Conlaminated brake discs or pads reduce stopping ability.. When reusing the pads, always reinstall the brake pads in their original positions to prevent loss of braking efficiency,

CAUTION: Do not spill brake fluid on the vehicle; it may damags the paint; it brake fluid does contast the paint, wash itoff immediately with water,

NOTE:

. Coat the piston. piston seal, and caliper bore with clean brake fluid.. Beplace all rubber parts with new ones whenever disassembled.o Clean all parts in brake fluid and air dry; blow out all passages with compressed air.a Before reassembling, check that all parts are free of dust and other foreign particles.

. Replace parts with new ones whenever specified to do so.. Make sure no dirt or other foreign matter is allowed to contaminate the brake fluid.. Always use Genuine Honda DOT3 Brake Fluid. Using a non-Honda brake fluid can cause corrosion and decrease the lifeof the svstem.

Type R Model:10 mm FLANGE BOLT34 N.m 13.5 kg{.m,25 tbtftlAll 6xc€pt Typ6 R Modet:8 mm FLANGE BOLT23 N.m {2.3 kgf.m, 17 tbf.ft)

BANJO BOLT3,0 N.m (3.5 kgt m, 2s tbtftl

Replace.

;,'"]@: Use recommended rubber grease in the caliper seal set.

.61, Use recommended seal grease in the catiper seal set.

PARKING NUTRETURN SPRING

27 N.m 12.8 kgt m, \2rtbt.frl \

ar"t"o *or"a"=-\9_r.r,e=

LEVER -------rCF

c^M Boor ---f

Re'lace

-==': /t8

"':sst /-

CALIPER BOLTS23 N.m12.3 kgf.m, 17 lbf.ft)

TNNERPADSHTM cAM

lAll except Typs R CALIPER EODYModel)

OUTER PAO SHIM

-db

PAD SPRTNG

a71 ^ V

BRAKEPA''

vUffifi*

,*,

^rrorr /Y'

,/ ^,

O.RINGBeplace.

PINS

BLEED SCREW9 N.m (0.9 kg{.m, 6.5 tbf.ft)

SEALING WASHERSReplace.

PIN BOOT

Page 772 of 1681

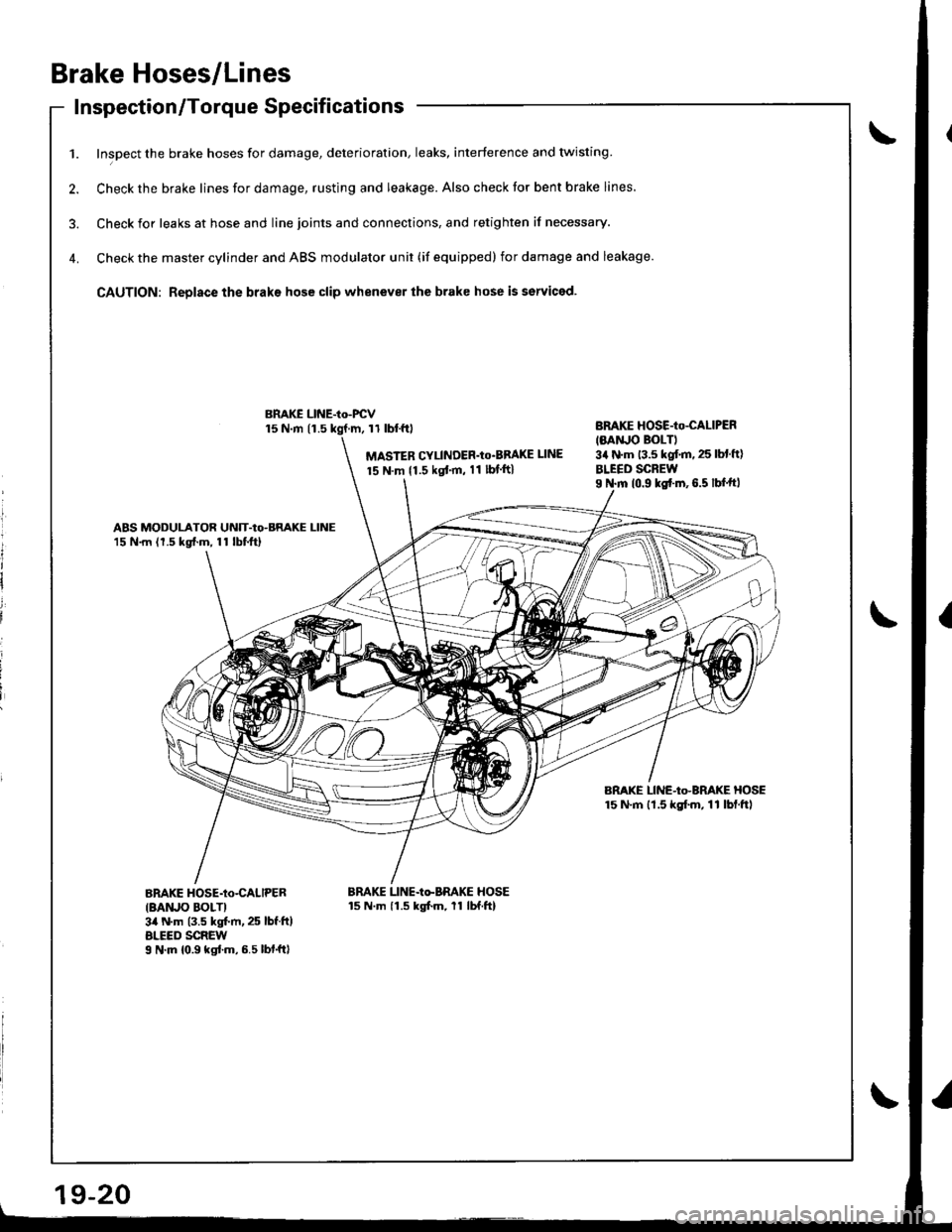

Brake Hoses/Lines

Inspection/Torque Specif icationsInspecuon/ | orque Dpecl carlon

1. Inspect the brake hoses for damage, deterioration, leaks, interference and twisting

2. Check the brake lines for damage, rusting and leakage. Also check tor bent brake lines.

3. Check ior leaks at hose and line joints and connections, and retighten if necessary.

4. Check the master cylinder and ABS modulator unit (if equipped) for damage and leakage.

CAUTION: Replace the braks hose clip whenever the brake hose is serviced.

15 N.m 11.511 tbl.f0

MASTER CYLINDER'Io'BBAKE UNE

15 N.m {1.5 kgt'm, 11 lbf ft}

BnAKE HOSE-Io-CALIPER

IMNJO BOLTI3a N'm 13.5 kgf.m. 25 lbl ft)

BLEED SCREWI N.m 10.9 ks{.m,6.5 lbf.ftl

ABS MODULATOR UNIT-Io-BRAKE LINE15 N.m (1.5 kg{.m, 11 lbtftl

BRAKE LINE-Io-BRAKE HOSE15 N'm lt.5 kgf.m, 11 lbf.ftl

BnAKE HOSE-Io-CALIPER

IBAruO BOLTI3il N.m (3.5 kgt m, 25 lbf.ft)ALEED SCREWI N'm 10.9 kgtm,6.5lbf.ftl

BRAKE LINE-Io-BRAKE HOSE15 N.m 11.5 kgfm, 11 lbf.ftl

BMKE LINE-Io-FCV

l

It

I

i

i

i

Page 773 of 1681

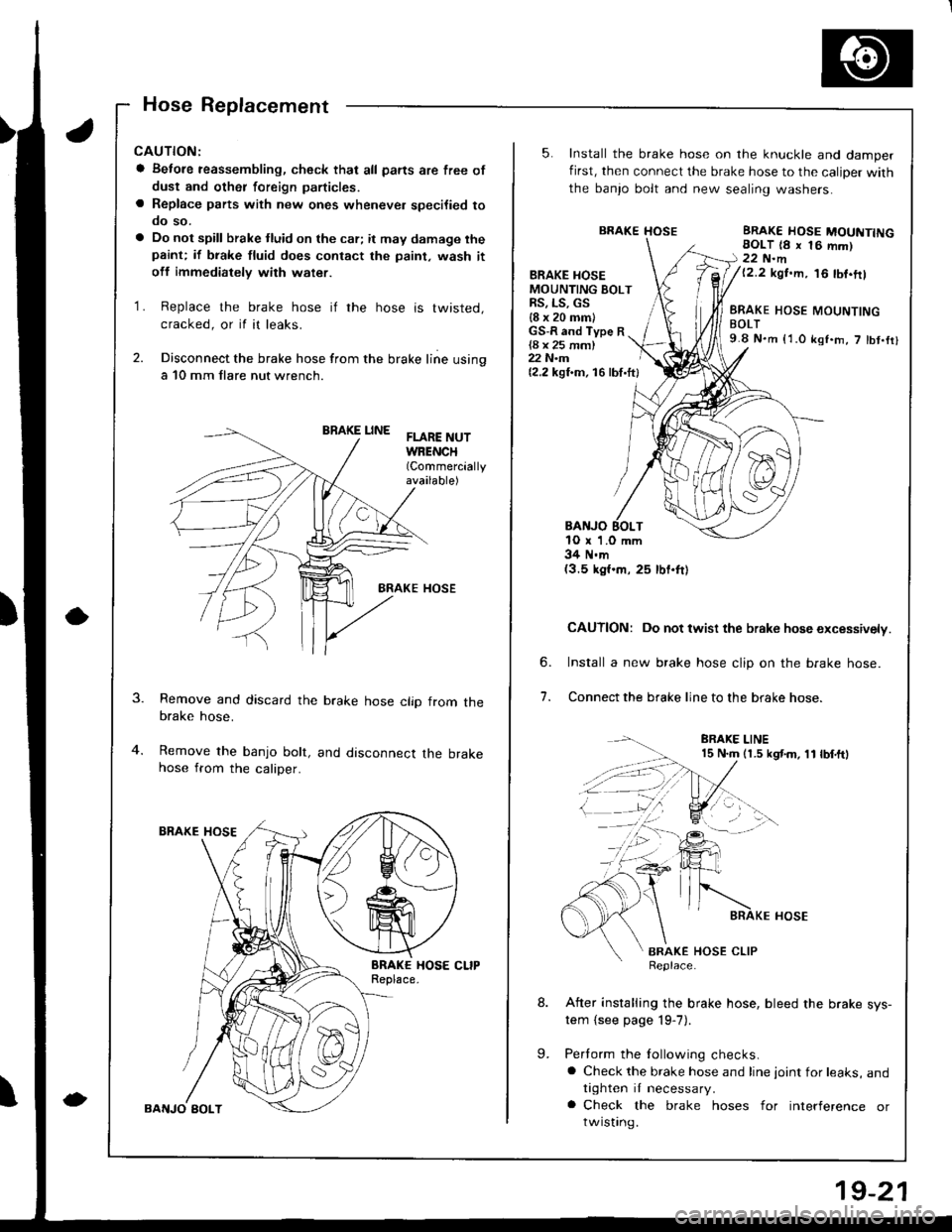

Hose Replacement

CAUTION:

a Betore reassembling, check thal all parts are free of

dust and othet foreign particles.

a Replace parts with new ones whenever specilied tooo so.

a Do not spill brake tluid on the car; it may damage thepaint; if biake fluid does contact the paint, wash it

off immediatelv with water.

1. Replace the brake hose if the hose is twisted,

cracked, or il ir leaks.

2. Disconnect the brake hose from the brake line using

a 10 mm llare nut wrench.

BRAKE LINEFLARE NUTWRENCH(Commercially

available)

BRAKE HOSE

Remove and discard the brake hose clip from thebrake hose.

Remove the banjo bolt, and disconnect the brakehose from the caliper.

5.

BRAKE HOSEMOUNTING BOLTRS, LS, GS{8 x 20 mm)

Install the brake hose on the knuckle and damper

first, then connect the brake hose to the caliDer with

the banjo bolt and new sealing washers.

BRAKE HOSEERAKE HOSE MOUNTINGEOLT 18 x 16 mm)22 N.m{2.2 kgt.m, 16 tbf.ftl

GS-R and Type R{8 x 25 mm)22 N.m(2,2 kgf.m, 16lbf.ftl

BANJO EOLTtO r 1.0 mm34 N.m(3.5 kgf.m, 25 lbf.ft)

CAUTION: Do not twist the brake hose excessively.

Install a new brake hose clip on the brake hose.

Connect the brake line to the brake hose.

6.

7.

BRAKE HOSE MOUNTINGBOLT9.8 N.m {'1.0 kst.m, 7 tbt.fi}

BRAKE LINE15 N.m (1.5 kgt m, 11 lbf.ftl

BRA(E HOSE CLIPReplace.

After installing the brake hose, bleed the brake sys-tem (see page 19-7).

Perlorm the following checks.a Check the brake hose and line joint for leaks, andtighten it necessary.

a Check the brake hoses for interference orrwrslrng.

.:2-.--l

L

19-21

Page 774 of 1681

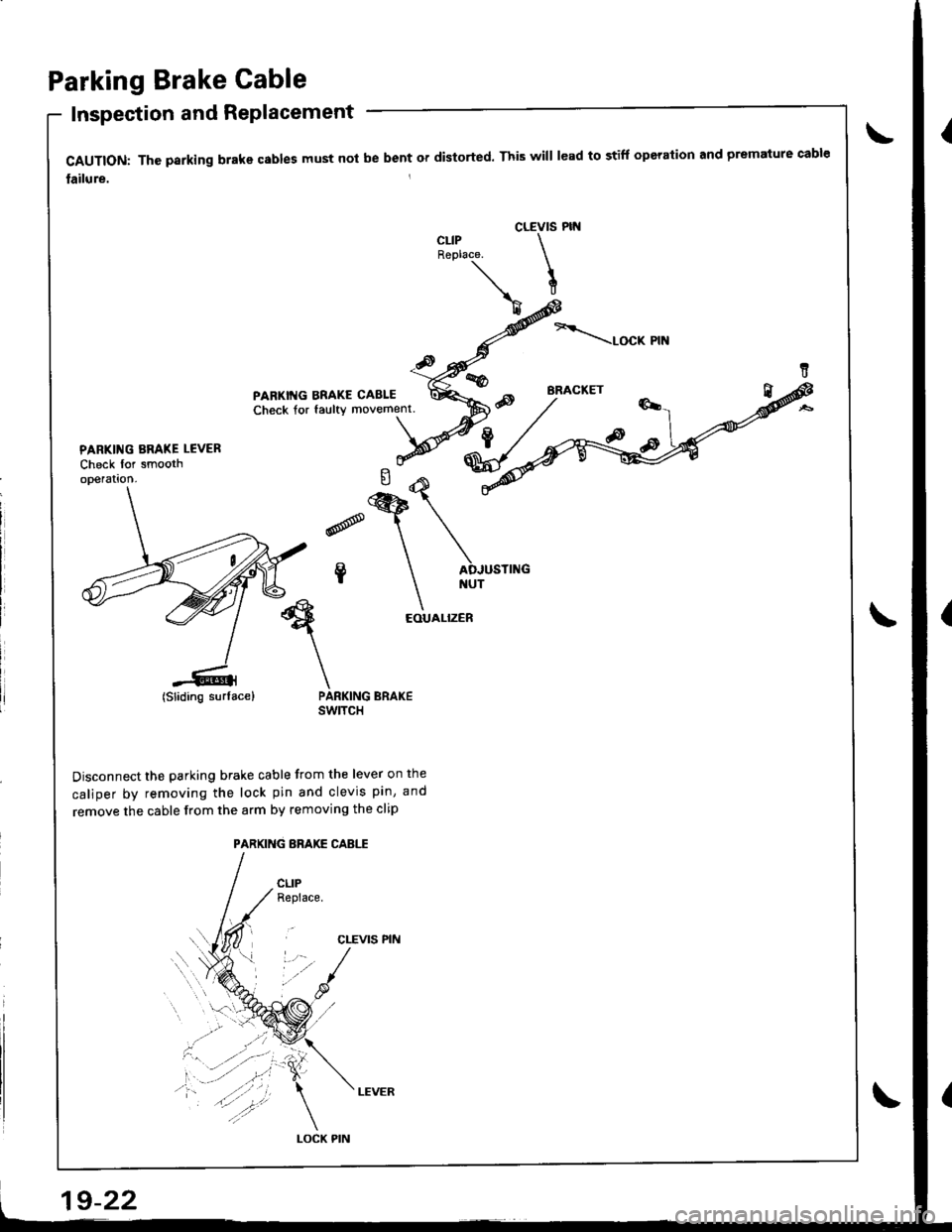

Parking Brake Cable

Inspection and Replacement

CAUTION: Thc psrking brake cables must not be bent or distorted. This will lead to stiff operation and premature cable

lailure.

CLEVIS PIN

LOCK PIN

PARKING ERAKE LCVER

Check for smooth

EOUALIZER

(Sliding surface) PARKING BRAKEswtTcH

Disconnect the parking brake cable from the lever on the

caliper by removing the lock pin and clevis pin, and

remove the cable from the arm by removing the clip

PARKING BRAKE CABLE

CLEVIS PIN

CLIPReplace.

lSliding surlace)

19-22

Page 775 of 1681

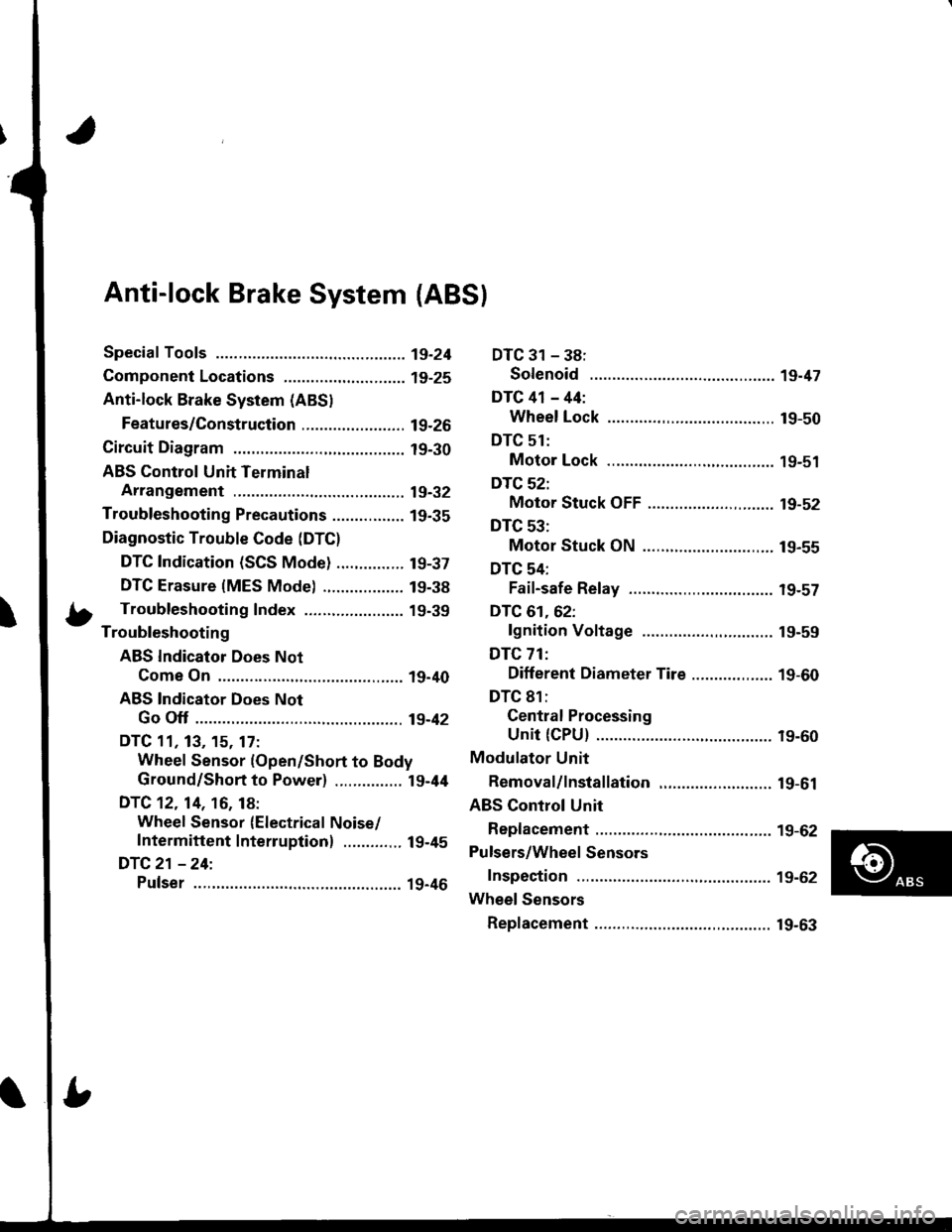

Anti-lock Brake System {ABS}

Speciaf Tools ............... 19-24

Component Locations,...........,..,........... 19-25

Anti-lock Brake System (ABSI

Features/Construction ....................... 19-2G

Circuit Diagram ........... 19-30

ABS Control Unit Terminal

Arrangement ........... 19-32

Troubleshooting Precautions ................ 1g-35

Diagnostic Trouble Code (DTC)

DTC Indication (SCS Mode) ............... t9-37

DTC Erasure {MES Mode) .................. 19-38

b Troubleshooting Index ...................... 19-39- Troubleshooting

ABS Indicator Does Not

Come On .............. 19-40

ABS Indicator Does Not

Go Off .............. ..... 19-42

DTC 11, 13, 15. 17:

Wheel Sensor (Open/Short to Body

Ground/Short to Power) ............... l9-44

DTC 12. 14, 16, 18:

Wheel Sensor (Electrical Noise/

Intermittent Interruption) ..........,.. 19-45

DTC21 -24:

Pulser ...,.......... ..... 19-46

DTC 31 - 38:

Solenoid .............. 19-47

DTC 41 - 44:

Wheel Lock .......... 19-50

DTC 51:

Motor Lock .......... 19-51

DTC 52:

Motor Stuck OFF ...................,........ 19-52

DTC 53:

Motor Stuck ON ............................. 19-55

DTC 54:

Fail-safe Relay ................................ t9-57

DTC 61.62:

lgnition Voltage ............................. 19-59

DTC 71:

Different Diameter Tire .................. 1 9-60

DTC 81:

Gentral Processing

Unit {CPU} ............ 19-60

Modulator Unit

Bemoval/lnstallation ......................... 19-61

ABS Control Unit

Replacement ............ 19-62

Pulsers/Wheel Sensors

Inspection ................ 19-62

Wheel Sensors

Replacement .,.......... 19-63

Page 778 of 1681

.,i

,I

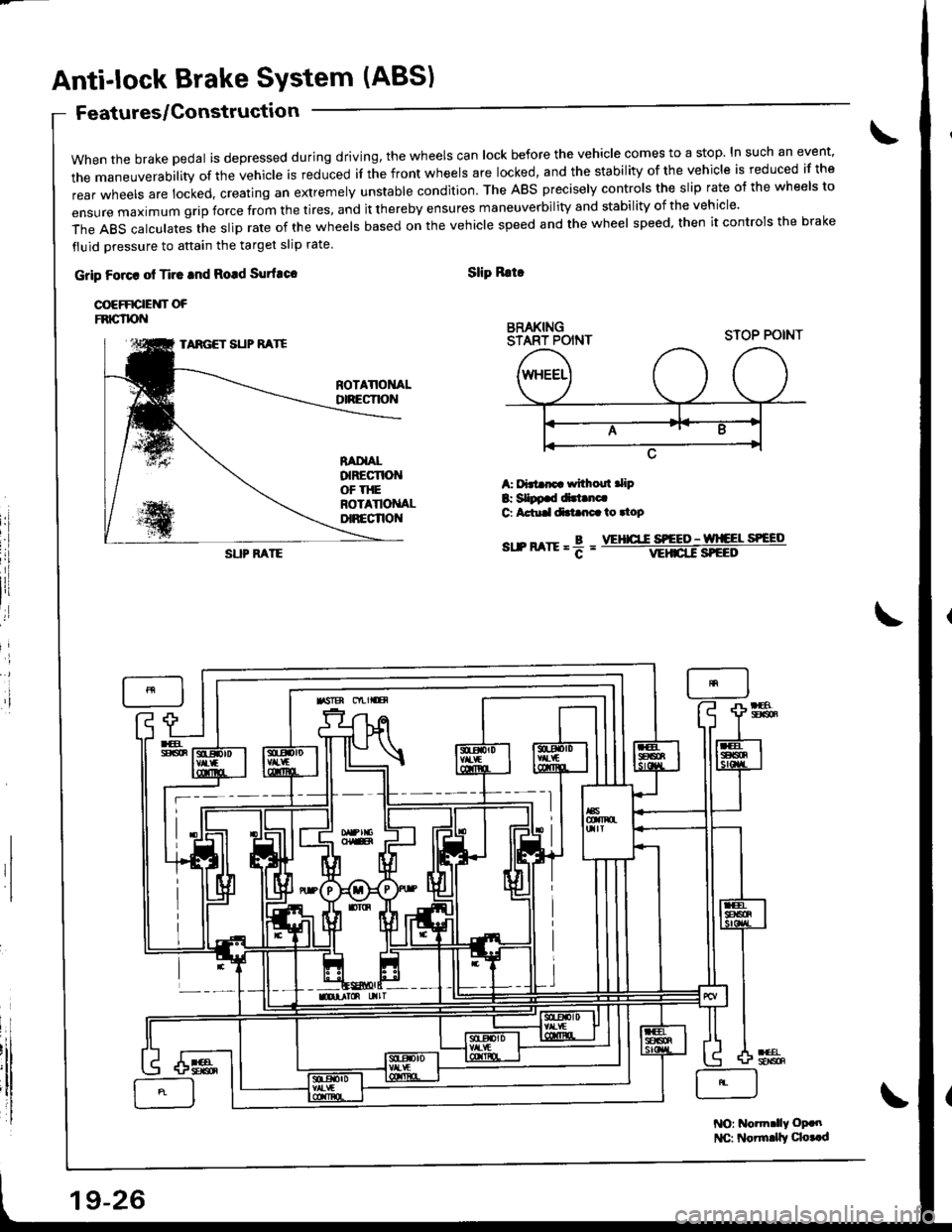

Anti-lock Brake SYstem (ABS)

when the brake pedal is depressed during driving, the wheels can lock before the vehicle comes to a stop. In such an event.

the maneuverability of the vehicle is reduced if the front wheels are locked, and the stability of the vehicle is reduced if the

rear wheels are locked, creating an extremely unstable condition. The ABS precisely controls the slip rate o{ the wheels to

ensUre maximum grip force from the tires, and it thereby ensures maneuverbiIity and stabiIity of the vehicIe.

The ABS calculates the slip rate of the wheels based on the vehicle speed and the wheel speed. then it controls the brake

fluid oressure to attain the target slip rate

Features/Gonstructio n

Grip Foact ot Ti.c tnd Rotd Surfuco

COEFFICIEUT OFFNIG"TPN

Slip Rrtr

BRAKINGSTART POINT

i'l

A: f'3t rp withoul .lip

B: SIDp.d dirt.nc.G Actu.ldtt nc.io.top

sr.n arrr = f =

STOP POINTTARGET SUP RATE

SUP FATEVEHICT.C S'EEO - wlCEL SPEED

NO: Notm.lly oP.n

l{C: Noirnrly qo..d

19-26

Page 780 of 1681

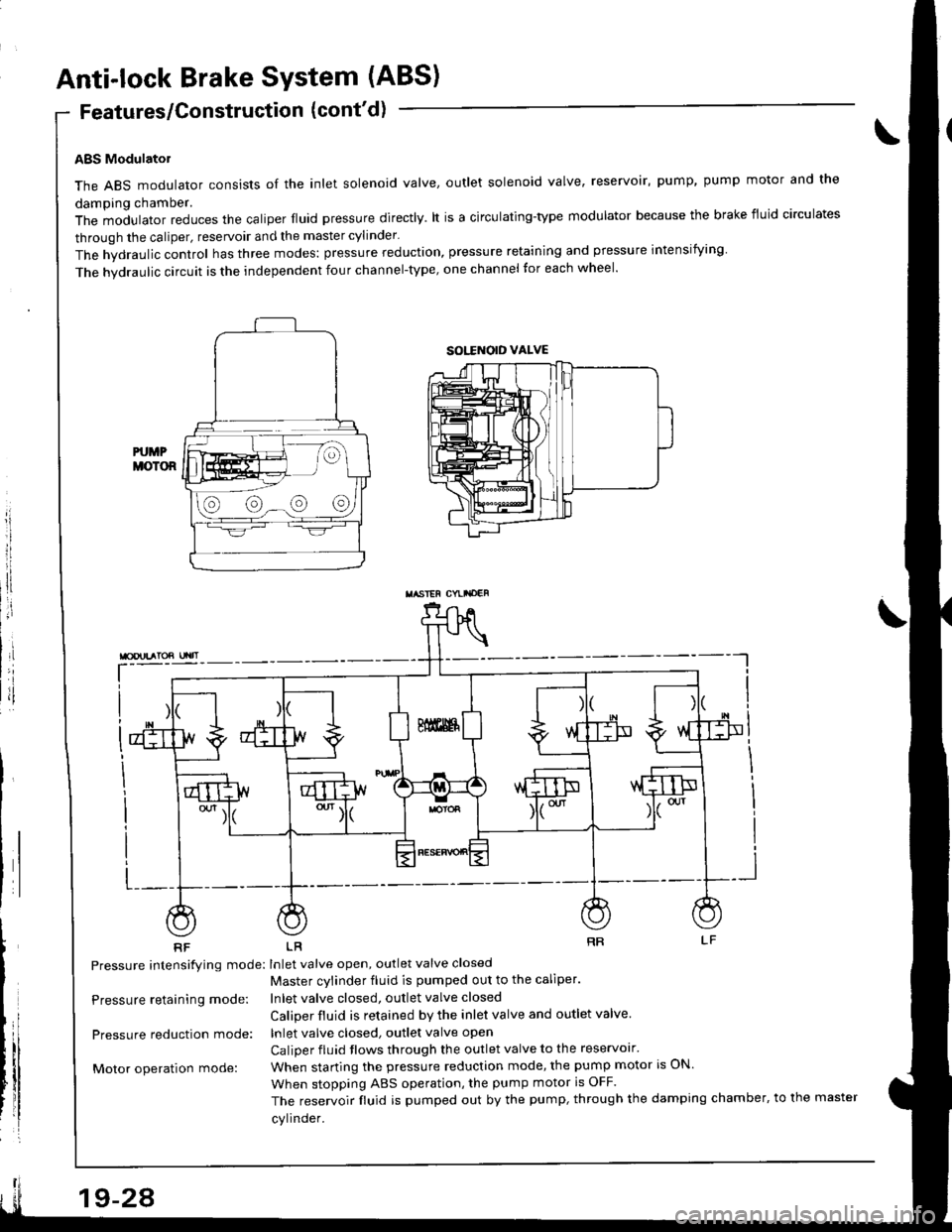

Anti-lock Brake System (ABS)

Features/Construction (cont'd)

ABS Modulatol

The ABS modulator consists of the inlet solenoid valve, outlet solenoid valve, reservoir, pump, pump motor and the

damping chamber.

The modulator reduces the caliper fluid pressure directly. lt is a circulating-type modulator because the brake fiuid circulates

through the caliper, reservoir and the master cylinder.

The hydraulic control has three modes: pressure reduction, pressure retaining and pressure intensiiying

The hvdraulic circuit is the independent four channel-type, one channel tor each wheel'

L-__

RF LR

Pressure intensifying mode: Inlet valve open, outlet valve closed

Master cvlinder fluid is pumped out to the caliper.

Inlet valve closed, outlet valve closed

Caliper fluid is retained by the inlet valve and outlet valve.

lnlet valve closed, outlet valve open

Caliper fluid flows through the outlet valve to the reservolr'

When starting the pressure reduction mode, the pump motor is ON.

When stopping ABS operation, the pump motor is OFF.

The reservoir fluid is pumped out by the pump, through the damping chamber, to the master

cylinder.

\

Pressure retaining mode:

Pressure reduction mode:

Motor operation mode:

sott orD vALvE

@@-@@

TASIEF CYLI'OEF

19-24

Page 784 of 1681

![HONDA INTEGRA 1998 4.G Manual PDF ABS Gontrol Unit Terminal Arrangement

ABS CONTROL UN]T 22P CONNECTOR

Wire side oI female t6rminals

Terminal

numbel

Wire

Golor

Terminsl sign

{Terminal

namet

Description

Measurgmgnt

TerminalConditions

{ HONDA INTEGRA 1998 4.G Manual PDF ABS Gontrol Unit Terminal Arrangement

ABS CONTROL UN]T 22P CONNECTOR

Wire side oI female t6rminals

Terminal

numbel

Wire

Golor

Terminsl sign

{Terminal

namet

Description

Measurgmgnt

TerminalConditions

{](/img/13/6069/w960_6069-783.png)

ABS Gontrol Unit Terminal Arrangement

ABS CONTROL UN]T 22P CONNECTOR

Wire side oI female t6rminals

Terminal

numbel

Wire

Golor

Terminsl sign

{Terminal

namet

Description

Measurgmgnt

TerminalConditions

{lgnition swhch ON {ll}}Voltage

1BLK/WHTGND3(Ground 3)

Ground1.GNDBelow 0.3 V

4GRN/REDPARK

{Parking)

Detects parking brake

switch signal4-GNDParking

brake

PulledBelow 0.3 V

Battery voltage

LT GRN/

BLK

FLW (-)

{FronLleft

wheel negative)

Detects left-front wheel

sensor srgnal

0.053 V or

above

0sci\oscope:

0.15 Vp-p or

above

7GBN/ORN

FLW (+)

(Front-left

wheel positive)- | Turn wheel at

E

1 turntsecona

l'GRN

FRW (-)

(Front-right

wheel negative)

Detects right-f ront wheel

sensor slgnal

8-9

1 FR\N (+)

I \GRN/BLK (Front-right

I I wheelpositiveStops0.25 - 1.15 V

10GRN/WHTSTOPDetects brake switch signal1O.GNDBrake pedalDepressedBaftery voltage

ReleasedBelow 0.3 V

11BLK/TELtG2

(lgnition 2)

Power source for activating

the system11-GNDlgnition

switch

oN {I)Battery voltage

Start (lll)Below 0.3 V

19-32

Page 788 of 1681

Troubleshooting Precautions

Kickback

L The motor operates when the ABS is functioning, and the fluid in the reservoir is forced out to the master cylinder,

causing kickback at the brake pedal.

Pump Motol

1. The pump motor operates when the ABS is functioning.

2. The ABS control unit checks the pump motor operation during initial diagnosis and when the vehicle is started. You

mav hear the motor operate at this time, but it is normal

Brake Fluid Replacement/Air Bleeding'1. Brake fluid replacement and air bleeding procedures are the same as vehicles without ABS. To ease bleeding, start

with the front wheels.

Troubleshooting

1. The troubleshooting flowcharts procedures assume that the cause of the problem is still present and the ABS indica-

tor is still on. Following the flowchart when the ABS indicator does not come on can result in incorrect diagnosis.

2. Ouestion the customer about the conditions when the problem occurred, and try to reproduce the same conditions

for troubleshooting.

Find out when the ABS indjcator came on. such as during initial diagnosis. during ABS control, after ABS control,

when vehicle speed was at a certain speed, etc.

3, When the ABS indicator does not come on during the test-drive, but troubleshooting is performed based on the DTC,

check for loose connectors, poor contact at the terminals, etc. before you start troubleshooting'

4. After troubleshooting, erase the DTC and test-drive the vehicle. Be sure the ABS indicator does not come on.

5. The connector illustrations show the female terminals with a single outline and the male terminals with a double outline.