power steering fluid HONDA INTEGRA 1998 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 683 of 1681

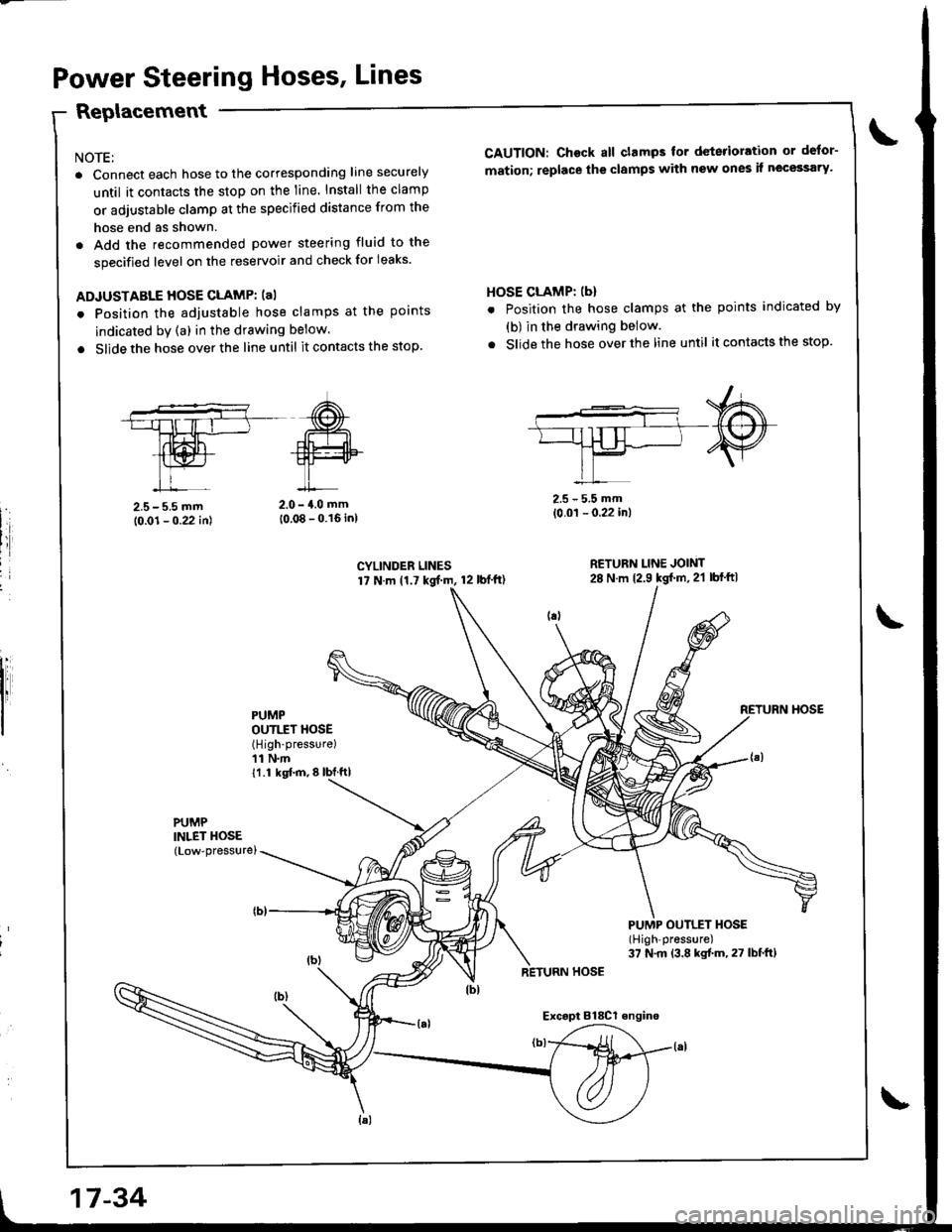

Power Steering Hoses, Lines

Replacement

NOTE:

. Connect each hose to the corresponding line securely

until it contacts the stop on the line. Install the clamp

or adjustable clamp at the specified distance from the

hose end as shown.

. Add the recommended power steering fluid to the

specified level on the reservoir and check for leaks.

ADJUSTABLE HOSE CLAMP: (al

. Position the adjustable hose clamps at the points

indicated by (a) in the drawing below.

. Slide the hose over the line until it contacts the stop.

CAUTION: Ch€ck all clamps for deterioration or defor-

mation; replace the clamps with new ones it necessary'

HOSE CLAMP: (b)

. Position the hose clamps at the points indicated by

(b) in the drawing below.

. Slide the hose over the line until itcontactsthe stop.

2.5 - 5.5 mm(0.01 - 0.22 in)

RETURN LINE JOINT28 N m 12.9 kg{'m,2'l lbf'ft|

PUMP OUTLET HOSE(High'pressure)

37 N.m (3.8 kgtm,27 lbf.ft)

2.5-5.5 mm

10.01 - 0.22 in)2.0 - {.0 mm

10.08 - 0.16 inl

CYLINDER LINES17 N.m (1.7 kgt m, 12 lbf'ft)

PUMPOUTI.IT HOSE(High-pressure)

11 N.m11.1 kgl.m,8lbJftl

PUMPINLET HOSE(Low-pressurel

RETURN HOSE

Exc.pt Bl8Cl engino

17-34

Page 684 of 1681

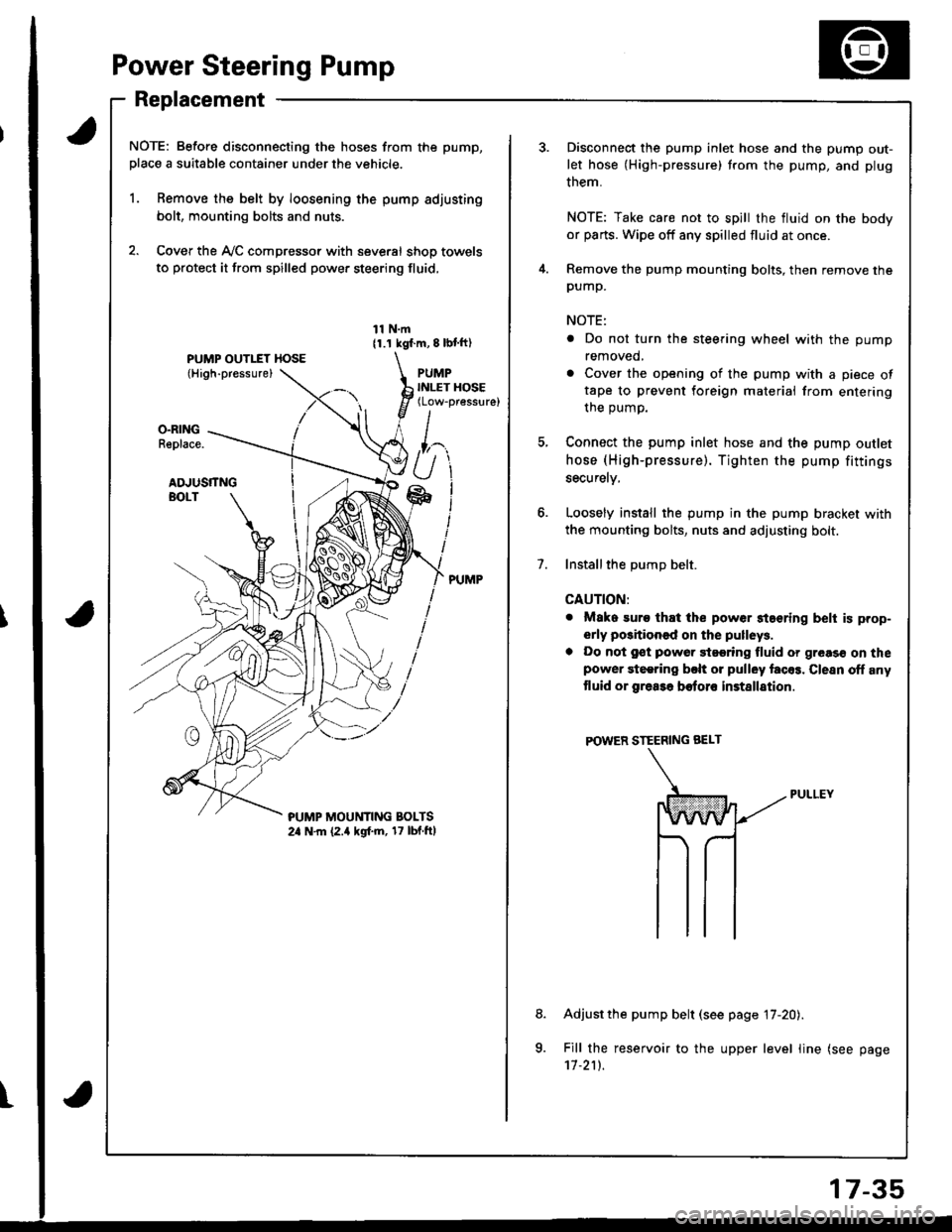

Power Steering Pump

Replacement

NOTE: Before disconnecting the hoses from the pump,

place a suitable container under the vehicle.

1. Remove the belt by loosening the pump adjusting

bolt, mounting bolts and nuts.

2. Cover the Ay'C compressor with several shop towels

to protect it from spilled power steering fluid,

11 N.m11.1 kgf.m, 8 lbl ft)

PUMPINLET HOSE(Low-pressure)

O.RINGReplace.

ADJUSTTNGBOLT

?UMP MOUt'lTlNG BOLTS2a N.m (2.a kgf.m, 17 lbf.ftl

t

7.

Disconnect the pump inlet hose and the pump out-

let hose (High-pressure) trom the pump, and plug

them.

NOTE: Take care not to spill the fluid on the body

or parts. Wipe off any spilled fluid at once.

Remove the pump mounting bolts, then remove thepump.

NOTE:

. Do not turn the steering wheel with the pump

removed,

. Cover the opening of the pump with a piece oftape to prevent foreign materiai from entering

the oumo.

Connect the pump inlet hose and the pump outlet

hose (High-pressure). Tighten the pump fittings

securelv,

Loosely install the pump in the pump bracket with

the mounting bolts, nuts and adjusting bolt.

Installthe DumD belt.

CAUTION:

. Mako suro that the power staering belt is prop-

erly positioned on the pulleys.

a Do not gst powor 9t99ring fluid or greas€ on thepower steering bclt or pulley facos. Clesn off any

tluid or grea3a botoro installation

POWER STEERING BEI-T

Adjust the pump belt (see page 17-20).

Fill the reservoir to the upper level line (see page'11.211.

8.

a

17-35

Page 685 of 1681

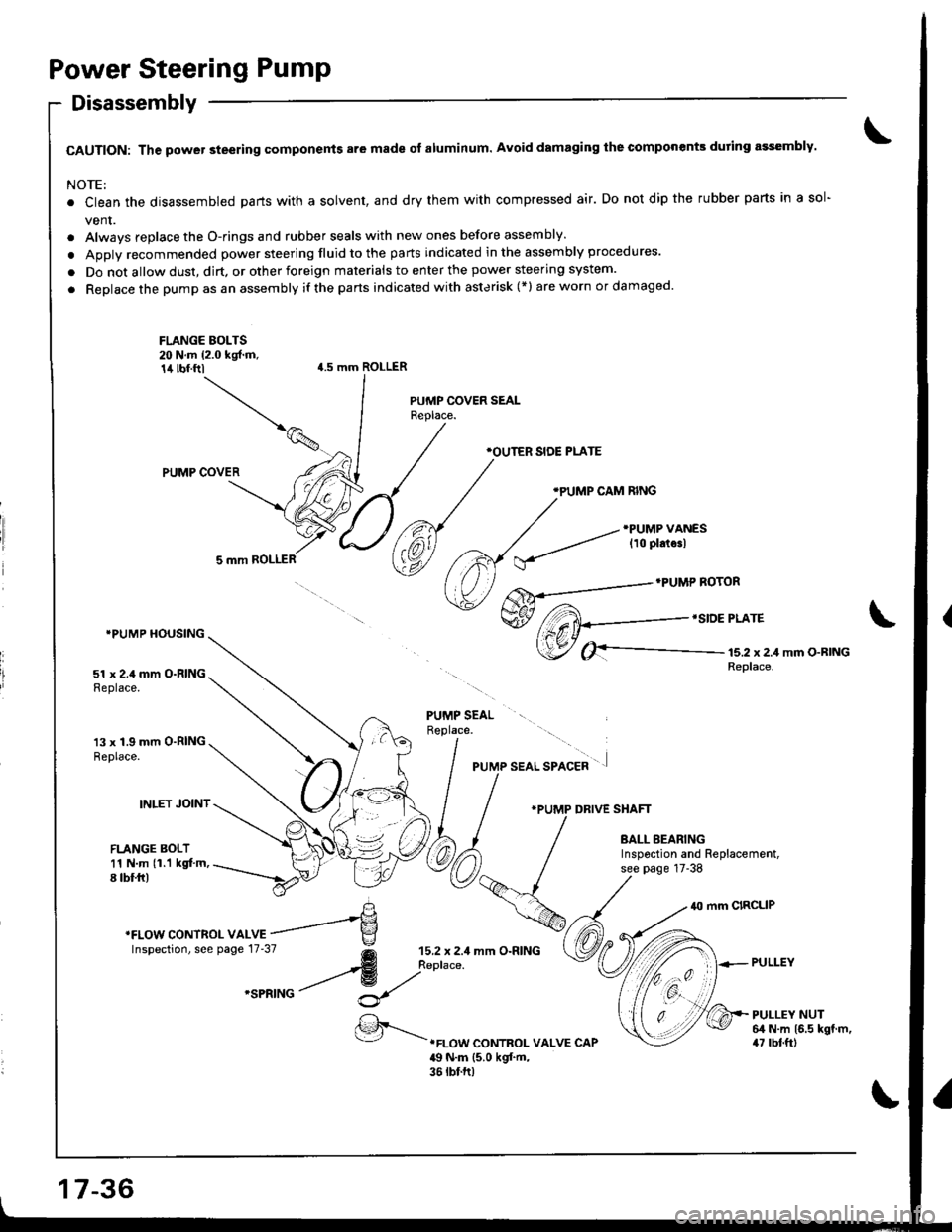

Power Steering Pump

Disassembly

CAUTION: The power steering components are made of aluminum. Avoid damaging the componenk during assembly.

NOTE:

. Clean the disassembled parts with a solvent, and dry them with compressed air. Do not dip the rubber parts in a sol-

vent.

. Always replace the O-rings and rubber seals with new ones before assembly.

. Apply recommended power steering fluid to the parts indicated in the assembly procedures.

. Do not allow dust, dirt, or other foreign materials to enter the power steering system.

. Replace the pump as an assembly if the parts indicated with asterisk (*l areworn ordamaged'

\

FLANGE BOLTS20 N.m (2.0 kgf.m,14 tbf.ftl{.5 mm ROLLER

PUMP COVER

5 mm ROLLER

IPUMP HOUSING

51 x 2.4 mm O-RINGReplace.

13 x 1.9 mm O-RINGReplace.

INLET JOINT

FLANGE BOLT11 N.m (1.1 kgt'm,8 tbf.fr)

PUMP SEALReplace.

,r"" aao, "ro"a* ' .]

*PUMP DRIVE SHAFT

BALL BEARINGInspoction and Replacement,see page 17-38

40 mm CIRCLIP

PULLEY

PULLEY NUT64 N.m 16.5 kgt.m,47 rbtft).FLOW CONTROI- VALVE CAP

49 N.m {5.0 kgf'm,36 tbt.ft)

'FLowcoNTRoLvA *r"=-'e

\

lnspectron, see pase 17.37

@ ;;:,:::

mm o.RrNG

'""^rro / ^t

17-36

Page 687 of 1681

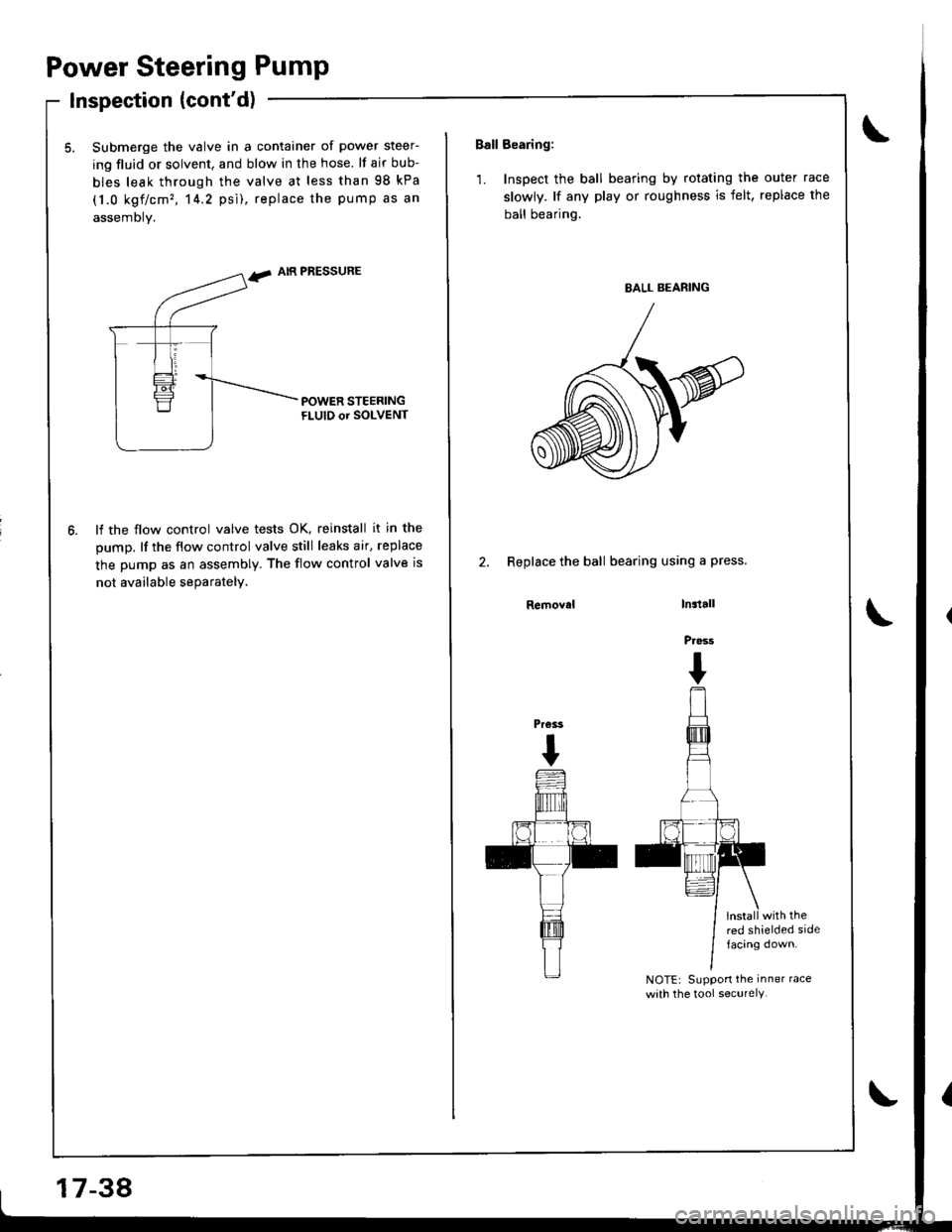

Power Steering Pump

lnspection {cont'd)

5. Submerge the valve in a container of power steer-

ing fluid or solvent, and blow in the hose. lf air bub-

bles leak through the valve at less than 98 kPa

(1.0 kgf/cm', 14.2 psi), replace the pump as an

assembly.

f. AIR PRESSURE

lf the flow control valve tests OK, reinstall it in the

pump. lf the flow control valve still leaks air, replace

the pump as an assembly. The flow control valve is

not available seDaratelv.

17-38

Ball Bearing:

1. Inspect the ball bearing by rotating the outer race

slowly. lf any play or roughness is felt, replace the

ball bearing.

2. Replace the ball bearing using a press.

Removalln3tall

Pross

I

install with thered shielded sidefacing down.

NOTEr Suppon the inner race

with the tool securelY.

Pr€ss

I

Page 689 of 1681

Power Steering Pump

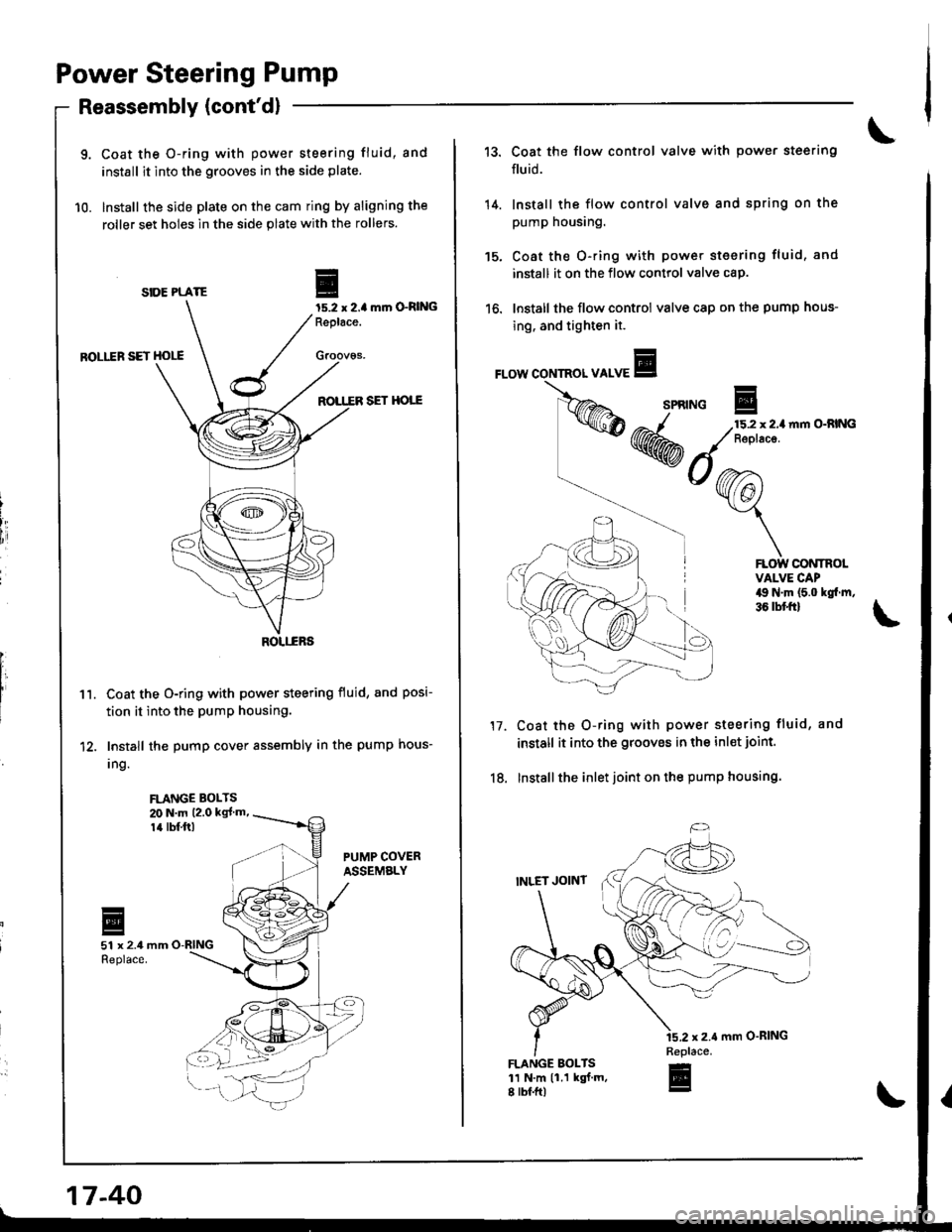

9. Coat the O-ring with power steering fluid, and

install it into the grooves in the side plate.

10. Install the side plate on the cam ring by aligning the

roller set holes in the side plate with the rollers.

SIOE PLATEmrn O-RltlG

ROLI.ER SET HOLE

ROTT.ER SET HOTT

Coat the O-ring with power steering fluid, and posi-

tion it into the pumP housing.

Install the pump cover assembly in the pump hous-

Ing.

Reassembly (cont'dl

FLANGE BOLTS20 N.m 12.0 kgl m,

14 rbf.ftl

-

EI15.2 | 2.4Replace.

Groov6s,

iI

[,

1'�I.

I

17-40

14.

tc.

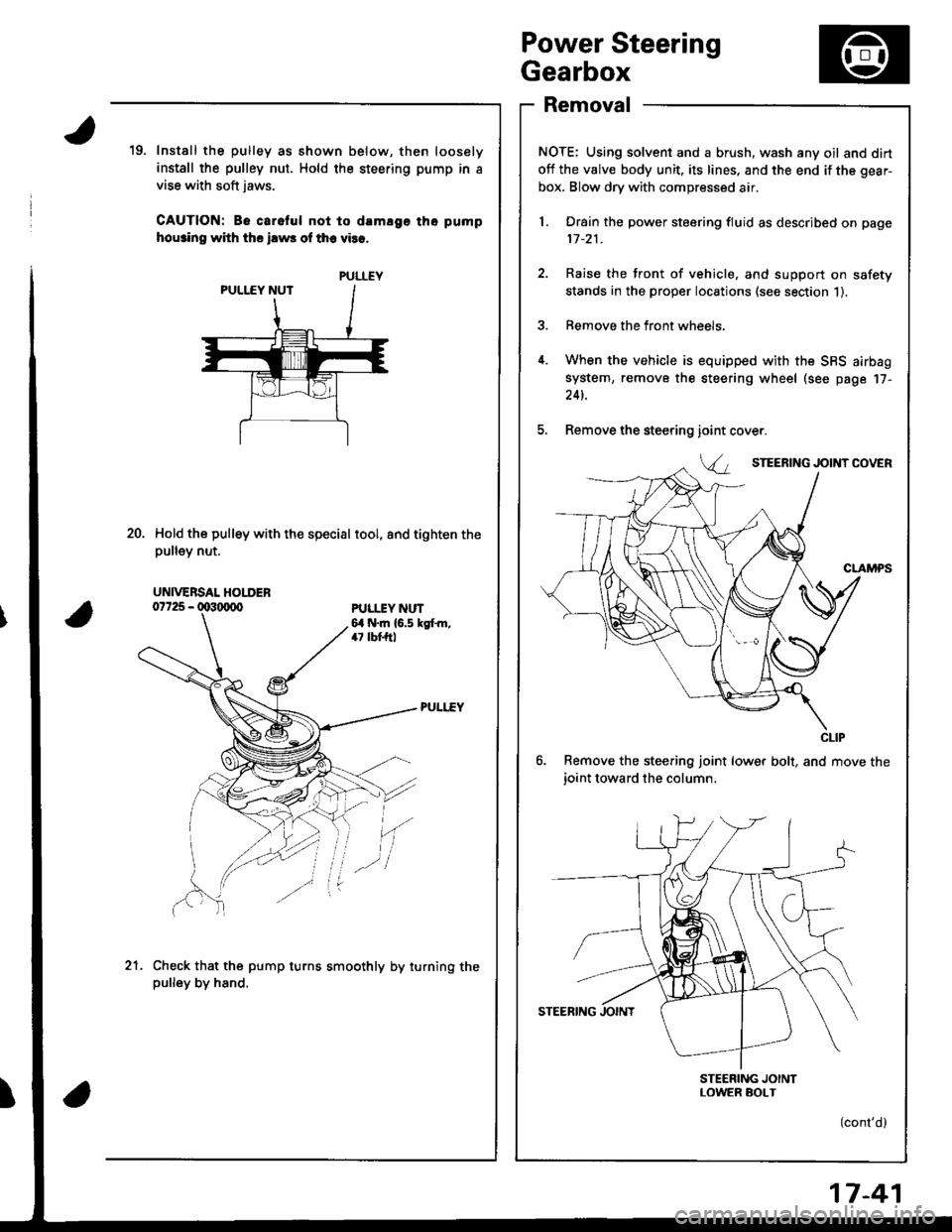

13. Coat the flow control valve with power steering

fluid.

Install the flow control valve and spring on the

pump housing.

Coat the O-ring with powet steering fluid, and

install it on the flow control valve cap.

Install the flow control valve cap on the pump hous-

ing. and tighten it.

FLOW CONTROL VALVE

n|m O-RING

SPRTNG E/-^-/ 215.2 x2.1

KWM ,// Reptace.

*o@ra

Y

l\i \

Coat the O-ring with power steering fluid, and

install it into the grooves in the inl€t joint.

Installthe inlet joint on the pump housing.

FLOW CONTROLVALVE CAP49 N'm (5.0 kgl.m,36 tbtft)

17.

18.

FLANGE BOLTS11 N.m 11.1 kgt.m,8 rbf.ftl

Replace.-

E

Page 690 of 1681

Power Steering

Gearbox

Removal

NOTE: Using solvent and a brush, wash any oil and dirt

off the valve body unit, its lines, and the end if the gear-

box. Blow dry with compressed air.

l. Drain the power steering fluid as described on page

11-21.

2. Raise the front of vehicle, and support on safety

stands in the proper locations (see section 1).

3. Remove the front wheels.

4. When the vehicle is equipped with the SBS airbag

system, remove the steering wheel (see page 17-

24t.

5. Remove the steering

6. Remove the steering joint lower bolt, and move the

ioint toward the column.

STEERING JOINTLOWER SOI-T

(cont'd)

19. Install the pulley as shown below, then loosely

install the pulley nut. Hold the steering pump in a

vise with soft jaws.

CAUTION: Be carelul not to damlge tho pump

hou3ino with ths ilws of th6 vies.

Hold the pulley with the special tool, and tighten thepu ey nut.

ioint

Va

20.

PULI.IY NUT6,1 N.m {6.5 kgt m,47 lbf,ftl

'(

Check that the pump turns smoothly by turning thepulley by hand.

.-l

21.

PULLEY

UNIVERSAL HOLDER

CLIP

17-41

Page 698 of 1681

ra

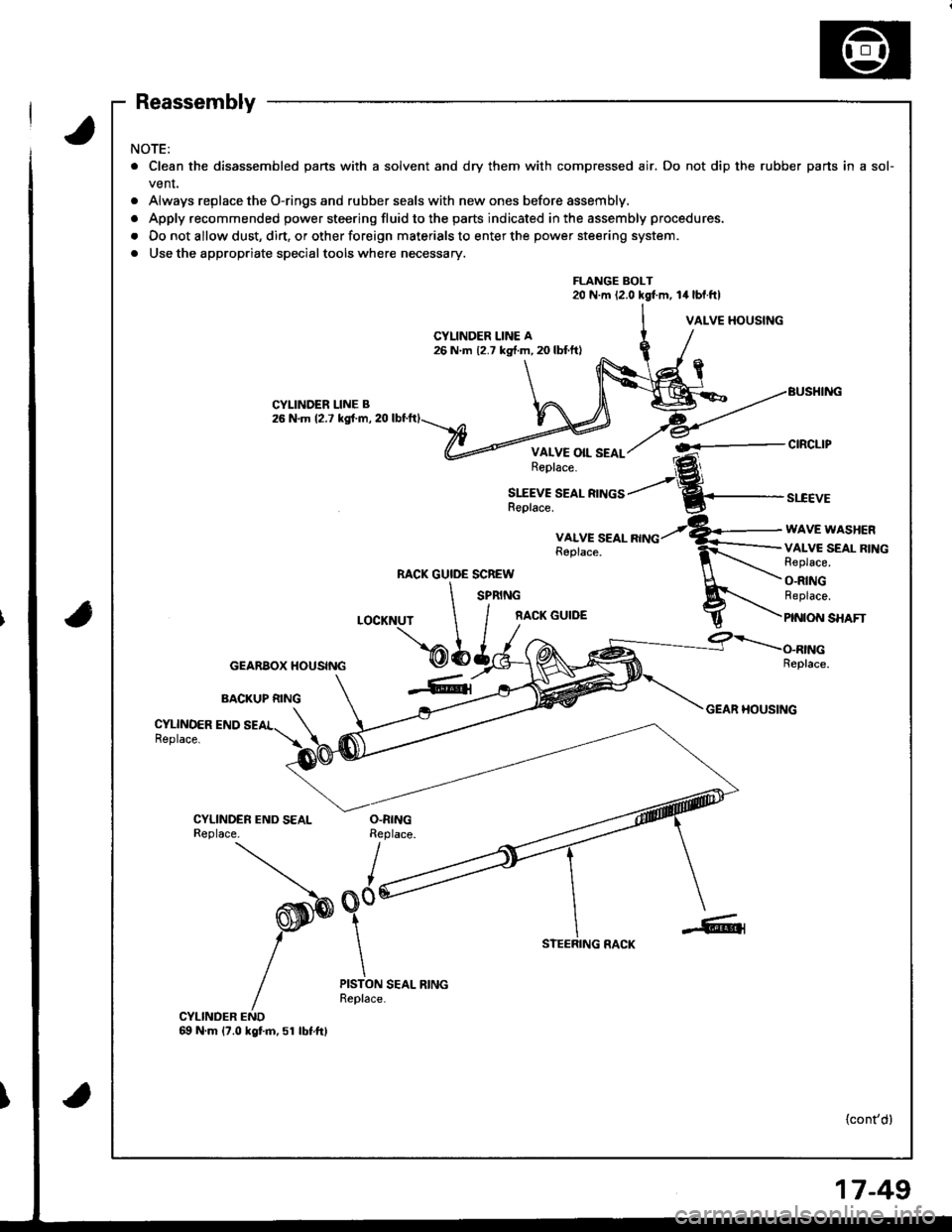

NOTE:

. Clean the disassembled parts with a solvent and dry them with compressed air. Do not dip the rubber parts in a sol-

venr,

. Always replace the O-rings and rubber seals with new ones before assembly,

. Apply recommended power steering fluid to the parts indicated in the assembly procedures.

. Do not allow dust, dirt, or other foreign materials to enter the power steering system.

. Use the appropriate specialtools where necessary.

FLANGE BOLT20 N.m 12.0 kgf.m, 14 lbl.ftl

VALVE HOUSING

CYLINDER LINE B26 N.m 12.7 kgf.m, 20

VALVE OIL SEALReplace.

SLEEVE SEAL RINGSReplace.st"cEvE

VALVE SEALReplace.

WAVE WASHER

VALVC SEAL RINGReplace.

O-RINGReplace.

PINION SHAFT

RACK GUIDE SCREW

LOCKNUT \

cEARBoxHousrNc \b

SPRING

f,ACK GUIDE

BACKUP RING

Replace.

GEAR HOUSINGCYLINDER ENDReplace.

CYLINDER END SEALReplace.O.RINGReplace.

I

o0'

STEERING RACK

PISTON SEAL RINGReplace.

CYLINDER END69 N.m {7.0 kgtm,51 lbtftl

{cont'd}

Page 699 of 1681

Power Steering Gearbox

Reassembly (cont'dl

i

valv6 Body Reasrombly

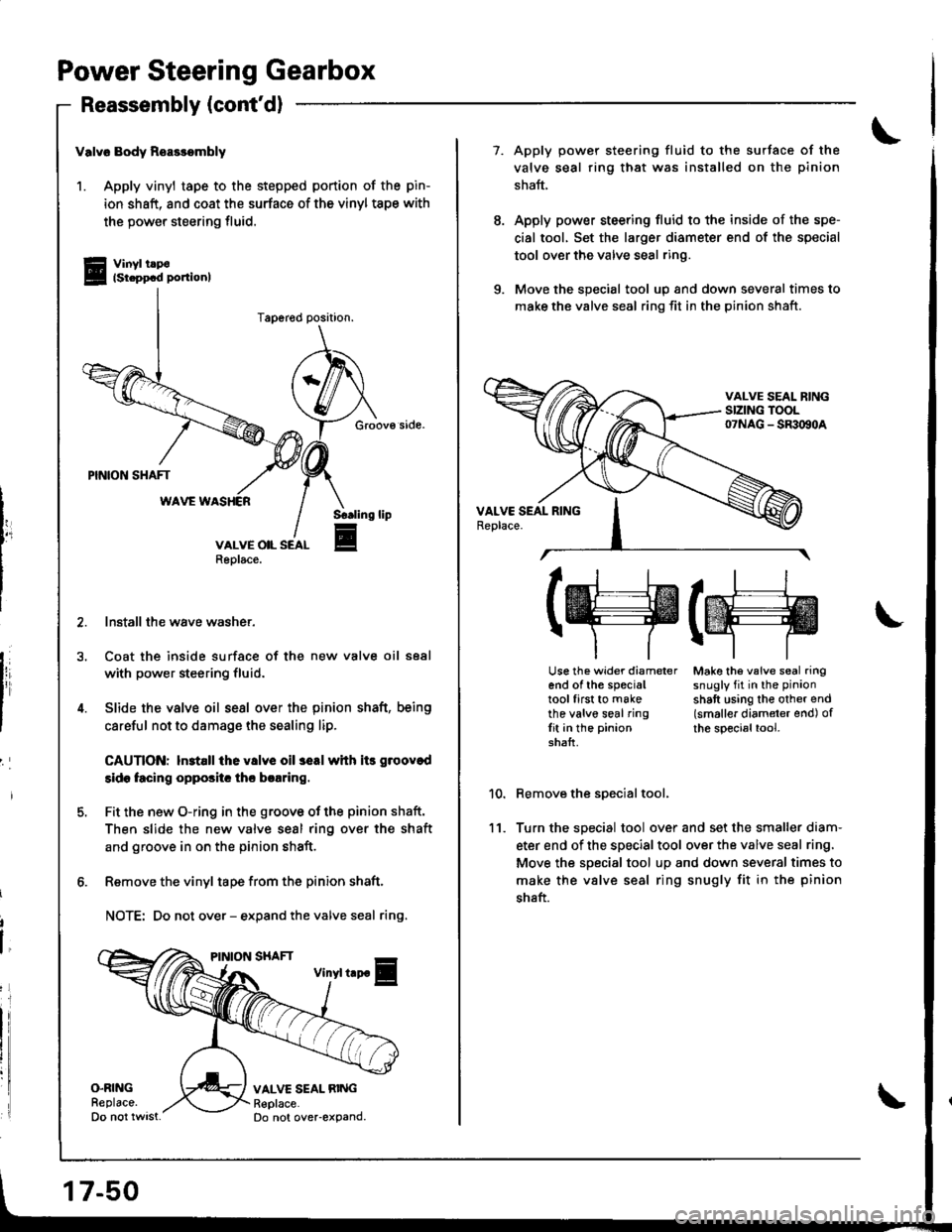

1. Apply vinyl tape to the stepped portion of the pin-

ion shaft, and coat the surface of the vinyl tspe with

the power steering fluid.

Vinyl tlp€lst.ppcd ponionl

Groov€ side.

Install the wave washer,

Coat the inside surface of the new valve oil seal

with power steering fluid.

Slide the valve oil sesl over the pinion shaft, being

careful not to damage the sealing lip.

CAUTIONT ln3tall the v8lve oil 3eal whh itr groovod

side facing oppositc thc braring.

Fit the new O-ring in the groovo of the pinion shaft.

Then slide the new valve sesl ring over the shaft

and groove in on the pinion shaft.

Remove the vinyl tape from the pinion shaft.

NOTE: Do not over - expand the valve seal ring.

Sr.lino

E

lip

VALVE SEAL RINGReplace.Do not over-expand.

17-50

7. Apply power steering fluid to the surJace of the

valve seal ring that was installed on the pinion

shaft,

Apply power steering fluid to the inside of the spe-

cial tool, Set the larger diameter end of the special

tool over the valve seal ring.

Move the sDecial tool uo and down several times to

make the valve seal ring fit in the pinion shaft.

11.

(w(ffi \

Use the wider diameter Make th6 valve seal ringend of the special snugly fit in the pinion

tool first to make shaft using the other endthe valve seal ring (smaller diameter end) ofIit in the pinion the special tool.shalt.

Remove the special tool,

Turn the special tool over and set the smaller diam-

eter end of the special tool over the valve seal ring,

Move the special tool up and down several times to

make the vslve seal ring snugly fit in the pinion

shaft.

Page 700 of 1681

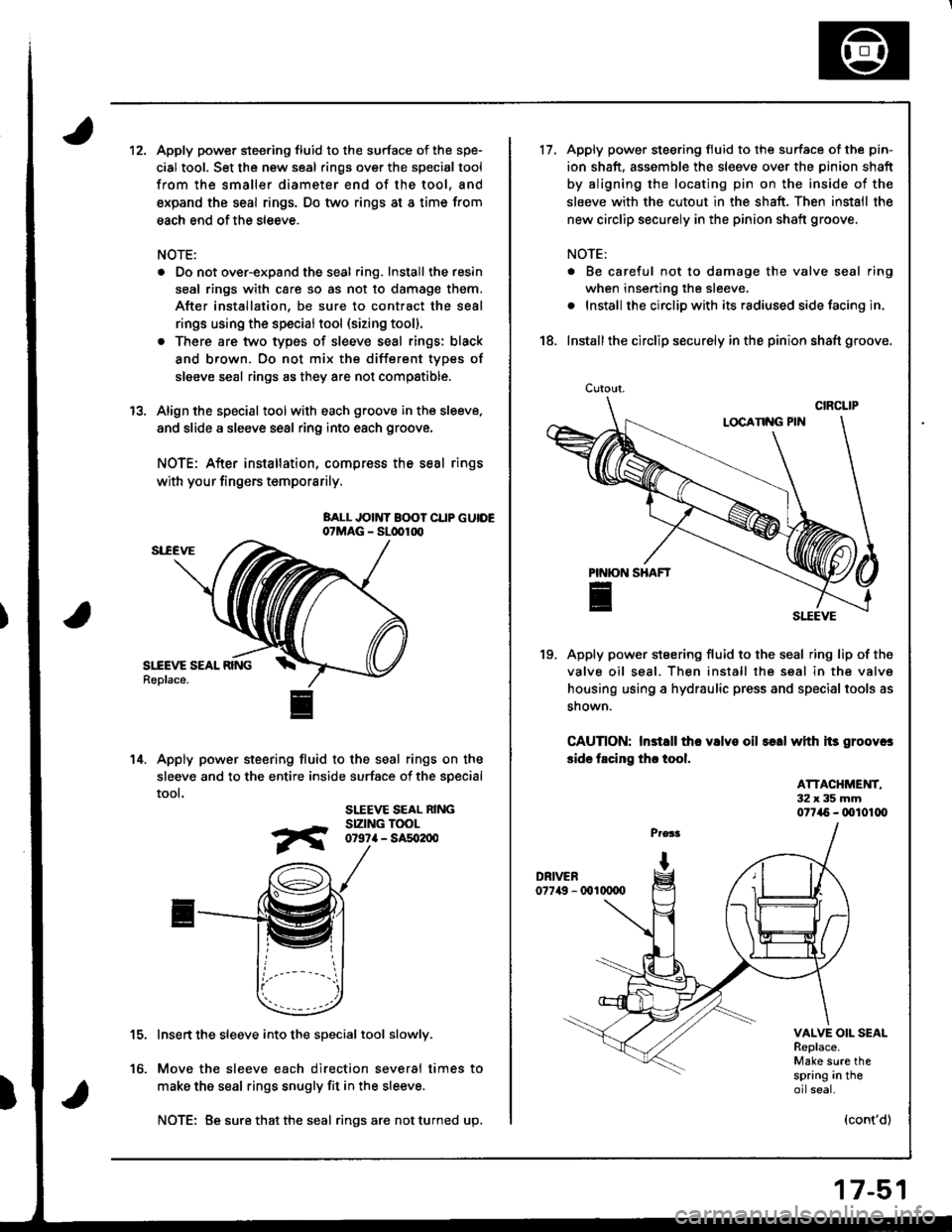

12.Apply power steering fluid to the surface of the spe-

cial tool. Set the new seal rings over the special tool

from the smaller diameter end of the tool, and

expand the seal rings. Do two rings at a time from

each end of the sleeve.

NOTE:

. Do not over-expand the seal ring. Install the resin

seal rings with care so as not to damage them.

After installation, be sure to contract the seal

rings using the specialtool (sizing tool).

. There are two types of sleeve seal rings: black

and brown. Oo not mix the different types of

sleeve seal rings as they are not compstible.

Align the special toolwith each groove in the sleeve.

and slide a sleeve seal ring into each groove.

NOTE: After installation, compress the seal rings

with your fingers temporarily.

BALL JOINT B(X)? CUP GUIDE07MAG - SLdrlrx,

Apply power steering fluid to the seal rings on the

sleeve and to the entire inside surface of the soecial

tool.

SLEEVE SEAL NINGSIZING TOOL0r9?a - sat02n0

Insert the sleeve into the special tool slowly.

Move the sleeve each direction several times to

make the seal rings snugly fit in the sleeve.

NOTE: Be sure that the seal ringsare notturned up.

13.

14.

to.

17-51

Cutout.

17.Apply power steering fluid to the surface of the pin-

ion shaft, assemble the sleeve over the pinion shaft

by aligning the locating pin on the inside of the

sleeve with the cutout in the shaft. Then install the

new circlip securely in the pinion shaft groove.

NOTE:

. Be careful not to damage the valve seal ring

when inserting the sleeve.

. Install the circlip with its radiused side facing in,

18. Installthe circlip securely in the pinion shaft groove.

Apply power steering fluid to the seal ring lip of the

valve oil seal. Then install the seal in the valve

housing using a hydraulic press and special tools as

snown.

CAUnON: Instsll tho valvo oil s€.| with its groovcs

side facing th. tool.

19.

ATTACHMET{T,32x35mm077i15 - (xll01lX,

VALVE OIL SEALReplace.Make sure thespring in theoilseal.

(cont'd)

Page 701 of 1681

Power Steering Gearbox

Reassembly (cont'dl

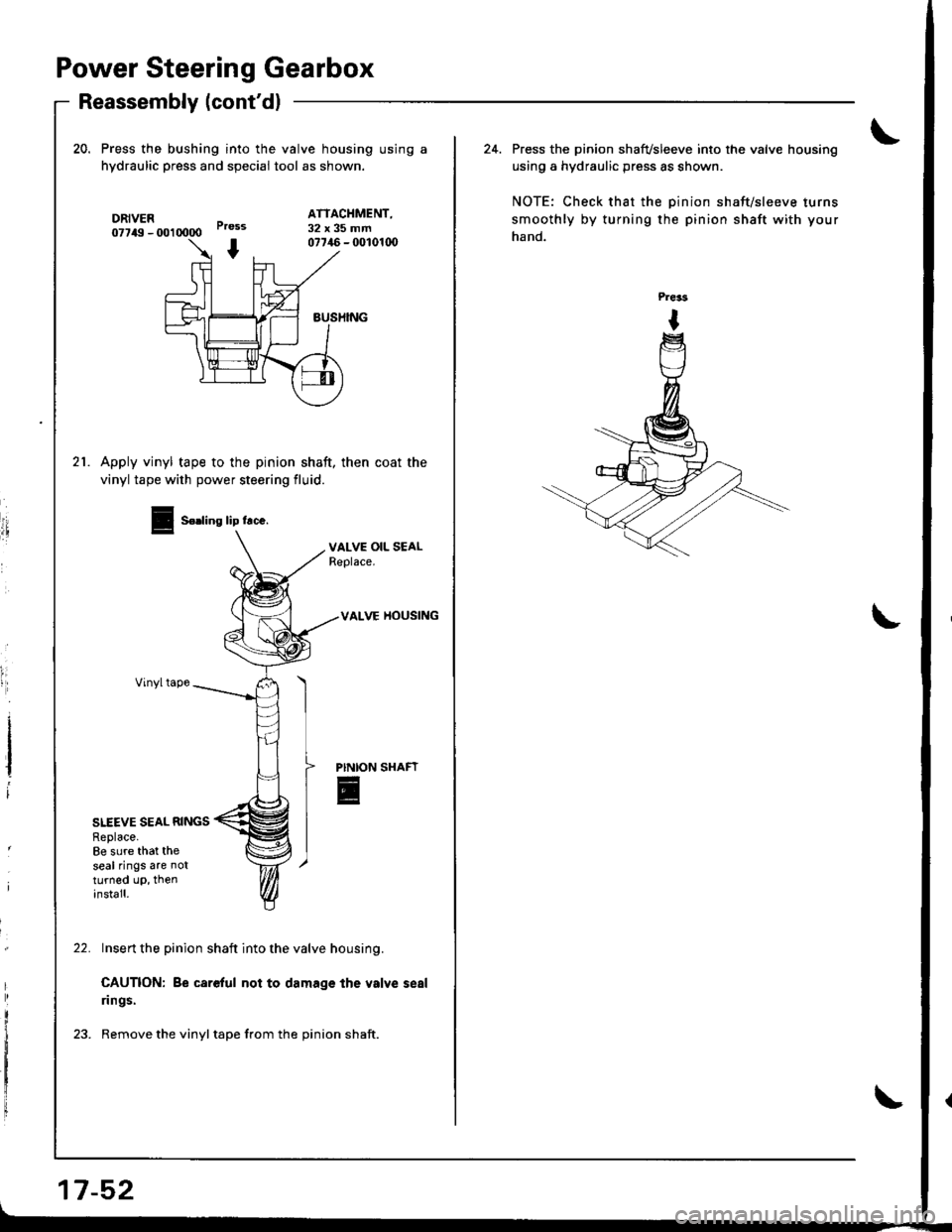

20. Press the bushing into the valve housing using a

hydraulic press and speciai tool as shown.

DRIVER07749 - U)l 0000

ATTACHMENT,32x35mmPress

I07746 - fi)l01(x)

sUSHING

21.Apply vinyl tape to the pinion shaft, then coat the

vinyl tape with power steering fluid.

I

i

I

VALVE OIL SEALReplace.

VALVE HOUSING

Vinyltape

PINION

E

SITEVE SEAL RINGSReplace.8e sure that theseal rings are notturned up, theninstall.

Insert the pinion shaft into the valve housing.

CAUTION: Be careful not to damage the valve seal

rings.

Remove the vinyl tape from the pinion shaft.

Seding lip lrce.

17-52

24. Press the pi.ion shafvsleeve into the valve housing

using a hydraulic press as shown.

NOTE: Check that the pinion shaft/sleeve turns

smoothly by turning the pinion shaft with your

hand.