throttle valve HONDA INTEGRA 1998 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 58 of 1681

Engine Removal/lnstallation

{cont'dl

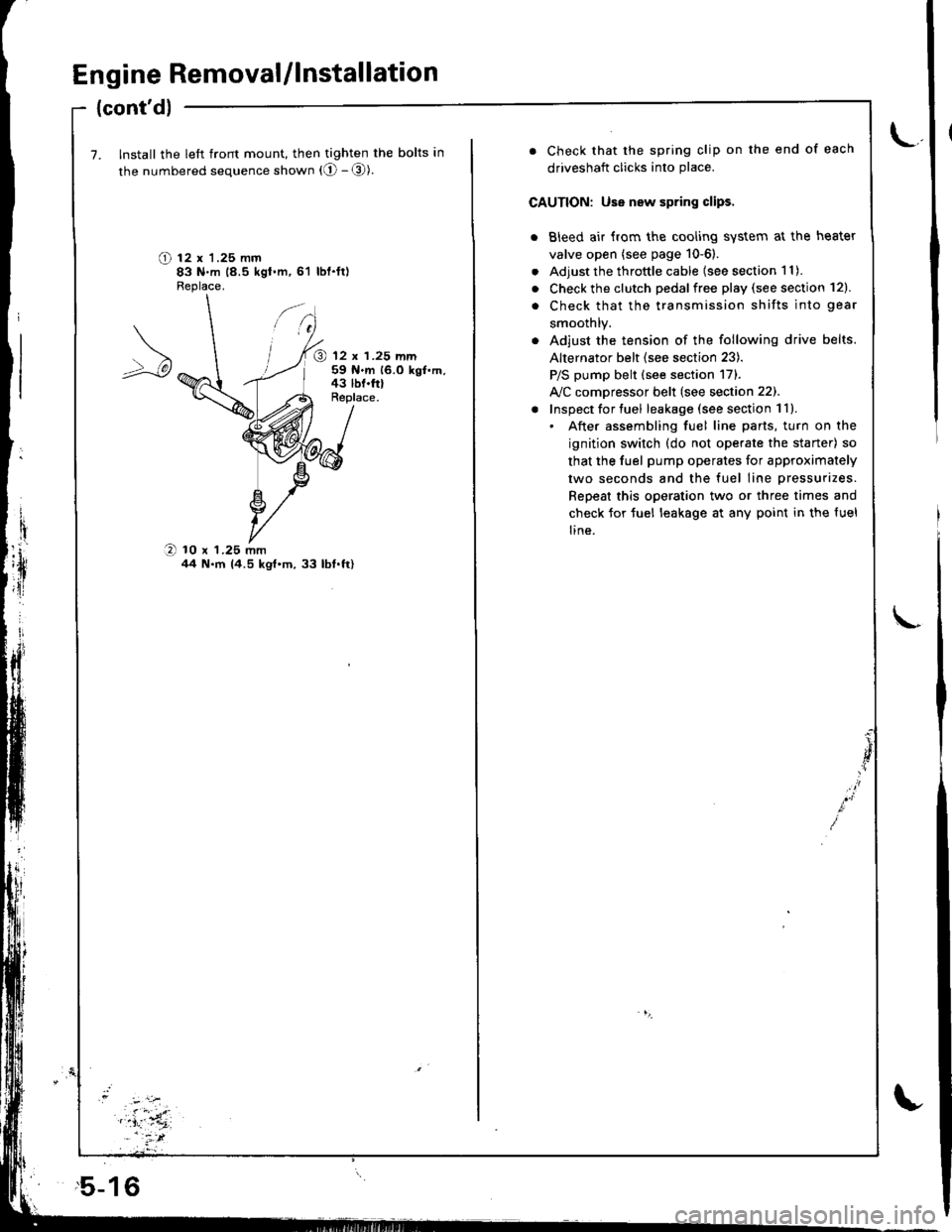

7. Install the left front mount, then tighten the bolts in

the numbered sequence shown (O - @).

O t2 x '1.25 mm83 N.m 18.5 kgt.m,61 lbl.ft)Fleplace.

@ 12 x 1.25 mm59 N.m 16.0 kgf.m,43 lbf.frlReplace.

O 10 x 1.25 mmil4 N.m 14.5 kgt'm,33 lbt.ft)

,5-16

. Check that the spring clip on the end of each

driveshaft clicks into place.

CAUTION: Use new spring clips.

. Bleed air {rom the cooling system at the heater

valve open (see page 10-6).

. Adjust the throttle cable (see section 1 1).

. Check the clutch pedalfree play (see section 12).

. Check that the transmission shifts into gear

smoothlY.

. Adjust the tension of the following drive belts.

Alternator belt {see section 23).

P/S pump belt (see section 171.

A/C comDressor belt (see section 22).

! Inspect for tuel leakage (see section 1ll.. After assembling fuel line parts, turn on the

ignition switch (do not operate the staner) so

that the fuel pump operates for approximately

two seconds and the fuel line pressurizes.

Repeat this operation two or three times and

check for tuel leakage at any point in the {uel

line.

Page 80 of 1681

Gylinder Head

Removal (cont'dl

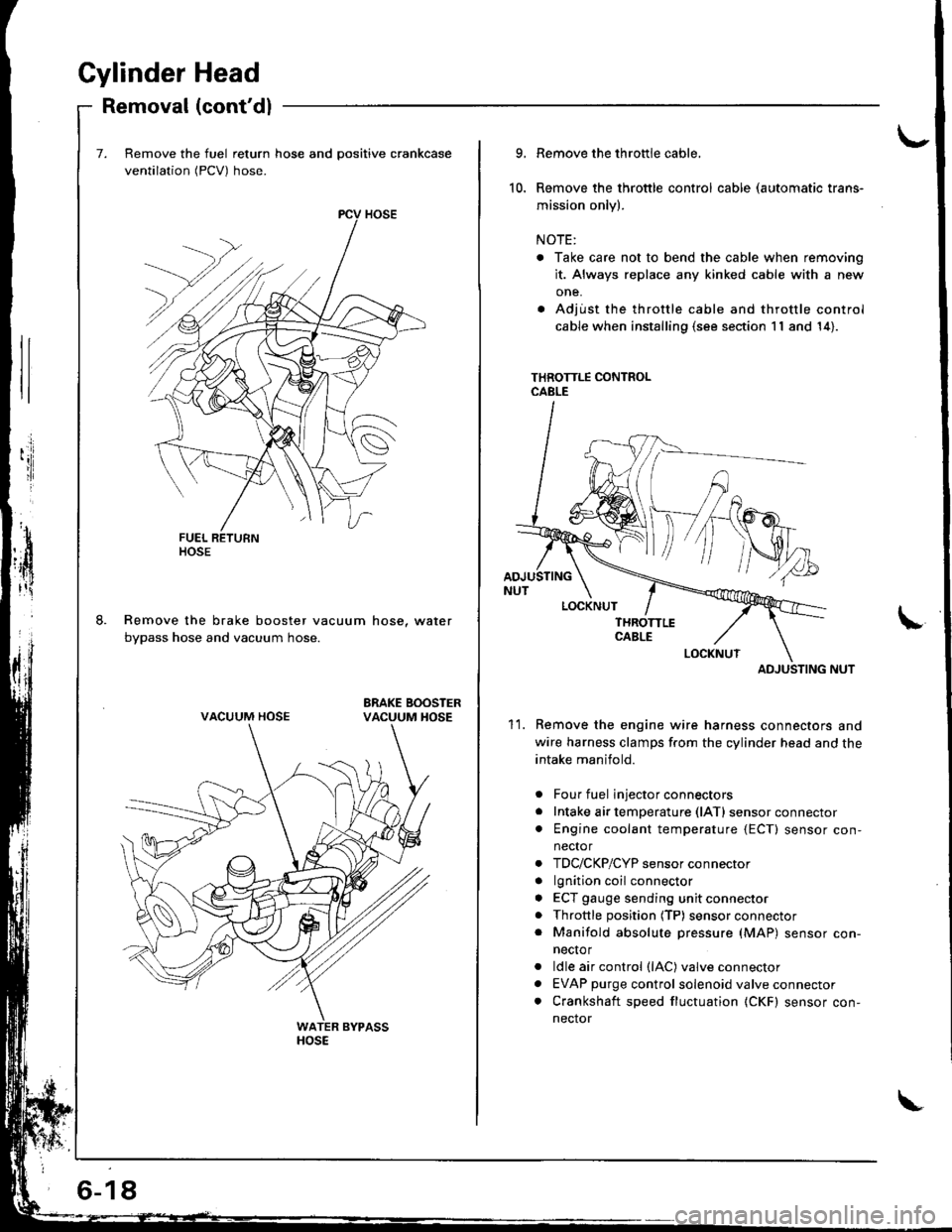

Remove the fuel return hose and positive crankcase

ventilation (PCV) hose.

Remove the brake booster vacuum hose, water

bypass hose and vacuum hose.

ltosE

VACUUM HOSE

6-18

10.

9.

11.

Remove the throttle cable,

Remove the throttle control cable (automatic trans-

mission only).

NOTE:

. Take care not to bend the cable when removing

it. Always replace any kinked cable with a new

one.

. Adjust the throttle cable and throttle control

cable when installing (s€e section 11 and 14).

THROTTLE CONTROLCABLE

ADJUSTING NUT

Remove the engine wire harness connectors and

wire harness clamps f.om the cylinder head and the

intake manifold.

Four fuel injector connectors

Intake air temperature (lATl sensor connector

Engine coolant temperature {ECT) sensor con,

nector

TDC/CKP/CYP sensor connector

lgnition coil connector

ECT gauge sending unit connector

Throttle position (TP) sensor connector

Manifold absolute pressure (MAP) sensor con-

necto r

ldle air control (lAC) valve connector

EVAP purge control solenoid valve connector

Crankshaft speed fluctuation (CKF) sensor con-

nector

a

a

a

a

a

a

a

a

ADJUSTING

Page 187 of 1681

lntake Manifold

Replacement

PURGE CONTROLSOLENOIO VALVE

8 x 1.25 mm22 N.m 12.2 kgl'm'

16

IDLE AIR

\

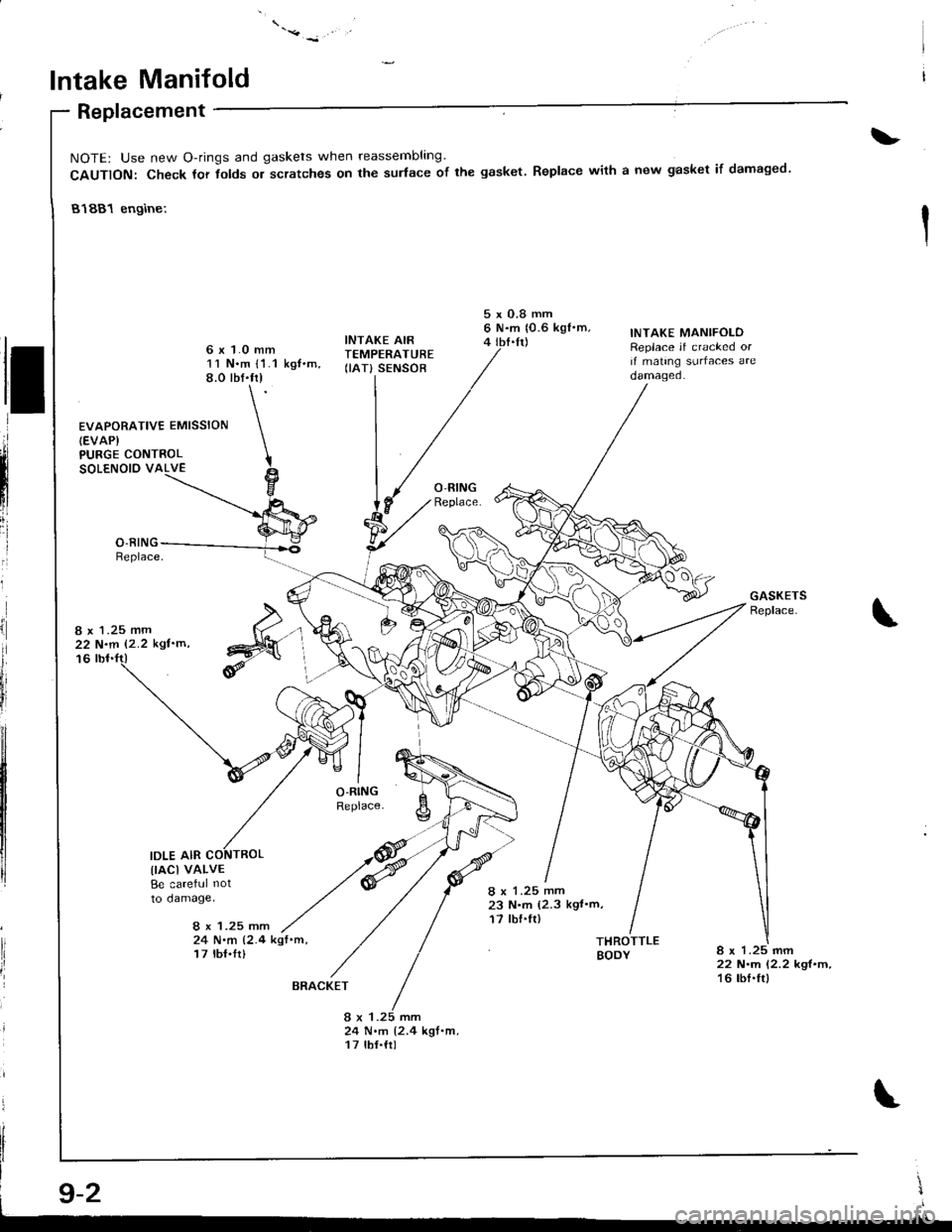

NOTE: Use new O-rings and gaskets when reassembling

CAUTION: Check tor tolds or scratches on the sudace of the gasket.

81881 engine:

Replace with a new gasket if damaged.

&

d

ll

,ii

ilnl

iii

I

I

ii

il

lli

fr

EVAPORATIVE EMISSION(EVAP}

11 N.m l'1.1 kg{.m,8.0 rbf.fr)

INTAKE AIRTEMPERATURE(IAT} SENSOB

5xO.8mm6 N.m 10.6 kgf'm,4 tbI.tt)

8 x 1.25 mm23 N.m (2.3 kgt'm,17 tbf.fl)

INTAKE MANIFOLOReplace if cracked orif mating surfaces areoamageo.

lrAcl vALvEBe careful not

to damage,

8 x 1.25 mm24 N.m 12.4 kqf .m,

17 lbI.Ir)THROTTLEBODY8 x 1.25 mm22 N.rn 12.2 kgl.m,16 tbf.frl

24 N.m {2.4 kgt.m,17 tbf.{r)

\I

.lll

BRACKET

Page 188 of 1681

.'.,.'.attj

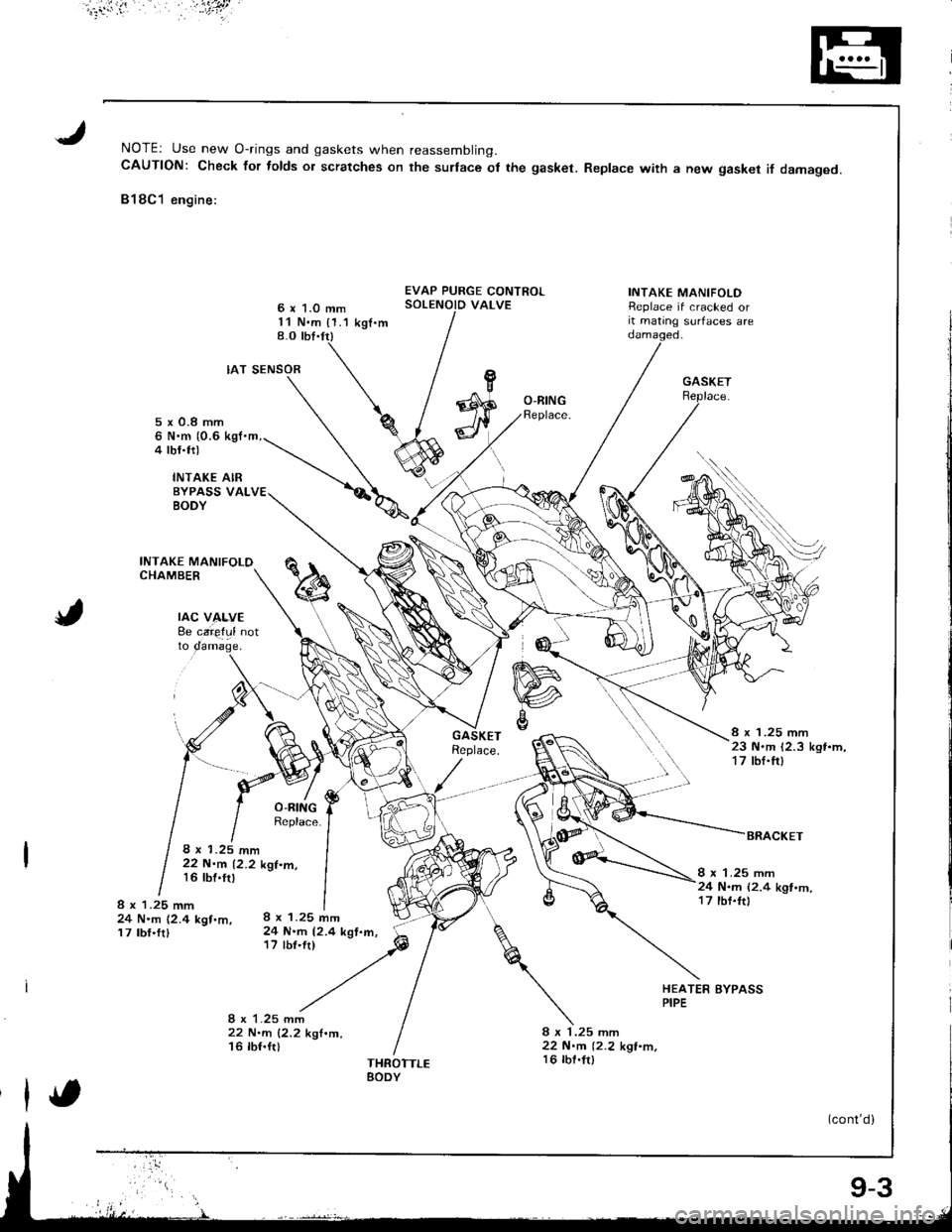

NOTEr Use new O-rings and gaskets when reassembling.CAUTION: Check for folds or scratches on the surlace ot the gasket. Replace with a new gasket if damaged.

818C1 engine:

6 x 1.0 mm11 N.m {1.1 kgt.m8.O tbt.trl

EVAP PURGE CONTROLSOLENOID VALVEINTAKE MANIFOLDReplace if cracked orit mating surfaces are

rAc v4f,vE8e caie{ul notto

IAT SENSOR

8 x 1.25 mm24 N.m 12.4 kgt.m,17 tbf'fr)

22 N.m 12.2 k'l.m,16 lbf.ftl

O-BINGReplace.5x0.8mm6 N.m (0.6 kgI'm,4 tbf.trl

INTAKE AIRBYPASS VALBODY

INTAKE MANIFOLOCHAMBER

8 x 1.25 mm23 N.m 12.3 kgt.m,17 tbf.ft)

8 x 1.25 mm22 N.m 12.2 kgt.m,16 tbt'tr)I x 1.25 mm24 N.m (2.4 kgl.m,17 tbf.ft)8 x 1.25 mm24 N.m (2.4 kgt.m,17 tbf.frl

HEATER BYPASSPIPE

8 x 1.25 mm22 N.m 12.2 kgt.m,16 lbt.fr)THROTTLEEODY

(cont'd)

9-3

Page 189 of 1681

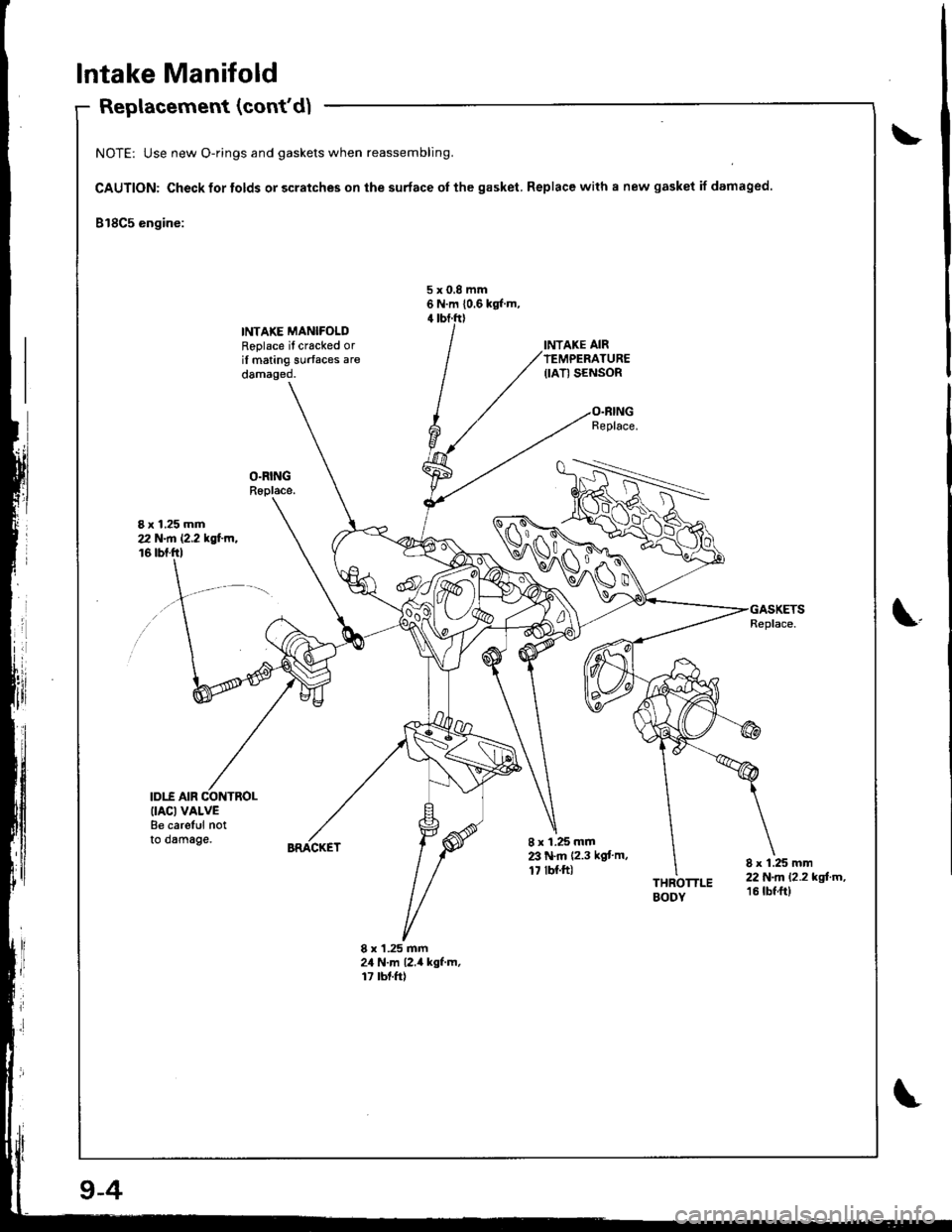

Intake Manifold

Replacement (con(d)

NOTE: Use new O-rings and gaskets when reassembling.

CAUTION: Check for tolds or scratches on the surface oI the gasket. Replace with a new gasket if damaged

818C5 engine:

5x0,8mm6 N.m 10.6 kgl m,

INTAKE MANIFOLDRoplace il cracked oril mating surfaces aredamaged.

I x 1.25 mm212 N.n 12.2 tsl'm,16 tbf.ftl

\.

IDI.f AIR CONTROL(IACI VALVEBe careful notto dsmage.8 x 1.25 mmZ' N.m 12.3 kgt'm,17 tbl.ft)THROTTLEBODY

8 x 1.25 mm22 N.m 12.2 kgtm,16 tbf ft)

8 x'1.25 mm24 N.m l2.il kgf.m,17 rbt.ft)

9-4

Page 208 of 1681

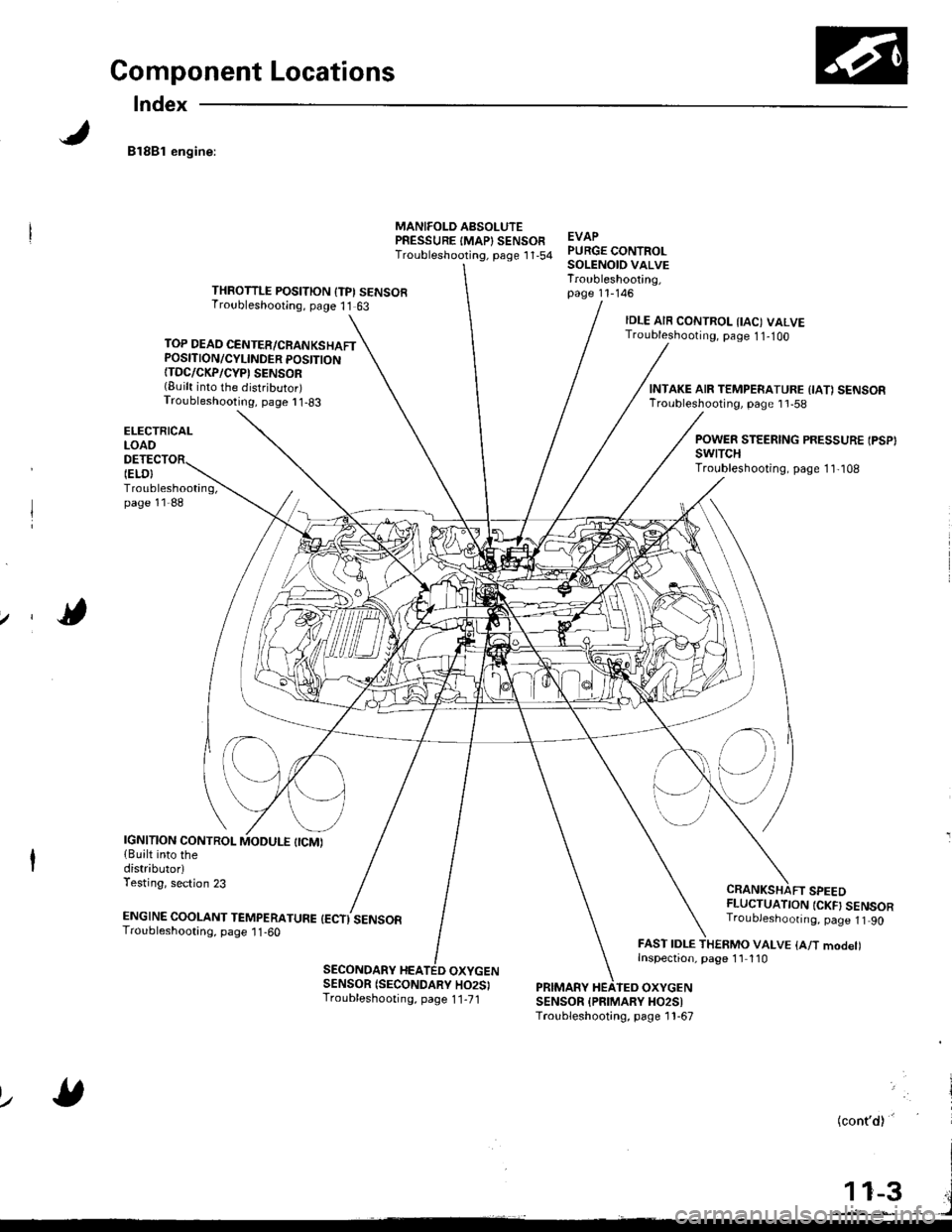

Component Locations

Index

81881 engine:

TOP DEAD CENTER/CRANKSHAFTPOSITION/CYLINDER POSITION{TDC/CKP/CYP' SENSOR(Built into the distributor)Troubleshooting, page I 1-83

ELECTRICALLOAO

Troubleshooting,page 11-88

MANIFOLD AsSOLUTEPRESSURE IMAP} SENSOFTroubleshooting, psge 1 '1,54EVAPPURGE CONTROLSOLENOID VALVETroubleshooting,page 11-146THROTTLE POSITION {TPI SENSORTroubleshooting, page 11 63

IELO}

IDLE AIR CONTROL IIAC) VALVETroubleshooting, page 1 1-1OO

CRANKSHAFT SPEEDFLUCTUATION {CKF} SENSORTroubJeshoonng. page 1t 90

FAST IDLE THERMO VALVE {A/T modet)Inspection, page 1'l 110

INTAKE AIR TEMPERATURE {IA1 SENSORTroubleshooting, page 1 'l -58

POWER STEERING PRESSURE IPSP}swtTcHTroubleshooting, page 1 1,108

IGNITION CONTROL{Built into thedistributorlTesting, section 23

ENGTNE cooLANT TEnapenerune {ectisensoaTroubleshooting, page 1 1 -60

SECONDARY HEATED OXYGENSENSOR (SECONDARY HO2SITroubleshooting, page 1 1-71PRIMARY HEATEO OXYGENSENSOR {PFIMARY HO2SITroubleshooting, page 1 1-67

lz

(cont'd)'

Page 209 of 1681

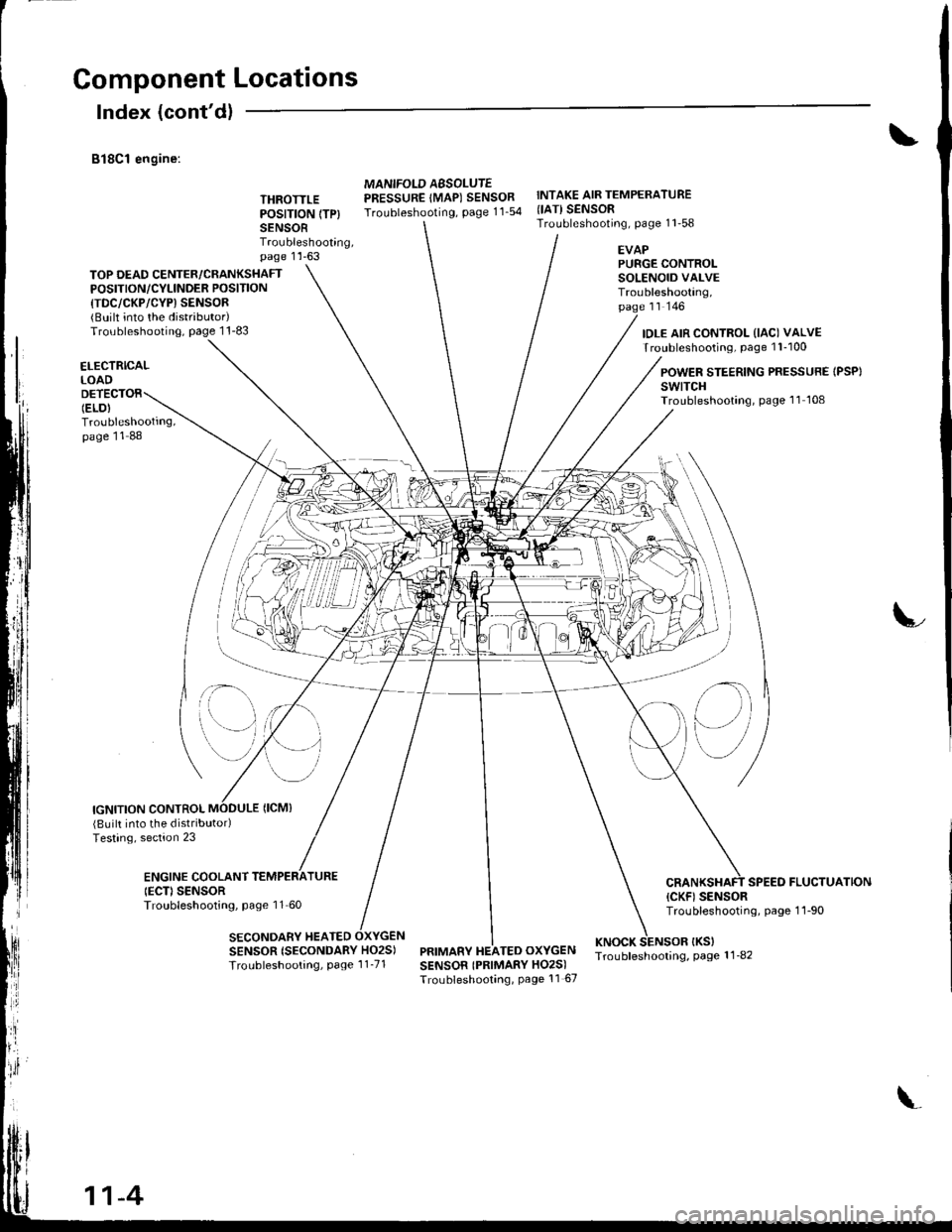

Component Locations

Index (cont'dl

B18C1 engine:

THROTTLEPOSITION (TP}

SENSORTroubleshooting,page 1 'l -63

MANIFOLD AESOLUTEPRESSURE IMAP) SENSORTroubleshooting, page 11_54

INTAKE AIR TEMPERATURE{IATI SENSORTroubleshooting, page 11'58

TOP DEAD CENTER/CRANKSHAFTPOSITION/CYLINOER POSITION

{TDC/CKP/CYP) SENSOR{BUilt into the distributor)Troubleshooting, page 1 1-83

EVAPPURGE CONTROLSOLENOID VALVETroubleshooting,page rr rqo

IDLE AIR CONTROL (IAC) VALVETroubleshooting, page 1 l-100

ELECTRICALLOAD

Troubleshooting,page 11 88

POWER STEERING PRESSURE IPSP}swtTcHTroubleshooting, page 'l1 108

IGNITION CONTROL

;- \

SENSOR {SECONDARY HO2S)

Troubleshooting, Page 1 1_71

(Built into the distributodTesting, section 23

ENGINE COOLANTIECD SENSORTroubleshooting, page 11 60

SECONDARY HEATED

SPEED FLUCTUATION(CKF) SENSORTroubleshooting, page 1 1-90

PRIMARY HEATED OXYGENKNOCK SENSOR IKSITroubleshooling, page 1 1_82SENSOR IPRIMARY HO2S)Troubleshooting, Page 11 67

il\

e)

11-4

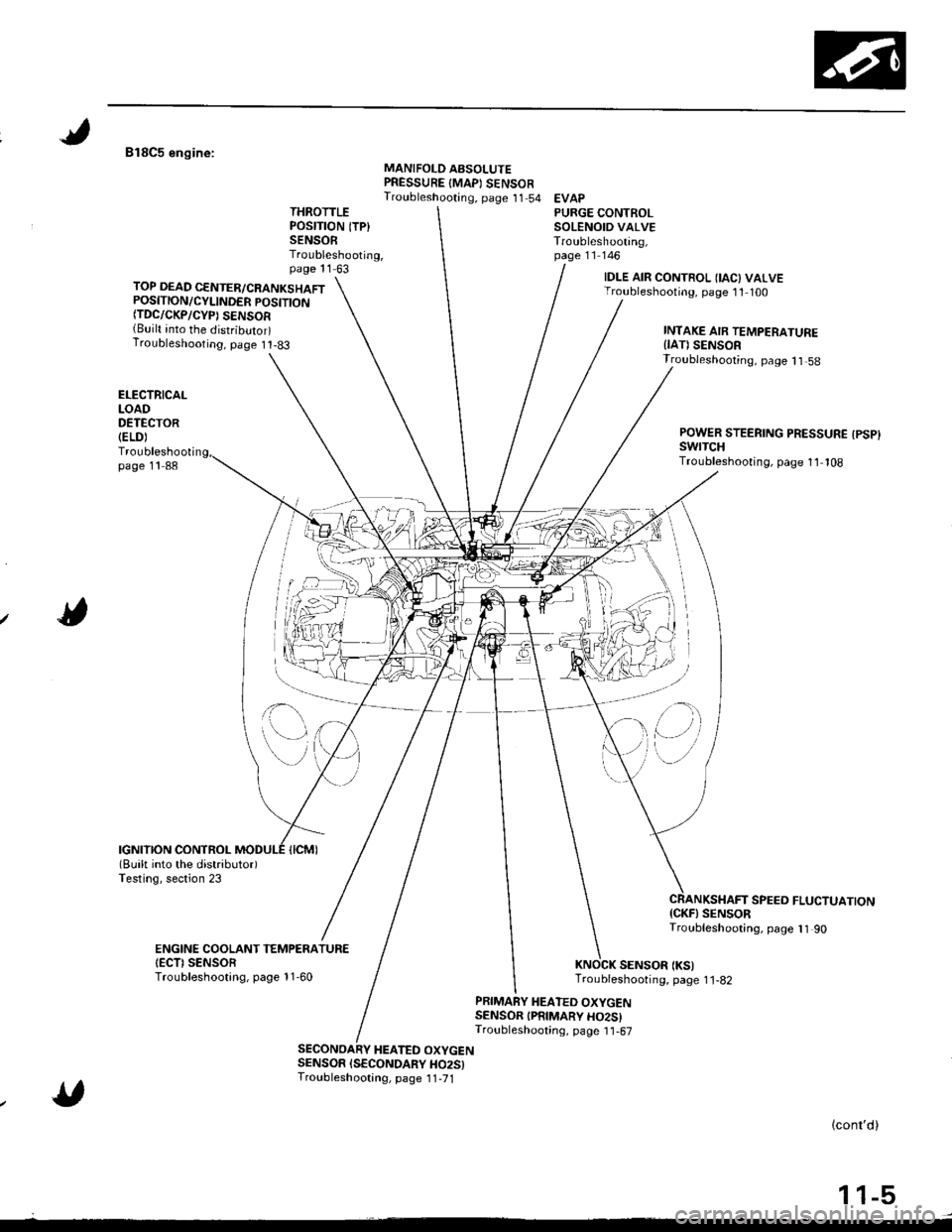

Page 210 of 1681

818C5 engine:MANIFOLD ABSOLUTEPRESSURE {MAPI SENSOFTroubleshooting, page 11 54 EVAPTHROTTLEPOSITION ITP}SENSORTroubleshooting,page 11 63

PURGE CONTROLSOLENOID VALVETroubleshooting,page 11 146

TOP DEAD CENTER/CRANKSHAFTPOSITION/CYLINDER POSITTONfiDC/CKP/CYP) SENSOR{Built into the distributor)Troubleshooting, page I t-83

IDLE AIR CONTROL IIAC) VALVETroubleshooting, page 11 100

INTAKE AIR TEMPERATUREIIAT) SENSOR

ELECTRICALLOADDETECTOR(ELD)

Troubleshootipage 11 88

Troubleshooting, page 1 1,58

POWER STEERING PRESSURE {PSP}swrTcHTroubleshooting, page 11 108

SPEEO FLUCTUATION{CKF} SENSORTroubleshooting, page 11 90

SENSOR (KS)Troubleshooting, page 1 1-82

ENGINE COOLANT TEMPENATUR€IECTI SENSORTroubleshootang, page 11-60

PRIMARY HEATED OXYGENSENSOR IPRIMARY HO2SITroubleshooting, page I1-67

HEATED OXYGENSENSOR ISECONDARY HO25)Troubleshootang, page 1 1,71

lcont'd)

1 1-5

,'(l)

Page 211 of 1681

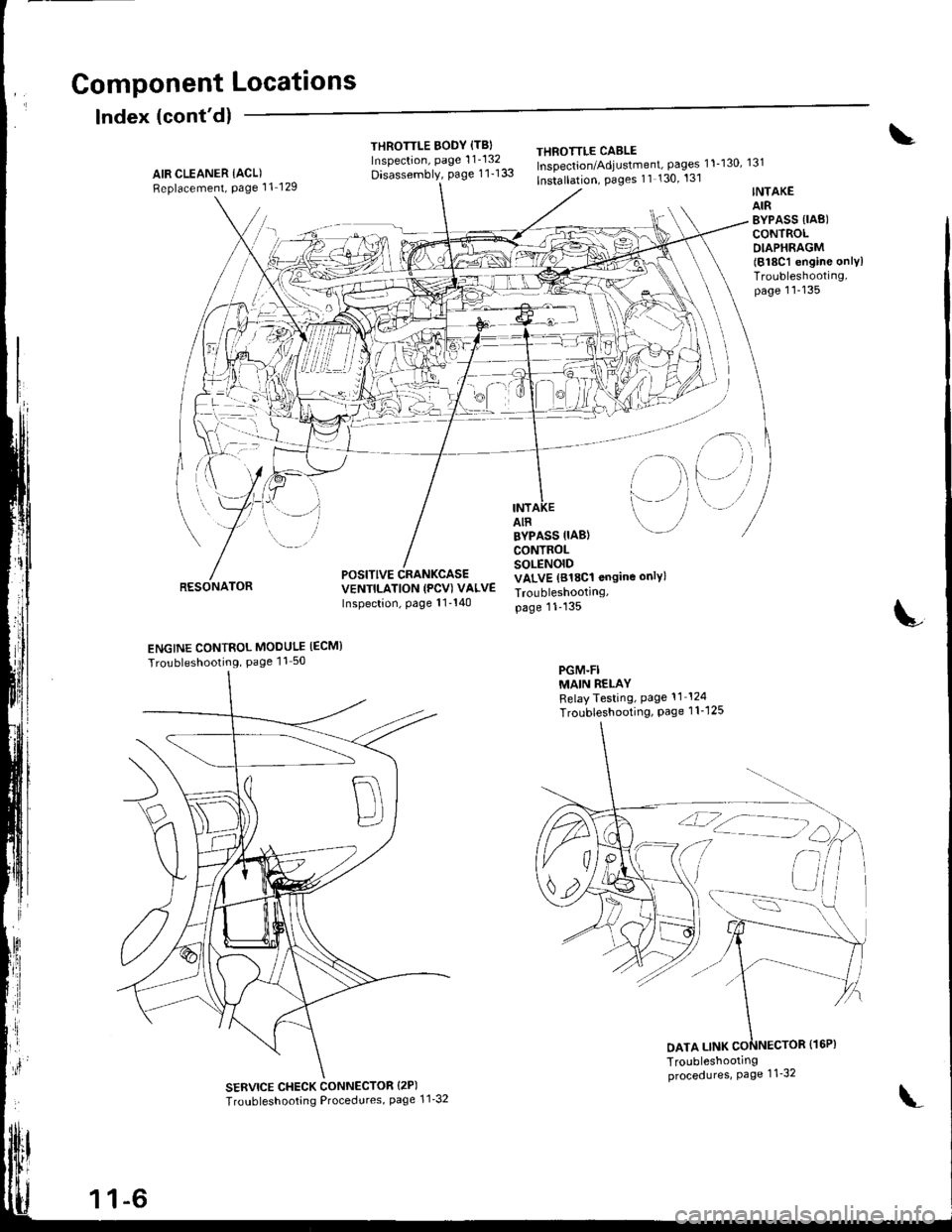

Gomponent Locations

Index (cont'dl

THROTTLE BODY {TBIInspection, page 1 1'132

Disassembly, page 1 1-133

THEOTTLE CABLEInspection/Adjustment, pages 11-130, 131

lnstallation, Pages 11 130' 131AIR CLEANER IACL)Replacement, Page 11 129

RESONATOR

INTAKEAIRBYPASS {IAB)CONTROLDIAPHRAGM(818C1 engine onlylTroubleshooting,page 11-135

i-)

i--- / /

i rl

l'-' i

INTAIR

POSITIVE CRANKCASEVENTILATION (PCV) VALVEInspection, page 11'140

BYPASS IIAB}CONTROLSOLENOIDVALVE (818C1 ongine only)

Troubleshootrng,page 11-135

PGM-FIMAIN RELAYRelayTesting, Page 11 124

Troubleshooting, Page 1 1-1 25

L

ENGINE CONTROL MODULE IECM}

Tro!bleshooting, Page 11 50

SERVICE CHECK CONNECTOR {2P)

Troubleshooting Procedures, page 1 1'32

DATA LINK

1 1-6

\'

Page 241 of 1681

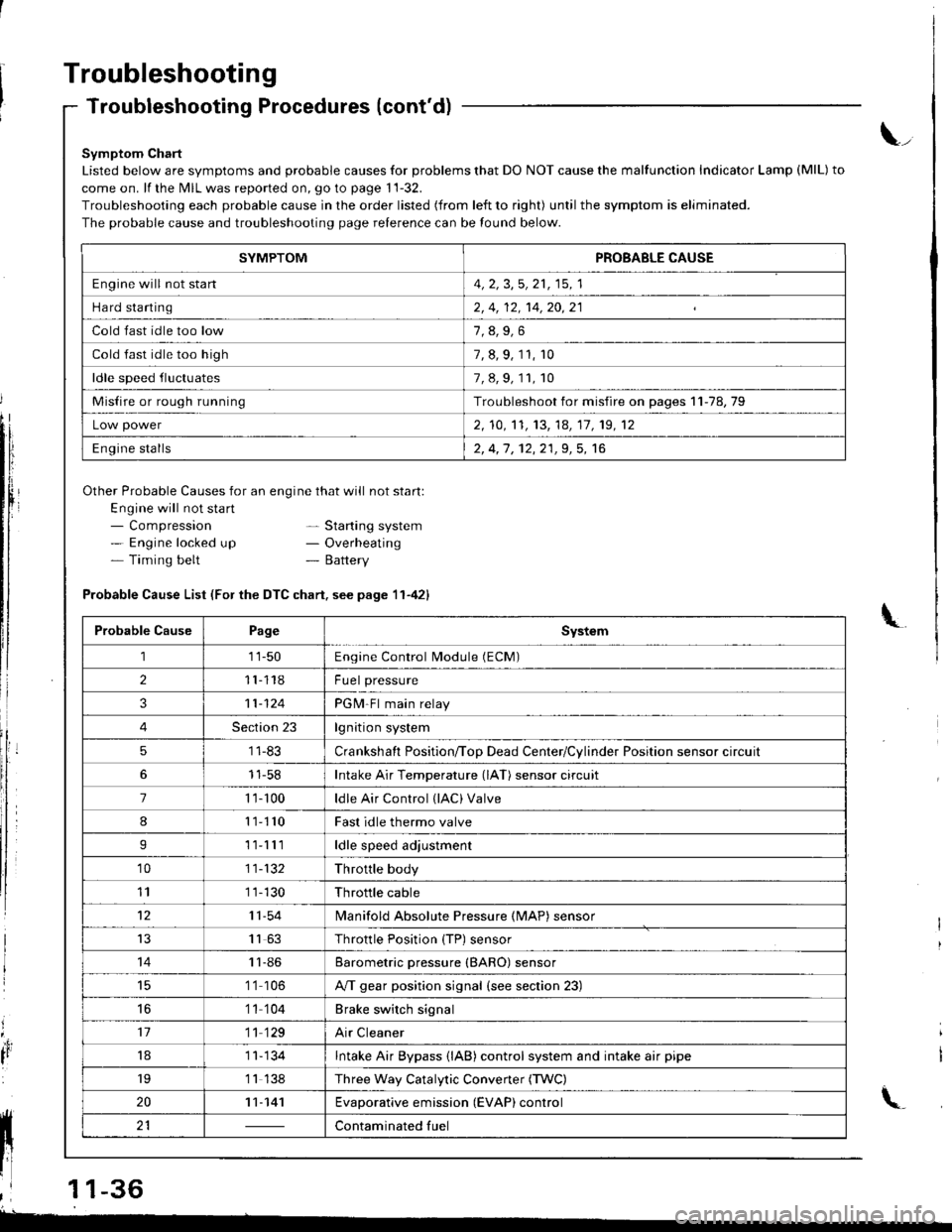

Troubleshooting

Troubleshooting Procedures (cont'd)

Symptom Chart

Listed below are symptoms and probable causes for problems that DO NOT cause the malfunction Indicator Lamp (MlL) to

come on. lf the MIL was reported on, go to page 11-32.

Troubleshooting each probable cause in the order listed (from left to right) until the symptom is eliminated.

The probable cause and troubleshooting page relerence can be found below.

Other Probable Causes for an engine that will not start:

Engine will not sta rt- Compression- Engine locked up- Timing belt

\_

- Starting system- Overheating- Battery

'4,

It

Probable Cause List (For the DTC chart. see page 11-421

Probable CausePageSystem

111-50Engine Control Module (ECM)

211118Fuel pressure

311-124PGM-Fl main relay

4Section 23lgnition system

51 1-83Crankshaft Position/ToD Dead Center/Cylinder Position sensor circuit

11-58Intake Air Temperature (lAT) sensor circuit

71 '�t- 100ldle Air Control (lAC) Valve

811110Fast idle thermo valve

I11lllldle speed adjustment

'1011-132Throttle body

111 1-130Throttle cable

1211-54lvlanifold Absolute Pressure {MAP) sensor

IJ1163Throttle Position {TP) sensor

1411-86Barometric pressure (BARO) sensor

1 '1 106A/T gear position signal {see section 23)

16'1 1 104Brake switch signal

1711 129Air Cleaner

181 1- 134Intake Air Bypass {lAB} control system and intake air pipe

19'1 1 138Three Way Catalytic Convener (TWC)

2011-141Evaporative emission (EVAP) control

21Contaminated fuelll ll 21 | - | cont"-in"t"o tu"

11 l-

I

,l 11-36

-

SYMPTOMPROBABLE CAUSE

Engine will not stan4, 2, 3,5, 21, 15, 1

Hard starting2, 4, 12, 14,20,21

Cold fast idle too low

Cold fast idle too high7, 8, 9, 11, r0

ldle speed fluctuates7,8,9,11,10

Misfire or rough runningTroubleshoot for misfire on pages 11-78,79

Low power2, 10,'t1, 13, 14, 17, 19, 12

Engine stalls2, 4,1 , 12,21,9, 5, 16