throttle valve HONDA INTEGRA 1998 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 243 of 1681

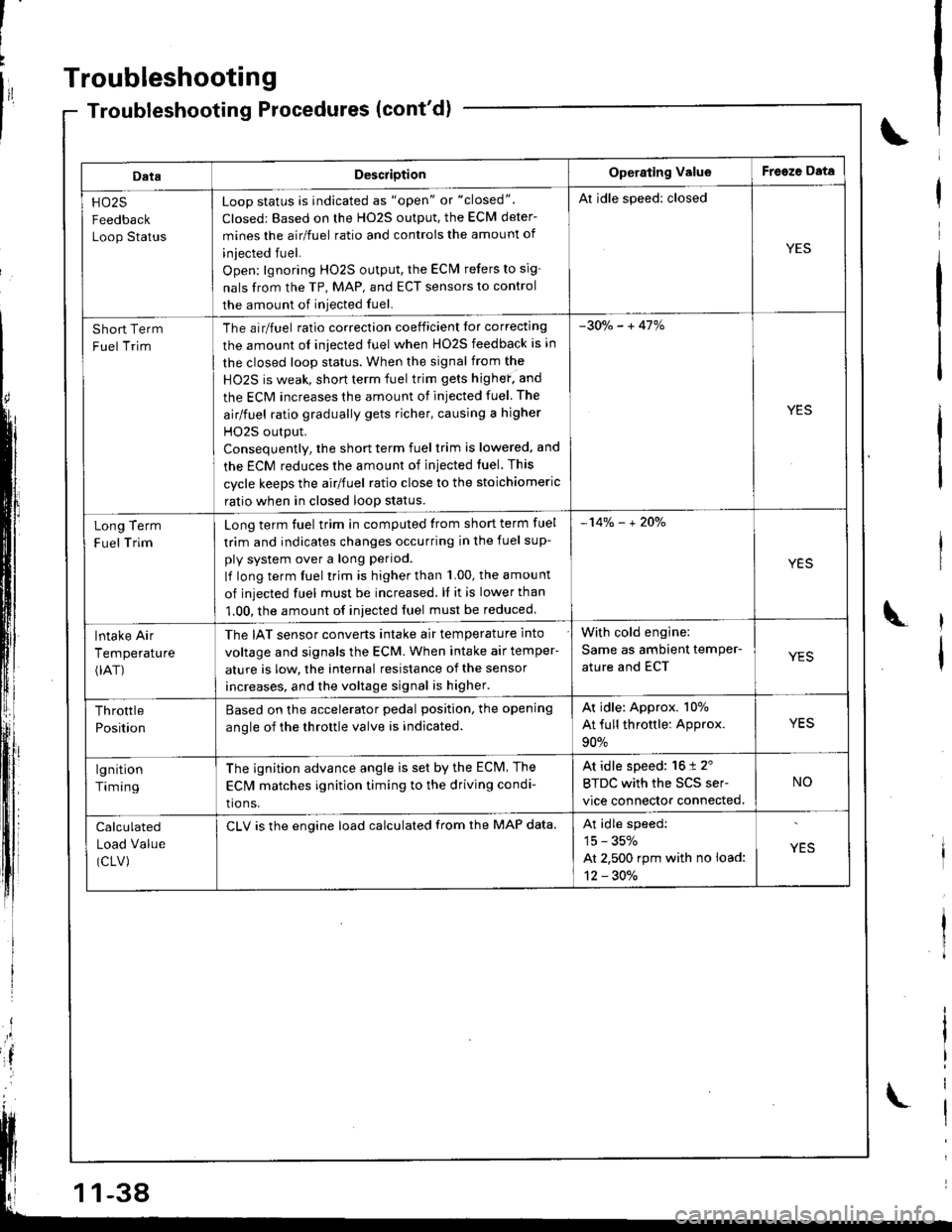

Troubleshooting

DataDescriotionOperating ValueFreeze Data

HO25

Feedback

Loop Status

Loop status is indicated as "open" or "closed".

Closed: Based on the H02S output, the ECM deter-

mines the airlfuel ratio and controis the amount of

iniected fuel.

Open: lgnoring HO2S output, the ECM refers to sig-

nals from the TP, MAP, and ECT sensors to control

the amount of iniected fuel.

Al idle speed: closed

YES

Short Term

Fuel Trim

The airlfuel ratio correclion coeificient lor correcting

the amount ol iniected fuel when HO2S feedback is in

the closed loop status. When the signal from the

HO2S is weak, short term fuel trim gets highef. and

the ECM increases the amount of injected fuel The

airlfuel ratio gradually gets richer, causing a higher

HO2S output.

Consequentlv, the short term fuel trim is lowered, and

the ECM reduces the amount of injected tuel. This

cycle keeps the airlfuel ratio close to the stoichiomeric

ratio when in closed loop status.

-30o/" - + 41%

YES

Term

Trim

Long

F uel

Long term fuel trim in computed trom short term fuel

trim and indicates changes occurring in the fuel sup-

ply system over a long period.

lf long term fuel trim is higher than 1.00, the amou nt

of injected fuel must be increased. ll it is lower than

1.00, the amount of iniected fuel must be reduced

-14% - + 2Oo/"

YES

lntake Air

Temperature(rAT)

The IAT sensor converts intake air temperature into

voltage and signals the ECM. When intake air temper-

ature is low, the internal resistance of the sensor

increases, and the voltage signal is higher.

With cold engine:

Same as ambient temPer-

ature and ECTYES

Throttle

Position

Based on the accelerator pedal position. the opening

anole of the throttle valve is indicated.

Ar idle: Approx. 107o

At full throttle: Approx.

90%

YES

lgnition

Timing

The ignition advance angle is set by the ECM. The

EClvl matches ignition timing to the driving condi-

tio ns.

At idle speed: 16 t 2'

BTDC with the SCS ser-

vice connector connected.

NO

Calculated

Load Value

(CLV)

CLV is the engine load calculated from the MAP data.At idle speedi

15 - 35%

At 2,500 rpm with no load:

12 - 30./.

YES

-38

Page 249 of 1681

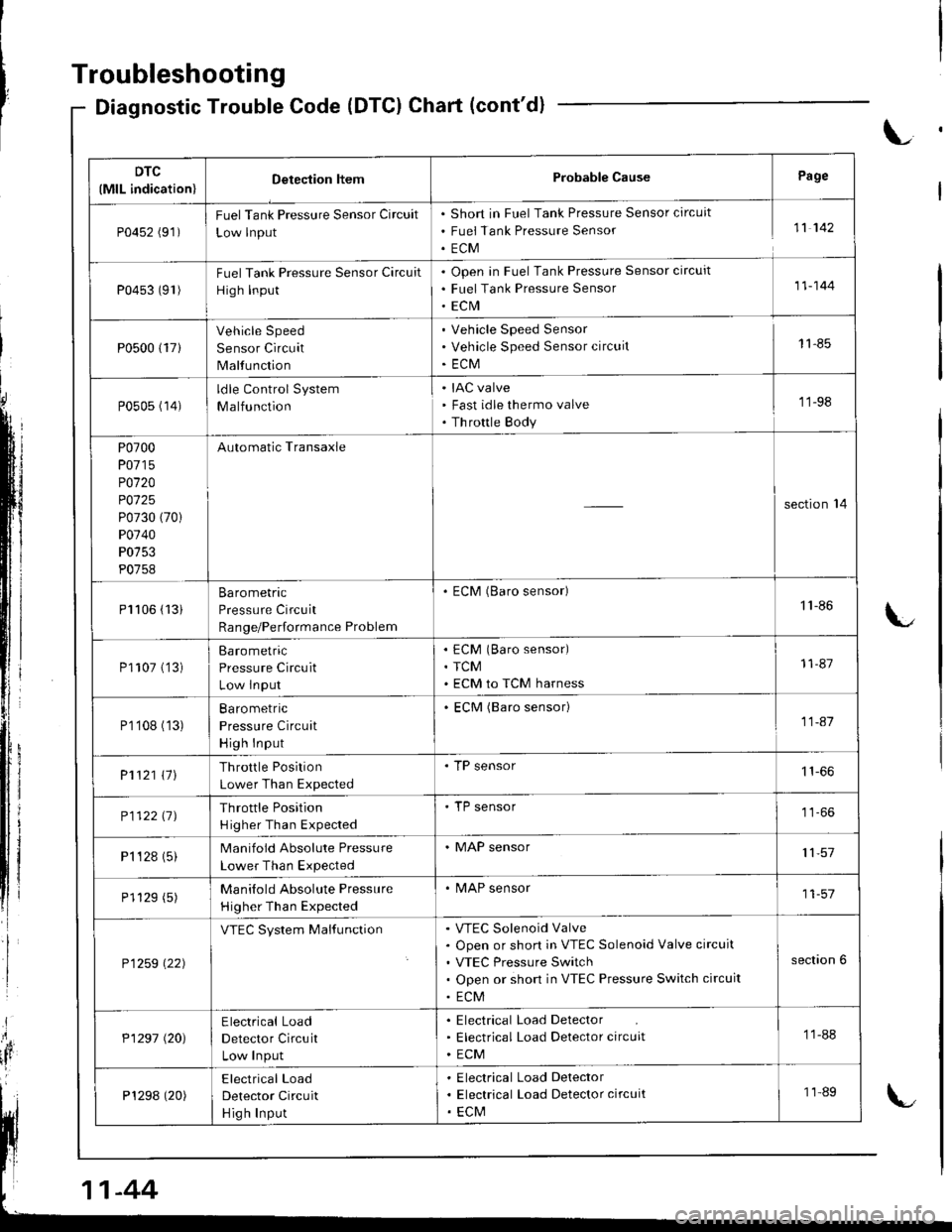

Troubleshooting

Diagnostic Trouble Code (DTCI Chart (cont'd)

L

DTC

(MlL indication)Detection ltemProbable CausePage

P0452 (91)FuelTank Pressure Sensor Circuit

Low lnput

Short in Fuel Tank Pressure Sensor circuit

Fuei Tank Pressure Sensor

ECM

11 142

P0453 (91)Fuel Tank Pressure Sensor Circuit

High Input

Open in Fuel Tank Pressure Sensor circuit

Fuel Tank Pressure Sensor

ECrVI

11-144

P0500 {17}

Vehicle Speed

Sensor Circuit

Malfunction

Vehicle Speed Sensor

Vehicle Speed Sensor circuit

ECM

11-85

P0505 (14)ldle Control System

Malfunction

IAC valve

Fast idle thermo valve

Th rottle Body

'11-98

P0700

P0715

P0120

P0125

P0730 (70)

P0740

P0753

P0758

Automatic Transaxle

section'14

Pl106 (13iBarometric

Pressure Circuit

Range/Performance Problem

. ECM (Baro sensor)1'l -86

P1107 ('�]3)Barometric

Pressure Circuit

Low lnput

ECM (Baro sensor)

TCM

ECM to TCM harness

11-87

P1'108 (13)Ba ro metric

Pressure Circuit

High Input

ECM (Baro sensor)11-41

P1121 \11Throttle Position

Lower Than Expected

. TP sensor

P112211JThrottle Position

H igher Than Expected

'TP sensor

P1 '�t 28 (5)Manifold Absolute Pressure

Lower Than Expected

. MAP sensor11,57

P1129 (5)Manilold Absolute Pressure

Higher Than Expected

. MAP sensor11-57

P1259 \22)

VTEC System MalfunctionVTEC Solenoid Valve

Open or short in VTEC Solenoid Valve circuit

VTEC Pressure Switch

Open or short in VTEC Pressure Switch circuit

ECM

section 6

P1297 (20)Electrical Load

Detector Circuit

Low Input

Electrical Load Detector

Electrical Load Detector circuit

ECM

11-88

P1298 (20)Electrical Load

Detector Circuit

Hig h Input

Electrical Load Delector

Electrical Load Detector circuit

ECM

11-89

-44

Page 268 of 1681

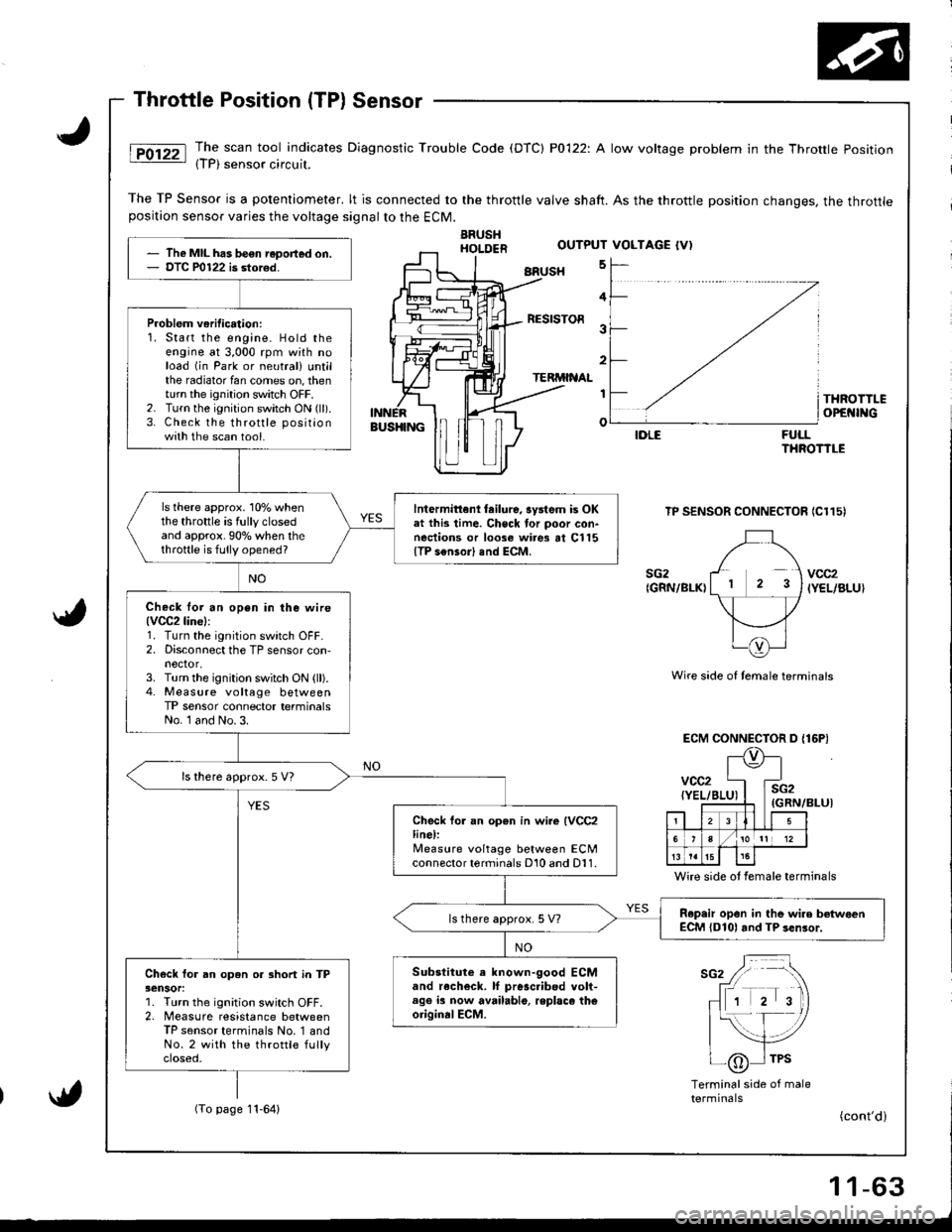

The scan tool indicates Diagnostic Trouble Code (DTC) P0122: A low voltage problem in the Throttle Position{TP) sensor circuil.

The TP Sensor is a potentiometer. lt is connected to the throttle valve shaft. As the throttle position changes, the throttleposition sensor varies the voltage signalto the ECM.

ARUSHHOI.DER

BRUSH 5

FULLTHROTTLE

TP SENSOR CONNECTOR IC115)

Wire side of temale terminals

ECM CONNECTOR D {16P)

(GRN/BLUI

Wire side ot female terminals

sG2 / -\

fr rrr r 'tr\

- 1 2 3)

|{- f- /

| _-,/tlI /6 I TPS-\j/

Terminalside of maletermrnats(To page 11-64)

The MIL has be€n reDort€d on.DTC P0122 is stor€d.

Problem veritication:1. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator fan comes on, thenturn the ignition switch OFF.2. Turn the ignition switch ON (ll).

3. Check the throttle positionwith the scan tool.

ls there approx. 10% whenthe throttle is fully closedand approx.90o/o when thethrottle is fully opened?

lntermittenl tailure, system is OKat this time. Check tor poor con-nections or loose wires at Cl15{TP s€nsor) end ECM.

Check lor an open in ihe wire(VCC2line):

1. Turn the ignition switch OFF.2. Disconnect the TP sensor con,nector,3. Turn the ignition switch ON (ll).4. Measure voltage betweenTP sensor connector terminalsNo. l and No. 3.

ls there approx. 5 V7

Check fo. an open in wire IVCC2line):lleasure voltage between ECMconnector terminals D10 and D11.

R.p.ir opon in tho wire betwoenECM {D101 and TP sen3or.ls there approx. 5 V?

Substitute a known-good ECMand recheck. lf pr6sc.ibed volt-age ia now available, replaco theoriginalECM.

Check for an open or 3hort in TP3ensor:1. Turn the ignition switch OFF.2. Measure resistance betweenTP sensor terminals No. '1 andNo.2 with the throttle fullyctoseo,

OUTPUT VOLTAGE {V)

4

RESISTOR3

2

TERMINAL

I

o

THROTTLEOPEI{INGBUS}IINGIDLE

sG2{GRN/BLK)vcc2IYEL/BLU}

vcc2{YEL/BI

l\e

4E

i2iRN,

. llLI5

6/101t 12

t515

(cont'd)

Page 303 of 1681

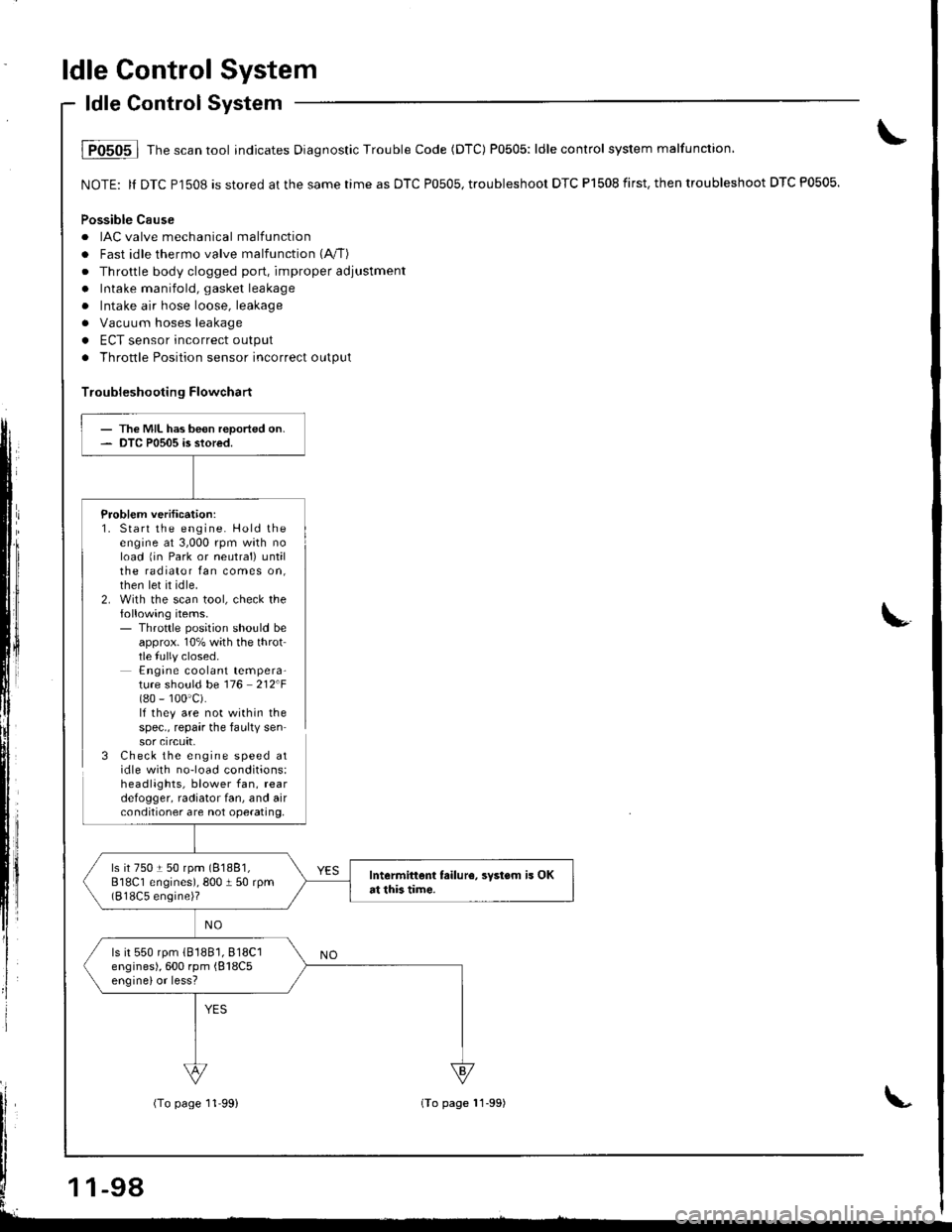

ldle Control System

ldle Control System

i P0505 | fne scan tool indicates Diagnostic Trouble Code (DTC) P0505: ldle control system malfunction,

NOTE: ll DTC Pl508 is stored at the same time as DTC P0505, troubleshoor DTC P1508 first. then troubleshoot DTC P0505.

Possible Cause

. IAC valve mechanical malfunctiorr

. Fast idle thermo valve malfunction (A"/T)

. Throttle body clogged port, improper adjustment

. Intake manifold, gasket leakage

. Intake air hose loose, leakage

a Vacuum hoses leakage

. ECT sensor incorrect output

. Throttle Position sensor incorrect output

Troubleshooting Flowchart

Problem verification:1. Start the engine. Hold theengine at 3,000 rpm wath noload 1in Park or neutral) untilthe radiator fan comes on,then let it idle.2. With the scan tool, check thefollowing items.- Throttle position should beapprox. 10% with the throttle fully closed.Engine coolant tempera-ture should be 116 212F(80 - 100'c).lf they are not within thespec., repair the faulty sensor crrcuft,3 Check the engine speed atidle with no-load conditions:headlights, blower fan, reardefogger, radiator fan, and airconditioner are not operating,

- The MIL has been reported on.- DTC P0505 is stored.

ls it 750 t 50 rpm (81881,

818C1 engines), 800 I 50 rpm(818C5 engine)?

Intermittent failur6, svstsm is OKat this tim€.

ls it 550 rpm (81881,818C1

engines), 600 rpm {818C5enginelor less?

-98

(To page 11'99)(To page 11-99)

Page 304 of 1681

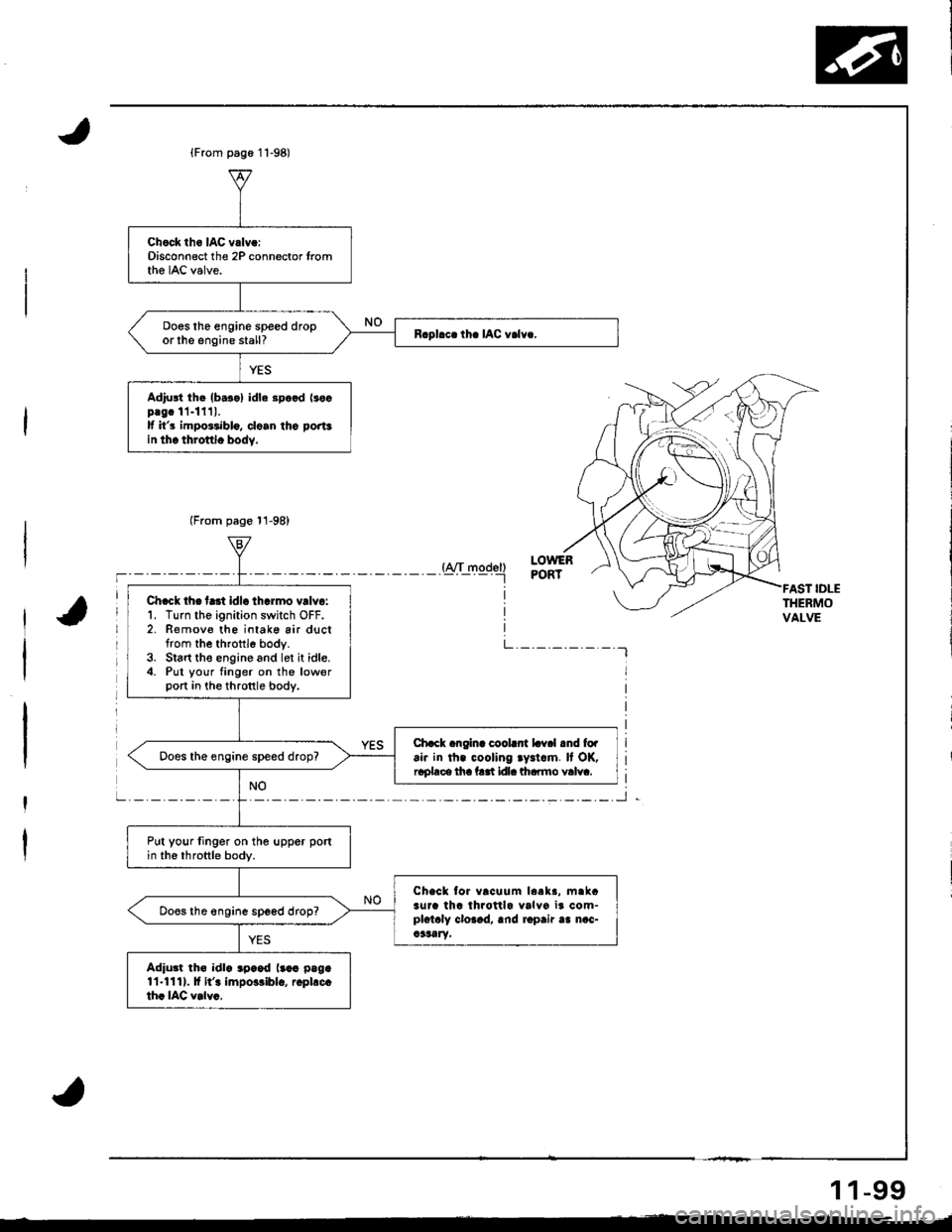

Chock th6 IAC vrlv.:Disconnect the 2P connector tromthe IAC valve.

ooes lhe engine speed droporlhe engine stall?

Adiu3t th. lb.r.l idle Bp..d lrocplgc 11-1111.lf it's impo3.iblo, clo.n tho portsin thc throftlc body.

Ch.ck th€ frtt idl. th.rmo vrlv.:1, Turn the ignition switch OFF.2. Remov€ th6 intake air ductfrom the throttle body.3. Slart the engine and let it idle.4. Put your finger on the lowerport in the thronle bodv.

Chack angina coobnt Lv.l and fo.ai. in th. cooling ry.l.m. It OK,r.place tha fatt ldla lftarmo valva.Does the engine speed drop?

Put your linger on the uppor portin the throttle body.

Chacl tor vrcuum leek3, m.lcilJa th6 throttlo valvo ir com-plotaly cloaad, rnd ropair aa nac-a3aatY,

ooes ihe engin6 speed drop?

Adiutt th€ idl. .p..d l..r p.g.11-1111. lf it'. impo3riblo, rcpl.c.thc IAC v.lvc.

{A/T model)----tLOWERPORT

L. _. _._. _. _. _.-l

IDLETHERMOVALVE

1 1-99

Page 305 of 1681

ldle Control System

Problem verification:'1. Do the ECM Feset Procedure.2. Sta rt the engine.

ldle Air Control (lAG) Valve

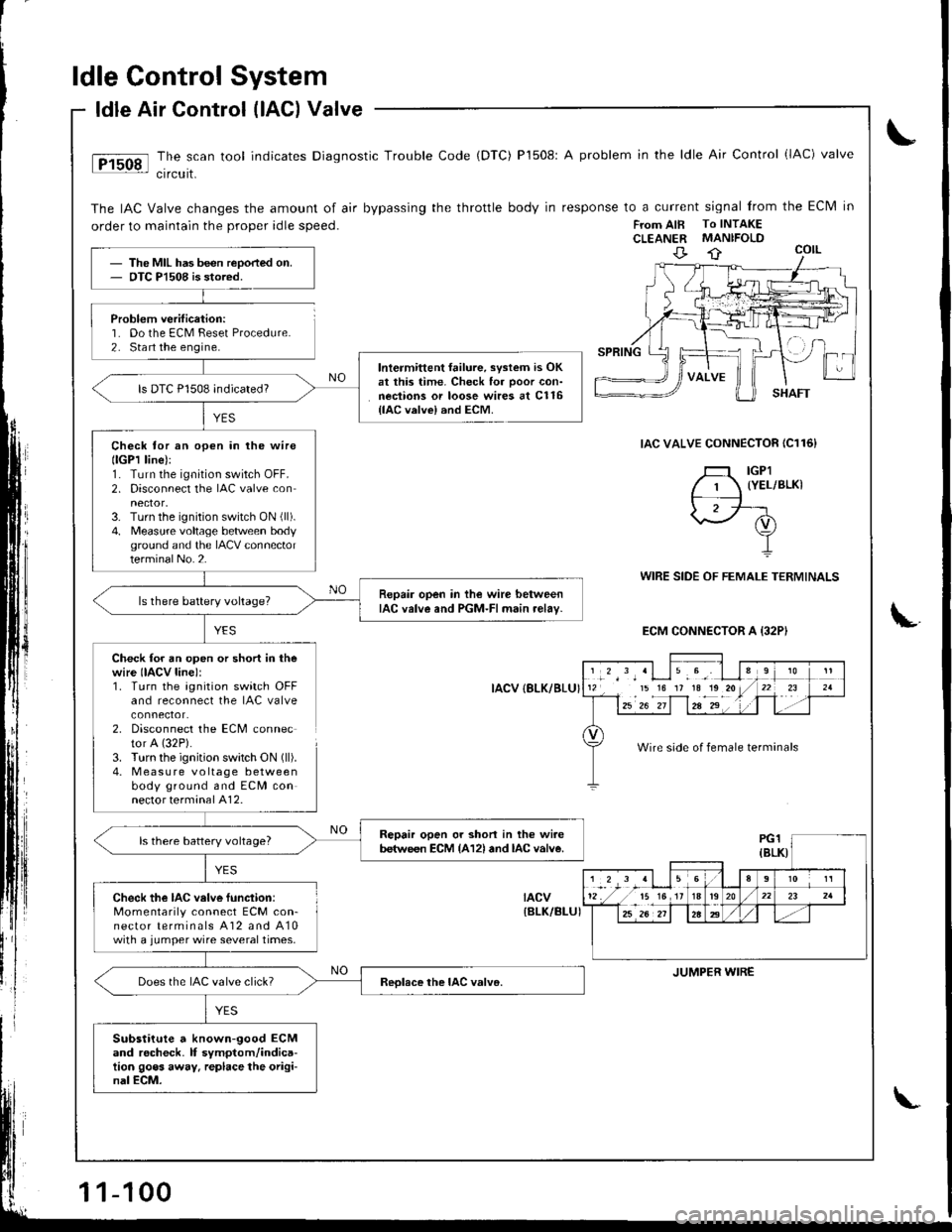

The scan tool indicates Diagnostic Trouble Code (DTC) P1508: A problem in the ldle Air Control (lAC) valve

crrcurt.

The IAC Valve changes the amount of air bypassing the throttle body in response to a current signal from the Eclvl in

order to maintain the proper idle speed.FTom AIB To INTAKECLEANER MANIFOLD

IAC VALVE CONNECTOR IC116}

YES

WIRE SIDE OF FEMALE TERMINALS

ECM CONNECTOR A {32PI

Check for an open or short in thewire IIACV line):1. Turn the agnition switch OFFand reconnect the IAC valve

2. Disconnect the ECM connector A (32P).

3. Turn the ignition swatch ON (ll).

4. M easu re voltage betweenbody ground and ECM connector terminal A12.

IACV {8LK/BLU}

tacv{BLK/BI-UI

The MIL has been reoorted on.OTC Pl508 is stored.

lntermittent failure, svstem is OKat this time. Check for ooor con-nections or loose wires at C116{lAC valvel and ECM.

ls DTC P1508 indicated?

Check tor an open in lhe wirellGPl line):1. Turn the ignition switch OFF.2. Disconnect the IAC valve con

3. Turn the ignition switch ON (ll).

4. Measure voltage betlveen bodyground and the IACV connectorterminalNo.2.

Repair open in the wire betweenIAC valve and PGM-FI main relav-ls there battery voltage?

Repair open or shon in the wi.ebetween ECM {A12l and lAc valve.ls there battery voltage?

Check the IAC velve function:Momentarily connect ECM con-nector terminals A12 and A10with a jumper wire several times.

Does the IAC valve click?

Substitute a known-good ECMand rocheck. lf symptom/indica-tion goes away. replace the origi-nal ECM.

','*',,'Llu.9', I l112 15 16 17 1a1o20/

l--12u1 z"-if1za-2"' . '1 .

910

t-r '21

Wire side of female terminals

JUMPER WIRE

1-100

Page 315 of 1681

ldle Control System

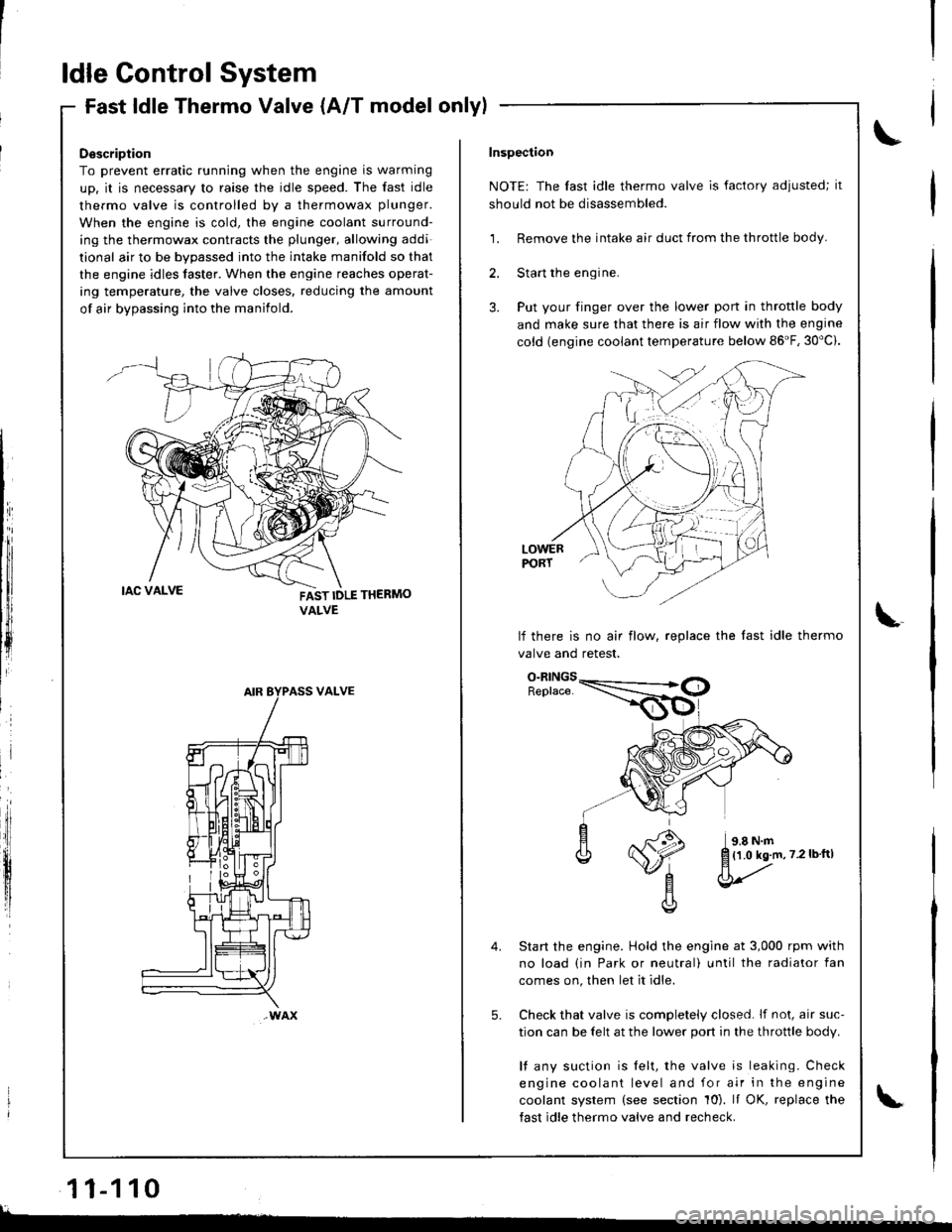

Fast ldle Thermo Valve (A/T model onlylFast ldle I nermo valve (A/ | mooel

Description

To prevent erratic running when the engine is warming

up. it is necessary to raise the idle speed. The fast idle

thermo valve is controlled by a thermowax plunger.

When the engine is cold, the engine coolant surround-

ing the thermowax contracts the plunger, allowing addi

tional air to be bvoassed into the intake manifold so that

the engine idles taster. When the engine reaches operat-

ing temperature, the valve closes. reducing the amount

of air bypassing into the manifold.

FAST IDLE THERMO

VALVE

VALVE

wAx

Inspection

NOTE: The fast idle thermo valve is factory adiusted; it

should not be disassembled.

1. Remove the intake air duct from the throttle body.

2. Start the engine.

3. Put your finger over the lower port in throttle body

and make sure that there is air flow with the engine

cold {engine coolant temperature below 86'F, 30"c).

LOWERPORT

lf there is no air flow, replace the last idle thermo

valve and retest.

Start the engine. Hold the engine at 3,000 rpm with

no load (in Park or neutral) until the radiator fan

comes on, then let it idle.

Check that valve is completely closed. lf not, air suc-

tion can be felt at the lower port in the throttle body.

l{ any suction is felt, the valve is leaking. Check

engine coolant level and for air in the engine

coolant system (see section 10). It OK, replace the

fast idle thermo valve and recheck.

5.

{1.0 kg.m,7.2lbftl

l

11-110

lL.�

Page 333 of 1681

r

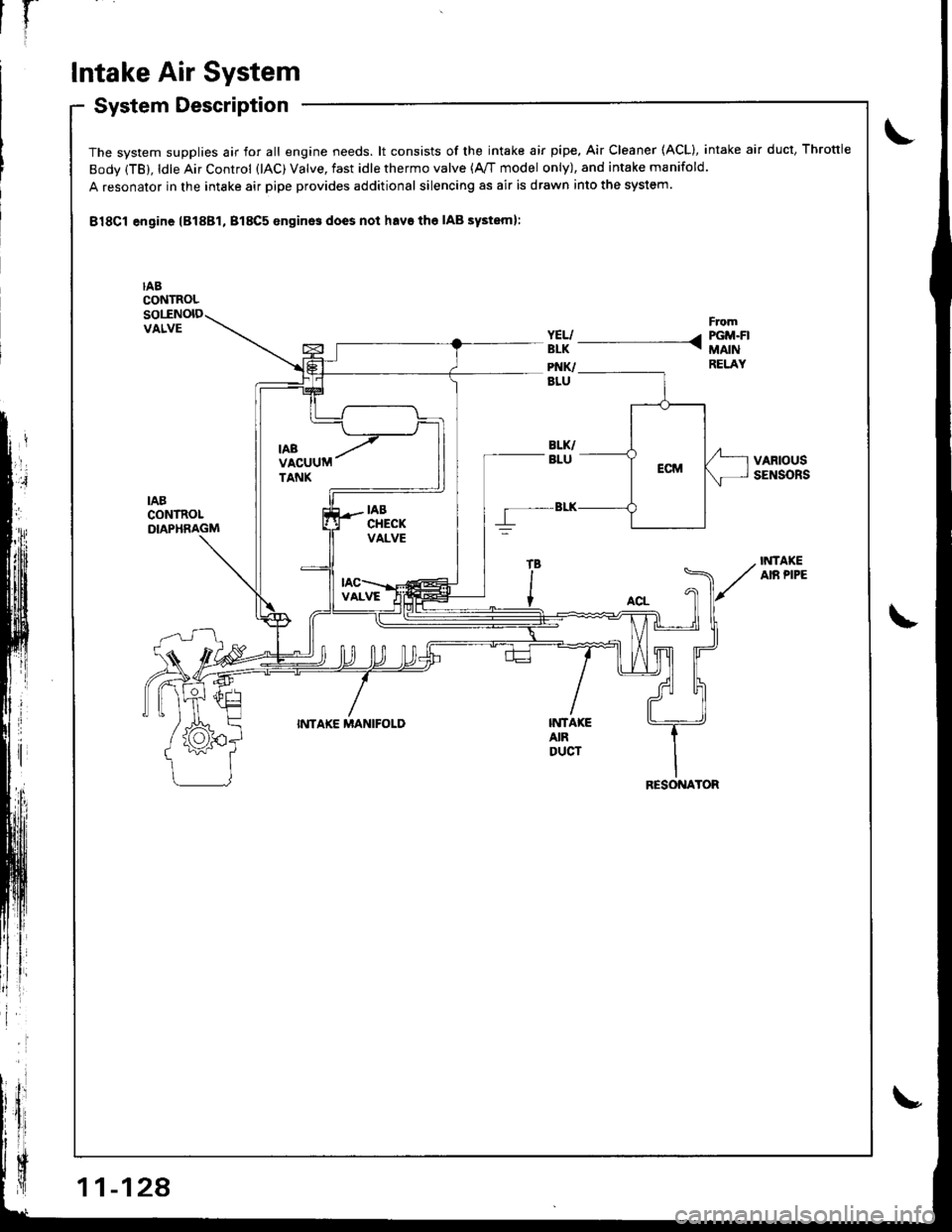

Intake Air System

System DescriptioSystem uescnpllon

The system supplies air for all engine needs. lt consists of the intake air pipe. Air Cleaner (ACL), intake air duct, Throttle

Body (TB), ldle Air Control (lAC) Valve, fast idle thermo valve (A,/T model only), and intake manifold.

A resonator in the intake air pipe provides additional silencing as air is drawn into the system.

B18Cl engine lB18Bl, B18C5 enginos does not havs the IAB systeml:

IABCONTROLsollNolDVALVE

VARIOUSSENSORS

IABCONTROLDIAPHRAGM

IiITAKEAIR PIPE

INTAKE MANIFOLDINTA|(EAIRDUCT

RESONATOR

Page 335 of 1681

l-

Intake Air System

LOCKNUT

DEFLECTION10-12mmBIA- 112in.l

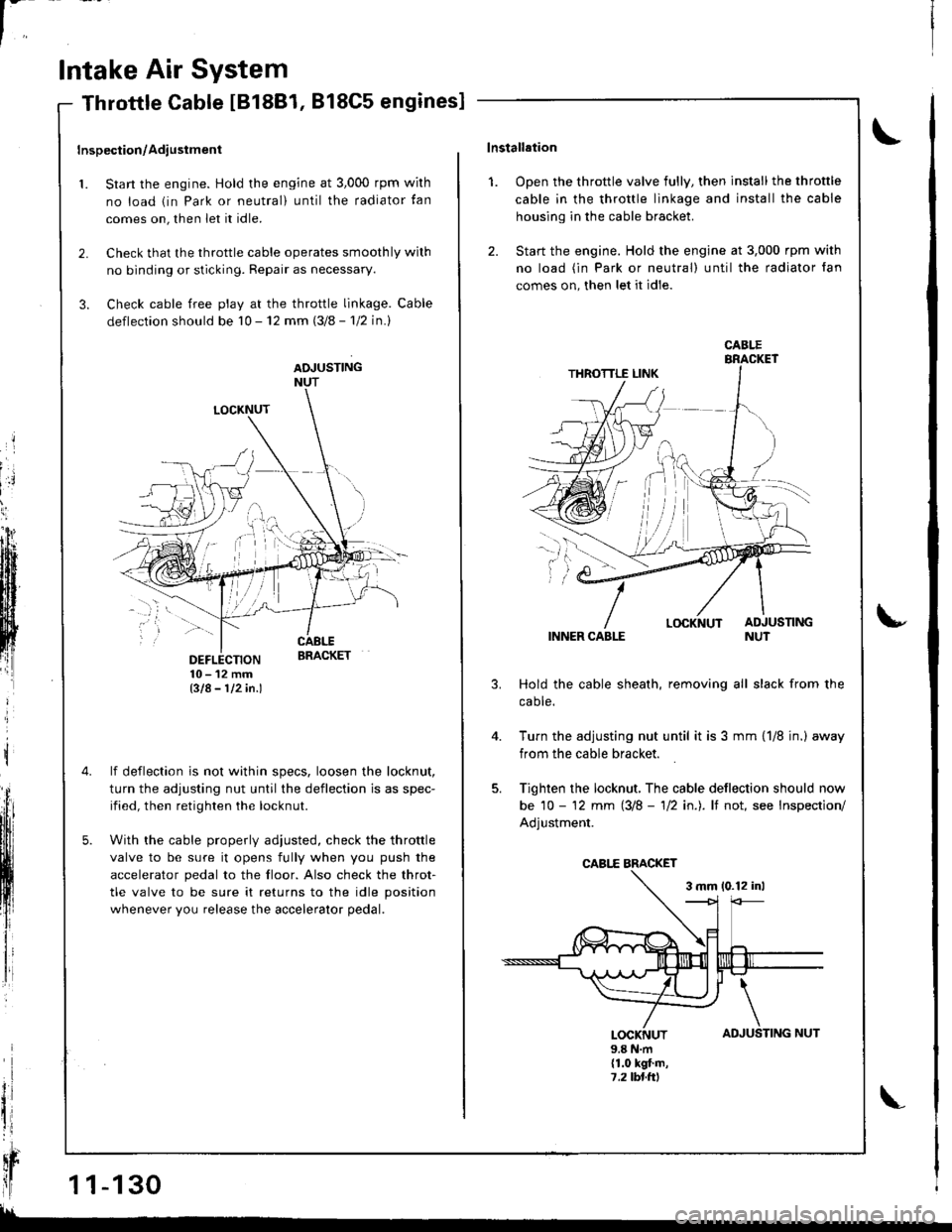

lf deflection is not within specs, loosen the locknut,

turn the adjusting nut until the deflection is as spec-

ified, then retighten the locknut.

With the cable properly adiusted, check the throttle

valve to be sure it opens fully when you push the

accelerator pedal to the floor. Also check the throt-

tle valve to be sure it returns to the idle position

whenever you release the accelerator pedal.

Throttle Cable IB18B1, 818C5 engines]

Inspection/Adiustment

1. Start the engine. Hold the engine at 3,000 rpm wirh

no load (in Park or neutral) until the radiator tan

comes on, then let it idle.

2. Check that the throttle cable operates smoothly wilh

no binding or sticking. Repair as necessary.

3. Check cable free play at the throttle linkage. Cable

deflection should be 10 - 12 mm (3/8 - 'l12 in.l

ADJUSTINGNUT

t

il

qr

ll1 1-130

!!

TING NUT

\lnstallation

1. Open the throttle valve fully, then install the throttle

cable in the throttle linkage and install the cable

housing in the cable bracket.

2. Start the engine. Hold the engine at 3,000 rpm with

no load (in Park or neutral) until the radiator fan

comes on, then let it idle.

INNER CABLE

Hold the cable sheath, removing all slack from the

caote.

Turn the adjusting nut until it is 3 mm {1/8 jn.) away

from the cable bracket.

Tighten the locknut, The cable deflection should now

be 10 - '12 mm (3/8 - 'll2 in.). lf not, see Inspection/

Adjustment.

3 mm 10.12 inl

u

4.

AD

\

JUSLOCKNUT9.8 N.m(1.0 kgt.m,7,2lbl.ttl

CABI.E

CABI,E BMCKET

Page 336 of 1681

't.

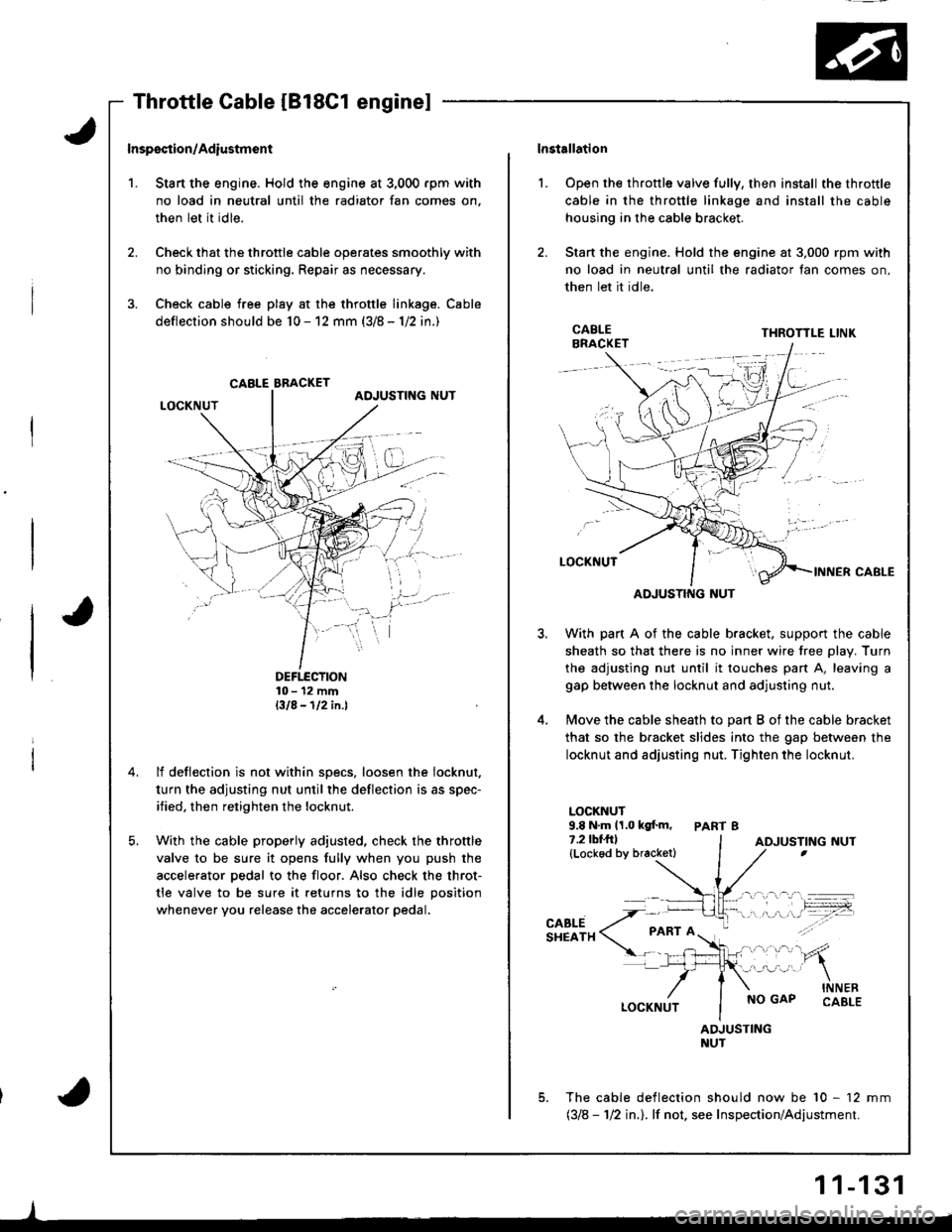

Inspsction/Adiustmsnt

Stan the engine. Hold the engine at 3,000 rpm with

no load in neutral until the radiator fan comes on,

then let it idle.

Check that the throttle cable operates smoothly with

no binding or sticking. Repair as necessary.

Check cable free play at the throttle linkage. Cable

deflection should be 10 - 12 mm (3/8 - 1/2 in.)

DEFTECTION10- 12 mmBIA-112in.l

lf deflection is not within specs, loosen the iocknut.

turn the adjusting nut until the deflection is as spec-

ified, then retighten the locknut.

With the cable properly adjusted, check the throttle

valve to be sure it opens fully when you push the

accelerator pedal to the floor. Also check the throt-

tle valve to be sure it returns to the idle position

whenever you release the accelerator pedal.

CABLE BBACKET

lnstallation

Open the throttle valve fully, then install the throttle

cable in the throttle linkage and install the cable

housing in the cable bracket.

Stan the engine. Hold the engine at 3,000 rpm with

no load in neutral until the radiator fan comes on,

then let it idle.

l.

3.

5.

CABLEBRACKETTHROTTLE LINK

ADJUSTING NUT

With part A of the cable bracket. support the cable

sheath so that there is no inner wire tree plav. Turn

the adjusting nut until it touches part A, leaving a

gap between the locknut and adjusting nut.

Move the cable sheath to oart B of the cable bracket

that so the bracket slides into the gap between the

locknut and adjusting nut. Tighten the locknut.

LOCKNUT9.8 N.m 11.0 kgf.m, PART 87.2lbf.frl(Lockod by bracketl

CABLESHEATH

NO GAPINNERCABLE

ADJUSTINGNUT

The cable deflection should now be 10 - 12 mm(318 - 112 in.l. lf not. see Inspection/Adjustment.

ADJUSTING NUT

1 1-131