engine Hyundai Accent 2006 Owner's Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2006, Model line: Accent, Model: Hyundai Accent 2006Pages: 599, PDF Size: 17.59 MB

Page 517 of 599

3 IN CASE OF EMERGENCY

4

7. Switch "ON" the main beamheadlamps before carefully remov- ing the jumper cables in the reverse order of attachment. Once the jumper cables have been removed,switch "OFF" the main beam headlamps.

CAUTION:

If the jump cable is incorrectly in-stalled, damage to the vehicle elec- trical system may occur, in particu-lar the electronic components such as the Fuel Injection system com- puter and the Automatic transaxlecomputer. The battery must never be disconnected whilst the engine is running.

!

!WARNING:

Motor vehicle batteries contain sulphuric acid and emit hydrogen gas. Protective clothing should beworn and care exercised to prevent the acid from coming into contact with skin or clothing and the ve-hicle. Naked lights should not be permitted in the vicinity of the bat- tery. Care should be exercised toprevent sparks occurring during connection. If acid accidentally comes into contact with skin oreyes, the affected area should im- mediately be flushed with copious amounts of water and medical as-sistance sought. 1. Ensure that the booster battery is

12 volt type. If the booster battery isinstalled in another vehicle, ensure that the two vehicles are not touch- ing.

2. Turn off all unnecessary electrical equipment in both vehicles.

3. Ensure that the engine of the ve- hicle providing the jump start is run- ning prior to connection of the jump cables.

4. Connect the red jump cable to the positive (+) terminal of the boosterbattery and the other end to thepositive (+) terminal of the dis- charged battery.

5. Attach the black jump cable to the

negative (-) terminal of the boosterbattery, and the other end to a ground point within the engine compart-ment of the vehicle with the flat battery. Do not connect to the nega- tive battery terminal of the flat bat-tery since sparks may be generated with the subsequent risk of explo- sion.

6. Raise the booster vehicle engine speed to 2,000 r.p.m. and start theengine of the vehicle with the flatbattery.

Page 518 of 599

3

IN CASE OF EMERGENCY

5IF THE ENGINE OVERHEATS

!

!

D030A01TB-EAT If the temperature gauge indicates overheating:

1. Pull off the road and stop as soon as

it is safe to do so.

2. Place the gear selector lever in "P"

(automatic), or neutral (manual transaxle) and set the parking brake. If the air conditioning is on, turn it off.

3. If coolant is running out under the car or steam is coming out from thebonnet, stop the engine. Do not open the bonnet until the coolanthas stopped running or the steam- ing has stopped. If there is no visible loss of coolant and no steam, leavethe engine running and check to be sure the engine cooling fan is oper- ating.If the fan is not running, turn the engine off.

4. Check to see if the water pump drive belt is missing. If it is not missing,check to see that it is tight. If the drive belt seems to be satisfactory,check for coolant leaking from the radiator, hoses or under the car. (If the air conditioning had been in use,it is normal for cold water to be draining from it). WARNING:

Whilst the engine is running, keep hands and clothing away from mov-ing parts such as the fan and drive belts to prevent injury.

WARNING (Diesel only):

Never work on injection system with engine running or within 30 sec- onds after shutting off engine. High pressure pump, rail, injectors andhigh pressure pipes are subject to high pressure even after the engine stopped. The fuel jet produced byfuel leaks may cause serious in- jury, if it touch the body. People using pacemakers should not movethan 12 in.(30 cm) closer to the ECU or wiring harness within the engine room whilst engine is running, sincethe high currents in the Common Rail system produce considerable magnetic fields. 5. If the water pump drive belt is broken

or coolant is leaking out, stop theengine immediately and call the near- est Hyundai dealer for assistance.

!WARNING:

Do not remove the radiator cap when the engine is hot since steam and boiling water may be ejected fromthe radiator resulting in burns or scalding.

6. If the cause of the overheating can- not be found, wait until the engine temperature has returned to nor- mal. Then, if coolant has been lost, carefully remove the radiator capand add water to bring the fluid level in the reservoir up to the base of the radiator fill opening. Fill the coolantexpansion tank to the halfway mark.

7. Proceed with caution until it is es-

tablished that the engine is operat-ing normally. If the engine over- heats repeatedly, the advice of a Hyundai dealer should be sought.

Page 526 of 599

3

IN CASE OF EMERGENCY

13

D080C02A

D080C01A

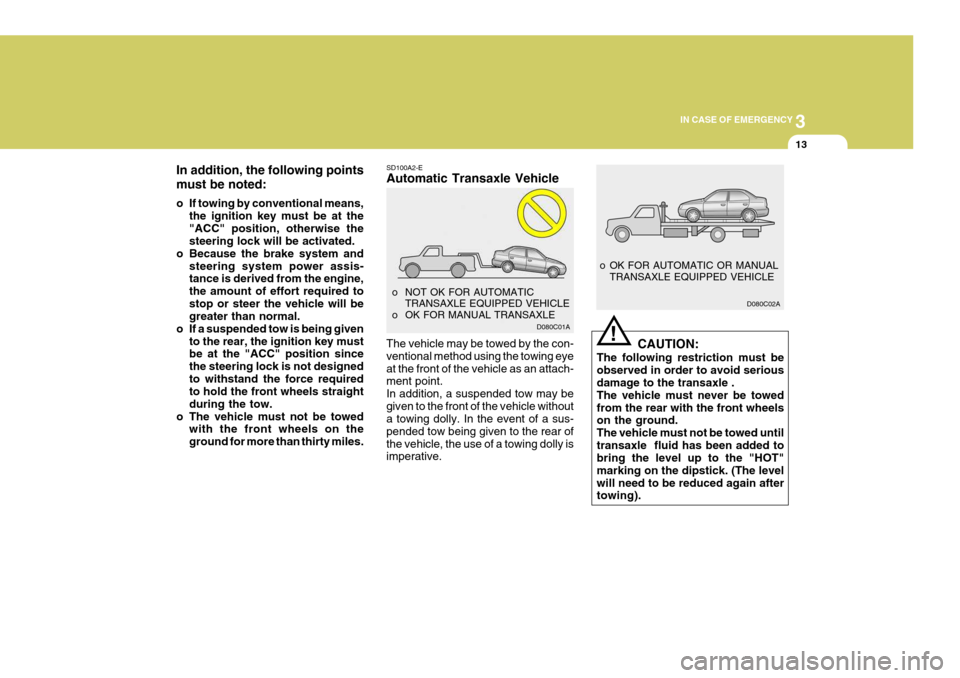

SD100A2-E Automatic Transaxle Vehicle The vehicle may be towed by the con- ventional method using the towing eyeat the front of the vehicle as an attach- ment point. In addition, a suspended tow may begiven to the front of the vehicle without a towing dolly. In the event of a sus- pended tow being given to the rear ofthe vehicle, the use of a towing dolly is imperative. o NOT OK FOR AUTOMATIC

TRANSAXLE EQUIPPED VEHICLE

o OK FOR MANUAL TRANSAXLE

In addition, the following points must be noted:

o If towing by conventional means,

the ignition key must be at the "ACC" position, otherwise the steering lock will be activated.

o Because the brake system and

steering system power assis-tance is derived from the engine, the amount of effort required tostop or steer the vehicle will be greater than normal.

o If a suspended tow is being given to the rear, the ignition key mustbe at the "ACC" position since the steering lock is not designedto withstand the force required to hold the front wheels straight during the tow.

o The vehicle must not be towed with the front wheels on theground for more than thirty miles.

! CAUTION:

The following restriction must be observed in order to avoid serious damage to the transaxle . The vehicle must never be towedfrom the rear with the front wheels on the ground. The vehicle must not be towed untiltransaxle fluid has been added to bring the level up to the "HOT" marking on the dipstick. (The levelwill need to be reduced again after towing).

o OK FOR AUTOMATIC OR MANUAL

TRANSAXLE EQUIPPED VEHICLE

Page 527 of 599

3 IN CASE OF EMERGENCY

14IF YOU LOSE YOUR KEYS

D120A01A-EAT Information about the key of immobiliser system will be found on page 1-4.

The vehicle must not be towed atspeeds faster than 25 mph. or dis- tances greater than fifty miles. Thegeneral points regarding the steer- ing lock etc. described in the pre- ceding section (Manual transaxlevehicle) should be observed.

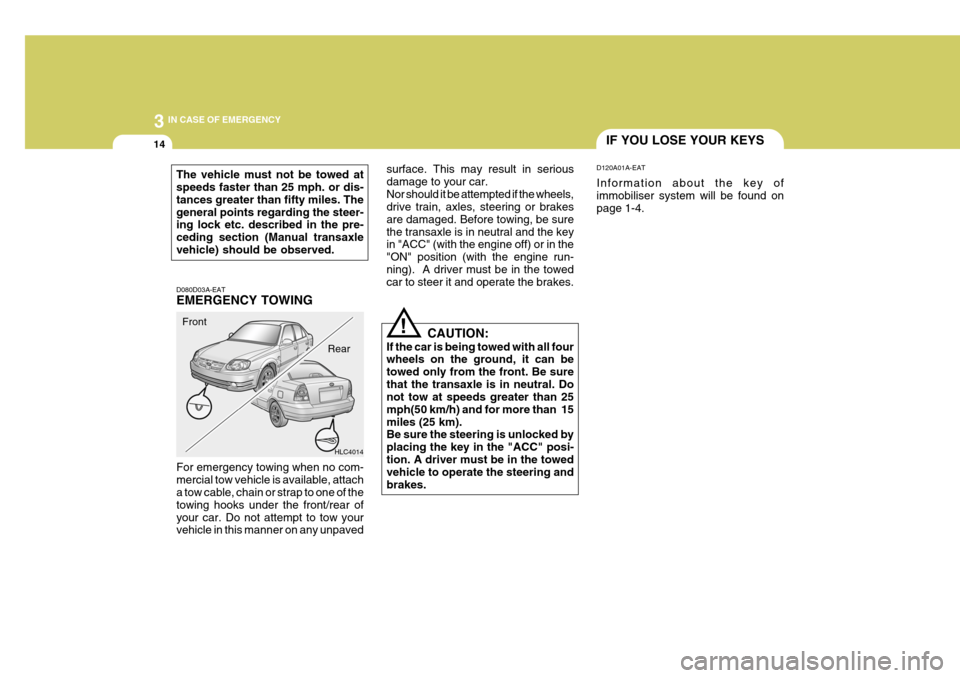

D080D03A-EAT EMERGENCY TOWING For emergency towing when no com- mercial tow vehicle is available, attach a tow cable, chain or strap to one of the towing hooks under the front/rear ofyour car. Do not attempt to tow your vehicle in this manner on any unpaved HLC4014surface. This may result in serious damage to your car.Nor should it be attempted if the wheels, drive train, axles, steering or brakes are damaged. Before towing, be surethe transaxle is in neutral and the key in "ACC" (with the engine off) or in the "ON" position (with the engine run-ning). A driver must be in the towed car to steer it and operate the brakes.

CAUTION:

If the car is being towed with all fourwheels on the ground, it can be towed only from the front. Be surethat the transaxle is in neutral. Do not tow at speeds greater than 25 mph(50 km/h) and for more than 15miles (25 km). Be sure the steering is unlocked by placing the key in the "ACC" posi-tion. A driver must be in the towed vehicle to operate the steering and brakes.

!

Front

Rear

Page 534 of 599

5VEHICLE MAINTENANCE REQUIREMENTS

2MAINTENANCE AND SER- VICING REQUIREMENTS

SF020A1-E To ensure the continued reliability and safety of the vehicle, certain routine maintenance operations are requiredat specific mileage or time intervals.It is the responsibility of the vehicleowner to ensure that the maintenanceschedules shown in both this Owners Manual and the Warranty and Service Passport are adhered to.The new vehicle warranty may beinvalidated if the routine maintenanceoperations are not performed in line with the recommendations outlined and the safety and durability of thevehicle adversely affected.It is recommended that all mainte-nance operations with the exceptionof the daily operating checks are en- trusted to a Hyundai dealer to ensure that the latest repair and maintenanceprocedures and specialized servicing tools are employed. In addition, the use of genuine Hyundai replacementparts will ensure that the vehicle safety and performance will not be compro- mised. NOTE:

The inspection and testing of cer-

tain electronic fuel injection/engine management and automatic trans- mission control systems requirespecialised electronic equipment specifically designed for Hyundai vehicles. The use of general pur-pose electrical test equipment may result in damage to the control unit microprocessors.

SF020C2-E

Specified Scheduled Procedures

The Specified scheduled procedures

are listed in the maintenance chartsbeginning at page 5-3. The opera- tions specified must be performed at the time or mileage intervals shownirrespective of whether the mileage interval has been reached before the specified time interval. Certain lubricants and components

degrade with both time and mileage(e.g. engine oil and brake fluid) and therefore it is not permissable to base the maintenance schedule upon mile-age alone. It is strongly recommended that the maintenance operations are performed by the factory-trained or distributor-trained technicians at yourHyundai dealer because of the need for specialized knowledge and tooling and to ensure that no possibility ofinvalidating the manufacturers war- ranty exists.

The maintenance schedules relate to

vehicles operated under normal con-ditions, vehicles which are operated under adverse conditions will requiremore frequent maintenance which is described at page 5-6. NOTE:

Service schedules may change de-

pending on individual country needs. Please ask your local Hyundai dealer for a copy of the service schedule that relates to thatcountry.

SF030B1-E

SERVICE HISTORY

It is important that all scheduled main-

tenance services are recorded in thewarranty and service passport to en-sure that proof of maintenance is avail- able when warranty service is required.

Page 535 of 599

5

VEHICLE MAINTENANCE REQUIREMENTS

3SCHEDULED MAINTENANCE

AF040C4-E In order to ensure the continued safety, reliability and longevity of the vehicle, the following maintenance service operations should be performed at the time or mileage intervals specified. It is recommended that all routine maintenance services are entrusted to a Hyundai dealer to ensure that the manufacturers recommended procedures are employed and that only genuine Hyundai replacement parts are used. Incorrect mainte- nance techniques or the use of non genuine replacement parts may invalidate the vehicle warranty. F030B03A-EAT R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if necessary

Note : (1) EVERY 6,000 MILES OR 6 MONTHS : "R" (2) EVERY 25,000 MILES : "R"

ENGINE CONTROL SYSTEM MAINTENANCE (PETROL)

1 ENGINE OIL & FILTER See Note (1)

2 DRIVE BELT (WATER PUMP, ALTERNATOR & A/CON)

3 FUEL FILTER (MPI)

4 FLUID LEAKS

5 TIMING BELT

6 VENTILATION HOSES

7 AIR CLEANER FILTER

8 SPARK PLUGS

NO. DESCRIPTION60 72

5060

4048

3036

2024

1012

MILES X 1000 MONTHS

R

I I

R

R

I

R I I

R

I

R I

R

R

II I

R

II

R

R

I I

See Note (2)

Page 536 of 599

5VEHICLE MAINTENANCE REQUIREMENTS

4

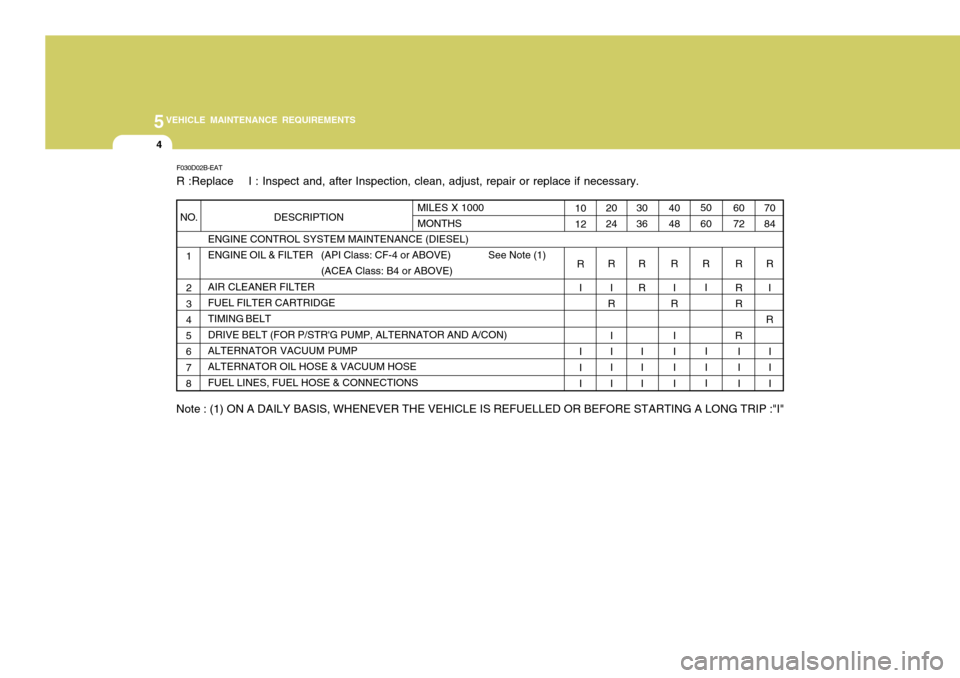

F030D02B-EAT

R :Replace I : Inspect and, after Inspection, clean, adjust, repair or replace if necessary.

ENGINE CONTROL SYSTEM MAINTENANCE (DIESEL)

ENGINE OIL & FILTER (API Class: CF-4 or ABOVE) See Note (1) (ACEA Class: B4 or ABOVE)

AIR CLEANER FILTERFUEL FILTER CARTRIDGE TIMING BELTDRIVE BELT (FOR P/STR'G PUMP, ALTERNATOR AND A/CON) ALTERNATOR VACUUM PUMP ALTERNATOR OIL HOSE & VACUUM HOSEFUEL LINES, FUEL HOSE & CONNECTIONS

1 2 3 4

56 78 6072

R R R

R I II

50 60

R I

III40 48 R I

R

I I II30 36

R R

I II20 24R I

R

I I II

10 12

R I I IIMILES X 1000 MONTHS70 84

R I

R III

Note : (1) ON A DAILY BASIS, WHENEVER THE VEHICLE IS REFUELLED OR BEFORE STARTING A LONG TRIP :"I"

NO. DESCRIPTION

Page 538 of 599

5VEHICLE MAINTENANCE REQUIREMENTS

6MAINTENANCE UNDER SEVERE USAGE CONDITIONS

F040A07A-EAT The following items must be serviced more frequently on cars normally used under severe driving conditions. Refer to the chart below for the appropriate maintenance intervals.

R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if necessary

SEVERE DRIVING CONDITIONS

A - Repeatly driving short distance of less than 5miles(8km) in normal temperature or less than 10miles(16km) in freezing temperature

B - Extensive engine idling or low speed driving for long distances

C - Driving on rough, dusty, muddy, unpaved, graveled or salt-spread roads

ENGINE OIL AND FILTER AIR CLEANER FILTER SPARK PLUGSTIMING BELTBRAKE PADS REAR BRAKE LININGS AND CYLINDERS SUSPENSION AND STEERING SYSTEMMANUAL TRANSAXLE OILAUTOMATIC TRANSAXLE FLUIDPOLLEN FILTER(FOR EVAPORATOR AND BLOWER UNIT)

EVERY 4,500 MILES OR 6 MONTHS MORE FREQUENTLY

MORE FREQUENTLY EVERY 37,000 MILES OR 48 MONTHSMORE FREQUENTLYMORE FREQUENTLY MORE FREQUENTLY EVERY 60,000 MILESEVERY 27,000 MILES

MORE FREQUENTLY

MAINTENANCE OPERATIONMAINTENANCE ITEM

R R R RI I I

R R R A, B, C, F, H, G, I, K A, B, C, F, H, I, JC, E B, H D, E, F, GC, D, G, H C, D, G, H C, D, E, FA, C, D, E, F, G, H, I, J A, C, E, F, G, H, I C,E

MAINTENANCE INTERVALS

DRIVING

CONDITION

D - Driving in areas using salt or other corrosive materials or in

very cold weather

E - Driving in sandy areas

F - Driving in heavy traffic area over 90°F(32°C)

G - Driving on uphill, downhill, or mountain road

H - Towing a Trailer, or using a camper, or roof rack

I - Driving as a patrol car, taxi, other commercial use or vehicle towing

J - Driving over 100 MPH(170 Km/h) K - Frequently driving in stop-and-go conditions

Petrol Diesel

Page 539 of 599

5

VEHICLE MAINTENANCE REQUIREMENTS

7EXPLANATION OF SCHED- ULED MAINTENANCE ITEMS

!

6ZF060M1-A

o Engine oil and filter

The engine oil and filter should be changed at the intervals specified in the maintenance schedule. If the car is being driven in severe conditions,more frequent oil and filter changes are required. 6ZF060B1-A

o Drive belts

Inspect all drive belts for evidence of cuts, cracks, excessive wear or oil saturation and replace if necessary. Drive belts should be checked peri-odically for proper tension and ad- justed as necessary. 6ZF060C1-A

o Fuel filter

A clogged filter can limit the speed at

which the vehicle may be driven, dam-age the emission system and cause hard starting. If an excessive amountof foreign matter accumulates in the fuel tank, the filter may require re- placement more frequently. After installing a new filter, run the

engine for several minutes, and checkfor leaks at the connections.

F060D01TB-EAT

o Fuel lines, fuel hoses and con-

nections

Check the fuel lines, fuel hoses and

connections for leakage and damage.Replace any damaged or leaking partsimmediately. WARNING (Diesel only):

Never work on injection system with engine running or within 30 seconds after shutting off engine.High pressure pump, rail, injectors and high pressure pipes are sub- jected to high pressure even afterthe engine has been switched off. The fuel jet produced by fuel leaks may cause serious injury, if it con-tacts with the body. People using pacemakers should not move closer than 12 in.(30 cm) to the ECUor wiring harness within the engine room with the engine running, since the high currents in the CommonRail system produce considerable magnetic fields.

Page 540 of 599

5VEHICLE MAINTENANCE REQUIREMENTS

8

6ZF070C1-A

o Coolant

The engine coolant should be changed

at the intervals specified in the main- tenance schedule. F060H01A-AAT

o Air cleaner filter

A Genuine Hyundai air cleaner filter is

recommended when the filter is re- placed.

6ZF060J1-A

o Spark plugs

(For Petrol Engine)

Make sure to install new spark plugs

of the correct heat range.

6ZF070B1-A

o Cooling system

Check the cooling system part, such as radiator, coolant reservoir, hoses and connections for leakage and dam- age. Replace any damaged parts.

6ZF060G1-A o Vapour hose and fuel filler cap The vapour hose and fuel filler cap should be inspected at those intervals specified in the maintenance sched- ule. Make sure that a new vapourhose or fuel filler cap is correctly re- placed. 6ZF060F1-A

o Vacuum, crankcase

ventilation hoses

Inspect the surface of hoses for evi-

dence of heat and/or mechanical dam-age. Hard and brittle rubber, cracking, tears, cuts, abrasions, and excessiveswelling indicate deterioration. Par- ticular attention should be paid to ex- amining those hose surfaces nearestto high heat sources, such as the exhaust manifold.

Inspect the hose routing to assure

that the hoses do not come in contactwith any heat source, sharp edges or moving component which might causeheat damage or mechanical wear. Inspect all hose connections, such as clamps and couplings, to make surethey are secure, and that no leaks are present. Hoses should be replaced immediately if there is any evidence ofdeterioration or damage.

6ZF060E1-A o Timing belt Replace timimg belt and inspect all associated parts related for damage and deformation. Replace any dam- aged parts immediately.