maintenance schedule Hyundai Coupe 2003 User Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2003, Model line: Coupe, Model: Hyundai Coupe 2003Pages: 310, PDF Size: 2.87 MB

Page 157 of 310

EMISSION CONTROL SYSTEMS 7-1

7. EMISSION

CONTROL SYSTEMS

H010B01F-GAT

1. Crankcase Emission Control Sys-

tem

The positive crankcase ventilation system is

employed to prevent air pollution caused by H010A01A-GAT

EMISSION CONTROL SYSTEMS (If Installed)

Your Hyundai is equipped with an emission

control system to meet all requirements of the Emission prohibition rules of your province.

There are three emission control systems which

are as follows.

(1) Crankcase emission control system (2) Evaporative emission control system(3) Exhaust emission control system In order to assure the proper function of the

emission control systems, it is recommended that you have your car inspected and main-tained by an authorized Hyundai dealer in ac-cordance with the maintenance schedule in thismanual. H010C01F-GAT

2. Evaporative Emission Control Sys-

tem (If Installed)

The evaporative emission control system is

designed to prevent fuel vapors from escapinginto the atmosphere. Canister

While the engine is inoperative, fuel vapors

generated inside the fuel tank are absorbed and stored in the canister. When the engine is

running, the fuel vapors absorbed in the canis-ter are drawn into the induction system throughthe purge control solenoid valve. Purge Control Solenoid Valve

The purge control solenoid valve is controlled

by the ECM; when the engine coolant tempera- ture is low, and during idling, it closes, so that

evaporated fuel is not taken into the engine.After engine warm-up, during ordinary driving, itopens so as to introduce evaporated fuel to theengine. H010D01A-AAT

3. Exhaust Emission Control System

The exhaust emission control system is a high-

ly effective system which controls exhaust emis-sions while maintaining good vehicleperformace.

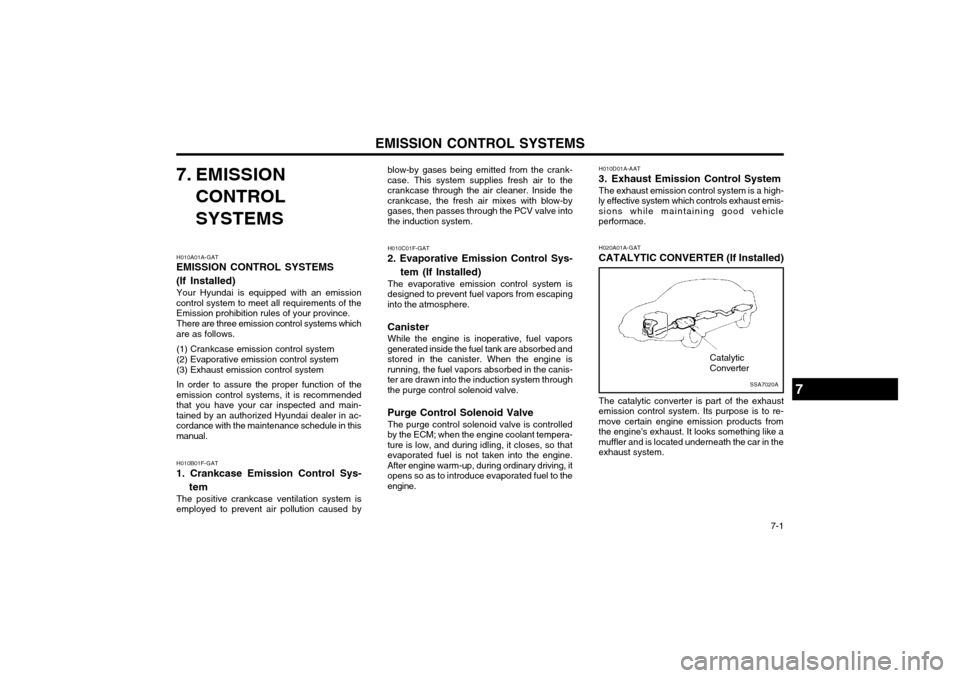

H020A01A-GAT

CATALYTIC CONVERTER (If Installed)

Catalytic Converter

SSA7020A

The catalytic converter is part of the exhaust

emission control system. Its purpose is to re- move certain engine emission products fromthe engine's exhaust. It looks something like amuffler and is located underneath the car in theexhaust system.

blow-by gases being emitted from the crank-

case. This system supplies fresh air to the

crankcase through the air cleaner. Inside thecrankcase, the fresh air mixes with blow-bygases, then passes through the PCV valve intothe induction system.

7

Page 167 of 310

INDEX10-3

R Rear Seats

Before Folding the Rear Seats ..................................................... 1-10

Fold down ..................................................................................... 1-10

Rear seat entry ............................................................................. 1-10

Rear Seat Pos itions ....................................................................... 1-9

Rear Window Defroster Switch ......................................................... 1-36

Rear Window Wiper and Switch .. ..................................................... 1-35

SSeat Belts 3-Point type .................................................................................. 1-13

Adjustable height .......................................................................... 1-13

Adjusting your seat belt ................................................................ 1-13

Care of seat belts ......................................................................... 1-12

Precautions ................................................................................... 1-11

Pre-tentioner Seat Belt ................................................................. 1-18

Spark Plugs ........................................................................................ 6-8

Spectacle Case ................................................................................. 1-40

Speedometer ..................................................................................... 1-30

Starting Procedures ............................................................................ 2-3Steering Wheel Free play ...................................................................................... 6-15

Tilt lever ........................................................................................ 1-47

Stereo Radio Operation (H250, H260) ....................................1-65, 1-72

Stereo Sound System ............................................................ 1-63 ~ 1-64Sun Visor .......................................................................................... 1-46

Sunroof .............................................................................................. 1-38

TTachometer ....................................................................................... 1-30

Tail Gate ........................................................................................... 1-45

TCS (Traction control system) .......................................................... 2-10

Theft Alarm System ............................................................................ 1-5

JJump Starting

...................................................................................... 3-1

K

Keys .................................................................................................. 1-2 If you lose your keys .................................................................... 3-10

Positions ......................................................................................... 2-2

L

Light Bulb Replacement .................................................................... 6-20

Lubrication Chart ................................................................................. 9-3

Luggage Net ...................................................................................... 1-47

M Maintenance Intervals Explanation of scheduled maintenance items ....................... 5-5 ~ 5-7

Maintenance under severe usage conditions ................................. 5-4

Scheduled maintenance ................................................................. 5-2

Service requirements ...................................................................... 5-1

Map Light .......................................................................................... 1-40

Mirros Day-night inside rearview ............................................................. 1-42

Outside rearview folding ............................................................... 1-42

Outsde rearview heating .............................................................. 1-41

Multi gauge ........................................................................................ 1-32

OOdometer .......................................................................................... 1-30

PParking Brake ................................................................................... 1-43

Power Steering Fluid Level ............................................................... 6-19

Page 174 of 310

A090A01A-AATResponsibilty For Maintenance

It is the responsibility of the vehicle owner/driver to ensure that all routine maintenance services are undertaken in line with the recommendations specifiedin Section 5 of this manual. In addition, in order to ensure continued validity of the new vehicle warranty and safe operation of the vehicle, non scheduled mainte- nance/running repairs should be undertaken at the earliest available opportunity.Under severe operating conditions, more frequent maintenance is required. Details of the maintenance schedule for such conditions are also given in section 5.It is recommended that all maintenance operations and repairs are entrusted to a franchised Hyundai dealer to ensure that the latest repair methods, specialized tooling and genuine Hyundai parts are used to ensure the continued reliability andsafety of the vehicle.

Page 254 of 310

DRIVING YOUR HYUNDAI 2- 11

heat, which reduces their effectiveness and may lead to more serious consequences.

o Take care of your tires. Keep them inflated to the recommended pressure. Incorrect infla-tion, either too much or too little, results inunnecessary tire wear. Check the tire pres-sures at least once a month.

o Be sure that the wheels are aligned cor- rectly. Improper alignment can result fromhitting curbs or driving too fast over irregularsurfaces. Poor alignment causes faster tirewear and may also result in other problemsas well as greater fuel consumption.

o Keep your car in good condition. For better fuel economy and reduced maintenancecosts, maintain your car in accordance withthe maintenance schedule in Section 5. Ifyou drive your car in severe conditions,more frequent maintenance is required (seeSection 5 for details).

o Keep your car clean. For maximum service, your car should be kept clean and free ofcorrosive materials. It is especially impor-tant that mud, dirt, ice, etc. not be allowed toaccumulate on the underside of the car. Thisextra weight can result in increased fuelconsumption and also contribute to corro-sion.

o Travel lightly. Don't carry unnecessary weight in your car. Weight is an enemy of good fueleconomy.

o Don't let the engine idle longer than neces- sary. If you are waiting (and not in traffic),turn off your engine and restart only whenyou're ready to go. o Remember, your car does not require ex-

tended warm-up. As soon as the engine isrunning smoothly, you can drive away. Invery cold weather, however, give your en-gine a slightly longer warm-up period.

o Don't "lug" or "over-rev" the engine. Lugging is driving too slowly in too high a gearresulting in the engine bucking. If this hap-pens to you, shift to a lower gear. Over-revving is racing the engine beyond its safe limit. This can be avoided by shifting atthe recommended speeds.

o Use your air conditioning sparingly. The air conditioning system is operated by the en-gine power so your fuel economy is reducedwhen you use it.

SC160A1-F

SMOOTH CORNERING

Avoid braking or gear changing in corners,

especially when roads are wet. Ideally, cornersshould always be taken under gentle accelera-tion. If you follow these suggestions, tire wearwill be held to a minimum.

SC170A1-E

WINTER MOTORING The onset of winter conditions subject motor

vehicles to greater operating demands. There-fore, the following suggestions will assist inmaintaining peak performance and reliabilityduring these periods: ZC170B1-E

Electrical System

Winter conditions impose severe demands uponvehicle electrical systems, particularly the charg-ing circuit. The battery condition and perfor-mance along with the alternator performanceand drive belt condition should be checked priorto the onset of winter. ZC170C1-E

Anti-freeze/Corrosion inhibitor The cooling system must always contain an Ethylene-Glycol based anti-freeze solution. Thesystem is filled during manufacture with solu-tion of the correct strength which should bechecked before the onset of winter and adjust- ed or changed as required. NOTE: The anti-freeze solution contains a corro- sion inhibitor to prevent degradation of thealuminum castings contained within theengine. Therefore, never, drain the systemand refill with water only. In addition, anti-freeze solution must ALWAYS be used in vehicles fitted with air conditioning,to prevent the heater matrix from freezing andsubsequently bursting with the refrigeration sys-tem in use.

Page 269 of 310

VEHICLE MAINTENANCE REQUIREMENTS 5-1

SF020A1-E MAINTENANCE AND SERVICINGREQUIREMENTS To ensure the continued reliability and safety ofthe vehicle, certain routine maintenance opera-tions are required at specific mileage or timeintervals.It is the responsibility of the vehicle owner toensure that the maintenance schedules shownin both this Owners Manual and the Warrantyand Service Passport are adhered to.The new vehicle warranty may be invalidated ifthe routine maintenance operations are not per-formed in line with the recommendations outlinedand the safety and durability of the vehicle ad-versely affected.It is recommended that all maintenance opera-tions with the exception of the daily operatingchecks are entrusted to a Hyundai dealer toensure that the latest repair and maintenanceprocedures and specialized servicing tools areemployed. In addition, the use of genuine Hyundaireplacement parts will ensure that the vehiclesafety and performance will not be compro-mised.

SF000A1-E

5. VEHICLE MAINTE-

NANCE REQUIRE- MENTS NOTE: The inspection and testing of certain elec-tronic fuel injection/engine management andautomatic transmission control systems re-quire specialised electronic equipment spe-cifically designed for Hyundai vehicles. Theuse of general purpose electrical test equip-ment may result in damage to the control unitmicroprocessors. SF020C1-E Specified Scheduled Procedures

The Specified scheduled procedures are listed

in the maintenance charts beginning at page 5- 2. The operations specified must be performedat the time or mileage intervals shown irrespec-tive of whether the mileage interval has beenreached before the specified time interval.

Certain lubricants and components degrade

with both time and mileage (e.g. engine oil andbrake fluid) and therefore it is not permissableto base the maintenance schedule upon mile-age alone. It is strongly recommended that themaintenance operations are performed by thefactory-trained or distributor-trained techniciansat your Hyundai dealer because of the need forspecialized knowledge and tooling and to en-sure that no possibility of invalidating the man-ufacturers warranty exists.

The maintenance schedules relate to vehicles

operated under normal conditions, vehicles which are operated under adverse conditionswill require more frequent maintenance which isdescribed at page 5-4. SF030B1-E SERVICE HISTORY It is important that all scheduled maintenance services are recorded in the warranty and ser-vice passport to ensure that proof of mainte-nance is available when warranty service isrequired.

5

Page 270 of 310

VEHICLE MAINTENANCE REQUIREMENTS

5- 2

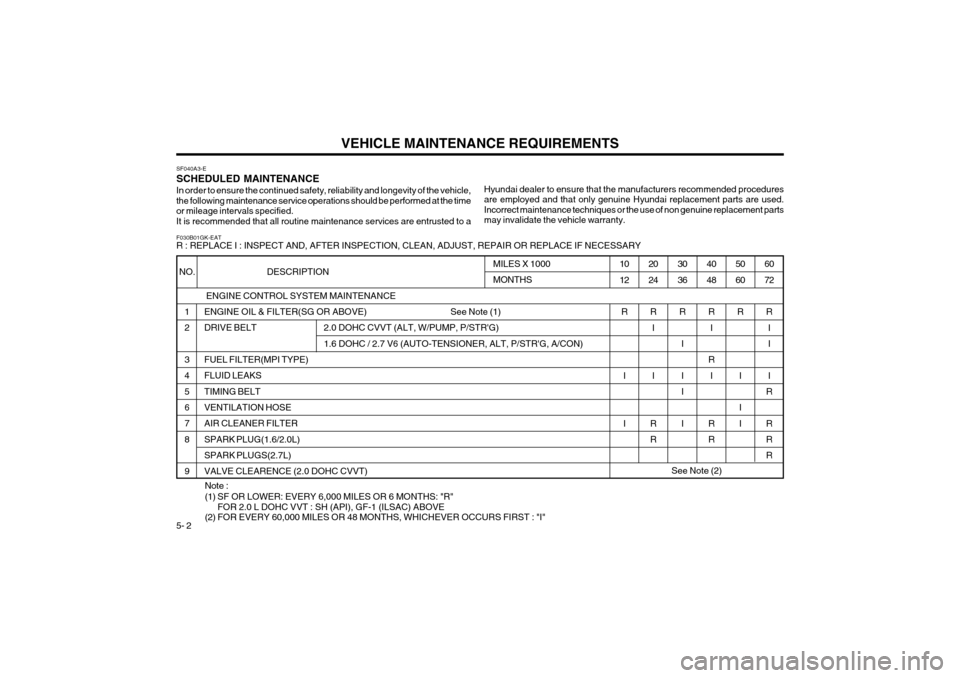

SF040A3-E SCHEDULED MAINTENANCEIn order to ensure the continued safety, reliability and longevity of the vehicle, the following maintenance service operations should be performed at the timeor mileage intervals specified.It is recommended that all routine maintenance services are entrusted to a

Hyundai dealer to ensure that the manufacturers recommended proceduresare employed and that only genuine Hyundai replacement parts are used.Incorrect maintenance techniques or the use of non genuine replacement partsmay invalidate the vehicle warranty.

F030B01GK-EAT R : REPLACE I : INSPECT AND, AFTER INSPECTION, CLEAN, ADJUST, REPAIR OR REPLACE IF NECESSARY

ENGINE CONTROL SYSTEM MAINTENANCE

ENGINE OIL & FILTER(SG OR ABOVE) See Note (1)

DRIVE BELT 2.0 DOHC CVVT (ALT, W/PUMP, P/STR'G) 1.6 DOHC / 2.7 V6 (AUTO-TENSIONER, ALT, P/STR'G, A/CON)

FUEL FILTER(MPI TYPE)FLUID LEAKS TIMING BELTVENTILATION HOSE AIR CLEANER FILTER SPARK PLUG(1.6/2.0L)SPARK PLUGS(2.7L) VALVE CLEARENCE (2.0 DOHC CVVT)

NO. DESCRIPTION60 72

R I I I

RR R R

5060

R

I I I

4048

R I

R I

R R

30 36

R I I I I

20 24

R I I

R R

10 12

R

I I

MILES X 1000 MONTHS

Note :

(1) SF OR LOWER: EVERY 6,000 MILES OR 6 MONTHS: "R"

FOR 2.0 L DOHC VVT : SH (API), GF-1 (ILSAC) ABOVE

(2) FOR EVERY 60,000 MILES OR 48 MONTHS, WHICHEVER OCCURS FIRST : "I"

1 2 3 4 56 7 8 9

See Note (2)

Page 273 of 310

VEHICLE MAINTENANCE REQUIREMENTS 5-5

6ZF060D1-A

o Fuel lines, fuel hoses and connec-

tions

Check the fuel lines, fuel hoses and connections for leakage and damage. Replace any damagedor leaking parts immediately. 6ZF060E1-A o Timing beltInspect all parts related to the timing belt for damage and deformation. Replace any dam-aged parts immediately. 6ZF060G1-A

o Vapour hose and fuel filler cap The vapor hose and fuel filler cap should be inspected at those intervals specified in the main-tenance schedule. Make sure that a new vapourhose or fuel filler cap is correctly replaced. 6ZF060F1-A

o Vacuum, crankcase

ventilation hoses

Inspect the surface of hoses for evidence of heat and/or mechanical damage. Hard and brittle rub-ber, cracking, tears, cuts, abrasions, and exces-sive swelling indicate deterioration. Particularattention should be paid to examining those hosesurfaces nearest to high heat sources, such asthe exhaust manifold.Inspect the hose routing to assure that the hoses do not come in contact with any heat source,sharp edges or moving component which mightcause heat damage or mechanical wear. Inspectall hose connections, such as clamps and cou-plings, to make sure they are secure, and that noleaks are present. Hoses should be replacedimmediately if there is any evidence of deteriora-tion or damage. 6ZF060H1-A

o Air cleaner filterA Genuine Hyundai air cleaner filter is recom- mended when the filter is replaced. 6ZF060J1-A

o Spark plugs Make sure to install new spark plugs of the correct heat range.

6ZF060A1-A EXPLANATION OF SCHEDULED MAINTENANCE ITEMS 6ZF060M1-A

o Engine oil and filterThe engine oil and filter should be changed at the intervals specified in the maintenance schedule.If the car is being driven in severe conditions,more frequent oil and filter changes are required. 6ZF060B2-A

o Drive belts Inspect all drive belts for evidence of cuts, cracks, excessive wear or oil saturation and replace ifnecessary. Drive belts should be checked peri-odically for proper tension and adjusted as nec-essary. 6ZF060C1-A

o Fuel filterA clogged filter can limit the speed at which the vehicle may be driven, damage the emissionsystem and cause hard starting. If an excessiveamount of foreign matter accumulates in the fueltank, the filter may require replacement morefrequently.After installing a new filter, run the engine forseveral minutes, and check for leaks at theconnections.

F060N02E-EAT

o Valve Clearance Inspect excessive valve noise and/or engine vibration and adjust if necessary. A qualifiedtechnician should perform the operation.

Page 274 of 310

VEHICLE MAINTENANCE REQUIREMENTS

5- 6

6ZF070D1-A

o Manual transaxle oil Inspect the manual transaxle oil according to the maintenance schedule. NOTE: If the oil level is low, check for possible leaksbefore adding oil. Do not overfill.

6ZF070H1-A

o Rear brake drums and linings/

parking brake

Check the rear brake drums and linings for scoring, burning, leaking fluid, broken parts, andexcessive wear. Inspect the parking brake sys-tem including the parking brake lever and cables.For detailed service procedures, refer to theShop Manual. 6ZF070J1-A

o Brake pads, calipers and rotorsCheck the pads for excessive wear, discs for run out and wear, and calipers for fluid leakage. 6ZF070K1-A

o Exhaust pipe and mufflerVisually inspect the exhaust pipes, muffler and hangers for cracks, deterioration, or damage.Start the engine and listen carefully for anyexhaust gas leakage. Tighten connections orreplace parts as necessary. 6ZF070L1-A

o Suspension mounting bolts Check the suspension connections for loose- ness or damage. Retighten to the specified torque.

F070E03A-AAT

o Automatic transaxle fluid The fluid level should be in the "HOT" range of the dipstick, after engine and transaxle are at normaloperating temperature. Check the AutomaticTransaxle Fluid level with the engine running andthe transaxle in neutral, with the parking brakeproperly applied. Use DIAMOND ATF SP- III,

SK ATF SP- III when adding or changing fluid. 6ZF070M1-A

o Steering gear box, linkage & boots/

lower arm ball joint

With the vehicle stopped and engine off, check for excessive freeplay in the steering wheel.Check the linkage for bends or damage. Checkthe dust boots and ball joints for deterioration,cracks, or damage. Replace any damaged parts. 6ZF070N1-A

o Power steering pump, belt and hos-

es

Check the power steering pump and hoses for leakage and damage. Replace any damaged orleaking parts immediately. Inspect the powersteering belt for evidence of cuts, cracks, exces-sive wear, oiliness and proper tension. Replaceor adjust it if necessary.

6ZF070F1-A o Brake hoses and linesVisually check for proper installation, chafing, cracks, deterioration and any leakage. Replaceany deteriorated or damaged parts immediately. 6ZF070G2-A

o Brake fluidCheck brake fluid level in the brake fluid reser- voir. The level should be between "MIN" and"MAX" marks on the side of the reservoir. Useonly hydraulic brake fluid conforming to DOT 3 orDOT 4.

6ZF070B1-A

o Cooling systemCheck the cooling system part, such as radiator, coolant reservoir, hoses and connections forleakage and damage. Replace any damagedparts. 6ZF070C1-A

o Coolant The coolant should be changed at the intervals specified in the maintenance schedule.

Page 281 of 310

OWNER MAINTENANCE

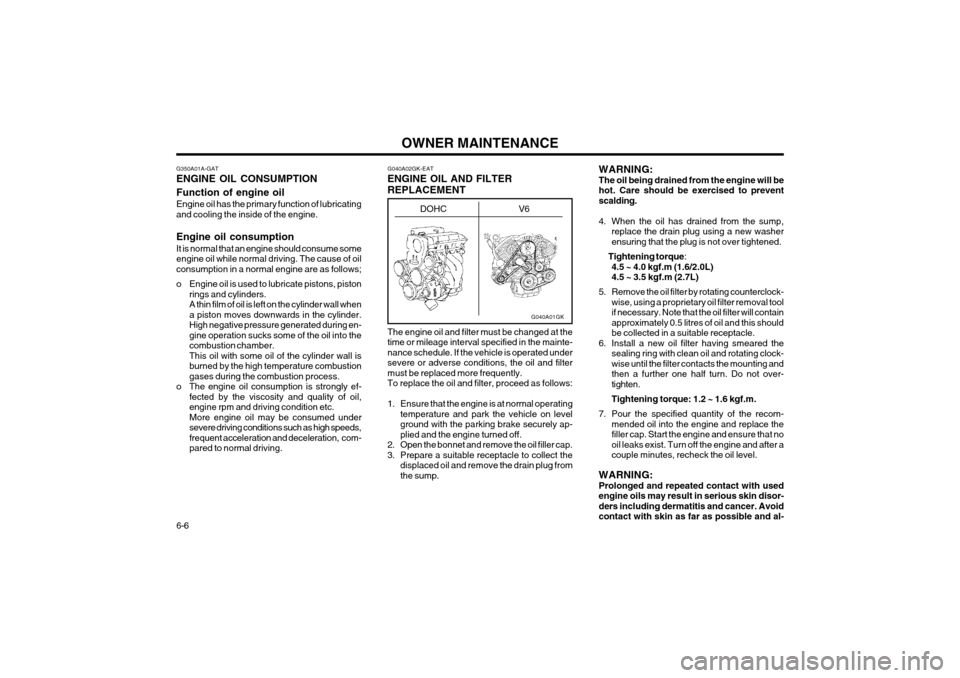

6-6 WARNING: The oil being drained from the engine will behot. Care should be exercised to preventscalding.

4. When the oil has drained from the sump,

replace the drain plug using a new washer ensuring that the plug is not over tightened.

Tightening torque :

4.5 ~ 4.0 kgf.m (1.6/2.0L)4.5 ~ 3.5 kgf.m (2.7L)

5. Remove the oil filter by rotating counterclock- wise, using a proprietary oil filter removal toolif necessary. Note that the oil filter will containapproximately 0.5 litres of oil and this shouldbe collected in a suitable receptacle.

6. Install a new oil filter having smeared the sealing ring with clean oil and rotating clock-wise until the filter contacts the mounting andthen a further one half turn. Do not over-tighten. Tightening torque: 1.2 ~ 1.6 kgf.m.

7. Pour the specified quantity of the recom- mended oil into the engine and replace the filler cap. Start the engine and ensure that nooil leaks exist. Turn off the engine and after acouple minutes, recheck the oil level.

WARNING:Prolonged and repeated contact with usedengine oils may result in serious skin disor-ders including dermatitis and cancer. Avoidcontact with skin as far as possible and al-

G040A02GK-EAT ENGINE OIL AND FILTER REPLACEMENT The engine oil and filter must be changed at the time or mileage interval specified in the mainte-nance schedule. If the vehicle is operated undersevere or adverse conditions, the oil and filtermust be replaced more frequently.To replace the oil and filter, proceed as follows:

1. Ensure that the engine is at normal operating

temperature and park the vehicle on level ground with the parking brake securely ap-plied and the engine turned off.

2. Open the bonnet and remove the oil filler cap.

3. Prepare a suitable receptacle to collect the displaced oil and remove the drain plug fromthe sump.

G350A01A-GAT ENGINE OIL CONSUMPTION Function of engine oil Engine oil has the primary function of lubricating and cooling the inside of the engine. Engine oil consumption It is normal that an engine should consume some engine oil while normal driving. The cause of oilconsumption in a normal engine are as follows;

o Engine oil is used to lubricate pistons, piston

rings and cylinders. A thin film of oil is left on the cylinder wall whena piston moves downwards in the cylinder.High negative pressure generated during en-gine operation sucks some of the oil into thecombustion chamber.This oil with some oil of the cylinder wall isburned by the high temperature combustiongases during the combustion process.

o The engine oil consumption is strongly ef- fected by the viscosity and quality of oil,engine rpm and driving condition etc.More engine oil may be consumed undersevere driving conditions such as high speeds,frequent acceleration and deceleration, com-pared to normal driving.

G040A01GK

DOHC V6

Page 282 of 310

OWNER MAINTENANCE 6-7

ways wash thoroughly after any contact. Keep used oils out of reach of children. It is illegalto pollute drains, water courses and soil. Useonly authorized waste collection facilitiesincluding civic amenity sites and garages forthe disposal of used oil and oil filters. If indoubt, contact the local authority for dis-posal instructions. SG050A1-E ENGINE COOLANT CHECKING AND REPLACING WARNING: Do not remove the radiator cap when the engine is hot, since the system is pressurizedand coolant may be ejected from the radiatorresulting in scalding. SG050B1-E Coolant recommendations

Only ethylene glycol based coolant with a corro- sion inhibitor suited to aluminium alloy enginecomponents should be used in the cooling sys-tem. No further additives or inhibitors should beused. The coolant specific gravity should bechecked as prescribed in the maintenance sched-ule to ensure adequate frost and corrosion pro-tection. In addition, the engine coolant must bereplaced at the specified interval since the corro-sion inhibitor properties deteriorate with time.It is important to note that whilst an increase in theconcentration of anti freeze gives an increase inthe level of frost protection, a solution which is inexcess of 65% anti freeze will result in reducedfrost protection and engine overheating. There-fore the recommended concentration of 50%should not be exceeded for general use.The use of methanol based anti freeze com-pounds may result in engine overheating and willinvalidate the vehicle warranty. NOTE: It is imperative that vehicles fitted with an airconditioning system have a coolant concen-tration of the recommended strength at alltimes. The use of the air conditioning systemwhen the cooling system is filled with wateronly will result in the heater matrix freezingand subsequently bursting.SG050C1-E Engine Coolant LevelThe engine coolant level may be observed through the side of the plastic coolant reservoir(expansion tank) when the engine is cold. If thelevel is below the "LOW" mark, add coolant of thecorrect concentration until the level is betweenthe "LOW" and "Full" marks. If the level fallsbelow the "LOW" mark on a regular basis despitebeing topped up, consult a Hyundai dealer. SG050D1-E To Change the Engine CoolantThe engine coolant should be changed at those intervals specified in the vehicle maintenanceschedule in Section 5. NOTE: Care should be taken to ensure that coolantis not allowed to spill onto the paintworksince the finish may become damaged. Ifcoolant spillage occurs, the affected areashould be rinsed thoroughly with water.

1. Park the vehicle on level ground and ensure

that the parking brake is firmly applied, and the engine allowed to cool.DO NOT ATTEMPT THIS OPERATIONWHILST THE ENGINE IS HOT SINCEBURN-ING OR SCALDING MAY RESULT.

2. Prepare a suitable receptacle to collect the displaced coolant and position this under theradiator drain tap.

HGK187