maintenance schedule Hyundai Coupe 2003 Owner's Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2003, Model line: Coupe, Model: Hyundai Coupe 2003Pages: 310, PDF Size: 2.87 MB

Page 285 of 310

OWNER MAINTENANCE

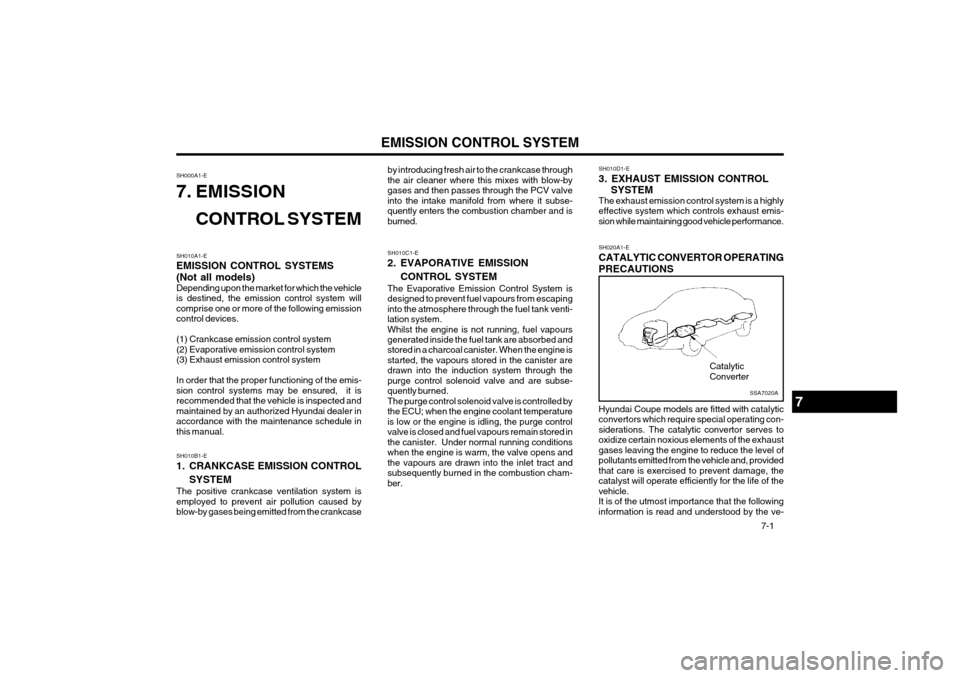

6-10 15 seconds continuously or when the reser- voir is empty since damage to the washerpump will result. SG100A1-E MANUAL TRANSAXLE LUBRICANT The manual transaxle lubricant must be checkedand/or changed at the intervals specified in themaintenance schedule. Only those lubricantsspecified should be used in order to prevent gearshifting difficulties or transaxle damage. WARNING: The transaxle lubricant level should only bechecked when the engine is cold to precludethe possibility of personal injury by contactwith hot components. Recommended Oil

SG080A2-E WINDSCREEN WIPER BLADES

SG090A1-EWINDSCREEN WASHER RESERVOIRREPLENISHMENT

The wiper blades should be carefully inspected from time to time and cleaned to remove accu-mulations of road film or other debris. To cleanthe wiper blades and arms, use a clean spongeor cloth with a mild soap or detergent and water.If the wipers continue to streak or smear theglass, replace them with genuine Hyundai re-placement. CAUTION:

o Do not operate the wipers on dry glass since rapid wear and damage to thewindscreen glass may result.

o Keep the blade rubber out of contact with petroleum products such as engine oil,petrol etc. The level of windscreen washer fluid availableshould be checked on a daily basis. The level offluid will be visible through the side of the reser-voir. When the fluid is to be replenished, only aproprietary screen wash additive should be usedand in the concentration recommended by themanufacturer. The windscreen washer reservoirhas a total capacity of 3 litres. CAUTION: Engine coolant anti freeze must not be usedin the windscreen washer system since dam-age to the paintwork may result.Undiluted windscreen washer additive mustnot be allowed to come into contact with thepaintwork. If spillage occurs, flush the af-fected area immediately with water. Do notoperate the windscreen washer for more than

HGK217

HEF119

To ensure maximum filtration performance and continued engine performance, only genuineHyundai replacements should be used.

G110A01E

Filler plug

Drain plug

Page 286 of 310

OWNER MAINTENANCE 6-11

Ensure that the vehicle is parked on level ground with the parking brake firmly applied and theengine cool. Remove the level plug from thetransaxle when lubricant should begin to dripfrom the level hole. If the level is low and nolubricant is seen to drip, add the required quantityof lubricant and replace the plug. scribed in the maintenance schedule. It is ofparamount importance that only the specifiedfluid is used when replenishing or changing thefluid. The use of other fluids may irreparablydamage the transaxle and invalidate the manu-facturers warranty. In addition the ingress of dirtor lint may prevent correct functioning of thetransaxle and care must be exercised to preventthe ingress of such matter. NOTE: Basically automatic transaxle fluid is red color.As driving distance increases, the fluid colorturns darkish red gradually. It is normal con-dition and you should not use fluid color as acriterion for replacing the transaxle fluid.You must replace the automatic transaxlefluid in accordance with intervals specified inthe vehicle maintenances schedule in sec-tion 5. CAUTION: The transaxle fluid level must be checkedwith the engine running and at normal oper-ating temperature and therefore care must beexercised to prevent injury occurring throughcontact with rotating or hot parts of the en-gine. G110B03A-AAT Recommended FluidYour Hyundai automatic transaxle is specially designed to operate with DIAMOND ATF SP-

III,

SK ATF SP- III.

Damage caused by a nonspecified fluid is notcovered by your new vehicle limited warranty. G110D02GK-EAT Transaxle fluid level checking The vehicle must be parked on level ground with the parking brake firmly applied and the engine atnormal operating temperature. (Normal operat-ing temperature will only be achieved when thevehicle has been driven for 6 miles or more).With the engine idling and the footbrake applied,the transaxle selector should be moved from the"P" position through to the "L" position and backto the "N" or "P" position.Open the bonnet and remove the transaxle dip-stick, remembering that care must be exercisedto prevent injury occurring through contact withhot or rotating parts of the engine.Wipe the dipstick, replace it fully and promptlyremove it again. The fluid level should be be-tween the upper and lower marks. Fluid needonly be added if the level is at or below the lowermark and must never be increased above the

DOHC V6

HGK212

Use only the approved transaxle lubricant. The recommended lubricants are complete in them-selves and the use of additives is neither re-quired nor recommended. The use of additivesmay invalidate the vehicle warranty. Transaxle Lubricant Level Checking SG110A2-E AUTOMATIC TRANSAXLE FLUID The automatic transaxle fluid level should bechecked and changed at those intervals pre-

SSA6100B

Page 299 of 310

EMISSION CONTROL SYSTEM 7-1

SH010A1-E EMISSION CONTROL SYSTEMS (Not all models) Depending upon the market for which the vehicleis destined, the emission control system willcomprise one or more of the following emissioncontrol devices. (1) Crankcase emission control system (2) Evaporative emission control system(3) Exhaust emission control system In order that the proper functioning of the emis- sion control systems may be ensured, it isrecommended that the vehicle is inspected andmaintained by an authorized Hyundai dealer inaccordance with the maintenance schedule inthis manual.

SH000A1-E

7. EMISSION

CONTROL SYSTEM

SH010B1-E

1. CRANKCASE EMISSION CONTROL SYSTEM

The positive crankcase ventilation system is employed to prevent air pollution caused byblow-by gases being emitted from the crankcase by introducing fresh air to the crankcase throughthe air cleaner where this mixes with blow-bygases and then passes through the PCV valveinto the intake manifold from where it subse-quently enters the combustion chamber and isburned.

SH010D1-E

3. EXHAUST EMISSION CONTROL SYSTEM The exhaust emission control system is a highlyeffective system which controls exhaust emis-sion while maintaining good vehicle performance.

SH010C1-E

2. EVAPORATIVE EMISSION CONTROL SYSTEM

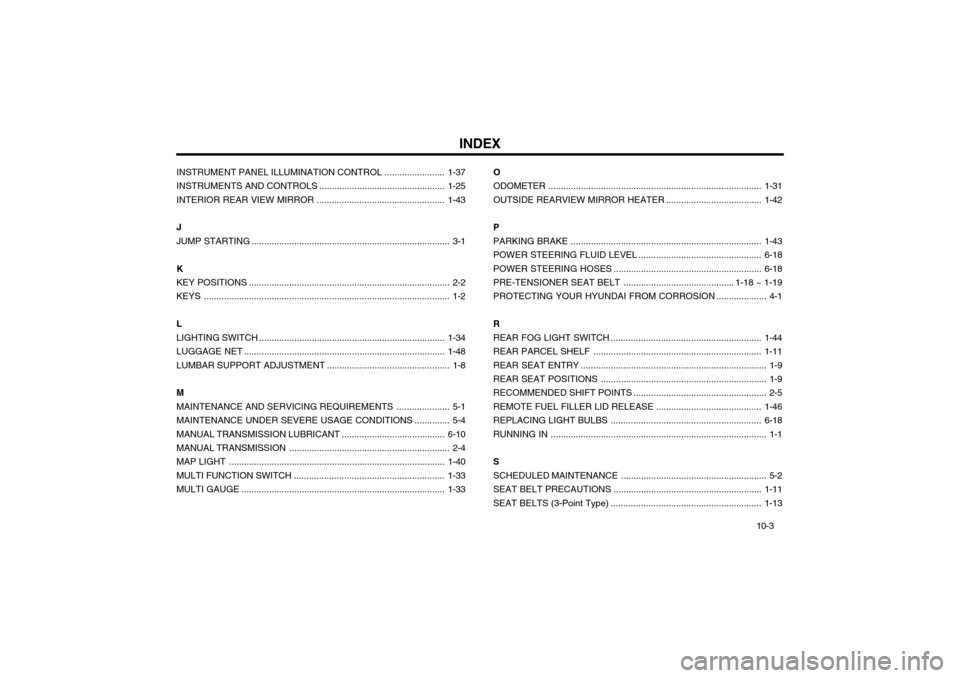

The Evaporative Emission Control System is designed to prevent fuel vapours from escapinginto the atmosphere through the fuel tank venti-lation system.Whilst the engine is not running, fuel vapours generated inside the fuel tank are absorbed and stored in a charcoal canister. When the engine isstarted, the vapours stored in the canister aredrawn into the induction system through thepurge control solenoid valve and are subse-quently burned.The purge control solenoid valve is controlled bythe ECU; when the engine coolant temperatureis low or the engine is idling, the purge controlvalve is closed and fuel vapours remain stored inthe canister. Under normal running conditionswhen the engine is warm, the valve opens andthe vapours are drawn into the inlet tract andsubsequently burned in the combustion cham-ber. SH020A1-E CATALYTIC CONVERTOR OPERATING PRECAUTIONS Hyundai Coupe models are fitted with catalytic convertors which require special operating con-siderations. The catalytic convertor serves tooxidize certain noxious elements of the exhaustgases leaving the engine to reduce the level ofpollutants emitted from the vehicle and, providedthat care is exercised to prevent damage, thecatalyst will operate efficiently for the life of thevehicle.It is of the utmost importance that the followinginformation is read and understood by the ve-

7

Catalytic Converter

SSA7020A

Page 309 of 310

INDEX10-3

INSTRUMENT PANEL ILLUMINATION CONTROL

........................1-37

INSTRUMENTS AND CONTROLS ..................................................1-25

INTERIOR REAR VIEW MIRROR ................................................... 1-43

J JUMP STARTING ............................................................................... 3-1

KKEY POSITIONS ................................................................................ 2-2

KEYS .................................................................................................. 1-2 L LIGHTING SWITCH .......................................................................... 1-34

LUGGAGE NET ................................................................................ 1-48

LUMBAR SUPPORT ADJUSTMENT ................................................. 1-8

M

MAINTENANCE AND SERVICING REQUIREMENTS ..................... 5-1

MAINTENANCE UNDER SEVERE USAGE CONDITIONS .............. 5-4

MANUAL TRANSMISSION LUBRICANT .............. ...........................6-10

MANUAL TRANSMISSION ................................................................ 2-4

MAP LIGHT ...................................................................................... 1-40

MULTI FUNCTION SWITCH ................................. ...........................1-33

MULTI GAUGE ................................................................................. 1-33OODOMETER

..................................................................................... 1-31

OUTSIDE REARVIEW MIRROR HEATER ...................................... 1-42

PPARKING BRAKE ............................................................................ 1-43

POWER STEERING FLUID LEVEL ................................................. 6-18

POWER STEERIN G HOSES ........................................................... 6-18

PRE-TENSIONER SEAT BELT ............................................ 1-18 ~ 1-19

PROTECTING YOUR HYUNDAI FROM CORROSION .................... 4-1

R

REAR FOG LIGHT SWITCH ............................................................ 1-44

REAR PARCEL SHELF ................................................................... 1-11

REAR SEAT ENTRY .......................................................................... 1-9

REAR SEAT POSITIONS .................................................................. 1-9

RECOMMENDED SHIFT POINTS ..................................................... 2-5

REMOTE FUEL FILLER LID RELEASE.......................................... 1-46

REPLACING LIGHT BULBS ...................... ......................................6-18

RUNNING IN ...................................................................................... 1-1

SSCHEDULED MAINTENANCE .......................................................... 5-2

SEAT BELT PRECAUTIONS ........................................................... 1-11

SEAT BELTS (3-Point Type) ............................... .............................1-13