fuel Hyundai Coupe 2006 Repair Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2006, Model line: Coupe, Model: Hyundai Coupe 2006Pages: 483, PDF Size: 12.73 MB

Page 424 of 483

5VEHICLE MAINTENANCE REQUIREMENTS

8EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

6ZF060M1-A

o Engine oil and filter The engine oil and filter should be changed at the intervals specified in the maintenance schedule. If the car is being driven in severe conditions,more frequent oil and filter changes are required. 6ZF060B2-A

o Drive belts Inspect all drive belts for evidence of cuts, cracks, excessive wear or oilsaturation and replace if necessary. Drive belts should be checked periodi- cally for proper tension and adjustedas necessary. 6ZF060D1-A

o Fuel lines, fuel hoses and

connections

Check the fuel lines, fuel hoses and

connections for leakage and damage. Have a trained technician replace any damaged or leaking parts immediately. 6ZF060E1-A

o Timing belt

Inspect all parts related to the timing

belt for damage and deformation. Replace any damaged parts immedi- ately.

6ZF060G1-E

o Vapour hose and fuel filler cap

The vapour hose and fuel filler cap

should be inspected at those intervalsspecified in the maintenance sched- ule. Make sure that a new vapour hose or fuel filler cap is correctly replaced.

F060C01A-AAT

o Fuel filter

A clogged filter can limit the speed at

which the vehicle may be driven, dam- age the emission system and cause hard starting. If an excessive amountof foreign matter accumulates in the fuel tank, the filter may require re- placement more frequently. After installing a new filter, run the

engine for several minutes, and checkfor leaks at the connections. Fuel fil- ters should be installed by trained technicians.

gkfluk-5.p65 12/26/2006, 5:23 PM

8

Page 432 of 483

6

OWNER MAINTENANCE

5

SG020B1-E The following items should be checked on a daily basis or whenever the vehicle is refuelled, whichever occurssooner.

o Engine oil level.

o Engine coolant level.

o Power steering fluid level.

o Brake fluid level.

o Windscreen washer fluid level.

o Battery condition.

o Tyre condition and pressures.

o Operation and cleanliness of all lighting equipment.

o Windscreen wiper and washer op-

eration.

o Horn operation.

o Warning lamp operation.

o Adjustment and cleanliness of mir- rors.

o Seat and seat belt adjustment and operation.

o Fluid leakage.

The vehicle must not be driven if the daily operating checks indicate that any item of equipment related to the safety or roadworthiness of the ve-hicle is not functioning correctly. DAILY OPERATING CHECKS

MAINTENANCE PRECAU- TIONS

!

G020D01TG-EAT Improper or incomplete service may result in problems. This section gives instructions only for the maintenanceitems that are easy to perform.Several procedures should be done byHyundai authorised repairer. NOTE: Improper owner maintenance dur- ing the warranty period may affectwarranty coverage.

WARNING:

o Performing maintenance work on a vehicle can be dangerous. You can be seriously injured whilst performing some maintenanceprocedures. If you lack sufficient knowledge and experience or the proper tools and equipment to dothe work, have it done by Hyundai authorised repairer.

o Working under the bonnet with the engine running is dangerous. It becomes even more dangerouswhen you wear jewellery or loose clothing. These can become en- tangled in moving parts and re-sult in injury. Therefore, if you must run the engine whilst work- ing under the bonnet, make cer-tain that you remove all jewellery (especially rings, bracelets, watches, and necklaces) and allneckties, scarves, and similar loose clothing before getting near the engine or cooling fans.

gkfluk-6.p65 12/26/2006, 5:24 PM

5

Page 433 of 483

6OWNER MAINTENANCE

6

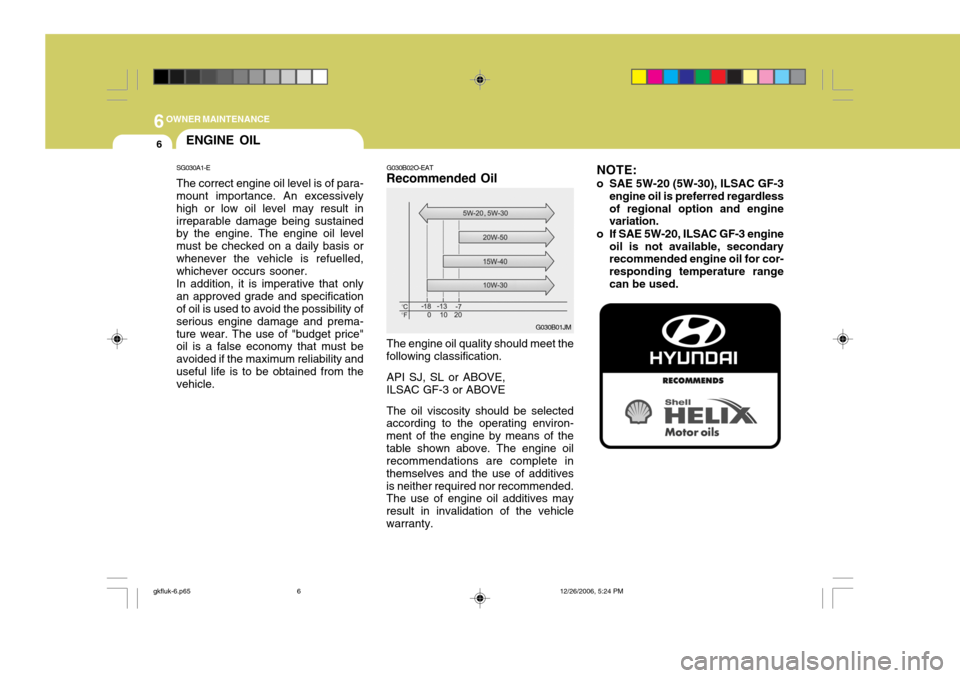

NOTE:

o SAE 5W-20 (5W-30), ILSAC GF-3 engine oil is preferred regardless of regional option and engine variation.

o If SAE 5W-20, ILSAC GF-3 engine oil is not available, secondaryrecommended engine oil for cor- responding temperature rangecan be used.ENGINE OIL

SG030A1-E The correct engine oil level is of para- mount importance. An excessively high or low oil level may result inirreparable damage being sustained by the engine. The engine oil level must be checked on a daily basis orwhenever the vehicle is refuelled, whichever occurs sooner. In addition, it is imperative that only an approved grade and specification of oil is used to avoid the possibility of serious engine damage and prema-ture wear. The use of "budget price" oil is a false economy that must be avoided if the maximum reliability anduseful life is to be obtained from the vehicle. G030B02O-EAT

Recommended Oil

The engine oil quality should meet the

following classification.

API SJ, SL or ABOVE, ILSAC GF-3 or ABOVE The oil viscosity should be selected

according to the operating environ- ment of the engine by means of thetable shown above. The engine oil recommendations are complete in themselves and the use of additivesis neither required nor recommended. The use of engine oil additives may result in invalidation of the vehiclewarranty.

G030B01JM

gkfluk-6.p65 12/26/2006, 5:24 PM

6

Page 451 of 483

6OWNER MAINTENANCE

24

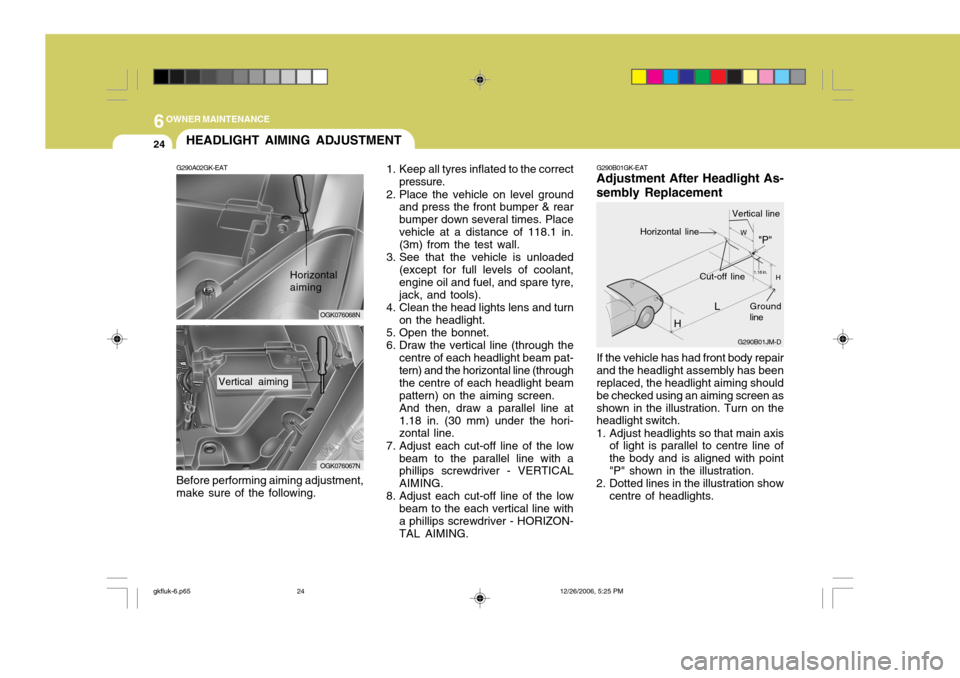

G290B01GK-EAT

Adjustment After Headlight As- sembly Replacement

If the vehicle has had front body repair and the headlight assembly has been replaced, the headlight aiming should be checked using an aiming screen asshown in the illustration. Turn on the headlight switch.

1. Adjust headlights so that main axis of light is parallel to centre line of the body and is aligned with point"P" shown in the illustration.

2. Dotted lines in the illustration show centre of headlights.

1. Keep all tyres inflated to the correct

pressure.

2. Place the vehicle on level ground and press the front bumper & rearbumper down several times. Placevehicle at a distance of 118.1 in. (3m) from the test wall.

3. See that the vehicle is unloaded (except for full levels of coolant, engine oil and fuel, and spare tyre,jack, and tools).

4. Clean the head lights lens and turn

on the headlight.

5. Open the bonnet.

6. Draw the vertical line (through the centre of each headlight beam pat- tern) and the horizontal line (through the centre of each headlight beampattern) on the aiming screen.And then, draw a parallel line at1.18 in. (30 mm) under the hori- zontal line.

7. Adjust each cut-off line of the low beam to the parallel line with aphillips screwdriver - VERTICAL AIMING.

8. Adjust each cut-off line of the low

beam to the each vertical line witha phillips screwdriver - HORIZON- TAL AIMING. L

G290B01JM-D

W

H

H Cut-off line"P"

Vertical lineHorizontal line

Ground line

1.18 in.

G290A02GK-EAT

HEADLIGHT AIMING ADJUSTMENT

Before performing aiming adjustment, make sure of the following.

OGK076068N

OGK076067N

Horizontal aiming

Vertical aiming

gkfluk-6.p65 12/26/2006, 5:25 PM

24

Page 462 of 483

6

OWNER MAINTENANCE

35

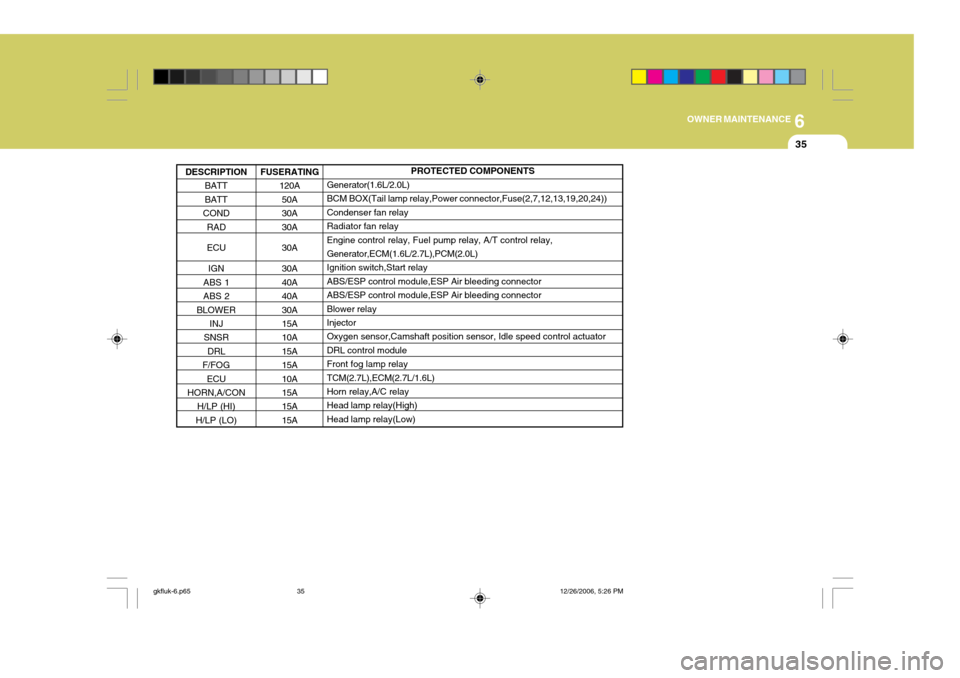

PROTECTED COMPONENTS

Generator(1.6L/2.0L) BCM BOX(Tail lamp relay,Power connector,Fuse(2,7,12,13,19,20,24))Condenser fan relayRadiator fan relayEngine control relay, Fuel pump relay, A/T control relay, Generator,ECM(1.6L/2.7L),PCM(2.0L) Ignition switch,Start relayABS/ESP control module,ESP Air bleeding connectorABS/ESP control module,ESP Air bleeding connectorBlower relayInjector Oxygen sensor,Camshaft position sensor, Idle speed control actuator DRL control moduleFront fog lamp relayTCM(2.7L),ECM(2.7L/1.6L)Horn relay,A/C relay Head lamp relay(High) Head lamp relay(Low)

FUSERATING 120A50A 30A30A 30A 30A 40A40A30A 15A 10A15A15A10A15A 15A 15A

DESCRIPTION

BATTBATT

COND RAD ECU

IGN

ABS 1 ABS 2

BLOWER INJ

SNSR DRL

F/FOG ECU

HORN,A/CON H/LP (HI)

H/LP (LO)

gkfluk-6.p65 12/26/2006, 5:26 PM

35

Page 466 of 483

7EMISSION CONTROL SYSTEMS

2

SH010A1-E (Not all models) Depending upon the market for which the vehicle is destined, the emission control system will comprise one or more of the following emission controldevices.

(1) Crankcase emission control sys-

tem

(2) Evaporative emission control sys- tem

(3) Exhaust emission control systemIn order that the proper functioning of the emission control systems may be ensured, it is recommended that the vehicle is inspected and maintainedby a Hyundai authorised repairer in accordance with the maintenance schedule in this manual. EMISSION CONTROL SYS- TEMS

DH010B1-E

1. Crankcase Emission Control

System

The positive crankcase ventilation (PCV) system is employed to prevent air pollution caused by blow-by gases being emitted from the crankcase. This system supplies fresh air to the crankcase through the air cleaner. In- side the crankcase, the fresh air mixeswith blow-by gases, then passes through the PCV valve into the intake system. When the engine is running, the fuelvapors absorbed in the canister aredrawn into the induction system through the purge control solenoid valve. Purge Control Solenoid Valve The purge control solenoid valve is controlled by the ECU (Engine Control Unit); when the engine coolant tem- perature is low, and during idling, itcloses, so that evaporated fuel is not taken into the surge tank. After engine warm-up, during ordinary driving, itopens to introduce evaporated fuel to the surge tank.

JH010D1-E

3. Exhaust Emission Control

System

This system helps control oxides of

nitrogen by recirculating a portion of the exhaust gases into the intake manifold, thereby reducing cylinder combustion temperatures.

ZH010C1-E

2. Evaporative Emission

Control System

The Evaporative Emission Control System is designed to prevent fuelvapors from escaping into the atmo- sphere. Canister Whilst the engine is inoperative, fuel vapors generated inside the fuel tank are absorbed and stored in the canis- ter.

gkfluk-7.p65 12/26/2006, 5:26 PM

2

Page 467 of 483

7

EMISSION CONTROL SYSTEMS

3CATALYTIC CONVERTOR

SH020A1-E Hyundai Coupe models are fitted with catalytic convertors which requirespecial operating considerations. The catalytic convertor serves to oxidize certain noxious elements of the ex-haust gases leaving the engine to reduce the level of pollutants emitted from the vehicle and, provided thatcare is exercised to prevent damage, the catalyst will operate efficiently for the life of the vehicle. It is of the utmost importance that the following information is read and un- derstood by the vehicle operator inorder to prevent operational problems arising from damage to the catalyst. Damage to the catalyst will result if contamination occurs through the useof leaded fuel. Whilst the vehicle is fitted with a reduced diameter filler neck to prevent charging of the fueltank with a leaded fuel pump nozzle, it is possible that the use of funnels or fuel cans will permit leaded fuel to beintroduced into the fuel tank.The catalyst is intolerant of unburntfuel and therefore if an engine misfirecondition exists, damage to the cata- lyst will occur. It is imperative that if a misfire condition develops, the ve-hicle is immediately presented to a Hyundai authorised repairer for rectifi- cation. Similarly, the practice of cer-tain ignition system diagnosis proce- dures which involve inducing a misfire (cylinder power balance tests for ex-ample) may result in catalyst damage.For these reasons, it is advisable thatthe exhaust gas emission be tested at each routine service with a gas analyzer having a Hydrocarbon mea-suring facility to ensure continued re- liability of the catalyst.

Catalytic Converter

OGK076501 Push or tow starting of the vehicle is to be avoided since unburnt fuel mayenter the catalyst and result in dam- age. (Note, it is impossible to push or tow start a Hyundai model equippedwith fuel injection since the fuel pump safety interlock will prevent the pump from operating under these conditions). Operation of the catalyst involves ex- tremely high temperatures being at- tained within the catalytic convertor,and although the convertor is fitted with heat shields, it is important that the vehicle is not parked over combus-tible or volatile material which may result in fire. If the above precautions are not ad- hered to and the catalyst becomes inoperative, the resultant increase incore temperature will result in a "melt down" where the catalyst core will melt and subsequently may block theexhaust system.Due to the fragile nature of the cata-lyst element, it is important that dam-age does not occur when the vehicle is raised by means of a garage jack. Care must also be exercised to avoiddriving over road hazards or debris which may cause damage to the cata- lyst element.

gkfluk-7.p65

12/26/2006, 5:26 PM

3

Page 476 of 483

9 VEHICLE SPECIFICATIONS

2

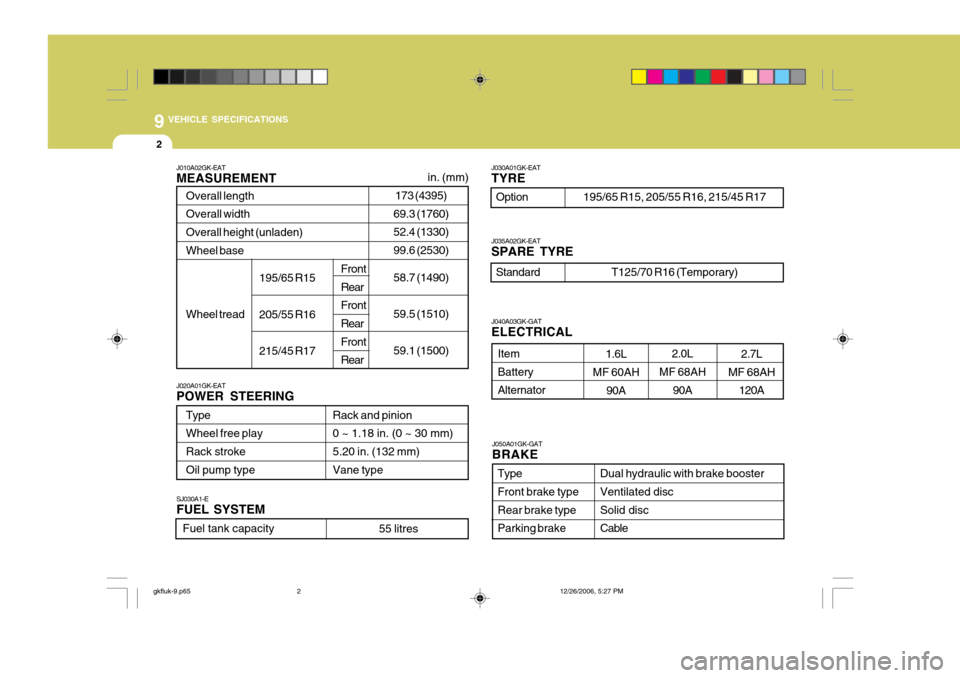

Type Wheel free play Rack stroke Oil pump type Rack and pinion0 ~ 1.18 in. (0 ~ 30 mm)5.20 in. (132 mm) Vane type

Option

Item BatteryAlternator

Fuel tank capacity 2.7L

MF 68AH 120A

195/65 R15, 205/55 R16, 215/45 R17

2.0L

MF 68AH

90A

Dual hydraulic with brake booster Ventilated disc Solid discCable

Type Front brake type Rear brake typeParking brake

55 litres

1.6L

MF 60AH 90A

SJ030A1-E FUEL SYSTEM

J020A01GK-EAT POWER STEERING J030A01GK-EAT TYRE J040A03GK-GAT ELECTRICAL

J050A01GK-GATBRAKE

J035A02GK-EATSPARE TYRE

Standard

T125/70 R16 (Temporary)

173 (4395)

69.3 (1760) 52.4 (1330)99.6 (2530) 58.7 (1490) 59.5 (1510)59.1 (1500)

J010A02GK-EAT MEASUREMENTOverall length Overall widthOverall height (unladen) Wheel base Wheel tread

195/65 R15 205/55 R16215/45 R17

in. (mm)

Front RearFront Rear FrontRear

gkfluk-9.p65

12/26/2006, 5:27 PM

2

Page 481 of 483

10

INDEX

3

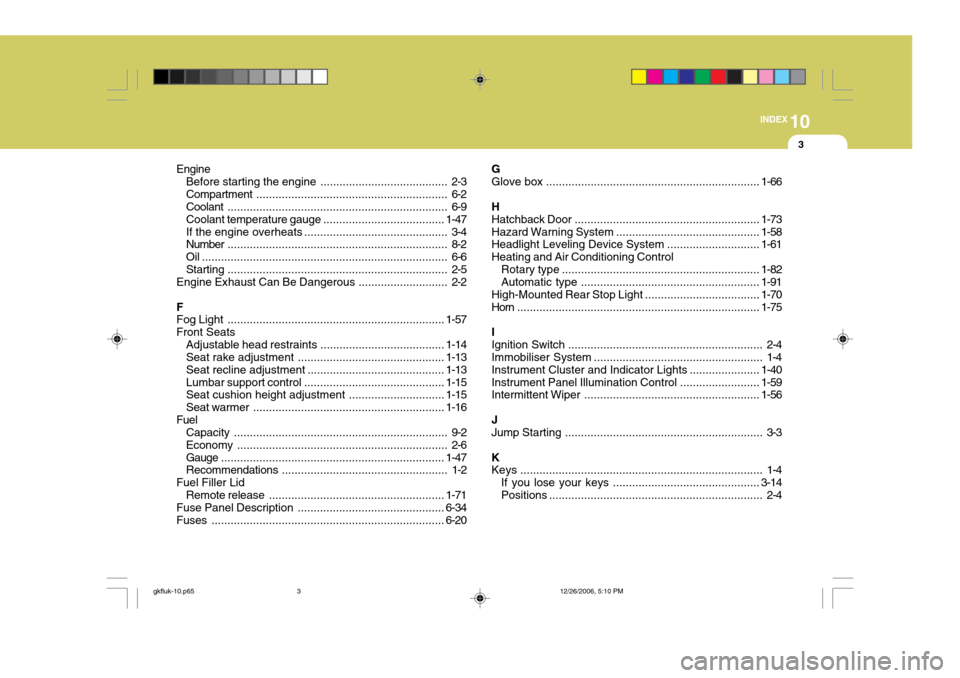

Engine Before starting the engine ........................................ 2-3 Compartment ............................................................ 6-2

Coolant ..................................................................... 6-9

Coolant temperature gauge ......................................1-47

If the engine overheats ............................................. 3-4

Number ..................................................................... 8-2

Oil ............................................................................. 6-6Starting ..................................................................... 2-5

Engine Exhaust Can Be Dangerous ............................ 2-2

F Fog Light .................................................................... 1-57

Front Seats Adjustable head restraints ....................................... 1-14

Seat rake adjustment .............................................. 1-13

Seat recline adjustment ........................................... 1-13

Lumbar support control ............................................ 1-15

Seat cushion height adjustment .............................. 1-15

Seat warmer ............................................................ 1-16

Fuel Capacity ................................................................... 9-2

Economy .................................................................. 2-6

Gauge ...................................................................... 1-47

Recommendations .................................................... 1-2

Fuel Filler Lid Remote release ....................................................... 1-71

Fuse Panel Description .............................................. 6-34

Fuses ......................................................................... 6-20G

Glove box ...................................................................

1-66

HHatchback Door .......................................................... 1-73

Hazard Warning System ............................................. 1-58

Headlight Leveling Device S ystem .............................1-61

Heating and Air Conditioning Control Rotary type .............................................................. 1-82

Automatic type ........................................................ 1-91

High-Mounted Rear Stop Light .................................... 1-70

Horn ............................................................................ 1-75

IIgnition Switch ............................................................. 2-4

Immobiliser System ..................................................... 1-4

Instrument Cluster and Indicator Lights ...................... 1-40

Instrument Panel Illumination Control .........................1-59

Intermittent Wiper ....................................................... 1-56

J Jump Starting .............................................................. 3-3

KKeys ............................................................................ 1-4

If you lose your keys .............................................. 3-14

Positions ................................................................... 2-4

gkfluk-10.p65 12/26/2006, 5:10 PM

3