coolant Hyundai Kona EV 2019 User Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2019, Model line: Kona EV, Model: Hyundai Kona EV 2019Pages: 540, PDF Size: 21.84 MB

Page 388 of 540

7-8

Maintenance

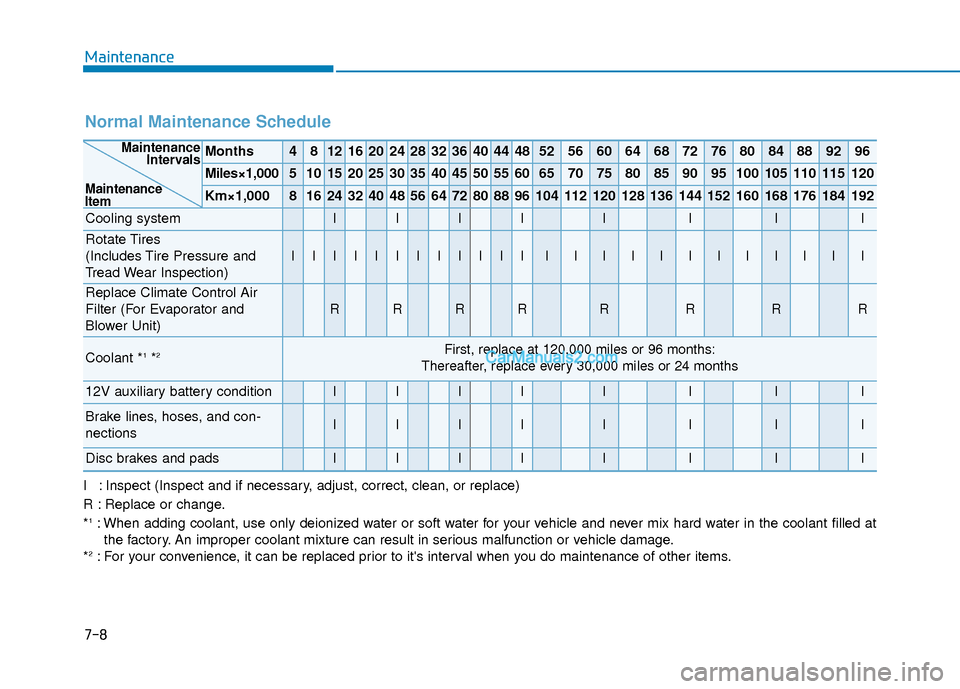

Normal Maintenance Schedule

Months4812162024283236404448525660646872768084889296

Miles×1,0005101520253035404550556065707580859095100105110115120

Km×1,00081624324048566472808896104112120128136144152160168176184192

Cooling systemIIIIIIII

Rotate Tires

(Includes Tire Pressure and

Tread Wear Inspection)

IIIIIIIIIIIIIIIIIIIIIIII

Replace Climate Control Air

Filter (For Evaporator and

Blower Unit)

RRRRRRRR

Coolant *1*2First, replace at 120,000 miles or 96 months:

Thereafter, replace every 30,000 miles or 24 months

12V auxiliary battery conditionIIIIIIII

Brake lines, hoses, and con-

nectionsIIIIIIII

Disc brakes and padsIIIIIIII

Maintenance Intervals

Maintenance

Item

I : Inspect (Inspect and if necessary, adjust, correct, clean, or replace)

R : Replace or change.

*

1: When adding coolant, use only deionized water or soft water for your vehicle and never mix hard water in the coolant filled at the factory. An improper coolant mixture can result in serious malfunction or vehicle damage.

*

2: For your convenience, it can be replaced prior to it's interval when you do maintenance of other items.

Page 391 of 540

7-11

7

Maintenance

E

EX

X P

PL

LA

A N

N A

AT

TI

IO

O N

N

O

O F

F

S

S C

C H

H E

ED

D U

U L

LE

E D

D

M

M A

AI

IN

N T

TE

EN

N A

AN

N C

CE

E

I

IT

T E

EM

M S

S

Cooling System

Check cooling system components,

such as radiator, coolant reservoir,

hoses and connections for leakage

and damage. Replace any damaged

parts.

Coolant

The coolant should be changed at

the intervals specified in the mainte-

nance schedule.

Reduction Gear Fluid

Inspect the reduction gear fluid

according to the maintenance sched-

ule.

Brake Hoses and Lines

Visually check for proper installation,

chafing, cracks, deterioration and

any leakage. Replace any deteriorat-

ed or damaged parts immediately.

Brake Fluid

Check brake fluid level in the brake

fluid reservoir. The level should be

between the MIN and the MAX

marks on the side of the reservoir.

Use only hydraulic brake fluid con-

forming to DOT 3 or DOT 4 specifi-

cation.

Brake Discs, Pads, Calipers

and Rotors

Check the pads for excessive wear,

discs for run out and wear, and

calipers for fluid leakage.

Suspension Mounting Bolts

Check the suspension connections

for looseness or damage. Retighten

to the specified torque.

Steering Gear Box, Linkage &

Boots/Lower Arm Ball Joint

With the vehicle stopped and the

vehicle off, check for excessive free-

play in the steering wheel. Check the

linkage for bends or damage. Check

the dust boots and ball joints for

deterioration, cracks, or damage.

Replace any damaged parts.

Drive Shafts and Boots

Check the drive shafts, boots and

clamps for cracks, deterioration, or

damage. Replace any damaged

parts and, if necessary, repack the

grease.

Air Conditioning Refrigerant

Check the air conditioning lines and

connections for leakage and dam-

age.

Page 392 of 540

7-12

Maintenance

C

CO

O O

OL

LA

A N

N T

T

The high-pressure cooling system

has a reservoir filled with year-round

antifreeze coolant. The reservoir is

filled at the factory.

Check the antifreeze protection and

coolant level at least once a year, at

the beginning of the winter season

and before traveling to a colder cli-

mate.Checking the Coolant Level

Check the condition and connections

of all cooling system hoses and

heater hoses. Replace any swollen

or deteriorated hoses.

The coolant level should be filled

between the MAX and the MIN

marks on the side of the coolant

reservoir when the parts in the motor

compartment are cool.

If the coolant level is low, add enough

distilled (deionized) water to bring

the level to the MAX mark, but do not

overfill. If frequent additions are

required, you see an authorized

HYUNDAI dealer for a cooling sys-

tem inspection.

Recommended coolant

When adding coolant, use only

distilled (deionized) water for your

vehicle and never mix hard water in

the coolant filled at the factory.

An improper coolant mixture can result in severe malfunction or

electric vehicle damage.

Do not use alcohol or methanol coolant or mix them with the spec-

ified coolant.

Do not use a solution that contains more than 60% antifreeze or less

than 35% antifreeze, which would

reduce the effectiveness of the

solution.

OOSEV078002

Page 393 of 540

7-13

7

Maintenance

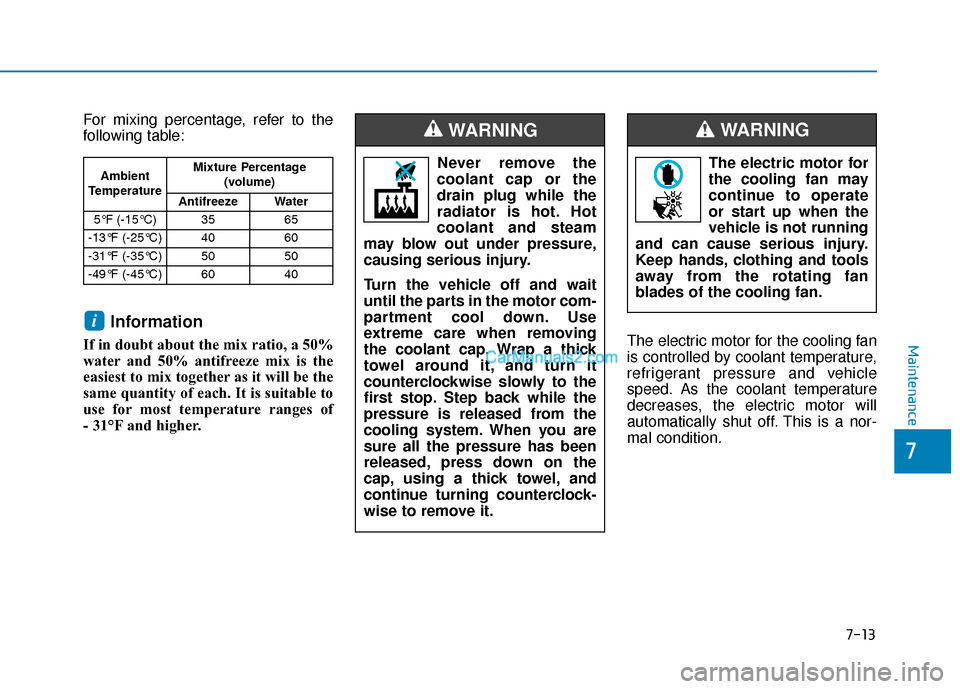

For mixing percentage, refer to the

following table:

Information

If in doubt about the mix ratio, a 50%

water and 50% antifreeze mix is the

easiest to mix together as it will be the

same quantity of each. It is suitable to

use for most temperature ranges of

- 31°F and higher.The electric motor for the cooling fan

is controlled by coolant temperature,

refrigerant pressure and vehicle

speed. As the coolant temperature

decreases, the electric motor will

automatically shut off. This is a nor-

mal condition.

i

Ambient

Temperature Mixture Percentage

(volume)

Antifreeze Water

5°F (-15°C) 35 65

-13°F (-25°C) 40 60

-31°F (-35°C) 50 50

-49°F (-45°C) 60 40Never remove the

coolant cap or the

drain plug while the

radiator is hot. Hot

coolant and steam

may blow out under pressure,

causing serious injury.

Turn the vehicle off and wait

until the parts in the motor com-

partment cool down. Use

extreme care when removing

the coolant cap. Wrap a thick

towel around it, and turn it

counterclockwise slowly to the

first stop. Step back while the

pressure is released from the

cooling system. When you are

sure all the pressure has been

released, press down on the

cap, using a thick towel, and

continue turning counterclock-

wise to remove it.

WARNING

The electric motor for

the cooling fan may

continue to operate

or start up when the

vehicle is not running

and can cause serious injury.

Keep hands, clothing and tools

away from the rotating fan

blades of the cooling fan.

WARNING

Page 394 of 540

7-14

Maintenance

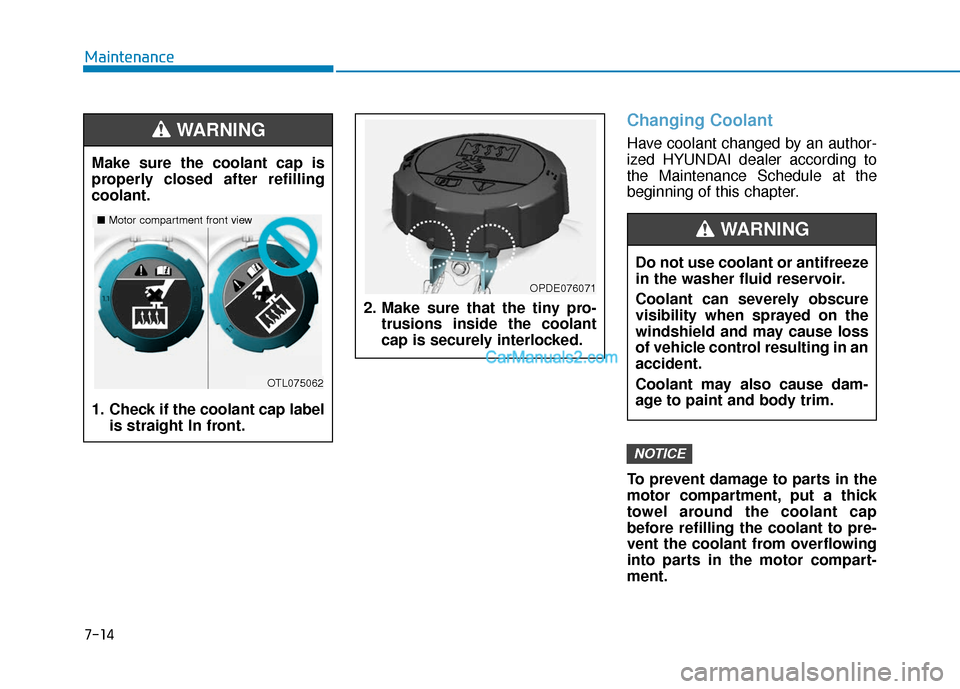

Changing Coolant

Have coolant changed by an author-

ized HYUNDAI dealer according to

the Maintenance Schedule at the

beginning of this chapter.

To prevent damage to parts in the

motor compartment, put a thick

towel around the coolant cap

before refilling the coolant to pre-

vent the coolant from overflowing

into parts in the motor compart-

ment.

NOTICE

Make sure the coolant cap is

properly closed after refilling

coolant.

1. Check if the coolant cap labelis straight In front.

WARNING

OTL075062

■Motor compartment front view

2. Make sure that the tiny pro-

trusions inside the coolant

cap is securely interlocked.

OPDE076071

Do not use coolant or antifreeze

in the washer fluid reservoir.

Coolant can severely obscure

visibility when sprayed on the

windshield and may cause loss

of vehicle control resulting in an

accident.

Coolant may also cause dam-

age to paint and body trim.

WARNING

Page 396 of 540

7-16

Maintenance

W

WA

AS

SH

H E

ER

R

F

F L

LU

U I

ID

D

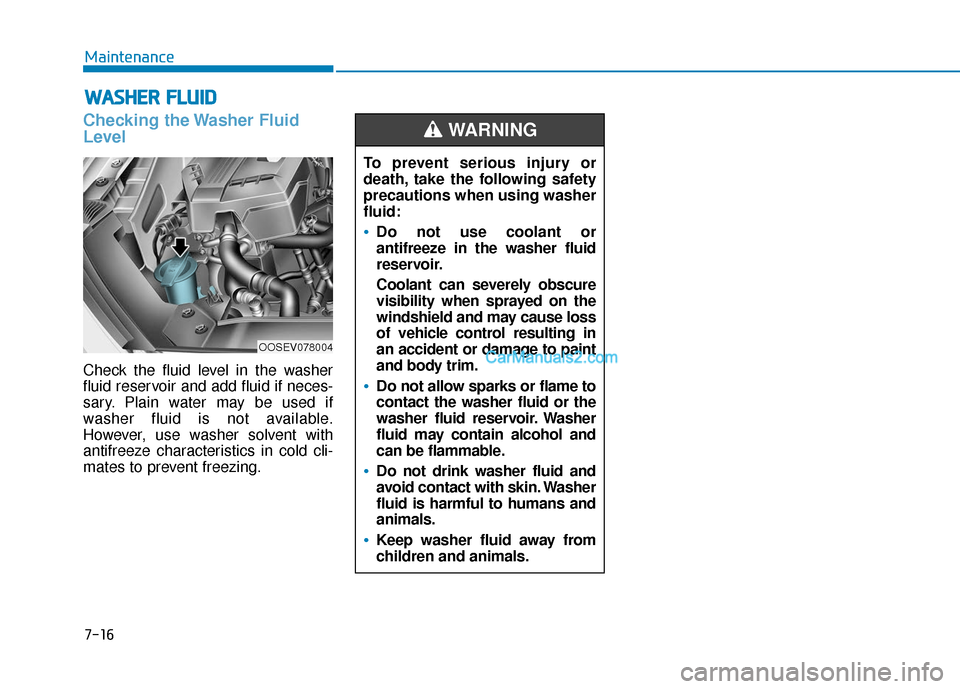

Checking the Washer Fluid

Level

Check the fluid level in the washer

fluid reservoir and add fluid if neces-

sary. Plain water may be used if

washer fluid is not available.

However, use washer solvent with

antifreeze characteristics in cold cli-

mates to prevent freezing.

OOSEV078004

To prevent serious injury or

death, take the following safety

precautions when using washer

fluid:

Do not use coolant or

antifreeze in the washer fluid

reservoir.

Coolant can severely obscure

visibility when sprayed on the

windshield and may cause loss

of vehicle control resulting in

an accident or damage to paint

and body trim.

Do not allow sparks or flame to

contact the washer fluid or the

washer fluid reservoir. Washer

fluid may contain alcohol and

can be flammable.

Do not drink washer fluid and

avoid contact with skin. Washer

fluid is harmful to humans and

animals.

Keep washer fluid away from

children and animals.

WARNING

Page 416 of 540

7-36

Maintenance

Bead

The tire bead contains steel wires

wrapped by steel cords that hold the

tire onto the rim.

Bias Ply Tire

A pneumatic tire in which the plies

are laid at alternate angles less than

90 degrees to the centerline of the

tread.

Cold Tire Pressure

The amount of air pressure in a tire,

measured in pounds per square inch

(psi) or kilopascals (kPa) before a tire

has built up heat from driving.

Curb Weight

This means the weight of a motor

vehicle with standard and optional

equipment including the maximum

capacity of fuel, oil and coolant, but

without passengers and cargo.

DOT Markings

A code molded into the sidewall of a

tire signifying that the tire is in com-

pliance with the U.S. Department of

Transportation motor vehicle safety

standards. The DOT code includes

the Tire Identification Number (TIN),

an alphanumeric designator which

can also identify the tire manufactur-

er, production plant, brand and date

of production.

GVWR

Gross Vehicle Weight Rating

GAWR FRT

Gross Axle Weight Rating for the

Front Axle.

GAWR RR

Gross Axle Weight Rating for the

Rear axle.

Intended Outboard Sidewall

The side of an asymmetrical tire, that

must always face outward when

mounted on a vehicle.

Kilopascal (kPa)

The metric unit for air pressure.

Light truck(LT) tire

A tire designated by its manufacturer

as primarily intended for use on light-

weight trucks or multipurpose pas-

senger vehicles.

Load ratings

The maximum load that a tire is rated

to carry for a given inflation pressure.

Load Index

An assigned number ranging from 1

to 279 that corresponds to the load

carrying capacity of a tire.

Page 432 of 540

7-52

Maintenance

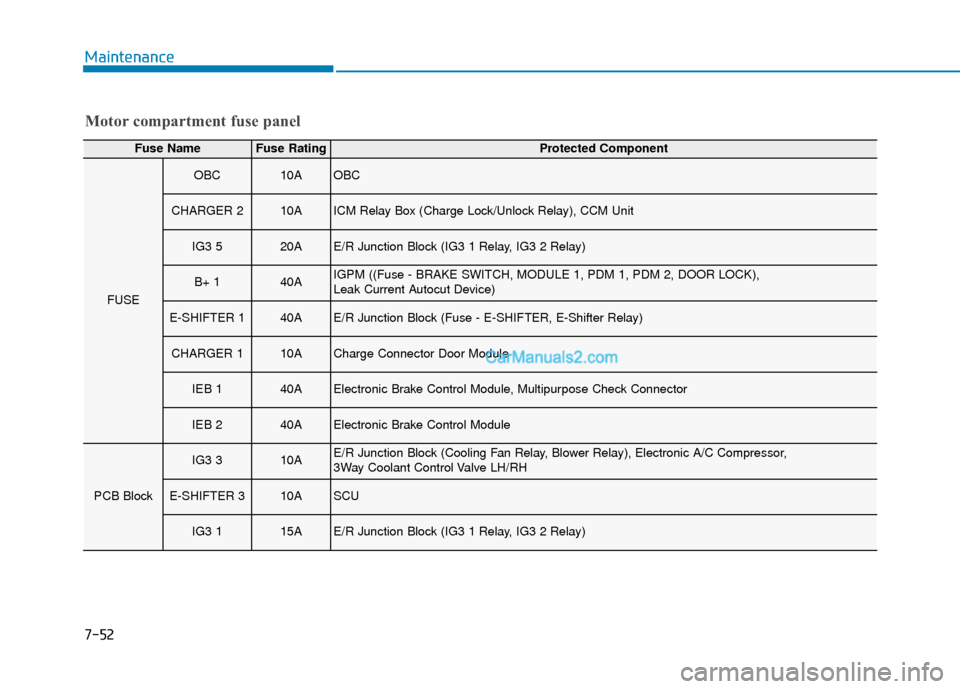

Motor compartment fuse panel

Fuse NameFuse RatingProtected Component

FUSE

OBC10AOBC

CHARGER 210AICM Relay Box (Charge Lock/Unlock Relay), CCM Unit

IG3 520AE/R Junction Block (IG3 1 Relay, IG3 2 Relay)

B+ 140AIGPM ((Fuse - BRAKE SWITCH, MODULE 1, PDM 1, PDM 2, DOOR LOCK),

Leak Current Autocut Device)

E-SHIFTER 140AE/R Junction Block (Fuse - E-SHIFTER, E-Shifter Relay)

CHARGER 110ACharge Connector Door Module

IEB 140AElectronic Brake Control Module, Multipurpose Check Connector

IEB 240AElectronic Brake Control Module

PCB Block

IG3 310AE/R Junction Block (Cooling Fan Relay, Blower Relay), Electronic A/C Compressor,

3Way Coolant Control Valve LH/RH

E-SHIFTER 310ASCU

IG3 115AE/R Junction Block (IG3 1 Relay, IG3 2 Relay)

Page 459 of 540

8-6

Specifications, Consumer information and Reporting safety defects

R

RE

EC

CO

O M

M M

ME

EN

N D

DE

ED

D

L

L U

U B

BR

RI

IC

C A

A N

N T

TS

S

A

A N

N D

D

C

C A

A P

PA

A C

CI

IT

T I

IE

E S

S

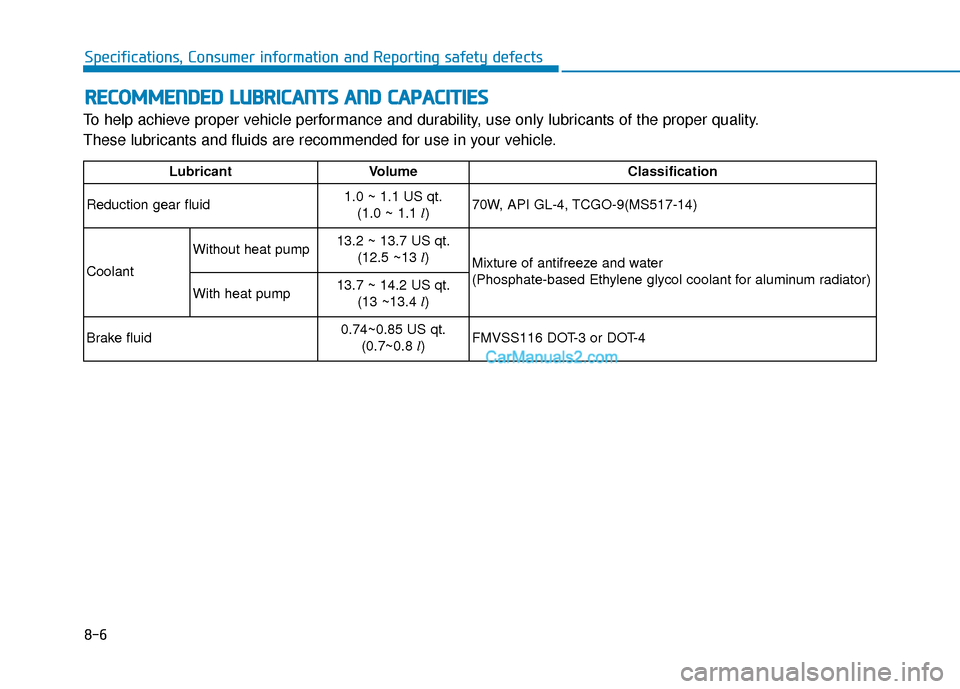

To help achieve proper vehicle performance and durability, use only lubricants of the proper quality.

These lubricants and fluids are recommended for use in your vehicle.

Lubricant Volume Classification

Reduction gear fluid 1.0 ~ 1.1 US qt.

(1.0 ~ 1.1 l) 70W, API GL-4, TCGO-9(MS517-14)

Coolant Without heat pump

13.2 ~ 13.7 US qt.

(12.5 ~13 l) Mixture of antifreeze and water

(Phosphate-based Ethylene glycol coolant for aluminum radiator)

With heat pump 13.7 ~ 14.2 US qt.

(13 ~13.4 l)

Brake fluid 0.74~0.85 US qt.

(0.7~0.8 l)FMVSS116 DOT-3 or DOT-4

Page 464 of 540

E

El

le

e c

ct

tr

r i

ic

c

V

V e

eh

h i

ic

c l

le

e

S

S y

ys

st

te

e m

m

O

O v

ve

e r

rv

v i

ie

e w

w

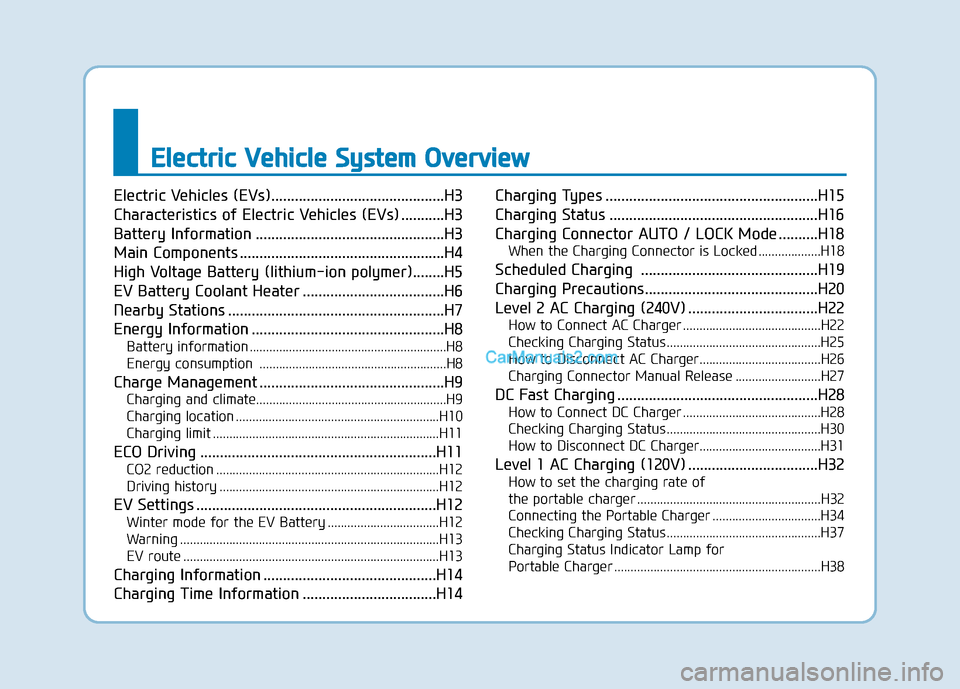

Electric Vehicles (EVs)............................................H3

Characteristics of Electric Vehicles (EVs) ...........H3

Battery Information ................................................H3

Main Components ....................................................H4

High Voltage Battery (lithium-ion polymer)........H5

EV Battery Coolant Heater ....................................H6

Nearby Stations .......................................................H7

Energy Information .................................................H8

Battery information ............................................................H8

Energy consumption .........................................................H8

Charge Management ...............................................H9

Charging and climate........................................................\

..H9

Charging location ..............................................................H10

Charging limit .....................................................................H11\

ECO Driving ............................................................H11

CO2 reduction ....................................................................H12

Driving history ...................................................................H12

EV Settings .............................................................H12

Winter mode for the EV Battery ..................................H12

Warning ........................................................................\

.......H13

EV route ........................................................................\

......H13

Charging Information ............................................H14

Charging Time Information ..................................H14 Charging Types ......................................................H15

Charging Status .....................................................H16

Charging Connector AUTO / LOCK Mode ..........H18

When the Charging Connector is Locked ...................H18

Scheduled Charging .............................................H19

Charging Precautions............................................H20

Level 2 AC Charging (240V) .................................H22

How to Connect AC Charger ..........................................H22

Checking Charging Status ...............................................H25

How to Disconnect AC Charger.....................................H26

Charging Connector Manual Release ..........................H27

DC Fast Charging ...................................................H28

How to Connect DC Charger ..........................................H28

Checking Charging Status ...............................................H30

How to Disconnect DC Charger.....................................H31

Level 1 AC Charging (120V) .................................H32

How to set the charging rate of

the portable charger ........................................................H32

Connecting the Portable Charger .................................H34

Checking Charging Status ...............................................H37

Charging Status Indicator Lamp for

Portable Charger ...............................................................H38