spare wheel Hyundai Matrix 2003 User Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2003, Model line: Matrix, Model: Hyundai Matrix 2003Pages: 312, PDF Size: 4.1 MB

Page 261 of 312

IN CASE OF EMERGENCY

3-4

SD070A1-E

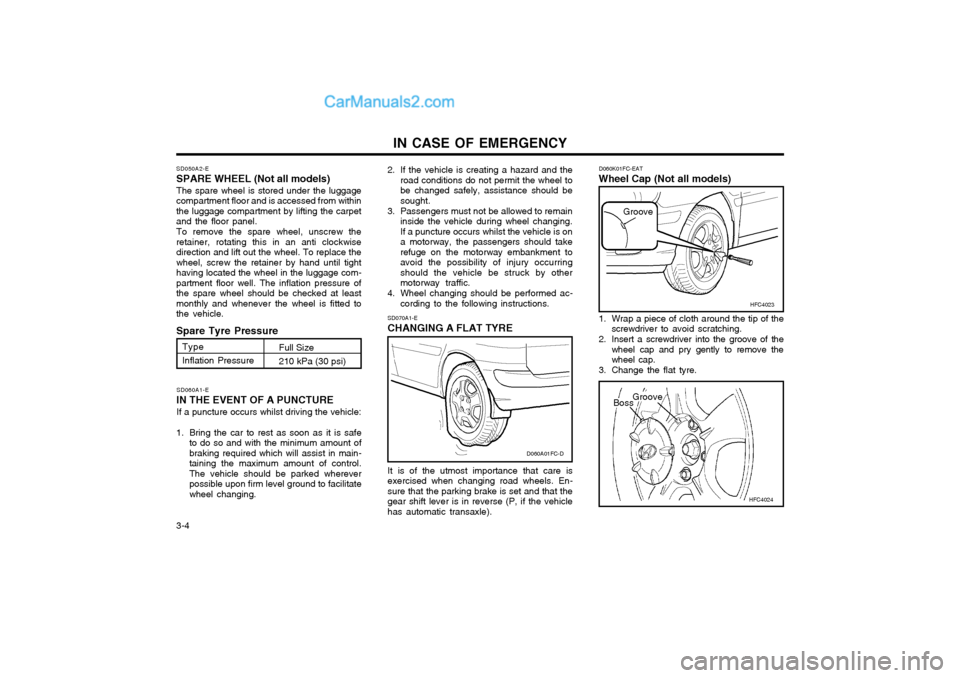

CHANGING A FLAT TYRE

It is of the utmost importance that care is exercised when changing road wheels. En-sure that the parking brake is set and that thegear shift lever is in reverse (P, if the vehiclehas automatic transaxle).

D060A01FC-D

D060K01FC-EAT

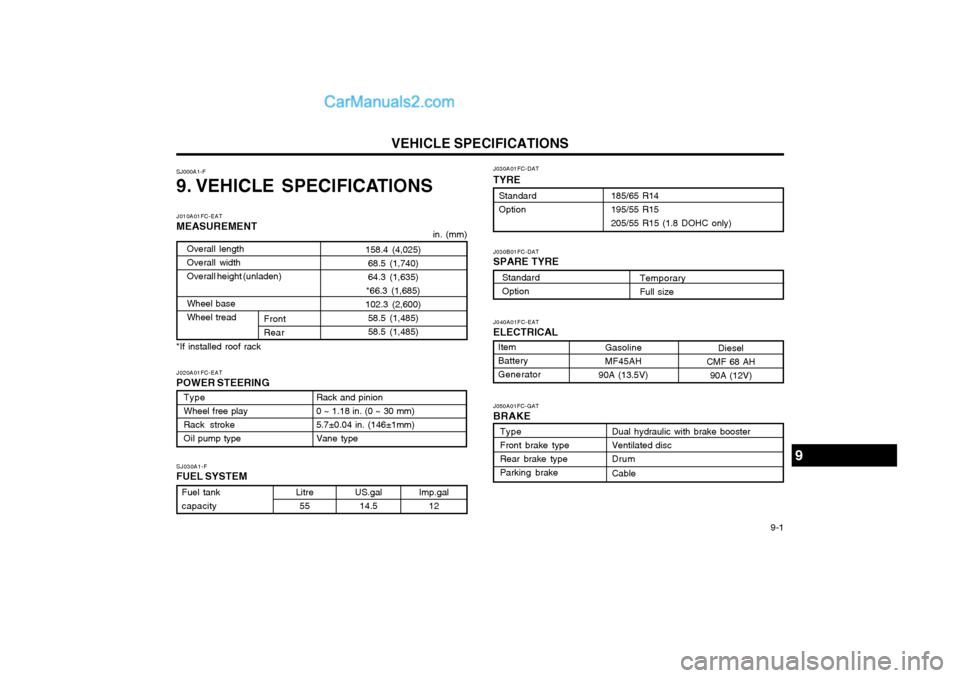

Wheel Cap (Not all models)

HFC4024

1. Wrap a piece of cloth around the tip of the

screwdriver to avoid scratching.

2. Insert a screwdriver into the groove of the wheel cap and pry gently to remove the wheel cap.

3. Change the flat tyre. HFC4023

Groove

BossGroove

SD060A1-E

IN THE EVENT OF A PUNCTURE If a puncture occurs whilst driving the vehicle:

1. Bring the car to rest as soon as it is safe to do so and with the minimum amount of braking required which will assist in main-taining the maximum amount of control.The vehicle should be parked whereverpossible upon firm level ground to facilitatewheel changing.

SD050A2-E SPARE WHEEL (Not all models) The spare wheel is stored under the luggage compartment floor and is accessed from withinthe luggage compartment by lifting the carpetand the floor panel. To remove the spare wheel, unscrew the retainer, rotating this in an anti clockwisedirection and lift out the wheel. To replace thewheel, screw the retainer by hand until tighthaving located the wheel in the luggage com-partment floor well. The inflation pressure ofthe spare wheel should be checked at leastmonthly and whenever the wheel is fitted tothe vehicle.

Spare Tyre Pressure

Type Inflation Pressure Full Size210 kPa (30 psi)

2. If the vehicle is creating a hazard and the

road conditions do not permit the wheel to be changed safely, assistance should besought.

3. Passengers must not be allowed to remain inside the vehicle during wheel changing.If a puncture occurs whilst the vehicle is ona motorway, the passengers should takerefuge on the motorway embankment toavoid the possibility of injury occurringshould the vehicle be struck by othermotorway traffic.

4. Wheel changing should be performed ac- cording to the following instructions.

Page 262 of 312

3-5

IN CASE OF EMERGENCY

Remove the spare wheel and take out the

jack and tool bag from the luggage room.

NOTE: The jack is equipped on the underside of

the luggage mat in the vehicle. Block the wheel that is diagonally opposite

from the flat tyre to prevent the vehicle from rolling when the car is raised on the jack.

D060B01FC-EAT

1. Obtain Spare Tyre and Tool SD070D1-E

2. Block the Wheel SD070E1-E 3. Loosen Wheel Nuts The wheel nuts should be loosened slightly

before raising the car. To loosen the nuts, turn the wheel brace counterclockwise. Ensurethat the wheel brace socket is seated properlyon the nut and that it cannot slip. Do notremove the nuts at this stage.

SD070F1-F

4. Put the Jack in Place

The base of the jack should be placed on firm,

level ground. The jack should be positionedas shown in the drawing.

4. Reinstall the wheel cap by fitting the boss of

the wheel cap in the groove of the wheel,

hitting the centre of the wheel cap with hand.

Flat tyre

HFC4005

D060D01FC-D

D060B01FC

HFC4006

Page 263 of 312

IN CASE OF EMERGENCY

3-6 WARNING: It is important that the faces of the wheel and hub are clean prior to installing thewheel. The prescence of dirt or other mat-ter in the wheel or hub faces could result inthe wheel nuts becoming loose whilst thevehicle is being driven. SD070I1-E

7. Re-install Wheel Nuts

Fit the wheel nuts onto the studs and tighten with the wheel brace.

SD070G1-E

5. Raising the Car SD070H1-E 6. Changing Wheels

After inserting a wrench bar into the wheel nut

wrench, install the wrench bar into the jack as shown in the drawing. To raise the vehicle, turnthe wheel nut wrench clockwise. As the jackbegins to raise the vehicle, double check that itis properly positioned and will not slip. If the jackis on soft ground or sand, it may be necessaryto place a stout piece of timber under the baseof the jack to prevent it from sinking. Raise the car high enough so that the fully

inflated spare wheel can be installed.

WARNING: Do not get under the car when it is support-

ed by the jack! The jack is solely designed for wheel changing and is not intended tosupport the vehicle for other purposes. Theuse of purpose designed supports is neces-sary whilst the vehicle is raised and theoperator is required to get underneath. Using the wheel brace, remove the nuts andslide the wheel off the hub and wheel studs.Lie the wheel flat to prevent it from rolling.Ensure that the faces of the wheel and hubare clean. Position the spare wheel over thestuds and slide it up to the hub.

STA3071H

D060H01FC-D

D060G01FCHFC4022

Wrench bar

Wheel nut wrench

Page 264 of 312

3-7

IN CASE OF EMERGENCY

SD070J1-E

8. Lower Vehicle and Tighten Nuts

Lower the car to the ground turning the wheel

nut wrench counterclockwise. When the ve- hicle is firmly on the ground, remove the jackand tighten the wheel nuts securely. At thefirst available opportunity, the wheel nut torqueshould be checked with a suitable torquewrench.

Wheel nut tightening torque Steel wheel & aluminium alloy wheel:900-1,100 kg.cm (65-80 lb.ft) SD070K1-E AFTER CHANGING WHEELS

SD080A1-E

VEHICLE TOWING OR RECOVERY

The pressure of the spare tyre should be checked at the first available opportunity. Ifany doubt exists as to the tyre pressure, thevehicle should be driven slowly to the nearestservice station and the tyre pressure checkedand adjusted as required. If the valve cap is lost from any of the valves, a replacement should be obtained and fittedat the first available opportunity. The valvecap prevents the ingress of dirt which maycause the valve to stick and therefore leakand is part of the valve sealing function. Ensure that the spare wheel, jack and wheel nut wrench as well tools are correctly locatedin the boot of the vehicle to prevent damageand noise. CAUTION:

An incorrect tow or recovery could result

in serious damage to the vehicle. If anydamage to the suspension, steering ortransaxle is apparent or suspected, a tow-ing ambulance must be used.

D060I01FC-DD060B01FC

o OK FOR AUTOMATIC OR MANUAL

TRANSAXLE EQUIPPED VEHICLE D080A01FC

Page 271 of 312

VEHICLE MAINTENANCE REQUIREMENTS

5- 4 F030C01E-EAT

R : REPLACE I : INSPECT AND, AFTER INSPECTION, CLEAN, ADJUST, REPAIR OR REPLACE IF NECESSARY

GENERAL MAINTENANCE COOLING SYSTEMCOOLANT GASOLINE ENGINEDIESEL ENGINE

ENGINE COOLANT SPECIFIC GRAVITYMANUAL TRANSAXLE OILAUTOMATIC TRANSAXLE FLUIDBRAKE PIPES, HOSES, AND CONNECTIONSBRAKE FLUIDCLUTCH FLUIDREAR BRAKE LININGS AND CYLINDERSBRAKE PADSSUSPENSION AND STEERING SYSTEMFRONT SUSPENSION BALL JOINTSPOLLEN FILTER (IN FRONT OF BLOWER UNIT)REAR WHEEL BEARINGSTYRE CONDITION AND PRESSURE (incl. Spare)LUBRICATE LOCKS AND HINGESCHECK ALL ELECTRICAL SYSTEMSROAD TESTCHECK ALL SYSTEMS WITH HI-SCAN

60 72

50 60

4048

I

R R

I I

R I

R R I I II

R

IIIII I

I I IIII I I I I

R I III I I

I

R IIII

R R I I I I

R I III I I

30 36

2024

I

R

I IIII I I II

R IIIIII

I

R IIII

R R I I I I

R I III I I

10 12

I I IIII I I I I

R I III I I

MILES X 1,000 MONTHS

NO. DESCRIPTION

1 2 3 456789

10111213141516171819

Page 304 of 312

CONSUMER INFORMATION

8-2 NOTE:

o Do not use the temporary spare tyre for tyre rotation.

o Aluminium wheels which are not sup- plied as Original Equipment should not be mixed on the same vehicle withthe original steel wheels. However, it isacceptable that the steel spare wheelbe used in conjunction with OriginalEquipment aluminium wheels since theoffset of both wheels is compatible.Radial and cross ply tyres should notbe mixed on the same vehicle.

I060A01FC-EAT

TYRE ROTATION

The tyre wear characteristics will vary be-

tween each tyre dependant upon the condi-tions of use. It is normal for the front tyres towear more rapidly than those fitted to the rearof the vehicle and therefore tyre rotation willprovide a means of helping to ensure an evenwear rate across the tyre set. For vehiclesfitted with radial ply tyres, rotation should beconfined to front to rear tyre alternation. It isnot recommended that radial ply tyres berotated from side to side. SI060A1-E

TYRE BALANCING Incorrect tyre balance will cause steering

vibration and uneven tyre wear. The vehicletyres are balanced during production but mayneed further balancing throughout the life ofthe tyres.

It is recommended that the tyres be balanced

on the car for best results and that the tyres arebalanced whenever they have been removedfrom the wheel for repair.

SI030A2-E

SNOW TYRES If it is desired to fit snow tyres to the vehicle,

it must be ascertained that the original sizeand load carrying capacity are met by thereplacement tyres. When using snow tyres,the vehicle should not be driven at speeds inexcess of 60 MPH.

SI040A1-E

TYRE CHAINS

Tyre chains, if necessary, should be installed

on the front wheels. Be sure that the chains arethe proper size and that they are installed inaccordance with the manufacturer's instruc-tions.

To minimize tyre and chain wear, do not contin-

ue to use tyre chains when they are no longerneeded.

CAUTION:When driving on roads covered with snow

or ice, drive at less than 20 mph (30 km/h). Tyre pressures should be increased by 3 psi

when the vehicle is driven fully laden or underconditions of sustained high speed motoring.

HA1409Spare tyre

Page 306 of 312

VEHICLE SPECIFICATIONS 9-1

Litre

55 Imp.gal

12

SJ000A1-F

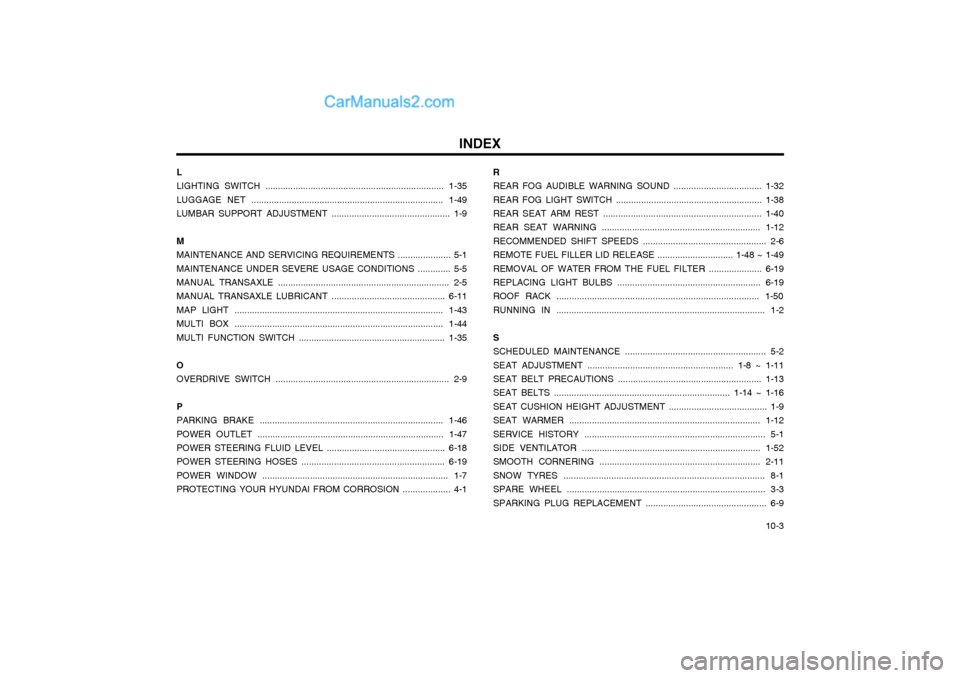

9. VEHICLE SPECIFICATIONS

Fuel tank capacity

Type Wheel free playRack strokeOil pump type

J010A01FC-EAT MEASUREMENT

in. (mm)

Item BatteryGeneratorDiesel

CMF 68 AH 90A (12V)

Gasoline MF45AH

90A (13.5V)

9

J040A01FC-EAT ELECTRICAL

SJ030A1-FFUEL SYSTEM

J020A01FC-EAT POWER STEERING

US.gal14.5

Rack and pinion 0 ~ 1.18 in. (0 ~ 30 mm)5.7±0.04 in. (146±1mm)Vane type J030A01FC-DAT

TYRE

185/65 R14 195/55 R15205/55 R15 (1.8 DOHC only)

StandardOption

Type Front brake typeRear brake typeParking brake Dual hydraulic with brake boosterVentilated discDrum Cable

J050A01FC-GAT BRAKE

Front Rear

Overall lengthOverall widthOverall height (unladen) Wheel base Wheel tread

158.4 (4,025)

68.5 (1,740)64.3 (1,635)

*66.3 (1,685)

102.3 (2,600) 58.5 (1,485)58.5 (1,485)

*If installed roof rack

Standard Option

J030B01FC-DAT SPARE TYRE

Temporary Full size

Page 311 of 312

INDEX10-3

L LIGHTING SWITCH ....................................................................... 1-35LUGGAGE NET ............................................................................ 1-49 LUMBAR SUPPORT ADJUSTMENT ............................................... 1-9 M MAINTENANCE AND SERVICING REQUIREMENTS ..................... 5-1MAINTENANCE UNDER SEVERE USAGE CONDITIONS ............. 5-5MANUAL TRANSAXLE .................................................................... 2-5 MANUAL TRANSAXLE LUBRICANT ............................................. 6-11 MAP LIGHT ................................................................................... 1-43MULTI BOX ................................................................................... 1-44MULTI FUNCTION SWITCH .......................................................... 1-35 O OVERDRIVE SWITCH ..................................................................... 2-9 P PARKING BRAKE ......................................................................... 1-46POWER OUTLET .......................................................................... 1-47POWER STEERING FLUID LEVEL ............................................... 6-18 POWER STEERING HOSES ......................................................... 6-19 POWER WINDOW .......................................................................... 1-7PROTECTING YOUR HYUNDAI FROM CORROSION ................... 4-1

RREAR FOG AUDIBLE WARNING SOUND ................................... 1-32REAR FOG LIGHT SWITCH .......................................................... 1-38 REAR SEAT ARM REST ............................................................... 1-40 REAR SEAT WARNING ............................................................... 1-12RECOMMENDED SHIFT SPEEDS ................................................. 2-6REMOTE FUEL FILLER LID RELEASE .............................. 1-48 ~ 1-49REMOVAL OF WATER FROM THE FUEL FILTER ..................... 6-19REPLACING LIGHT BULBS ......................................................... 6-19 ROOF RACK ................................................................................ 1-50 RUNNING IN ................................................................................... 1-2 S SCHEDULED MAINTENANCE ........................................................ 5-2SEAT ADJUSTMENT .......................................................... 1-8 ~ 1-11 SEAT BELT PRECAUTIONS ......................................................... 1-13 SEAT BELTS ...................................................................... 1-14 ~ 1-16SEAT CUSHION HEIGHT ADJUSTMENT ....................................... 1-9SEAT WARMER ............................................................................ 1-12SERVICE HISTORY ........................................................................ 5-1SIDE VENTILATOR ....................................................................... 1-52 SMOOTH CORNERING ................................................................ 2-11 SNOW TYRES ................................................................................ 8-1SPARE WHEEL ............................................................................... 3-3SPARKING PLUG REPLACEMENT ................................................ 6-9