Hyundai Matrix 2003 Owner's Manual

Manufacturer: HYUNDAI, Model Year: 2003, Model line: Matrix, Model: Hyundai Matrix 2003Pages: 312, PDF Size: 4.1 MB

Page 301 of 312

EMISSION CONTROL SYSTEM 7-1

SH000A1-E

7. EMISSION

CONTROL SYSTEM

SH010A1-E EMISSION CONTROL SYSTEMS (Not all models) Depending upon the market for which the ve-hicle is destined, the emission control systemwill comprise one or more of the followingemission control devices. (1) Crankcase emission control system (2) Evaporative emission control system (3) Exhaust emission control system In order that the proper functioning of the emis- sion control systems may be ensured, it isrecommended that the vehicle is inspected andmaintained by an authorized Hyundai dealer inaccordance with the maintenance schedule inthis manual. SH010B1-E 1. CRANKCASE EMISSION CONTROL SYSTEM

The positive crankcase ventilation system is employed to prevent air pollution caused byblow-by gases being emitted from the crank-case by introducing fresh air to the crankcase through the air cleaner where this mixes withblow-by gases and then passes through thePCV valve into the intake manifold from whereit subsequently enters the combustion cham-ber and is burned.

SH010D1-E 3. EXHAUST EMISSION CONTROL SYSTEM The exhaust emission control system is a highlyeffective system which controls exhaust emis-sion while maintaining good vehicle perfor-mance.

SH010C1-E

2. EVAPORATIVE EMISSION

CONTROL SYSTEM

The Evaporative Emission Control System is designed to prevent fuel vapours from escap-ing into the atmosphere through the fuel tankventilation system.Whilst the engine is not running, fuel vapoursgenerated inside the fuel tank are absorbedand stored in a charcoal canister. When theengine is started, the vapours stored in thecanister are drawn into the induction systemthrough the purge control solenoid valve andare subsequently burned.The purge control solenoid valve is controlledby the ECU; when the engine coolant tempera-ture is low or the engine is idling, the purgecontrol valve is closed and fuel vapours remainstored in the canister. Under normal runningconditions when the engine is warm, the valveopens and the vapours are drawn into the inlettract and subsequently burned in the combus-tion chamber. SH020A1-E

Catalytic Convertor Operation Precautions; For a gasoline engine Hyundai Matrix models are fitted with catalytic convertors which require special operatingconsiderations. The catalytic convertor servesto oxidize certain noxious elements of theexhaust gases leaving the engine to reduce thelevel of pollutants emitted from the vehicle and,provided that care is exercised to prevent dam-age, the catalyst will operate efficiently for thelife of the vehicle.

7HFC5013

Catalytic Converter

Page 302 of 312

EMISSION CONTROL SYSTEM

7-2

It is of the utmost importance that the following information is read and understood by thevehicle operator in order to prevent operationalproblems arising from damage to the catalyst.Damage to the catalyst will result if contamina-tion occurs through the use of leaded fuel.Whilst the vehicle is fitted with a reduced diam-eter filler neck to prevent charging of the fueltank with a leaded fuel pump nozzle, it ispossible that the use of funnels or jerry cans willpermit leaded fuel to be introduced into the fueltank.The catalyst is intolerant of unburnt fuel andtherefore if an engine misfire condition exists,damage to the catalyst will occur. It is impera-tive that if a misfire condition develops, thevehicle is immediately presented to a Hyundaidealer for rectification. Similarly, the practice ofcertain ignition system diagnosis procedureswhich involve inducing a misfire (cylinder powerbalance tests for example) may result in cata-lyst damage.For these reasons, it is advisable that theexhaust gas emission be tested at each routineservice with a gas analyzer having a Hydrocar-bon measuring facility to ensure continuedreliability of the catalyst.Push or tow starting of the vehicle is to beavoided since unburnt fuel may be enter thecatalyst and result in damage. (Note, it isimpossible to push or tow start a Hyundaimodel equipped with fuel injection since thefuel pump safety interlock will prevent the pumpfrom operating under these conditions).

Operation of the catalyst involves extremelyhigh temperatures being attained within thecatalytic convertor, and although the convertoris fitted with heat shields, it is important that thevehicle is not parked over combustible or vola-tile material which may result in fire.If the above precautions are not adhered to andthe catalyst becomes inoperative, the resultantincrease in core temperature will result in a"melt down" where the catalyst core will meltand subsequently may block the exhaust sys-tem.Due to the fragile nature of the catalyst ele-ment, it is important that damage does notoccur when the vehicle is raised by means of agarage jack. Care must also be exercised toavoid driving over road hazards or debris whichmay cause damage to the catalyst element.

H020D01S-GAT CATALYTIC CONVERTER ; For a diesel engine All Hyundai vehicles are equipped with oxida- tion type catalytic converter to reduce the car-bon monoxide, hydrocarbons and particulatecontained in the exhaust gas.

H020C01S-GAT EGR SYSTEM ; For a diesel engine This system helps control oxides of nitrogen by recirculating a part of the exhaust gas into theengine.

Page 303 of 312

CONSUMER INFORMATION 8-1

SI010B1-E

Engine Number

SI000A1-E

8. CONSUMER

INFORMATION

I010A01FC-EAT

VEHICLE IDENTIFICATION

NUMBER (VIN) The vehicle identification number (VIN) is

unique to each individual vehicle and is the number (sometimes referred to as chassisnumber) used upon the vehicle registrationdocument to identify the vehicle.

It can be found on the identification plate

attached to apron panel located on the driver'sside of the engine compartment. The engine number is stamped on the engine

block as shown in the drawing. I030A01FC-EAT

TYRE PRESSURES

In modern high-speed motoring, correct tyre

pressures are vitally important. Incorrect tyrepressures can affect vehicle safety by caus-ing reduced adhesion, steering response andtyre failure through overheating. The tyrepressure must only be checked when thetyres are cold. The correct tyre pressuresare indicated on the label affixed to the driver'sside "C" piller outer panel and below.

Diesel engine

I010B01B8

HFC6001

EADA010C

Gasoline engine

5.5Jx14 5.5Jx15 6.0Jx15 3.5Jx153.5Jx15

TYRE

SIZE

RIM

SIZE PRESSURE, kPa (PSI)

185/65R14195/55R15 205/55R15

T115/70D15 T115/70R15 REAR

210(30)210(30)210(30)420(60)420(60) FRONT

250(36)250(36) 250(36) 420(60)420(60)

UP TO 2

PERSONS UP TO

MAX. LOAD

REAR

250(36)250(36) 250(36) 420(60)420(60)

FRONT210(30)210(30)210(30) 420(60) 420(60)

I030A01FC-D

Page 304 of 312

CONSUMER INFORMATION

8-2 NOTE:

o Do not use the temporary spare tyre for tyre rotation.

o Aluminium wheels which are not sup- plied as Original Equipment should not be mixed on the same vehicle withthe original steel wheels. However, it isacceptable that the steel spare wheelbe used in conjunction with OriginalEquipment aluminium wheels since theoffset of both wheels is compatible.Radial and cross ply tyres should notbe mixed on the same vehicle.

I060A01FC-EAT

TYRE ROTATION

The tyre wear characteristics will vary be-

tween each tyre dependant upon the condi-tions of use. It is normal for the front tyres towear more rapidly than those fitted to the rearof the vehicle and therefore tyre rotation willprovide a means of helping to ensure an evenwear rate across the tyre set. For vehiclesfitted with radial ply tyres, rotation should beconfined to front to rear tyre alternation. It isnot recommended that radial ply tyres berotated from side to side. SI060A1-E

TYRE BALANCING Incorrect tyre balance will cause steering

vibration and uneven tyre wear. The vehicletyres are balanced during production but mayneed further balancing throughout the life ofthe tyres.

It is recommended that the tyres be balanced

on the car for best results and that the tyres arebalanced whenever they have been removedfrom the wheel for repair.

SI030A2-E

SNOW TYRES If it is desired to fit snow tyres to the vehicle,

it must be ascertained that the original sizeand load carrying capacity are met by thereplacement tyres. When using snow tyres,the vehicle should not be driven at speeds inexcess of 60 MPH.

SI040A1-E

TYRE CHAINS

Tyre chains, if necessary, should be installed

on the front wheels. Be sure that the chains arethe proper size and that they are installed inaccordance with the manufacturer's instruc-tions.

To minimize tyre and chain wear, do not contin-

ue to use tyre chains when they are no longerneeded.

CAUTION:When driving on roads covered with snow

or ice, drive at less than 20 mph (30 km/h). Tyre pressures should be increased by 3 psi

when the vehicle is driven fully laden or underconditions of sustained high speed motoring.

HA1409Spare tyre

Page 305 of 312

CONSUMER INFORMATION 8-3

SI060B1-E

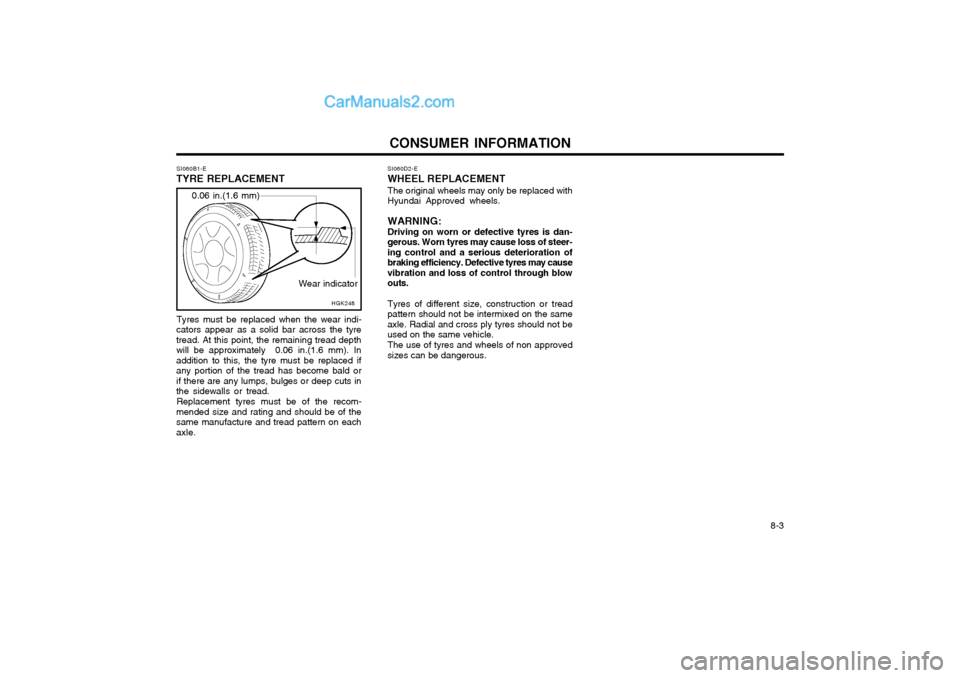

TYRE REPLACEMENT

Wear indicator

0.06 in.(1.6 mm)

HGK248SI060D2-E

WHEEL REPLACEMENT

The original wheels may only be replaced with

Hyundai Approved wheels.

WARNING: Driving on worn or defective tyres is dan-

gerous. Worn tyres may cause loss of steer- ing control and a serious deterioration ofbraking efficiency. Defective tyres may causevibration and loss of control through blowouts.

Tyres of different size, construction or tread

pattern should not be intermixed on the sameaxle. Radial and cross ply tyres should not beused on the same vehicle.

The use of tyres and wheels of non approved

sizes can be dangerous.

Tyres must be replaced when the wear indi-

cators appear as a solid bar across the tyretread. At this point, the remaining tread depthwill be approximately 0.06 in.(1.6 mm). Inaddition to this, the tyre must be replaced ifany portion of the tread has become bald orif there are any lumps, bulges or deep cuts inthe sidewalls or tread.

Replacement tyres must be of the recom-

mended size and rating and should be of thesame manufacture and tread pattern on eachaxle.

Page 306 of 312

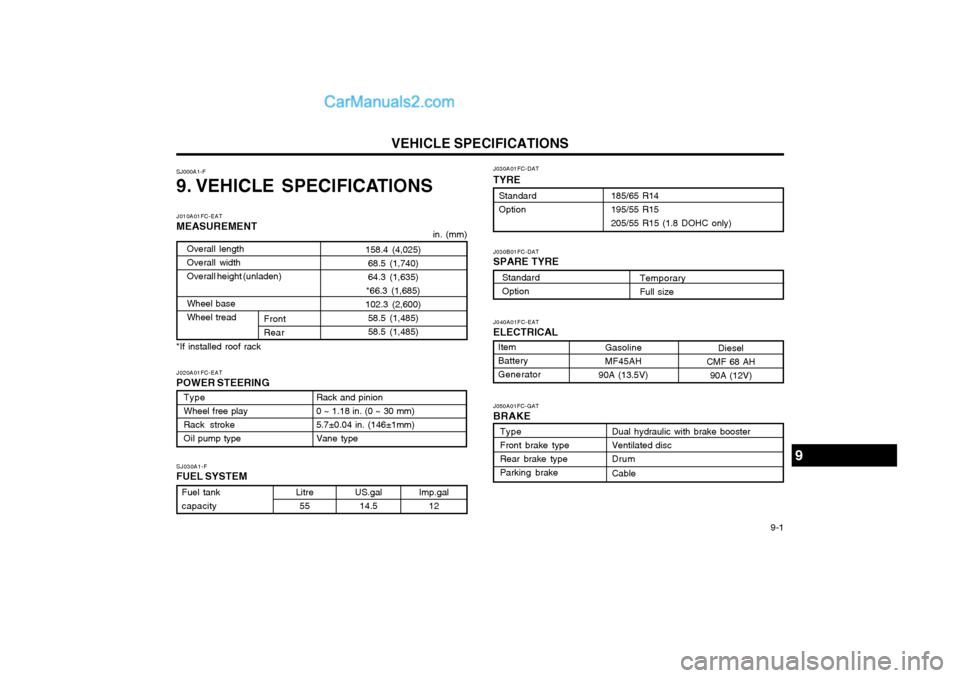

VEHICLE SPECIFICATIONS 9-1

Litre

55 Imp.gal

12

SJ000A1-F

9. VEHICLE SPECIFICATIONS

Fuel tank capacity

Type Wheel free playRack strokeOil pump type

J010A01FC-EAT MEASUREMENT

in. (mm)

Item BatteryGeneratorDiesel

CMF 68 AH 90A (12V)

Gasoline MF45AH

90A (13.5V)

9

J040A01FC-EAT ELECTRICAL

SJ030A1-FFUEL SYSTEM

J020A01FC-EAT POWER STEERING

US.gal14.5

Rack and pinion 0 ~ 1.18 in. (0 ~ 30 mm)5.7±0.04 in. (146±1mm)Vane type J030A01FC-DAT

TYRE

185/65 R14 195/55 R15205/55 R15 (1.8 DOHC only)

StandardOption

Type Front brake typeRear brake typeParking brake Dual hydraulic with brake boosterVentilated discDrum Cable

J050A01FC-GAT BRAKE

Front Rear

Overall lengthOverall widthOverall height (unladen) Wheel base Wheel tread

158.4 (4,025)

68.5 (1,740)64.3 (1,635)

*66.3 (1,685)

102.3 (2,600) 58.5 (1,485)58.5 (1,485)

*If installed roof rack

Standard Option

J030B01FC-DAT SPARE TYRE

Temporary Full size

Page 307 of 312

VEHICLE SPECIFICATIONS

9-2 GASOLINE

1.6/1.8 4Cylinder in-line DOHC

800 ± 100 (1.6L), 750 ± 100 (1.8L) 800 ± 100 (1.6L), 800 ± 100 (1.8L)

BKR5ES-11RC10YC4

0.039 ~ 0.043 in. (1.0 ~ 1.1 mm)

AUTO LASH (1.6 DOHC), 0.0067~0.0091 in.(0.17~0.23mm) (1.8 DOHC)

AUTO LASH (1.6 DOHC), 0.0098~0.0122 in.(0.25~0.31mm) (1.8 DOHC) BTDC 5° ± 5° (1.6L), BTDC 7° ± 5° (1.8L)

1 - 3 - 4 - 2

ITEMS

Engine Type Idle Speed (RPM) Spark Plug Spark Plug Gap Valve Clearance (Cold engine:20 ± 5°C) Ignition Timing Firing Order

A/CON OFF A/CON ON NGK CHAMPION Intake Exhaust DIESEL

1.5 4Cylinder in-line SOHC 800 ± 100800 ± 100- - -

AUTO LASH

AUTO LASH -

1 - 3 - 2

J070A02FC-EAT ENGINE

Page 308 of 312

VEHICLE SPECIFICATIONS 9-3

Item

Engine Oil (Gasoline engine) Engine Oil (Diesel engine) Engine Oil Consumption Transaxle

Power Steering Brake Fluid Coolant

J080A02FC-EAT LUBRICATION CHART

Q'ty (litre)

1.6 DOHC - 3.3 (with oil filter)(3.5 us qts., 2.9 lmp. qts) 1.8 DOHC - 3.85 (with oil filter) (4.07us qts., 3.39 lmp. qts)

1.5 SOHC - 4.8 (with oil filter)(5.1 us qts., 4.2 lmp. qts)

MAX. 1 L / 1,500 Km

MAX. 1L / 1,000 Km 2.15 (2.3 us. qts., 1.86 Imp. qts) 6.1 (6.4 us qts., 5.3 lmp. qts) (1.6 DOHC)6.7 (7.0 us qts., 5.8 lmp. qts) (1.8 DOHC) As required As requiredGasoline engine : 6.2 (1.6 DOHC), 6.5 (1.8 DOHC) Diesel engine : 6.3Oil & Grease Standard

API SG SAE 20W-40, 20W-50 (ABOVE -10°C)

or ABOVE SAE 15W-40, 15W-50 (ABOVE -15°C)

SAE 10W-30 (-25°C ~ 40°C) SAE 10W-40, 10W-50 (ABOVE -25°C) SAE 5W-20 (BELOW -10°C) *1, *2SAE 5W-30 (BELOW 10°C) *1 SAE 5W-40 (BELOW 20°C) *1

API CF-4 SAE 30 (0°C ~ 40°C)

or ABOVE, SAE 20W-40 (ABOVE -10°C)

ACEA B4 SAE 15W-40 (ABOVE -15°C)

or ABOVE SAE 10W-30 (-20°C ~ 40°C) SAE 5W-30 (-25°C ~ 10°C)SAE 0W-30 (BELOW 10°C) *1, *2

*1. Restricted to driving condition and area *2. Not recommended for sustained high speed vehicle operation Normal driving conditionSevere driving condition HYUNDAI GENUINE PARTS MTF 75W/90 (API GL-4) DIAMOND ATF SP-III, SK ATF SP-III PSF-3 DOT 3, DOT 4 or equivalent Ethylene glycol base for aluminum radiator

Manual Auto

Page 309 of 312

INDEX10-1

A ACCESSORY TRAY ...................................................................... 1-47AIR CONDITIONING SWITCH ....................................................... 1-56AIR CONDITIONING SYSTEM MAINTENANCE ............................ 6-15AIR CLEANER ELEMENT REPLACEMENT .................................. 6-10ANTENNA ...................................................................................... 1-61 ANTI-THEFT ALARM SYSTEM ............................................ 1-5 ~ 1-7 AUTO FUEL CUT SWITCH ............................................................ 1-50AUTOMATIC TRANSAXLE .................................................... 2-6 ~ 2-9AUTOMATIC TRANSAXLE FLUID ...................................... 6-12 ~ 6-13 B BATTERY MAINTENANCE ........................................................... 6-17BEFORE STARTING THE ENGINE ................................................ 2-2BONNET RELEASE ...................................................................... 1-48BRAKE PEDAL FREEPLAY .......................................................... 6-16BRAKE TRACTION CONTROL SYSTEM .................................... 2-10 BRAKE SYSTEM CHECKING ....................................................... 6-13 C CARE OF SEAT BELTS ................................................................ 1-13CARGO AREA COVER ................................................................. 1-50 CATALYTIC CONVERTOR OPERATING PRECAUTIONS ............. 7-1CENTRE VENTILATOR ................................................................. 1-52CENTRAL DOOR LOCKS ............................................................... 1-5 CHANGING A FLAT TYRE .............................................................. 3-4 CHECKING THE CLUTCH FLUID .................................................. 6-14CHILD-PROOF REAR DOOR LOCK ............................................... 1-4CHILD RESTRAINT SYSTEM ............................................ 1-16 ~ 1-17CIGAR LIGHTER ........................................................................... 1-39CLUTCH PEDAL FREEPLAY ............................................ 6-15 ~ 6-16 COMBINATION IGNITION SWITCH AND STEERING LOCK ......... 2-2 COOLANT TEMPERATURE GAUGE ............................................ 1-32 D DAILY OPERATING CHECKS ......................................................... 6-4DIGITAL CLOCK ........................................................................... 1-39 DOOR LOCKS ................................................................................. 1-3 DOOR WINDOWS ........................................................................... 1-7DRINK HOLDER ............................................................................ 1-40DRIVE BELTS ............................................................................... 6-16DRIVING FOR ECONOMY ............................................................ 2-11 E EFFECTIVE BRAKING .................................................................... 2-9ELECTRIC COOLING FANS ......................................................... 6-18EMISSION CONTROL SYSTEM ..................................................... 7-1

JK000A1-A 10. INDEX

10

Page 310 of 312

INDEX

10-2 ENGINE COMPARTMENT ..................................................... 6-1 ~ 6-3 ENGINE COOLANT CHECKING AND REPLACING ........................6-7ENGINE OIL AND FILTER REPLACEMENT .................................. 6-6 ENGINE OIL CONSUMPTION ......................................................... 6-6 ENGINE OIL REPLENISHMENT .................................................... 6-5ENGINE OIL .................................................................................... 6-4EXTERIOR REAR VIEW MIRROR ..................................... 1-44 ~ 1-45 F FOLDING REAR SEATBACK AND SEAT CUSHION ......... 1-11 ~ 1-12 FOLD-UP TRAY ............................................................................ 1-47FRONT ASHTRAY ........................................................................ 1-39FRONT FOG LIGHT SWITCH ....................................................... 1-38FUEL ECONOMY ............................................................................ 2-4FUEL GAUGE ............................................................................... 1-32 FUEL RECOMMENDATIONS .......................................................... 1-1 FUSIBLE LINKS ............................................................................ 6-17 G GLOVE BOX ................................................................................. 1-44 H HAZARD WARNING SYSTEM ....................................................... 1-37HEADLIGHT AIMING ADJUSTEMENT .......................................... 6-20HEADLIGHT BULB ............................................................. 6-19 ~ 6-20

HEADLIGHT LEVELING DEVICE SYSTEM ................................. 1-41HEAD RESTRAINT ADJUSTMENT ........................................ 1-9, 1-11HEATED REAR WINDOW ............................................................. 1-38 HEATING CONTROL .................................................................... 1-55 HEIGHT ADJUSTABLE FRONT SEAT SHOULDER BELT ............. 1-14HORN ............................................................................................ 1-51 I IF THE ENGINE CANNOT BE CRANKED ...................................... 3-1 IF THE ENGINE WILL NOT START ................................................ 3-1 IF THE EVENT OF A PUNCTURE ................................................. 3-4IMMOBILIZER SYSTEM ..........................................................1-2 ~ 1-3INDIVIDUAL CIRCUIT FUSES ....................................................... 6-17INSTRUMENT CLUSTER AND INDICATORS ..................... 1-27 ~ 1-28INSTRUMENTS AND CONTROLS ............................................... 1-26 INTERIOR LIGHT .......................................................................... 1-43 INTERIOR REAR VIEW MIRROR ................................................ 1-46 J JUMP STARTING ............................................................................ 3-1 K KEY POSITIONS ............................................................................. 2-2