clock Hyundai Matrix 2003 Owner's Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2003, Model line: Matrix, Model: Hyundai Matrix 2003Pages: 312, PDF Size: 4.1 MB

Page 262 of 312

3-5

IN CASE OF EMERGENCY

Remove the spare wheel and take out the

jack and tool bag from the luggage room.

NOTE: The jack is equipped on the underside of

the luggage mat in the vehicle. Block the wheel that is diagonally opposite

from the flat tyre to prevent the vehicle from rolling when the car is raised on the jack.

D060B01FC-EAT

1. Obtain Spare Tyre and Tool SD070D1-E

2. Block the Wheel SD070E1-E 3. Loosen Wheel Nuts The wheel nuts should be loosened slightly

before raising the car. To loosen the nuts, turn the wheel brace counterclockwise. Ensurethat the wheel brace socket is seated properlyon the nut and that it cannot slip. Do notremove the nuts at this stage.

SD070F1-F

4. Put the Jack in Place

The base of the jack should be placed on firm,

level ground. The jack should be positionedas shown in the drawing.

4. Reinstall the wheel cap by fitting the boss of

the wheel cap in the groove of the wheel,

hitting the centre of the wheel cap with hand.

Flat tyre

HFC4005

D060D01FC-D

D060B01FC

HFC4006

Page 263 of 312

IN CASE OF EMERGENCY

3-6 WARNING: It is important that the faces of the wheel and hub are clean prior to installing thewheel. The prescence of dirt or other mat-ter in the wheel or hub faces could result inthe wheel nuts becoming loose whilst thevehicle is being driven. SD070I1-E

7. Re-install Wheel Nuts

Fit the wheel nuts onto the studs and tighten with the wheel brace.

SD070G1-E

5. Raising the Car SD070H1-E 6. Changing Wheels

After inserting a wrench bar into the wheel nut

wrench, install the wrench bar into the jack as shown in the drawing. To raise the vehicle, turnthe wheel nut wrench clockwise. As the jackbegins to raise the vehicle, double check that itis properly positioned and will not slip. If the jackis on soft ground or sand, it may be necessaryto place a stout piece of timber under the baseof the jack to prevent it from sinking. Raise the car high enough so that the fully

inflated spare wheel can be installed.

WARNING: Do not get under the car when it is support-

ed by the jack! The jack is solely designed for wheel changing and is not intended tosupport the vehicle for other purposes. Theuse of purpose designed supports is neces-sary whilst the vehicle is raised and theoperator is required to get underneath. Using the wheel brace, remove the nuts andslide the wheel off the hub and wheel studs.Lie the wheel flat to prevent it from rolling.Ensure that the faces of the wheel and hubare clean. Position the spare wheel over thestuds and slide it up to the hub.

STA3071H

D060H01FC-D

D060G01FCHFC4022

Wrench bar

Wheel nut wrench

Page 264 of 312

3-7

IN CASE OF EMERGENCY

SD070J1-E

8. Lower Vehicle and Tighten Nuts

Lower the car to the ground turning the wheel

nut wrench counterclockwise. When the ve- hicle is firmly on the ground, remove the jackand tighten the wheel nuts securely. At thefirst available opportunity, the wheel nut torqueshould be checked with a suitable torquewrench.

Wheel nut tightening torque Steel wheel & aluminium alloy wheel:900-1,100 kg.cm (65-80 lb.ft) SD070K1-E AFTER CHANGING WHEELS

SD080A1-E

VEHICLE TOWING OR RECOVERY

The pressure of the spare tyre should be checked at the first available opportunity. Ifany doubt exists as to the tyre pressure, thevehicle should be driven slowly to the nearestservice station and the tyre pressure checkedand adjusted as required. If the valve cap is lost from any of the valves, a replacement should be obtained and fittedat the first available opportunity. The valvecap prevents the ingress of dirt which maycause the valve to stick and therefore leakand is part of the valve sealing function. Ensure that the spare wheel, jack and wheel nut wrench as well tools are correctly locatedin the boot of the vehicle to prevent damageand noise. CAUTION:

An incorrect tow or recovery could result

in serious damage to the vehicle. If anydamage to the suspension, steering ortransaxle is apparent or suspected, a tow-ing ambulance must be used.

D060I01FC-DD060B01FC

o OK FOR AUTOMATIC OR MANUAL

TRANSAXLE EQUIPPED VEHICLE D080A01FC

Page 280 of 312

OWNER MAINTENANCE 6-5

SG030C1-E

Engine Oil Level NOTE: SAE 0W-30 oil is for extra cold zone and

to be restricted by driving condition and dealing area. (Especially, not recommend-ed for sustained high loaded and highspeed operation.) The engine oil level should be checked with

the engine at normal operating temperatureand the vehicle parked upon level ground.

Prior to checking the level, the vehicle should

be allowed to stand for several minutes after theengine has been switched off to allow the oil todrain back to the sump.

Withdraw the dipstick and wipe it with a clean

rag. Replace the dipstick fully and withdrawagain when the oil level may be read from thestick. Normal oil level is indicated when the oilis present between the two marks on thestick. It is not necessary to add oil if the levelis above the lower mark and in any case, oilmust not be added to the degree that the levelexceeds the upper mark. Replace the dip-stick fully after checking the level. SG030D2-E

ENGINE OIL REPLENISHMENT

If the indicated oil level is at or below the lower

mark of the dipstick, oil should be added untilthe level is at or below the upper mark.

To add oil to the engine, remove the filler cap by

rotating in an counterclockwise direction andpour engine oil into the engine. Before checking

HFC5007

HFC5009

G030C02FC

Gasoline engine

Diesel engine

G030D02FC

Gasoline engine

Diesel engine

Page 281 of 312

OWNER MAINTENANCE

6-6 the level again, allow several minutes for the oil to drain into the sump. Replace the oil fillercap rotating it in a clockwise direction untiltight. The quantity of oil required to raise the level from the minimum to maximum level is approx-imately 1 litre. The distance between the "F" and "L" marks is equal to about 1 liter(Gasoline Engine)/1.2liter(Diesel Engine) of oil.

o The engine oil consumption is strongly

effected by the viscosity and quality of oil,engine rpm and driving condition etc. The engine oil is more consumed under severe driving conditions such as highspeeds and frequent acceleration and de-celeration than normal driving condition.

ZG030E1-A

ENGINE OIL CONSUMPTION Function of engine oil

Engine oil has the primary function of lubricat-

ing and cooling the inside of the engine. Engine oil consumption

It is normal that an engine should consume

some engine oil while normal driving. The cause of oil consumption in a normal engine are asfollows;

o Engine oil is used to lubricate pistons, piston rings and cylinders. A thin film of oil is left on the cylinder wallwhen a piston moves downwards in thecylinder. High negative pressure generatedduring engine operation sucks some of theoil into the combustion chamber. This oil with some oil of the cylinder wall is burned by the high temperature combustiongases during the combustion process. SG040A1-E

ENGINE OIL AND FILTER

REPLACEMENT

SSA6040A

Oil filler cap

Drain plug

Oil filter The engine oil and filter must be changed at

the time or mileage interval specified in the maintenance schedule. If the vehicle is oper-ated under severe or adverse conditions, theoil and filter must be replaced more frequently.

To replace the oil and filter, proceed as fol-

lows:

1. Ensure that the engine is at normal operat- ing temperature and park the vehicle on level ground with the parking brake se-curely applied and the engine turned off.

2. Open the bonnet and remove the oil filler cap.

3. Prepare a suitable receptacle to collect the displaced oil and remove the drain plugfrom the sump.

CAUTION: The oil being drained from the engine will

be hot. Care should be exercised to pre- vent scalding.

Diesel engine

Gasoline engine Drain plug

Oil filter

KCHB001A-1

Page 282 of 312

OWNER MAINTENANCE 6-7

SG050A1-E

ENGINE COOLANT CHECKING AND REPLACING WARNING: Do not remove the radiator cap when the

engine is hot, since the system is pressur- ized and coolant may be ejected from theradiator resulting in scalding.

SG050B1-E

Coolant recommendations

G050B01FC

G050B02FC

Gasoline engine Diesel engine

Only ethylene glycol based coolant with a

corrosion inhibitor suited to aluminium alloy engine components should be used in thecooling system. No further additives or inhibi- tors should be used. The coolant specific gravity should be checked as prescribed inthe maintenance schedule to ensure adequatefrost and corrosion protection. In addition, theengine coolant must be replaced at the speci-fied interval since the corrosion inhibitor prop-erties deteriorate with time.

It is important to note that whilst an increase

in the concentration of anti freeze gives anincrease in the level of frost protection, asolution which is in excess of 65% anti freezewill result in reduced frost protection andengine overheating. Therefore the recom-mended concentration of 50% should not beexceeded for general use.

The use of methanol based anti freeze com-

pounds may result in engine overheating andwill invalidate the vehicle warranty.

4. When the oil has drained from the sump,

replace the drain plug using a new washerensuring that the plug is not over tight-ened.

5. Remove the oil filter by rotating counter- clockwise, using a proprietary oil filter re-moval tool if necessary. Note that the oilfilter will contain approximately 0.5 litres ofoil and this should be collected in a suit-able receptacle.

6. Install a new oil filter having smeared the sealing ring with clean oil and rotatingclockwise until the filter contacts the mount-ing and then a further one half turn. Do notover-tighten Tightening torque: 2.3 ~ 2.5 kgf.m

7. Pour the specified quantity of the recom- mended oil into the engine and replace the filler cap. Start the engine and ensure thatno oil leaks exist. Turn off the engine andafter a couple minutes, recheck the oillevel.

WARNING:Prolonged and repeated contact with used

engine oils may result in serious skin dis-orders including dermatitis and cancer.Avoid contact with skin as far as possibleand always wash thoroughly after any con-tact. Keep used oils out of reach of chil-dren. It is illegal to pollute drains, watercourses and soil. Use only authorized wastecollection facilities including civic amenity sites and garages for the disposal of usedoil and oil filters. If in doubt, contact thelocal authority for disposal instructions.

Page 284 of 312

OWNER MAINTENANCE 6-9

SG060A1-E

SPARKING PLUG REPLACEMENT

SSA6060A

0.039 ~ 0.043 in. (1.0 ~ 1.1 mm)

This operation should only be performed when

the engine is cold.

1. Remove the centre cover from the engine rocker cover.

2. Remove plug lead from the sparking plug to be replaced, pulling the lead by the rubber cap. (Pulling the lead may damage the car-bon conductor).SSA6061CSSA6060B

Prior to installing a sparking plug, the gap between the centre and outer electrodes mustbe checked and adjusted as necessary.Adjustment is facilitated by bending the outerelectrode towards or away from the centreelectrode. Under no circumstances should at-tempts be made to adjust the position of thecentre electrode.

4. Insert the sparking plug into the cylinder head and screw by the wrench and until theplug contacts the seating area. Tighten theplug with the socket by a further 1/2 to 3/4 ofa turn only.

3. Clean around the base of the plug to be

removed, and install the plug socket ensur-ing that the ceramic insulator does not be-come damaged. Turn the socket counter-clockwise to remove the plug.

CAUTION: Sparking plugs must only be cleaned using

purpose designed equipment. Wire brush- ing may damage the centre electrodein-sulator causing misfiring to occur. Only thecorrect grade of sparking plug should beused. Use of an incorrect grade may resultin serious engine damage.

you are not injured by a rotating fan blade.As the engine coolant temperature decreas-es, the fan will automatically shut off. Thisis a normal condition.

Page 309 of 312

INDEX10-1

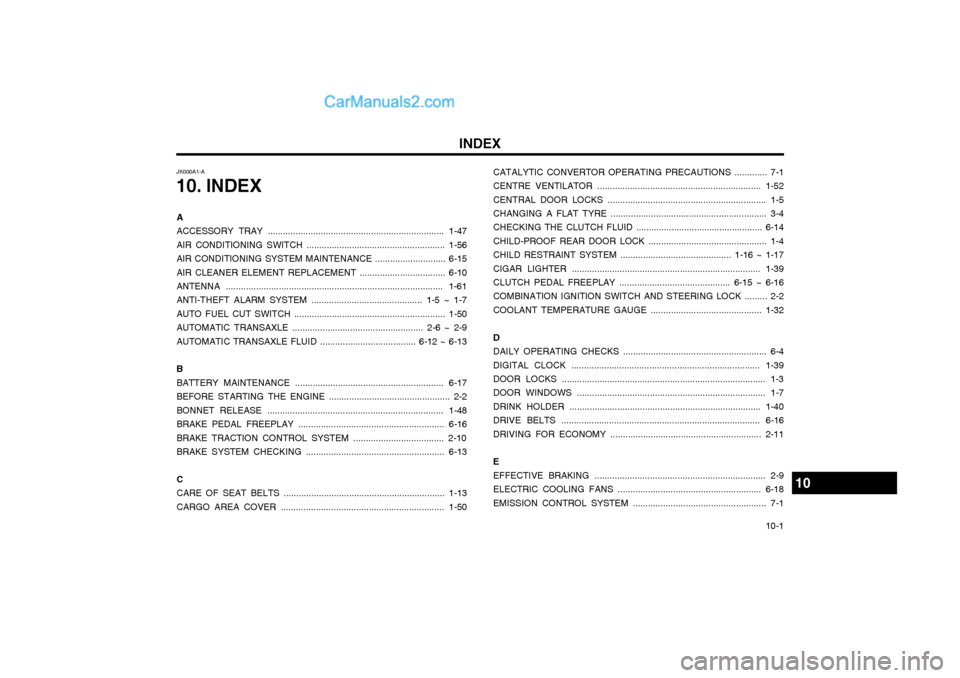

A ACCESSORY TRAY ...................................................................... 1-47AIR CONDITIONING SWITCH ....................................................... 1-56AIR CONDITIONING SYSTEM MAINTENANCE ............................ 6-15AIR CLEANER ELEMENT REPLACEMENT .................................. 6-10ANTENNA ...................................................................................... 1-61 ANTI-THEFT ALARM SYSTEM ............................................ 1-5 ~ 1-7 AUTO FUEL CUT SWITCH ............................................................ 1-50AUTOMATIC TRANSAXLE .................................................... 2-6 ~ 2-9AUTOMATIC TRANSAXLE FLUID ...................................... 6-12 ~ 6-13 B BATTERY MAINTENANCE ........................................................... 6-17BEFORE STARTING THE ENGINE ................................................ 2-2BONNET RELEASE ...................................................................... 1-48BRAKE PEDAL FREEPLAY .......................................................... 6-16BRAKE TRACTION CONTROL SYSTEM .................................... 2-10 BRAKE SYSTEM CHECKING ....................................................... 6-13 C CARE OF SEAT BELTS ................................................................ 1-13CARGO AREA COVER ................................................................. 1-50 CATALYTIC CONVERTOR OPERATING PRECAUTIONS ............. 7-1CENTRE VENTILATOR ................................................................. 1-52CENTRAL DOOR LOCKS ............................................................... 1-5 CHANGING A FLAT TYRE .............................................................. 3-4 CHECKING THE CLUTCH FLUID .................................................. 6-14CHILD-PROOF REAR DOOR LOCK ............................................... 1-4CHILD RESTRAINT SYSTEM ............................................ 1-16 ~ 1-17CIGAR LIGHTER ........................................................................... 1-39CLUTCH PEDAL FREEPLAY ............................................ 6-15 ~ 6-16 COMBINATION IGNITION SWITCH AND STEERING LOCK ......... 2-2 COOLANT TEMPERATURE GAUGE ............................................ 1-32 D DAILY OPERATING CHECKS ......................................................... 6-4DIGITAL CLOCK ........................................................................... 1-39 DOOR LOCKS ................................................................................. 1-3 DOOR WINDOWS ........................................................................... 1-7DRINK HOLDER ............................................................................ 1-40DRIVE BELTS ............................................................................... 6-16DRIVING FOR ECONOMY ............................................................ 2-11 E EFFECTIVE BRAKING .................................................................... 2-9ELECTRIC COOLING FANS ......................................................... 6-18EMISSION CONTROL SYSTEM ..................................................... 7-1

JK000A1-A 10. INDEX

10