check engine Hyundai Matrix 2006 Manual Online

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2006, Model line: Matrix, Model: Hyundai Matrix 2006Pages: 490, PDF Size: 11.58 MB

Page 402 of 490

3 IN CASE OF EMERGENCY

2IF THE ENGINE WILL NOT START

SD020B1-E If the Engine Cannot be Cranked

1. If the vehicle is fitted with manualtransaxle, ensure that the clutch pedal is depressed whilst cranking the engine. If the vehicle is fitted with automatic transaxle, ensure that the transaxle

selector is at the "P" or "N" position.

2. Check the battery terminals and con-

nections to ensure that these areclean and also tight.

3. If the ignition warning lights dim when

the engine is cranked and the batteryterminals have been checked, a dis- charged battery is indicated.

4. Do not attempt to push or tow start

the vehicle, refer to "Jump Starting"for information regarding engine start- ing when the battery is discharged. D010C02A-EAT If Engine Turns Over Normally but Does Not Start

D010B01FC 1. Check fuel level.

2. With the key in the "OFF" position,check all connectors at ignition coilsand spark plugs(For Petrol Engine)or check all connectors at glow plug and glow plug relay(For Diesel En- gine). Reconnect any that may bedisconnected or loose.

3. Check fuel line in the engine com-

partment.

4. If engine still refuses to start, call a Hyundai authorised repairer or seekother qualified assistance. SSA3020C

!

SD020A1-E Seek assistance from the nearest Hyundai authorised repairer with regardto the method of ignition and fuel sys- tem diagnosis.

CAUTION:

If the engine refuses to start, noattempt should be made to push or tow start the vehicle. Vehicles withautomatic transaxle or fuel injection will not be able to be started in this manner since no drive is transmittedthrough the automatic transaxle whilst the engine is not running, and in the case of fuel injected deriva-tives, the fuel pump will not operate under tow start conditions. In addi- tion, if the vehicle is equipped withan exhaust catalyst, damage to the catalyst may result if the vehicle is tow started.

Page 404 of 490

3 IN CASE OF EMERGENCY

4IF THE ENGINE OVERHEATS

SD040A2-E If the temperature gauge indicates over- heating:

1. Pull off the road and stop as soon as it is safe to do so.

2. Place the gear selector lever in "P" (automatic) or neutral (manual transaxle) and set the parking brake.If the air conditioning is on, turn it off.

3. If coolant is running out under the car

or steam is coming out from underthe bonnet stop the engine. Do not open the bonnet until the coolant has stopped running or the steaming hasstopped. If there is no visible loss of coolant and no steam, leave the engine running and check to be surethe engine cooling fan is operating. If the fan is not running, turn the engine off.

4. Check to see if the water pump drive belt is broken. If it is not broken,check to see that it is tight.If the drive belt seems to be satisfac- tory, check for coolant leaking from the radiator, hoses or under the car.(If the air conditioning had been in use, it is normal for cold water to be draining from it).

4. Connect the red jump cable to the

positive (+) terminal of the boosterbattery and the other end to the positive (+) terminal of the discharged battery.

5. Attach the black jump cable to the negative (-) terminal of the boosterbattery, and the other end to a groundpoint within the engine compartment of the vehicle with the flat battery. Do not connect to the negative batteryterminal of the flat battery since sparks may be generated with the subsequent risk of explosion.

6. Raise the booster vehicle engine speed to 2,000 r.p.m. and start theengine of the vehicle with the flatbattery.

7. Switch "ON" the main beam

headlamps before carefully remov-ing the jumper cables in the reverse order of attachment. Once the jumper cables have been removed, switch"OFF" the main beam headlamps. CAUTION:

If the jump cables are incorrectlyinstalled, damage to the vehicle elec- trical system may occur, in particu- lar the electronic components suchas the Fuel Injection system com- puter and the Automatic Transaxle computer. The battery must never bedisconnected whilst the engine is running.

!

Page 405 of 490

3

IN CASE OF EMERGENCY

5

!

!

!WARNING:

Whilst the engine is running, keep hands and clothing away from mov- ing parts such as the fan and drive belts to prevent injury. 5. If the water pump drive belt is broken

or coolant is leaking out, stop theengine immediately and call the near- est Hyundai authorised repairer for assistance.

WARNING (Diesel only):

Never work on injection system with engine running or within 30 seconds after shutting off engine. High pres-sure pump, rail, injectors and high pressure pipes are subject to high pressure even after the enginestopped. The fuel jet produced by fuel leaks may cause serious injury, if it touch the body. People usingpacemakers should ensure that they keep a distance of 30cm from the ECU or wiring harness within theengine room whilst engine is run- ning, since the high currents in the Common Rail system produce con-siderable magnetic fields.!

WARNING:

Do not remove the radiator cap when the engine is hot since steam and boiling water may be ejected fromthe radiator resulting in burns or scalding.

6. If the cause of the overheating can- not be found, wait until the engine temperature has returned to normal. Then, if coolant has been lost, care-fully remove the radiator cap and add water to bring the fluid level in the reservoir up to the base of the radia-tor fill opening. Fill the coolant ex- pansion tank to the halfway mark.

7. Proceed with caution until it is estab- lished that the engine is operatingnormally. If the engine overheats repeatedly, the advice of a Hyundaiauthorised repairer should be sought. CAUTION:

Serious loss of coolant indicatesthere is a leak in the cooling system and this should be checked as soon as possible by a Hyundai authorisedrepairer.

Page 414 of 490

3 IN CASE OF EMERGENCY

14IF YOU LOSE YOUR KEYS

NOTE: Before towing, check the level of the automatic transaxle fluid. If it is be- low the "HOT" range on the dipstick,add fluid. If you cannot add fluid, a towing dolly must be used. D120A01A-EAT Information about the key of immobiliser system will be found on page 1-4.

!

EMERGENCY TOWING

D080D04A-EAT For emergency towing when no com- mercial tow vehicle is available, attach a tow cable, chain or strap to one of thetowing hooks under the front/rear of your vehicle. Do not attempt to tow your vehicle in this manner on any unpavedsurface. This could result in serious damage to your vehicle. Nor should towing be attempted if thewheels, drive train, axles, steering or brakes are damaged. Before towing, be sure the transaxle is in neutral and thekey is in "ACC" (with the engine off) or in the "ON" position (with the engine running). A driver must be in the towedvehicle to steer it and operate the brakes. D080D04FC

Front

Rear CAUTION:

If the car is being towed with all four wheels on the ground, it can be towed only from the front. Be sure that the transaxle is in neutral. Do not tow at speeds greater than 30 mph(50 km/h) and for more than 15 miles (25 km). Be sure the steering is unlocked byplacing the key in the "ACC" posi- tion. A driver must be in the towed vehicle to operate the steering andbrakes

Page 421 of 490

5VEHICLE MAINTENANCE REQUIREMENTS

2

SF030B1-E

SERVICE HISTORY

It is important that all scheduled main-

tenance services are recorded in the warranty and service passport to en- sure that proof of maintenance is avail-able when warranty service is required.

SF020C2-E

Specified Scheduled Procedures

The Specified scheduled procedures

are listed in the maintenance chartsbeginning at page 5-3. The operations specified must be performed at the time or mileage intervals shown irre-spective of whether the mileage inter- val has been reached before the speci- fied time interval.

Certain lubricants and components

degrade with both time and mileage(e.g. engine oil and brake fluid) andtherefore it is not permissable to base the maintenance schedule upon mile- age alone. It is strongly recommendedthat the maintenance operations are

SF020A1-E To ensure the continued reliability and safety of the vehicle, certain routine maintenance operations are requiredat specific mileage or time intervals.It is the responsibility of the vehicleowner to ensure that the maintenanceschedules shown in both this Owners Manual and the Warranty and Service Passport are adhered to.The new vehicle warranty may beinvalidated if the routine maintenanceoperations are not performed in line with the recommendations outlined and the safety and durability of the vehicleadversely affected.It is recommended that all mainte-nance operations with the exception ofthe daily operating checks are en- trusted to a Hyundai authorised re- pairer to ensure that the latest repairand maintenance procedures and specialised servicing tools are em- ployed.In addition, the use of genuine Hyundaireplacement parts will ensure that thevehicle safety and performance will not be compromised.

performed by the factory-trained or distributor-trained technicians at yourHyundai authorised repairer because of the need for specialised knowledge and tooling and to ensure that nopossibility of invalidating the manufac- turers warranty exists.

The maintenance schedules relate to

vehicles operated under normal condi-tions, vehicles which are operated under adverse conditions will requiremore frequent maintenance which is described at page 5-6. NOTE:

Service schedules may change de-

pending on individual country needs. Please ask your localHyundai authorised repairer for a copy of the service schedule that relates to that country.

MAINTENANCE AND SERVICING REQUIREMENTS

NOTE:The inspection and testing of cer-

tain electronic fuel injection/engine management and automatic trans- mission control systems requirespecialised electronic equipment specifically designed for Hyundai vehicles. The use of general pur-pose electrical test equipment may result in damage to the control unit microprocessors.

Page 424 of 490

5

VEHICLE MAINTENANCE REQUIREMENTS

5

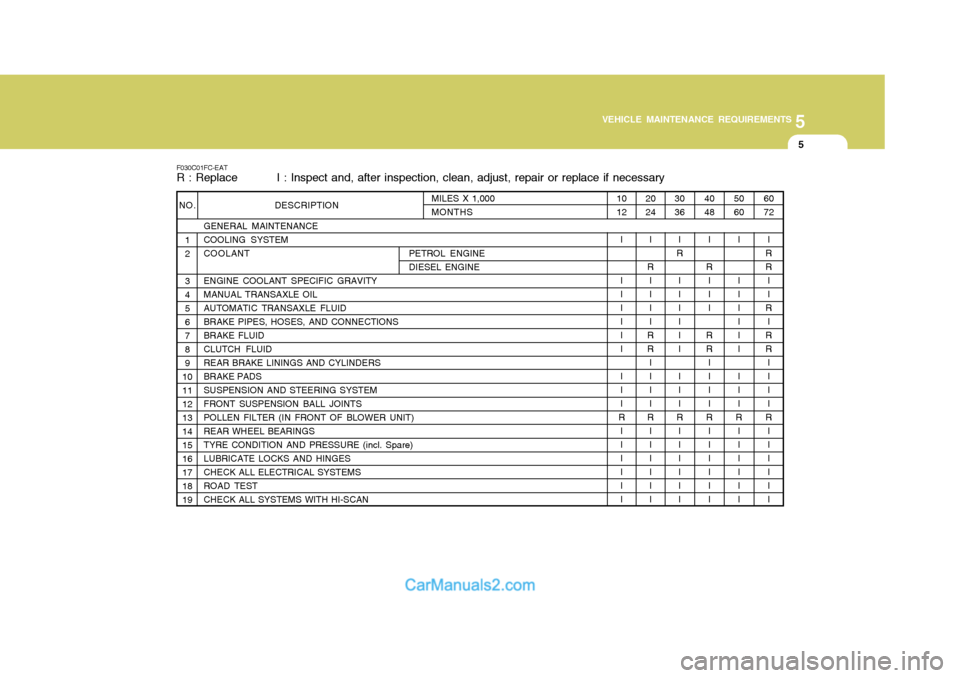

F030C01FC-EAT R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if necessary

DESCRIPTION

GENERAL MAINTENANCE COOLING SYSTEMCOOLANT PETROL ENGINEDIESEL ENGINE

ENGINE COOLANT SPECIFIC GRAVITYMANUAL TRANSAXLE OILAUTOMATIC TRANSAXLE FLUIDBRAKE PIPES, HOSES, AND CONNECTIONSBRAKE FLUIDCLUTCH FLUIDREAR BRAKE LININGS AND CYLINDERSBRAKE PADSSUSPENSION AND STEERING SYSTEMFRONT SUSPENSION BALL JOINTSPOLLEN FILTER (IN FRONT OF BLOWER UNIT)REAR WHEEL BEARINGSTYRE CONDITION AND PRESSURE (incl. Spare)LUBRICATE LOCKS AND HINGESCHECK ALL ELECTRICAL SYSTEMSROAD TESTCHECK ALL SYSTEMS WITH HI-SCAN

NO.

12 3 456789

10111213141516171819

60 72

I

RR II

R I

RR IIII

R IIIIII

5060

I I IIIII I II

R IIIIII

4048

I

R III

RR IIII

R IIIIII

3036

I

R

IIIIII I II

R IIIIII

2024

I

R IIII

RR IIII

R IIIIII

1012

I I IIIII I II

R IIIIII

MILES X 1,000 MONTHS

Page 426 of 490

5

VEHICLE MAINTENANCE REQUIREMENTS

7EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

!

6ZF060M1-A

o Engine Oil and Filter

The engine oil and filter should be changed at the intervals specified in the maintenance schedule. If the car is being driven in severe conditions,more frequent oil and filter changes are required. 6ZF060B1-A

o Drive Belts

Inspect all drive belts for evidence of cuts, cracks, excessive wear or oil contamination and replace if neces- sary. Drive belts should be checkedperiodically for proper tension and ad- justed as necessary. 6ZF060C1-A

o Fuel Filter A clogged filter can limit the speed at which the vehicle may be driven, dam- age the emission system and cause hard starting. If an excessive amountof foreign matter accumulates in the fuel tank, the filter may require re- placement more frequently.After installing a new filter, run theengine for several minutes, and checkfor leaks at the connections.

WARNING (Diesel only):

Never work on injection system with engine running or within 30 sec- onds after shutting off engine. Highpressure pump, rail, injectors and high pressure pipes are subject to high pressure even after the enginestopped. The fuel jet produced by fuel leaks may cause serious injury, if it contacts the body. People usingpacemakers should ensure that they keep a distance of 30cm from the ECU or wiring harness within theengine room whilst engine is run- ning, since the high currents in the Common Rail system produce con-siderable magnetic fields.

6ZF060D2-A

o Fuel lines, Fuel Hoses and

Connections

Check the fuel lines, fuel hoses and connections for leakage and damage. Replace any damaged or leaking parts immediately.

Page 427 of 490

5VEHICLE MAINTENANCE REQUIREMENTS

8

6ZF060H1-A

o Air Cleaner Filter

A Genuine Hyundai air cleaner filter is

recommended when filter is replaced.

6ZF060J1-A

o Spark Plugs

Make sure to install new spark plugs

of the correct heat range.

6ZF070B1-A

o Cooling System

Check the cooling system part, such

as radiator, coolant reservoir, hoses and connections for leakage and dam- age. Replace any damaged parts.

6ZF060E1-A

o Timing Belt Replace timimg belt and inspect all associated parts related for damage and deformation. Replace any dam- aged parts immediately. 6ZF060G1-A

o Vapour Hose and Fuel Filler Cap The vapour hose and fuel filler cap should be inspected at those intervals specified in the maintenance sched-ule. Make sure that a new vapour hose or fuel filler cap is correctly replaced.

6ZF060F1-A

o Vacuum, Crankcase

Ventilation Hoses

Inspect the surface of hoses for evi-

dence of heat and/or mechanical dam-age. Hard and brittle rubber, cracking, tears, cuts, abrasions, and excessiveswelling indicate deterioration. Partic- ular attention should be paid to exam- ining those hose surfaces nearest tohigh heat sources, such as the ex- haust manifold.

Inspect the hose routing to assure that

the hoses do not come in contact withany heat source, sharp edges or mov- ing component which might cause heatdamage or mechanical wear. Inspect all hose connections, such as clamps and couplings, to make sure they aresecure, and that no leaks are present. Hoses should be replaced immedi- ately if there is any evidence of dete-rioration or damage. F060N02E-AAT

o Valve Clearance

Inspect excessive valve noise and/or

engine vibration and adjust if neces-sary. A qualified technician should perform the operation.

Page 428 of 490

5

VEHICLE MAINTENANCE REQUIREMENTS

9

6ZF070F1-A

o Brake Hoses and Lines Visually check for proper installation, chafing, cracks, deterioration and any leakage. Replace any deteriorated or damaged parts immediately. 6ZF070G2-A

o Brake Fluid Check brake fluid level in the brake fluid reservoir. The level should be between "MIN" and "MAX" marks on the side of the reservoir. Use onlyhydraulic brake fluid conforming to DOT 3 or DOT 4.

6ZF070H1-A

o Rear Brake Drums And

Linings/Parking Brake

Check the rear brake drums and lin-

ings for scoring, burning, leaking fluid, broken parts, and excessive wear. In- spect the parking brake system in- cluding the parking brake lever andcables. For detailed service proce- dures, refer to the Shop Manual.

6ZF070D1-A

o Manual Transaxle Oil

Inspect the manual transaxle oil ac-

cording to the maintenance schedule. NOTE:

If the oil level is low, check for

possible leaks before adding oil. Do not overfill. F070E05A-AAT

o Automatic Transaxle Fluid The fluid level should be in the "HOT" range of the dipstick, after the engine and transaxle are at normal operating temperature. Check the automatictransaxle fluid level with the engine running and the transaxle in neutral, with the parking brake properly ap-plied. Use Hyundai Genuine ATF SP- III, DIAMOND ATF SP-III, SK ATF SP-III or other brands approved byHyundai Motor Co., when adding or changing fluid.

6ZF070C1-A

o Engine Coolant

The coolant should be changed at

the intervals specified in the mainte-nance schedule.

Page 429 of 490

5VEHICLE MAINTENANCE REQUIREMENTS

10

6ZF070L1-A

o Suspension Mounting Bolts Check the suspension connections for looseness or damage. Retighten to thespecified torque.6ZF070J1-A

o Brake Pads, Calipers and Rotors

Check the pads for excessive wear,

discs for run out and wear, and cali- pers for fluid leakage.

6ZF070K1-A

o Exhaust Pipe and Muffler

Visually inspect the exhaust pipes,

silencer and hangers for cracks, dete- rioration, or damage. Start the engine and listen carefully for any exhaust gas leakage. Tighten connections orreplace parts as necessary. 6ZF070M1-A

o Steering Gear Box, Linkage &

Boots/Lower arm Ball Joint

With the vehicle stopped and engine

off, check for excessive freeplay in the steering wheel.

Check the linkage for bends or dam-

age. Check the dust boots and balljoints for deterioration, cracks, or dam- age. Replace any damaged parts.

6ZF070N1-A

o Power Steering Pump, Belt

and Hoses

Check the power steering pump and

hoses for leakage and damage. Re- place any damaged or leaking parts immediately. Inspect the power steer-ing belt for evidence of cuts, cracks, excessive wear, oil contamination and proper tension. Replace or adjust it ifnecessary. 6ZF070P1-A

o Driveshafts and Boots

Check the drive shafts, boots andclamps for cracks, deterioration, or damage. Replace any damaged parts and, if necessary, repack the grease. 6ZF070Q1-A

o Air conditioning Refrigerant

Check the air conditioning lines and connections for leakage and damage.Check air conditioning performance according to the relevant shop manual if necessary.