engine coolant Hyundai Terracan 2004 Owner's Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2004, Model line: Terracan, Model: Hyundai Terracan 2004Pages: 361, PDF Size: 4.69 MB

Page 165 of 361

DO-IT-YOURSELF MAINTENANCE 6-13

G110D03Y

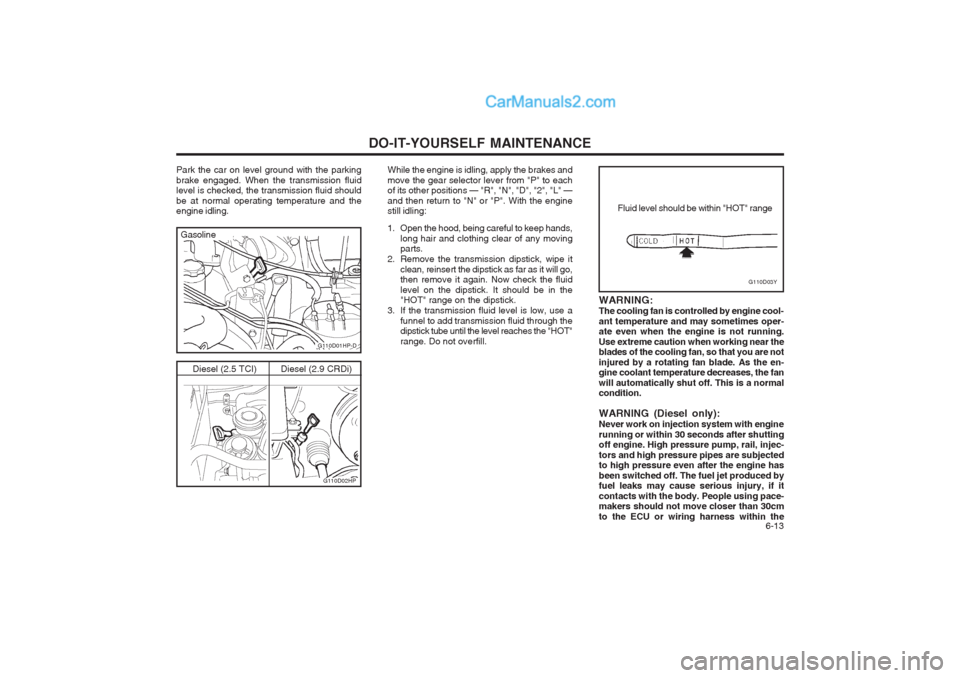

Fluid level should be within "HOT" range

WARNING: The cooling fan is controlled by engine cool-ant temperature and may sometimes oper- ate even when the engine is not running. Use extreme caution when working near the blades of the cooling fan, so that you are not injured by a rotating fan blade. As the en- gine coolant temperature decreases, the fan will automatically shut off. This is a normal condition. WARNING (Diesel only): Never work on injection system with enginerunning or within 30 seconds after shutting off engine. High pressure pump, rail, injec- tors and high pressure pipes are subjected to high pressure even after the engine has been switched off. The fuel jet produced by fuel leaks may cause serious injury, if it contacts with the body. People using pace- makers should not move closer than 30cm to the ECU or wiring harness within the

Park the car on level ground with the parking brake engaged. When the transmission fluid level is checked, the transmission fluid should be at normal operating temperature and the engine idling.

While the engine is idling, apply the brakes and move the gear selector lever from "P" to each of its other positions — "R", "N", "D", "2", "L" — and then return to "N" or "P". With the engine still idling:

1. Open the hood, being careful to keep hands,

long hair and clothing clear of any moving parts.

2. Remove the transmission dipstick, wipe it clean, reinsert the dipstick as far as it will go,then remove it again. Now check the fluid level on the dipstick. It should be in the "HOT" range on the dipstick.

3. If the transmission fluid level is low, use a funnel to add transmission fluid through thedipstick tube until the level reaches the "HOT" range. Do not overfill.

G110D01HP-D

Gasoline

Diesel (2.9 CRDi)

Diesel (2.5 TCI)

G110D02HP

Page 172 of 361

DO-IT-YOURSELF MAINTENANCE

6-20

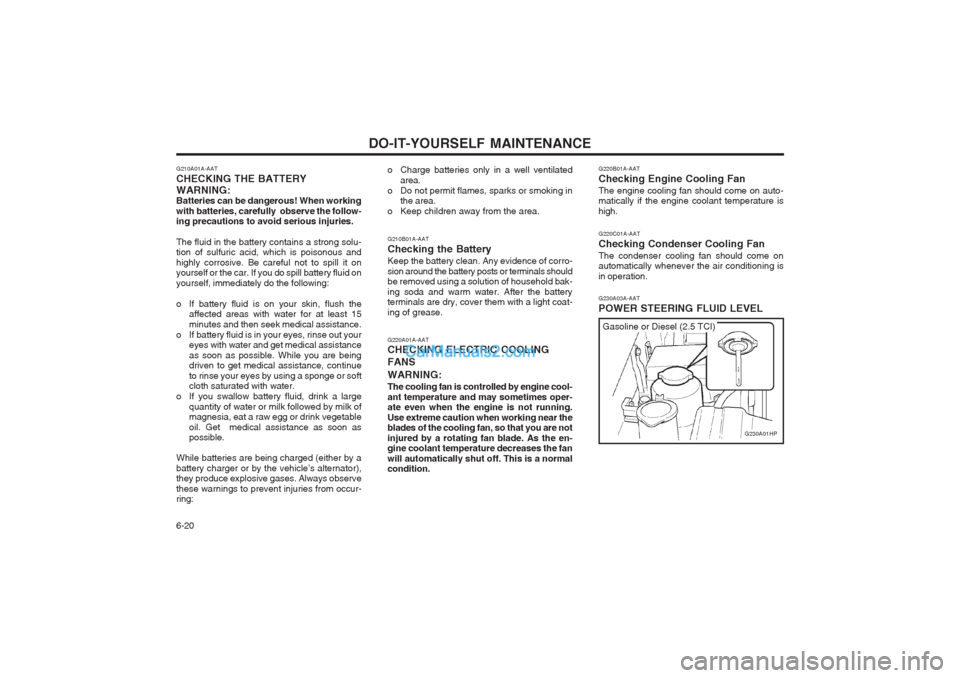

G220B01A-AAT Checking Engine Cooling FanThe engine cooling fan should come on auto- matically if the engine coolant temperature is high. G220C01A-AAT Checking Condenser Cooling FanThe condenser cooling fan should come on automatically whenever the air conditioning is in operation. G230A03A-AAT POWER STEERING FLUID LEVEL

G230A01HP

Gasoline or Diesel (2.5 TCI)

o Charge batteries only in a well ventilated

area.

o Do not permit flames, sparks or smoking in the area.

o Keep children away from the area. G210B01A-AAT Checking the BatteryKeep the battery clean. Any evidence of corro- sion around the battery posts or terminals should be removed using a solution of household bak- ing soda and warm water. After the battery terminals are dry, cover them with a light coat- ing of grease. G220A01A-AAT CHECKING ELECTRIC COOLING FANS WARNING: The cooling fan is controlled by engine cool- ant temperature and may sometimes oper- ate even when the engine is not running. Use extreme caution when working near the blades of the cooling fan, so that you are not injured by a rotating fan blade. As the en- gine coolant temperature decreases the fan will automatically shut off. This is a normal condition.

G210A01A-AAT CHECKING THE BATTERYWARNING: Batteries can be dangerous! When working with batteries, carefully observe the follow- ing precautions to avoid serious injuries. The fluid in the battery contains a strong solu- tion of sulfuric acid, which is poisonous and highly corrosive. Be careful not to spill it on yourself or the car. If you do spill battery fluid on yourself, immediately do the following:

o If battery fluid is on your skin, flush the

affected areas with water for at least 15 minutes and then seek medical assistance.

o If battery fluid is in your eyes, rinse out your eyes with water and get medical assistanceas soon as possible. While you are being driven to get medical assistance, continue to rinse your eyes by using a sponge or soft cloth saturated with water.

o If you swallow battery fluid, drink a large quantity of water or milk followed by milk ofmagnesia, eat a raw egg or drink vegetable oil. Get medical assistance as soon as possible.

While batteries are being charged (either by a battery charger or by the vehicle’s alternator), they produce explosive gases. Always observe these warnings to prevent injuries from occur- ring:

Page 175 of 361

DO-IT-YOURSELF MAINTENANCE 6-23

G260A01HP-GAT

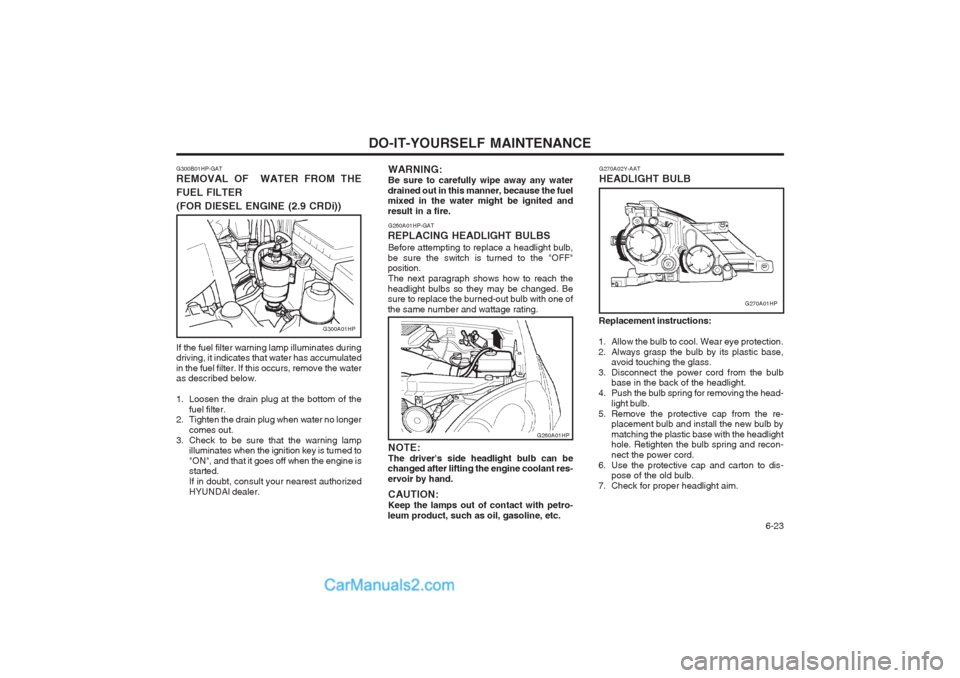

REPLACING HEADLIGHT BULBS Before attempting to replace a headlight bulb,

be sure the switch is turned to the "OFF" position. The next paragraph shows how to reach the

headlight bulbs so they may be changed. Besure to replace the burned-out bulb with one of the same number and wattage rating. WARNING:Be sure to carefully wipe away any water

drained out in this manner, because the fuel mixed in the water might be ignited and result in a fire.

NOTE:The driver's side headlight bulb can be

changed after lifting the engine coolant res-ervoir by hand.

CAUTION:Keep the lamps out of contact with petro-

leum product, such as oil, gasoline, etc.

G260A01HP Replacement instructions:

1. Allow the bulb to cool. Wear eye protection.

2. Always grasp the bulb by its plastic base, avoid touching the glass.

3. Disconnect the power cord from the bulb base in the back of the headlight.

4. Push the bulb spring for removing the head-

light bulb.

5. Remove the protective cap from the re- placement bulb and install the new bulb bymatching the plastic base with the headlight hole. Retighten the bulb spring and recon- nect the power cord.

6. Use the protective cap and carton to dis- pose of the old bulb.

7. Check for proper headlight aim. G270A02Y-AAT HEADLIGHT BULB

G270A01HP

G300B01HP-GAT REMOVAL OF WATER FROM THE FUEL FILTER

(FOR DIESEL ENGINE (2.9 CRDi))

G300A01HP

If the fuel filter warning lamp illuminates during driving, it indicates that water has accumulated in the fuel filter. If this occurs, remove the water as described below.

1. Loosen the drain plug at the bottom of the fuel filter.

2. Tighten the drain plug when water no longer

comes out.

3. Check to be sure that the warning lamp illuminates when the ignition key is turned to "ON", and that it goes off when the engine is started. If in doubt, consult your nearest authorizedHYUNDAI dealer.

Page 176 of 361

DO-IT-YOURSELF MAINTENANCE

6-24 6. Draw the vertical line (through the center of

each headlight) and the horizontal line (through the center of each headlight) on the aiming screen.

(1) Horizontal line dimension from ground :Low Beam : 894 mm (35.1 in.)

High Beam : 839 mm (33 in.)

(2) Distance between each vertical line : Low Beam : 1,316 mm (51.8 in.)

High Beam : 1,076 mm (42.4 in.)

And then, draw a parallel line at 38 mm (1.50 in.) under the horizontal line in case of adjusting the low beam or at 21 mm (0.83 in.) under the horizontal line in case of adjusting the high beam.

7. Adjust each cut-off line of the low beam to the parallel line with a phillips screwdriver - VERTICAL AIMING.

8. Adjust each cut-off line of the low beam to

the each vertical line with a phillips screw-driver - HORIZONTAL AIMING.

G290A01HP-GAT

HEADLIGHT AIMING ADJUSTMENT

G290A01HP

Horizontal aiming (Low Beam)

Vertical aiming (Low Beam)

Before performing aiming adjustment, make sure of the following.

1. Keep all tires inflated to the correct pres- sure.

2. Place the vehicle on level ground and press the front bumper & rear bumper down sev-eral times. Place vehicle at a distance of 3m (118.1 in.) from the test wall.

3. See that the vehicle is unloaded (except for

full levels of coolant, engine oil and fuel, andspare tire, jack, and tools). Have the driver or equivalent weight placed in driver's seat.

4. Clean the headlight lens and turn on the headlight.

5. Open the hood. Vertical aiming (High Beam)

Horizontal aiming(High Beam)

G270A02HP

WARNING: The halogen bulb contains gas under pres- sure and if impacted could shatter, resulting in flying fragments. Always wear eye pro- tection when servicing the bulb. Protect the bulb against abrasions or scratches and against liquids when lighted. Turn the bulb on only when installing in a headlight. Re- place the headlight if damaged or cracked. Keep the bulb out of the reach of children and dispose of the used bulb with care.

Page 179 of 361

EMISSION CONTROL SYSTEMS 7-1

7. EMISSION

CONTROL SYSTEMS

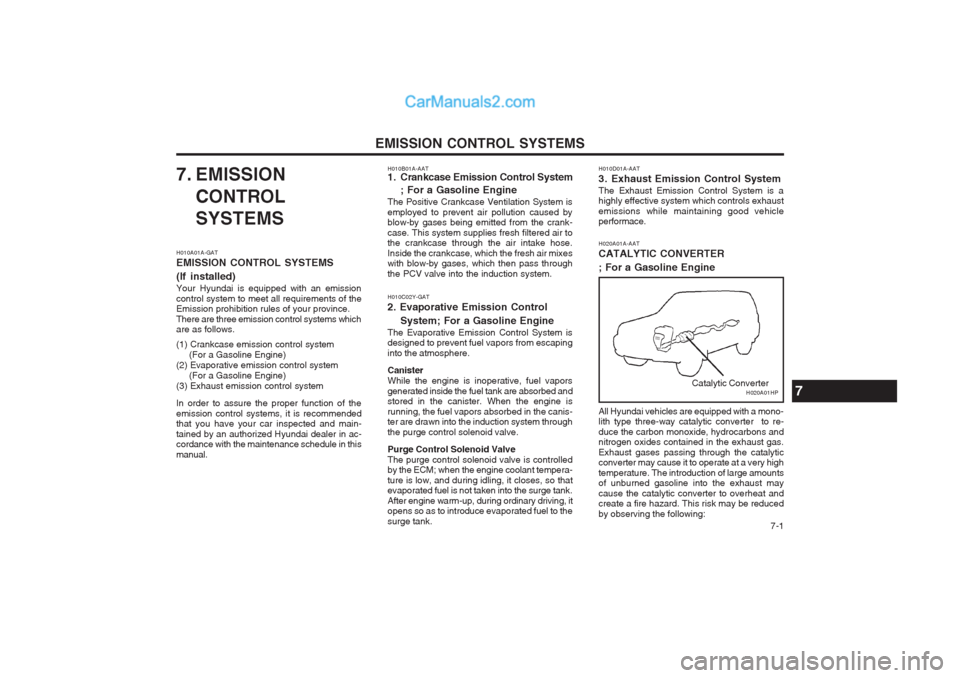

H010A01A-GAT EMISSION CONTROL SYSTEMS (If installed) Your Hyundai is equipped with an emission control system to meet all requirements of the Emission prohibition rules of your province. There are three emission control systems which are as follows. (1) Crankcase emission control system (For a Gasoline Engine)

(2) Evaporative emission control system (For a Gasoline Engine)

(3) Exhaust emission control system In order to assure the proper function of the emission control systems, it is recommended that you have your car inspected and main- tained by an authorized Hyundai dealer in ac- cordance with the maintenance schedule in this manual. H010C02Y-GAT 2. Evaporative Emission Control

System; For a Gasoline Engine

The Evaporative Emission Control System is

designed to prevent fuel vapors from escaping into the atmosphere. Canister While the engine is inoperative, fuel vapors

generated inside the fuel tank are absorbed and stored in the canister. When the engine is

running, the fuel vapors absorbed in the canis- ter are drawn into the induction system through the purge control solenoid valve. Purge Control Solenoid Valve The purge control solenoid valve is controlled

by the ECM; when the engine coolant tempera- ture is low, and during idling, it closes, so that evaporated fuel is not taken into the surge tank.

After engine warm-up, during ordinary driving, it opens so as to introduce evaporated fuel to the surge tank. H020A01A-AAT CATALYTIC CONVERTER ; For a Gasoline Engine

H020A01HP

Catalytic Converter

All Hyundai vehicles are equipped with a mono- lith type three-way catalytic converter to re- duce the carbon monoxide, hydrocarbons and nitrogen oxides contained in the exhaust gas. Exhaust gases passing through the catalytic converter may cause it to operate at a very high temperature. The introduction of large amounts of unburned gasoline into the exhaust may cause the catalytic converter to overheat and create a fire hazard. This risk may be reduced by observing the following:

H010B01A-AAT

1. Crankcase Emission Control System

; For a Gasoline Engine

The Positive Crankcase Ventilation System is employed to prevent air pollution caused by blow-by gases being emitted from the crank- case. This system supplies fresh filtered air to the crankcase through the air intake hose. Inside the crankcase, which the fresh air mixes with blow-by gases, which then pass through the PCV valve into the induction system.7

H010D01A-AAT

3. Exhaust Emission Control SystemThe Exhaust Emission Control System is a highly effective system which controls exhaust emissions while maintaining good vehicle performace.

Page 189 of 361

INDEX

10-2 D Defrosting/Defogging

......................................................................... 1-71

Door Locking, unlocking front door with a key ........................................ 1-6

Drink Holder ...................................................................................... 1-53

Drive Belts ............................................................................... 6-15, 6-18

Driving Driving for economy ...................................................................... 2-14

Smooth cornering .......................................................................... 2-15

Winter driving ................................................................................ 2-15

E Emission Control System ................................................................... 7-1

Engine

Before starting the engine ............................................................... 2-2Compartment (3.5 V6) ..................................................................... 6-1

Compartment (2.5 TCI) ................................................................... 6-2

Compartment (2.9 CRDi) ................................................................ 6-3

Coolant ............................................................................................ 6-7

Coolant temperature gauge ........................................................... 1-43

If the engine overheats ................................................................... 3-2

Number ............................................................................................ 8-1

Oil .................................................................................................... 6-4Starting ............................................................................................ 2-3

Engine Exhaust Can Be Dangerous ................................................... 2-1

FFan Speed Con trol ................................................................... 1-66, 1-75Fog Light

Front .............................................................................................. 1-48

Rear .............................................................................................. 1-48

Front Seats

Adjustable front seats ................................................................... 1-11

Adjustable headrests ..................................................................... 1-12

Adjusting seat forward and rearward ............................................1-11

Adjusting seatback angle .............................................................. 1-11

Fuel Capacity .......................................................................................... 9-1

Gauge ............................................................................................ 1-43

Unleaded gasoline ........................................................................... 1-1

Fuel Filler Lid Remote release ............................................................................. 1-62

Full-time 4WD Operation .................... ................................... 2-10 ~ 2-13

Fuses ................................................................................................ 6-18

G General Checks .................................................................................. 6-4

Glove Box ......................................................................................... 1-56

H Hazard Warning System ................................................................... 1-51

Headlight Aiming Adjustment ............................................................ 6-24

Headlight Leveling Device System ................................................... 1-65

Heating and Ventilation

Air flow control ......................................................... 1-68 ~ 1-69, 1-77

Temperature control ...................................................................... 1-69

Page 232 of 361

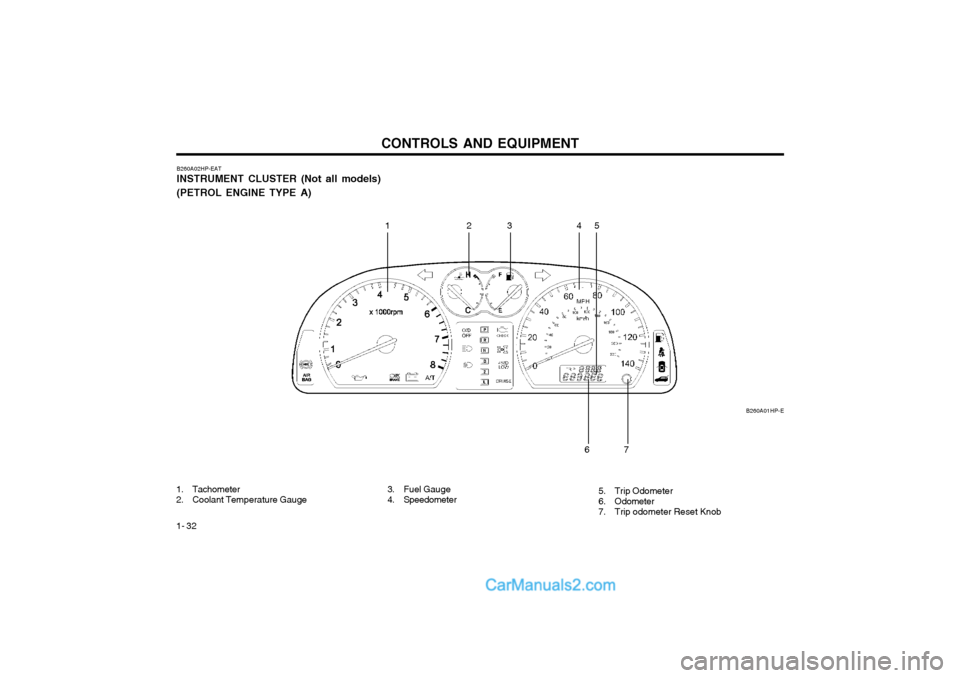

CONTROLS AND EQUIPMENT

1- 32

B260A01HP-E

B260A02HP-EAT INSTRUMENT CLUSTER (Not all models) (PETROL ENGINE TYPE A)

1. Tachometer

2. Coolant Temperature Gauge

12 345

7

6

3. Fuel Gauge

4. Speedometer 5. Trip Odometer

6. Odometer

7. Trip odometer Reset Knob

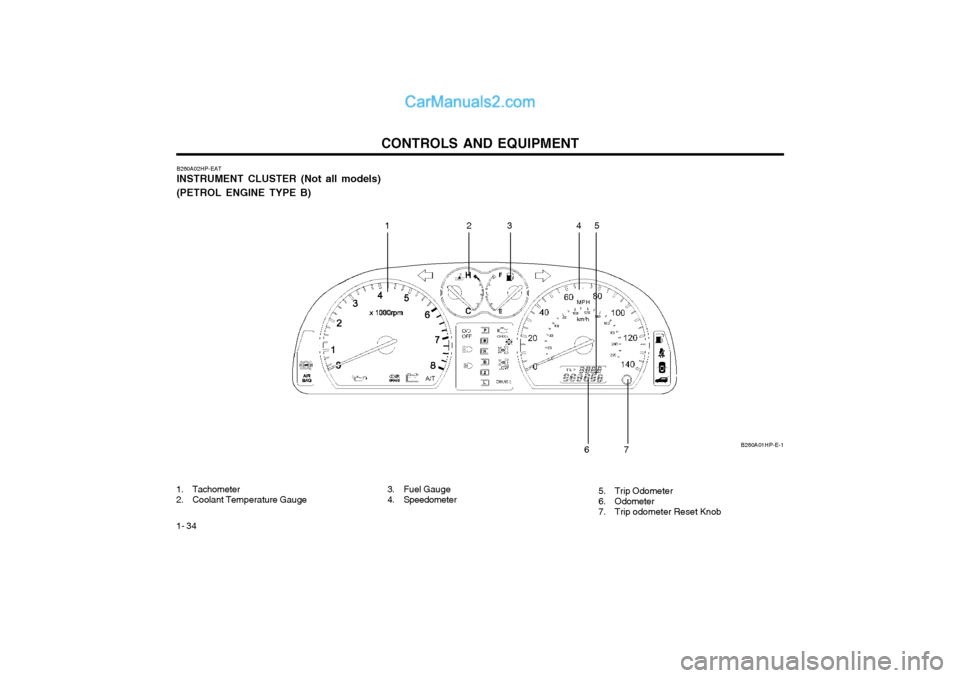

Page 234 of 361

CONTROLS AND EQUIPMENT

1- 34

B260A01HP-E-1

B260A02HP-EAT INSTRUMENT CLUSTER (Not all models) (PETROL ENGINE TYPE B)

1. Tachometer

2. Coolant Temperature Gauge

12 345

7

6

3. Fuel Gauge

4. Speedometer 5. Trip Odometer

6. Odometer

7. Trip odometer Reset Knob

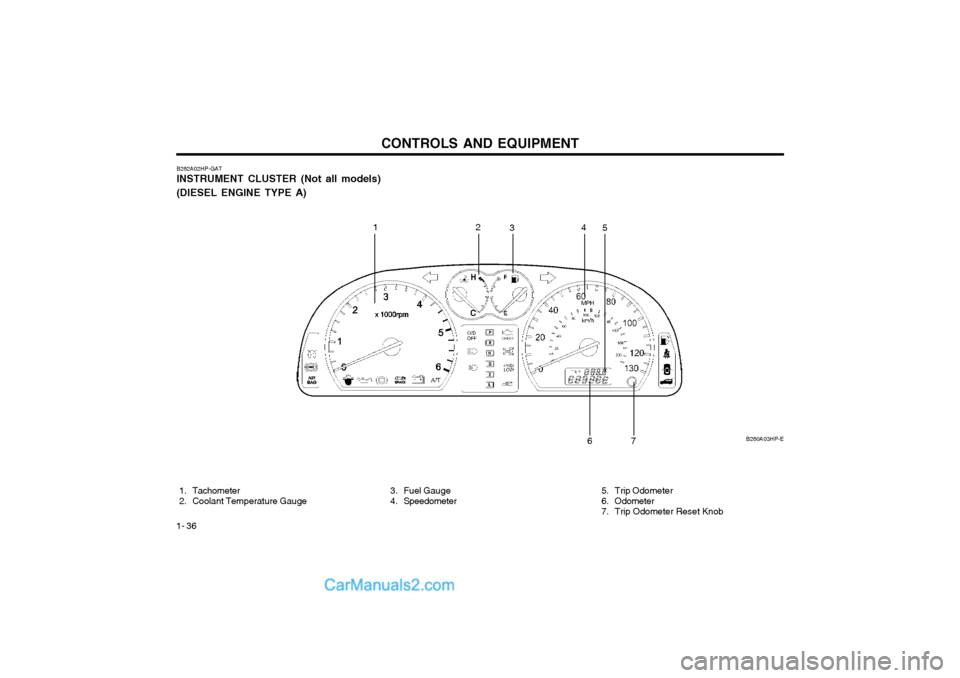

Page 236 of 361

CONTROLS AND EQUIPMENT

1- 36

B260A03HP-E

B262A02HP-GAT INSTRUMENT CLUSTER (Not all models) (DIESEL ENGINE TYPE A)

1. Tachometer

2. Coolant Temperature Gauge 3. Fuel Gauge

4. Speedometer

12

34

5

6

7

5. Trip Odometer

6. Odometer

7. Trip Odometer Reset Knob

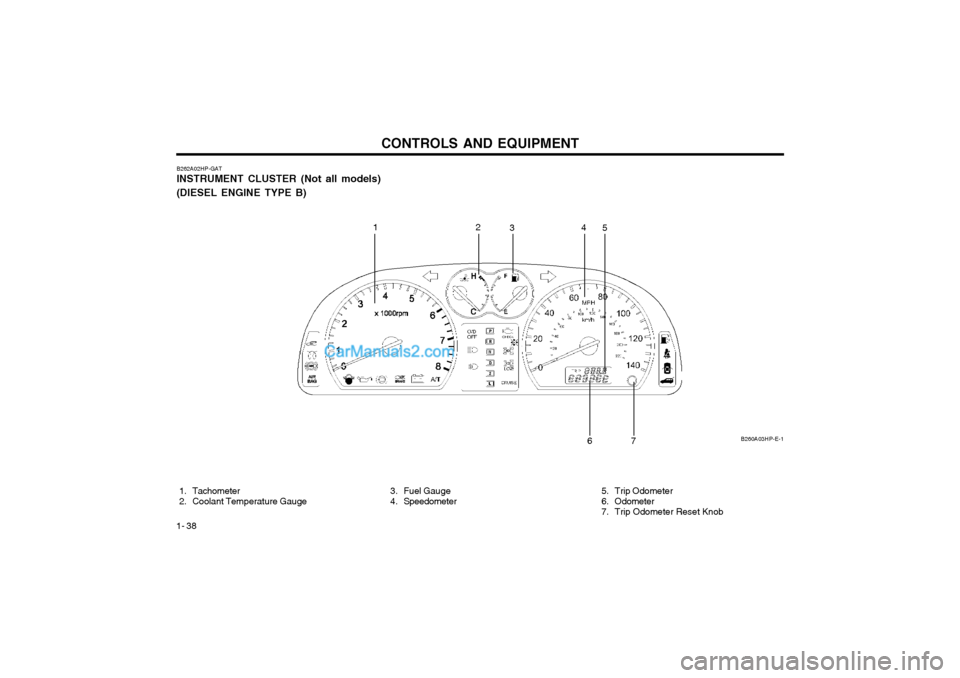

Page 238 of 361

CONTROLS AND EQUIPMENT

1- 38

B260A03HP-E-1

B262A02HP-GAT INSTRUMENT CLUSTER (Not all models) (DIESEL ENGINE TYPE B)

1. Tachometer

2. Coolant Temperature Gauge 3. Fuel Gauge

4. Speedometer

12

34

5

6

7

5. Trip Odometer

6. Odometer

7. Trip Odometer Reset Knob