belt Hyundai Terracan 2004 Owner's Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2004, Model line: Terracan, Model: Hyundai Terracan 2004Pages: 361, PDF Size: 4.69 MB

Page 125 of 361

DRIVING YOUR HYUNDAI

2- 16

C160H01A-AAT Use Approved Anti-Freeze in Window Washer System To keep the water in the window washer system from freezing, add an approved anti-freeze solu- tion in accordance with instructions on the con- tainer. Window washer anti-freeze is available from Hyundai dealers and most auto parts out- lets. Do not use engine coolant or other types of anti-freeze as these may damage the finish.

C160F01A-AAT Check Spark Plugs and Ignition System Inspect your spark plugs as described in Section 6 and replace them if necessary. Also check all ignition wiring and components to be sure they are not cracked, worn or damaged in any way.

C160G02A-GAT To Keep Locks from Freezing To keep the locks from freezing, squirt an ap- proved de-icer fluid or glycerine into the key opening. If a lock is covered with ice, squirt it with an approved de-icing fluid to remove the ice. If the lock is frozen internally, you may be able to thaw it out by using a heated key. Handle the heated key with care to avoid

injury.

NOTE: The proper temperature for using the immo- bilizer key is from -40°C (-40°F) to 80°C (176°F). If you heat the immobilizer key over 80°C (176°F) to open the frozen lock, it may cause damage to the transponder in its head. C160I01HP-GAT Don’t Let Your Parking Brake Freeze Under some conditions your parking brake can freeze in the engaged position. This is most likely to happen when there is an accumulation of snow or ice around or near the rear brakes or if the brakes are wet. If there is a risk the parking brake may freeze, apply it only temporarily while you put the gear selector lever in "P" (automatic) or in first or reverse gear (manual transmission) and block the rear wheels so the car cannot roll. Then release the parking brake. C160K01A-AAT Carry Emergency Equipment Depending on the severity of the weather where you drive your car, you should carry appropriate emergency equipment. Some of the items you may want to carry include tire chains, tow straps or chains, flashlight, emergency flares, sand, a shovel, jumper cables, a window scraper, gloves, ground cloth, coveralls, a blanket, etc.

C160J01A-AAT Don’t Let Ice and Snow Accumulate Underneath Under some conditions, snow and ice can build up under the fenders and interfere with the steer- ing. When driving in severe winter conditions where this may happen, you should periodically check underneath the car to be sure the move- ment of the front wheels and the steering compo- nents is not obstructed.

C180A01A-AAT USE OF LIGHTS Check your lights regularly for correct operation and always keep them clean. When driving dur- ing the day in conditions of poor visibility, it is helpful to drive with headlights on low beam. This enables you to be seen as well as to see.

C170A01A-AAT HIGHER SPEED MOTORING Pre-Trip Inspections 1. Tires: Adjust the tire inflation pressures to specifica- tion. Low tire inflation pressures will result in overheating and possible failure of the tires. Avoid using worn or damaged tires which may result in reduced traction or tire failure. NOTE: Never exceed the maximum tire inflation pres- sure shown on the tires. 2. Fuel, engine coolant and engine oil: High speed travel consumes more fuel than urban motoring. Do not forget to check both engine coolant and engine oil. 3. Drive belt: A loose or damaged drive belt may result in overheating of the engine.

Page 130 of 361

WHAT TO DO IN AN EMERGENCY

3-2 tinue to apply water to the affected area with a sponge or cloth.

o The gas produced by the battery during the

jump-start operation is highly explosive. Do not smoke or allow a spark or an open flame in the vicinity.

o The battery being used to provide the jump

start must be 12-volt. If you cannot determine that it is a 12-volt battery, do not attempt to use it for the jump start.

o To jump start a car with a discharged battery,

follow this procedure exactly:

1. If the booster battery is installed in another vehicle, be sure the two vehicles are nottouching.

2. Turn off all unnecessary lights and acces-

sories in both vehicles.

3. Attach the clamps of the jumper cable in the

exact location shown in the illustration. First, attach one clamp of the jumper cable to the positive (+) post or cable of the discharged battery. Then attach the other end of the same cable to the positive (+) post or cable of the booster battery. Next, using the other cable, attach one clamp to the negative (-) post or cable of the booster battery. Then attach the other end of that cable to a solid metal part of the engine away from the battery. Do not connect the cable to any moving part. 4. Start the engine in the car with the booster

battery and let it run for a few minutes. Thiswill help to assure that the booster battery is fully charged. During the jumping operation, run the engine in this vehicle at about 2000 rpm.

5. Start the engine in the car with the discharged

battery using the normal starting procedure. After the engine starts, leave the jumper cables connected and let the engine run at fast idle or about 2000 rpm for several min- utes.

6. Carefully remove the jumper cables in the

reverse order of attachment.

If you do not know why your battery became discharged (because the lights were left on, etc.), have the charging system checked by your Hyundai dealer. D030A02HP-AAT IF THE ENGINE OVERHEATS If your temperature gauge indicates overheating, you experience a loss of power, or hear loud pinging or knocking, the engine is probably too hot. If this happens to you, you should:

1. Pull off the road and stop as soon as it is safe

to do so.

2. Place the gear selector lever in "P" (auto- matic), or neutral (manual transmission) and set the parking brake. If the air conditioning is on, turn it off.

3. If engine coolant is running out under the car or steam is coming out from under the hood, stop the engine. Do not open the hood until the engine coolant has stopped running or the steaming has stopped. If there is no visible loss of coolant and no steam, leave the engine running and check to be sure the engine cooling fan is operating. If the fan is not running, turn the engine off.

4. Check to see if the water pump drive belt is

missing. If it is not missing, check to see that it is tight. If the drive belt seems to be satis- factory, check for engine coolant leaking from the radiator, hoses or under the car. (If the air conditioning had been in use, it is normal for cold water to be draining from it when you stop).

Page 131 of 361

WHAT TO DO IN AN EMERGENCY 3-3

WARNING: While the engine is running, keep hands and clothing away from moving parts such as the fan and drive belts to prevent injury. WARNING (Diesel only): Never work on injection system with engine running or within 30 seconds after shutting off engine. High pressure pump, rail, injec- tors and high pressure pipes are subject to high pressure even after the engine stopped. The fuel jet produced by fuel leaks may cause serious injury, if it touch the body. People using pacemakers should not move than 30cm closer to the ECU or wiring harness within the engine room while engine is running, since the high currents in the Common Rail system produce considerable magnetic fields.

5. If the water pump drive belt is broken or

coolant is leaking out, stop the engine im- mediately and call the nearest Hyundai deal- er for assistance.

WARNING: Do not remove the radiator cap when the engine is hot. This can allow coolant to be blown out of the opening and cause serious burns. D040A01HP-GAT SPARE TIREThe following instructions for the FULL SIZE spare tire should be observed: Check inflation pressure as soon as possible after installing the spare tire, and adjust to the specified pressure. The tire pressure should be periodically checked and maintained at the spec- ified pressure while the tire is stored.

Inflation Pressure

Tire Size

Full Size 200 kPa (29 psi)

Spare Tire Pressure

D040B03HP-GAT Handling the Spare Tire

1. Obtain the spare wheel rod (Jack handle)

after folding up the seat cushion of the second seat . To fold up the seat cushion, refer to the page 1-15.

The second seat

6. If you cannot find the cause of the overheat-

ing, wait until the engine temperature has returned to normal. Then, if coolant has been lost, carefully add coolant to the reservoir (Page 6-8) to bring the fluid level in the reser- voir up to the halfway mark.

7. Proceed with caution, keeping alert for fur-

ther signs of overheating. If overheating hap- pens again, call a Hyundai dealer for assis- tance.

CAUTION: Serious loss of coolant indicates there is a leak in the cooling system and this should be checked as soon as possible by a Hyundai dealer.

D040B01HP

D060B01HPB090B02HP

Page 143 of 361

CORROSION PREVENTION AND APPEARANCE CARE

4-4 E040E01A-AAT Cleaning the Windows You may use any household window cleaner on the windows. However, when cleaning the inside of the rear window be careful not to damage the rear window defroster wiring. E050A01A-AAT Any Questions? If you have any questions about the care of your car, consult your Hyundai dealer.

E040D01A-AAT Cleaning the Seat Belts To clean the seat belts, use a cloth or sponge with mild soap or detergent and warm water. Do not use strong detergents, dye, bleach or abra- sive materials on the seat belts as this may weaken the fabric. While cleaning the belts, inspect them for exces- sive wear, cuts, fraying or other signs of damage and replace them if necessary.

E040C01A-AAT Cleaning the Carpets Use a foam-type carpet cleaner. Cleaners of this type are available in aerosol cans in liquid form or powder. Read the instructions and follow them exactly. Using a vacuum cleaner with the appro- priate attachment, remove as much dirt from the carpets as possible. Apply the foam following the manufacturer’s directions, then rub in overlap- ping circles. Do not add water. These cleaners work best when the carpet is kept as dry as possible.

Page 145 of 361

VEHICLE MAINTENANCE REQUIREMENTS

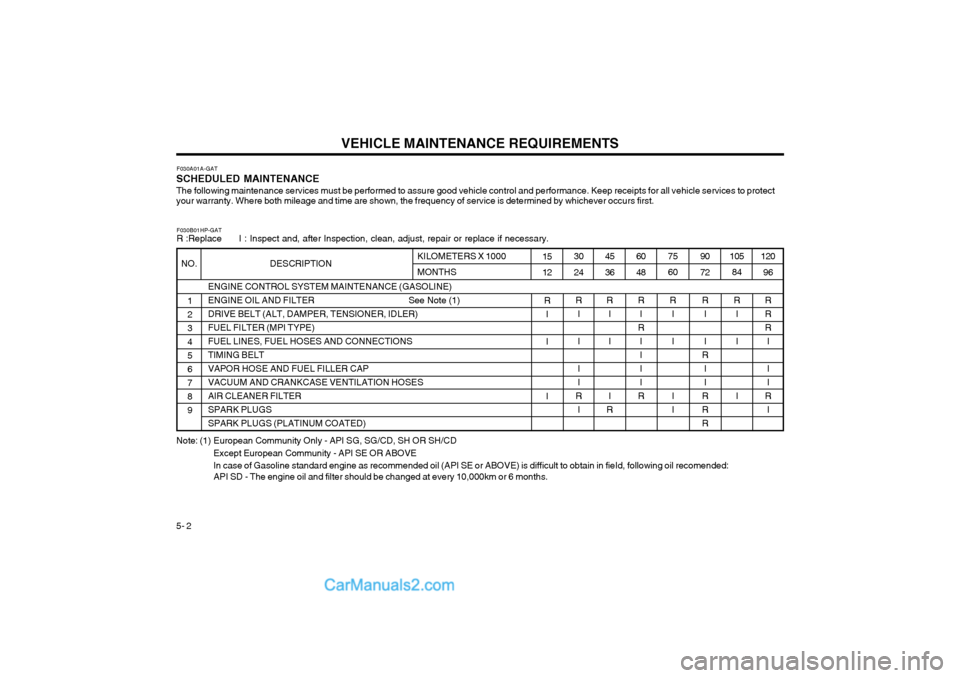

5- 2 F030A01A-GAT

SCHEDULED MAINTENANCE The following maintenance services must be performed to assure good vehicle control and performance. Keep receipts for all vehi cle services to protect

your warranty. Where both mileage and time are shown, the frequency of service is determined by whichever occurs first.

F030B01HP-GAT R :Replace I : Inspect and, after Inspection, clean, adjust, repair or replace if necessary.

ENGINE CONTROL SYSTEM MAINTENANCE (GASOLINE)

ENGINE OIL AND FILTER See Note (1)DRIVE BELT (ALT, DAMPER, TENSIONER, IDLER)FUEL FILTER (MPI TYPE)FUEL LINES, FUEL HOSES AND CONNECTIONSTIMING BELTVAPOR HOSE AND FUEL FILLER CAPVACUUM AND CRANKCASE VENTILATION HOSESAIR CLEANER FILTERSPARK PLUGSSPARK PLUGS (PLATINUM COATED)

NO. DESCRIPTION

1 2 3 4 5 6 7 8 9 120

96

RRR I I I

R I105

84

R I I I90 72

R I I

R I I

RRR75 60

R I I I I60 48

R I

R I III

R45 36

R I I I

R30 24

R I II I

R I

15 12

R I I IKILOMETERS X 1000 MONTHS

Note: (1) European Community Only - API SG, SG/CD, SH OR SH/CD Except European Community - API SE OR ABOVE

In case of Gasoline standard engine as recommended oil (API SE or ABOVE) is difficult to obtain in fieId, following oil recomen ded:

API SD - The engine oil and filter should be changed at every 10,000km or 6 months.

Page 146 of 361

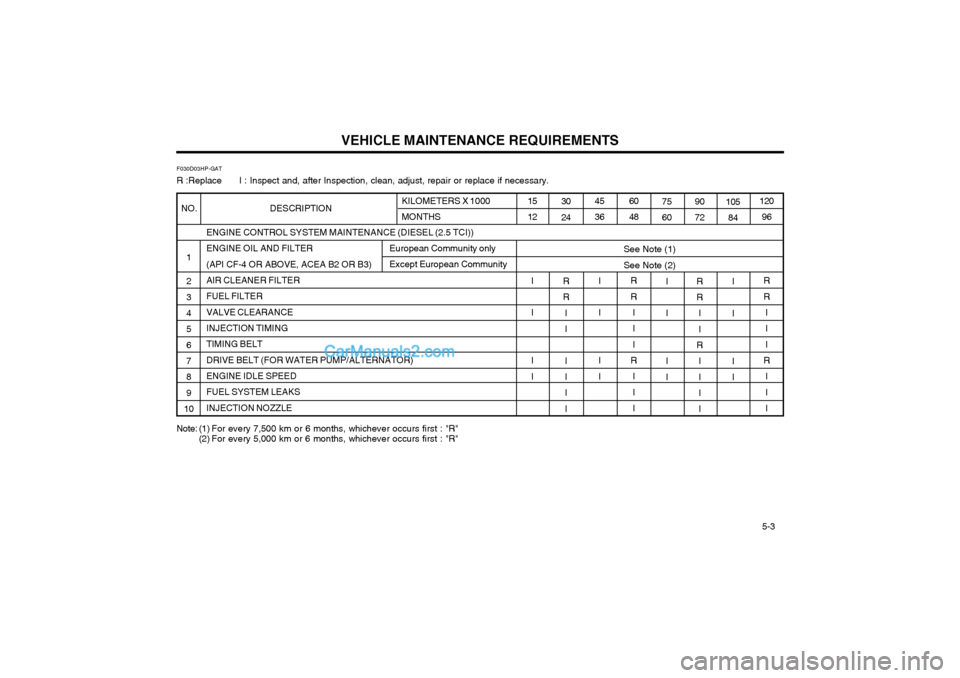

VEHICLE MAINTENANCE REQUIREMENTS 5-3

KILOMETERS X 1000 MONTHS

F030D03HP-GAT R :Replace I : Inspect and, after Inspection, clean, adjust, repair or replace if necessary.

ENGINE CONTROL SYSTEM MAINTENANCE (DIESEL (2.5 TCI)) ENGINE OIL AND FILTER(API CF-4 OR ABOVE, ACEA B2 OR B3) AIR CLEANER FILTER FUEL FILTERVALVE CLEARANCE INJECTION TIMING TIMING BELTDRIVE BELT (FOR WATER PUMP/ALTERNATOR) ENGINE IDLE SPEED FUEL SYSTEM LEAKSINJECTION NOZZLE

NO. DESCRIPTION

1 2 34 5 67 8 9

10120 96

R R I I I

R III105 84

I I I I90 72R R II

R

II I I75 60

I I I I60 48RR I I I

R III45 36

I I I I30 24R R I I I I I I15 12

I I I I

See Note (1) See Note (2)

Note: (1) For every 7,500 km or 6 months, whichever occurs first : "R" (2) For every 5,000 km or 6 months, whichever occurs first : "R"European Community only Except European Community

Page 147 of 361

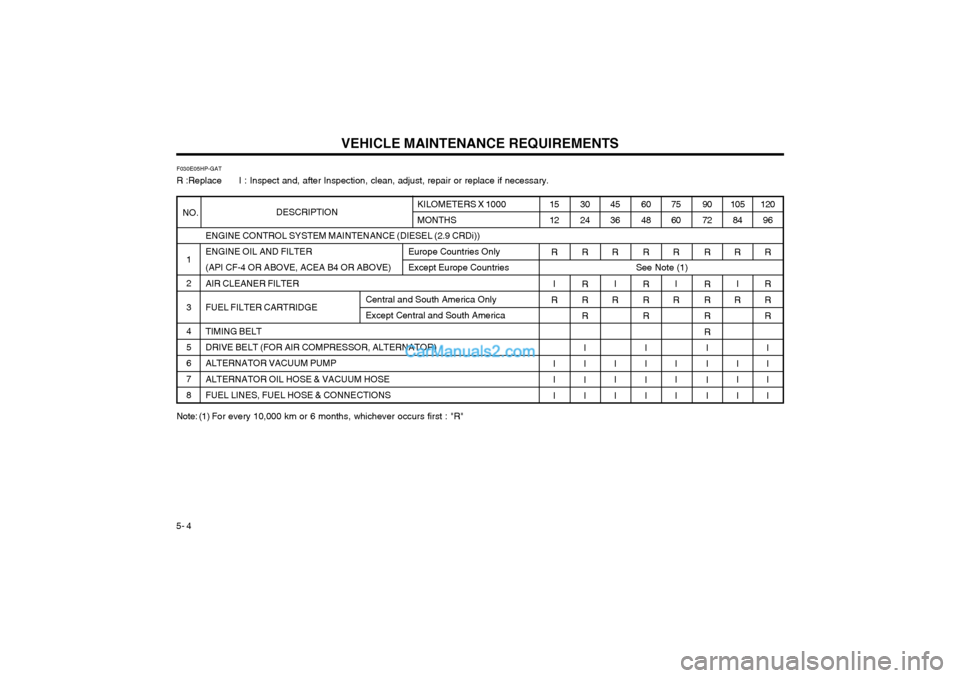

VEHICLE MAINTENANCE REQUIREMENTS

5- 4

F030E05HP-GAT R :Replace I : Inspect and, after Inspection, clean, adjust, repair or replace if necessary.

ENGINE CONTROL SYSTEM MAINTENANCE (DIESEL (2.9 CRDi)) ENGINE OIL AND FILTER (API CF-4 OR ABOVE, ACEA B4 OR ABOVE)AIR CLEANER FILTER FUEL FILTER CARTRIDGETIMING BELT DRIVE BELT (FOR AIR COMPRESSOR, ALTERNATOR) ALTERNATOR VACUUM PUMPALTERNATOR OIL HOSE & VACUUM HOSE FUEL LINES, FUEL HOSE & CONNECTIONS

1 234 56 7 8 120

96

R R RR II I I

105

84

R I

R

I I I

90 72

R R R R R III I

7560

R I

R

I II

60 48

R R R R I II I

45 36

R I

R

I I I

30 24

R R R R I II I

15 12

R I

R

I I I

KILOMETERS X 1000 MONTHS

DESCRIPTION

NO.

Europe Countries Only Except Europe Countries

See Note (1)

Note: (1) For every 10,000 km or 6 months, whichever occurs first : "R"

Central and South America Only Except Central and South America

Page 149 of 361

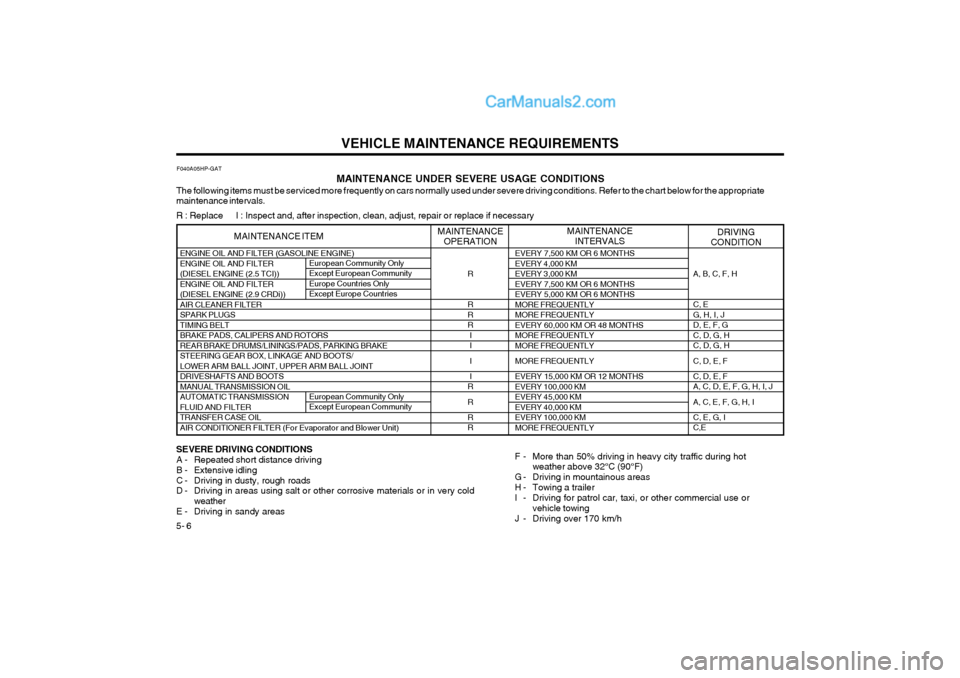

VEHICLE MAINTENANCE REQUIREMENTS

5- 6 ENGINE OIL AND FILTER (GASOLINE ENGINE) ENGINE OIL AND FILTER(DIESEL ENGINE (2.5 TCI))ENGINE OIL AND FILTER

(DIESEL ENGINE (2.9 CRDi))AIR CLEANER FILTERSPARK PLUGSTIMING BELTBRAKE PADS, CALIPERS AND ROTORSREAR BRAKE DRUMS/LININGS/PADS, PARKING BRAKESTEERING GEAR BOX, LINKAGE AND BOOTS/LOWER ARM BALL JOINT, UPPER ARM BALL JOINTDRIVESHAFTS AND BOOTSMANUAL TRANSMISSION OILAUTOMATIC TRANSMISSIONFLUID AND FILTERTRANSFER CASE OILAIR CONDITIONER FILTER (For Evaporator and Blower Unit)

R R RR

II I I

R R R R

European Community OnlyExcept European CommunityEurope Countries OnlyExcept Europe Countries

A, B, C, F, H C, E G, H, I, JD, E, F, GC, D, G, HC, D, G, H C, D, E, F C, D, E, F A, C, D, E, F, G, H, I, J A, C, E, F, G, H, I C, E, G, I C,E

F040A05HP-GAT

MAINTENANCE UNDER SEVERE USAGE CONDITIONS

The following items must be serviced more frequently on cars normally used under severe driving conditions. Refer to the chart below for the appropriate maintenance intervals. R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if necessary SEVERE DRIVING CONDITIONS

A - Repeated short distance driving

B - Extensive idling

C - Driving in dusty, rough roads

D - Driving in areas using salt or other corrosive materials or in very cold weather

E - Driving in sandy areas F - More than 50% driving in heavy city traffic during hot

weather above 32°C (90°F)

G - Driving in mountainous areas

H - Towing a trailer

I - Driving for patrol car, taxi, or other commercial use or

vehicle towing

J - Driving over 170 km/h

MAINTENANCE ITEM

European Community Only Except European Community

DRIVING

CONDITION

MAINTENANCE

OPERATION MAINTENANCE

INTERVALS

EVERY 7,500 KM OR 6 MONTHS EVERY 4,000 KMEVERY 3,000 KMEVERY 7,500 KM OR 6 MONTHSEVERY 5,000 KM OR 6 MONTHSMORE FREQUENTLYMORE FREQUENTLYEVERY 60,000 KM OR 48 MONTHSMORE FREQUENTLYMORE FREQUENTLY MORE FREQUENTLY EVERY 15,000 KM OR 12 MONTHS EVERY 100,000 KMEVERY 45,000 KMEVERY 40,000 KMEVERY 100,000 KMMORE FREQUENTLY

Page 150 of 361

VEHICLE MAINTENANCE REQUIREMENTS 5-7

F060A01A-AAT

EXPLANATION OF SCHEDULED MAIN- TENANCE ITEMS

F060M01A-AAT

o Engine Oil and Filter The engine oil and filter should be changed at

the intervals specified in the maintenance sched- ule. If the car is being driven in severe condi-tions, more frequent oil and filter changes arerequired.

F060B01A-AAT

o Drive Belts Inspect all drive belts for evidence of cuts,

cracks, excessive wear or oil saturation andreplace if necessary. Drive belts should bechecked periodically for proper tension andadjusted as necessary.

F060C01A-AAT

o Fuel Filter

A clogged filter can limit the speed at which the

vehicle may be driven, damage the emissionsystem and cause hard starting. If an exces-sive amount of foreign matter accumulates inthe fuel tank, the filter may require replacementmore frequently.

After installing a new filter, run the engine for

several minutes, and check for leaks at theconnections. Fuel filters should be installed bytrained technicians. F060D01TB-GAT

o Fuel Lines, Fuel Hoses and Connec-

tions

Check the fuel lines, fuel hoses and connec-

tions for leakage and damage. Have a trainedtechnician replace any damaged or leaking partsimmediately. WARNING (Diesel only): Never work on injection system with engine

running or within 30 seconds after shutting off engine. High pressure pump, rail, injec-tors and high pressure pipes are subjectedto high pressure even after the engine hasbeen switched off. The fuel jet produced byfuel leaks may cause serious injury, if itcontacts with the body. People using pace-makers should not move closer than 30cmto the ECU or wiring harness within theengine room with the engine running, sincethe high currents in the Common Rail sys-tem produce considerable magnetic fields.

F060E01A-AAT

o Timing Belt Inspect all parts related to the timing belt for

damage and deformation. Replace any dam-aged parts immediately. F060G01A-AAT

o Vapor Hose and Fuel Filler Cap

The vapor hose and fuel filler cap should be

inspected at those intervals specified in themaintenance schedule. Make sure that a newvapor hose or fuel filler cap is correctly re-placed.

F060F01A-AAT

o Vacuum, Crankcase

Ventilation Hoses

Inspect the surface of hoses for evidence of

heat and/or mechanical damage. Hard and brit-tle rubber, cracking, tears, cuts, abrasions, andexcessive swelling indicate deterioration. Par-ticular attention should be paid to examinethose hose surfaces nearest to high heat sourc-es, such as the exhaust manifold.

Inspect the hose routing to assure that the

hoses do not come in contact with any heatsource, sharp edges or moving componentwhich might cause heat damage or mechanicalwear. Inspect all hose connections, such asclamps and couplings, to make sure they aresecure, and that no leaks are present. Hosesshould be replaced immediately if there is anyevidence of deterioration or damage.

Page 152 of 361

VEHICLE MAINTENANCE REQUIREMENTS 5-9

F070N01A-AAT

o Power Steering Pump, Belt and

Hoses

Check the power steering pump and hoses for

leakage and damage. Replace any damaged or leaking parts immediately. Inspect the powersteering belt for evidence of cuts, cracks, ex-cessive wear, oiliness and proper tension. Re-place or adjust it if necessary.

F070P01A-AAT

o Driveshafts and Boots Check the drive shafts, boots and clamps for

cracks, deterioration, or damage. Replace anydamaged parts and, if necessary, repack thegrease.

F070Q01A-AAT

o Air Conditioning Refrigerant Check the air conditioning lines and connec-

tions for leakage and damage. Check air condi-tioning performance according to the relevantshop manual if necessary. F070M01B-AAT

o Steering Gear Box, Linkage & Boots/

Lower Arm Ball Joint, Upper Arm Ball Joint

With the vehicle stopped and engine off, check

for excessive free-play in the steering wheel.

Check the linkage for bends or damage. Check

the dust boots and ball joints for deterioration, cracks, or damage. Replace any damaged parts.