display INFINITI FX35 2007 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: FX35, Model: INFINITI FX35 2007Pages: 4366, PDF Size: 55.42 MB

Page 4097 of 4366

AUTOMATIC DRIVE POSITIONER SE-59

C

D E

F

G H

J

K L

M A

B

SE

Revision: 2006 July 2007 FX35/FX45

Check Telescopic Sensor CircuitNIS001VE

1. CHECK FUNCTION

With CONSULT-II

Operate the telescopic switch with “TELESCO SEN” on the DATA MONITOR to make sure the voltage

changes.

Without CONSULT-II

1. Turn ignition switch OFF.

2. Check voltage between automatic drive positioner control unit connector and ground.

OK or NG

OK >> Telescopic sensor circuit is OK.

NG >> GO TO 2.

2. CHECK HARNESS CONTINUITY

1. Disconnect automatic drive positioner control unit connector and tilt sensor and telescopic sensor connec- tor.

2. Check continuity harness between automatic drive positioner control unit connector M49 terminals 23 and tilt sensor and tele-

scopic sensor connector M28 terminals 3.

3. Check continuity harness between automatic drive positioner control unit connector M49 terminals 23 and ground.

OK or NG

OK >> Replace tilt sensor and telescopic sensor.

NG >> Repair or replace harness between automatic drive positioner control unit and tilt sensor and telescopic sensor.

Monitor item

[OPERATION or UNIT] Contents

TELESCO

SEN “V”

The telescoping position (voltage) judged from the tele-

scoping sensor signal is displayed.

PIIA0295E

Connector Terminals

(Wire color) Condition Voltage (V)

(Approx.)

(+) (–)

M49 23 (Y/B) Ground Telescopic

top position 1

Telescopic

bottom position 4

PIIA5070E

23 (Y/B) – 3 (Y/B) : Continuity should exist.

23 (Y/B) – Ground : Continuity should not exist.

PIIA5079E

Page 4098 of 4366

SE-60

AUTOMATIC DRIVE POSITIONER

Revision: 2006 July 2007 FX35/FX45

Check Tilt Sensor CircuitNIS001VF

1. CHECK TILT SENSOR

With CONSULT-II

With “TILT SEN” on the DATA MONITOR, operate the tilt switch to make sure voltage changes.

Without CONSULT-II

1. Turn ignition switch OFF.

2. Check voltage between automatic drive positioner control unit connector and ground.

OK or NG

OK >> Tilt sensor circuit is OK.

NG >> GO TO 2.

2. CHECK HARNESS

1. Disconnect automatic drive positioner control unit connector and tilt sensor and telescopic sensor connec- tor.

2. Check continuity harness between automatic drive positioner control unit connector M49 terminals 7 and tilt sensor and tele-

scopic sensor connector M28 terminals 2.

3. Check continuity harness between automatic drive positioner control unit connector M49 terminals 7 and ground.

OK or NG

OK >> Replace tilt sensor and telescopic sensor.

NG >> Repair or replace harness between automatic drive positioner control unit and tilt sensor and telescopic sensor.

Monitor item

[OPERATION or UNIT] Contents

TILT SEN “V” The tilt position (voltage) judged from the tilt sensor sig-

nal is displayed.

PIIA0295E

Connector Terminals

(Wire color) Condition Voltage (V)

(Approx.)

(+) (–)

M49 7 (Y/R) Ground Tilt top position 2

Tilt bottom position 4

PIIA5069E

7 (Y/R) – 2 (Y/R) : Continuity should exist.

7 (Y/R) – Ground : Continuity should not exist.

PIIA5080E

Page 4099 of 4366

AUTOMATIC DRIVE POSITIONER SE-61

C

D E

F

G H

J

K L

M A

B

SE

Revision: 2006 July 2007 FX35/FX45

Check Driver Side Mirror Sensor Circuit NIS001VG

1. CHECK DOOR MIRROR FUNCTION

Check the following.

Operation malfunction in memory control

NOTE:

If a door mirror face position is set to an implausible angle, the set position may not be reproduced.

OK or NG

OK >> GO TO 2.

NG >> Repair the malfunctioning parts, and check the symptom again.

2. CHECK MIRROR SENSOR INSPECTION

With CONSULT-II

Make sure “ON” is displayed on “MIR/SE LH R–L, MIR/SE LH U–D” in the DATA MONITOR.

Without CONSULT-II

1. Turn ignition switch to ACC position.

2. Check voltage between door mirror (driver side) connector and ground.

OK or NG

OK >> Driver side mirror sensor circuit is OK.

NG >> GO TO 3.

Monitor item

[OPERATION or UNIT] Contents

MIR/SE LH R–L “V” Voltage output from LH door mirror sensor

(LH/RH) is displayed.

MIR/SE LH U–D “V” Voltage output from LH door mirror sensor

(UP/DOWN) is displayed.

PIIA0197E

Con-

nector Terminals (Wire color)

Condition Voltage (V)

(Approx,)

(+) (–)

D2 2 (W)

Ground When motor is

UP or DOWN

operation Changes between

3 (close to perk) – 1 (close to valley)

10 (LG) When motor is

LEFT or RIGHT

operation Changes between

3 (close to right edge) –

1 (close to left edge)

PIIB8585E

Page 4101 of 4366

AUTOMATIC DRIVE POSITIONER SE-63

C

D E

F

G H

J

K L

M A

B

SE

Revision: 2006 July 2007 FX35/FX45

2. CHECK MIRROR SENSOR INSPECTION

With CONSULT-II

Make sure “ON” is displayed on “MIR/SE RH R–L, MIR/SE RH U–D” in the DATA MONITOR.

Without CONSULT-II

1. Turn ignition switch to ACC position.

2. Check voltage between door mirror (passenger side) connector and ground.

OK or NG

OK >> Passenger side mirror sensor circuit is OK.

NG >> GO TO 3.

3. CHECK HARNESS CONTINUITY 1

1. Disconnect automatic drive positioner control unit and door mirror (passenger side) connector.

2. Check continuity between automatic drive positioner control unit connector M50 terminal 33, 41 and door mirror (passenger side)

connector D32 terminal 1, 9.

3. Check continuity between automatic drive positioner control unit connector M50 terminals 33, 41 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness between automatic drive positioner control unit and door mirror (pas- senger side).

Monitor item

[OPERATION or UNIT] Contents

MIR/SE RH R–L “V” Voltage output from RH door mirror sensor

(LH/RH) is displayed.

MIR/SE RH U–D “V” Voltage output from RH door mirror sensor

(UP/DOWN) is displayed.

PIIA0197E

Con-

nector Terminals (Wire color)

Condition Voltage (V)

(Approx.)

(+) (–)

D32 2 (LG)

Ground When motor is

UP or DOWN

operation Changes between

3 (close to perk) –

1 (close to valley)

10 (P) When motor is

LEFT or RIGHT

operation Changes between

1 (close to left edge) – 3 (close to right edge)

PIIB8585E

33 (G/W) – 1 (BR) : Continuity should exist.

41 (B/Y) – 9 (G) : Continuity should exist.

33 (G/W) – Ground : Continuity should not exist.

41 (B/Y) – Ground : Continuity should not exist.

PIIB8586E

Page 4103 of 4366

AUTOMATIC DRIVE POSITIONER SE-65

C

D E

F

G H

J

K L

M A

B

SE

Revision: 2006 July 2007 FX35/FX45

3. CHECK HARNESS CONTINUITY (DOOR MIRROR SENSOR)

1. Disconnect automatic drive positioner control unit and door mirror (driver side or passenger side) connec- tor.

2. Check continuity between automatic drive positioner control unit connector M50 terminal 33, 41 and door mirror connector D2

(driver side) or D32 (passenger side) terminal 1, 9.

3. Check continuity between automatic drive positioner control unit connector M50 terminal 33, 41 and ground.

OK or NG

OK >> Check the condition of the harness and connector.

NG >> Repair or replace harness between automatic drive positioner control unit and door mirror (driver side or passenger side).

4. CHECK HARNESS CONTINUITY (STEERING SENSOR)

1. Disconnect automatic drive positioner control unit and tilt sensor and telescopic sensor connector.

2. Check continuity between automatic drive positioner control unit connector M50 terminal 33, 41 and tilt sensor and telescopic

sensor connector M28 terminal 1, 4.

3. Check continuity between automatic drive positioner control unit connector M50 terminal 33, 41 and ground.

OK or NG

OK >> Check the condition of the harness and connector.

NG >> Repair or replace harness between automatic drive positioner control unit and tilt sensor and tele- scopic sensor.

Check Front Door Switch (Driver Side) CircuitNIS001VJ

1. CHECK FUNCTION (WITH CONSULT-II)

With CONSULT-II

Touch “BCM” with “DOOR SW-DR” on the DATA MONITOR, check ON/OFF operation when the driver door is

open and closed. *: Refer to BL-37, "

Data Monitor" .

OK or NG

OK >> Front door switch (driver side) circuit is OK.

NG >> GO TO 2. 33 (G/W) – 1 (OR) : Continuity should exist.

41 (B/Y) – 9 (BR) : Continuity should exist.

33 (G/W) – Ground : Continuity should not exist.

41 (B/Y) – Ground : Continuity should not exist.

PIIB8586E

33 (G/W) – 1 (G/W) : Continuity should exist.

41 (B/Y) – 4 (B/Y) : Continuity should exist.

33 (G/W) – Ground : Continuity should not exist.

41 (B/Y) – Ground : Continuity should not exist.

PIIB8588E

Monitor item

[OPERATION or UNIT] Contents

DOOR SW*

DR “ON/

OFF” Door open (ON)/door closed (OFF) status judged from

the driver door switch is displayed.

PIIA0291E

Page 4105 of 4366

AUTOMATIC DRIVE POSITIONER SE-67

C

D E

F

G H

J

K L

M A

B

SE

Revision: 2006 July 2007 FX35/FX45

Check Sliding Switch CircuitNIS001VK

1. CHECK FUNCTION

With CONSULT-II

With “SLIDE SW-FR, SLIDE SW-RR” on the DATA MONITOR, operate the sliding switch to check ON/OFF

operation.

Without CONSULT-II

1. Turn ignition switch OFF.

2. Sliding switch operate, check voltage between driver seat control unit connector and ground.

OK or NG

OK >> Sliding switch circuit is OK.

NG >> GO TO 2.

2. CHECK HARNESS CONTINUITY

1. Disconnect driver seat control unit connector and power seat switch connector.

2. Check continuity between driver seat control unit connector B152 terminals 24, 37 and power seat switch connector B175

terminals 24, 37.

3. Check continuity between driver seat control unit connector B152 terminals 24, 37 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness between driver seat control unit and power seat switch.

Monitor item

[OPERATION or UNIT] Contents

SLIDE SW – FR “ON/

OFF” ON/OFF status judged from the sliding switch

(FR) signal is displayed.

SLIDE SW – RR “ON/

OFF” ON/OFF status judged from the sliding switch

(RR) signal is displayed.

PIIA0313E

Connector Te r m i n a l s

(Wire color) Sliding switch condition Voltage (V)

(Approx.)

(+) (-)

B152 24 (L/R)

Ground FORWARD 0

Other than above Battery voltage

37 (W) BACKWARD 0

Other than above Battery voltage

PIIA6711E

24 (L/R) – 24 (L/R) : Continuity should exist.

37 (W) – 37 (W) : Continuity should exist.

24 (L/R) – Ground : Continuity should not exist.

37 (W) – Ground : Continuity should not exist.

PIIB8589E

Page 4106 of 4366

SE-68

AUTOMATIC DRIVE POSITIONER

Revision: 2006 July 2007 FX35/FX45

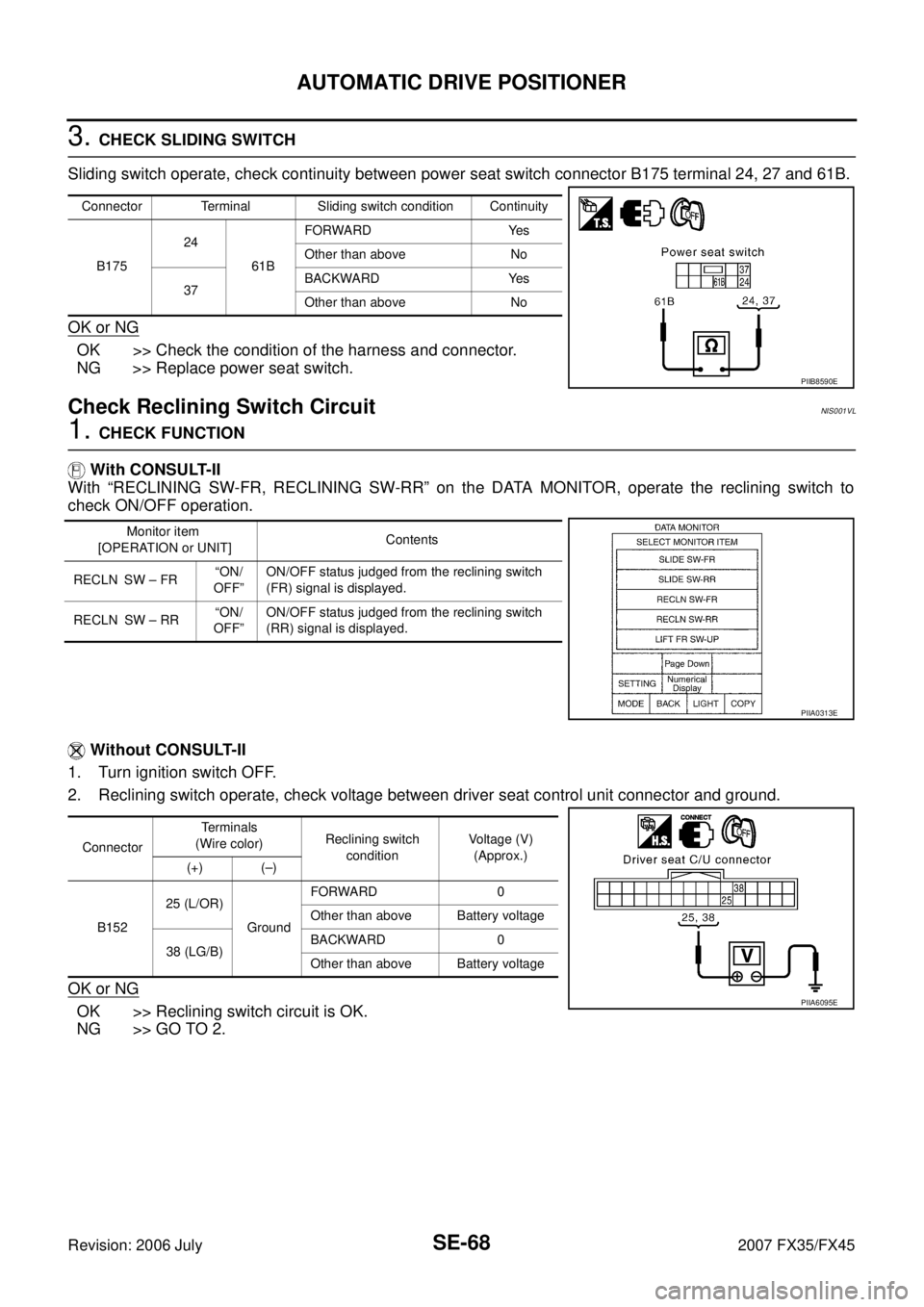

3. CHECK SLIDING SWITCH

Sliding switch operate, check continuity between power seat switch connector B175 terminal 24, 27 and 61B.

OK or NG

OK >> Check the condition of the harness and connector.

NG >> Replace power seat switch.

Check Reclining Switch CircuitNIS001VL

1. CHECK FUNCTION

With CONSULT-II

With “RECLINING SW-FR, RECLINING SW-RR” on the DATA MONITOR, operate the reclining switch to

check ON/OFF operation.

Without CONSULT-II

1. Turn ignition switch OFF.

2. Reclining switch operate, check voltage between driver seat control unit connector and ground.

OK or NG

OK >> Reclining switch circuit is OK.

NG >> GO TO 2.

Connector Terminal Sliding switch condition Continuity

B175 24

61B FORWARD Yes

Other than above No

37 BACKWARD Yes

Other than above No

PIIB8590E

Monitor item

[OPERATION or UNIT] Contents

RECLN SW – FR “ON/

OFF” ON/OFF status judged from the reclining switch

(FR) signal is displayed.

RECLN SW – RR “ON/

OFF” ON/OFF status judged from the reclining switch

(RR) signal is displayed.

PIIA0313E

Connector Te r m i n a l s

(Wire color) Reclining switch

condition Voltage (V)

(Approx.)

(+) (–)

B152 25 (L/OR)

Ground FORWARD 0

Other than above Battery voltage

38 (LG/B) BACKWARD 0

Other than above Battery voltage

PIIA6095E

Page 4108 of 4366

SE-70

AUTOMATIC DRIVE POSITIONER

Revision: 2006 July 2007 FX35/FX45

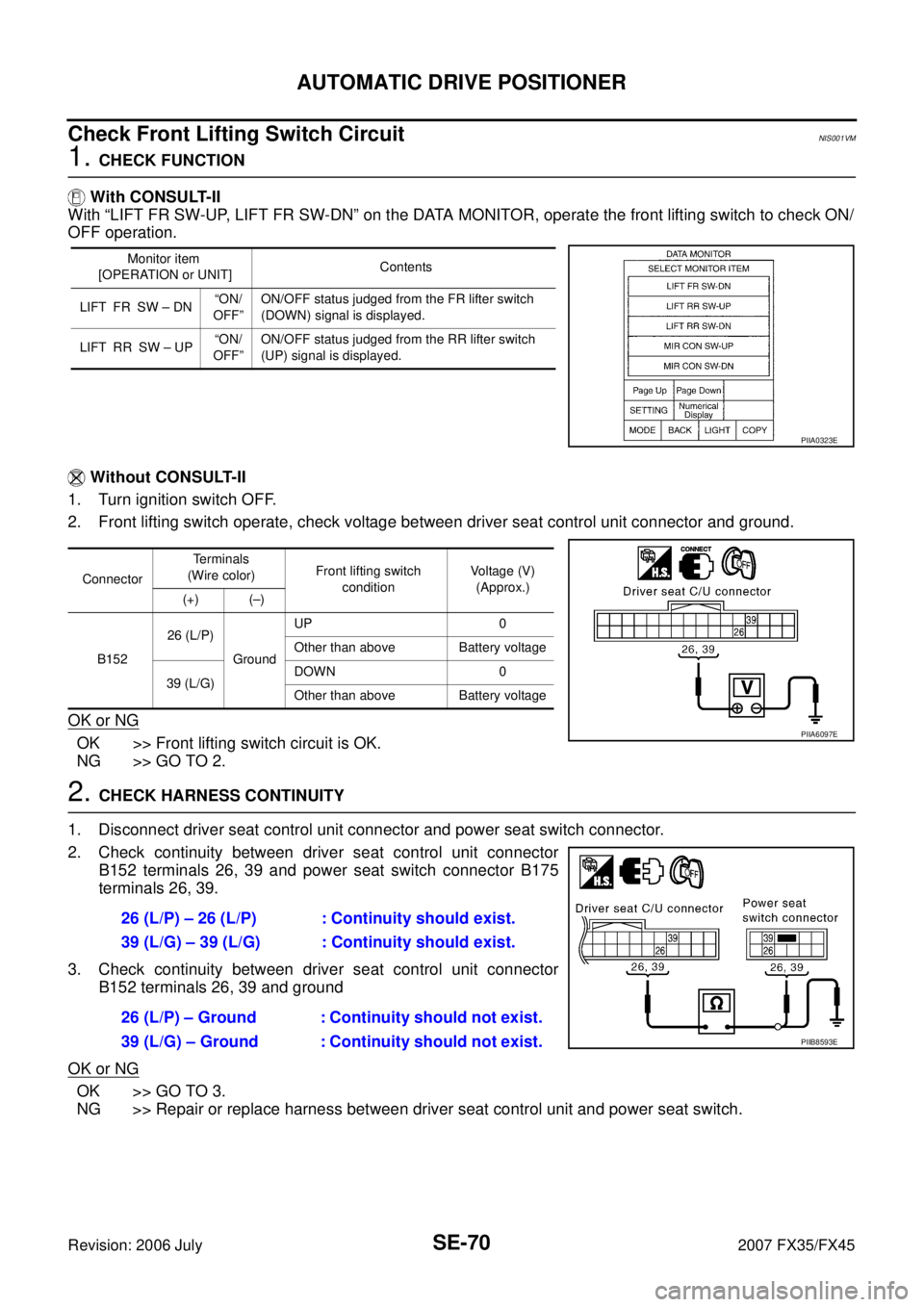

Check Front Lifting Switch CircuitNIS001VM

1. CHECK FUNCTION

With CONSULT-II

With “LIFT FR SW-UP, LIFT FR SW-DN” on the DATA MONITOR, operate the front lifting switch to check ON/

OFF operation.

Without CONSULT-II

1. Turn ignition switch OFF.

2. Front lifting switch operate, check voltage between driver seat control unit connector and ground.

OK or NG

OK >> Front lifting switch circuit is OK.

NG >> GO TO 2.

2. CHECK HARNESS CONTINUITY

1. Disconnect driver seat control unit connector and power seat switch connector.

2. Check continuity between driver seat control unit connector B152 terminals 26, 39 and power seat switch connector B175

terminals 26, 39.

3. Check continuity between driver seat control unit connector B152 terminals 26, 39 and ground

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness between driver seat control unit and power seat switch.

Monitor item

[OPERATION or UNIT] Contents

LIFT FR SW – DN “ON/

OFF” ON/OFF status judged from the FR lifter switch

(DOWN) signal is displayed.

LIFT RR SW – UP “ON/

OFF” ON/OFF status judged from the RR lifter switch

(UP) signal is displayed.

PIIA0323E

Connector Terminals

(Wire color) Front lifting switch

condition Voltage (V)

(Approx.)

(+) (–)

B152 26 (L/P)

Ground UP 0

Other than above Battery voltage

39 (L/G) DOWN 0

Other than above Battery voltage

PIIA6097E

26 (L/P) – 26 (L/P) : Continuity should exist.

39 (L/G) – 39 (L/G) : Continuity should exist.

26 (L/P) – Ground : Continuity should not exist.

39 (L/G) – Ground : Continuity should not exist.

PIIB8593E

Page 4109 of 4366

AUTOMATIC DRIVE POSITIONER SE-71

C

D E

F

G H

J

K L

M A

B

SE

Revision: 2006 July 2007 FX35/FX45

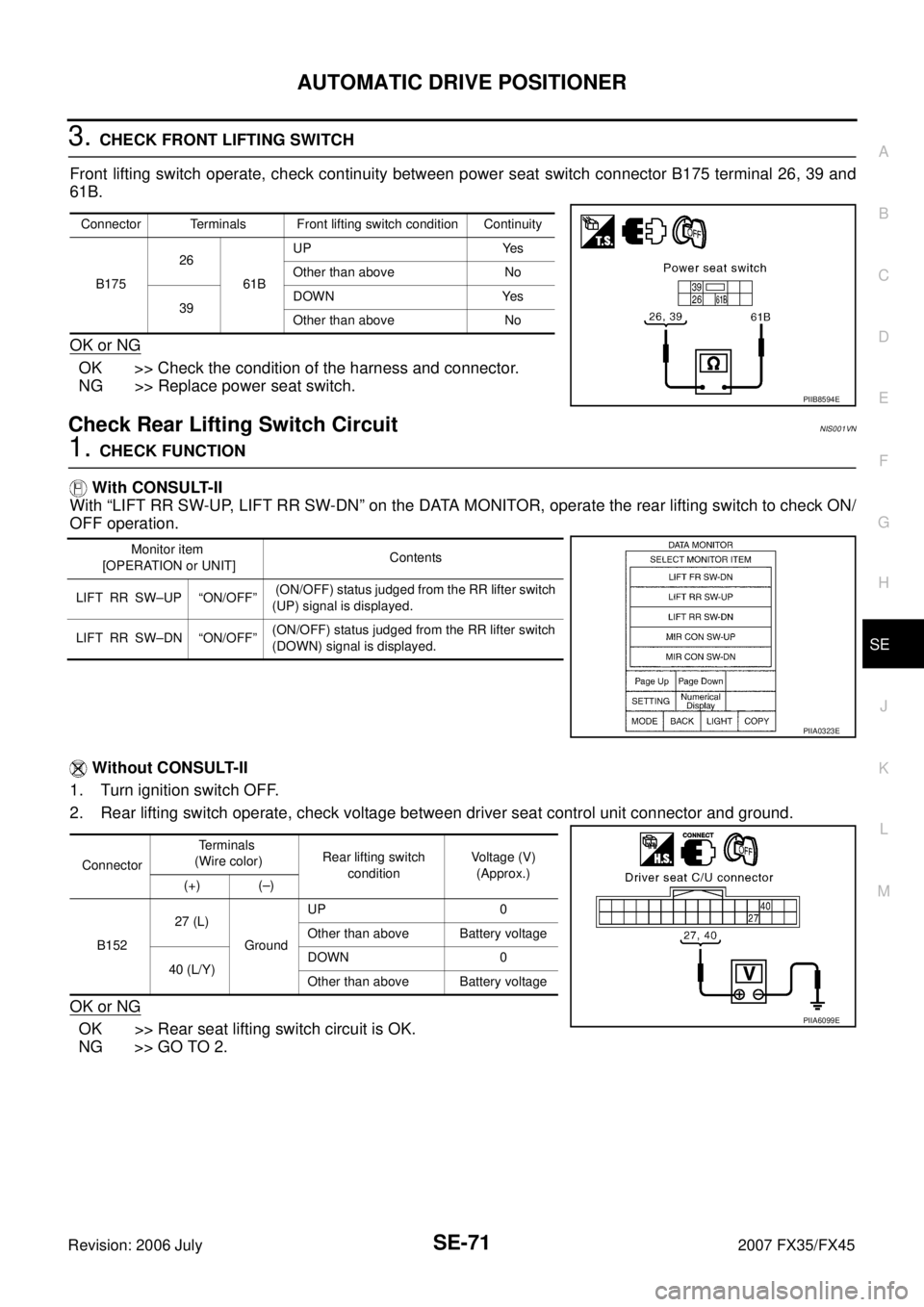

3. CHECK FRONT LIFTING SWITCH

Front lifting switch operate, check continuity between power seat switch connector B175 terminal 26, 39 and

61B.

OK or NG

OK >> Check the condition of the harness and connector.

NG >> Replace power seat switch.

Check Rear Lifting Switch CircuitNIS001VN

1. CHECK FUNCTION

With CONSULT-II

With “LIFT RR SW-UP, LIFT RR SW-DN” on the DATA MONITOR, operate the rear lifting switch to check ON/

OFF operation.

Without CONSULT-II

1. Turn ignition switch OFF.

2. Rear lifting switch operate, check voltage between driver seat control unit connector and ground.

OK or NG

OK >> Rear seat lifting switch circuit is OK.

NG >> GO TO 2.

Connector Terminals Front lifting switch condition Continuity

B175 26

61B UP Yes

Other than above No

39 DOWN Yes

Other than above No

PIIB8594E

Monitor item

[OPERATION or UNIT] Contents

LIFT RR SW–UP “ON/OFF” (ON/OFF) status judged from the RR lifter switch

(UP) signal is displayed.

LIFT RR SW–DN “ON/OFF” (ON/OFF) status judged from the RR lifter switch

(DOWN) signal is displayed.

PIIA0323E

Connector Terminals

(Wire color) Rear lifting switch

condition Voltage (V)

(Approx.)

(+) (–)

B152 27 (L)

Ground UP 0

Other than above Battery voltage

40 (L/Y) DOWN 0

Other than above Battery voltage

PIIA6099E

Page 4111 of 4366

AUTOMATIC DRIVE POSITIONER SE-73

C

D E

F

G H

J

K L

M A

B

SE

Revision: 2006 July 2007 FX35/FX45

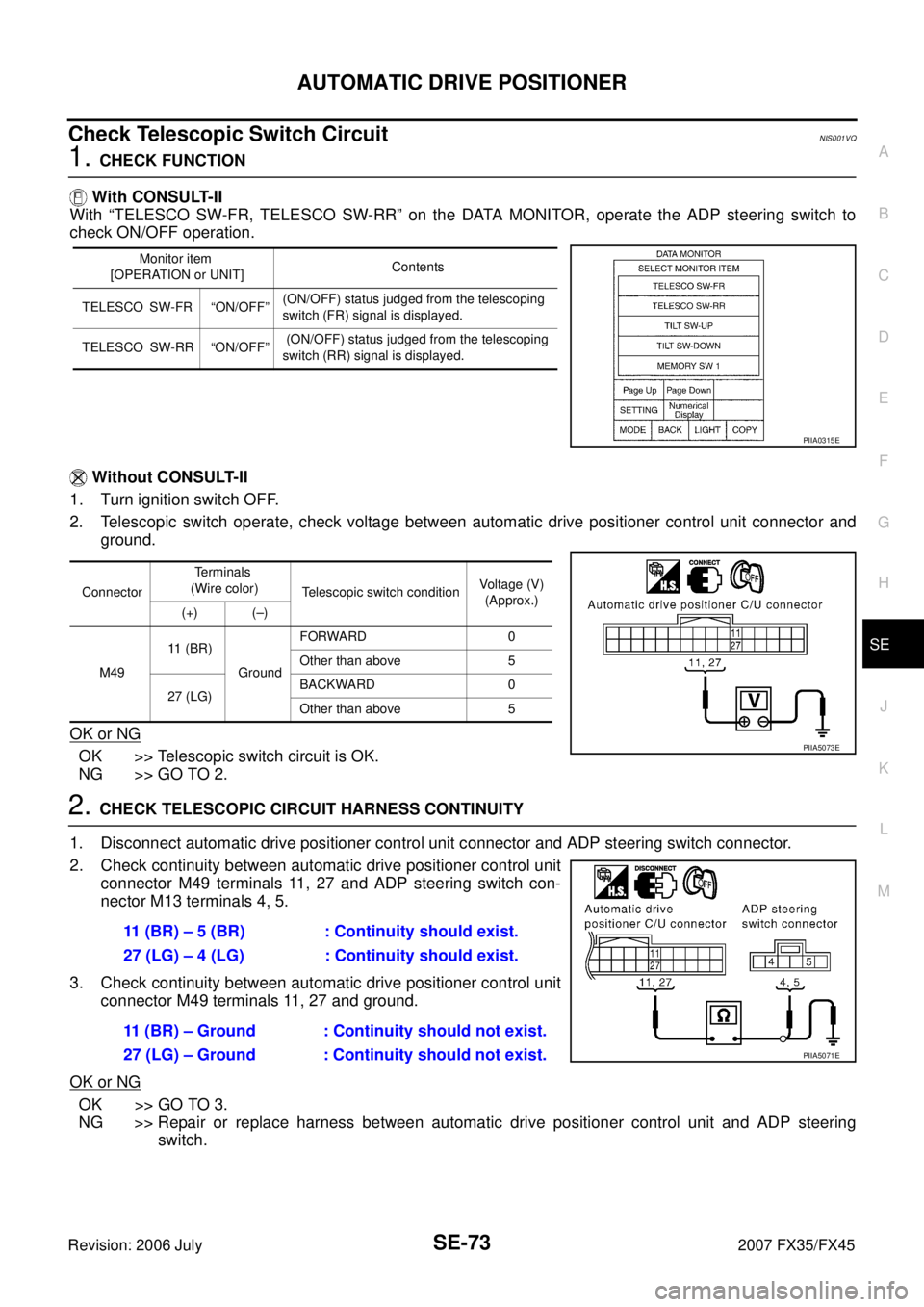

Check Telescopic Switch CircuitNIS001VQ

1. CHECK FUNCTION

With CONSULT-II

With “TELESCO SW-FR, TELESCO SW-RR” on the DATA MONITOR, operate the ADP steering switch to

check ON/OFF operation.

Without CONSULT-II

1. Turn ignition switch OFF.

2. Telescopic switch operate, check voltage between automatic drive positioner control unit connector and ground.

OK or NG

OK >> Telescopic switch circuit is OK.

NG >> GO TO 2.

2. CHECK TELESCOPIC CIRCUIT HARNESS CONTINUITY

1. Disconnect automatic drive positioner control unit connector and ADP steering switch connector.

2. Check continuity between automatic drive positioner control unit connector M49 terminals 11, 27 and ADP steering switch con-

nector M13 terminals 4, 5.

3. Check continuity between automatic drive positioner control unit connector M49 terminals 11, 27 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness between automatic drive positioner control unit and ADP steering switch.

Monitor item

[OPERATION or UNIT] Contents

TELESCO SW-FR “ON/OFF” (ON/OFF) status judged from the telescoping

switch (FR) signal is displayed.

TELESCO SW-RR “ON/OFF” (ON/OFF) status judged from the telescoping

switch (RR) signal is displayed.

PIIA0315E

Connector Terminals

(Wire color) Telescopic switch condition Voltage (V)

(Approx.)

(+) (–)

M49 11 ( B R )

Ground FORWARD 0

Other than above 5

27 (LG) BACKWARD 0

Other than above 5

PIIA5073E

11 (BR) – 5 (BR) : Continuity should exist.

27 (LG) – 4 (LG) : Continuity should exist.

11 (BR) – Ground : Continuity should not exist.

27 (LG) – Ground : Continuity should not exist.

PIIA5071E