service indicator INFINITI FX35 2008 Owners Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 1208 of 3924

![INFINITI FX35 2008 Owners Manual

DI-82

< SERVICE INFORMATION >

LANE DEPARTURE WARNING SYSTEM

NOTE:

When a DTC is detected, the LDW system dose not operate.

When the DTC except “ABNRML TEMP DETECT [C1B03] ” is detected, the INFINITI FX35 2008 Owners Manual

DI-82

< SERVICE INFORMATION >

LANE DEPARTURE WARNING SYSTEM

NOTE:

When a DTC is detected, the LDW system dose not operate.

When the DTC except “ABNRML TEMP DETECT [C1B03] ” is detected, the](/img/42/57017/w960_57017-1207.png)

DI-82

< SERVICE INFORMATION >

LANE DEPARTURE WARNING SYSTEM

NOTE:

When a DTC is detected, the LDW system dose not operate.

When the DTC except “ABNRML TEMP DETECT [C1B03] ” is detected, the LDW indicator lamp turns ON.

When the DTC “ABNRML TEMP DETECT [C1B03] ” is detected, the LDW system ON indicator lamp blinks.

DATA MONITOR

Display Item

ACTIVE TEST

CAUTION:

Never perform the active test while driving.

Active test cannot be started while LDW indicator lamp is illuminated.

Display item [Code] Malfunctions detected where... Reference

page

CAMERA UNIT MALF [C1B00] LDW camera unit internal malfunction DI-85

CAM AIMING INCMP [C1B01] LDW camera aiming is not adjusted. DI-85

VHCL SPD DATA MALF [C1B02]LDW camera unit detected different vehicle speed signal from TCM and ABS ac-

tuator and electric unit (control unit). DI-85

ABNRML TEMP DETECT [C1B03] Temperature around LDW camera unit is excessively high.

DI-86

CAN COMM CIRCUIT [U1000] LDW camera unit detected CAN communication malfunction. DI-86

CONTROL UNIT (CAN) [U1010] LDW camera unit detected internal CAN communication circuit malfunction. DI-86

Monitored Item [unit] Description

VHCL SPD SE [km/h] or [mph] Displays vehicle speed calculated by LDW camera unit through CAN communication [ABS

actuator and electric unit (control unit) transmits wheel sensor signal through CAN communi-

cation].

VHCL SPD AT [km/h] or [mph] Displays vehicle speed calculated from A/T vehicle speed sensor by LDW camera unit

through CAN communication (TCM transmits A/T vehicle speed sensor signal through CAN

communication).

FCTRY AIM YAW [deg] Displays camera unit installation condition.

FCTRY AIM ROL [deg] Displays camera unit installation condition.

FCTRY AIM PIT [deg] Displays camera unit installation condition.

XOFFSET [pixel] Displays camera unit installation condition.

MAIN SW [On/Off] Displays [On/Off] status as judged from LDW switch signal.

SW ON LAMP [On/Off] Displays [On/Off] status of LDW system ON indicator signal output.

INDICATE LAMP [On/Off] Displays [On/Off] status of LDW indicator signal output.

BUZZER OUTPUT [On/Off] Displays [On/Off] status of LDW chime operation signal output.

LDW INACCURAT [On/Off] Displays LDW camera unit status.

TURN SIGNAL [Off/LH/RH] Displays “Tur n signal” status, determined from BCM thro ugh CAN communication.

LANE DETCT LH [On/Off] Displays left lane marker is detected.

LANE DETCT RH [On/Off] Displays right lane marker is detected.

CROSS LANE LH [On/Off] Displays vehicle is crossing left lane.

CROSS LANE RH [On/Off] Displays vehicle is crossing right lane.

WARN LANE LH [On/Off] Displays warning for left lane.

WARN LANE RH [On/Off] Displays warning for right lane.

VALID POS LH [VLD/INVLD] Displays lateral position for left lane marker is valid.

VALID POS RH [VLD/INVLD] Displays lateral position for right lane marker is valid.

AIMING DONE [OK/NG] Displa ys camera aiming done.

AIMING RESULT [OK/NOK] Disp lays camera aiming result.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1209 of 3924

LANE DEPARTURE WARNING SYSTEMDI-83

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

1. Select “Active Test”.

2. Select any field, “BUZZER DRIVE ”, “SYSTEM ON LAMP DRIVE” and “INDICATOR LAMP DRIVE”, on

selection screen.

3. Select necessary item and “Start”.

4. Active test screen will be shown.

Display Item

BUZZER DRIVE

Select “On” and “Off” to check if LDW chime operates as follows.

SYSTEM ON LAMP DRIVE

Select “ON” and “OFF” to check if LDW s ystem ON indicator operates as follows.

NOTE:

Perform “SYSTEM ON LAMP DRIVE” when LDW system ON indicator turns OFF.

INDICATOR LAMP DRIVE

Select “On” and “Off” to check that LDW indicator lamp operates as follows.

Trouble DiagnosisINFOID:0000000001328501

HOW TO PERFORM TROUBLE DIAGNOSIS

1. Check the symptom and customer complaint.

2. Understand the outline of system. Refer to DI-69, "

System Description".

3. Perform the preliminary inspection. Refer to DI-84, "

Preliminary Check".

4. Referring to symptom chart, repair or replace the cause of the malfunction. Refer to "SYMPTOM CHART".

5. Erase DTC and perform self-diagnosis of LDW sys tem again. Then perform LDW system running test.

Refer to DI-81, "

CONSULT-III Function (LDW)" and DI-71, "Action Test".

6. Does LDW system operate normally? If it oper ates normally, GO TO 7. If not, GO TO 3.

7. INSPECTION END

SYMPTOM CHART

Active test item Operation item Function

BUZZER DRIVE LDW chime This test is able to check LDW chime operation.

SYSTEM ON LAMP DRIVE LDW system ON indicator This test is able to check LDW system ON indicator operation.

INDICATOR LAMP DRIVE LDW indicator lamp This test is able to check LDW indicator lamp operation.

“BUZZER DRIVE”

Select “On” : LDW chime is activated.

Select “Off” : LDW chime is not activated.

“SYSTEM ON LAMP DRIVE”

Select “On” : LDW system ON indicator illuminates.

Select “Off” : LDW system ON indicator turns OFF.

“INDICATOR LAMP DRIVE”

Select “On” : LDW indicator lamp illuminates.

Select “Off” : LDW indicator lamp OFF.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1210 of 3924

DI-84

< SERVICE INFORMATION >

LANE DEPARTURE WARNING SYSTEM

Preliminary Check

INFOID:0000000001328502

1.CHECK CAMERA LENS AND WINDSHIELD

Are camera lens and windshield contaminated with foreign materials?

YES >> Clean camera lens and windshield.

NO >> GO TO 2.

2.CHECK CAMERA UNIT IN STALLATION CONDITION

Check camera unit installation condition (installat ion position, properly tightened, a bent bracket).

OK or NG

OK >> GO TO 3.

NG >> Install camera unit properly, and adjust camera aiming. Refer to DI-71, "

Camera Aiming Adjust-

ment".

3.CHECK VEHICLE HEIGHT

Check vehicle height. Refer to GI-47, "

Dimensions".

Is vehicle height appropriate?

OK >> GO TO 4.

NG >> Repair vehicle to appropriate height.

4.CHECK LDW CAMERA UNIT (CONSULT-III)

Perform self-diagnosis of LDW camera unit. Refer to DI-81, "

CONSULT-III Function (LDW)".

Self

-diagnosis results

No malfunction detected >> GO TO 5.

Malfunction detected >> Check applicable parts, and repair or replace corresponding parts.

5.CHECK COMBINATION METER

Check combination meter function.

Do speedometer and turn signal indicator normal function?

YES >> INSPECTION END

NO >> Check combination meter. Refer to DI-15, "

Trouble Diagnosis".

Power Supply and Ground Circuit InspectionINFOID:0000000001328503

1.CHECK FUSE

Check for blown LDW camera unit fuse.

Symptom Diagnoses/Service procedure

LDW system is not activated.

(LDW system ON indicator turns ON/OFF.) Perform the following inspections.

1.

DI-86, "

LDW Chime Circuit Inspection"

2.DI-90, "LDW Indicator Lamp Circuit Inspection"

Replace LDW camera unit, check function in the above inspections.

LDW system does not turn ON/OFF.

(LDW system ON indicator does not turn ON/OFF.) Perform

DI-88, "

LDW Switch Circuit Inspection".

Replace LDW camera unit, check function in the above inspection.

Warning functions are untimely. (Example)

Warning does not function when driving on lane markers.

Warning functions when driving in a lane.

Different position from actual condition functions. Perform

DI-71, "

Camera Aiming Adjustment".

Functions when changing the course to the turn signal direction. Perform

DI-91, "

Turn Signal Input Inspection".

Replace LDW camera unit, check function in the above inspection.

LDW indicator lamp does not illuminate with ignition switch ON. Perform

DI-90, "

LDW Indicator Lamp Circuit Inspection".

Replace LDW camera unit, check function in the above inspection.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1214 of 3924

DI-88

< SERVICE INFORMATION >

LANE DEPARTURE WARNING SYSTEM

LDW Switch Circuit Inspection

INFOID:0000000001328511

1.CHECK OPERATION OF LDW SYSTEM ON INDICATOR

1. Turn ignition switch ON.

2. Check LDW system ON indicator operation when LDW switch is ON/OFF.

OK or NG

OK >> INSPECTION END

NG >> GO TO 2.

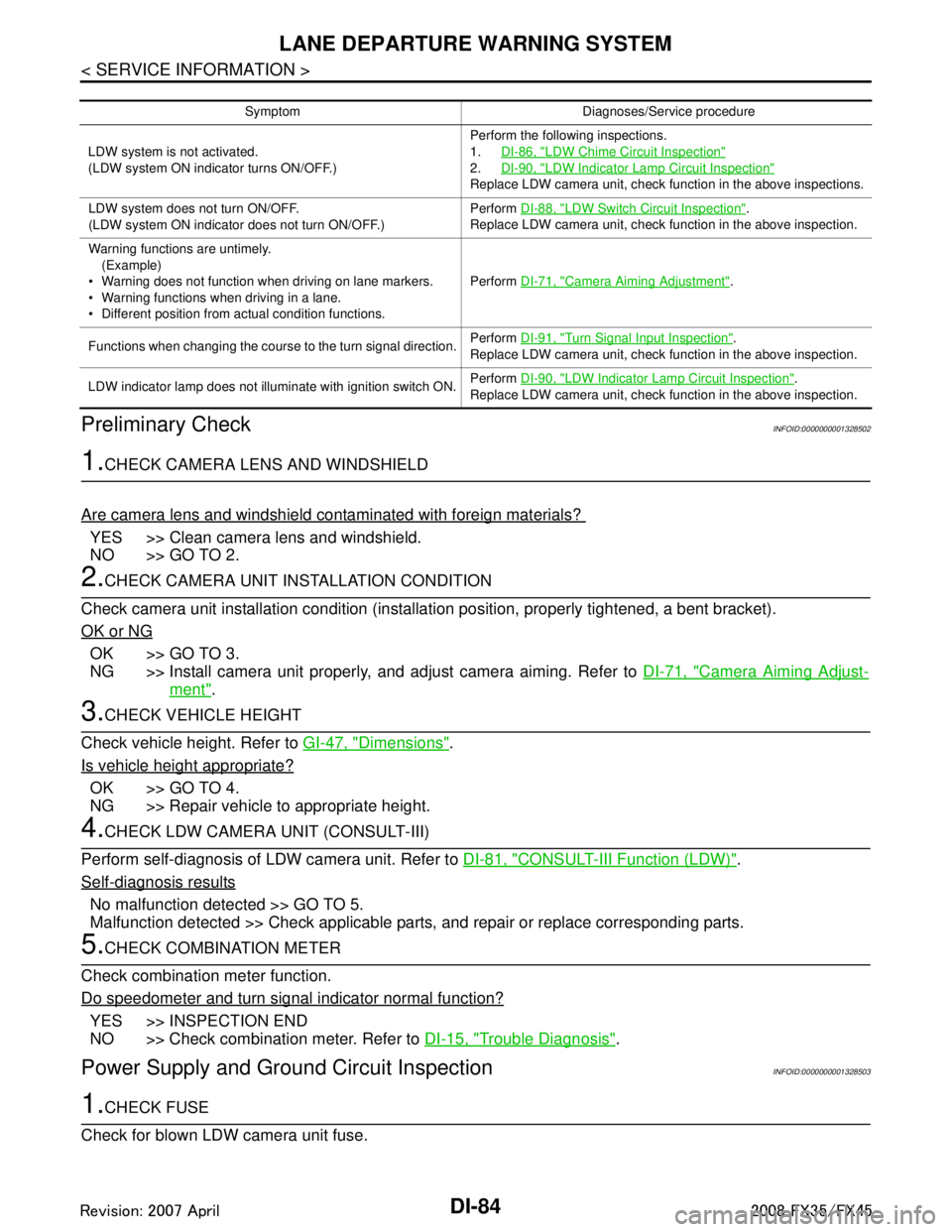

2.CHECK LDW SWITCH SIGNAL INPUT

Check voltage between LDW camera unit harness connector R9 ter-

minal 9 and ground.

OK or NG

OK >> GO TO 6.

NG >> GO TO 3.

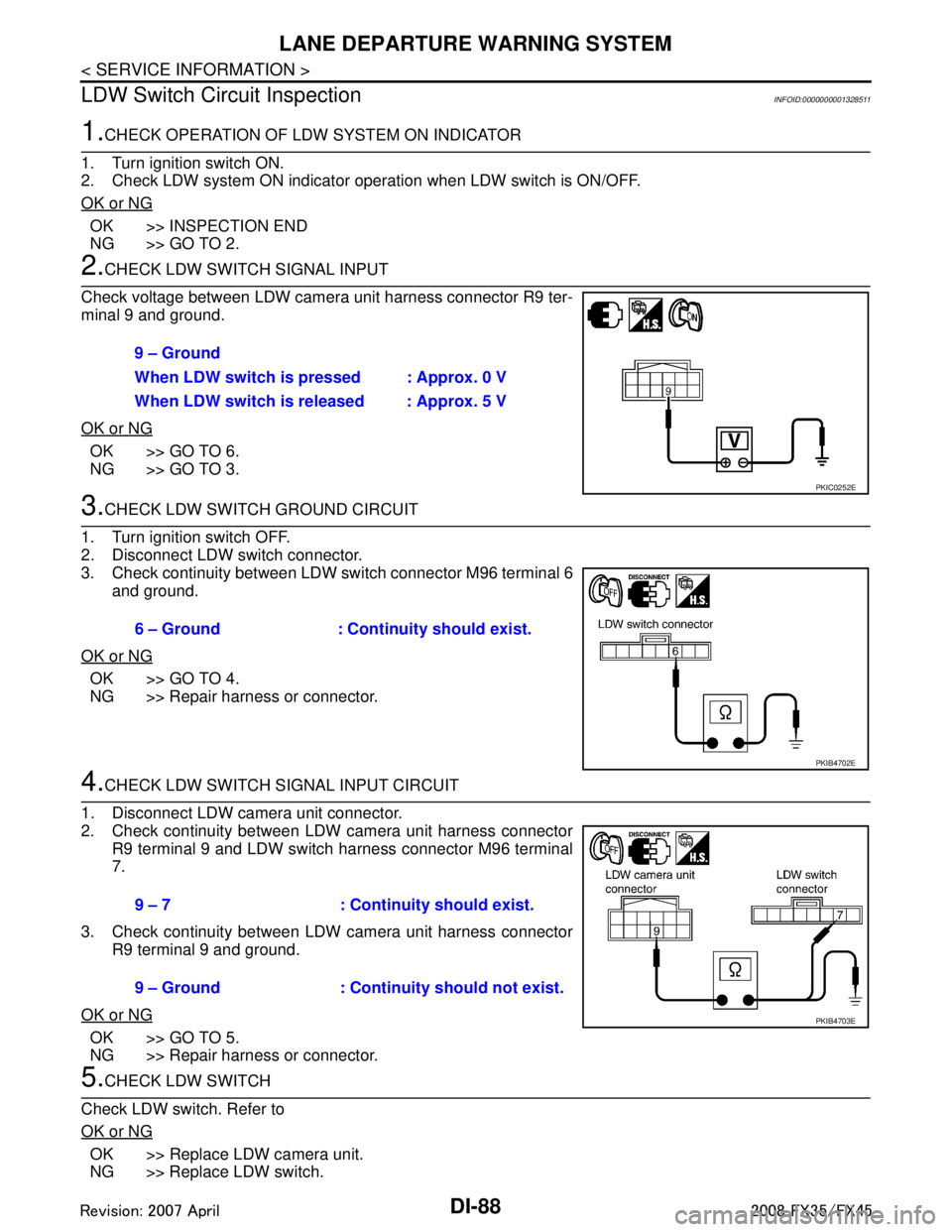

3.CHECK LDW SWITCH GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect LDW switch connector.

3. Check continuity between LDW switch connector M96 terminal 6 and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair harness or connector.

4.CHECK LDW SWITCH SIGNAL INPUT CIRCUIT

1. Disconnect LDW camera unit connector.

2. Check continuity between LDW camera unit harness connector R9 terminal 9 and LDW switch harness connector M96 terminal

7.

3. Check continuity between LDW camera unit harness connector R9 terminal 9 and ground.

OK or NG

OK >> GO TO 5.

NG >> Repair harness or connector.

5.CHECK LDW SWITCH

Check LDW switch. Refer to

OK or NG

OK >> Replace LDW camera unit.

NG >> Replace LDW switch. 9 – Ground

When LDW switch is pressed : Approx. 0 V

When LDW switch is released : Approx. 5 V

PKIC0252E

6 – Ground : Continuity should exist.

PKIB4702E

9 – 7 : Continuity should exist.

9 – Ground : Continuity should not exist.

PKIB4703E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1215 of 3924

LANE DEPARTURE WARNING SYSTEMDI-89

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

6.CHECK OPERATION OF LDW SYSTEM ON INDICATOR

Check LDW system ON indicator oper ation “SYSTEM ON LAMP DRIVE” in “Active Test” mode with CON-

SULT-III.

NOTE:

Perform “SYSTEM ON LAMP DRIVE” when LDW system ON indicator turns OFF.

OK or NG

OK >> Replace LDW camera unit.

NG >> GO TO 7.

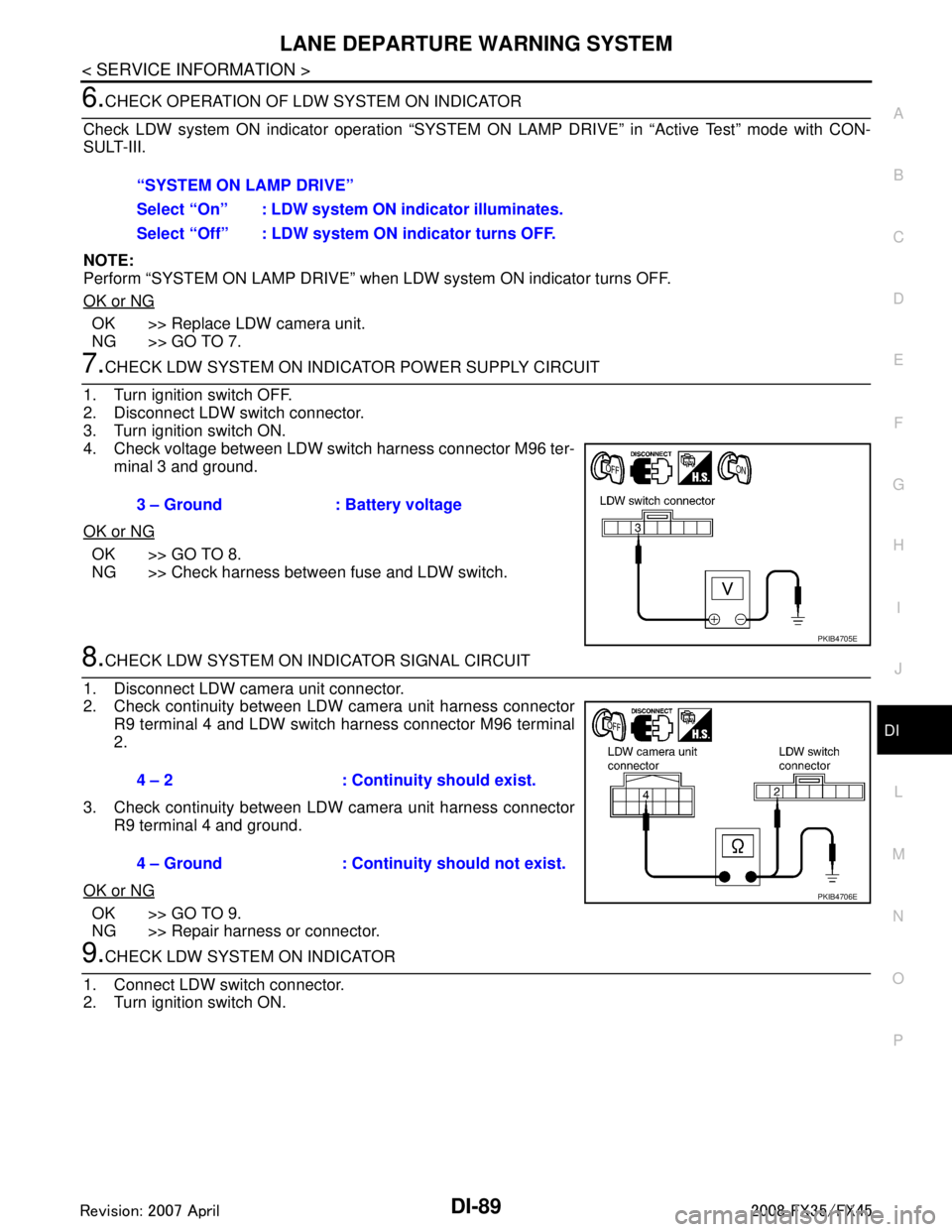

7.CHECK LDW SYSTEM ON INDICATOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect LDW switch connector.

3. Turn ignition switch ON.

4. Check voltage between LDW switch harness connector M96 ter- minal 3 and ground.

OK or NG

OK >> GO TO 8.

NG >> Check harness between fuse and LDW switch.

8.CHECK LDW SYSTEM ON INDICATOR SIGNAL CIRCUIT

1. Disconnect LDW camera unit connector.

2. Check continuity between LDW camera unit harness connector R9 terminal 4 and LDW switch harness connector M96 terminal

2.

3. Check continuity between LDW camera unit harness connector R9 terminal 4 and ground.

OK or NG

OK >> GO TO 9.

NG >> Repair harness or connector.

9.CHECK LDW SYSTEM ON INDICATOR

1. Connect LDW switch connector.

2. Turn ignition switch ON. “SYSTEM ON LAMP DRIVE”

Select “On” : LDW system ON

indicator illuminates.

Select “Off” : LDW system ON indicator turns OFF.

3 – Ground : Battery voltage

PKIB4705E

4 – 2 : Continuity should exist.

4 – Ground : Continuity should not exist.

PKIB4706E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1216 of 3924

DI-90

< SERVICE INFORMATION >

LANE DEPARTURE WARNING SYSTEM

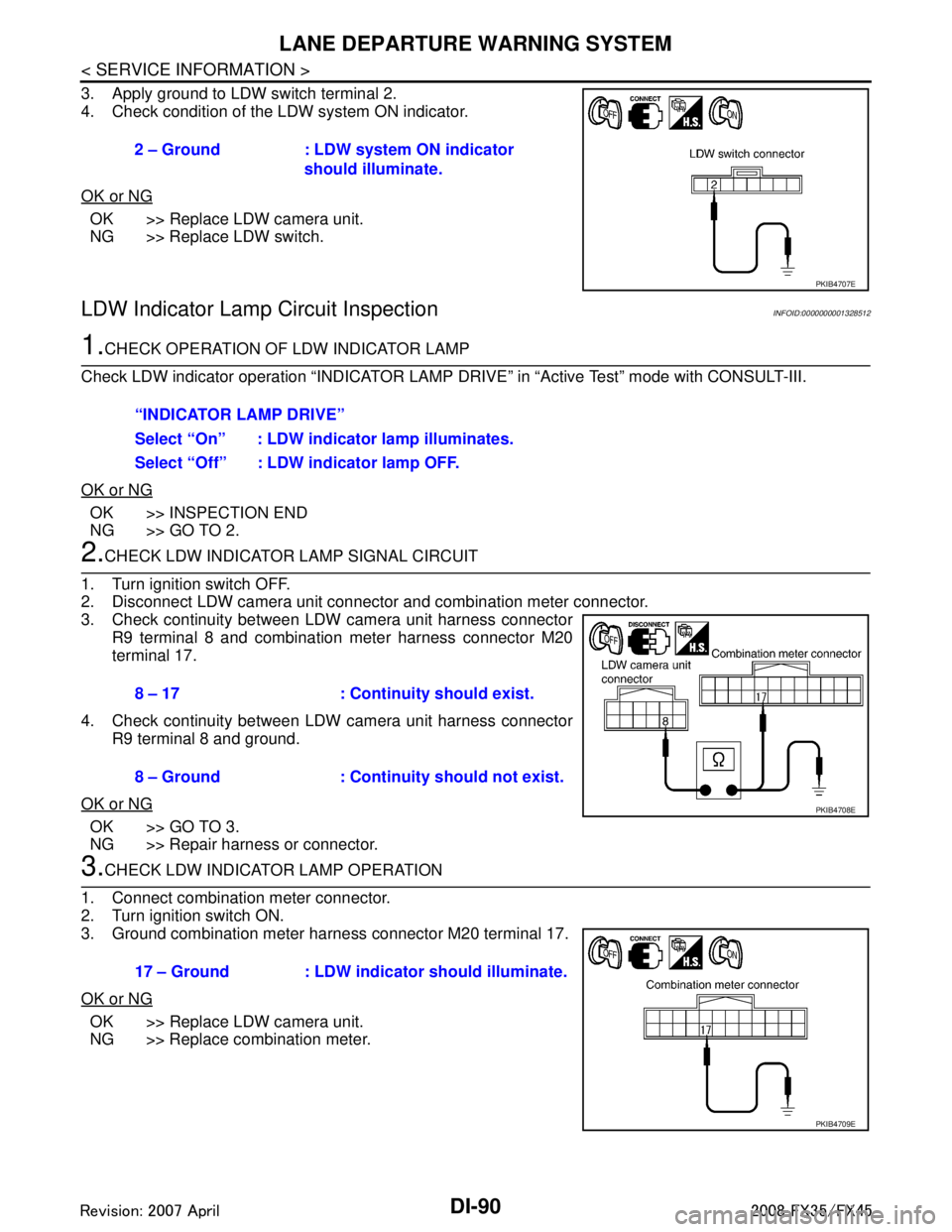

3. Apply ground to LDW switch terminal 2.

4. Check condition of the LDW system ON indicator.

OK or NG

OK >> Replace LDW camera unit.

NG >> Replace LDW switch.

LDW Indicator Lamp Circuit InspectionINFOID:0000000001328512

1.CHECK OPERATION OF LDW INDICATOR LAMP

Check LDW indicator operation “INDICATOR LAMP DR IVE” in “Active Test” mode with CONSULT-III.

OK or NG

OK >> INSPECTION END

NG >> GO TO 2.

2.CHECK LDW INDICATOR LAMP SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect LDW camera unit connector and combination meter connector.

3. Check continuity between LDW camera unit harness connector R9 terminal 8 and combination meter harness connector M20

terminal 17.

4. Check continuity between LDW camera unit harness connector R9 terminal 8 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK LDW INDICATOR LAMP OPERATION

1. Connect combination meter connector.

2. Turn ignition switch ON.

3. Ground combination meter harness connector M20 terminal 17.

OK or NG

OK >> Replace LDW camera unit.

NG >> Replace combination meter. 2 – Ground : LDW system ON indicator

should illuminate.

PKIB4707E

“INDICATOR LAMP DRIVE”

Select “On” : LDW indicator lamp illuminates.

Select “Off” : LDW indicator lamp OFF.

8 – 17 : Continuity should exist.

8 – Ground : Continuity should not exist.

PKIB4708E

17 – Ground : LDW indicator should illuminate.

PKIB4709E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1221 of 3924

COMPASSDI-95

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

During normal operation, the Compass Mirror will cont inuously update the compass calibration to adjust for

gradual changes in the vehicle's magnetic “remnant” field. If the vehicle is subjected to high magnetic influ-

ences, the compass may appear to indicate false headings , become locked, or appear that it is unable to be

calibrated. If this occurs, perform the calibration procedure.

If at any time the compass continually displays the inco rrect direction or the reading is erratic or locked, ver-

ify the correct zone variance.

Troubleshooting Chart

Zone Variation Setting ProcedureINFOID:0000000001328523

NOTE:

The zone setting is factory preset (“default” setting) to zone 8.

1. Press and hold the inside mirror switch for 6 – 9 seconds.

2. The current zone setting appears on the compass display.

3. Find the current geographical location number in the Zone Varia-

tion Chart.

4. Select the new zone number. (Press the inside mirror switch until the new zone number appears on the compass display.)

5. After select the new zone number, the compass display will automatically shows a direction within a few seconds.

6. Preform the following Calibration Procedure for more accurate indications.

Calibration ProcedureINFOID:0000000001328524

NOTE:

The compass calibrates itself under normal driving conditions. However, occasional circumstances may cause

the compass to operate inaccurately. Example: Driving from rural (wide open) areas to crowded city areas, or

Symptom Cause Solution / Reference

The compass display reads “C”.

Compass is not calibrated.

Incorrect zone variance setting.

Large change in magnetic field (Steel bridges, subways, concentrations of met-

al, carwashes, etc.)

Compass was calibrated incorrectly or in

the presence of a strong magnetic field. Perform Calibration.

Refer to

DI-95, "

Calibration Procedure".

Compass shows the wrong direction.

Compass does not change direction – ap-

pears “Locked”.

Compass does not show all the directions,

one or more is missing.

The compass was calibrated but it “loses”

calibration.

On long trips the compass shows the wrong

direction.

Perform Zone Variatio

n Setting if correct

reading is desired in that location.

Refer to DI-95, "

Zone Variation Setting Pro-

cedure".

Compass does not work – No direction is

displayed. Compass not turned ON.

Check for green LED indicator (inside mir-

ror switch).

No power to inside mirror. Check power supply circuit.

SEL168Y

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1241 of 3924

EC-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION EC

A

EC

N

O P

CONTENTS

ENGINE CONTROL SYSTEM

VQ35DE

SERVICE INFORMATION .. .........................

17

INDEX FOR DTC ............................................ ....17

DTC No. Index .................................................... ....17

Alphabetical Index ...................................................20

PRECAUTIONS ..................................................25

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

25

Precaution for Procedure without Cowl Top Cover ....25

On Board Diagnosis (OBD) System of Engine and

A/T ...........................................................................

25

Precaution ...............................................................26

PREPARATION ..................................................29

Special Service Tool ........................................... ....29

Commercial Service Tool ........................................30

ENGINE CONTROL SYSTEM ............................31

Schematic ........................................................... ....31

Multiport Fuel Injection (MFI) System .....................31

Electronic Ignition (EI) System ................................34

Fuel Cut Control (at No Load and High Engine

Speed) .....................................................................

34

AIR CONDITIONING CUT CONTROL ...............36

Input/Output Signal Chart .................................... ....36

System Description .................................................36

AUTOMATIC SPEED CONTROL DEVICE

(ASCD) ...............................................................

37

System Description ............................................. ....37

Component Description ...........................................38

CAN COMMUNICATION ....................................39

System Description ............................................. ....39

EVAPORATIVE EMISSION SYSTEM ................40

Description .......................................................... ....40

Component Inspection ......................................... ....42

Removal and Installation .........................................44

How to Detect Fuel Vapor Leakage .........................44

ON BOARD REFUELING VAPOR RECOV-

ERY (ORVR) ......................................................

46

System Description ..................................................46

Diagnosis Procedure ...............................................46

Component Inspection .............................................48

POSITIVE CRANKCASE VENTILATION .........51

Description ...............................................................51

Component Inspection .............................................51

IVIS (INFINITI VEHICLE IMMOBILIZER SYS-

TEM-NATS) .......................................................

53

Description ...............................................................53

ON BOARD DIAGNOSTIC (OBD) SYSTEM ....54

Introduction ..............................................................54

Two Trip Detection Logic .........................................54

Emission-Related Diagnostic Information ................55

Malfunction Indicator Lamp (MIL) ............................71

OBD System Operation Chart .................................74

BASIC SERVICE PROCEDURE .......................80

Basic Inspection ......................................................80

Idle Speed and Ignition Timing Check .....................84

Procedure After Replacing ECM .............................84

VIN Registration ......................................................84

Accelerator Pedal Released Position Learning .......85

Throttle Valve Closed Position Learning .................85

Idle Air Volume Learning .........................................85

Fuel Pressure Check ...............................................87

TROUBLE DIAGNOSIS ....................................89

Trouble Diagnosis Introduction ................................89

DTC Inspection Priority Chart ..................................93

Fail-Safe Chart ........................................................95

Symptom Matrix Chart .............................................96

Engine Control Component Parts Location ...........100

Vacuum Hose Drawing ..........................................106

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1248 of 3924

EC-8

Component Inspection ...........................................545

ASCD INDICATOR ..........................................547

Component Description ....................................... ..547

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

547

Wiring Diagram ......................................................548

Diagnosis Procedure .............................................548

ELECTRICAL LOAD SIGNAL .........................550

Description ........................................................... ..550

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

550

Diagnosis Procedure .............................................550

FUEL INJECTOR .............................................552

Component Description ....................................... ..552

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

552

Wiring Diagram ......................................................553

Diagnosis Procedure .............................................554

Component Inspection ...........................................557

Removal and Installation .......................................557

FUEL PUMP .....................................................558

Description ........................................................... ..558

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

558

Wiring Diagram ......................................................559

Diagnosis Procedure .............................................560

Component Inspection ...........................................562

Removal and Installation .......................................562

ICC BRAKE SWITCH ......................................563

Component Description ....................................... ..563

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

563

Wiring Diagram ......................................................564

Diagnosis Procedure .............................................565

Component Inspection ...........................................567

IGNITION SIGNAL ...........................................569

Component Description ....................................... ..569

Wiring Diagram ......................................................570

Diagnosis Procedure .............................................575

Component Inspection ...........................................578

Removal and Installation .......................................580

REFRIGERANT PRESSURE SENSOR ..........581

Component Description ....................................... ..581

Wiring Diagram ......................................................582

Diagnosis Procedure .............................................583

Removal and Installation .......................................585

SNOW MODE SWITCH ...................................586

Description ........................................................... ..586

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

586

Wiring Diagram ......................................................587

Diagnosis Procedure .............................................587

Component Inspection ...........................................589

MIL AND DATA LINK CONNECTOR ...............591

Wiring Diagram .................................................... .591

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................

593

Fuel Pressure ....................................................... .593

Idle Speed and Ignition Timing .............................593

Calculated Load Value ..........................................593

Mass Air Flow Sensor ...........................................593

Intake Air Temperature Sensor .............................593

Engine Coolant Temperature Sensor ...................593

Air Fuel Ratio (A/F) Sensor 1 Heater ....................593

Heated Oxygen sensor 2 Heater ..........................593

Crankshaft Position Sensor (POS) .......................594

Camshaft Position Sensor (PHASE) .....................594

Throttle Control Motor .......................................... .594

Fuel Injector ..........................................................594

Fuel Pump .............................................................594

VK45DE

SERVICE INFORMATION .. .......................

595

INDEX FOR DTC ............................................ ..595

DTC No. Index ..................................................... .595

Alphabetical Index .................................................598

PRECAUTIONS .............................................. ..603

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. .

603

Precaution for Procedure without Cowl Top Cover .603

On Board Diagnosis (OBD) System of Engine and

A/T ........................................................................

603

Precaution .............................................................604

PREPARATION ................................................607

Special Service Tool ............................................ .607

Commercial Service Tool ......................................608

ENGINE CONTROL SYSTEM ..........................609

Schematic ............................................................ .609

Multiport Fuel Injection (MFI) System ...................609

Electronic Ignition (EI) System ..............................612

Fuel Cut Control (at No Load and High Engine

Speed) ..................................................................

612

AIR CONDITIONING CUT CONTROL .............614

Input/Output Signal Chart .................................... .614

System Description ...............................................614

AUTOMATIC SPEED CONTROL DEVICE

(ASCD) ..............................................................

615

System Description .............................................. .615

Component Description ........................................616

CAN COMMUNICATION ..................................617

System Description .............................................. .617

EVAPORATIVE EMISSION SYSTEM ..............618

Description ........................................................... .618

Component Inspection ..........................................620

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1249 of 3924

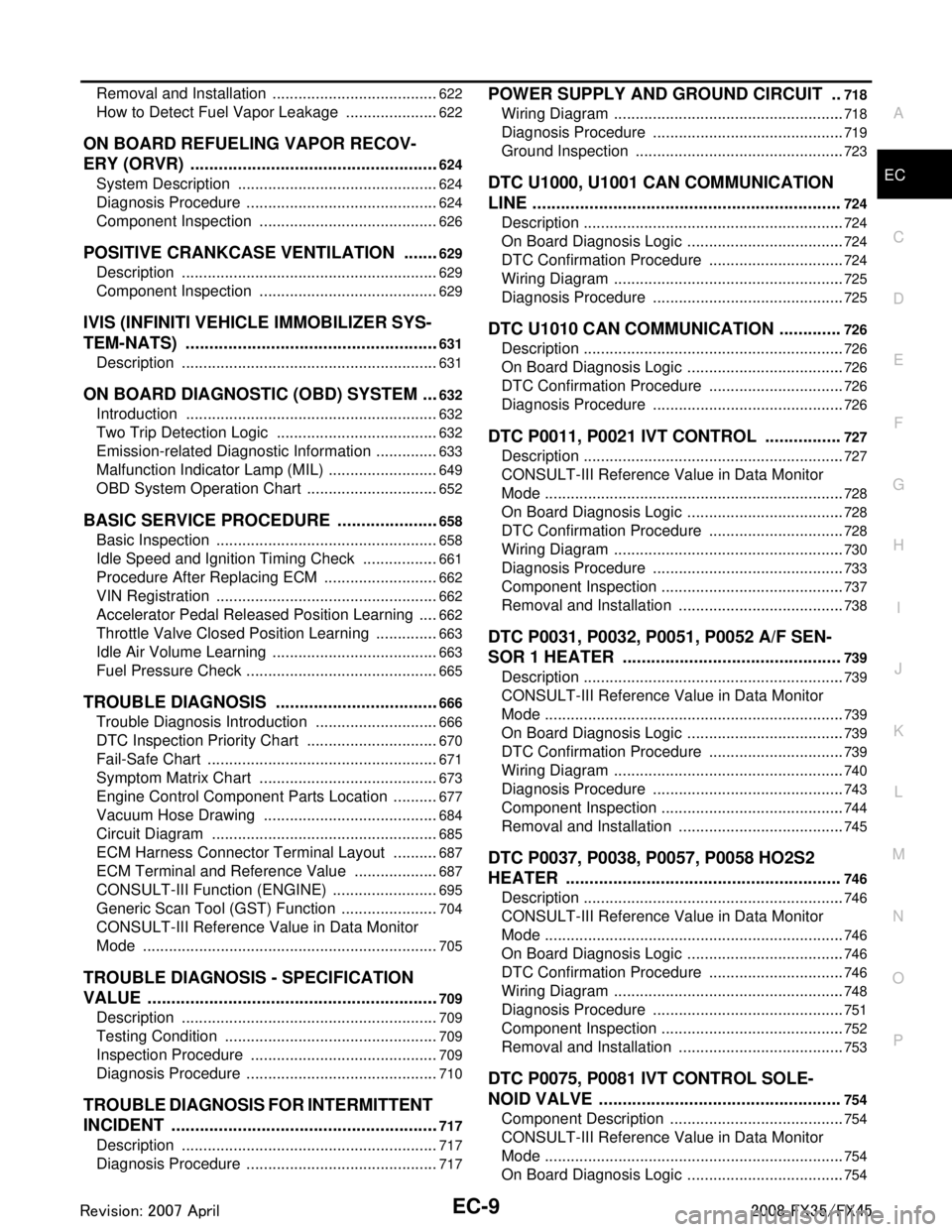

EC-9

C

DE

F

G H

I

J

K L

M

EC A

N

O P

Removal and Installation .....................................

..

622

How to Detect Fuel Vapor Leakage ......................622

ON BOARD REFUELING VAPOR RECOV-

ERY (ORVR) .....................................................

624

System Description ............................................. ..624

Diagnosis Procedure .............................................624

Component Inspection ..........................................626

POSITIVE CRANKCASE VENTILATION ........629

Description .......................................................... ..629

Component Inspection ..........................................629

IVIS (INFINITI VEHICLE IMMOBILIZER SYS-

TEM-NATS) ......................................................

631

Description .......................................................... ..631

ON BOARD DIAGNOSTIC (OBD) SYSTEM ....632

Introduction ......................................................... ..632

Two Trip Detection Logic ......................................632

Emission-related Diagnostic Information ...............633

Malfunction Indicator Lamp (MIL) ..........................649

OBD System Operation Chart ...............................652

BASIC SERVICE PROCEDURE ......................658

Basic Inspection .................................................. ..658

Idle Speed and Ignition Timing Check ..................661

Procedure After Replacing ECM ...........................662

VIN Registration ....................................................662

Accelerator Pedal Released Position Learning .....662

Throttle Valve Closed Position Learning ...............663

Idle Air Volume Learning .......................................663

Fuel Pressure Check .............................................665

TROUBLE DIAGNOSIS ...................................666

Trouble Diagnosis Introduction ........................... ..666

DTC Inspection Priority Chart ...............................670

Fail-Safe Chart ......................................................671

Symptom Matrix Chart ..........................................673

Engine Control Component Parts Location ...........677

Vacuum Hose Drawing .........................................684

Circuit Diagram .....................................................685

ECM Harness Connector Terminal Layout ...........687

ECM Terminal and Reference Value ....................687

CONSULT-III Function (ENGINE) .........................695

Generic Scan Tool (GST) Function .......................704

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ..

705

TROUBLE DIAGNOSIS - SPECIFICATION

VALUE ..............................................................

709

Description .......................................................... ..709

Testing Condition ..................................................709

Inspection Procedure ............................................709

Diagnosis Procedure .............................................710

TROUBLE DIAGNOSIS FOR INTERMITTENT

INCIDENT .........................................................

717

Description .......................................................... ..717

Diagnosis Procedure .............................................717

POWER SUPPLY AND GROUND CIRCUIT ..718

Wiring Diagram .................................................... ..718

Diagnosis Procedure .............................................719

Ground Inspection .................................................723

DTC U1000, U1001 CAN COMMUNICATION

LINE .................................................................

724

Description .............................................................724

On Board Diagnosis Logic .....................................724

DTC Confirmation Procedure ................................724

Wiring Diagram ......................................................725

Diagnosis Procedure .............................................725

DTC U1010 CAN COMMUNICATION .............726

Description .............................................................726

On Board Diagnosis Logic .....................................726

DTC Confirmation Procedure ................................726

Diagnosis Procedure .............................................726

DTC P0011, P0021 IVT CONTROL ................727

Description .............................................................727

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

728

On Board Diagnosis Logic .....................................728

DTC Confirmation Procedure ................................728

Wiring Diagram ......................................................730

Diagnosis Procedure .............................................733

Component Inspection ...........................................737

Removal and Installation .......................................738

DTC P0031, P0032, P0051, P0052 A/F SEN-

SOR 1 HEATER ..............................................

739

Description .............................................................739

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

739

On Board Diagnosis Logic .....................................739

DTC Confirmation Procedure ................................739

Wiring Diagram ......................................................740

Diagnosis Procedure .............................................743

Component Inspection ...........................................744

Removal and Installation .......................................745

DTC P0037, P0038, P0057, P0058 HO2S2

HEATER ..........................................................

746

Description .............................................................746

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

746

On Board Diagnosis Logic .....................................746

DTC Confirmation Procedure ................................746

Wiring Diagram ......................................................748

Diagnosis Procedure .............................................751

Component Inspection ...........................................752

Removal and Installation .......................................753

DTC P0075, P0081 IVT CONTROL SOLE-

NOID VALVE ...................................................

754

Component Description .........................................754

CONSULT-III Reference Value in Data Monitor

Mode ......................................................................

754

On Board Diagnosis Logic .....................................754

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C