engine INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 423 of 3924

ATC-18

< SERVICE INFORMATION >

REFRIGERATION SYSTEM

Evaporator intake air temperature is less than 20°C (68 °F).

Engine is running at speeds less than 1,500 rpm.

This is because the V-6 compressor prov ides a means of “capacity” control.

2. The V-6 variable compressor provides refrigerant c ontrol under varying conditions. During cold winters, it

may not produce high refrigerant pressure discharge (compared to previous units) when used with air

conditioning systems.

3. A “clanking” sound may occasionally be heard during re frigerant charge. The sound indicates that the tilt

angle of the wobble (swash) plate has changed and is not a malfunction.

4. For air conditioning systems with the V-6 compresso r, the clutch remains engaged unless: the system

main switch, fan switch or ignition switch is tur ned OFF. When ambient (outside) temperatures are low or

when the amount of refrigerant is insufficient, t he clutch is disengaged to protect the compressor.

DESCRIPTION

General

The variable compressor is a swash plate type that c hanges piston stroke in response to the required cooling

capacity.

The tilt of the wobble (swash) plate allows the piston’ s stroke to change so that refrigerant discharge continu-

ously change from 14.5 to 184 cm

3 (0.885 to 11.228 cu in).

RJIA1260E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 427 of 3924

ATC-22

< SERVICE INFORMATION >

LUBRICANT

LUBRICANT

Maintenance of Lubricant Quantity in CompressorINFOID:0000000001328166

The lubricant in the compressor circulates through the system with the refrigerant. Add lubricant to compres-

sor when replacing any component or after a large refriger ant leakage occurred. It is important to maintain the

specified amount.

If lubricant quantity is not maintained properly, the following malfunctions may result:

Lack of lubricant: May lead to a seized compressor.

Excessive lubricant: Inadequate cooling (thermal exchange interference)

LUBRICANT

LUBRICANT RETURN OPERATION

Adjust the lubricant quantity according to the test group shown below.

1.CHECK LUBRICANT RETURN OPERATION

Can lubricant return operation be performed?

A/C system works properly.

There is no evidence of a lar ge amount of lubricant leakage.

CAUTION:

If excessive lubricant leakage is noted, never perform the lubricant return operation.

OK or NG

OK >> GO TO 2.

NG >> GO TO 3.

2.PERFORM LUBRICANT RETURN OPERATION, PROCEEDING AS FOLLOWS

1. Start the engine, and set to the following conditions:

- Engine speed: Idling to 1,200 rpm

- A/C switch: ON

- Blower speed: Max. position

- Temp. control: Optional [Set so that intake air temperature is 25 to 30 °C (77 to 86 °F).]

- Intake position: Recirculation (REC)

2. Perform lubricant return operation for about 10 minutes.

3. Stop the engine.

>> GO TO 3.

3.CHECK REPLACEMENT PART

Should the compressor be replaced?

YES >> Go to "LUBRICANT ADJUSTING PROCEDURE FOR COMPRESSOR REPLACEMENT".

NO >> Go to "LUBRICANT ADJUSTING PROCEDURE FOR COMPONENTS REPLACEMENT EXCEPT COMPRESSOR".

LUBRICANT ADJUSTING PROCEDURE FOR COMPONENTS REPLACEMENT EXCEPT COM-

PRESSOR

After replacing any of the followi ng major components, add the correct am ount of lubricant to the system.

Amount of lubricant to be added: Name : NISSAN A/C System Oil Type S

Part replaced

Lubricant to be added to system

Remarks

Amount of lubricant

m (US fl oz., Imp fl oz.)

Evaporator 75 (2.5, 2.6) —

Condenser 35 (1.2, 1.2) —

Liquid tank 10 (0.3, 0.4) —

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 431 of 3924

ATC-26

< SERVICE INFORMATION >

AIR CONDITIONER CONTROL

The air mix doors are automatically controlled so that in-vehicle temperature is maintained at a predetermined

value by the temperature setting, ambient temper ature, in-vehicle temperature and amount of sunload.

FAN SPEED CONTROL

Blower speed is automatically controlled by the temperature setting, ambient temperature, in-vehicle tempera-

ture, intake temperature, amount of sunload and air mix door position.

With pressing AUTO switch, the blower motor starts to gradually increase air flow volume.

When engine coolant temperature is low, the blower moto r operation is delayed to prevent cool air from flow-

ing.

INTAKE DOOR CONTROL

The intake doors are automatically controlled by the tem perature setting, ambient temperature, in-vehicle tem-

perature, intake temperature, amount of s unload and ON/OFF operation of the compressor.

MODE DOOR CONTROL

The mode door is automatically controlled by the temperat ure setting, ambient temperature, in-vehicle temper-

ature, intake temperature and amount of sunload.

MAGNET CLUTCH CONTROL

When A/C switch, AUTO switch or DEF switch is pr essed, unified meter and A/C amp. transmits compressor

ON signal to BCM.

BCM sends compressor ON signal to ECM, via CAN communication.

ECM judges whether compressor can be turned ON, based on each sensor status (refrigerant-pressure sen-

sor signal, throttle angle, etc.). If it judges compre ssor can be turned ON, it sends compressor ON signal to

IPDM E/R, via CAN communication.

Upon receipt of compressor ON signal from ECM, IPDM E/R turns air conditioner relay ON to operate com-

pressor.

When sending compressor ON signal to IPDM E/R via CAN communication, ECM simultaneously sends com-

pressor feedback signal to unified meter and A/C amp. via CAN communication.

Unified meter and A/C amp., then, uses input compressor feedback signal to control air inlet.

SELF-DIAGNOSIS SYSTEM

The self-diagnosis system is built into the unified mete r and A/C amp. to quickly locate the cause of malfunc-

tions.

RJIA1957E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 439 of 3924

ATC-34

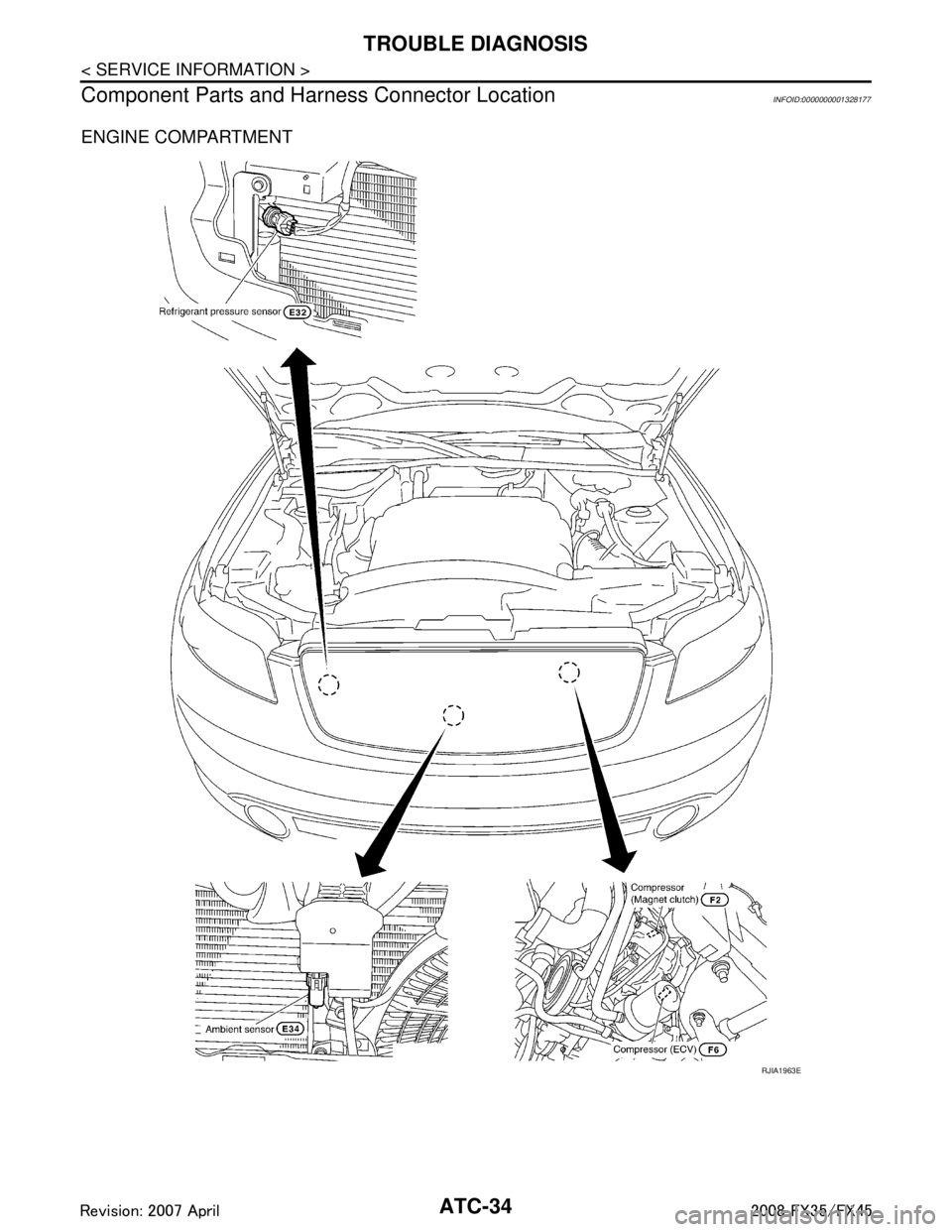

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

Component Parts and Harn ess Connector Location

INFOID:0000000001328177

ENGINE COMPARTMENT

RJIA1963E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 448 of 3924

TROUBLE DIAGNOSISATC-43

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

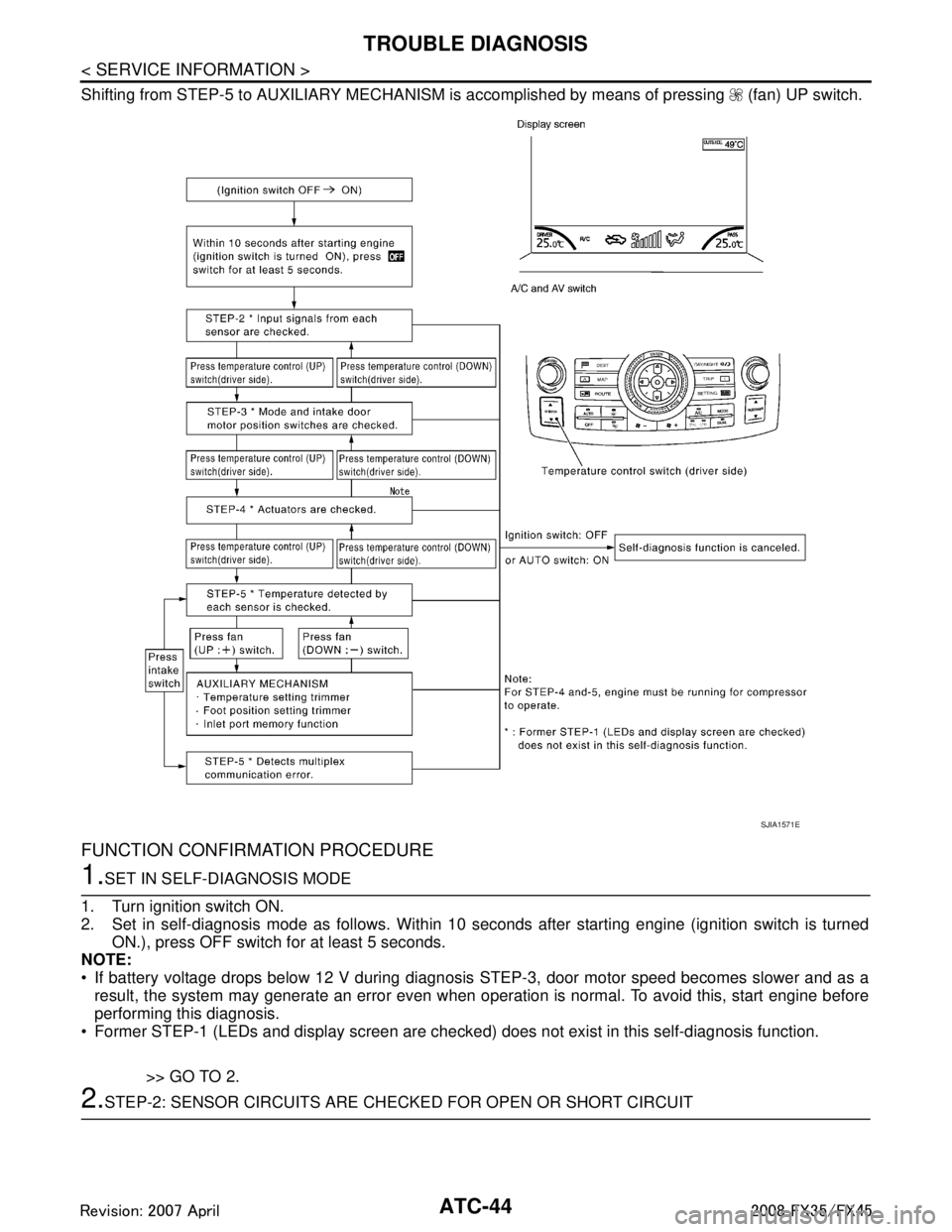

Self-Diagnosis FunctionINFOID:0000000001328181

DESCRIPTION

The self-diagnosis system diagnoses sensors, door motors, blower motor, etc. by system line. Refer to appli-

cable sections (items) for details. Shifting from norma l control to the self-diagnosis system is accomplished by

starting the engine (turning the ignition switch ON) and pr essing OFF switch for at least 5 seconds. The OFF

switch must be pressed within 10 seconds after starting the engine (ignition switch is turned ON). This system

will be canceled by either pressing AUTO switch or turn ing the ignition switch OFF. Shifting from one step is

accomplished by means of pressi ng temperature control switch (driver side), as required.

43 G/B A/C LAN signal ON —

45 PU/WECV (Electric Control Valve)

signal ONSelf-diagnosis. STEP-4

(Code No. 45)

46 L/W Power supply for IGN2 ON — Battery voltage

49 W/G Sensor ground ON — Approx. 0

50 LG Sunload sensor — — —

53 G Blower motor control signal ON Blower speed: 1st speed (man-

ual)

54 Y/R Power supply for each door

motor ON — Battery voltage

57 BR/Y Blower motor ON signal ON A/C switch: ON

(Blower motor operates.)

Approx. 0

OFF switch: ON

(A/C system: OFF)

Te r m i n a l

No. Wire

color ItemIgnition

switch Condition Vol tag e

(V)

SJIA1453J

SJIA1607E

SJIA1454J

SJIA1474J

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 449 of 3924

ATC-44

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

Shifting from STEP-5 to AUXILIARY MECHANISM is accomplished by means of pressing (fan) UP switch.

FUNCTION CONFIRMATION PROCEDURE

1.SET IN SELF-DIAGNOSIS MODE

1. Turn ignition switch ON.

2. Set in self-diagnosis mode as follows. Within 10 seconds after starting engine (ignition switch is turned ON.), press OFF switch for at least 5 seconds.

NOTE:

If battery voltage drops below 12 V during diagnosis STEP-3, door motor speed becomes slower and as a

result, the system may generate an error even when operation is normal. To avoid this, start engine before

performing this diagnosis.

Former STEP-1 (LEDs and display screen are checked) does not exist in this self-diagnosis function.

>> GO TO 2.

2.STEP-2: SENSOR CIRCUITS ARE CHECK ED FOR OPEN OR SHORT CIRCUIT

SJIA1571E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 455 of 3924

ATC-50

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

4. Press the mode switch as desired.

When battery cable is disconnected or battery voltage is below 10 V, trimmer operation is canceled. Wind dis-

tribution ratio set becomes that of initial condition.

AUXILIARY MECHANISM: INLET PORT MEMORY FUNCTION

When ignition switch is turned from OFF to ON, inlet port memory function at manual mode can be set.

Operating procedures for this trimmer are as follows:1. Begin self-diagnosis STEP-5 mode. Refer to "Self-diagnosis Function".

2. Press (fan) UP switch to set system in auxiliary mode.

3. Press the intake switch as desired.

When battery cable is disconnected or battery voltage is below 10 V, memory function is canceled. Memory

function set becomes that of initial condition.

Operational CheckINFOID:0000000001328182

The purpose of the operational check is to c heck if the individual system operates properly.

CHECKING MEMORY FUNCTION

1. Press the temperature control (UP) switch (driver side) until 32°C (90 °F) is displayed.

2. Press OFF switch.

3. Turn ignition switch OFF.

4. Turn ignition switch ON.

5. Press the AUTO switch.

6. Confirm that the set temperature remains at previous temperature.

7. Press OFF switch.

If NG, go to trouble diagnosis procedure for ATC-85, "

Memory Function".

If OK, continue the check.

CHECKING BLOWER

SJIA1581E

LED status of

FRE position LED status of

REC position Setting status

Setting changeover

method

FRE REC

OFF OFF AUTO control AUTO control

Intake SW: ON

OFF ON AUTO control (Initial setting)

Manual REC status is memorized.

(Initial setting)

ON OFF Manual FRE status is memorized. AUTO control

ON ON Manual FRE status is memorized. Manual REC status is memorized.

Conditions : Engine running at normal operating temperature

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 471 of 3924

ATC-66

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

Intake sensor

System Operation

Automatic Mode

In the automatic mode, the blower motor speed is calculated by the unified meter and A/C amp. based on the

input from the PBR, in-vehicle sensor, sunl oad sensor, intake sensor and ambient sensor.

When the air flow is increased, the duty ratio of the blower fan motor’s drive signal is changed at 8%/sec. to

prevent a sudden increase in air flow.

In addition to manual air flow control and the usual automat ic air flow control, starting air flow control, low

water temperature starting control and high passenger co mpartment temperature starting control are avail-

able.

Starting Fan Speed Control

Start up from COLD SOAK Condition (Automatic mode)

In a cold start up condition where the engine coolant temperature is below 56 °C (133 °F), the blower will not

operate for a short period of time (up to 150 seconds ). The exact start delay time varies depending on the

ambient and engine coolant temperature.

In the most extreme case (very low ambient) the blower starting delay will be 150 seconds as described

above. After this delay, the blower will operate at lo w speed until the engine coolant temperature rises above

56 °C (133 °F), and then the blower speed will increase to the objective speed.

Start up from usual or HOT SOAK Condition (Automatic mode)

The blower will begin operation momentarily after the AU TO switch is pressed. The blower speed will gradu-

ally rise to the objective speed over a time period of 3 seconds or less (actual time depends on the objective

blower speed).

Blower Speed Compensation

Sunload

When the in-vehicle temperature and the set temperature are very close, the blower will be operating at low

speed. The low speed will vary depending on the sunload. Du ring conditions of low or no sunload, the blower

speed is at duty ratio 25%. During high sunload conditi ons, the unified meter and A/C amp. raise the blower

speed (duty ratio 49%).

Fan Speed Control Specification

RJIA1995E

RJIA1996E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 477 of 3924

ATC-72

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

3. Check continuity between BCM harness connector M3 terminal27 and unified meter and A/C amp. harness connector M57 ter-

minal 42.

OK or NG

OK >> GO TO 7.

NG >> Repair harness or connector.

7.CHECK VOLTAGE FOR UNIFIED METER AND A/C AMP. (COMPRESSOR ON SIGNAL)

1. Reconnect BCM connector and unified meter and A/C amp. connector.

2. Turn ignition switch ON.

3. Check voltage between unified meter and A/C amp. harness connector M57 terminal 42 and ground using an oscilloscope.

OK or NG

OK >> GO TO 8.

NG-1 >> If the voltage is approx. 5 V when A/C switch is ON: Replace unified meter and A/C amp.

NG-2 >> If the voltage is approx. 0 V w hen A/C switch is OFF: Replace BCM.

8.CHECK REFRIGERANT PRESSURE SENSOR

WITH CONSULT-III

1. Start the engine.

2. Check voltage of refrigerant pressure sensor in “Data monitor”. Refer to EC-127, "

CONSULT-III Reference

Value in Data Monitor Mode" (VQ35DE) or EC-705, "CONSULT-III Reference Value in Data Monitor

Mode" (VK45DE).

WITHOUT CONSULT-III

1. Start the engine. 27 – 42 : Continuity should exist.

RJIA2006E

RJIA2007E

Te r m i n a l s

Condition Voltage

(+)

(− )

Unified meter

and A/C amp.

connector Te r m i n a l

No.

M57 42 Ground A/C switch: ON

(Blower motor operates.)

Approx. 0 V

OFF switch: ON

(A/C system: OFF)

SJIA1423J

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 483 of 3924

ATC-78

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

Test Reading

Recirculating-to-discharge Air Temperature Table

Ambient Air Temperature-to -operating Pressure Table

TROUBLE DIAGNOSIS FOR UNUSUAL PRESSURE

Whenever system’s high and/or low side pressure(s) is/are unusual, diagnose using a manifold gauge. The

marker above the gauge scale in the following tables indicates the standard (usual) pressure range. Since the

standard (usual) pressure, however, differs from vehicle to vehicle, refer to above table (Ambient air tempera-

ture-to-operating pressure table).

Both High- and Low-pressure Sides are Too High

Hood Open

TEMP. Max. COLD

Mode switch (Ventilation) set

Intake switch (Recirculation) set

Fan (blower) speed Max. speed set

Engine speed Idle speed

Operate the air conditioning system for 10 minutes before taking measurements.

Inside air (Recirculating air) at blower assembly inlet Discharge air temperature at center ventilator

°C ( °F)

Relative humidity

% Air temperature

°C ( °F)

50 - 60 20 (68) 11.2 - 13.2 (52 - 56)

25 (77) 12.2 - 14.8 (54 - 59)

30 (86) 15.5 - 18.6 (60 - 65)

35 (95) 21.0 - 24.5 (70 - 76)

40 (104) 28.7 - 32.6 (84 - 91)

60 - 70 20 (68) 13.2 - 15.2 (56 - 59)

25 (77) 14.8 - 17.3 (59 - 63)

30 (86) 18.6 - 21.6 (65 - 71)

35 (95) 24.5 - 28.0 (76 - 82)

40 (104) 32.6 - 36.5 (91 - 98)

Ambient air High-pressure (Discharge side)

kPa (kg/cm

2, psi) Low-pressure (Suction side)

kPa (kg/cm2, psi)

Relative humidity

% Air temperature

°C ( °F)

50 - 70 20 (68)

961 - 1,167

(9.8 - 11.9, 139 - 169) 216 - 265

(2.2 - 2.7, 31 - 38)

25 (77) 1,108 - 1,353

(11.3 - 13.8, 161 - 196) 230 - 281

(2.3 - 2.9, 33 - 41)

30 (86) 1,275 - 1,549

(13.0 - 15.8, 185 - 225) 261 - 320

(2.7 - 3.3, 38 - 46)

35 (95) 1,549 - 1,893

(15.8 - 19.3, 225 - 274) 297 - 364

(3.0 - 3.7, 43 - 53)

40 (104) 1,814 - 2,216

(18.5 - 22.6, 263 - 321) 357 - 435

(3.6 - 4.4, 52 - 63)

Vehicle condition Indoors or in the shade (in a well-ventilated place)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C