engine INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 666 of 3924

NAVIGATION SYSTEMAV-119

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

AV

N

O P

Confirmation/Adjustment ModeINFOID:0000000001328755

OPERATION PROCEDURE

1. Start the engine.

2. Turn the audio system OFF.

Self-diagnosis result screen Possible cause Action to take

NAVI control unit malfunction is detect-

ed. Replace NAVI control unit.

Refer to

AV- 1 4 1 , "

Removal and Installa-

tion of NAVI Control Unit".

Malfunction is detected on DVD- ROM drive pickup lens in NAVI con-

trol unit.

There is dirt and damage on the

DVD-ROM. 1. Check if the inserted DVD-ROM is

specified for this navigation system,

and the DVD-ROM is dirty, scratched

or warped.

2. If the results from the above checkup show no malfunction, insert the

same DVD-ROM, and then restart

self-diagnosis.

3. If self-diagnosis results still show any malfunction, replace NAVI control

unit.

DVD-ROM not inserted is detected. Insert DVD-ROM.

GPS antenna connection malfunction

is detected. 1. Check if GPS antenna feeder line is

snapped or pinched.

2. If the results from the above checkup

show no malfunction, replace GPS

antenna, and then restart self-diag-

nosis.

3. If self-diagnosis results still show any malfunction, replace NAVI control

unit.

SKIB7773E

SKIB7774E

SKIB7775E

SKIB7776E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 672 of 3924

NAVIGATION SYSTEMAV-125

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

AV

N

O P

Erase the connection history of unit and error history that is recorded

in NAVI control unit (clear the connection history of the removed

unit).

CAN Diagnostic Support MonitorINFOID:0000000001328756

OPERATION PROCEDURE

1. Start the engine.

2. Turn the audio system OFF.

3. While pressing the “4” button, turn the volume control dial clock- wise or counterclockwise for 30 clicks or more. (When the self-

diagnosis mode is started, a short beep will be heard.)

Shifting from current screen to previous screen is performedby pressing “BACK” button.

4. The initial trouble diagnosis screen will be shown, and items “Self Diagnosis (DCU)”, “Self Diagnosis (NAVI)”, “Confirmation/

Adjustment” and “CAN DIAG SUPPORT MONITOR” will

become selective.

5. Select “CAN DIAG SUPPORT MONITOR”.

6. The transmitting/receiving of CAN communication can be moni- tored.

SKIB6979E

SKIB8642E

SKIB7874E

Item Content Error counter

(Reference value)

CAN_COMM OK/NG 0 - 50

CAN_CIRC_1 OK/UNKWN 0 - 50

CAN_CIRC_2 OK/UNKWN 0 - 50

CAN_CIRC_3 OK/UNKWN 0 - 50

CAN_CIRC_4 OK/UNKWN 0 - 50

CAN_CIRC_5 OK/UNKWN 0 - 50

CAN_CIRC_6 OK/UNKWN 0 - 50

CAN_CIRC_7 OK/UNKWN 0 - 50

SKIA4288E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 714 of 3924

TELEPHONEAV-167

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

AV

N

O P

Self-Diagnosis FunctionINFOID:0000000001328794

The followings are diagnosis functions performed by TEL adapter unit.

Performs the unit self −diagnosis and antenna diagnosis, and informs results with the indicator and voice

guidance.

Informs vehicle speed pulse count from the time of key switch ON with voice guidance, and enables to check

vehicle speed signal.

Outputs voice giving to microphone with speaker, and enables to check microphone function.

OPERATION PROCEDURE

1. Start the engine.

2. Press and hold switch for 5 seconds or more.

This allows the indicator to blink concurrently with voice guidance outputs, and determines if there is any

current error in the state of blinking.

17 (R/W) Ground Remote control A Output ON Press switch

Approx. 0 V

Press SEEK UP switch Approx. 1.7 V

Press VOL UP switch Approx. 3.3 V

Except for above Approx. 5 V

18 (G/W) Ground Remote control B Output ON Press switch

Approx. 0 V

Press SEEK DOWN switch Approx. 1.7 V

Press VOL DOWN switch Approx. 3.3 V

Except for above Approx. 5 V

19 (B/Y) Ground Remote control

ground — ON — Approx. 0 V

22 (B) Ground Ground — ON — Approx. 0 V

23 (B) Ground Ground — ON — Approx. 0 V

28 (G) Ground Ve h i c l e

speed signal

(8-pulse) Input ON

When vehicle speed is ap-

prox. 40 km/h (25 MPH)

29 (W) Ground MIC. VCC Output ON — Approx. 5 V 41 — TEL signal — — — — Te r m i n a l

(Wire color) ItemSignal

input/

output Condition

Reference value

+– Ignition

switch Operation

SKIA6649J

SKIB7570E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 738 of 3924

BL-4

< SERVICE INFORMATION >

DTC INDEX

SERVICE INFORMATION

DTC INDEX

INTELLGENT KEY UNIT U1000INFOID:0000000001529387

INTELLGENT KEY UNIT B2013-B2014INFOID:0000000001529388

ECM P1610-P1615INFOID:0000000001529389

CONSULT display Descr iption Reference page

U1000: CAN COMM CIRCUIT M alfunction is detected in CA N communication.

BCS-13, "

U1000 CAN

Communication Circuit"

CONSULT display Descr iption Reference page

B2013: STRG COMM 1 .Malfunction is detected in communication of Intelligent

Key unit and steering lock unit BL-124, "

Check Steering

Lock Unit"

B2014: STRG COMM 2

Malfunction is detected in communication of Intelligent Key

unit and steering lock unit. BL-124, "Check Steering

Lock Unit"

CONSULT display Descr

iption Reference page

P1610: LOCK MODE When the starting operation is carried out 5 or more times

consecutively under the following conditions, IVIS(NATS)

will shift the mode to prevent the engine start.

• unregistered ignition key is used (without intelligent key

system)

BCM or ECM malfunctioning BL-198, "

Diagnosis Proce-

dure 5"

P1611: ID DISCORD, IMM-ECM

The result of ID verification between BCM and ECM is NG.

System initialization is required. BL-197, "Diagnosis Proce-

dure 4"

P1612: CHAIN OF ECM-IMMU Communication impossible between ECM and BCM.

BL-197, "Diagnosis Proce-

dure 2"

P1613: ECM INT CIRC-IMMUThe malfunction of ECM internal circuit to BCM communi-

cation line is detected. BL-195, "Diagnosis Proce-

dure 1"

P1614: CHAIN OF IMMU-KEY BCM cannot receive the key ID signal.

BL-200, "Diagnosis Proce-

dure 6"

P1615: DIFFERENCE OF KEY

BCM can receive the key ID signal but the result of ID ver-

ification between key ID and BCM is NG. BL-197, "Diagnosis Proce-

dure 3"

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 740 of 3924

BL-6

< SERVICE INFORMATION >

PREPARATION

PREPARATION

Special Service ToolINFOID:0000000001327778

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service ToolINFOID:0000000001327779

Tool number

(Kent-Moore No.)

Tool name Description

(J-39570)

Chassis ear Locating the noise

(J-43980)

NISSAN Squeak and Rat-

tle Kit Repairing the cause of the noise

SIIA0993E

SIIA0994E

Tool name Description

Engine ear Locating the noise

Power tool Loosening bolts and nuts

SIIA0995E

PIIB1407E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 742 of 3924

BL-8

< SERVICE INFORMATION >

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle "twist".

5) At idle, apply engine load (electrical load, half- clutch on M/T model, drive position on A/T model).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

If it is difficult to duplicate the noise, drive the v ehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, chec k ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follo w the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pi npoint the source of the noise, use a listening tool

(Chassis Ear: J-39570, Engine Ear and mechanics stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

removing the components in the area that you suspect the noise is coming from.

Do not use too much force when removing clips and fasteners, otherwise clips and fastener can be broken

or lost during the repair, resulting in the creation of new noise.

tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will only be eliminated tem-

porarily.

feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

placing a piece of paper between components that you suspect are causing the noise.

looking for loose components and contact marks. Refer to BL-9, "

Generic Squeak and Rattle Troubleshooting".

REPAIR THE CAUSE

If the cause is a loose component, tighten the component securely.

If the cause is insufficient clearance between components:

- separate components by repositioning or loos ening and retightening the component, if possible.

- insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or urethane

tape. A Nissan Squeak and Rattle Kit (J-43980) is av ailable through your authorized Nissan Parts Depart-

ment.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

NOTE:

Always check with the Parts Departm ent for the latest parts information.

The following materials are contained in the Nissan Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100 × 135 mm (3.94 × 5.31 in)/76884-71L01: 60 × 85 mm (2.36 × 3.35 in)/76884-71L02: 15 ×

25 mm(0.59 × 0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50 × 50 mm (1.97 × 1.97 in)/73982-50Y00: 10 mm (0.39 in) thick, 50

× 50 mm (1.97 × 1.97 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30 × 50 mm (1.18 × 1.97 in)

FELT CLOTHTAPE

Used to insulate where movement does not occu r. Ideal for instrument panel applications.

68370-4B000: 15 × 25 mm (0.59 × 0.98 in) pad/68239-13E00: 5 mm (0.20 in) wide tape roll The following

materials, not found in the kit, can al so be used to repair squeaks and rattles.

UHMW(TEFLON) TAPE

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 744 of 3924

BL-10

< SERVICE INFORMATION >

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area c an often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

SEATS

When isolating seat noise it's important to note the pos ition the seat is in and the load placed on the seat when

the noise is present. These conditions should be dupl icated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of thes e incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger room.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the \

vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 750 of 3924

BL-16

< SERVICE INFORMATION >

HOOD

6. Remove the grommet on the dashboard, and pull the hood lock cable toward the passenger room.CAUTION:

While pulling, be careful not to damage (p eeling) the outside of the hood lock cable.

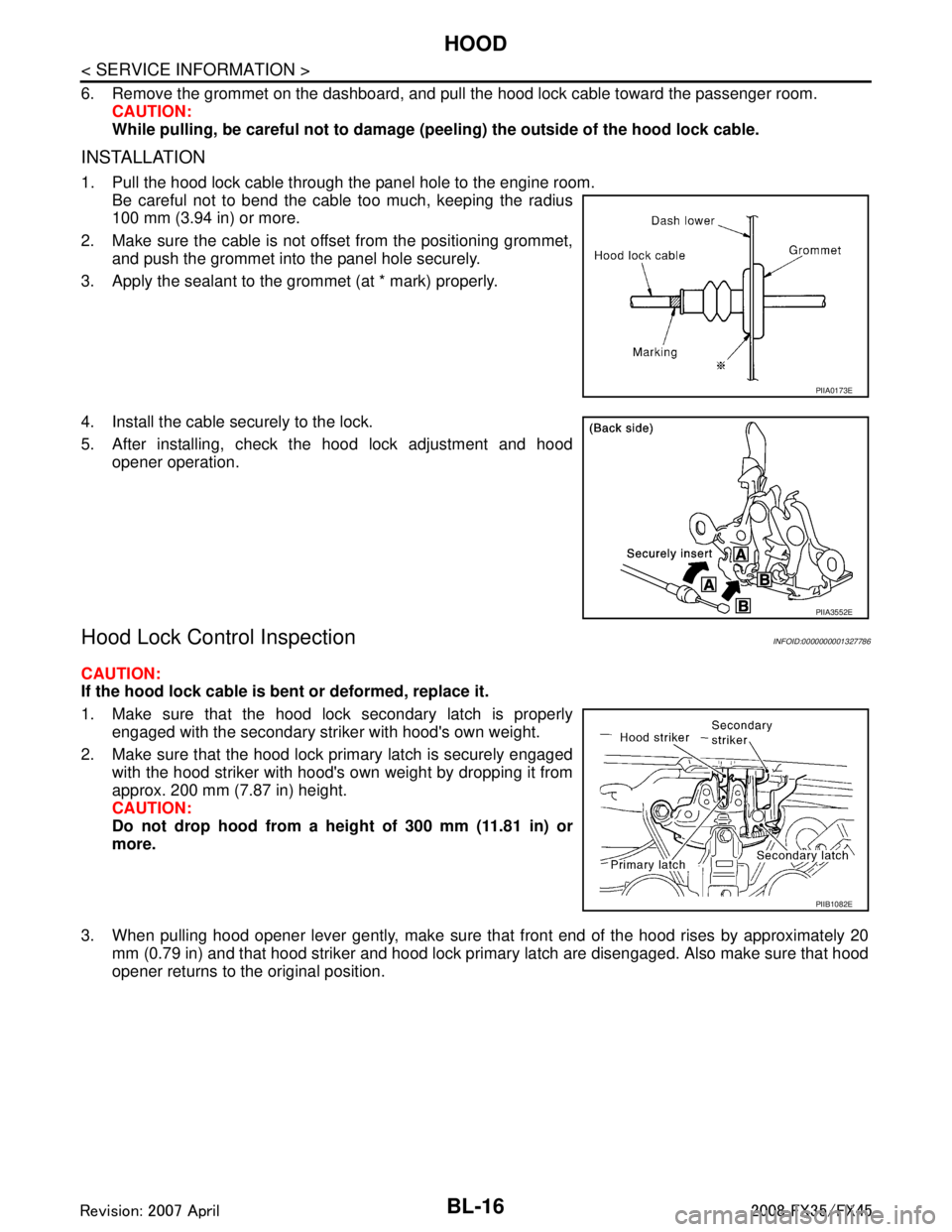

INSTALLATION

1. Pull the hood lock cable through the panel hole to the engine room.

Be careful not to bend the cable too much, keeping the radius

100 mm (3.94 in) or more.

2. Make sure the cable is not offset from the positioning grommet, and push the grommet into the panel hole securely.

3. Apply the sealant to the grommet (at * mark) properly.

4. Install the cable securely to the lock.

5. After installing, check the hood lock adjustment and hood opener operation.

Hood Lock Control InspectionINFOID:0000000001327786

CAUTION:

If the hood lock cable is bent or deformed, replace it.

1. Make sure that the hood lock secondary latch is properlyengaged with the secondary striker with hood's own weight.

2. Make sure that the hood lock primary latch is securely engaged with the hood striker with hood's own weight by dropping it from

approx. 200 mm (7.87 in) height.

CAUTION:

Do not drop hood from a he ight of 300 mm (11.81 in) or

more.

3. When pulling hood opener lever gently, make sure that front end of the hood rises by approximately 20 mm (0.79 in) and that hood striker and hood lock primary latch are disengaged. Also make sure that hood

opener returns to the original position.

PIIA0173E

PIIA3552E

PIIB1082E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 812 of 3924

BL-78

< SERVICE INFORMATION >

INTELLIGENT KEY SYSTEM

System Description

INFOID:0000000001327837

The Intelligent Key system is a system which can lock and unlock the doors (door lock function) and start the engine (engine start function) by carrying around the Intelligent Key, which operates based on the results of

electrical key-ID verification using two-way comm unications between the Intelligent Key and the vehicle

Operation of the remote control buttons on the Intelli gent Key also provides the same functions as the

remote control entry system. (Remote control entry functions)

As an ignition key warning function, when a door is lock ed or unlocked with entry switch or remote controller

button operation, the hazard lamps flash and the Intelligent Key warning buzzer sounds.

Even if the vehicle or Intelligent Key battery r uns down, the door can be locked and unlocked and the engine

started with the mechanical key built into the Intelligent Key.

If an Intelligent Key was lost, a new Intelligent Key can be registered. A maximum of 4 Intelligent Keys can be registered.

It has been made possible to diagnose the system, c hange the function setting and register an Intelligent

Key with the CONSULT-III.

DOOR LOCK FUNCTION

Operation Description

When the driver door, passenger door, or back door request switch is pressed, Intelligent Key unit sends a request signal from the transmission antenna corresponding to the pressed door request switch, key-ID ver-

ification is performed using two-way communication with In telligent Key, and if ID is successfully verified, a

door lock/unlock request signal is sent to BCM (Body Control Module) using CAN communication to lock/

unlock the door lock.

When door is locking, door is unlocked, when door is unlocking, door is locked.

When door is locked/unlocked by door request switch operation, hazard lamps flash and Intelligent Key

warning buzzer sounds.

With the locking operation of door request switch , door lock actuators of all door are locked.

Driver side door request switch operation

When door request switch (driver side) is pushed (unlock), driver side door lock actuator is unlocked. (Selec-

tive door unlock function)

When door request switch (driver side) is pushed (unlock) for the second time within 5 seconds after the first

operation, door lock actuators on pass enger's and other's doors are unlocked.

PIIB4645E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 814 of 3924

BL-80

< SERVICE INFORMATION >

INTELLIGENT KEY SYSTEM

door switch OFF (when all the doors are closed);

Remote control button of Intelligent Key turns on interior lamp (for 30 seconds) with input of UNLOCK signal

from Intelligent Key.

Panic Alarm Function

When key switch is OFF and ignition knob is not pushed (when mechanical key is not inserted in ignition

knob), BCM turns ON and OFF horn and headlamp intermit tently with input of PANIC ALARM signal from

Intelligent Key. The alarm automatically turns off after 25 seconds or when Intelligent Key unit receives any

signal from Intelligent Key.

Panic alarm operation mode can be changed using “WORK SUPPORT” mode in “PANIC ALARM DELAY”.

Refer to BL-104, "

CONSULT-III Application Item".

Remote Control Power Window Down (Open) Operation

When Intelligent Key unlock switch is turned ON with i gnition switch OFF, and Intelligent Key unlock switch is

detected to be on continuously for 3 seconds, the driver's door and passenger's door power windows are

simultaneously opened.

Power window is operated to open and the operation continues as long as the Intelligent Key unlock switch is

pressed.

Remote control power window down operation mode can be changed using “P/W DOWN DELAY” mode in

“WORK SUPPORT”. Refer to BL-104, "

CONSULT-III Application Item".

Key Reminder Function

As an operation verification function, when doors are lock ed or unlocked using Intelligent Key remote control-

ler button operation, hazard lamps flash and horn sounds.

ENGINE STARTUP FUNCTION

Operation Description

When ignition knob is pressed, Intelligent Key unit sends request signal from inside key antenna, key-ID ver- ification is conducted with Intelligent Key using two-wa y communication, and if verification is successful, an

ignition rotation prohibition latch release signal is sent to steering lock unit. Steering lock unit releases igni-

tion knob rotation prohibition latch. (Ignition knob can now be turned.)

When it becomes possible to rotate the ignition knob, “KEY” warning lamp in combination meter lights up green to notify driver that ignition knob can be turned.

NOTE:

When it becomes impossible to rotate the ignition knob, “KEY” warning lamp in combination meter lights up

red.

When key-ID verification is successful and ignition knob switch is in the ON state, Intelligent Key unit uses CAN communication to send engine start permission signal to BCM.

When BCM receives engine start permission signal, it uses CAN communication to sent starter request sig-

nal to IPDM E/R so that the engine will start when ignition knob is rotated to START position.

Operation Range

Engine can be started when Intelligent Key is in the v ehicle. However, sometimes engine might not start when

Intelligent Key is on instrument panel, rear parcel shelf, or in glove box.

NOTE:

luggage room can enable detection of Intelligent Key by a CONSULT-III function. Refer to BL-104, "

CON-

SULT-III Application Item".

Active Check Function

Confirm whether or not ignition knob can be rotated by checking the color of warning lamp in combination

meter.

WARNING AND ALARM FUNCTION

Vehicle operation Hazard lamp Horn

Door unlocking operation Once —

Door locking operation Twice Once

Condition Operation

Ignition knob rotation possib le “KEY” warning lamp in combin ation meter is lit up green.

Ignition rotation not possibl e “KEY” warning lamp in combin ation meter is lit up red.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C