battery INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 1155 of 3924

UNIFIED METER AND A/C AMPDI-29

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

NOTE:

Monitored item that does not match the vehicle is deleted from the display automatically.

*1: It dose not change when fastening or unfastening the passenger seat belt.

*2: Monitor keeps indicating “off” when brake warning lamp is on by the parking brake operation or low brake fluid level.

Power Supply and Gro und Circuit InspectionINFOID:0000000001328459

1.CHECK FUSE

Check for blown unified meter and A/C amp. fuses.

OK or NG

OK >> GO TO 2.

NG >> Be sure to eliminate cause of malfunction before installing new fuse. Refer to PG-3, "

Schematic".

2.CHECK POWER SUPPLY CIRCUIT

OIL W/L [On/Off] X Indicates [On/Off] condition of oil pressure warning lamp.

VDC/TCS IND [On/Off] X Indicates [On/Off] condition of VDC OFF indicator lamp.

ABS W/L [On/Off] X Indicates [On/Off] condition of ABS warning lamp.

SLIP IND [On/Off] X Indicates [On/Off] condition of SLIP indicator lamp.

BRAKE W/L [On/Off]

*2X Indicates [On/Off] condition of brake warning lamp.

KEY G W/L [On/Off] X Indicates [On/Off] condition of key warning lamp (green).

KEY R W/L [On/Off] X Indicates [On/Off] condition of key warning lamp (red).

KEY KNOB W/L [On/Off] X Indicates [On/Off] condition of key knob warning lamp.

M RANGE SW [On/Off] X X Indicates [On/Off] condition of manual mode range switch.

NM RANGE SW [On/Off] X X Indicates [On/Off] condition of except for manual mode range

switch.

AT SFT UP SW [On/Off] X X Indicates [On/Off] condition of A/T shift-up switch.

AT SFT DWN SW [On/Off] X X Indicates [On/Off] condition of A/T shift-down switch.

BRAKE SW [On/Off] X Indicates [On/Off] condition of brake switch (stop lamp switch).

AT-M IND [On/Off] X X Indicates [On/Off] condition of A/T manual mode indicator.

AT-M GEAR [5-1] X X Indicates [5-1] condition of A/T manual mode gear position.

P RANGE IND [On/Off] X X Indicates [On/Off] condition of A/T shift P range indicator.

R RANGE IND [On/Off] X X Indicates [On/Off] condition of A/T shift R range indicator.

N RANGE IND [On/Off] X X Indicates [On/Off] condition of A/T shift N range indicator.

D RANGE IND [On/Off] X X Indicates [On/Off] condition of A/T shift D range indicator.

AT CHECK W/L X Indicates [On/Off] cond ition of AT CHECK warning lamp.

CRUISE IND [On/Off] X Indicates [On/Off] condition of CRUISE indicator lamp.

SET IND [On/Off] X Indicates [On/Off] condition of SET indicator lamp.

CRUISE W/L [On/Off] X Indicates [On/Of f] condition of ICC warning lamp.

4WD LOCK SW [On/Off] X This item is not used for this model. “off” is always displayed.

4WD LOCK IND [On/Off] X This item is not used for this model. “off” is always displayed.

4WD W/L [On/Off] X Indicates [On/Off] condition of AWD warning lamp.

RR COMB STATE [OK/NG] X Indicates [OK/NG] condition of rear combination lamp circuit. Display item [Unit]

MAIN

SIGNALS SELECTION

FROM MENU Contents

Power source Fuse No.

Battery power supply 19 ACC power supply 10, 11

Ignition power supply 12

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1156 of 3924

DI-30

< SERVICE INFORMATION >

UNIFIED METER AND A/C AMP

Check voltage between unified meter and A/C amp. harness con-

nector terminals and ground.

OK or NG

OK >> GO TO 3.

NG >> Check harness between unified meter and A/C amp. and fuse.

3.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect unified meter and A/C amp. connector.

3. Check continuity between unified meter and A/C amp. harness connector M56 terminals 29, 30 and ground.

OK or NG

OK >> INSPECTION END

NG >> Repair harness or connector.

DTC [U1000] CAN Communication CircuitINFOID:0000000001328460

Symptom: Display “CAN COMM CIRC [U1000]” at the re sult of self-diagnosis for unified meter and A/C amp.

1.CHECK CAN COMMUNICATION

1. Turn ignition switch ON and wait for 2 seconds or more.

2. Check “Self Diagnostic Result” of “METER/M&A”

YES >> Refer to LAN-14, "

Trouble Diagnosis Flow Chart".

NO >> Refer to GI-35, "

CONSULT-III/GST Data Link Connector (DLC) Circuit".

DTC [B2202] Meter Communication CircuitINFOID:0000000001328461

Symptom: Display “METER COMM CI RC [B2202]” at the result of self-diagnosis for unified meter and A/C

amp.

1.CHECK CONNECTOR

Check combination meter, unified meter and A/C amp. and terminals (combination meter side, unified meter

and A/C amp. side, and harness side) for looseness or bent terminals.

OK or NG

OK >> GO TO 2.

NG >> Repair terminal or connector.

2.CHECK METER/GAUGES VISUALLY

Check the pointer on the meter/gauge fluctuate at the engine start.

Is the fluctuation acceptable?

YES >> GO TO 3.

Terminals Ignition switch position

(+) (–) OFF ACC ON

Connector Terminal

M56 21

Ground Battery

voltage Battery

voltage Battery

voltage

22 0 V 0 V Battery

voltage

M57 46 0 V Battery

voltage Battery

voltage

PKIB3570E

29 – Ground : Continuity should exist.

30 – Ground

SKIA5202E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1184 of 3924

DI-58

< SERVICE INFORMATION >

WARNING CHIME

Te r -mi-

nal

No. Wire

color Item Measuring condition

Reference value

Igni-

tion

switc h Operation or condition

2G/Y Combination switch

input 5 ONLighting, turn, wiper switch

(Wiper intermittent dial posi-

tion 4) OFF Approx. 0 V

Lighting switch

1ST

Approx. 1.0 V

33 G Combination switch

output 4 ONLighting, turn, wiper switch

(Wiper intermittent dial posi-

tion 4) OFF

Approx. 7.2 V

Lighting switch

1ST Approx. 1.2 V

37 B/W Key switch signal OFF When key is removed to ignition key cylinder. Approx. 0 V

When key is inserted to ignition key cylinder. Battery voltage

38 W/L Ignition power supply ON — Battery voltage

39 L CAN-H OFF — —

40 P CAN-L OFF — —

42 L/R Battery power supply OFF — Battery voltage

49 B Ground ON — Approx. 0 V

52

55 G Battery power supp ly OFF — Battery voltage

62 W Front door switch DR

signal

OFF Front door switch DR ON (open) Approx. 0 V

OFF (closed)

Approx. 7.0 - 7.5 V

PKIB4959J

PKIB4960J

PKIB4958J

PKIB4960J

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1185 of 3924

WARNING CHIMEDI-59

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

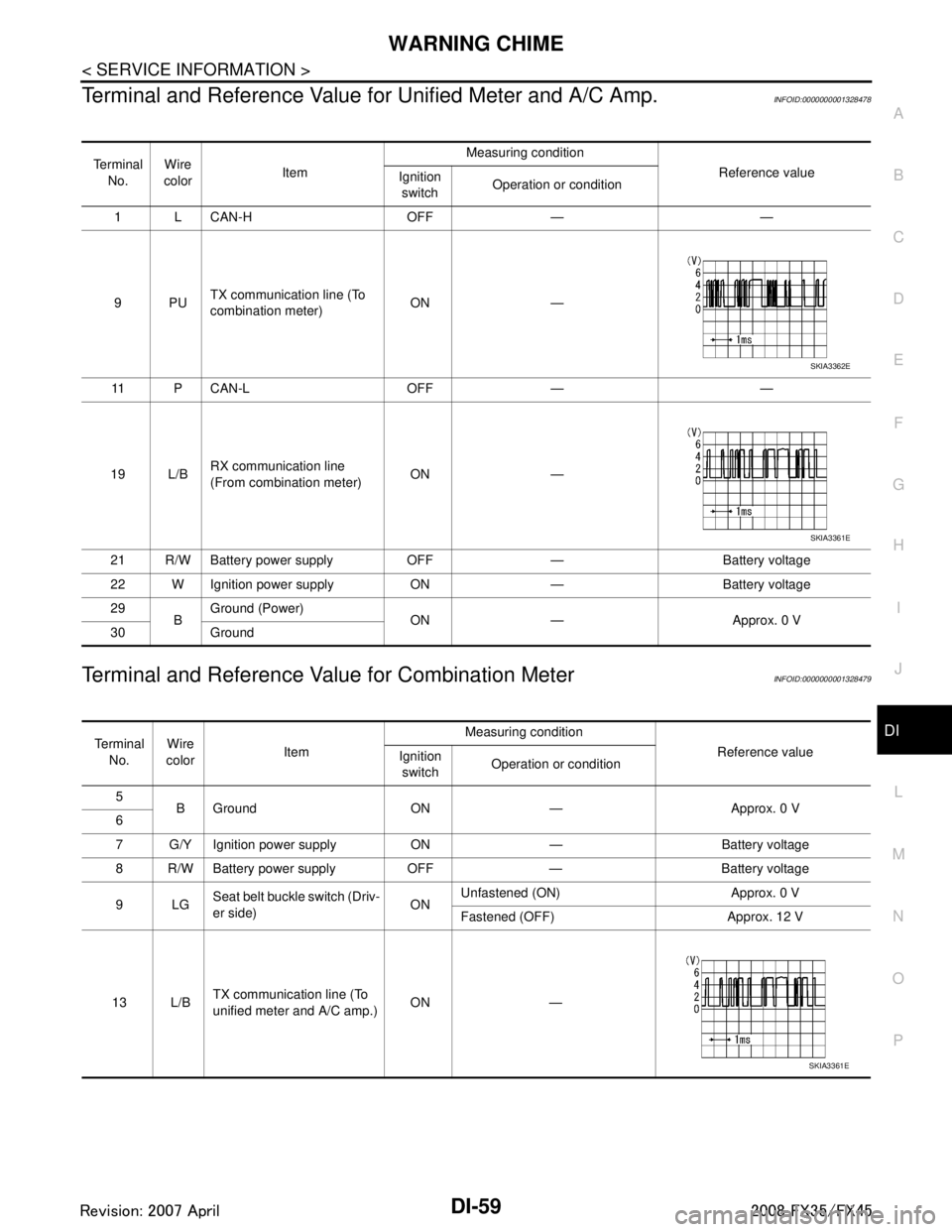

Terminal and Reference Value for Unified Meter and A/C Amp.INFOID:0000000001328478

Terminal and Reference Value for Combination MeterINFOID:0000000001328479

Te r m i n a l

No. Wire

color Item Measuring condition

Reference value

Ignition

switch Operation or condition

1 L CAN-H OFF — —

9PU TX communication line (To

combination meter) ON —

11 P C A N - L O F F — —

19 L/B RX communication line

(From combination meter) ON —

21 R/W Battery power supply OFF — Battery voltage

22 W Ignition power supply ON — Battery voltage

29 BGround (Power)

ON — Approx. 0 V

30 Ground

SKIA3362E

SKIA3361E

Te r m i n a l

No. Wire

color Item Measuring condition

Reference value

Ignition

switch Operation or condition

5 B Ground ON — Approx. 0 V

6

7 G/Y Ignition power supply ON — Battery voltage

8 R/W Battery power supply OFF — Battery voltage

9LG Seat belt buckle switch (Driv-

er side) ONUnfastened (ON) Approx. 0 V

Fastened (OFF) Approx. 12 V

13 L/B TX communication line (To

unified meter and A/C amp.)

ON —

SKIA3361E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1188 of 3924

DI-62

< SERVICE INFORMATION >

WARNING CHIME

OK or NG

OK >> GO TO 2.

NG >> Be sure to eliminate cause of malfunction before installing new fuse or fusible link. Refer to PG-3

.

2.CHECK POWER SUPPLY CIRCUIT

Check voltage between BCM harness connector terminals and

ground.

OK or NG

OK >> GO TO 3.

NG >> Check harness between BCM and fuse.

3.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check continuity between BCM harness connector M35 terminal 52 and ground.

OK or NG

OK >> INSPECTION END

NG >> Repair harness or connector.

Combination Meter Buzzer Circuit InspectionINFOID:0000000001328485

1.CHECK OPERATION OF COMBINATION METER BUZZER

1. Select “BUZZER” of “BCM” on CONSULT-III.

2. Perform “LIGHT WARN ALM”, “IGN KEY WARN AL M” or “SEAT BELT WARN TEST” of “Active Test”.

Does chime sound?

YES >> GO TO 4.

NO >> GO TO 2.

2.CHECK UNIFIED METER AND A/C AMP. INPUT SIGNAL

1. Select “METER/M&A” on CONSULT-III.

2. Operate switches to meet the requirements to s ound warning chime with “BUZZER” of “Data Monitor” and

check operation status.

Power source Fuse and fusible link No.

Battery power supply M

22

Ignition power supply 1

Terminals Ignition switch position

(+) (–) OFF ON

Connector Terminal

M34 38 Ground0 V Battery voltage

M35 42

Battery voltage Battery voltage

55

PKIB3988E

52 – Ground : Continui ty should exist.

PKIB5011E

“BUZZER”

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1189 of 3924

WARNING CHIMEDI-63

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

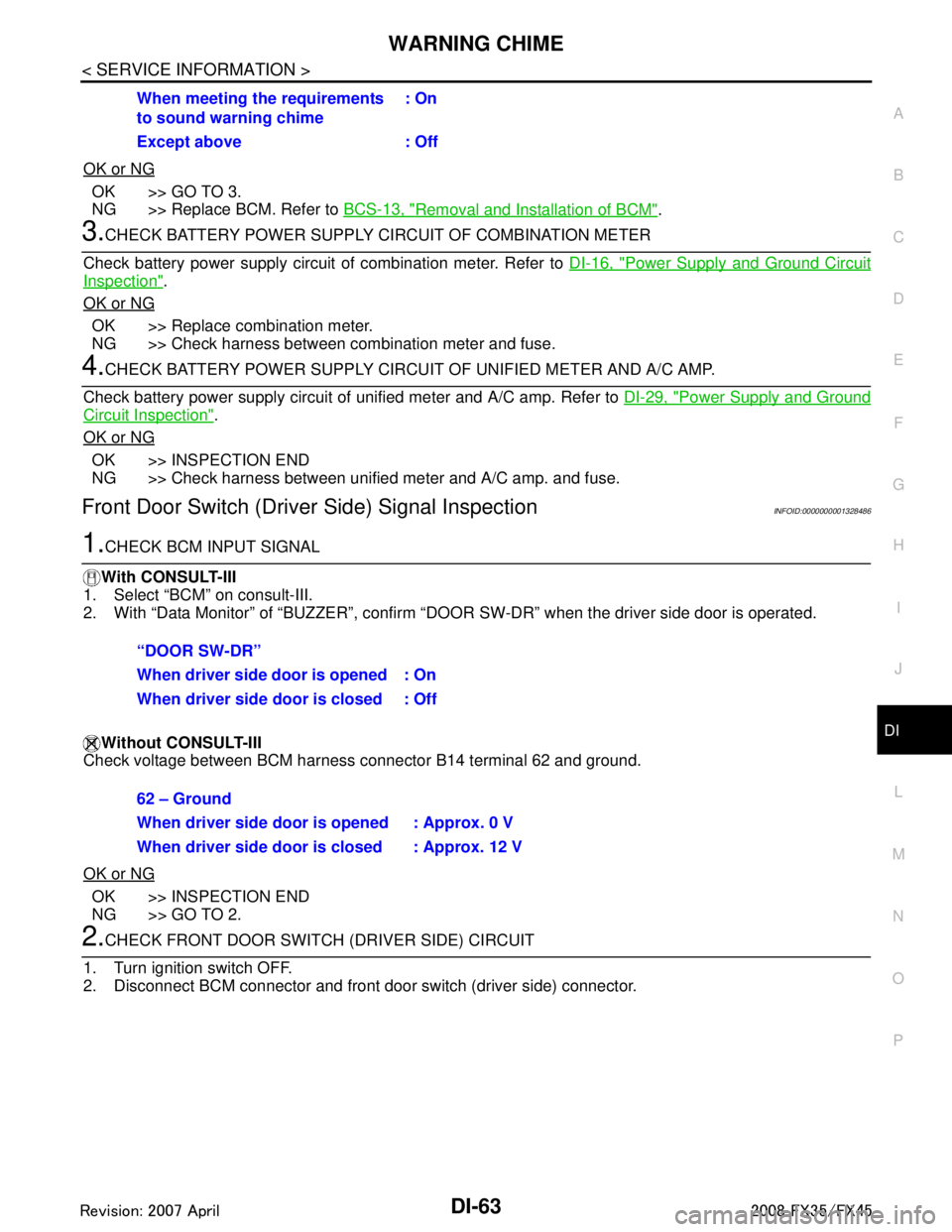

OK or NG

OK >> GO TO 3.

NG >> Replace BCM. Refer to BCS-13, "

Removal and Installation of BCM".

3.CHECK BATTERY POWER SUPPLY CIRCUIT OF COMBINATION METER

Check battery power supply circuit of combination meter. Refer to DI-16, "

Power Supply and Ground Circuit

Inspection".

OK or NG

OK >> Replace combination meter.

NG >> Check harness between combination meter and fuse.

4.CHECK BATTERY POWER SUPPLY CIRCUI T OF UNIFIED METER AND A/C AMP.

Check battery power supply circuit of unified meter and A/C amp. Refer to DI-29, "

Power Supply and Ground

Circuit Inspection".

OK or NG

OK >> INSPECTION END

NG >> Check harness between unified meter and A/C amp. and fuse.

Front Door Switch (Drive r Side) Signal InspectionINFOID:0000000001328486

1.CHECK BCM INPUT SIGNAL

With CONSULT-III

1. Select “BCM” on consult-III.

2. With “Data Monitor” of “BUZZER”, confirm “D OOR SW-DR” when the driver side door is operated.

Without CONSULT-III

Check voltage between BCM harness connector B14 terminal 62 and ground.

OK or NG

OK >> INSPECTION END

NG >> GO TO 2.

2.CHECK FRONT DOOR SWIT CH (DRIVER SIDE) CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector and front door switch (driver side) connector. When meeting the requirements

to sound warning chime

: On

Except above : Off

“DOOR SW-DR”

When driver side door is opened : On

When driver side door is closed : Off

62 – Ground

When driver side door is opened : Approx. 0 V

When driver side door is closed : Approx. 12 V

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1191 of 3924

WARNING CHIMEDI-65

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

2. Check continuity between BCM harness connector M3 terminal 37 and key switch harness connector M23 terminal 1.

3. Check continuity between BCM harness connector M3 terminal 37 and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair harness or connector.

4.CHECK KEY SWITCH POWER SUPPLY CIRCUIT

Check voltage between key switch harness connector M23 terminal

2 and ground.

OK or NG

OK >> Replace BCM. Refer to BCS-13, "Removal and Installa-

tion of BCM".

NG >> Check harness between key switch and fuse.

Key Switch and Ignition Knob Switch Signal Inspection (With Intelligent Key, When Me-

chanical Key Is Used)

INFOID:0000000001328488

1.CHECK BCM INPUT SIGNAL

With CONSULT-III

1. Select “BCM” on consult-III.

2. With “Data Monitor” of “BUZZER”, conf irm “KEY ON SW” when the key is operated.

Without CONSULT-III

Check voltage between BCM harness connector M3 terminal 37 and ground.

OK or NG

OK >> INSPECTION END

NG >> GO TO 2.

2.CHECK KEY SWITCH AND IG NITION KNOB SWITCH

1. Turn ignition switch OFF.

2. Disconnect key switch and i gnition knob switch connector.

3. Check key switch and ignition knob switch. Refer to DI-67, "

Component Inspection".

37 – 1 : Continuity should exist.

37 – Ground : Continuity should not exist.

PKIB3833E

2 – Ground : Battery voltage

SKIA5051E

“KEY ON SW”

When key is inserted to ignition

key cylinder

: On

When key is removed from igni-

tion key cylinder : Off

37 – Ground

When key is inserted to ignition

key cylinder: Approx. 12 V

When key is removed from igni-

tion key cylinder : Approx. 0 V

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1192 of 3924

DI-66

< SERVICE INFORMATION >

WARNING CHIME

OK or NG

OK >> GO TO 3.

NG >> Replace key switch and ignition knob switch.

3.CHECK KEY SWITCH AND IGNITION KNOB SWITCH CIRCUIT

1. Disconnect BCM connector.

2. Check continuity between BCM harness connector M3 terminal 37 and key switch and ignition knob switch harness connector

M22 terminal 4.

3. Check continuity between BCM harness connector M3 terminal 37 and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair harness or connector.

4.CHECK KEY SWITCH PO WER SUPPLY CIRCUIT

Check voltage between key switch and ignition knob switch harness

connector M22 terminal 3 and ground.

OK or NG

OK >> Replace BCM. Refer to BCS-13, "Removal and Installa-

tion of BCM".

NG >> Check harness between key switch and ignition knob switch and fuse.

Lighting Switch Signal InspectionINFOID:0000000001328489

1.CHECK BCM INPUT SIGNAL

1. Select “BCM” on CONSULT-III.

2. With “Data Monitor” of “BUZZER”, confirm “LIG HT SW 1ST” when the lighting switch is operated.

OK or NG

OK >> INSPECTION END

NG >> Check the lighting switch. Refer to LT-104, "

Combination Switch Inspection".

Seat Belt Buckle Switch (Driver Side) Signal InspectionINFOID:0000000001328490

1.CHECK UNIFIED METER AND A/C AMP. INPUT SIGNAL

1. Select “METER/M&A” on CONSULT-III.

2. With “Data Monitor” of “MET ER/M&A”, confirm “SEAT BELT W/L” when the seat belt is operated.

37 – 4 : Continuity should exist.

37 – Ground : Continuity should not exist.

PKIB3578E

3 – Ground : Battery voltage

SKIA5063E

“LIGHT SW 1ST”

Lighting switch ON (1st position) : On

Lighting switch OFF : Off

“SEAT BELT W/L”

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1207 of 3924

LANE DEPARTURE WARNING SYSTEMDI-81

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

Terminal and Reference Va lue for LDW Camera UnitINFOID:0000000001328499

NOTE:

*: Perform “Active Test” with CONSULT-III. Refer to DI-81, "

CONSULT-III Function (LDW)".

CONSULT-III Function (LDW)INFOID:0000000001328500

DESCRIPTION

CONSULT-III performs the following functions communicating with the LDW camera unit.

WORK SUPPORT

Display Item

SELF DIAGNOSTIC RESULT

Display Item

Te r m i n a l

No. Wire

Color Item Condition

Reference Value

(Approx. [V])

Ignition

switch Operation or condition

1 B/R Ignition power supply ON — Battery voltage

3 R/W LDW chime ON LDW chime Activated

*0

Not activated 12

4 Y System ON indicator ON LDW system ON 0

OFF 12

5 R CAN-L — — —

6 B Ground ON — 0

8 G/W LDW indicator lamp ON LDW indicator lamp Illuminated

*0

Turned OFF 12

9 G LDW switch ON LDW switch Pressed 0

Released 5

10 L CAN-H — — — 11 — Shield — — —

12 B Ground ON — 0

Select diag mode Function

Work support Displays causes of automatic cancellation of the LDW system.

Self Diagnostic Result Displays malfunctioning system memorized in LDW camera unit.

Data Monitor Displays real-time input/output data of LDW camera unit.

CAN DIAG SUPPORT MNTR The results of transmit/receive diagnosis of CAN communication can be read.

Active Test Enables operation check of electrical loads by sending driving signal to them.

Ecu Identification Displays part number of LDW camera unit.

Operation Function Reference page

AUTO AIM Outputs camera unit, calculates dislocation of the camera, and displays adjustment di-

rection.

DI-71, "

Camera

Aiming Adjust-

ment"

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1211 of 3924

LANE DEPARTURE WARNING SYSTEMDI-85

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

OK or NG

OK >> GO TO 2.

NG >> Be sure to eliminate cause of malfunction before installing new fuse. Refer to PG-77, "

Terminal

Arrangement".

2.CHECK POWER SUPPLY CIRCUIT

Check voltage between LDW camera unit and ground.

OK or NG

OK >> GO TO 3.

NG >> Check harness between LDW camera unit and fuse.

3.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect LDW camera unit connector.

3. Check continuity between LDW camera unit harness connector R9 terminals 6, 12 and ground.

OK or NG

OK >> INSPECTION END

NG >> Repair ground harness.

DTC [C1B00] CAMERA UNIT MALFINFOID:0000000001328504

1.CHECK LDW CAMERA UNIT

1. Perform self-diagnosis of LDW camera unit.

2. Check if any item other than “[C1B00] CAMERA UNIT” is displayed on self-diagnosis display.

Is any displayed?

YES >> Repair or replace applicable item.

NO >> Replace LDW camera unit.

DTC [C1B01] CAM AIMING INCMPINFOID:0000000001328505

1.PREFORM CAMERA AIMING ADJUSTMENT

1. Preform camera aiming adjustment. Refer to DI-71, "

Camera Aiming Adjustment".

2. Erase DTC and perform the self-diagnosis LDW camera unit.

Self

-diagnosis results

No malfunction detected >> INSPECTION END

Malfunction detected >> Replace LDW camera unit.

DTC [C1B02] VHCL SPD DATA MALFINFOID:0000000001328506

1.CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) (CONSULT-III)

Power source Fuse No.

Ignition power supply 12

Terminals Ignition switch position

(+) (–) OFF ON

Connector Terminal

R9 1 Ground 0 V Battery voltage

PKIC0246E

6 – Ground : Continuity should exist.

12 – Ground

PKIC0247E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C