differential INFINITI FX35 2008 User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 2799 of 3924

FFD-8

< SERVICE INFORMATION >

DIFFERENTIAL GEAR OIL

DIFFERENTIAL GEAR OIL

Changing Differential Gear OilINFOID:0000000001327481

DRAINING

1. Stop engine.

2. Remove drain plug (1) and drain gear oil.

3. Set a gasket on drain plug (1) and install it to final drive assem-bly and tighten to the specified torque. Refer to FFD-17, "

Disas-

sembly and Assembly", FFD-17, "Disassembly and Assembly".

CAUTION:

Never reuse gasket.

FILLING

1. Remove filler plug (1). Fill with new gear oil until oil level reaches the specified level near filler plug mounting hole.

2. After refilling oil, check oil level. Set a gasket to filler plug (1), then install it to final drive assembly. Refer to FFD-17, "

Disas-

sembly and Assembly", FFD-17, "Disassembly and Assembly".

CAUTION:

Never reuse gasket.

Checking Differential Gear OilINFOID:0000000001327482

OIL LEAKAGE AND OIL LEVEL

Make sure that oil is not leaking fr om final drive assembly or around it.

Remove filler plug (1) and check oil level from filler plug mounting hole as shown in the figure.

CAUTION:

Never start engine while checking oil level.

Set a gasket on filler plug (1) and install it on final drive assembly.

Refer to FFD-17, "

Disassembly and Assembly", FFD-17, "Disas-

sembly and Assembly".

CAUTION:

Never reuse gasket.

PDIA0781J

Oil grade and Viscosity:

Refer to MA-9, "

Fluids and Lubricants".

Oil capacity:

Approx. 0.65 (1-3/8 US pt, 1-1/8 Imp pt)

PDIA0782J

PDIA0782J

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2800 of 3924

FRONT OIL SEALFFD-9

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

FFD

N

O P

FRONT OIL SEAL

Removal and InstallationINFOID:0000000001327483

REMOVAL

1. Drain gear oil. Refer to FFD-8, "Changing Differential Gear Oil".

2. Remove front propeller shaft. Refer to PR-4, "

Removal and Installation".

3. Remove front drive shaft both. Refer to FAX-16, "

Removal and Installation (Right Side)", FAX-15,

"Removal and Installation (Left Side)".

4. Remove side shaft assembly.

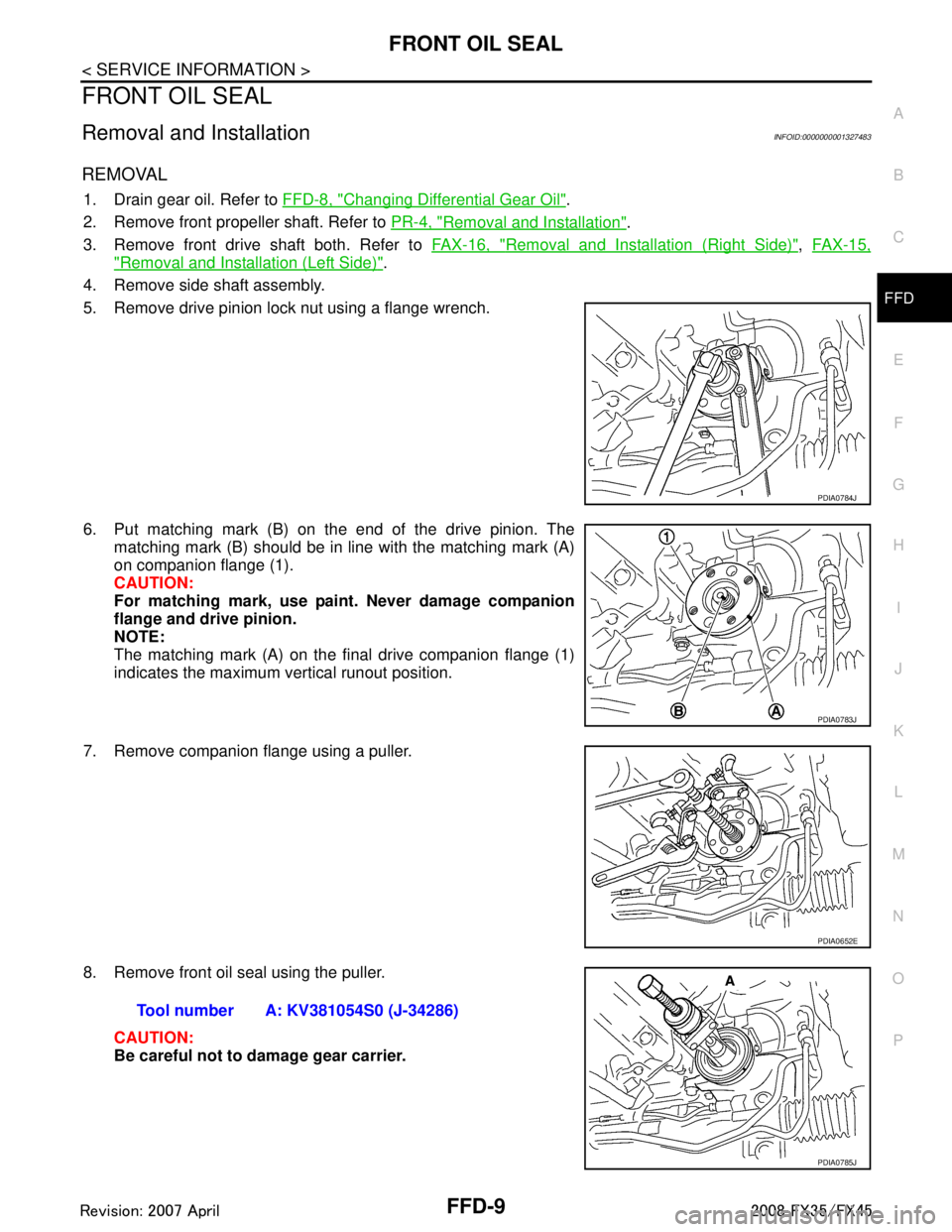

5. Remove drive pinion lock nut using a flange wrench.

6. Put matching mark (B) on the end of the drive pinion. The matching mark (B) should be in line with the matching mark (A)

on companion flange (1).

CAUTION:

For matching mark, use pain t. Never damage companion

flange and drive pinion.

NOTE:

The matching mark (A) on the final drive companion flange (1)

indicates the maximum vertical runout position.

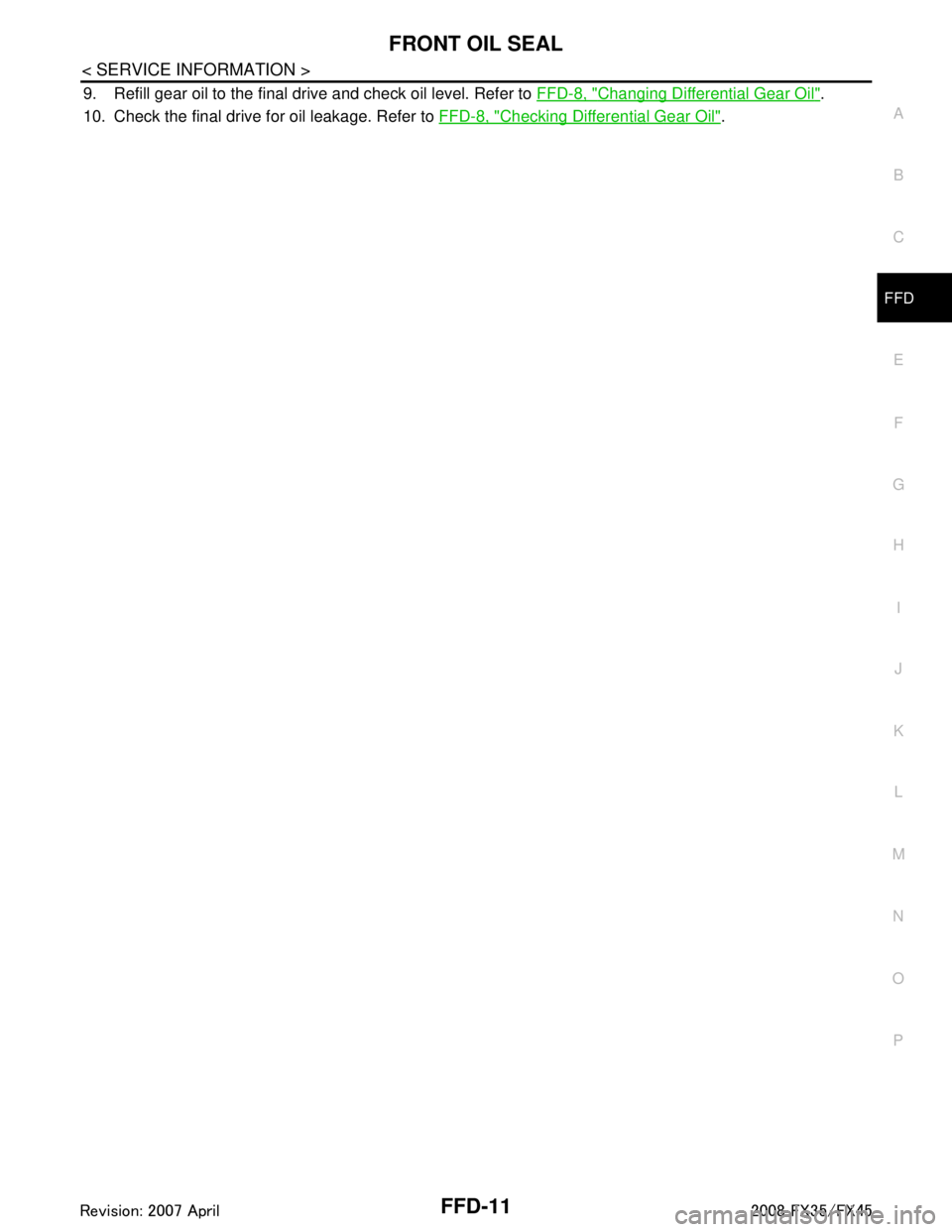

7. Remove companion flange using a puller.

8. Remove front oil seal using the puller. CAUTION:

Be careful not to damage gear carrier.

PDIA0784J

PDIA0783J

PDIA0652E

Tool number A: KV381054S0 (J-34286)

PDIA0785J

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2802 of 3924

FRONT OIL SEALFFD-11

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

FFD

N

O P

9. Refill gear oil to the final drive and check oil level. Refer to FFD-8, "Changing Differential Gear Oil".

10. Check the final drive for oil leakage. Refer to FFD-8, "

Checking Differential Gear Oil".

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2804 of 3924

SIDE OIL SEALFFD-13

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

FFD

N

O P

4. Install the front drive shaft. Refer to FAX-15, "Removal and Installation (Left Side)".

5. When oil leaks while removing, check oil level after the installation. Refer to FFD-8, "

Checking Differential

Gear Oil".

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2806 of 3924

FRONT FINAL DRIVE ASSEMBLYFFD-15

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

FFD

N

O P

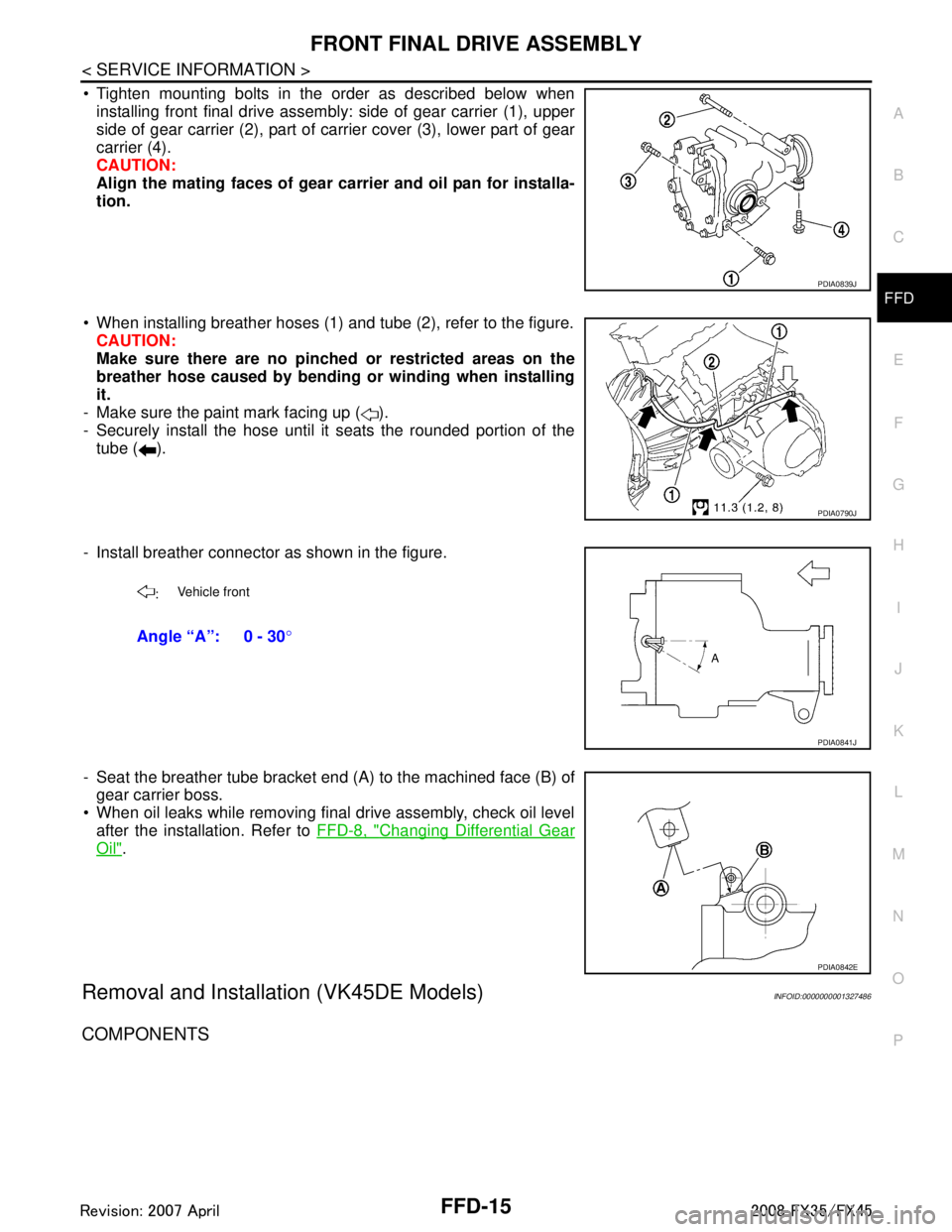

Tighten mounting bolts in the order as described below when installing front final drive assembly: side of gear carrier (1), upper

side of gear carrier (2), part of ca rrier cover (3), lower part of gear

carrier (4).

CAUTION:

Align the mating faces of gear car rier and oil pan for installa-

tion.

When installing breather hoses (1) and tube (2), refer to the figure. CAUTION:

Make sure there are no pinched or restricted areas on the

breather hose caused by bending or winding when installing

it.

- Make sure the paint mark facing up ( ).

- Securely install the hose until it seats the rounded portion of the

tube ( ).

- Install breather connector as shown in the figure.

- Seat the breather tube bracket end (A) to the machined face (B) of gear carrier boss.

When oil leaks while removing final drive assembly, check oil level after the installation. Refer to FFD-8, "

Changing Differential Gear

Oil".

Removal and Installation (VK45DE Models)INFOID:0000000001327486

COMPONENTS

PDIA0839J

PDIA0790J

:Vehicle front

Angle “A”: 0 - 30

°

PDIA0841J

PDIA0842E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2808 of 3924

FRONT FINAL DRIVE ASSEMBLYFFD-17

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

FFD

N

O P

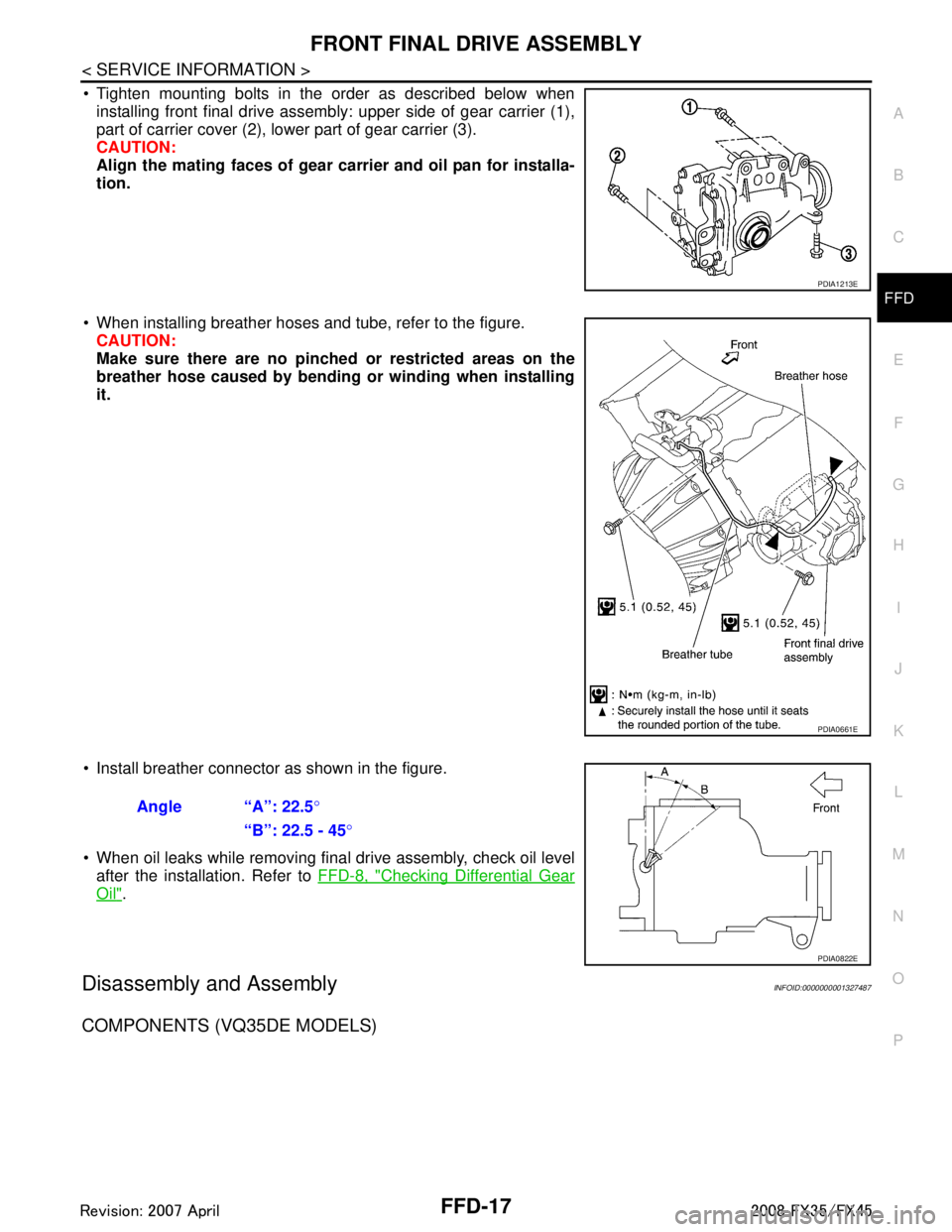

Tighten mounting bolts in the order as described below when installing front final drive assembly: upper side of gear carrier (1),

part of carrier cover (2), lower part of gear carrier (3).

CAUTION:

Align the mating faces of gear car rier and oil pan for installa-

tion.

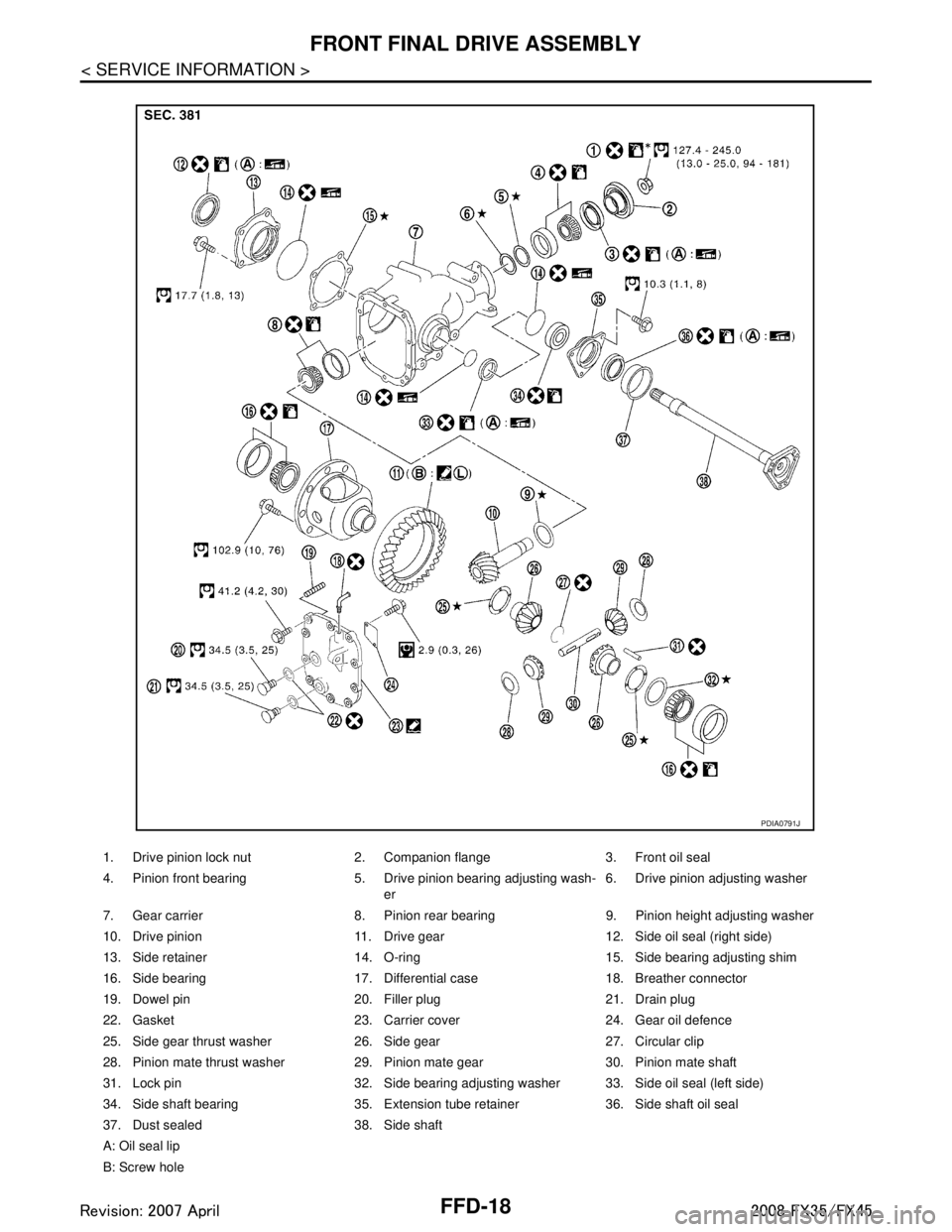

When installing breather hoses and tube, refer to the figure. CAUTION:

Make sure there are no pinched or restricted areas on the

breather hose caused by bending or winding when installing

it.

Install breather connector as shown in the figure.

When oil leaks while removing final drive assembly, check oil level after the installation. Refer to FFD-8, "

Checking Differential Gear

Oil".

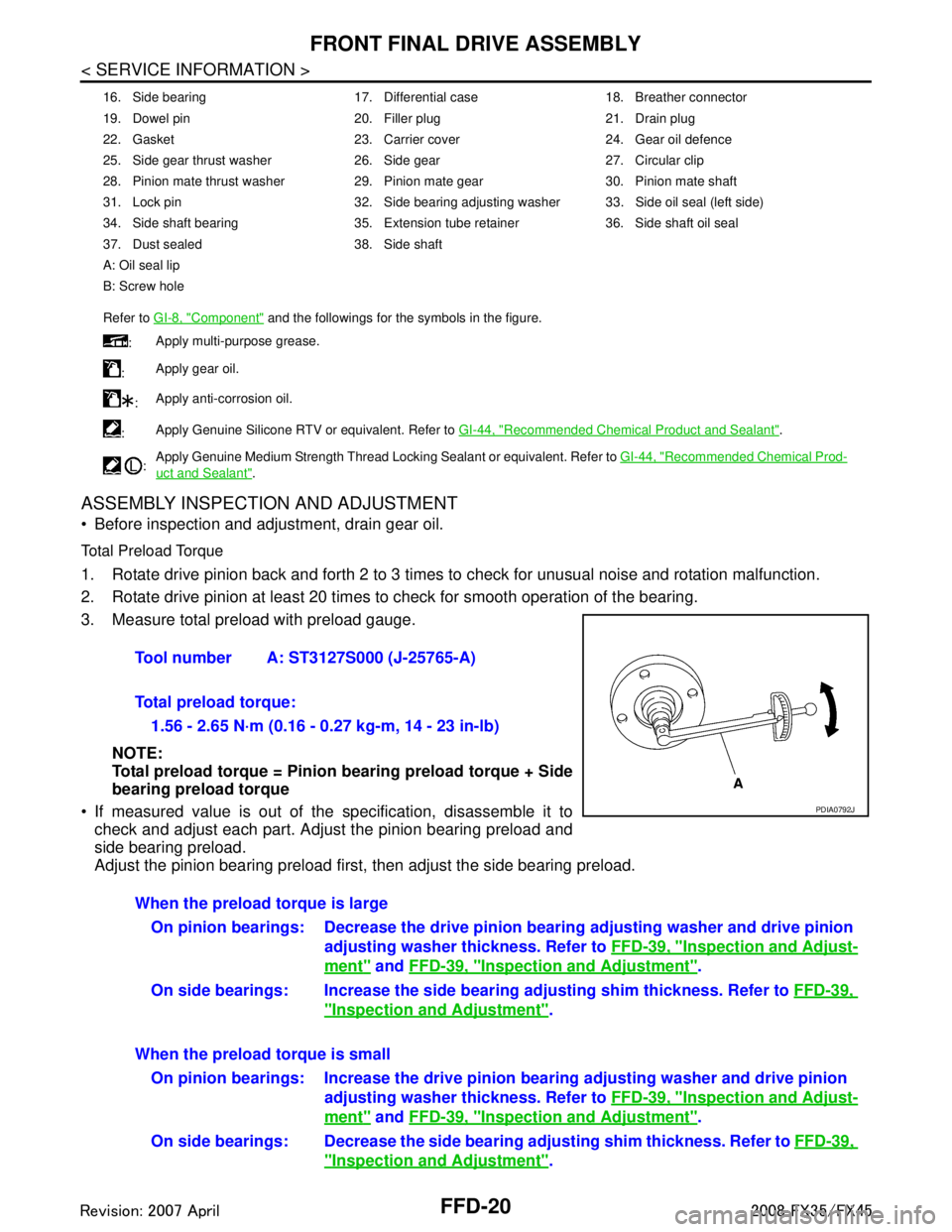

Disassembly and AssemblyINFOID:0000000001327487

COMPONENTS (VQ35DE MODELS)

PDIA1213E

PDIA0661E

Angle “A”: 22.5°

“B”: 22.5 - 45 °

PDIA0822E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2809 of 3924

FFD-18

< SERVICE INFORMATION >

FRONT FINAL DRIVE ASSEMBLY

1. Drive pinion lock nut 2. Companion flange 3. Front oil seal

4. Pinion front bearing 5. Drive pinion bearing adjusting wash-er6. Drive pinion adjusting washer

7. Gear carrier 8. Pinion rear bearing 9. Pinion height adjusting washer

10. Drive pinion 11. Drive gear 12. Side oil seal (right side)

13. Side retainer 14. O-ring 15. Side bearing adjusting shim

16. Side bearing 17. Differential case 18. Breather connector

19. Dowel pin 20. Filler plug 21. Drain plug

22. Gasket 23. Carrier cover 24. Gear oil defence

25. Side gear thrust washer 26. Side gear 27. Circular clip

28. Pinion mate thrust washer 29. Pinion mate gear 30. Pinion mate shaft

31. Lock pin 32. Side bearing adjusting washer 33. Side oil seal (left side)

34. Side shaft bearing 35. Extension tube retainer 36. Side shaft oil seal

37. Dust sealed 38. Side shaft

A: Oil seal lip

B: Screw hole

PDIA0791J

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2811 of 3924

FFD-20

< SERVICE INFORMATION >

FRONT FINAL DRIVE ASSEMBLY

ASSEMBLY INSPECTION AND ADJUSTMENT

Before inspection and adjustment, drain gear oil.

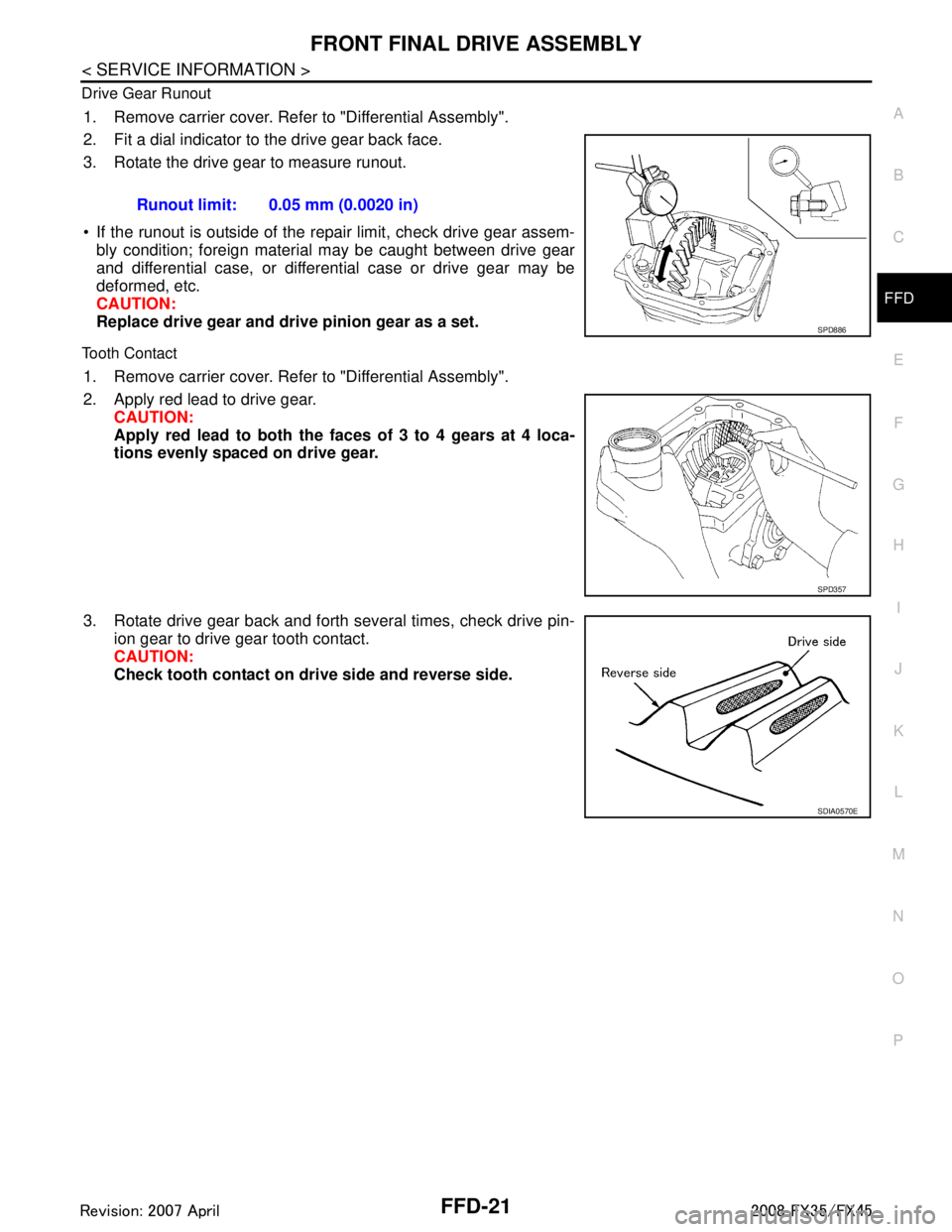

Total Preload Torque

1. Rotate drive pinion back and forth 2 to 3 times to check for unusual noise and rotation malfunction.

2. Rotate drive pinion at least 20 times to check for smooth operation of the bearing.

3. Measure total preload with preload gauge.NOTE:

Total preload torque = Pinion bearing preload torque + Side

bearing preload torque

If measured value is out of the specification, disassemble it to check and adjust each part. Adjust the pinion bearing preload and

side bearing preload.

Adjust the pinion bearing preload first, then adjust the side bearing preload.

16. Side bearing 17. Differential case 18. Breather connector

19. Dowel pin 20. Filler plug 21. Drain plug

22. Gasket 23. Carrier cover 24. Gear oil defence

25. Side gear thrust washer 26. Side gear 27. Circular clip

28. Pinion mate thrust washer 29. Pinion mate gear 30. Pinion mate shaft

31. Lock pin 32. Side bearing adjusting washer 33. Side oil seal (left side)

34. Side shaft bearing 35. Extension tube retainer 36. Side shaft oil seal

37. Dust sealed 38. Side shaft

A: Oil seal lip

B: Screw hole

Refer to GI-8, "

Component" and the followings for the symbols in the figure.

: Apply multi-purpose grease.

: Apply gear oil.

: Apply anti-corrosion oil.

: Apply Genuine Silicone RTV or equivalent. Refer to

GI-44, "

Recommended Chemical Product and Sealant".

: Apply Genuine Medium Strength Thread Locking Sealant or equivalent. Refer to

GI-44, "

Recommended Chemical Prod-

uct and Sealant".

Tool number A: ST3127S000 (J-25765-A)

Total preload torque:

1.56 - 2.65 N·m (0.16 - 0.27 kg-m, 14 - 23 in-lb)

PDIA0792J

When the preload torque is largeOn pinion bearings: Decrease the drive pinion bearing adjusting washer and drive pinion

adjusting washer thickness. Refer to FFD-39, "

Inspection and Adjust-

ment" and FFD-39, "Inspection and Adjustment".

On side bearings: Increase the side bear ing adjusting shim thickness. Refer to FFD-39,

"Inspection and Adjustment".

When the preload torque is small On pinion bearings: Increase the drive pinion bearing adjusting washer and drive pinion

adjusting washer thickness. Refer to FFD-39, "

Inspection and Adjust-

ment" and FFD-39, "Inspection and Adjustment".

On side bearings: Decrease the side bearin g adjusting shim thickness. Refer to FFD-39,

"Inspection and Adjustment".

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2812 of 3924

FRONT FINAL DRIVE ASSEMBLYFFD-21

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

FFD

N

O P

Drive Gear Runout

1. Remove carrier cover. Refer to "Differential Assembly".

2. Fit a dial indicator to the drive gear back face.

3. Rotate the drive gear to measure runout.

If the runout is outside of the repair limit, check drive gear assem-

bly condition; foreign material may be caught between drive gear

and differential case, or differential case or drive gear may be

deformed, etc.

CAUTION:

Replace drive gear and dri ve pinion gear as a set.

Tooth Contact

1. Remove carrier cover. Refer to "Differential Assembly".

2. Apply red lead to drive gear.

CAUTION:

Apply red lead to both the f aces of 3 to 4 gears at 4 loca-

tions evenly spaced on drive gear.

3. Rotate drive gear back and forth several times, check drive pin- ion gear to drive gear tooth contact.

CAUTION:

Check tooth contact on dri ve side and reverse side.

Runout limit: 0.05 mm (0.0020 in)

SPD886

SPD357

SDIA0570E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2814 of 3924

FRONT FINAL DRIVE ASSEMBLYFFD-23

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

FFD

N

O P

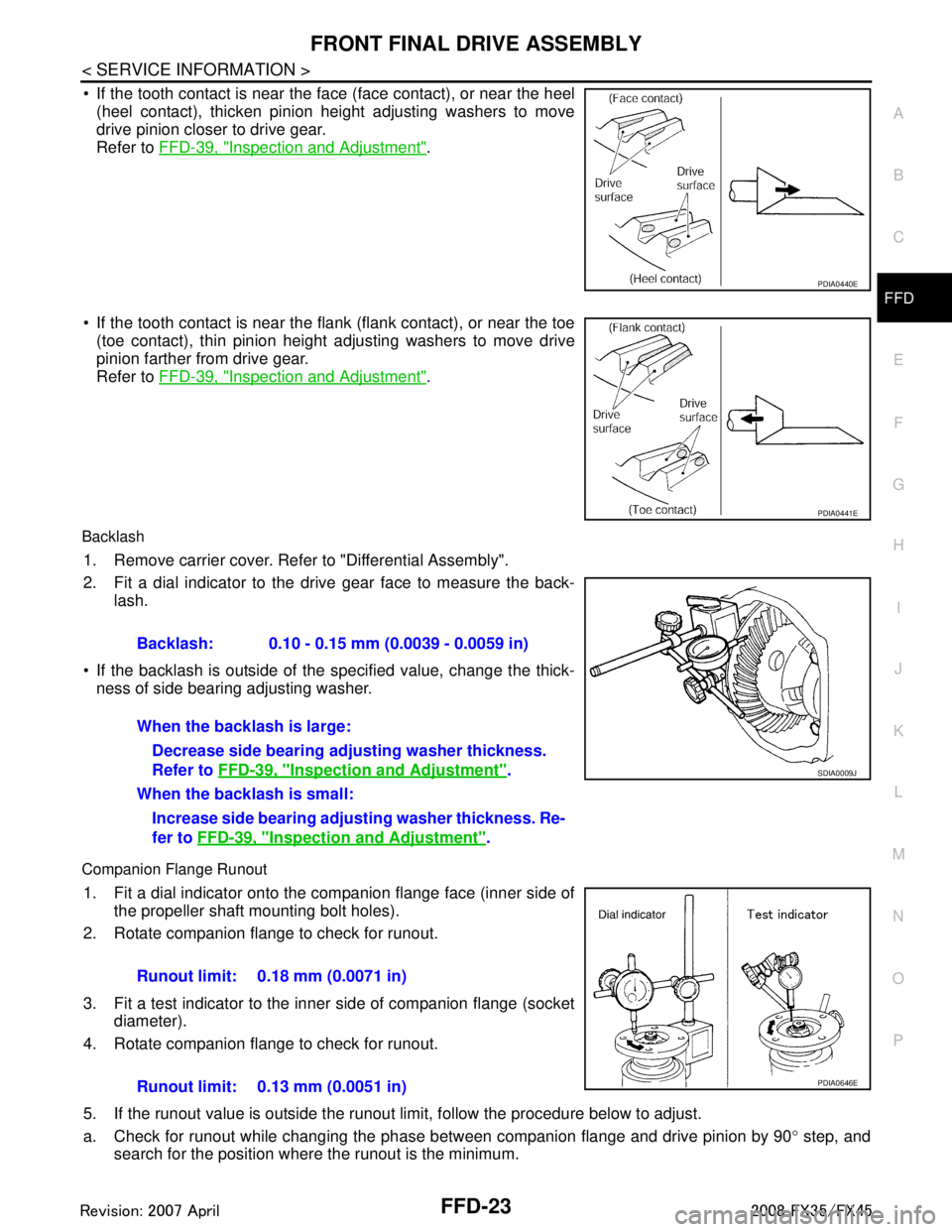

If the tooth contact is near the face (face contact), or near the heel (heel contact), thicken pinion height adjusting washers to move

drive pinion closer to drive gear.

Refer to FFD-39, "

Inspection and Adjustment".

If the tooth contact is near the flank (flank contact), or near the toe

(toe contact), thin pinion height adjusting washers to move drive

pinion farther from drive gear.

Refer to FFD-39, "

Inspection and Adjustment".

Backlash

1. Remove carrier cover. Refer to "Differential Assembly".

2. Fit a dial indicator to the drive gear face to measure the back-

lash.

If the backlash is outside of the specified value, change the thick- ness of side bearing adjusting washer.

Companion Flange Runout

1. Fit a dial indicator onto the companion flange face (inner side of the propeller shaft mounting bolt holes).

2. Rotate companion flange to check for runout.

3. Fit a test indicator to the inner side of companion flange (socket diameter).

4. Rotate companion flange to check for runout.

5. If the runout value is outside the runout limit, follow the procedure below to adjust.

a. Check for runout while changing the phase between companion flange and drive pinion by 90 ° step, and

search for the position where the runout is the minimum.

PDIA0440E

PDIA0441E

Backlash: 0.10 - 0.15 mm (0.0039 - 0.0059 in)

When the backlash is large:

Decrease side bearing adju sting washer thickness.

Refer to FFD-39, "

Inspection and Adjustment".

When the backlash is small: Increase side bearing adjust ing washer thickness. Re-

fer to FFD-39, "

Inspection and Adjustment".

SDIA0009J

Runout limit: 0.18 mm (0.0071 in)

Runout limit: 0.13 mm (0.0051 in)

PDIA0646E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C