wheel INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 3774 of 3924

SPIRAL CABLESRS-37

< SERVICE INFORMATION >

C

DE

F

G

I

J

K L

M A

B

SRS

N

O P

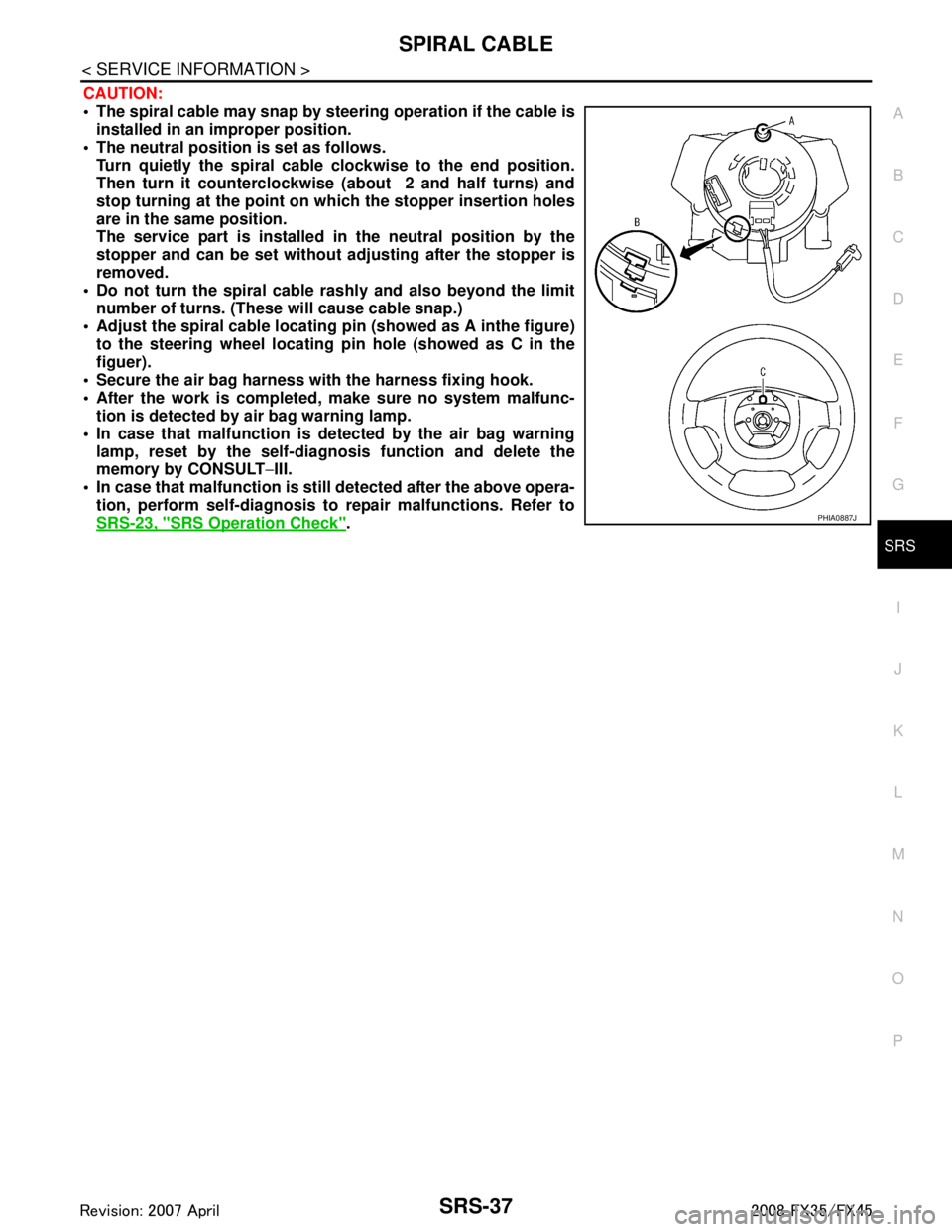

CAUTION:

The spiral cable may snap by steering operation if the cable is

installed in an improper position.

The neutral position is set as follows. Turn quietly the spiral cable clockwise to the end position.

Then turn it counterclockwise (about 2 and half turns) and

stop turning at the point on which the stopper insertion holes

are in the same position.

The service part is installed in the neutral position by the

stopper and can be set without adjusting after the stopper is

removed.

Do not turn the spiral cable r ashly and also beyond the limit

number of turns. (These will cause cable snap.)

Adjust the spiral cable locating pin (showed as A inthe figure) to the steering wheel locating pin hole (showed as C in the

figuer).

Secure the air bag harness wi th the harness fixing hook.

After the work is completed, make sure no system malfunc- tion is detected by air bag warning lamp.

In case that malfunction is detected by the air bag warning lamp, reset by the self-diagnosis function and delete the

memory by CONSULT −III.

In case that malfunction is still detected after the above opera-

tion, perform self-diagnosis to repair malfunctions. Refer to

SRS-23, "

SRS Operation Check".PHIA0887J

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3784 of 3924

COLLISION DIAGNOSISSRS-47

< SERVICE INFORMATION >

C

DE

F

G

I

J

K L

M A

B

SRS

N

O P

COLLISION DIAGNOSIS

For Frontal CollisionINFOID:0000000001327773

To repair the SRS, perform the following steps.

When SRS (except the front side air bag and sidecurt ain air bag modules) is activated in a collision:

1. Replace the diagnosis sensor unit.

2. Remove the air bag modules (except the front side air bag modulesand side curtain air bag modules),

crash zone sensor assembly, bracket andseat belt pre-tensioner assemblies.

3. Check the SRS components using the table below:

- Replace any SRS components showing visible signs of damage (dents,cracks and deformation).

4. Install new air bag modules (except the front side air bag modules and side curtain air bag modules) crash

zone sensor assembly, bracket and seat belt pre-tensioner assemblies.

5. Conduct self-diagnosis using CONSULT-III or “AIR BAG”warning lamp. Refer to SRS-23, "

SRS Operation

Check" for details. Ensure entire SRS operates properly.

When SRS is not acti vated in a collision:

1. Check the SRS components using the table below:

- Replace any SRS components showing visible signs of damage (dents, cracks and deformation).

2. Conduct self-diagnosis using CONSULT-III or “AIR BAG” warning lamp. Refer to SRS-23, "

SRS Operation

Check" for details. Ensure entire SRS operates properly.

When only one front air bag modu le is activated in a collision:

1. Replace the following components:

- Diagnosis sensor unit

- Crash zone sensor

- Activated front air bag and seat belt pre-tensioner.

2. Check the other SRS components using the table below. (Refer to “SRS is NOT activated”.)

- Replace any SRS components showing visible signs of damage (dents, cracks and deformation).

3. Conduct self-diagnosis using CONSULT-III or “AIR BAG” warning lamp. Refer to SRS-23, "

SRS Operation

Check" for details. Ensure entire SRS operates properly.

Only one front air bag may inflate a crash, depending on t he crash severity and whether the front occupants

are belted or unbelted. This does not indicate improper performance of the system. Perform self-diagnosis to

make sure the entire SRS operates properly.

SRS INSPECTION (FOR FRONTAL COLLISION)

Part SRS is activated SRS is NOT activated

Driver airbag

module If the Driver airbag has deployed:

REPLACE.

Install with new fasteners. If the Driver air bag has NOT been activated:

[same text as in current manual]

Passenger front

airbag module If the Passenger front airbag has deployed:

REPLACE.

Install with new fasteners. If the Passenger front air bag has NOT been activated:

[same text as in current manual]

Crash zone

sensor If any of the front airbags or seat belt pre-

tensionsers have been activated:

REPLACE the crash zone sensor and bracket

with new fasteners. If the front airbags or seat belt pre-tensionsers have NOT

been activated:

[same text as in current manual]

Seat belt pre-ten-

sioner assemblies If the driver or passenger Seat belt pre-tension-

er has been activated:

REPLACE the seat belt pre-tensioner

assemblies with new fasteners. If the pre-tensioners have NOT been activated:

[same text as in current manual]

Diagnosis sensor

unit If any of the SRS components have been

activated:

REPLACE the Diagnosis sensor unit.

Install with new fasteners. If none of the SRS components have been activated:

[same text as in current manual]

Steering wheel [same text as in current manual]

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3787 of 3924

TF-1

DRIVELINE/AXLE

CEF

G H

I

J

K L

M

SECTION TF

A

B

TF

N

O P

CONTENTS

TRANSFER

SERVICE INFORMATION .. ..........................3

DTC INDEX ..................................................... .....3

C1201-C1210, U1000 ......................................... ......3

PRECAUTIONS ...................................................4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

4

Precaution .................................................................4

Service Notice or Precaution .....................................5

PREPARATION ...................................................6

Special Service Tool ........................................... ......6

Commercial Service Tool ..........................................7

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING .............................

9

NVH Troubleshooting Chart ................................ ......9

TRANSFER FLUID .............................................10

Replacement ....................................................... ....10

Inspection ................................................................10

AWD SYSTEM ................................................ ....11

Power Transfer Diagram ..................................... ....11

System Description .................................................11

Schematic ...............................................................13

CAN Communication ...............................................13

TROUBLE DIAGNOSIS .....................................14

Fail-Safe Function ............................................... ....14

How to Perform Trouble Diagnosis .........................14

Location of Electrical Parts ......................................15

Circuit Diagram .......................................................16

Wiring Diagram - AWD - ..........................................17

Trouble Diagnosis Chart by Symptom ....................20

AWD Control Unit Input/Output Signal Reference

Value ................................................................... ....

20

CONSULT-III Function (ALL MODE AWD/4WD) ....21

TROUBLE DIAGNOSIS FOR SYSTEM .............24

DTC C1201 CONTROLLER FAILURE ................ ....24

DTC C1203 ABS SYSTEM ......................................24

DTC C1204 4WD SOLENOID ............................. ....25

DTC C1205 4WD ACTUATOR RLY ........................27

DTC C1210 ENGINE SIGNAL 1 ..............................28

DTC U1000 CAN COMM CIRCUIT .........................28

Power Supply Circuit for AWD Control Unit .............28

TROUBLE DIAGNOSIS FOR SYMPTOMS ......30

AWD Warning Lamp Does Not Turn ON When the

Ignition Switch Is Turned to ON ...............................

30

AWD Warning Lamp Does Not Turn OFF Several

Seconds after Engine Started ..................................

30

Heavy Tight-Corner Braking Symptom Occurs

When the Vehicle Is Driven and the Steering

Wheel Is Turned Fully to Either Side after the En-

gine Is Started .........................................................

32

Vehicle Does Not Enter AWD Mode Even Though

AWD Warning Lamp Turned to OFF .......................

33

While Driving, AWD Warning Lamp Flashes Rap-

idly (When Flashing in Approx. 1 Minute and Then

Turning OFF) ....................................................... ....

33

While Driving, AWD Warning Lamp Flashes Slow-

ly (When Continuing to Flash until Turning Ignition

Switch OFF) .............................................................

33

AWD CONTROL UNIT ......................................35

Removal and Installation .........................................35

FRONT OIL SEAL .............................................36

Removal and Installation .........................................36

REAR OIL SEAL ...............................................37

Removal and Installation .........................................37

AIR BREATHER HOSE ....................................39

Removal and Installation .........................................39

TRANSFER ASSEMBLY ..................................40

Removal and Installation .........................................40

Disassembly and Assembly .....................................40

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3797 of 3924

AWD SYSTEMTF-11

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

TF

N

O P

AWD SYSTEM

Power Transfer DiagramINFOID:0000000001327431

System DescriptionINFOID:0000000001327432

DESCRIPTION

Electronic control allows optimal distribution of torque to front/rear wheels to match road conditions.

Makes possible stable driving, with no wheel sp in, on snowy roads or other slippery surfaces.

On roads which do not require AWD, it contributes to improved fuel economy by driving in conditions close to

rear-wheel drive.

Sensor inputs determine the vehicle's turning conditi on, and in response tight cornering/braking are con-

trolled by distributing optimum torque to front wheels.

NOTE:

When driving, if there is a large difference between front and rear wheel speed which continues for a long

time, fluid temperature of drive system parts becom es too high and AWD warning lamp flashes rapidly.

(When AWD warning lamp flashes, vehicle changes to r ear-wheel drive conditions.) Also, optional distribu-

tion of torque sometimes becomes rigid before lamp flashes rapidly, but it is not malfunction.

If AWD warning lamp is flashing rapidly, stop vehicle and allow it to idle for some time. Flashing will stop and AWD system will be restored.

When driving, AWD warning lamp may flash slowly if ther e is a significant difference in diameter of the tires.

At this time, vehicle performance is not fully avail able and cautious driving is required. (Continues until

engine is turned OFF.)

If the warning lamp flashes slowly during driving but remains OFF after engine is restarted, the system is

normal. If it again flashes slowly after driving for some time, vehicle must be inspected.

When the difference of revolution speed between the front and rear wheel mode the shift occasionally

changes to direct 4-wheel driving conditions automatically. This is not malfunction.

ELECTRIC CONTROLLED COUPLING

Operation Principle

SDIA1611E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3798 of 3924

TF-12

< SERVICE INFORMATION >

AWD SYSTEM

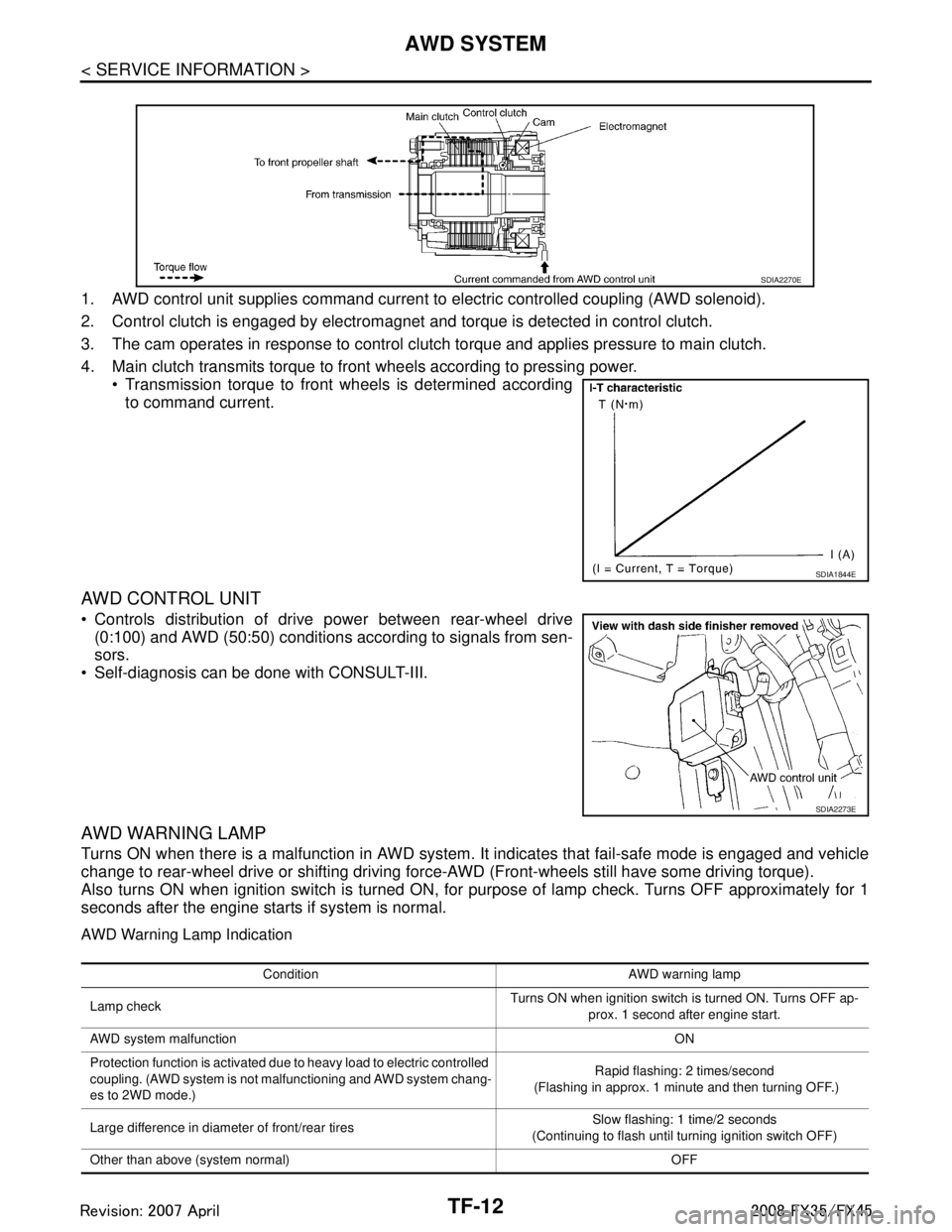

1. AWD control unit supplies command current to electric controlled coupling (AWD solenoid).

2. Control clutch is engaged by electromagnet and torque is detected in control clutch.

3. The cam operates in response to control clutch torque and applies pressure to main clutch.

4. Main clutch transmits torque to front wheels according to pressing power. Transmission torque to front wheels is determined accordingto command current.

AWD CONTROL UNIT

Controls distribution of drive power between rear-wheel drive(0:100) and AWD (50:50) conditions according to signals from sen-

sors.

Self-diagnosis can be done with CONSULT-III.

AWD WARNING LAMP

Turns ON when there is a malfunction in AWD system. It indicates that fail-safe mode is engaged and vehicle

change to rear-wheel drive or shifting driving force- AWD (Front-wheels still have some driving torque).

Also turns ON when ignition switch is turned ON, for purpose of lamp check. Turns OFF approximately for 1

seconds after the engine starts if system is normal.

AWD Warning Lamp Indication

SDIA2270E

SDIA1844E

SDIA2273E

Condition AWD warning lamp

Lamp check Turns ON when ignition switch is turned ON. Turns OFF ap-

prox. 1 second after engine start.

AWD system malfunction ON

Protection function is activated due to heavy load to electric controlled

coupling. (AWD system is not malfunctioning and AWD system chang-

es to 2WD mode.) Rapid flashing: 2 times/second

(Flashing in approx. 1 minute and then turning OFF.)

Large difference in diameter of front/rear tires Slow flashing: 1 time/2 seconds

(Continuing to flash until turning ignition switch OFF)

Other than above (system normal) OFF

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3799 of 3924

AWD SYSTEMTF-13

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

TF

N

O P

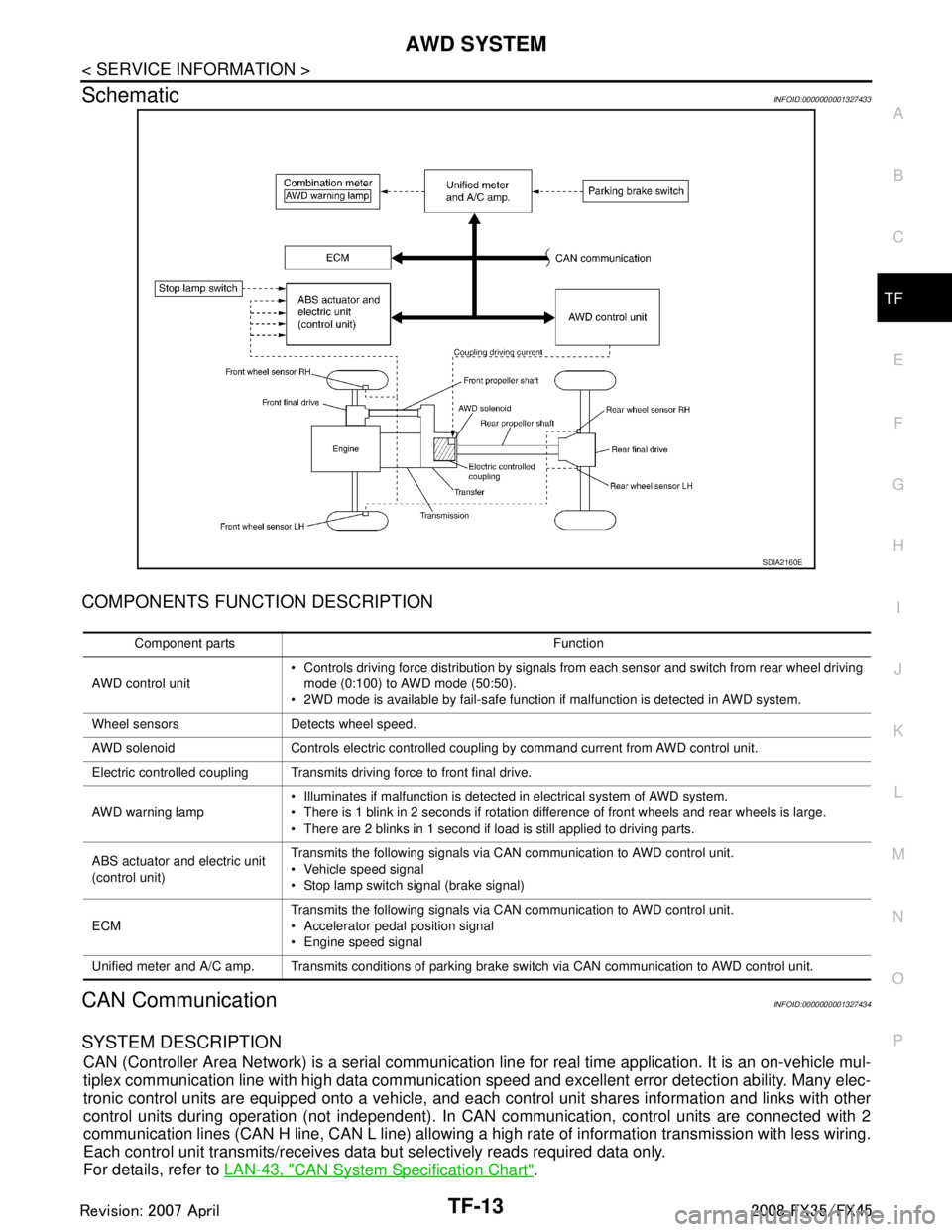

SchematicINFOID:0000000001327433

COMPONENTS FUNCTION DESCRIPTION

CAN CommunicationINFOID:0000000001327434

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication li ne for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

For details, refer to LAN-43, "

CAN System Specification Chart".

SDIA2160E

Component parts Function

AWD control unit Controls driving force distribution by signals from each sensor and switch from rear wheel driving

mode (0:100) to AWD mode (50:50).

2WD mode is available by fail-safe function if malfunction is detected in AWD system.

Wheel sensors Detects wheel speed.

AWD solenoid Controls electric controlled coupling by command current from AWD control unit.

Electric controlled coupling Transmits driving force to front final drive.

AWD warning lamp Illuminates if malfunction is detected in electrical system of AWD system.

There is 1 blink in 2 seconds if rotation difference of front wheels and rear wheels is large.

There are 2 blinks in 1 second if load is still applied to driving parts.

ABS actuator and electric unit

(control unit) Transmits the following signals via CAN communication to AWD control unit.

Vehicle speed signal

Stop lamp switch signal (brake signal)

ECM Transmits the following signals via CAN communication to AWD control unit.

Accelerator pedal position signal

Engine speed signal

Unified meter and A/C amp. Transmits conditions of parking brake switch via CAN communication to AWD control unit.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3800 of 3924

TF-14

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

TROUBLE DIAGNOSIS

Fail-Safe FunctionINFOID:0000000001327435

If any malfunction occurs in AWD electrical system, and control unit detects the malfunction, AWD warning

lamp on combination meter turns ON to indicate system malfunction.

When AWD warning lamp is ON, vehicle changes to rear-wheel drive or shifting driving force-AWD (Front-

wheels still have some driving torque).

How to Perform Trouble DiagnosisINFOID:0000000001327436

BASIC CONCEPT

To perform trouble diagnosis, it is the most import ant to have understanding about vehicle systems (control

and mechanism) thoroughly.

It is also important to clarify customer complaints before inspec-

tion.

First of all, reproduce symptoms, and understand them fully.

Ask customer about his/her complaints carefully. In some cases, it

will be necessary to check symptoms by driving vehicle with cus-

tomer.

CAUTION:

Customers are not professional. It is dangerous to make an

easy guess like “maybe the customer means that...,” or

“maybe the customer mentions this symptom”.

It is essential to check symptoms right from the beginning in order to repair malfunctions completely.

For intermittent malfunctions, reproduce symptoms based on inter-

view with customer and past examples. Do not perform inspection

on ad hoc basis. Most intermittent malfunctions are caused by

poor contacts. In this case, it will be effective to shake suspected

harness or connector by hand. When repairing without any symp-

tom diagnosis, you cannot judge if malfunctions have actually been

eliminated.

After completing diagnosis, always erase diagnostic memory. Refer to TF-21, "

CONSULT-III Function (ALL MODE AWD/4WD)".

For intermittent malfunctions, move harness or harness connector by hand. Then check for poor contact or reproduced open circuit.

SEF233G

SEF234G

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3806 of 3924

TF-20

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

Trouble Diagnosis Chart by Symptom

INFOID:0000000001327440

If AWD warning lamp turns ON, perform self-diagnosis. Refer to TF-21, "CONSULT-III Function (ALL MODE AWD/4WD)".

NOTE:

Light tight-corner braking symptom may occur depending on driving conditions. This is not malfunction.

AWD Control Unit Input/Output Signal Reference ValueINFOID:0000000001327441

AWD CONTROL UNIT INSPECTION TABLE

Specifications with CONSULT-III

Symptom Condition Check item Reference page

AWD warning lamp does not turn ON when

the ignition switch is turned to ON.

(AWD warning lamp check) Ignition switch: ONCAN communication line

TF-30

Unified meter and A/C amp.

Unified meter control unit

AWD warning lamp does not turn OFF sev-

eral seconds after engine started. Engine runningCAN communication line

TF-30

Power supply and ground for AWD con-

trol unit

Unified meter and A/C amp.

Unified meter control unit

AWD solenoid

AWD actuator relay (integrated in AWD

control unit)

Wheel sensor

Heavy tight-corner braking symptom occurs

when the vehicle is driven and the steering

wheel is turned fully to either side after the

engine is started. (See NOTE.) While driving

Steering wheel is

turned fully to either

sides CAN communication line

TF-32

Accelerator pedal position signal

AWD solenoid

Mechanical malfunction of electric con-

trolled coupling (clutch sticking etc.)

Vehicle does not enter AWD mode even

though AWD warning lamp turned to OFF. While drivingAWD solenoid

TF-33

Mechanical malfunction of electric con-

trolled coupling (Mechanical engage-

ment of clutch is not possible.)

While driving, AWD warning lamp flashes

rapidly. (When flashing in approx. 1 minute

and then turning OFF.)

Rapid flashing: 2 times/second While drivingProtection function is activated due to

heavy load to electric controlled cou-

pling. (AWD system is not malfunction-

ing. Also, optional distribution of torque

sometimes becomes rigid before lamp

flashes rapidly, but it is not malfunction.) TF-33

While driving, AWD warning lamp flashes

slowly. (When continuing to flash until turn-

ing ignition switch OFF)

Slow flashing: 1 time/2 seconds While driving

Vehicle speed: 20 km/h

(12 MPH) or more Tire size is different between front and

rear of vehicle.

TF-33

Monitored item [Unit] Content Condition Display value

FR RH SENSOR [km/h] or [mph] Wheel speed (Front wheel

right)Vehicle stopped 0.00 km/h (0.00 mph)

Vehicle running

CAUTION:

Check air pressure of tire under

standard condition.

Approximately equal to

the indication on speed-

ometer (Inside of

±10%)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3807 of 3924

TROUBLE DIAGNOSISTF-21

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

TF

N

O P

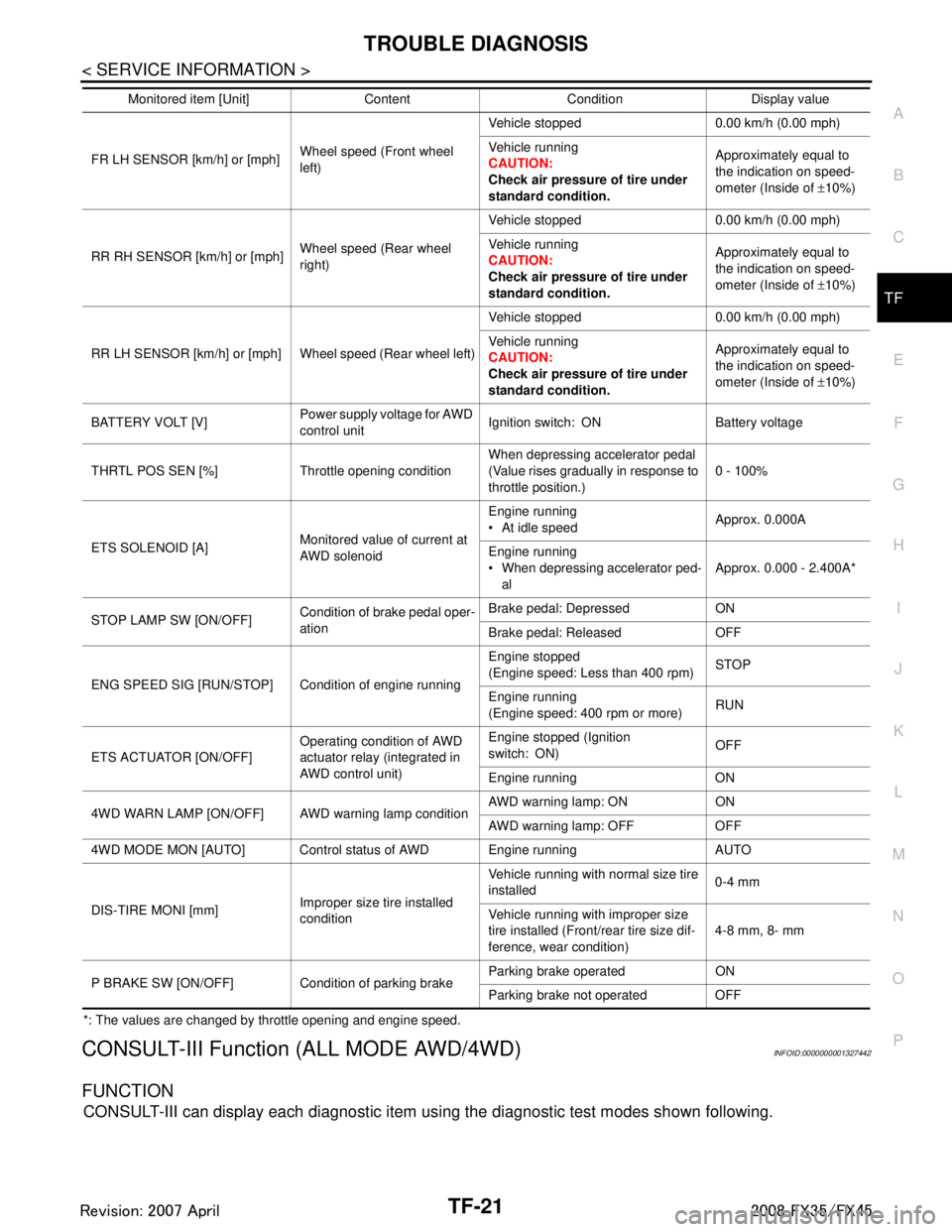

*: The values are changed by throttle opening and engine speed.

CONSULT-III Function (ALL MODE AWD/4WD)INFOID:0000000001327442

FUNCTION

CONSULT-III can display each diagnostic item using the diagnostic test modes shown following.

FR LH SENSOR [km/h] or [mph] Wheel speed (Front wheel

left)Vehicle stopped 0.00 km/h (0.00 mph)

Vehicle running

CAUTION:

Check air pressure of tire under

standard condition.

Approximately equal to

the indication on speed-

ometer (Inside of

±10%)

RR RH SENSOR [km/h] or [mph] Wheel speed (Rear wheel

right)Vehicle stopped 0.00 km/h (0.00 mph)

Vehicle running

CAUTION:

Check air pressure of tire under

standard condition.

Approximately equal to

the indication on speed-

ometer (Inside of

±10%)

RR LH SENSOR [km/h] or [mph] Wheel speed (Rear wheel left) Vehicle stopped 0.00 km/h (0.00 mph)

Vehicle running

CAUTION:

Check air pressure of tire under

standard condition.Approximately equal to

the indication on speed-

ometer (Inside of

±10%)

BATTERY VOLT [V] Power supply voltage for AWD

control unitIgnition switch: ON Battery voltage

THRTL POS SEN [%] Throttle opening condition When depressing accelerator pedal

(Value rises gradually in response to

throttle position.)0 - 100%

ETS SOLENOID [A] Monitored value of current at

AWD solenoidEngine running

At idle speed

Approx. 0.000A

Engine running

When depressing accelerator ped- al Approx. 0.000 - 2.400A*

STOP LAMP SW [ON/OFF] Condition of brake pedal oper-

ationBrake pedal: Depressed ON

Brake pedal: Released OFF

ENG SPEED SIG [RUN/STOP] Condi tion of engine runningEngine stopped

(Engine speed: Less than 400 rpm)

STOP

Engine running

(Engine speed: 400 rpm or more) RUN

ETS ACTUATOR [ON/OFF] Operating condition of AWD

actuator relay (integrated in

AWD control unit)Engine stopped (Ignition

switch: ON)

OFF

Engine running ON

4WD WARN LAMP [ON/OFF] AWD warning lamp conditionAWD warning lamp: ON ON

AWD warning lamp: OFF OFF

4WD MODE MON [AUTO] Control status of AWD Engine running AUTO

DIS-TIRE MONI [mm] Improper size tire installed

conditionVehicle running with normal size tire

installed

0-4 mm

Vehicle running with improper size

tire installed (Front /rear tire size dif-

ference, wear condition) 4-8 mm, 8- mm

P BRAKE SW [ON/OFF] Condition of parking brake Parking brake operated ON

Parking brake not operated OFF

Monitored item [Unit] Content Condition Display value

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3808 of 3924

TF-22

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

SELF-DIAG RESULT MODE

Drive at 30 km/h or more for approximately 1 minute before performing the self-diagnosis.

Display Item List

CAUTION:

If “CAN COMM CIRCUIT [U1000]” is displayed with other DTCs, first perform the trouble diagnosis for CAN communication

line.

Make sure that ABS warning lamp turns OFF by driving for a minute at vehicle speed of 30 km/h (19 MPH) or more after turn- ing ignition switch “OFF” if AWD warning lamp turns ON with system malfunction of “ABS SYSTEM [C1203]”. AWD warning

lamp may not turn OFF if it is normal unless ignition switch turns OFF at once and engine restarts after that.

How to Erase Self-Diagnostic Results

Before erasing DTC memory, start the engine and drive at 30 km/h or more for approximately 1 minute.

Checkthat ABS warning lamp turns OFF.

NOTE:

Make sure that ABS warning lamp turns OFF by driv ing for a minute at vehicle speed of 30 km/h (19

MPH) or more after turning ignition switch “OFF ” if AWD warning lamp turns ON with system malfunc-

tion of “ABS SYSTE M [C1203]”. AWD warning lamp may not turn OFF if it is normal unless ignition

switch turns OFF at once and engine restarts after that.

DATA MONITOR MODE

Display Item List

Diagnostic test mode Function

ECU part number 4WD control unit part number can be read.

Self-diagnostic results Self-diagnostic results can be read and erased quickly.

Data monitor Input/Output data in the 4WD control unit can be read.

Active test Diagnostic Test Mode in which CONSULT-III drives some actuators apart from the 4WD control unit

and also shifts some parameters in a specified range.

Items (CONSULT-III screen

terms) Diagnostic item is detected when... Check item

CONTROLLER FAILURE

[C1201] Malfunction has occurred inside AWD control unit. TF-24, "

DTC C1201 CON-

TROLLER FAILURE"

ABS SYSTEM

[C1203]Malfunction related to wheel sensor

has been detected by ABS actu-

ator and electric unit (control unit). TF-24, "DTC C1203 ABS

SYSTEM"

4WD SOLENOID

[C1204]

Malfunction related to AWD solenoid has been detected.

TF-25, "DTC C1204 4WD

SOLENOID"

4WD ACTUATOR RLY

[C1205]Malfunction has been detected from AWD actuator relay integrated

with AWD control unit, or malfunction related to AWD solenoid has

been detected. TF-27, "

DTC C1205 4WD

ACTUATOR RLY" or

TF-25,

"DTC C1204 4WD SOLE-

NOID"

ENGINE SIGNAL 1

[C1210] Malfunction has been detected from ECM. TF-28, "DTC C1210 EN-

GINE SIGNAL 1"

CAN COMM CIRCUIT

[U1000]When AWD control unit is not transmitting or receiving CAN commu-

nication signal for 2 seconds or more. TF-28, "DTC U1000 CAN

COMM CIRCUIT"

NO DTC IS DETECTED.

FURTHER TESTING MAY BE

REQUIRED.

No NG item has been detected. —

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C