wheel INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 3809 of 3924

TROUBLE DIAGNOSISTF-23

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

TF

N

O P

× : Standard : Not applicable

ACTIVE TEST MODE

Description

Use this mode to determine and identify the details of a malfunction based on self-diagnostic results or data

monitor. AWD control unit gives drive signal to actuat or with receiving command from CONSULT-III to check

operation of actuator.

Test Item

CAUTION:

Do not continuously energize for a long time.

Monitored item (Unit) Monitor Menu

Remarks

ECU INPUT

SIGNALS MAIN

SIGNALS

FR RH SENSOR [km/h] or [mph] ××Wheel speed calculated by front wheel sensor

RH signal is displayed.

FR LH SENSOR [km/h] or [mph] ××Wheel speed calculated by front wheel sensor LH

signal is displayed.

RR RH SENSOR [km/h] or [mph] ××Wheel speed calculated by rear wheel sensor RH

signal is displayed.

RR LH SENSOR [km/h] or [mph] ××Wheel speed calculated by rear wheel sensor LH

signal is displayed.

BATTERY VOLT [V] Power supply voltage for AWD control unit

THRTL POS SEN [%] Throttle opening status is displayed.

ETS SOLENOID [A] Monitored value of current at AWD solenoid

STOP LAMP SW [ON/OFF] Stop lamp switch signal status via CAN commu-

nication line is displayed.

ENG SPEED SIG [RUN/STOP] Eng ine status is displayed.

ETS ACTUATOR [ON/OFF] Operating condition of AWD actuator relay (inte-

grated in AWD control unit) is displayed.

4WD WARN LAMP [ON/OFF] Control status of AWD warning lamp is displayed.

4WD MODE SW [AUTO] AWD lock switch is not equipped, but displayed.

4WD MODE MON [AUTO] Control status of AWD is displayed.

DIS-TIRE MONI [mm] Improper size tire installed condition is displayed.

P BRAKE SW [ON/OFF] Parking switch signal status via CAN communi-

cation line is displayed.

Test item Condition Description

ETS S/V

(Detects AWD solenoid valve) Vehicle stopped

Engine running

No DTC detected Change command current value to AWD solenoid, and then change driving

mode. (Monitor value is normal if it is within approximately ±10% of com-

mand value.)

Qu: Increase current value in increments of 0.20A

Qd: Decrease current value in increments of 0.20A

UP: Increase current value in increments of 0.02A

DOWN: Decrease current value in increments of 0.02A

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3818 of 3924

TF-32

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

3. Start the engine, and then make sure that “4WD W/L” display turns from “ON” to “OFF” after several sec-

onds.

OK or NG

OK >> GO TO 6.

NG >> Perform trouble diagnosis for combination meter. Refer to DI-15, "

Trouble Diagnosis".

6.SYMPTOM CHECK

Check again.

OK or NG

OK >> INSPECTION END

NG >> Replace unified meter control unit assembly. Refer to DI-23, "

Disassembly and Assembly of Com-

bination Meter".

Heavy Tight-Corner Braking Symptom Occurs When the Vehicle Is Driven and the

Steering Wheel Is Turned Fu lly to Either Side after the Engine Is Started

INFOID:0000000001327452

NOTE:

Light tight-corner braking symptom may occur depending on driving conditions. This is not malfunc-

tion.

DIAGNOSTIC PROCEDURE

1.CHECK SYSTEM FOR CAN COMMUNICATION LINE

Perform self-diagnosis. Refer to TF-21, "

CONSULT-III Function (ALL MODE AWD/4WD)".

Is the

“CAN COMM CIRCUIT [U1000]” displayed?

YES >> Perform trouble diagnosis for CAN communication line. Refer to TF-28, "DTC U1000 CAN COMM

CIRCUIT".

NO >> GO TO 2.

2.CHECK ACCELERATOR PEDAL POSITION SIGNAL CIRCUIT

Perform self-diagnosis for ECM. Refer to EC-55, "

Emission-Related Diagnostic Information" (VQ35DE mod-

els) or EC-633, "

Emission-related Diagnostic Information" (VK45DE models).

Is any malfunction detec ted by self-diagnosis?

YES >> Check the malfunctioning system.

NO >> GO TO 3.

3.CHECK SYSTEM FOR AWD SOLENOID

Perform trouble diagnosis for AWD solenoid system. Refer to TF-25, "

DTC C1204 4WD SOLENOID".

OK or NG

OK >> GO TO 4.

NG >> Repair or replace damaged parts.

4.CHECK ELECTRIC CONTROLLED COUPLING

1. Turn ignition switch “OFF”.

2. Set the selector lever to “N” (neutral) position and disengage the parking brake.

3. Lift up the vehicle.

4. Rotate the rear propeller shaft by hand.

5. Hold front propeller shaft lightly.

Does front propeller shaft rotate?

YES >> Replace electric controlled coupling for mec hanical malfunction (clutch sticking etc.). Refer to TF-

40, "Disassembly and Assembly".

NO >> GO TO 5.

Monitor item Condition Display value

4WD W/L Ignition switch ON ON

Start engine (after several seconds) OFF

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3841 of 3924

WT-1

SUSPENSION

C

DF

G H

I

J

K L

M

SECTION WT

A

B

WT

N

O PCONTENTS

ROAD WHEELS & TIRES

SERVICE INFORMATION .. ..........................2

INDEX FOR DTC ............................................ .....2

DTC No. Index .................................................... ......2

PRECAUTIONS ...................................................3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution .................................................................3

Service Notice or Precaution .....................................4

PREPARATION ...................................................5

Special Service Tool ........................................... ......5

Commercial Service Tool ..........................................5

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING .............................

6

NVH Troubleshooting Chart ................................ ......6

ROAD WHEEL ....................................................7

Inspection ............................................................ ......7

ROAD WHEEL TIRE ASSEMBLY ......................8

Balancing Wheels (Bonding Weight Type) .......... ......8

Tire Rotation ..............................................................9

TIRE PRESSURE MONITORING SYSTEM .......10

System Component ............................................. ....10

System Description .................................................10

CAN COMMUNICATION ....................................13

System Description ............................................. ....13

TROUBLE DIAGNOSES ....................................14

Schematic ........................................................... ....14

Wiring Diagram- T/WARN - .....................................15

Control Unit Input/Output Signal Standard ..............17

ID Registration Procedure ................................... ....19

Transmitter Wake Up Operation ..............................20

Self-Diagnosis .........................................................20

CONSULT-III Function (BCM) .................................22

How to Perform Trouble Diagnosis for Quick and

Accurate Repair .......................................................

24

Preliminary Check ...................................................25

Malfunction Code/Symptom Chart ...........................26

TROUBLE DIAGNOSIS FOR SELF-DIAG-

NOSTIC ITEMS .................................................

28

Transmitter or Control Unit (BCM) ...........................28

Transmitter - 1 .........................................................28

Transmitter - 2 .........................................................29

Vehicle Speed Signal ..............................................29

TROUBLE DIAGNOSIS FOR SYMPTOMS ......30

Low Tire Pressure Warning Lamp Does Not Come

On When Ignition Switch Is Turned On ...................

30

Low Tire Pressure Warning Lamp Stays On When

Ignition Switch Is Turned On ............................... ....

30

Low Tire Pressure Warning Lamp Blinks When Ig-

nition Switch Is Turned On ......................................

31

Run-Flat Tire Warning Lamp Stays On When Igni-

tion Switch Is Turned On .........................................

32

Turn Signal Lamp Blinks When Ignition Switch Is

Turned On ...............................................................

32

ID Registration Cannot Be Completed ....................32

REMOVAL AND INSTALLATION .....................33

Transmitter ..............................................................33

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

35

Road Wheel .............................................................35

Tire ..........................................................................35

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3844 of 3924

WT-4

< SERVICE INFORMATION >

PRECAUTIONS

Before replacing BCM, perform c ontrol unit input/output sig-

nal inspection and make sure whether BCM functions prop-

erly or not. Refer to WT-17, "

Control Unit Input/Output Signal

Standard".

Service Notice or PrecautionINFOID:0000000001327569

Low tire pressure warning lamp flashes 1min, then turns ON when occurring any malfunction except low tire

pressure. Delete the memory with CONSULT-III, or regi ster the ID to turn low tire pressure warning lamp

OFF. Refer to WT-22, "

CONSULT-III Function (BCM)", WT-19, "ID Registration Procedure".

ID registration is required when replacing or rotati ng wheels, replacing transmitter or BCM. Refer to WT-19,

"ID Registration Procedure".

Replace grommet seal, valve core and cap of the transmi tter in TPMS every tire replacement by reaching

wear limit of tire.

SDIA1848E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3846 of 3924

WT-6

< SERVICE INFORMATION >

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000001327572

Use the chart below to help you find the cause of the sy mptom. If necessary, repair or replace these parts.

×: Applicable

Reference

FAX-4

,

FAX-11

, FSU-5

WT-7WT-8WT-35WT-9—

—

WT-35

NVH in PR section

NVH in RFD section

NVH in FAX and FSU section

NVH in RAX and RSU section Refer to TIRE in this chart.

Refer to ROAD WHEEL in this chart. NVH in FAX, RAX sectionNVH in BR section

NVH in PS section

Possible cause an d SUSPECTED PARTS

Improper installation, looseness

Out-of-round

Unbalance

Incorrect tire pressure

Uneven tire wear

Deformation or damage

Non-uniformity

Incorrect tire size

PROPELLER SHAFT

DIFFERENTIAL

FRONT AXLE AND FRONT SUSPENSION

REAR AXLE AND REAR SUSPENSION

TIRE

ROAD WHEEL

DRIVE SHAFT

BRAKE

STEERING

SymptomTIRE Noise

× ×××××× ×××× ××××

Shake ××××××××××××××

Vibration ×××××××

Shimmy × ××××××× ×× × ××

Judder ××××××× ×××××

Poor quality ride

or handling × ××××× × ×× ×

ROAD WHEEL Noise

× ×× × ××××× ×××

Shake × ×× × × ××× ×××

Shimmy, Judder ×××× ×××××

Poor quality ride

or handling ××× × ×××

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3847 of 3924

ROAD WHEELWT-7

< SERVICE INFORMATION >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

ROAD WHEEL

InspectionINFOID:0000000001327573

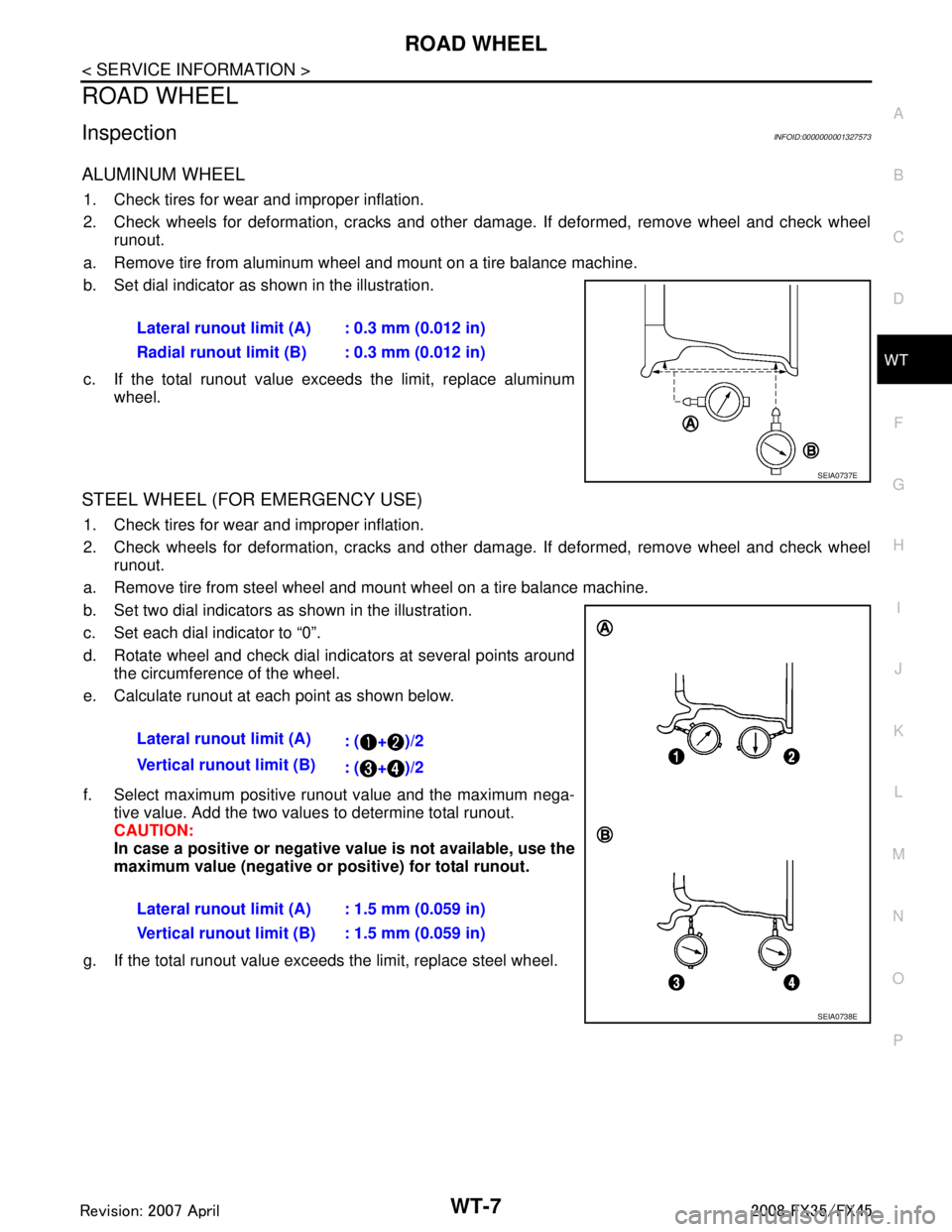

ALUMINUM WHEEL

1. Check tires for wear and improper inflation.

2. Check wheels for deformation, cracks and other damage. If deformed, remove wheel and check wheel runout.

a. Remove tire from aluminum wheel and mount on a tire balance machine.

b. Set dial indicator as shown in the illustration.

c. If the total runout value exceeds the limit, replace aluminum wheel.

STEEL WHEEL (FOR EMERGENCY USE)

1. Check tires for wear and improper inflation.

2. Check wheels for deformation, cracks and other damage. If deformed, remove wheel and check wheelrunout.

a. Remove tire from steel wheel and mount wheel on a tire balance machine.

b. Set two dial indicators as shown in the illustration.

c. Set each dial indicator to “0”.

d. Rotate wheel and check dial indicators at several points around the circumference of the wheel.

e. Calculate runout at each point as shown below.

f. Select maximum positive runout value and the maximum nega- tive value. Add the two values to determine total runout.

CAUTION:

In case a positive or negative val ue is not available, use the

maximum value (negative or positive) for total runout.

g. If the total runout value exceeds the limit, replace steel wheel.

Lateral runout limit (A) : 0.3 mm (0.012 in)

Radial runout limit (B) : 0.3 mm (0.012 in)

SEIA0737E

Lateral runout limit (A)

: ( + )/2

Vertical runout limit (B) : ( + )/2

Lateral runout limit (A) : 1.5 mm (0.059 in)

Vertical runout limit (B) : 1.5 mm (0.059 in)

SEIA0738E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3848 of 3924

WT-8

< SERVICE INFORMATION >

ROAD WHEEL TIRE ASSEMBLY

ROAD WHEEL TIRE ASSEMBLY

Balancing Wheels (Bonding Weight Type)INFOID:0000000001327574

REMOVAL

Using releasing agent, remove double-faced adhesive tape from the road wheel.

CAUTION:

Be careful not to scratch th e road wheel during removal.

After removing double-faced adhesive tape, wi pe clean traces of releasing agent from the road

wheel.

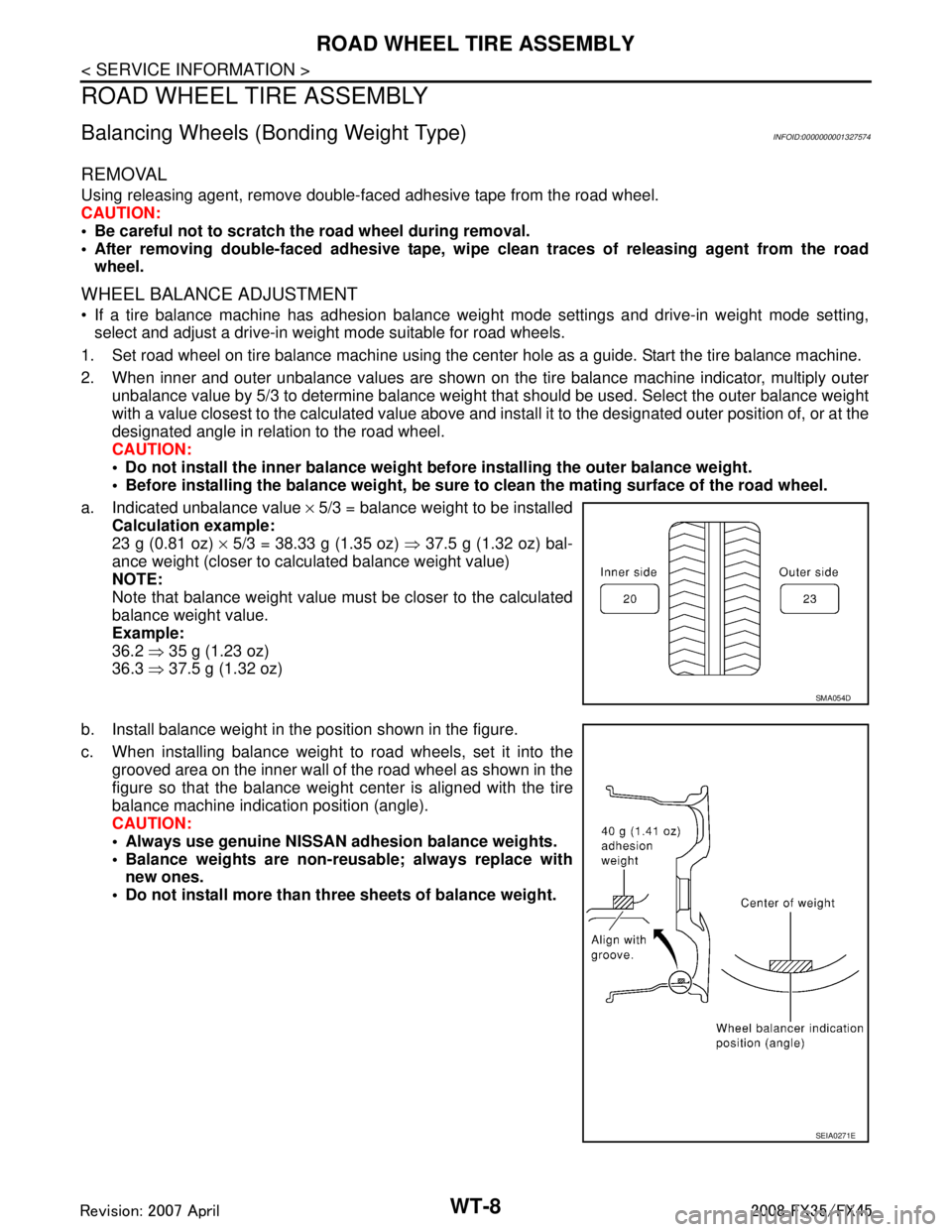

WHEEL BALANCE ADJUSTMENT

If a tire balance machine has adhesion balance weight mode settings and drive-in weight mode setting,

select and adjust a drive-in weight mode suitable for road wheels.

1. Set road wheel on tire balance machine using the center hole as a guide. Start the tire balance machine.

2. When inner and outer unbalance values are shown on the tire balance machine indicator, multiply outer unbalance value by 5/3 to determine balance weight t hat should be used. Select the outer balance weight

with a value closest to the calculated value above and inst all it to the designated outer position of, or at the

designated angle in relation to the road wheel.

CAUTION:

Do not install the inner balance weight before installing the outer balance weight.

Before installing the balance weight, be sure to clean the mating surface of the road wheel.

a. Indicated unbalance value × 5/3 = balance weight to be installed

Calculation example:

23 g (0.81 oz) × 5/3 = 38.33 g (1.35 oz) ⇒ 37.5 g (1.32 oz) bal-

ance weight (closer to calculated balance weight value)

NOTE:

Note that balance weight value must be closer to the calculated

balance weight value.

Example:

36.2 ⇒ 35 g (1.23 oz)

36.3 ⇒ 37.5 g (1.32 oz)

b. Install balance weight in the position shown in the figure.

c. When installing balance weight to road wheels, set it into the grooved area on the inner wall of the road wheel as shown in the

figure so that the balance weight center is aligned with the tire

balance machine indication position (angle).

CAUTION:

Always use genuine NISSAN adhesion balance weights.

Balance weights are non-reusable; always replace with new ones.

Do not install more than three sheets of balance weight.

SMA054D

SEIA0271E

:

Page 3849 of 3924

ROAD WHEEL TIRE ASSEMBLYWT-9

< SERVICE INFORMATION >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

d. If calculated balance weight value exceeds 50 g (1.76 oz), install two balance weight sheets in line with each other as shown in

the figure.

CAUTION:

Do not install one balance weig ht sheet on top of another.

3. Start tire balance machine again.

4. Install drive-in balance weight on inner side of road wheel in the tire balance machine indication position (angle).

CAUTION:

Do not install more than two balance weights.

5. Start tire balance machine. Make sure that inner and outer resid- ual unbalance values are 5 g (0.2 oz) each or below.

6. If either residual unbalance value exceeds 5 g (0.2 oz), repeat installation procedures.

Tire RotationINFOID:0000000001327575

1. Follow the maintenance schedule for tire rotation service intervals. Refer to MA-5, "Introduction of Peri-

odic Maintenance".

2. Do not include the spare tire when rotating the tires.

3. When installing the wheel, tighten wheel nuts to the specified torque.

CAUTION:

When installing wheels, tighten th em diagonally by dividing the work two to three times in order

to prevent the wheels from developing any distortion.

Be careful not to tighten wheel nut at torque exceeding the criteria for preventing strain of disc

rotor.

4. Perform the ID registration, after tire rotation. Refer to WT-19, "

ID Registration Procedure".

Wheel balance Dynamic (At rim flange) Static (At rim flange)

Maximum allowable un-

balance 5 g (0.2 oz) (one side) 20 g (0.7 oz)

SMA056D

Wheel nuts : 108 N·m (11 kg-m, 80 ft-lb)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3850 of 3924

WT-10

< SERVICE INFORMATION >

TIRE PRESSURE MONITORING SYSTEM

TIRE PRESSURE MONITORING SYSTEM

System ComponentINFOID:0000000001327576

System DescriptionINFOID:0000000001327577

TRANSMITTER

A sensor-transmitter integrated with a valve is installed on a wheel,

and transmits a detected air pressure signal in the form of a radio

wave.

REMOTE KEYLESS ENTRY RECEIVER

The remote keyless entry receiver receives the air pressure signal

transmitted by the transmitter in each wheel.

BCM (BODY CONTROL MODULE)

SEIA0599E

SEIA0521E

SEIA0431E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3852 of 3924

WT-12

< SERVICE INFORMATION >

TIRE PRESSURE MONITORING SYSTEM

Note 1: Standard air pressure is for 220 kpa (2.2 kg/cm2, 32 psi) vehicles.

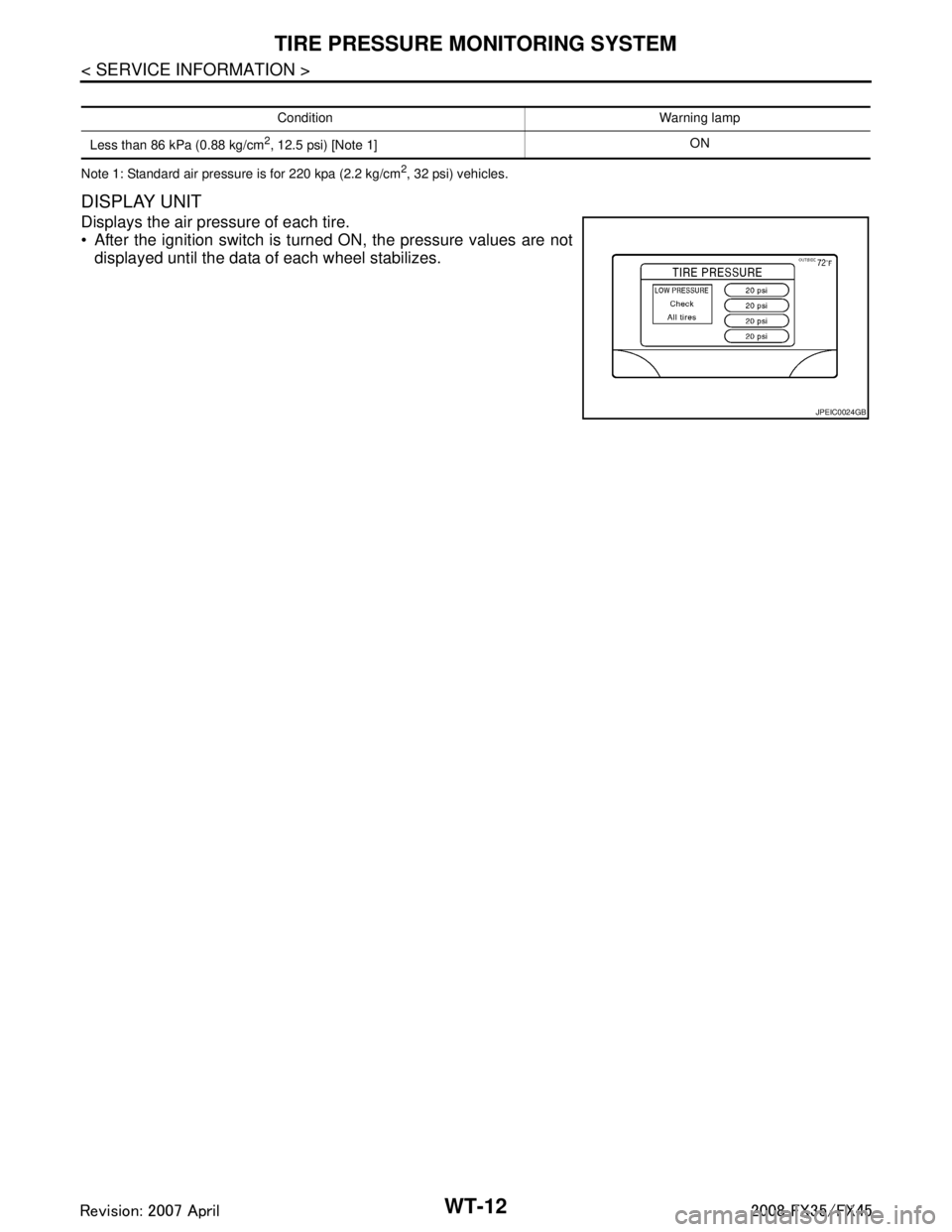

DISPLAY UNIT

Displays the air pressure of each tire.

After the ignition switch is turned ON, the pressure values are notdisplayed until the data of each wheel stabilizes.

Condition Warning lamp

Less than 86 kPa (0.88 kg/cm

2, 12.5 psi) [Note 1] ON

JPEIC0024GB

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C