INFINITI FX35 2008 Service Manual

Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 3901 of 3924

WW-26

< SERVICE INFORMATION >

FRONT WIPER AND WASHER SYSTEM

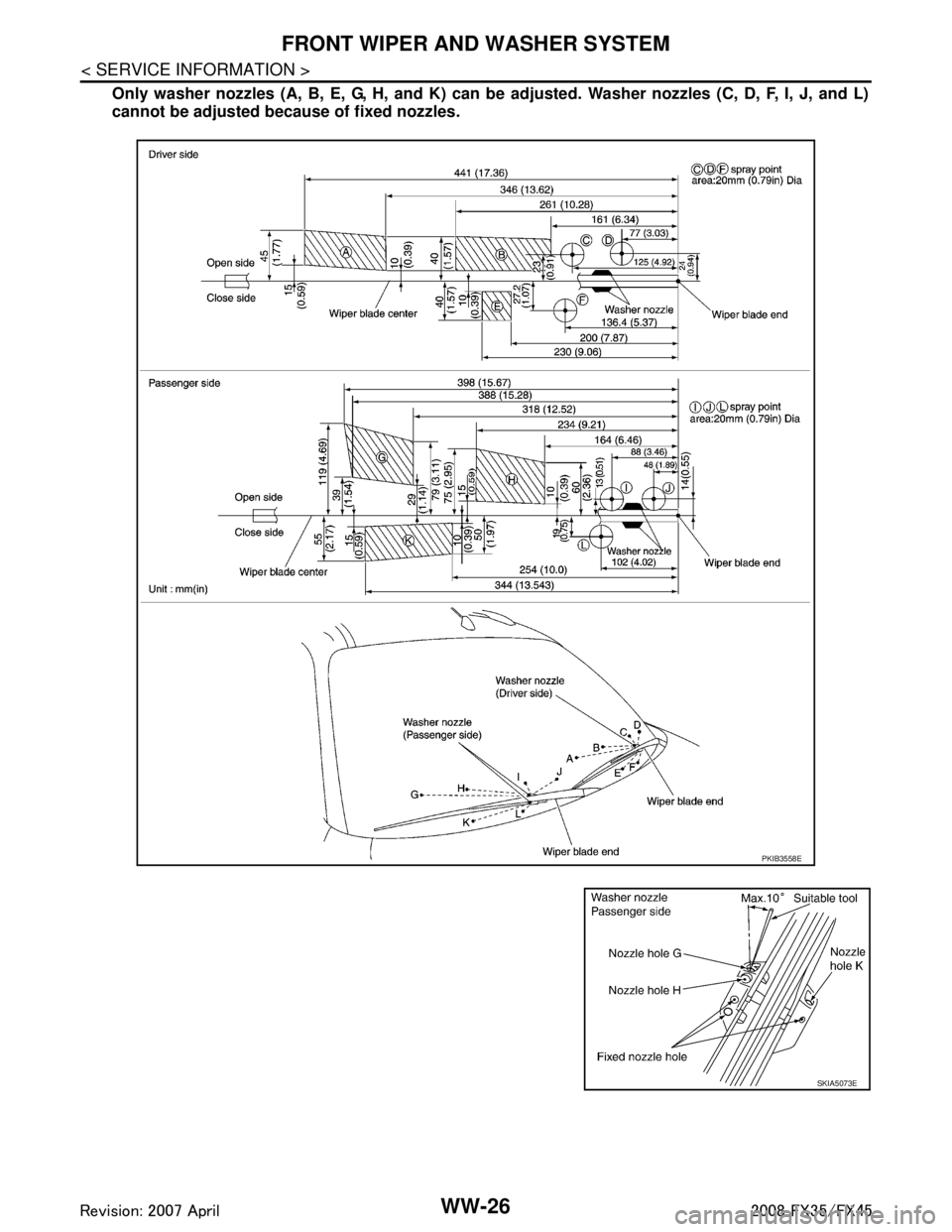

Only washer nozzles (A, B, E, G, H, and K) can be adjusted. Washer nozzles (C, D, F, I, J, and L)

cannot be adjusted because of fixed nozzles.

PKIB3558E

SKIA5073E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3902 of 3924

FRONT WIPER AND WASHER SYSTEMWW-27

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

WW

N

O P

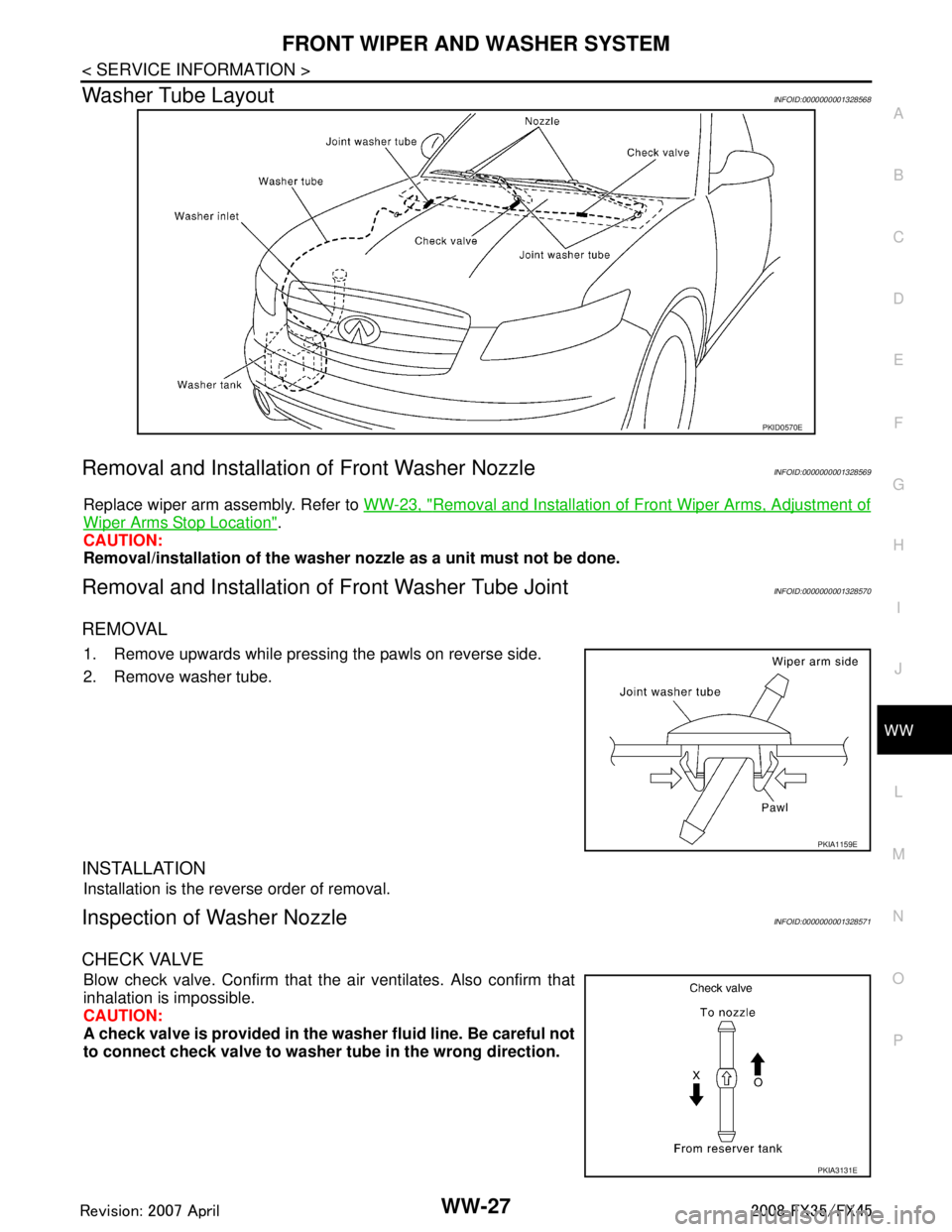

Washer Tube LayoutINFOID:0000000001328568

Removal and Installation of Front Washer NozzleINFOID:0000000001328569

Replace wiper arm assembly. Refer to WW-23, "Removal and Installation of Front Wiper Arms, Adjustment of

Wiper Arms Stop Location".

CAUTION:

Removal/installation of the washer no zzle as a unit must not be done.

Removal and Installation of Front Washer Tube JointINFOID:0000000001328570

REMOVAL

1. Remove upwards while pressing the pawls on reverse side.

2. Remove washer tube.

INSTALLATION

Installation is the reverse order of removal.

Inspection of Washer NozzleINFOID:0000000001328571

CHECK VALVE

Blow check valve. Confirm that t he air ventilates. Also confirm that

inhalation is impossible.

CAUTION:

A check valve is provided in the w asher fluid line. Be careful not

to connect check valve to washer tube in the wrong direction.

PKID0570E

PKIA1159E

PKIA3131E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3903 of 3924

WW-28

< SERVICE INFORMATION >

FRONT WIPER AND WASHER SYSTEM

Inspection of Front Wiper and Washer Switch Circuit

INFOID:0000000001328572

Refer to LT-104, "Combination Switch Inspection".

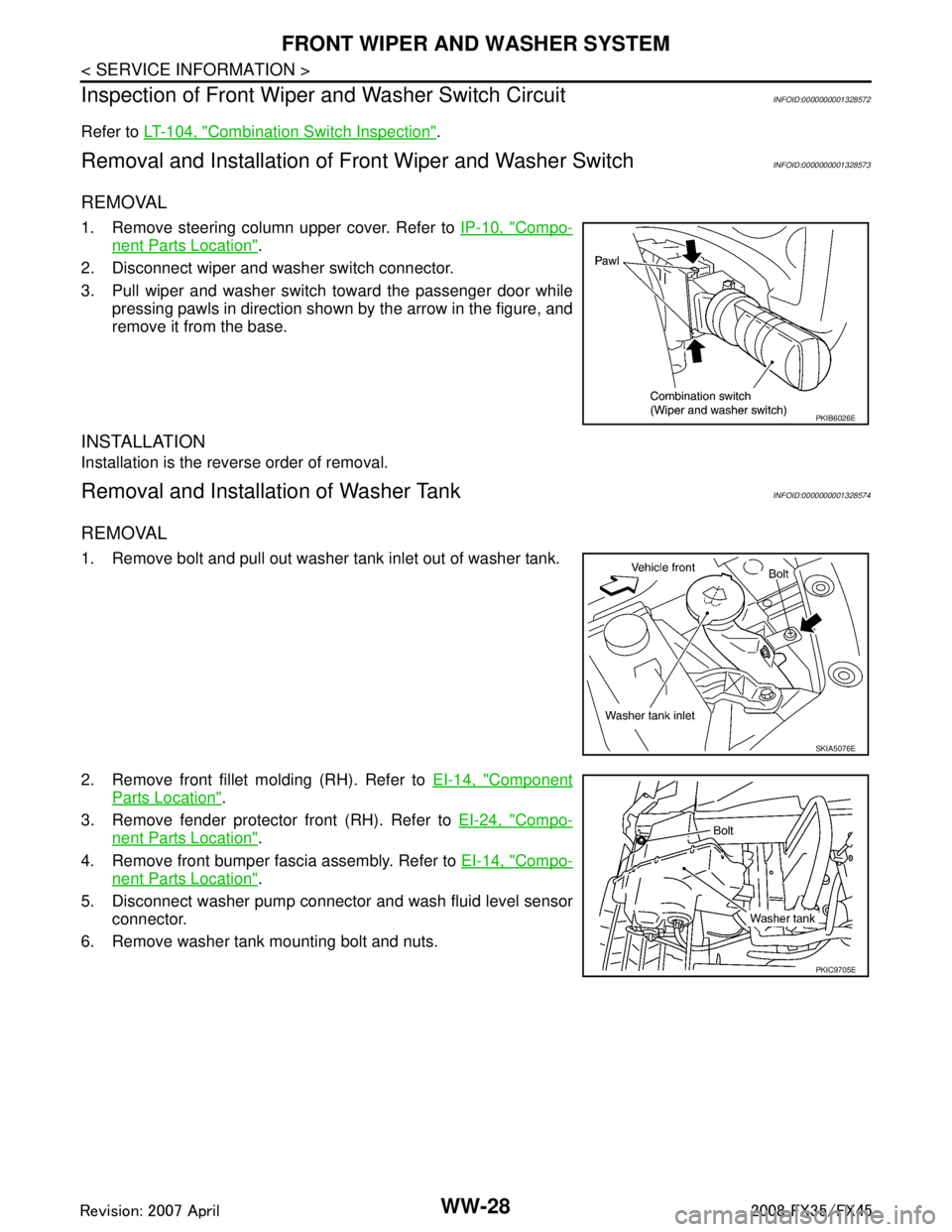

Removal and Installation of Fr ont Wiper and Washer SwitchINFOID:0000000001328573

REMOVAL

1. Remove steering column upper cover. Refer to IP-10, "Compo-

nent Parts Location".

2. Disconnect wiper and washer switch connector.

3. Pull wiper and washer switch toward the passenger door while pressing pawls in direction shown by the arrow in the figure, and

remove it from the base.

INSTALLATION

Installation is the reverse order of removal.

Removal and Installation of Washer TankINFOID:0000000001328574

REMOVAL

1. Remove bolt and pull out washer tank inlet out of washer tank.

2. Remove front fillet molding (RH). Refer to EI-14, "

Component

Parts Location".

3. Remove fender protector front (RH). Refer to EI-24, "

Compo-

nent Parts Location".

4. Remove front bumper fascia assembly. Refer to EI-14, "

Compo-

nent Parts Location".

5. Disconnect washer pump connector and wash fluid level sensor connector.

6. Remove washer tank mounting bolt and nuts.

PKIB6026E

SKIA5076E

PKIC9705E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3904 of 3924

FRONT WIPER AND WASHER SYSTEMWW-29

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

WW

N

O P

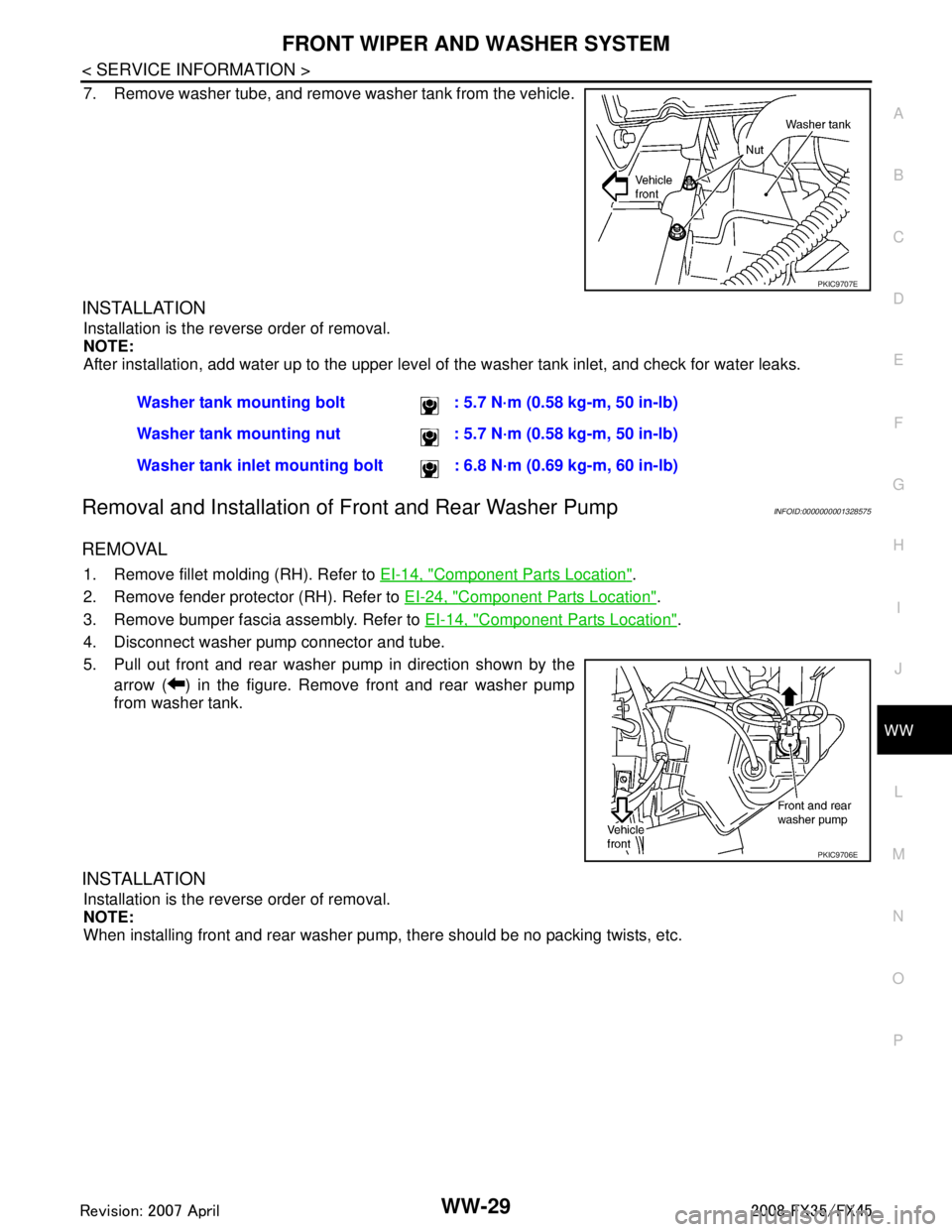

7. Remove washer tube, and remove washer tank from the vehicle.

INSTALLATION

Installation is the reverse order of removal.

NOTE:

After installation, add water up to the upper level of the washer tank inlet, and check for water leaks.

Removal and Installation of Front and Rear Washer PumpINFOID:0000000001328575

REMOVAL

1. Remove fillet molding (RH). Refer to EI-14, "Component Parts Location".

2. Remove fender protector (RH). Refer to EI-24, "

Component Parts Location".

3. Remove bumper fascia assembly. Refer to EI-14, "

Component Parts Location".

4. Disconnect washer pump connector and tube.

5. Pull out front and rear washer pump in direction shown by the arrow ( ) in the figure. Remove front and rear washer pump

from washer tank.

INSTALLATION

Installation is the reverse order of removal.

NOTE:

When installing front and rear washer pump, there should be no packing twists, etc.

PKIC9707E

Washer tank mounting bolt : 5.7 N·m (0.58 kg-m, 50 in-lb)

Washer tank mounting nut : 5.7 N·m (0.58 kg-m, 50 in-lb)

Washer tank inlet mounting bol t : 6.8 N·m (0.69 kg-m, 60 in-lb)

PKIC9706E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3905 of 3924

WW-30

< SERVICE INFORMATION >

REAR WIPER AND WASHER SYSTEM

REAR WIPER AND WASHER SYSTEM

Component Parts and Harness Connector LocationINFOID:0000000001328576

System DescriptionINFOID:0000000001328577

Wiper switch (combination switch) is composed of a combination of 5 output terminals and 5 input terminals.

Terminal combination status is read by BCM ( body control module) when switch is turned ON.

BCM controls rear wiper ON and INT (intermittent) operation.

Power supplied at all times

through 50 A fusible link (letter M, located in fuse, fusible link and relay box)

to BCM terminal 55,

through 15 A fuse [No. 22, located in fuse block (J/B)]

to BCM terminal 42.

When ignition switch ON or START position, power is supplied

through 15 A fuse [No.1, located in fuse block (J/B)]

to BCM terminal 38,

through 10 A fuse [No. 84, located in IPDM E/R (intelligent power distribution module engine room)]

to combination switch terminal 14.

Ground is supplied

to BCM terminals 49 and 52

through grounds M35, M45 and M85,

to combination switch terminal 12

through grounds M35, M45 and M85.

REAR WIPER OPERATION

When the wiper switch is in rear wiper ON position, BCM detects rear wiper ON signal by BCM wiper switch

reading function.

BCM operates rear wiper motor, power is supplied

through BCM terminal 70

to rear wiper motor 4.

Ground is supplied

to rear wiper motor terminal 2

through grounds B15 and B45.

With power and ground supplied, the rear wiper operates.

PKIC9708E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3906 of 3924

REAR WIPER AND WASHER SYSTEMWW-31

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

WW

N

O P

INTERMITTENT OPERATION

The rear wiper motor operates the wiper arms at low speed approximately every 7 seconds.

When the wiper switch is in rear wiper INT position, BCM detects rear wiper INT signal by BCM wiper switch

reading function (Refer to BCS-4, "

System Description").

BCM operates rear wiper motor, power supplied

through BCM terminal 70

to rear wiper motor terminal 4.

Ground is supplied

to rear wiper motor terminal 2

through grounds B15 and B45.

With power and ground supplied, rear wiper operates at intermittent.

AUTO STOP OPERATION

With rear wiper switch turned OFF, rear wiper motor will continue to operate until wiper arm reaches rear wiper

stopper.

Then wiper motor turns the other way and wiper arm moves once until wiper arm reaches stopper.

WASHER OPERATION

When the wiper switch is in rear wiper washer positi on, BCM detects rear wiper washer signal by BCM wiper

switch reading function (Refer to BCS-4, "

System Description"), and combination switch (wiper switch) ground

is supplied

to combination switch terminal 11

through front and rear washer pump terminal 2,

to front and rear washer pump terminal 1

through combination switch terminal 13

through combination switch terminal 12

through grounds M35, M45 and M85.

With ground supplied, front and rear washer pump is operated.

When the BCM detects that washer pump has operated fo r. 0.4 seconds or linger, BCM operates rear wiper

pump low speed.

When the BCM detects washer switch is OFF, low speed operation cycles approximately 3 times and then

stops.

BCM WIPER SWITCH READING FUNCTION

Refer to BCS-4, "System Description".

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3907 of 3924

WW-32

< SERVICE INFORMATION >

REAR WIPER AND WASHER SYSTEM

Wiring Diagram - WIP/ R -

INFOID:0000000001328578

TKWM4376E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3908 of 3924

REAR WIPER AND WASHER SYSTEMWW-33

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

WW

N

O P

Terminal and Reference Value for BCMINFOID:0000000001328579

CAUTION:

Check combination switch system terminal wavef orm under the loaded condition with lighting

switch, turn signal switch an d wiper switch OFF not to be fluctuated by overloaded.

Turn wiper intermittent dial position to 4 except when checking waveform or voltage of wiper inter-

mittent dial position. Wiper intermittent dial position can be confirmed on CONSULT-III. Refer to WW-

15, "CONSULT-III Functions (BCM)".

TKWM4377E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3909 of 3924

WW-34

< SERVICE INFORMATION >

REAR WIPER AND WASHER SYSTEM

Te r m i n a l No. Wire

color Signal name Measuring condition

Reference value

Ignition

switch Operation or condition

5Y/R Combination

switch input 2 ONLighting, turn, wip-

er switch

(Wiper intermittent

dial position 4) OFF Approx. 0 V

Rear washer switch

Approx. 1.0 V

Rear wiper switch ON Approx. 0.8 v

6SB Combination

switch input 1 ONLighting, turn,

wiper switch

(Wiper intermittent

dial position 4) OFF Approx. 0 V

Rear wiper INT

Approx. 1.0 V

32 GY/R Combination

switch output 5

ONLighting, turn,

wiper switch

(Wiper intermittent

dial position 4) OFF

Approx. 7.0 - 7.5 V

Rear wiper ON Approx. 1.0 V

PKIB4959J

PKIB4955J

PKIB4959J

PKIB4960J

PKIB4956J

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3910 of 3924

REAR WIPER AND WASHER SYSTEMWW-35

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

WW

N

O P

How to Proceed with Trouble DiagnosisINFOID:0000000001328580

1. Confirm the symptoms and customer complaint.

33 G Combination

switch output 4 ONLighting, turn, wip-

er switch

(Wiper intermittent

dial position 4) OFF

Approx. 7.2 V

Rear wiper switch INT Approx. 1.2 V

34 W/B Combination

switch output 3

ONLighting, turn, wip-

er switch

(Wiper intermittent

dial position 4) OFF

Approx. 7.2 V

Rear washer switch Approx. 1.2 V

38 W/L Ignition switch

(ON) ON — Battery voltage

39 L CAN − H— — —

40 P CAN − L— — —

42 L/R Battery power

supply

OFF — Battery voltage

49 B Ground ON — Approx. 0 V

52 B Ground ON — Approx. 0 V

55 G Battery power

supply OFF — Battery voltage

59 Y Rear wiper auto

stop signal

ONWiper operating Approx. 0 V

Wiper stopped Battery voltage

70 SB Rear wiper mo-

tor output signal ON Wiper switch OFF Approx. 0 V

ON Battery voltage

Te r m i n a l

No. Wire

color Signal name Measuring condition

Reference value

Ignition

switch Operation or condition

PKIB4960J

PKIB4958J

PKIB4960J

PKIB4958J

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C