INFINITI FX35 2008 Service Manual

Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 3891 of 3924

WW-16

< SERVICE INFORMATION >

FRONT WIPER AND WASHER SYSTEM

NOTE:

This item is displayed, but cannot be monitored.

ACTIVE TEST

Display Item List

CONSULT-III Functions (IPDM E/R)INFOID:0000000001328553

CONSULT-III can display each diagnostic item using the diagnostic test mode shown following.

DATA MONITOR

All Signals, Main Signals, Selection From Menu

NOTE:

Perform monitoring of IPDM E/R data with ignition switch ON. When ignition switch is at ACC, the display may

not be correct.

ACTIVE TEST

FR WIPER INT “ON/OFF” Displays status (front wiper switch intermittent position: ON/other: OFF) of front wiper intermit-

tent switch judged from the front wiper switch signal.

FR WASHER SW “ON/OFF” Displays status (front washer switch ON posi

tion: ON/other: OFF) of front washer switch

judged from the front wiper switch signal.

INT VOLUME “1 - 7” Displays status (wiper intermittent dial position setting 1- 7) of intermittent volume switch

judged from the front wiper switch signal.

FR WIPER STOP “ON/OFF” Displays status (front wiper stop position: ON/move: OFF) of front wiper motor stop judged

from the front wiper auto stop signal.

VEHICLE SPEED “km/h” Displays st atus vehicle speed as judged from vehicle speed signal.

RR WIPER ON “OFF” Displays status (rear wiper switch ON position

: ON/other: OFF) of rear wiper switch judged

from the rear wiper switch signal.

RR WIPER INT “OFF” Displays status (rear wiper switch intermittent position: ON/other: OFF) of rear wiper intermit-

tent switch judged from the rear wiper switch signal.

RR WASHER SW “OFF” Displays status (rear washer switch ON position: ON/other: OFF) of rear washer switch judged

from the rear wiper switch signal.

RR WIPER STOP “OFF” Displays status (rear wiper stop position: OFF/move: ON) of rear wiper motor stop judged from

the rear wiper auto stop signal.

H/L WASH SW

NOTE“ON/OFF” —

Monitor item Contents

Test item Display on CONSULT-III screen Description

Front wiper output FR WIPER With a certain operation (OFF, HI, LO, INT), front wiper can be operated. Rear wiper output RR WIPER Rear wiper can be operated by any ON-OFF operation

Diagnosis Mode Description

SELF-DIAG RESULTS Refer to PG-18, "

CONSULT-III Function (IPDM E/R)".

DATA MONITOR The input/output data of IPDM E/R is displayed in real time.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

ACTIVE TEST IPDM E/R sends a drive signal to electronic components to check their operation.

Item name CONSULT-III

screen display Display or unit Monitor item selection

Description

ALL

SIGNALS MAIN

SIGNALS SELECTION

FROM MENU

FR wiper request FR WIP REQ STOP/LOW/HI ×× ×Signal status input from BCM

Wiper auto stop WIP AUTO STOP ACT P/STOP P ×× ×Output status of IPDM E/R

Wiper protection WIP PROT OFF/BLOCK ×× ×Control status of IPDM E/R

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3892 of 3924

FRONT WIPER AND WASHER SYSTEMWW-17

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

WW

N

O P

Front Wiper Does Not OperateINFOID:0000000001328554

CAUTION:

During IPDM E/R fail-safe control, fr ont wipers may not operate. Refer to PG-17, "

System Description"

in “PG IPDM E/R” to make sure that it is not in fail-safe status.

1.ACTIVE TEST

With CONSULT-III

1. Select “FRONT WIPER” of IPDM E/R active test item.

2. With operating the test item, check that front wiper “LO” and “HI” operation.

Without CONSULT-III

Start up auto active test. Refer to PG-20, "

Auto Active Test".

Does front wiper operate normally?

YES >> GO TO 5.

NO >> GO TO 2.

2.CHECK FRONT WIPER CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector and front wiper motor connector.

3. Check continuity between IPDM E/R harness connector and front wiper motor harness connector.

4. Check continuity between IPDM E/R harness connector and Ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK GROUND CIRCUIT

Check continuity between front wiper motor harness connector and

ground.

OK or NG

OK >> GO TO 4.

NG >> Repair harness or connector.

4.CHECK IPDM E/R

Test item CONSULT-III screen display Description

Front wiper (HI, LO) output FR WIPER With a certain operation (OFF, HI ON,

LO ON), front wiper relay (Lo, Hi)

can be operated.

IPDM E/R Front wiper motor Continuity

Connector Terminal Connector Terminal

E7 21

E57 1

Ye s

31 4

IPDM E/R connector Terminal GroundContinuity

E7 21

No

31

PKIA7650E

2 – Ground : Continuity should exist.

PKIA5193E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3893 of 3924

WW-18

< SERVICE INFORMATION >

FRONT WIPER AND WASHER SYSTEM

With CONSULT-III

1. Connect IPDM E/R connector and front wiper motor connector.

2. Select “FRONT WIPER” of IPDM E/R active test item.

3. With operating the test item , check voltage between IPDM E/R

harness connector and ground.

Without CONSULT-III

1. Connect IPDM E/R connector and front wiper motor connector.

2. Start up auto active test. Refer to PG-20, "

Auto Active Test".

3. Check voltage between IPDM E/R harness connector and ground.

OK or NG

OK >> Replace front wiper motor.

NG >> Replace IPDM E/R.

5.CHECK CIRCUIT BETWEEN COMB INATION SWITCH AND BCM

With CONSULT-III

1. Select “FR WIPER INT”, “FR WIPER LOW”, and “FR WIPER HI” of BCM data monitor item.

2. With operating the wiper switch, check the monitor status.

Without CONSULT-III

Refer to LT-104, "

Combination Switch Inspection".

OK or NG

OK >> GO TO 6.

NG >> Check combination switch (wiper switch). Refer to LT-104, "

Combination Switch Inspection".

6.CHECK CIRCUIT BETWEEN IPDM E/R AND BCM

Select “BCM” on CONSULT-III, and perform self-diagnosis for “BCM”.

Displayed self

-diagnosis results

NO DTC>>Replace BCM. Refer to BCS-13, "Removal and Installation of BCM".

CAN COMM CIRCUIT>>Check CAN communi cation line of BCM. Refer to LAN-43, "

CAN System Specifica-

tion Chart".

Front Wiper Does Not Return to Stop PositionINFOID:0000000001328555

1.CHECK FRONT WIPER STOP SIGNAL

With CONSULT-III

1. Select “WIP AUTO STOP” of IPDM E/R data monitor item.

2. Check that “WIP AUTO STOP” turns “ACT P” - “STOP P” linked with wiper operation.

Without CONSULT-III

GO TO 2.

(+)

(-) Condition Vol tag e

(Approx.)

IPDM E/R

connector Te r m i n a l

E7 21

Ground Stopped 0 V

LO operation Battery voltage

31 Stopped 0 V

HI operation Battery voltage

(+) (-) Condition Vol tag e

(Approx.)

IPDM E/R

connector Te r m i n a l

E7 21

Ground Stopped 0 V

LO operation Battery voltage

31 Stopped 0 V

HI operation Battery voltage

PKIA5194E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3894 of 3924

FRONT WIPER AND WASHER SYSTEMWW-19

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

WW

N

O P

OK or NG

OK >> Replace IPDM E/R.

NG >> GO TO 2.

2.CHECK IPDM E/R

1. Turn ignition switch OFF.

2. Disconnect front wiper motor connector.

3. Turn ignition switch ON.

4. Check voltage between front wiper harness connector and ground.

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

3.CHECK FRONT WIPER AUTO STOP CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between IPDM E/R harness connector and front wiper motor harness connector.

4. Check continuity between IPDM E/R harness connector and ground.

OK or NG

OK >> Replace IPDM E/R.

NG >> Repair harness or connector.

4.CHECK IPDM E/R

1. Turn ignition switch OFF.

2. Connect front wiper motor connector.

3. Turn ignition switch ON.

4. Check voltage between IPDM E/R harness connector and ground while front wiper motor is stopped and while it is operat-

ing.

OK or NG

OK >> Replace IPDM E/R.

NG >> Replace front wiper motor.

Only Front Wiper Low Does Not OperateINFOID:0000000001328556

1.ACTIVE TEST

With CONSULT-III

1. Select “FRONT WIPER” of IPDM E/R active test item.

5 – Ground : Battery voltage.

PKIA7662E

32 – 5 : Continuity should exist.

32 – Ground : Continuity should not exist.

PKIA5195E

(+)

(-) Condition Voltag e

(Approx.)

IPDM E/R connector Terminal

E7 32 Ground Wiper stopped 0 V

Wiper operating Battery voltage

PKIA5196E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3895 of 3924

WW-20

< SERVICE INFORMATION >

FRONT WIPER AND WASHER SYSTEM

2. With operating the test item, check that front wiper “LO” operation.

Without CONSULT-III

Start up auto active test. Refer to PG-20, "

Auto Active Test"

Does front wiper operate normally?

YES >> Check combination switch (wiper switch). Refer to LT-104, "Combination Switch Inspection".

NO >> GO TO 2.

2.CHECK FRONT WIPER MOTOR CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector and front wiper motor connector.

3. Check continuity between IPDM E/R harness connector and front wiper motor harness connector.

4. Check continuity between IPDM E/R harness connector and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK IPDM E/R

With CONSULT-III

1. Connect IPDM E/R connector and front wiper motor connector.

2. Select “FRONT WIPER” of IPDM E/R active test item.

3. With operating the test item , check voltage between IPDM E/R

harness connector and ground.

Without CONSULT-III

1. Connect IPDM E/R connector and front wiper motor connector.

2. Start up auto active test. Refer to PG-20, "

Auto Active Test".

3. Check voltage between IPDM E/R harness connector and ground.

OK or NG

OK >> Replace front wiper motor.

NG >> Replace IPDM E/R.

Only Front Wiper Hi gh Does Not OperateINFOID:0000000001328557

1.ACTIVE TEST

With CONSULT-III

1. Select “FRONT WIPER” of IPDM E/R active test item.

2. With operating the test item, che ck that front wiper “HI” operation.

Without CONSULT-III

Start up auto active test. Refer to PG-20, "

Auto Active Test".

Does front wiper operate normally?

YES >> Check combination switch (wiper switch). Refer to LT-104, "Combination Switch Inspection".

NO >> GO TO 2.

2.CHECK FRONT WIPER MOTOR CIRCUIT

1. Turn ignition switch OFF.

21 – 1 : Continuity should exist.

21 – Ground : Continuity should not exist.

PKIB6024E

21 – Ground : Battery voltage.

21 – Ground : Battery voltage.

SKIA9167E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3896 of 3924

FRONT WIPER AND WASHER SYSTEMWW-21

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

WW

N

O P

2. Disconnect IPDM E/R connector and front wiper motor connector.

3. Check continuity between IPDM E/R harness connector and front wiper motor harness connector.

4. Check continuity between IPDM E/R harness connector and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK IPDM E/R

With CONSULT-III

1. Connect IPDM E/R connector and front wiper motor connector.

2. Select “FRONT WIPER” of IPDM E/R active test item.

3. With operating the test item, check voltage between IPDM E/R harness connector and ground.

Without CONSULT-III

1. Connect IPDM E/R connector and front wiper motor connector.

2. Start up auto active test. Refer to PG-20, "

Auto Active Test".

3. Check voltage between IPDM E/R harness connector and

ground.

OK or NG

OK >> Replace front wiper motor.

NG >> Replace IPDM E/R.

Only Front Wiper Intermi ttent Does Not OperateINFOID:0000000001328558

1.CHECK COMBINATION SWITCH

With CONSULT-III

1. Select “FR WIPER INT” of BCM data monitor item.

2. With operating the front wiper switch, check the monitor status.

Without CONSULT-III

Refer to LT-104, "

Combination Switch Inspection".

OK or NG

OK >> Replace BCM. Refer to BCS-13, "Removal and Installation of BCM".

NG >> Check combination switch (wiper switch) Refer to LT-104, "

Combination Switch Inspection".

Front Wiper Interval Time Is Not Controlled by Vehicle SpeedINFOID:0000000001328559

1.CHECK FUNCTION OF COMBINATION METER

Confirm that speedometer operates normally.

Does speedometer operate normally?

YES >> GO TO 2.

NO >> Combination meter vehicle speed system malfunction. Refer to DI-17, "

Vehicle Speed Signal

Inspection".

2.CHECK CAN COMMUNICATION BETWEEN BCM AND COMBINATION METER

Select “BCM” on CONSULT-III, and perform self-diagnosis for “BCM”.

31 – 4 : Continui

ty should exist.

31 – Ground : Continuity should not exist.

PKIA5197E

31 – Ground : Battery voltage.

31 – Ground : Battery voltage.

PKIA5198E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3897 of 3924

WW-22

< SERVICE INFORMATION >

FRONT WIPER AND WASHER SYSTEM

Displayed self-diagnosis results

NO DTC>>Replace BCM. Refer to BCS-13, "Removal and Installation of BCM".

CAN COMM CIRCUIT>>Check CAN communi cation line of BCM. Refer to LAN-43, "

CAN System Specifica-

tion Chart".

Front Wiper Intermittent Operation S witch Position Cannot Be AdjustedINFOID:0000000001328560

1.CHECK CIRCUIT BETWEEN COMB INATION SWITCH AND BCM

With CONSULT-III

1. Select “INT VOLUME” of BCM data monitor item.

2. Check that “INT VOLUME”, changes in order fo rm 1 to 7 according to wiper switch operation.

Without CONSULT-III

Refer to LT-104, "

Combination Switch Inspection".

OK or NG

OK >> Replace BCM. Refer to BCS-13, "Removal and Installation of BCM".

NG >> Check combination switch (wiper switch). Refer to LT-104, "

Combination Switch Inspection".

Wiper Does Not Wipe When Front Washer OperatesINFOID:0000000001328561

1.CHECK CIRCUIT BETWEEN COMB INATION SWITCH AND BCM

With CONSULT-III

1. Select “FR WASHER SW” of BCM data monitor item.

2. Check that “FR WASHER SW” turn ON-OFF according to front wiper switch operation.

Without CONSULT-III

Refer to LT-104, "

Combination Switch Inspection".

OK or NG

OK >> Replace BCM Refer to BCS-13, "Removal and Installation of BCM".

NG >> Check combination switch (wiper switch). Refer to LT-104, "

Combination Switch Inspection".

After Front Wiper Operate for 10 Seconds, They Stop for 20 Seconds, and After Re-

peating the Operation Five Time s, They Become Inoperative

INFOID:0000000001328562

CAUTION:

When auto-stop signal has not varied for 10 seconds or longer while IPDM E/R is operating front wip-

ers, IPDM E/R considers that front wipers are locked, and stops wiper output. That causes this symp-

tom.

This status can be checked by “DATA MONITOR” of “IPDM E/R” on which “WIPER PROTECTION”

item shows “BLOCK”.

1.CHECK WIPER MOTOR SIGNAL

With CONSULT-III

1. Select “WIP AUTO STOP” of BCM data monitor item.

2. Check that “WIP AUTO STOP” turns “ACT P” - “STOP P” linked with wiper operation.

Without CONSULT-III

GO TO 2.

OK or NG

OK >> Replace IPDM E/R.

NG >> GO TO 2.

2.CHECK WIPER AUTO STOP CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector and front wiper motor connector.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3898 of 3924

FRONT WIPER AND WASHER SYSTEMWW-23

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

WW

N

O P

3. Check continuity between IPDM E/R harness connector and front wiper motor harness connector.

4. Check continuity between IPDM E/R harness connector and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK FRONT WIPER MOTOR

1. Connect IPDM E/R connector and front wiper connector.

2. Turn ignition switch ON.

3. Check voltage between IPDM E/R harness connector and ground while front wiper motor is stopped and while it is operat-

ing.

OK or NG

OK >> Replace IPDM E/R.

NG >> Replace front wiper motor.

Front Wiper Does Not StopINFOID:0000000001328563

1.CHECK CIRCUIT BETWEEN COMB INATION SWITCH AND BCM

With CONSULT-III

1. Select “FR WIPER INT”, “FR WI PER LOW”, “FR WIPER HI”, and “FR WASHER SW” of BCM data moni-

tor item.

2. With operating the wiper switch, check the monitor status.

Without CONSULT-III

Refer to LT-104, "

Combination Switch Inspection".

OK or NG

OK >> Replace IPDM E/R.

NG >> Check combination switch (wiper switch). Refer to LT-104, "

Combination Switch Inspection".

Removal and Installation of Front Wiper Arms, Adjustment of Wiper Arms Stop Loca-

tion

INFOID:0000000001328564

REMOVAL

1. Turn front wiper switch ON to operate wiper moto r, and then turn front wiper switch OFF (auto stop).

2. Open hood, remove front wiper arm caps, and remove washer tube from washer tube joint.

3. Remove front wiper arm nuts.

4. Raise front wiper arms, and remove front wiper arms from the vehicle.

INSTALLATION

32 – 5 : Continuity should exist.

32 – Ground : Continuity should not exist.

PKIA5195E

(+) (-) Condition Vo l ta g e

(Approx.)

IPDM E/R connector Terminal

E7 32 Ground Wiper stopped 0 V

Wiper operating Battery voltage

PKIA5196E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3899 of 3924

WW-24

< SERVICE INFORMATION >

FRONT WIPER AND WASHER SYSTEM

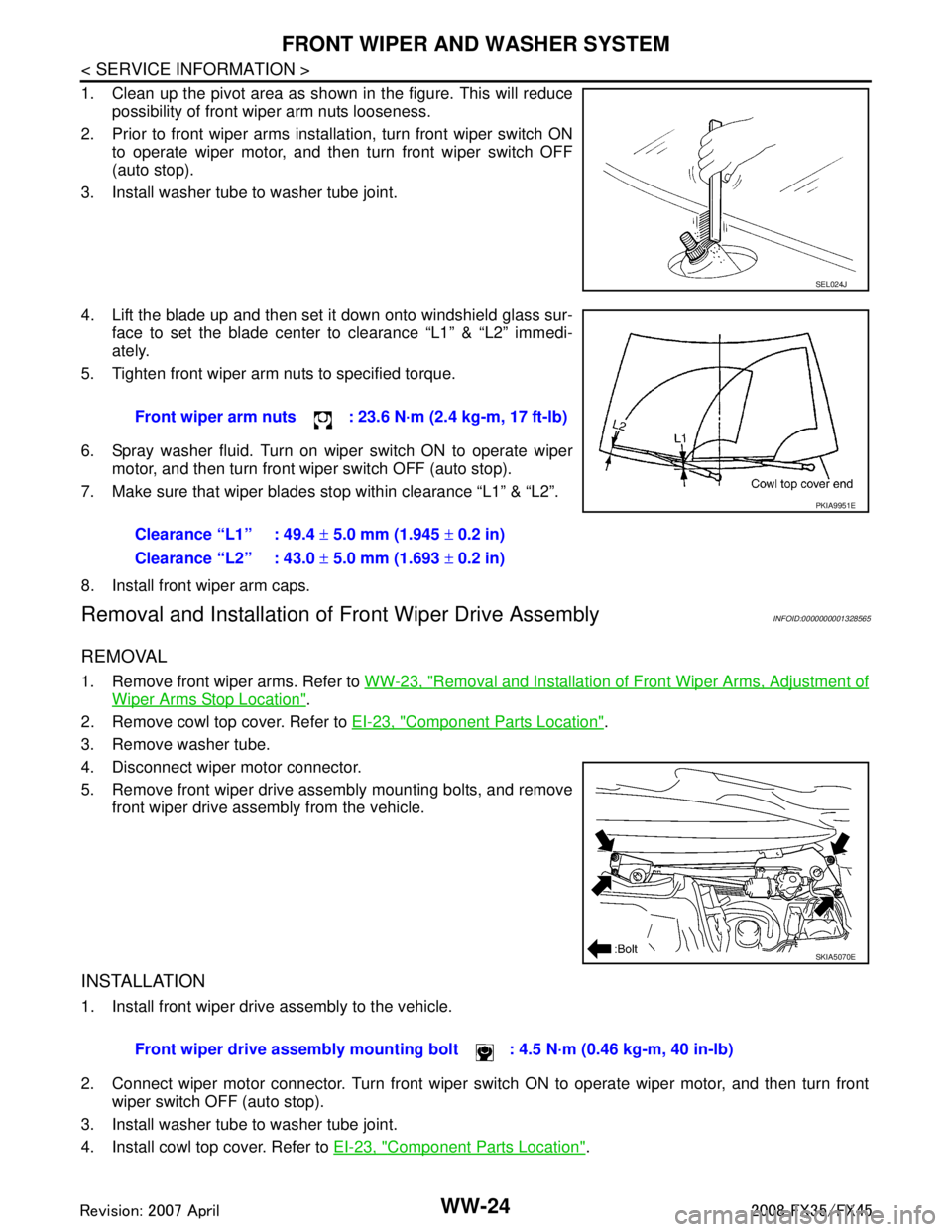

1. Clean up the pivot area as shown in the figure. This will reducepossibility of front wiper arm nuts looseness.

2. Prior to front wiper arms installation, turn front wiper switch ON to operate wiper motor, and then turn front wiper switch OFF

(auto stop).

3. Install washer tube to washer tube joint.

4. Lift the blade up and then set it down onto windshield glass sur- face to set the blade center to clearance “L1” & “L2” immedi-

ately.

5. Tighten front wiper arm nuts to specified torque.

6. Spray washer fluid. Turn on wiper switch ON to operate wiper motor, and then turn front wiper switch OFF (auto stop).

7. Make sure that wiper blades stop within clearance “L1” & “L2”.

8. Install front wiper arm caps.

Removal and Installation of Front Wiper Drive AssemblyINFOID:0000000001328565

REMOVAL

1. Remove front wiper arms. Refer to WW-23, "Removal and Installation of Front Wiper Arms, Adjustment of

Wiper Arms Stop Location".

2. Remove cowl top cover. Refer to EI-23, "

Component Parts Location".

3. Remove washer tube.

4. Disconnect wiper motor connector.

5. Remove front wiper drive assembly mounting bolts, and remove front wiper drive assembly from the vehicle.

INSTALLATION

1. Install front wiper drive assembly to the vehicle.

2. Connect wiper motor connector. Turn front wiper switch ON to operate wiper motor, and then turn frontwiper switch OFF (auto stop).

3. Install washer tube to washer tube joint.

4. Install cowl top cover. Refer to EI-23, "

Component Parts Location".

SEL024J

Front wiper arm nuts : 23.6 N·m (2.4 kg-m, 17 ft-lb)

Clearance “L1” : 49.4 ± 5.0 mm (1.945 ± 0.2 in)

Clearance “L2” : 43.0 ± 5.0 mm (1.693 ± 0.2 in)

PKIA9951E

SKIA5070E

Front wiper drive assembly mounting bo lt : 4.5 N·m (0.46 kg-m, 40 in-lb)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3900 of 3924

FRONT WIPER AND WASHER SYSTEMWW-25

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

WW

N

O P

5. Install front wiper arms and arm caps. Refer to WW-23, "Removal and Installation of Front Wiper Arms,

Adjustment of Wiper Arms Stop Location".

6. Install front wiper arm washer tube.

Disassembly and Assembly of Front Wiper Drive AssemblyINFOID:0000000001328566

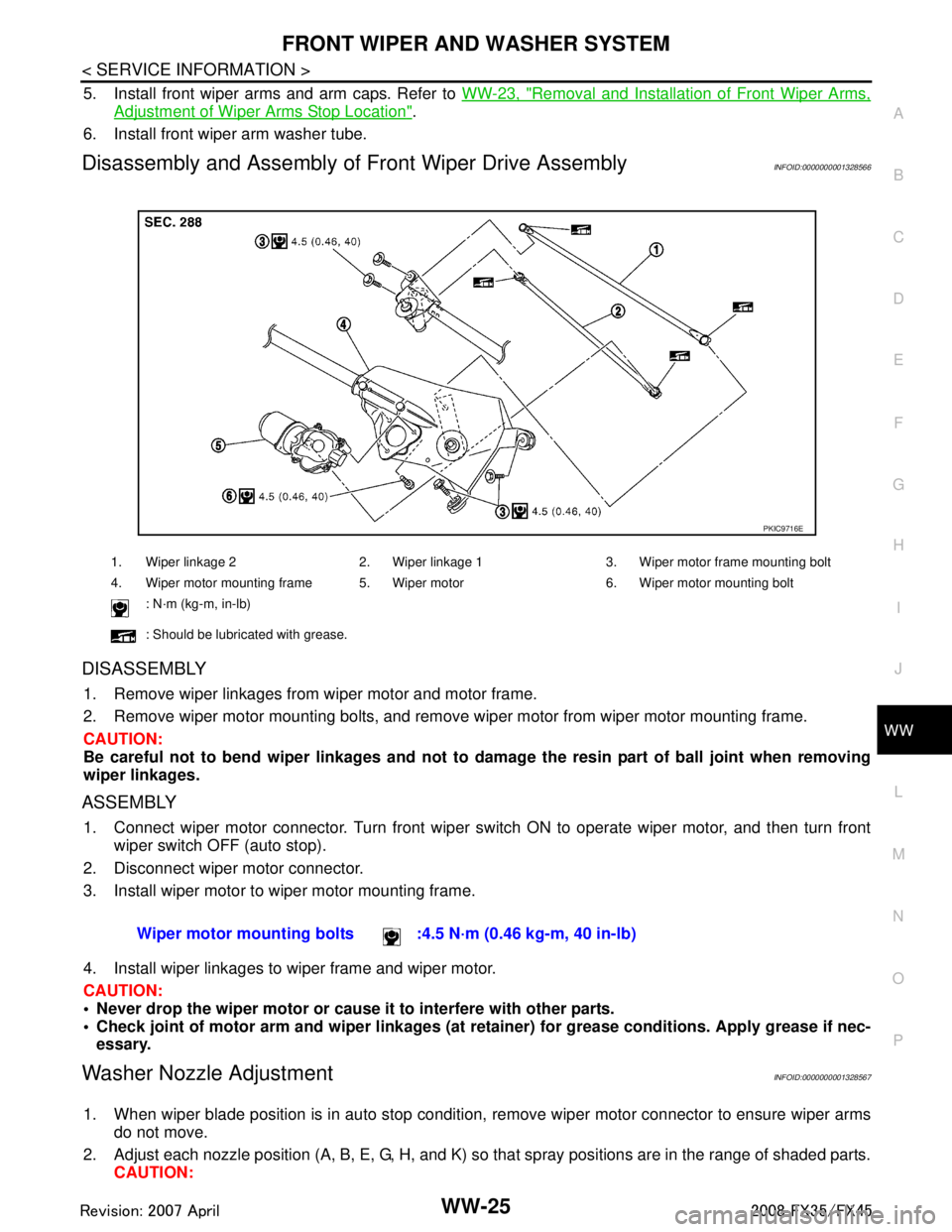

DISASSEMBLY

1. Remove wiper linkages from wiper motor and motor frame.

2. Remove wiper motor mounting bolts, and remove wiper motor from wiper motor mounting frame.

CAUTION:

Be careful not to bend wiper lin kages and not to damage the resin pa rt of ball joint when removing

wiper linkages.

ASSEMBLY

1. Connect wiper motor connector. Turn front wiper switch ON to operate wiper motor, and then turn front wiper switch OFF (auto stop).

2. Disconnect wiper motor connector.

3. Install wiper motor to wiper motor mounting frame.

4. Install wiper linkages to wiper frame and wiper motor.

CAUTION:

Never drop the wiper motor or cause it to interfere with other parts.

Check joint of motor arm and wiper linkages (at retainer) for grease conditions. Apply grease if nec-

essary.

Washer Nozzle AdjustmentINFOID:0000000001328567

1. When wiper blade position is in auto stop condition, remove wiper motor connector to ensure wiper arms

do not move.

2. Adjust each nozzle position (A, B, E, G, H, and K) so that spray positions are in the range of shaded parts.

CAUTION:

1. Wiper linkage 2 2. Wiper linkage 1 3. Wiper motor frame mounting bolt

4. Wiper motor mounting frame 5. Wiper motor 6. Wiper motor mounting bolt

: N·m (kg-m, in-lb)

: Should be lubricated with grease.

PKIC9716E

Wiper motor mounting bolts :4.5 N·m (0.46 kg-m, 40 in-lb)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C